Patents

Literature

56results about How to "Expand the range of working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

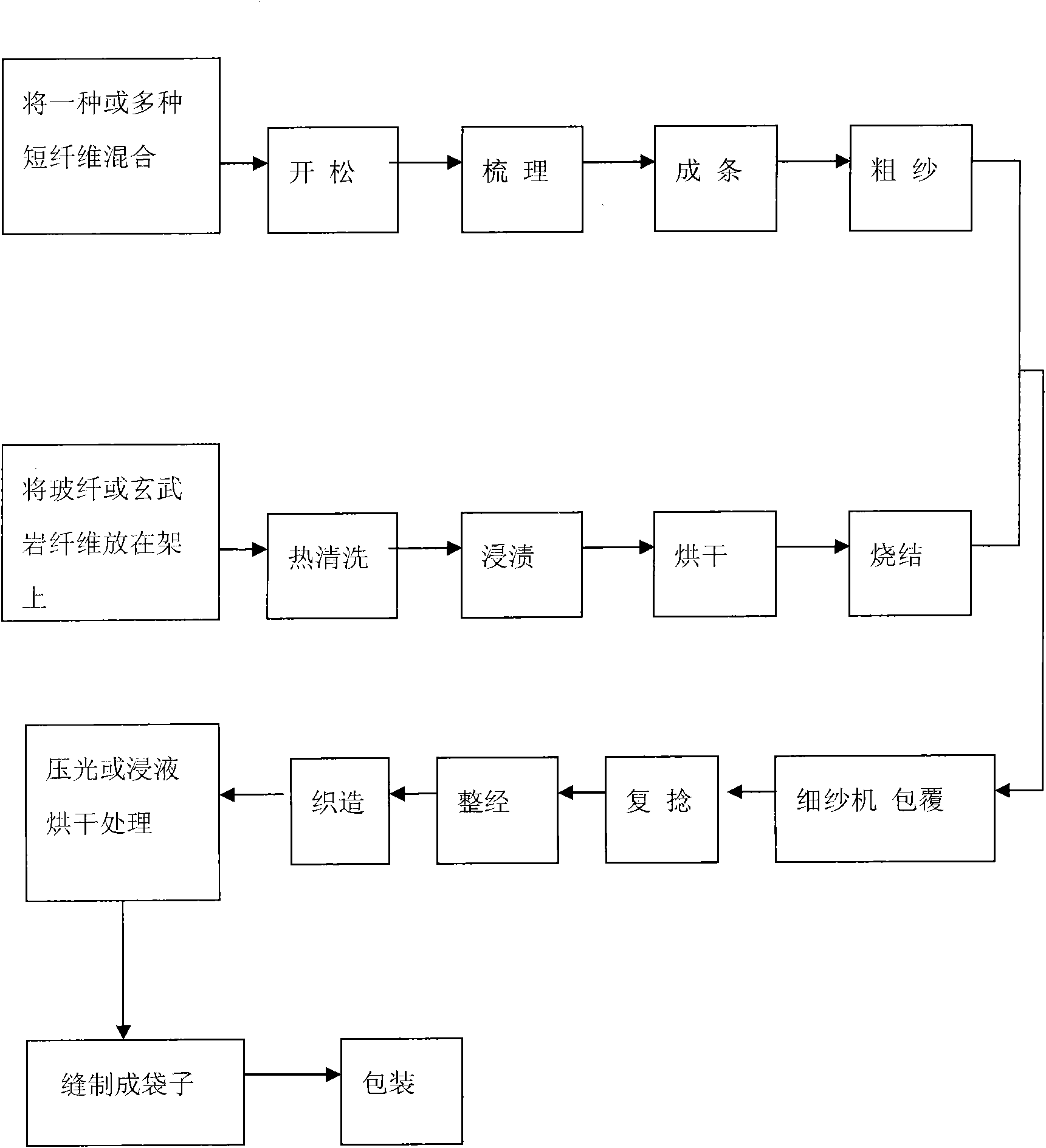

Composite covered yarn, and manufacturing method and use thereof

The invention relates to a composite covered yarn and a manufacturing method thereof and also relates to a high-temperature filter cloth. The composite covered yarn comprises an outer layer of coveredyarn made of short fiber and an inner layer of reinforcing rib made of long fiber, wherein the composite covered yarn is formed by using the covered yarn, made of one or a plurality of types of shortfibers, to cover the reinforcing rib or the metal wire reinforcing rib made of one or a plurality of types of long fibers by thermal cleaning, dipping, drying and sintering. The composite covered yarn manufactured by the method not only saves cost, but also combines the characteristics of high strength of the long fiber and good abrasion resistance and toughness of the short fiber and enhances service life, strength, high-temperature resistance and stability of the composite covered yarn. The composite covered yarn can be made into the filter cloth.

Owner:辽宁新洪源环保材料有限公司

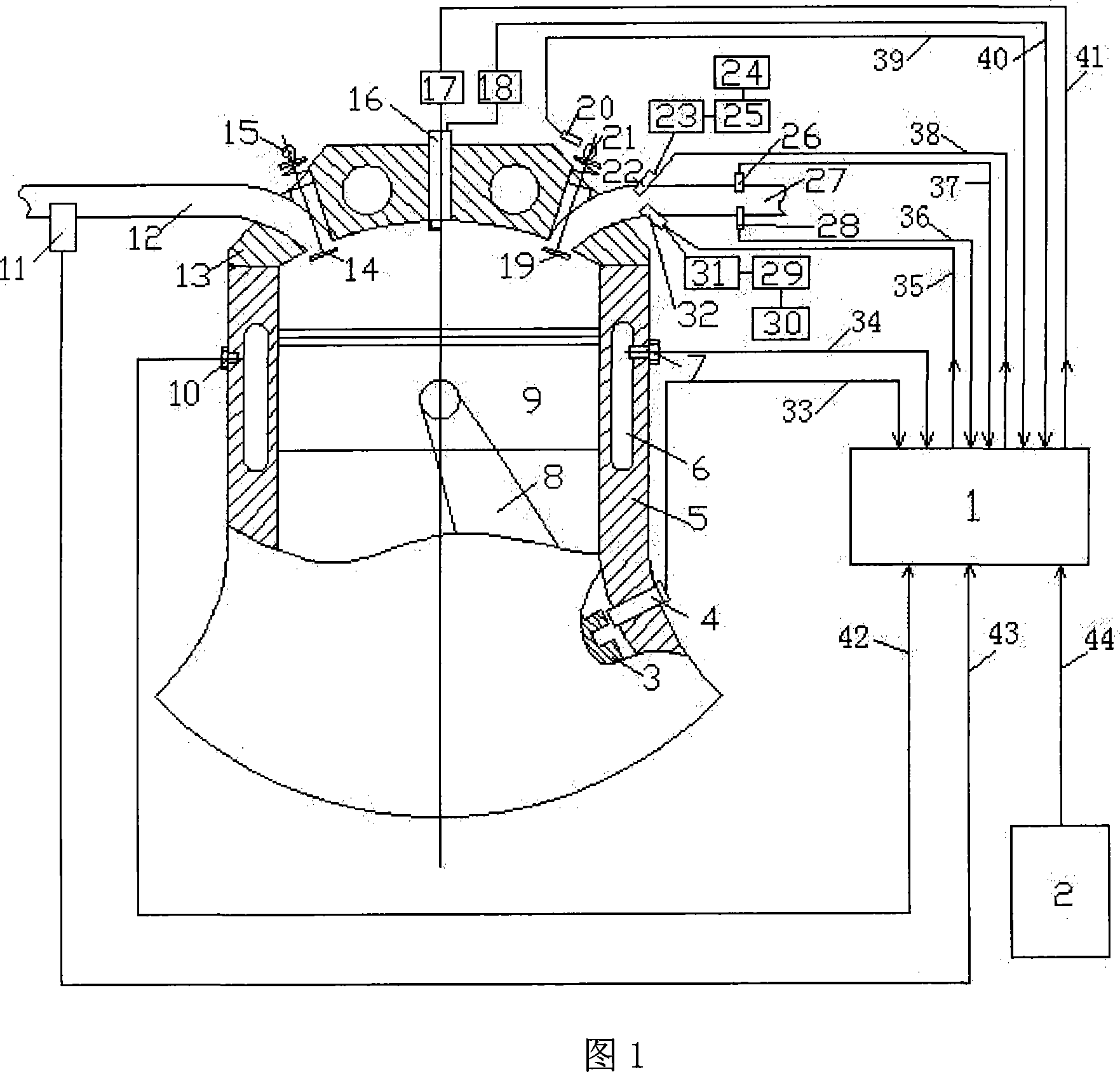

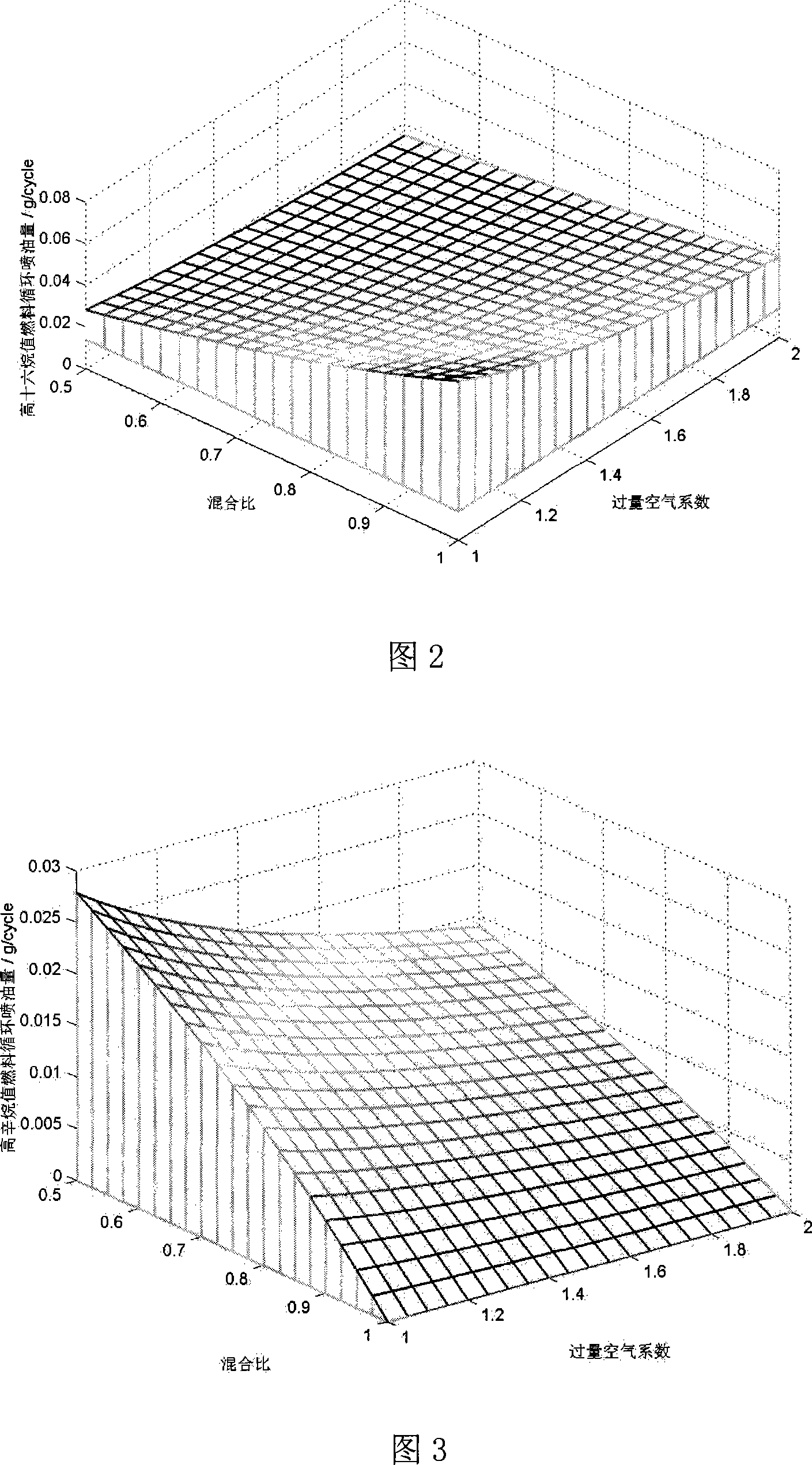

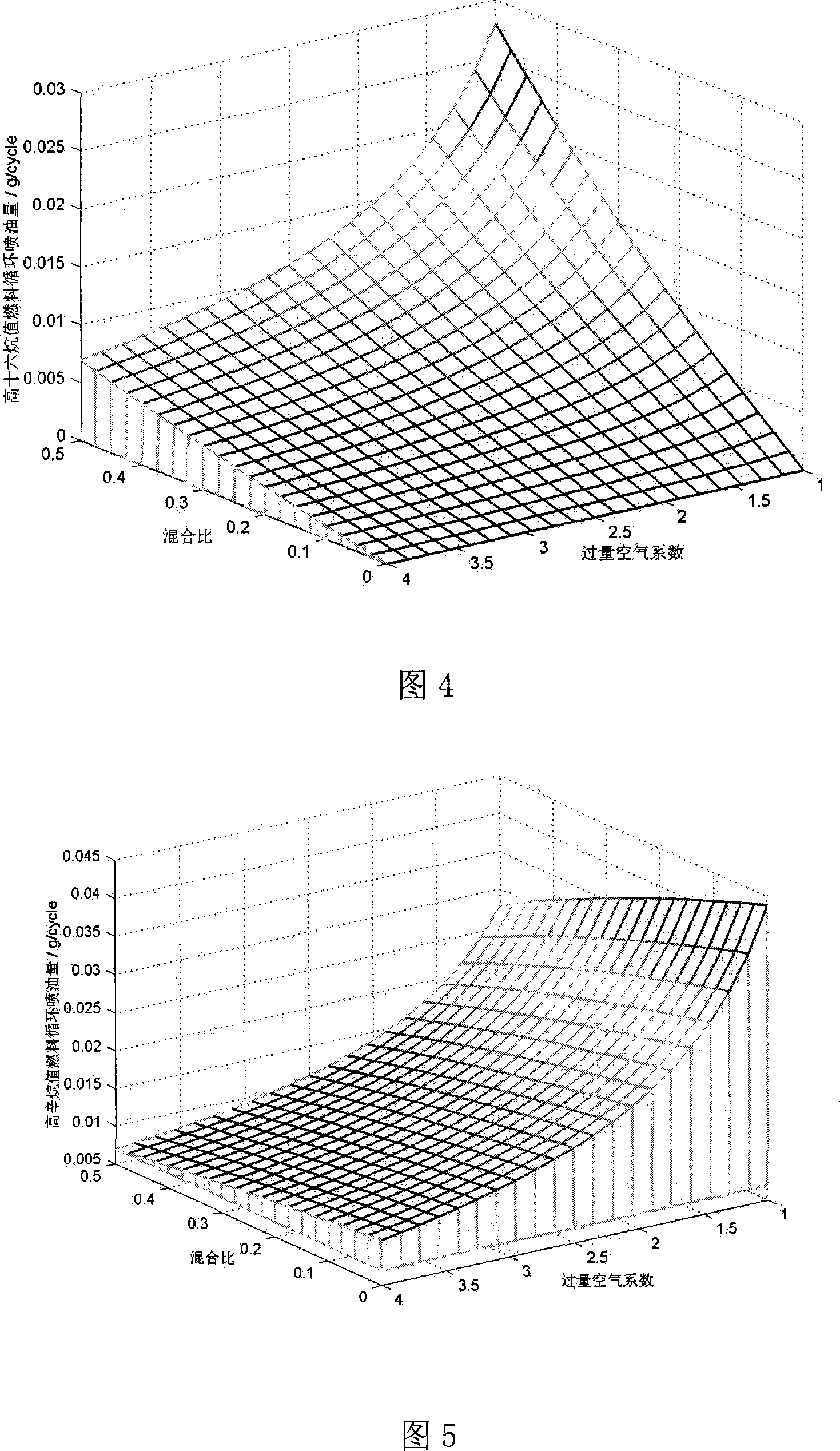

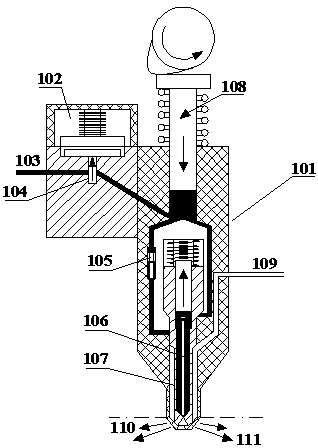

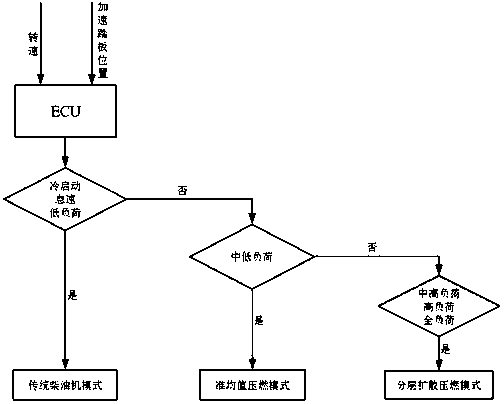

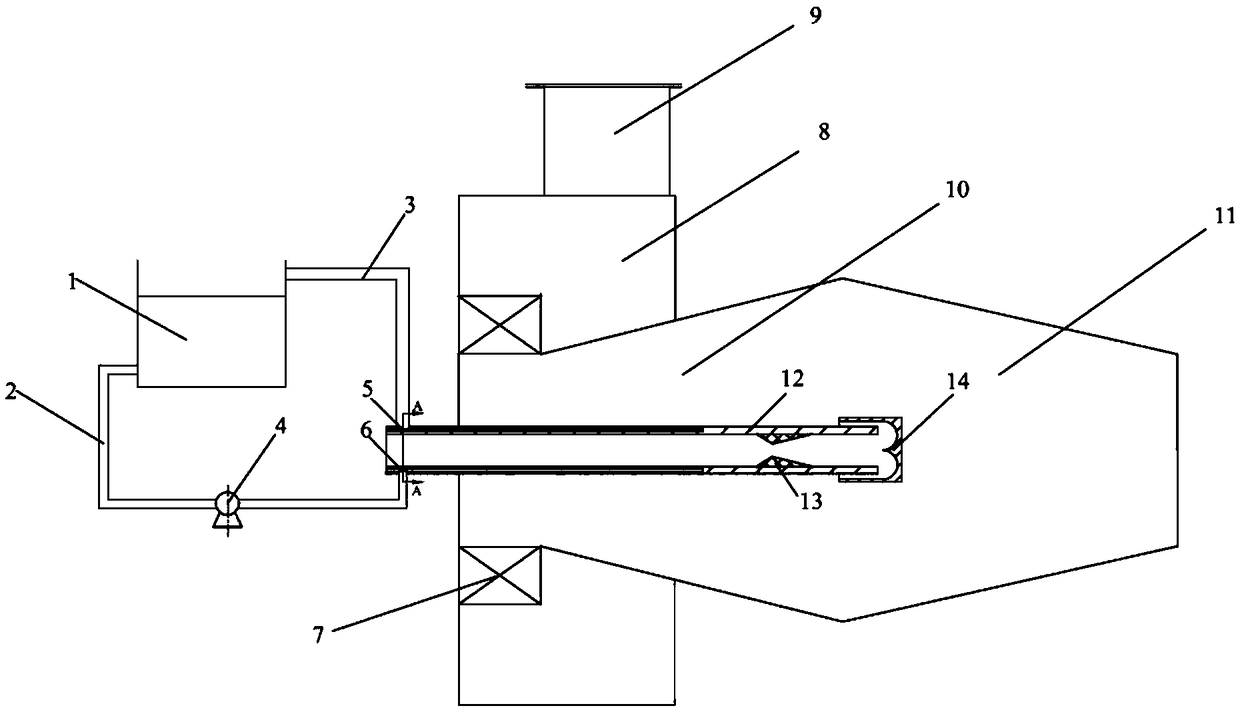

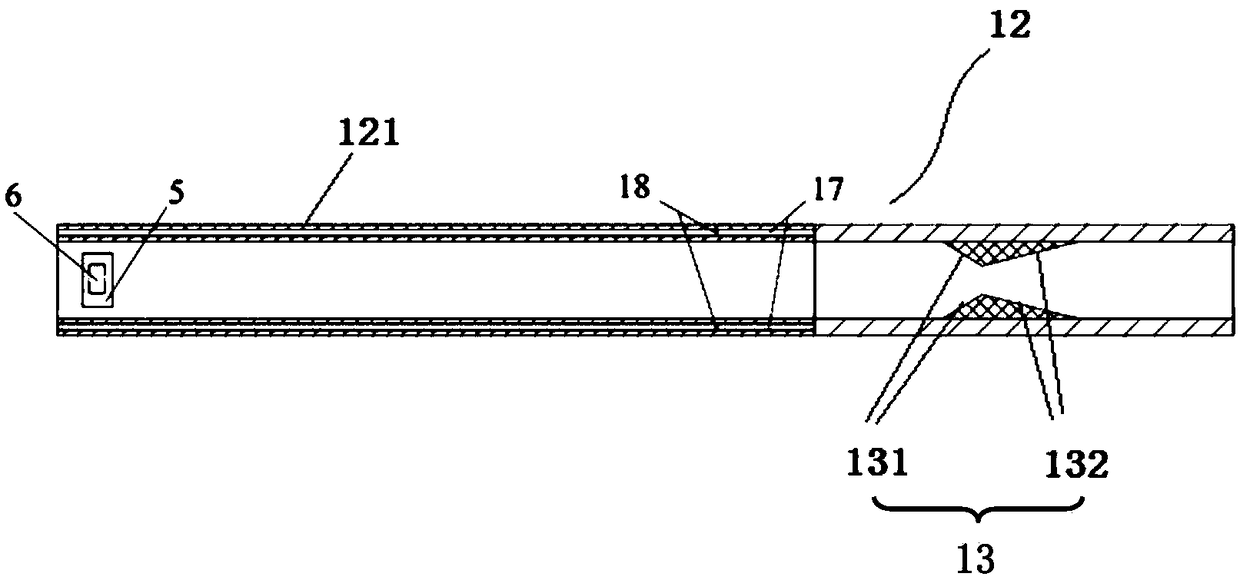

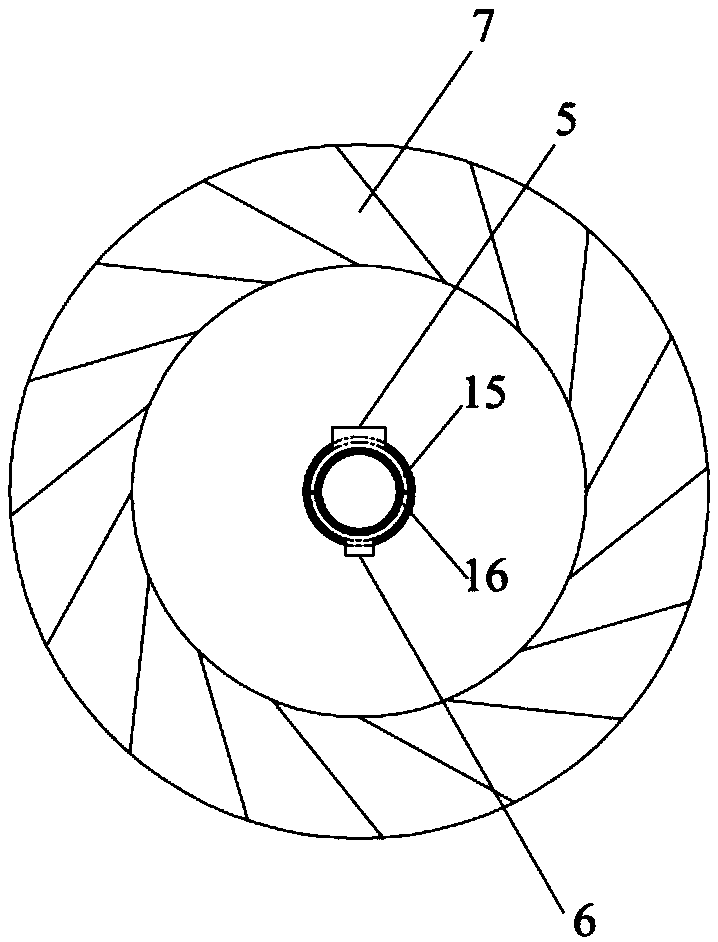

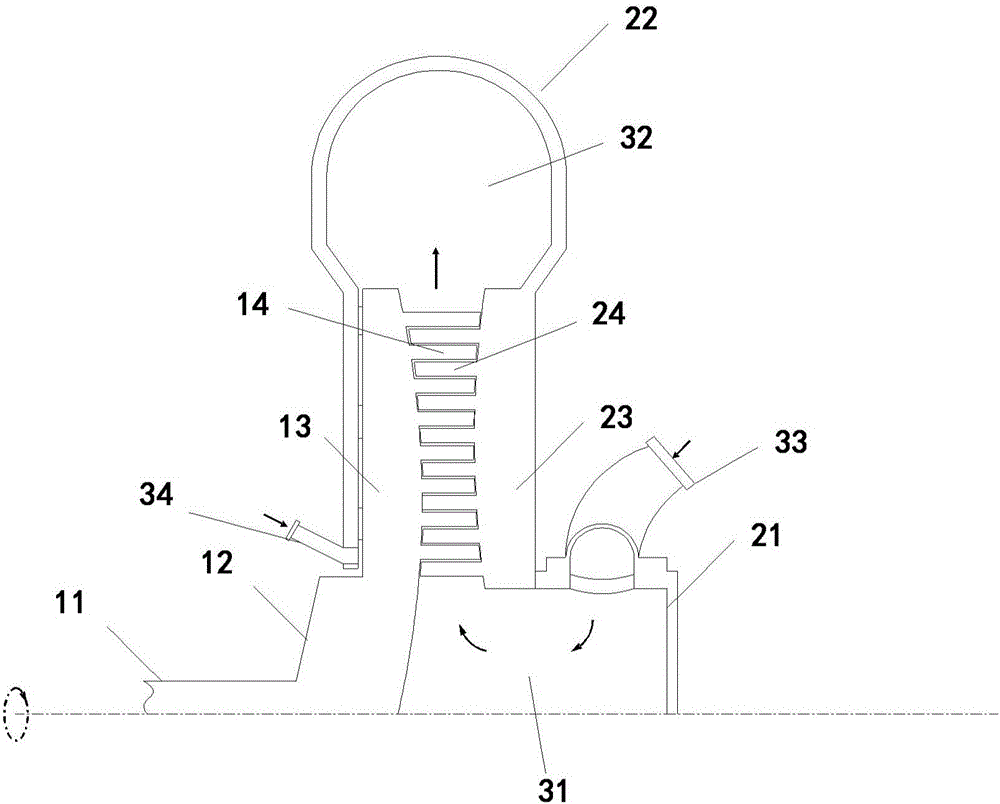

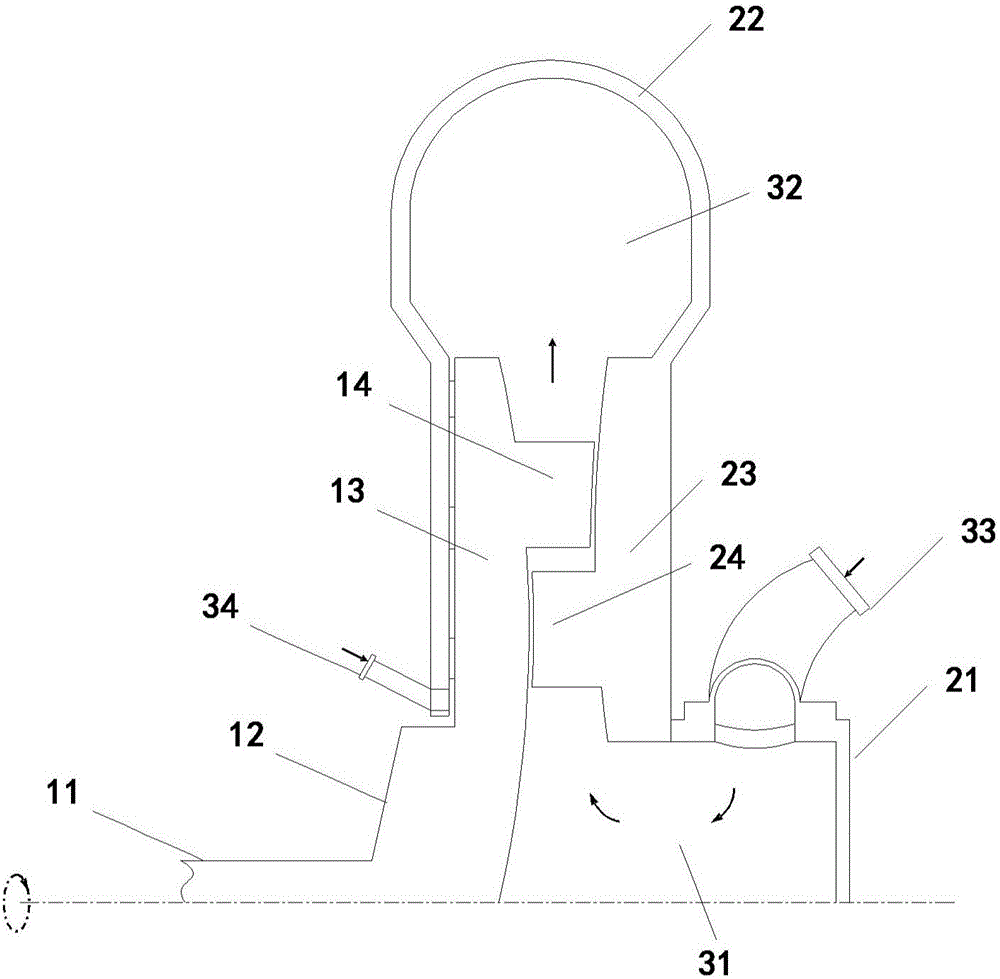

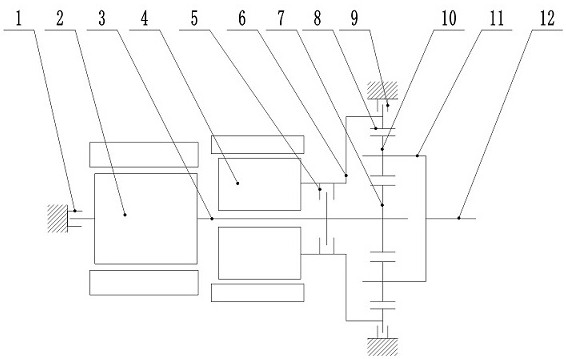

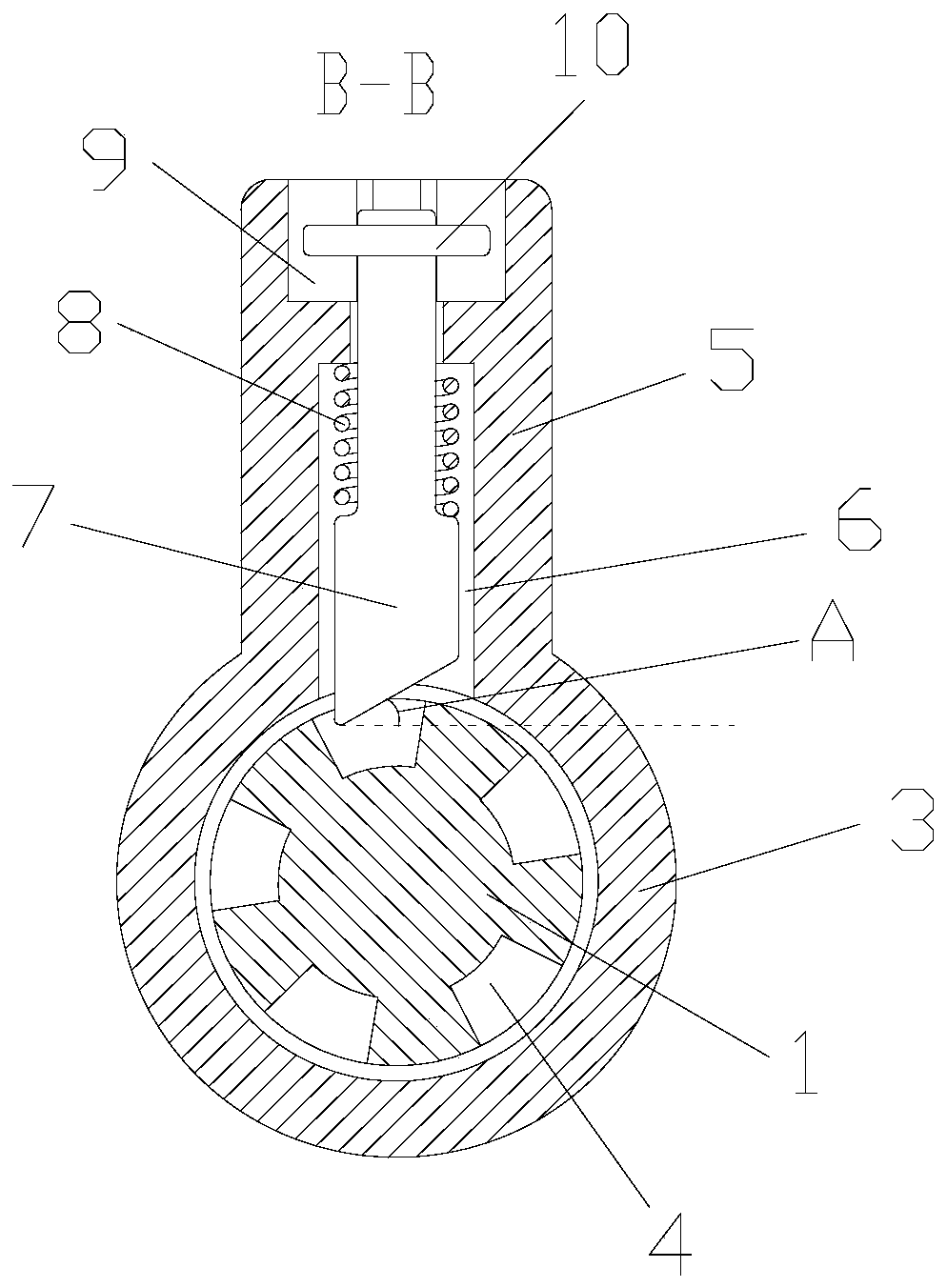

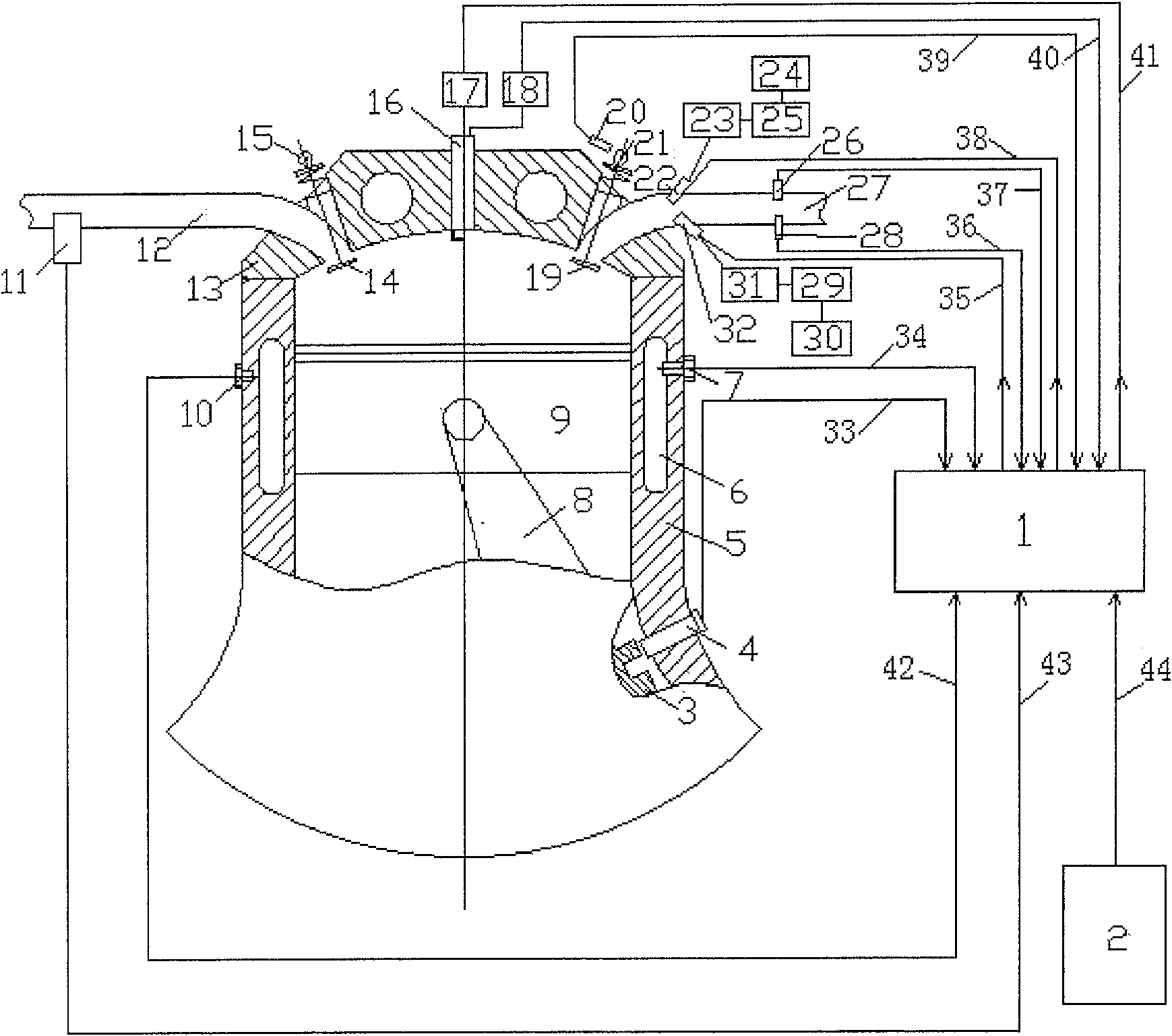

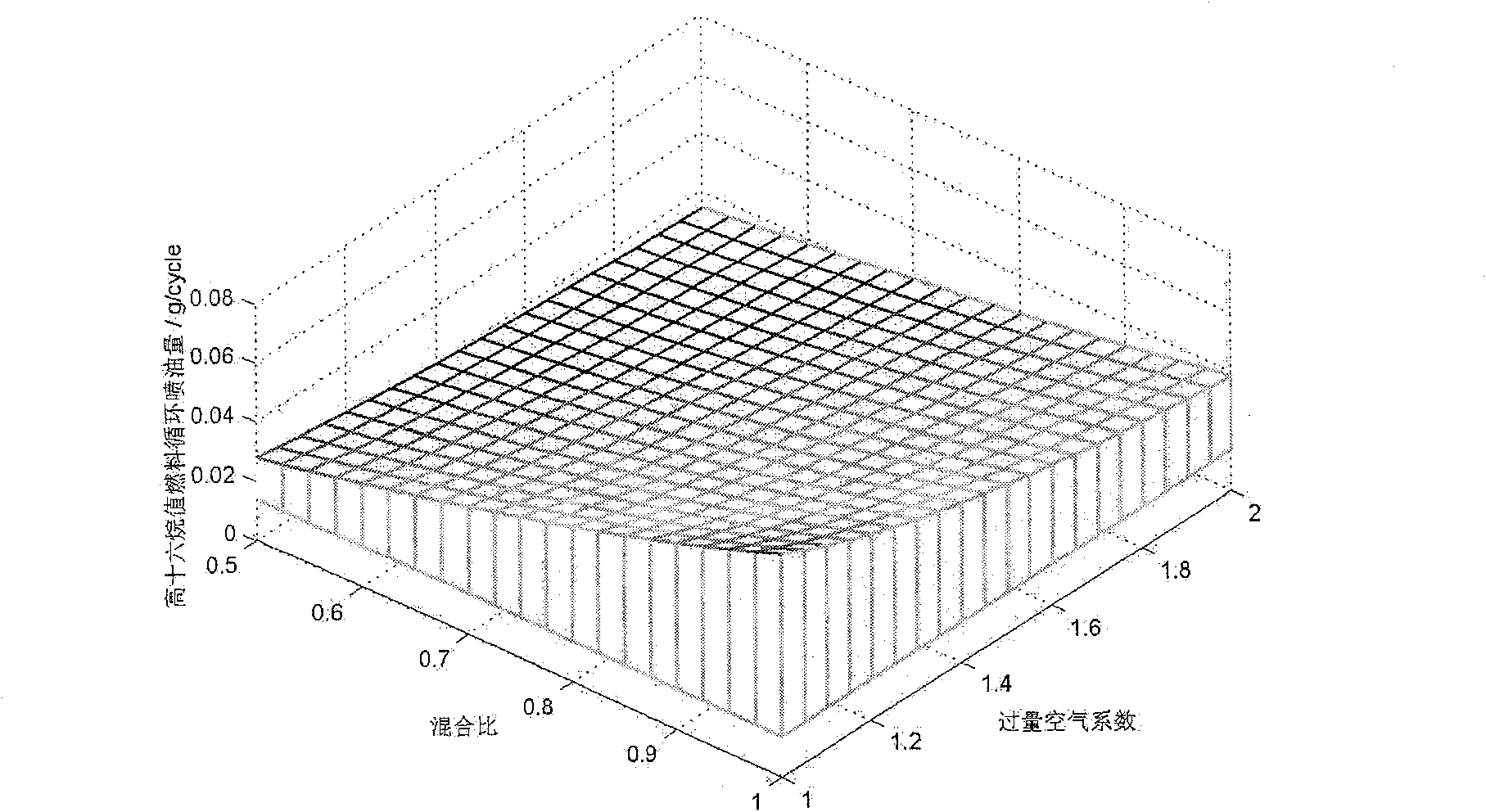

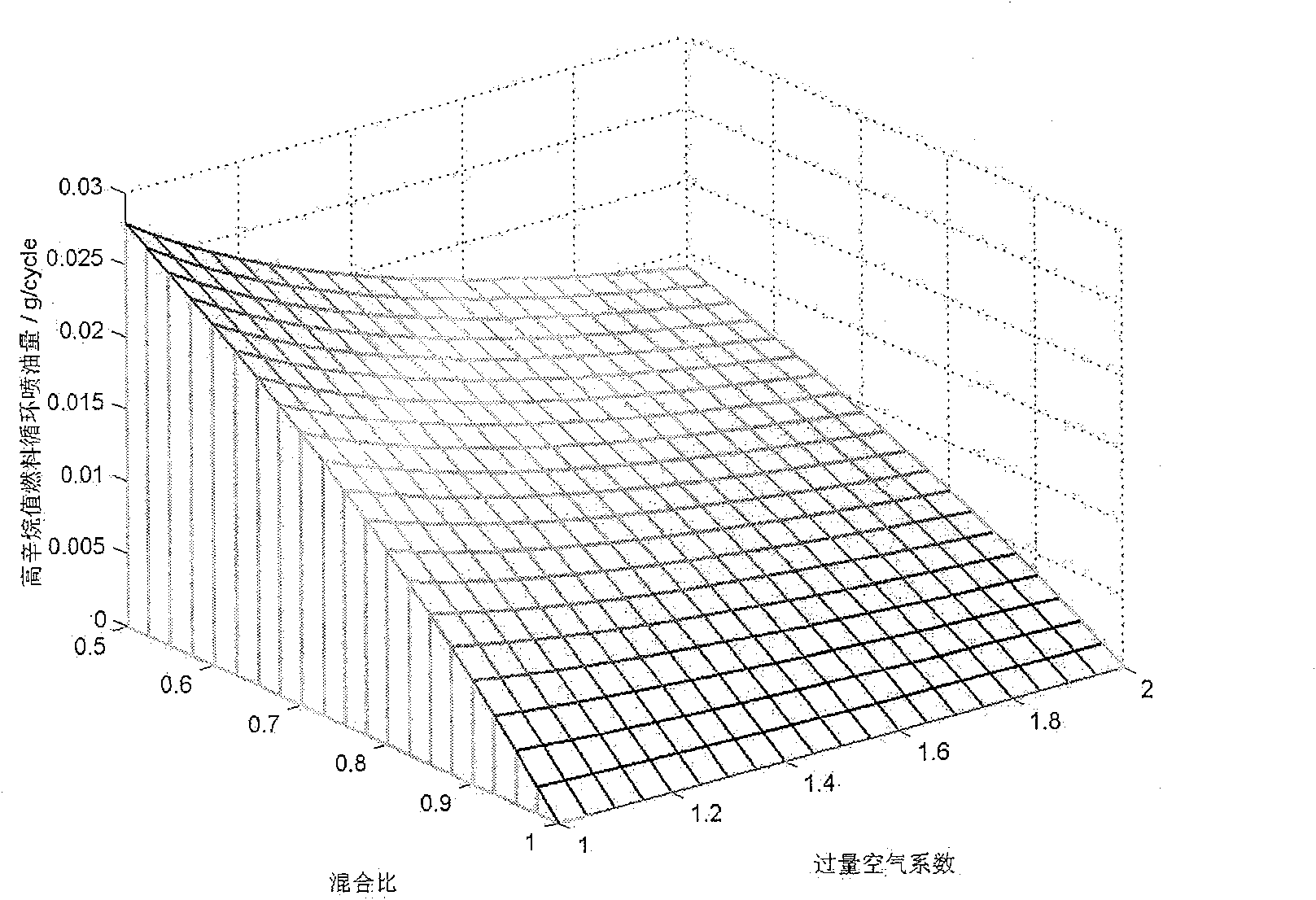

Fuel on-site mixing and compressed ignition internal combustion engine and control method

InactiveCN101215996AWide adaptabilityExpand the range of working conditionsElectrical controlMachines/enginesMixed fuelPower performance

The invention provides a fuel field mixing compression ignition internal combustion engine and a control method thereof, in particular relates to fuel preparation, supply and combustion control of a combustion engine. The invention adopts a high-octane and high-cetane fuel field mixing and auxiliary ignition technology, and can meet the requirement that the internal combustion engine makes use of the fuel of different octane numbers under different loads, namely, more high-cetane fuel is mixed in the high-octane fuel under low load or ignition is assisted in, to improve the ignition property of the mixed fuel so that the mixed fuel can be fired reliably under low load and temperature with the firing time controllable. The quantity of high-cetane fuel to be mixed in is reduced under medium load; a signal high-octane fuel is adopted under large load to avoid engine detonation. By adopting the fuel field mixing compression ignition combustion mode, not only an even premixing compression ignition engine is prevented from being on fire under low load, but also the working condition range under large load can be widened. In addition, the power performance of the engine is improved. In this way, the even premixing compression ignition engine is practical.

Owner:BEIJING UNIV OF TECH

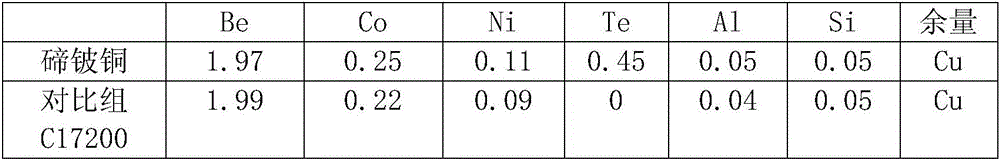

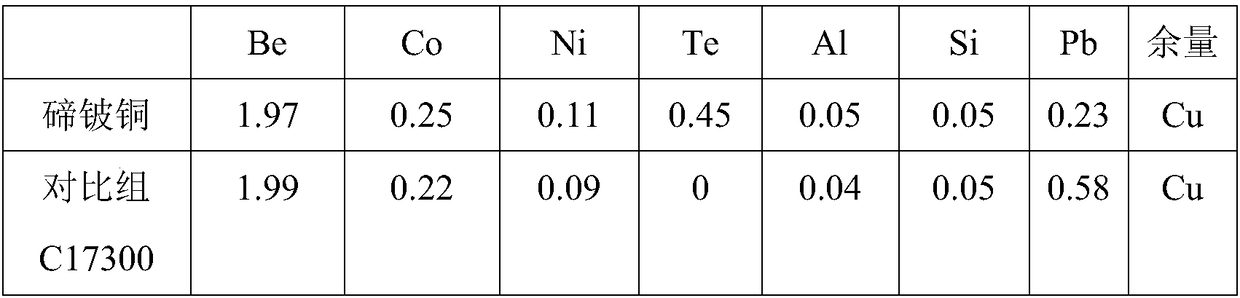

Tellurium berylco alloy and preparation method thereof

The invention discloses a tellurium berylco alloy; the tellurium berylco alloy is prepared from 0.2-2.1 wt.% of Be, 0.1-0.7 wt.% of Te, and others including Co, Ni, Ti, rare-earth elements and impurity elements of which total is not more than 4% wt; the rest is Cu; the preparation method includes steps of a, dosing, feeding, smelting and casting raw materials to acquire an ingot blank according to weight percent; b, orderly performing homogenizing heat treatment, heat processing technique, cold processing technique and annealing, solid dissolving, and aging heat treatment on the ingot blank acquired in step a orderly; and preparing the tellurium berylco alloy. Through adding tellurium in the berylco alloy, tellurium and a copper base can form Cu2Te; the tellurium berylco alloy is good in high-temperature stability, remains the excellent physical performance and corrosive resistance of tellurium beryllium copper, and greatly improves the material cutting performance on the basis of environmental protection, and also performs the plasticity performance.

Owner:KINKOU SUZHOU COPPER IND CO LTD

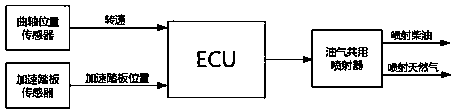

Diesel oil/natural gas dual-fuel engine emission control strategy

InactiveCN108561233AAvoid poor coolingExpand the range of working conditionsElectrical controlFuel injection apparatusOil and natural gasProcess engineering

The invention relates to a diesel oil / natural gas dual-fuel engine emission control strategy which is characterized by comprising the following specific steps: S1, sensing the crankshaft position andjudging load; and S2, controlling an oil gas shared ejector. Ejection of diesel oil and natural gas can be controlled in real time through the oil gas shared ejector and a dual-fuel ECU to adjust concentration distribution and characteristic distribution of fuel in an oil cylinder in real time; and aiming at different working conditions and the combustion characteristics of fuel, and by combiningthe flexible ejection strategy and proper EGR, the mixing characteristic and the ignition characteristic of the interior of the cylinder can be effectively controlled to optimize cylinder interior combustion and reduce emission of NOX, PM, HC and CO at the same time.

Owner:JIANGSU UNIV OF SCI & TECH +1

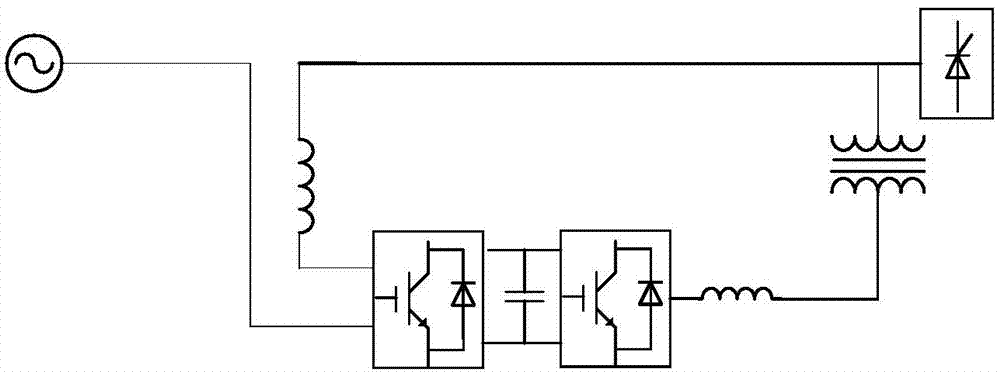

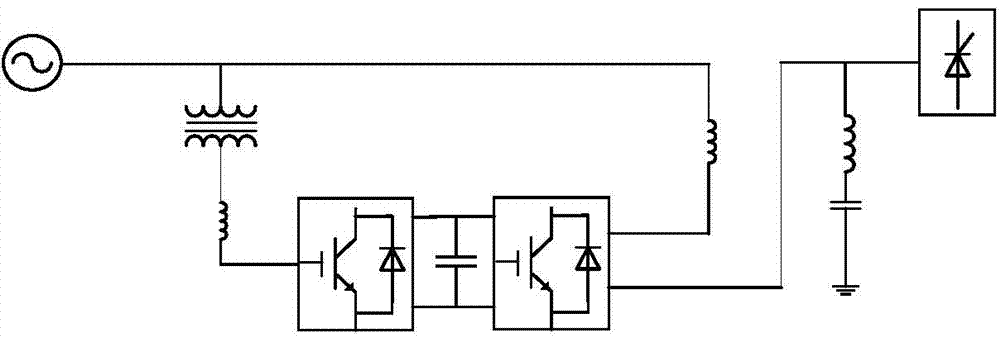

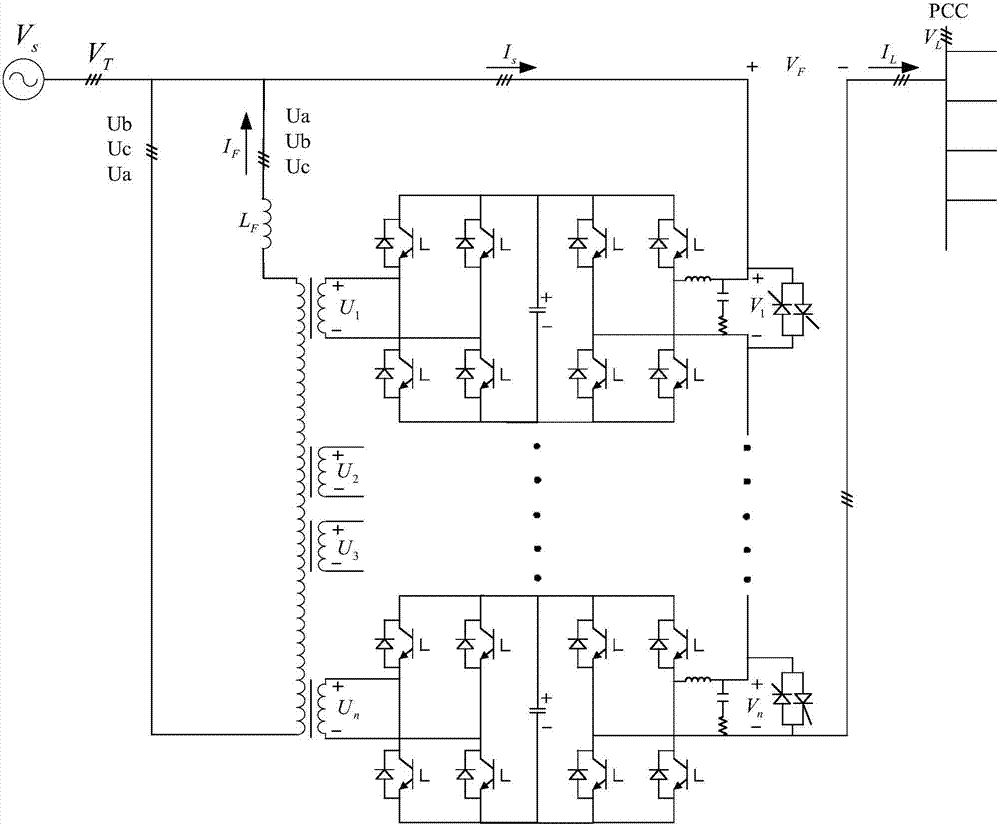

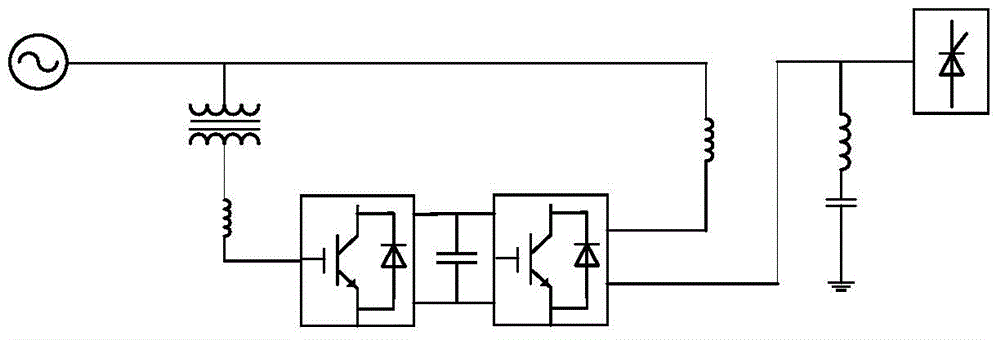

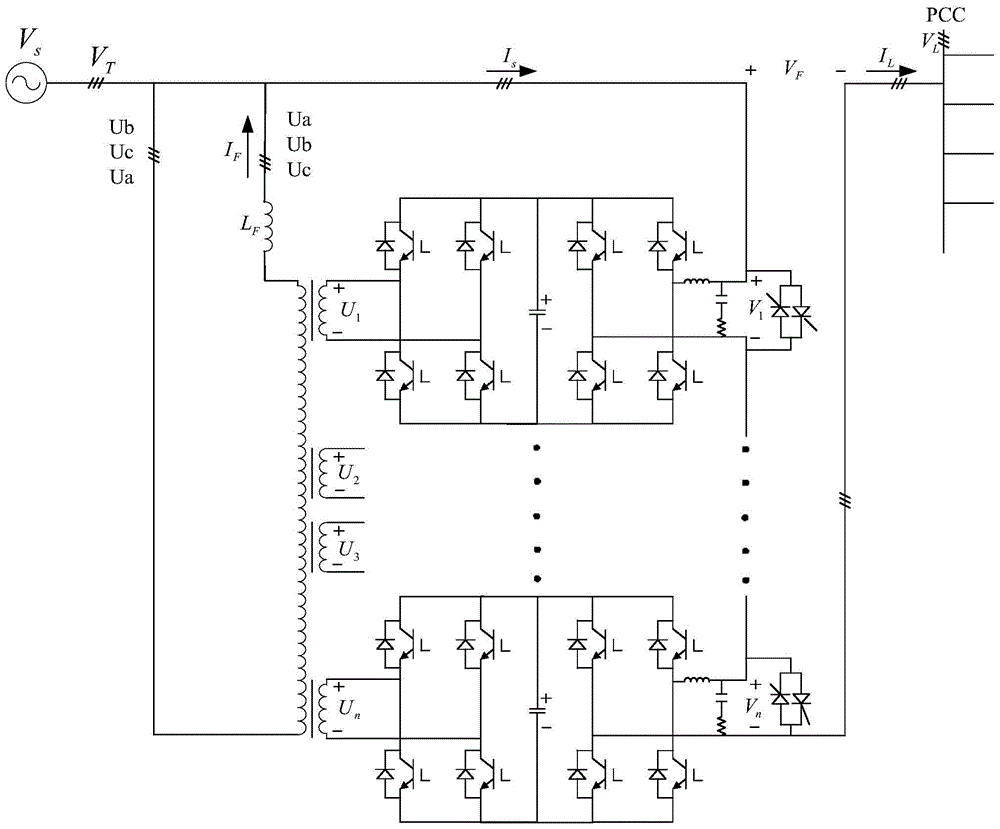

High-capacity UPQC and control method thereof

ActiveCN103618310AAchieve controllabilityRealize functionPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionOrthogonal coordinatesElectric power system

The invention relates to a UPQC for flexibility power transmission and distribution of a power system, in particular to a high-capacity UPQC and a control method of the high-capacity UPQC. The high-capacity UPQC is applied to the parallel-connection side of the UPQC by using the structure that a secondary side of a multi-winding transformer is connected with an H-bridge convertor. Three phases on the parallel-connection side are equivalent to three single-phase rectifier models connected to line voltage in a cross mode. As being controlled independently, each H-bridge rectifier is not affected by unbalance of three-phase voltage, and the stability of voltage across the direct current side of the UPQC when network voltage fluctuates is facilitated. A control method based on virtual orthogonal coordinate conversion is adopted, the single-phase rectifier models on the parallel-connection side of the UPQC are equivalent to a three-phase rectifier model, the functions of the controllable power factor and harmonic suppression of a three-phase rectifier are achieved, and all functions of the three-phase rectifier on the condition of the symmetric system voltage can be completely achieved.

Owner:STATE GRID CORP OF CHINA +1

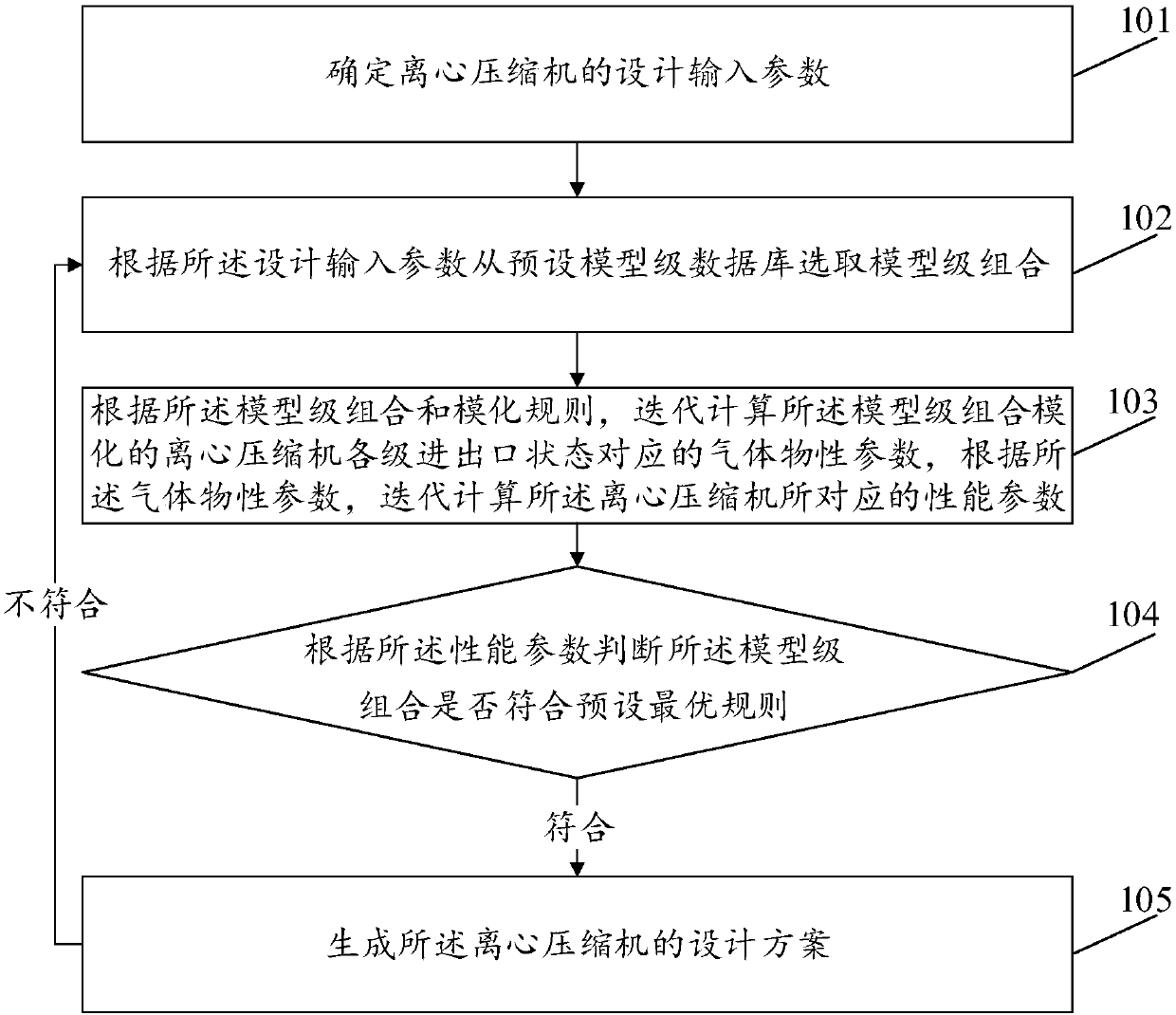

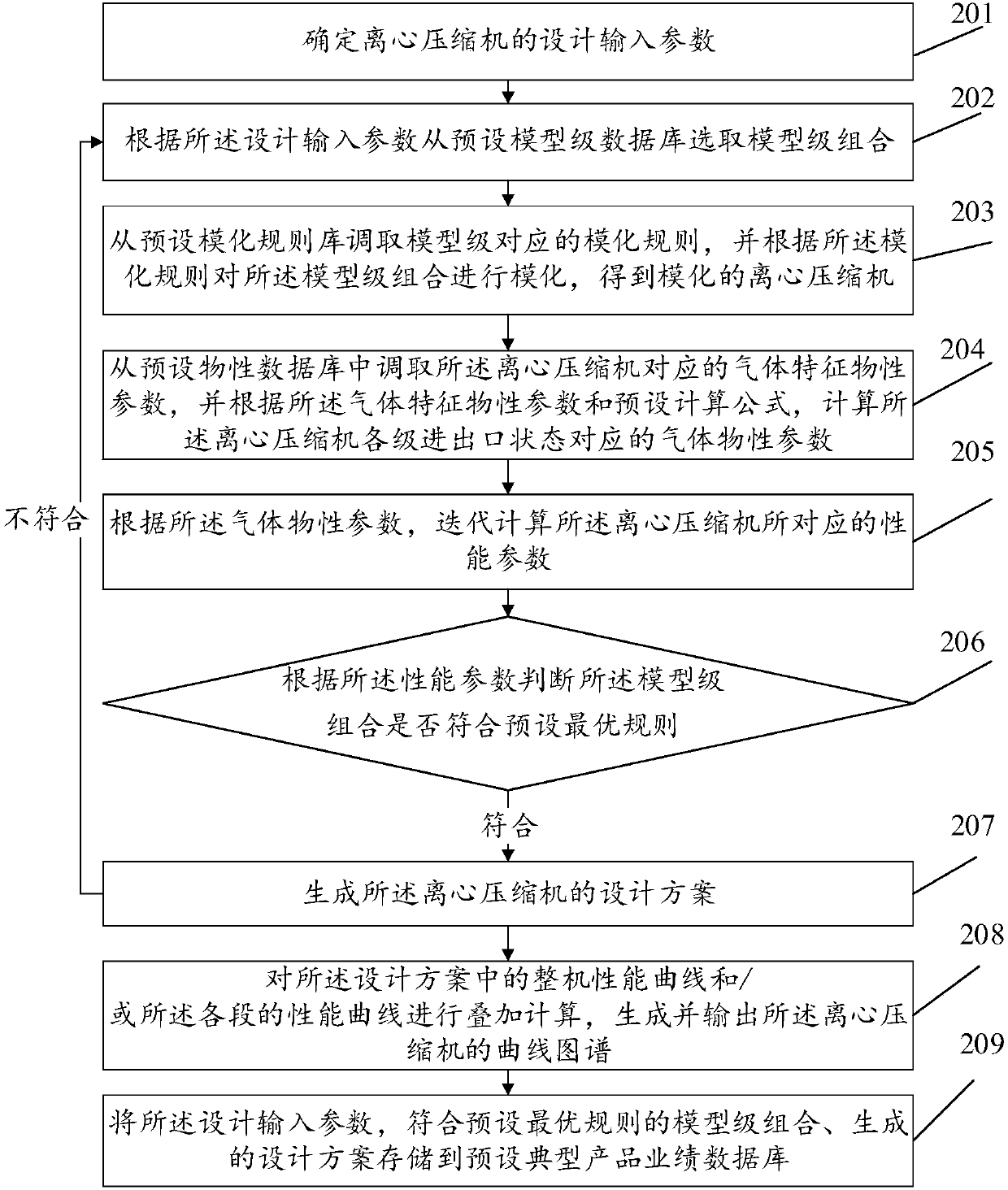

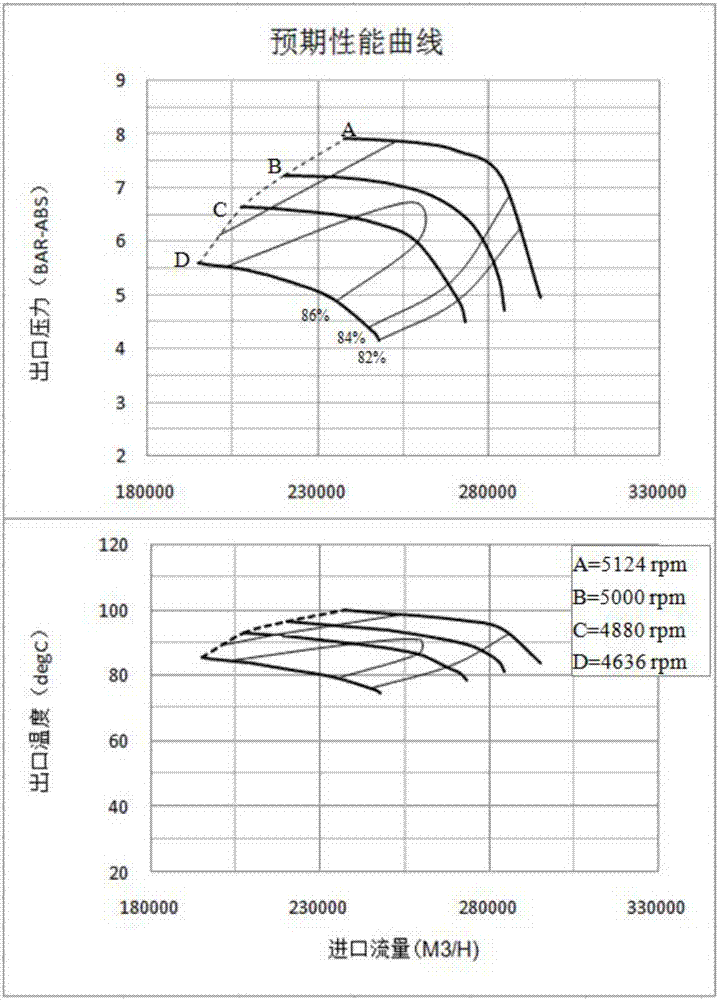

Method for designing centrifugal compressor

ActiveCN108073772AImprove efficiencyEliminate limitationsGeometric CADSpecial data processing applicationsComputational modelLevel data

The invention discloses a method for designing a centrifugal compressor and relates to the field of centrifugal compressor design. The main purpose is to eliminate the limitation of the model level selected based on experience, and to improve the efficiency of the centrifugal compressor designed and the range of broadened working conditions. The method includes selecting a model level combinationfrom a preset model level database according to design input parameters of the centrifugal compressor, wherein the preset model level database stores various tested model level data; according to themodel level combination and modeling rules, performing iterative computation on gas property parameters corresponding to inlet and outlet states at each level of the centrifugal compressor; accordingto the gas property parameters, performing iterative computation on performance parameters corresponding to the centrifugal compressor; according to the performance parameters, determining whether themodel level combination conforms to a preset optimal rule; if yes, generating a design scheme of the centrifugal compressor; and if not, reselecting the model level combination and performing calculation, until the model level combination conforms to the preset optimal rule. The method is suitable for designing the centrifugal compressor.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

Pneumatic steady flame center staged combustor

InactiveCN105402772ASimple geometryImprove flame stabilityContinuous combustion chamberCombustion chamberLiquid fuel

The invention discloses a pneumatic steady flame center staged combustor. A main combustion stage annular direct-injection type nozzle consists of a first oil inlet, a second oil inlet, an oil collecting cavity and an injection hole; a pre-combustion stage nozzle is provided with two independent gas collecting chambers and two rows of spray orifices which respectively spray nitrogen and methane / air premixed gas; and after entering an inlet of an annular combustion chamber, air is distributed into different flows which respectively enter a main combustion stage annular flow path and a pre-combustion stage pre-mixing channel. The main combustion stage direct-injection type nozzle transversely sprays liquid fuel oil into the main combustion stage annular flow path, and then the liquid fuel oil is mixed with main combustion stage air flow. The methane / air premixed gas and the nitrogen are obliquely and upwards sprayed into a backward-facing step pre-combustion stage by pre-combustion stage air flow; an electric spark igniter is positioned on a methane / air premixed gas injection track, and ignition starting of the pre-combustion stage is realized; and then high-temperature fuel gas of the pre-combustion stage ignites a main combustion stage. Mechanical components of the pneumatic steady flame center staged combustor are simple, stable and reliable in structure, and the liquid fuel oil can be efficiently and stably combusted in a wider incoming flow working condition range.

Owner:BEIHANG UNIV

Double-cone inverse-spray pulverized coal burner capable of preventing overheating deformation of primary air pipe

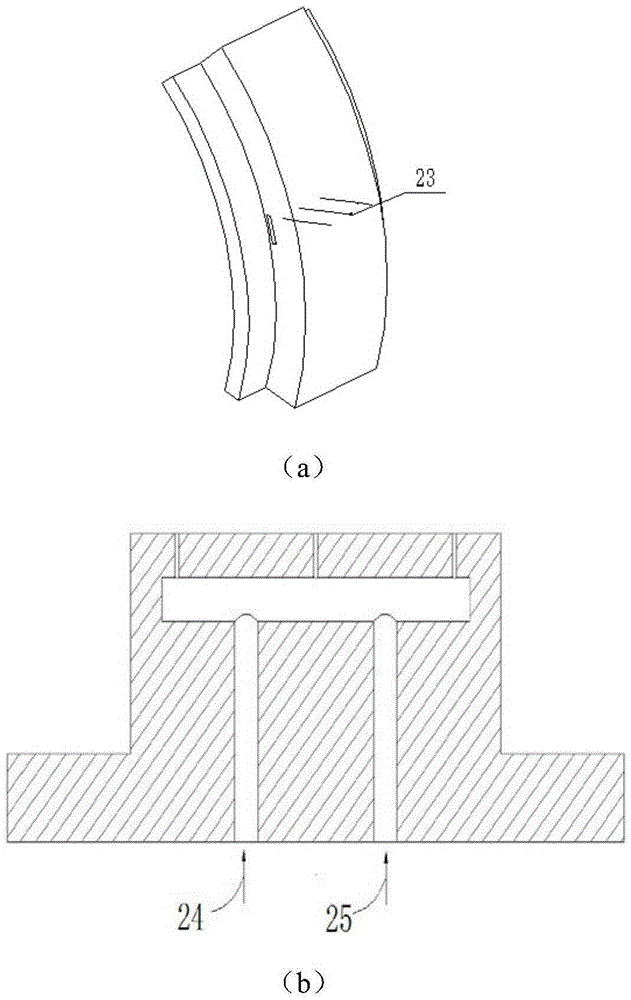

PendingCN109140433AReduce the temperatureSolve the defect of being prone to overheating and deformationPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationAir cooling systemCoal

The invention discloses a double-cone inverse-spray pulverized coal burner capable of preventing overheating deformation of a primary air pipe. The double-cone inverse-spray pulverized coal burner ischaracterized by comprising a precombustion chamber and the primary air pipe, wherein the outlet end of the primary air pipe is arranged in the precombustion chamber; the inlet end of the primary airpipe is located outside the precombustion chamber; a cooling system used for cooling the primary air pipe is arranged at the inlet end of the primary air pipe. The temperature of the primary air pipecan be effectively reduced by a water-cooling system or an air-cooling system, and the problem that the primary air pipe is prone to occurring overheating deformation is solved.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

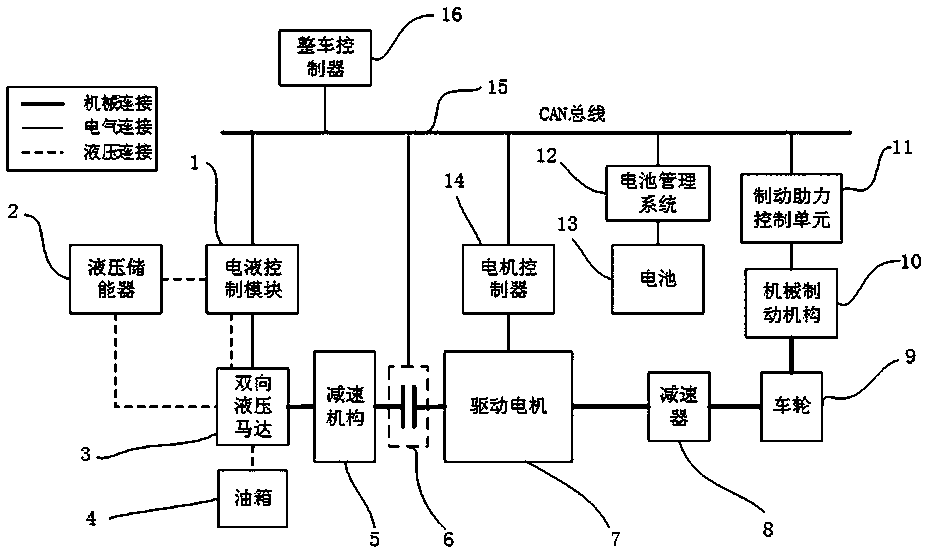

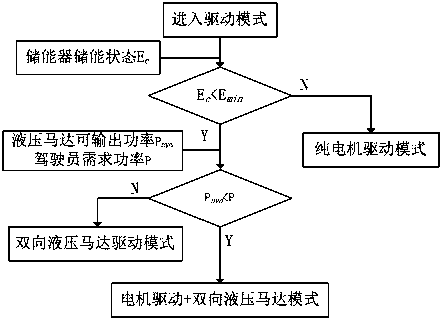

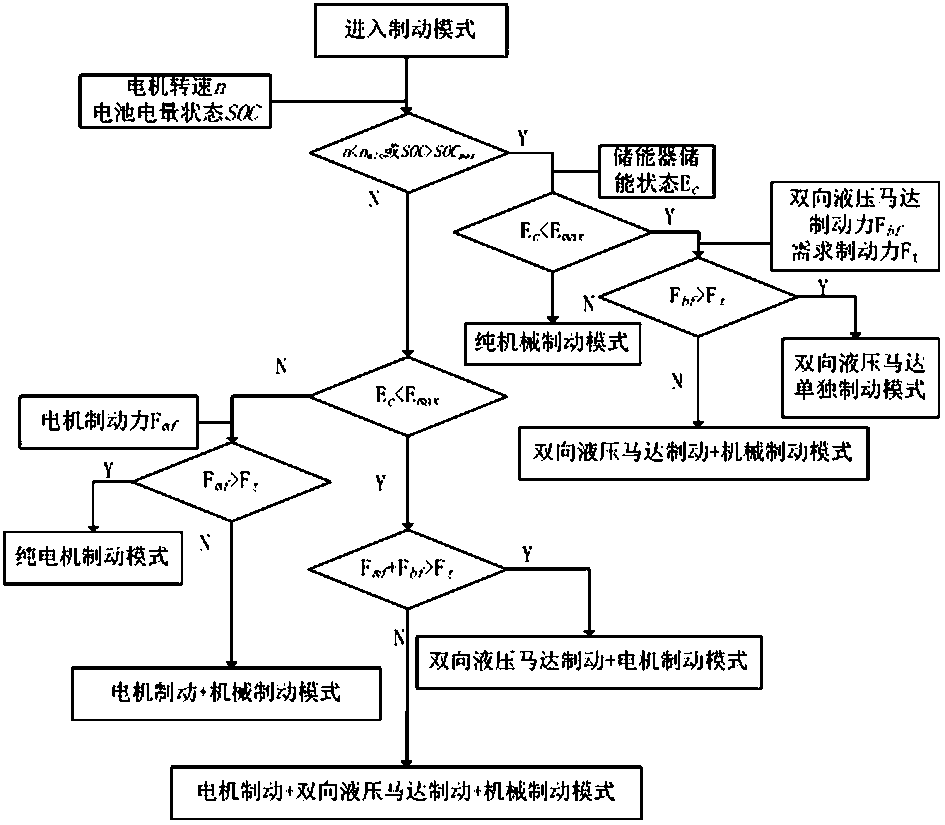

Hydraulic and battery integrated vehicle composite energy system and control method thereof

ActiveCN110962616AExpand the range of working conditionsHigh recycling rateSpeed controllerElectrodynamic brake systemsReduction driveControl cell

The invention provides a hydraulic and battery integrated vehicle composite energy system and a control method thereof. The system comprises a vehicle control unit, a hydraulic accumulator, an electro-hydraulic control module, a bidirectional hydraulic motor, a speed reducing mechanism, a clutch, a driving motor, a speed reducer, a battery, a motor controller, a battery management system, a brakeboosting control unit and a CAN bus. An output shaft of the bidirectional hydraulic motor is connected with one end of a rotor of a driving motor through a reducing mechanism and a clutch; the other end of the rotor of the driving motor is connected with wheels through a reducer; a control port of the bidirectional hydraulic motor is electrically connected with the electro-hydraulic control module, and the bidirectional hydraulic motor, the electro-hydraulic control module, the clutch, the battery management system and the brake boosting control unit are connected to the CAN bus in parallel. Braking energy recovery can be implemented under the working conditions that the SOC value of the battery is higher than the highest charging threshold and the rotating speed of the driving system is lower than the lowest generating threshold rotating speed of the motor, the working condition range of braking energy recovery is expanded, and the braking energy recovery ratio is increased.

Owner:XIANGTAN UNIV

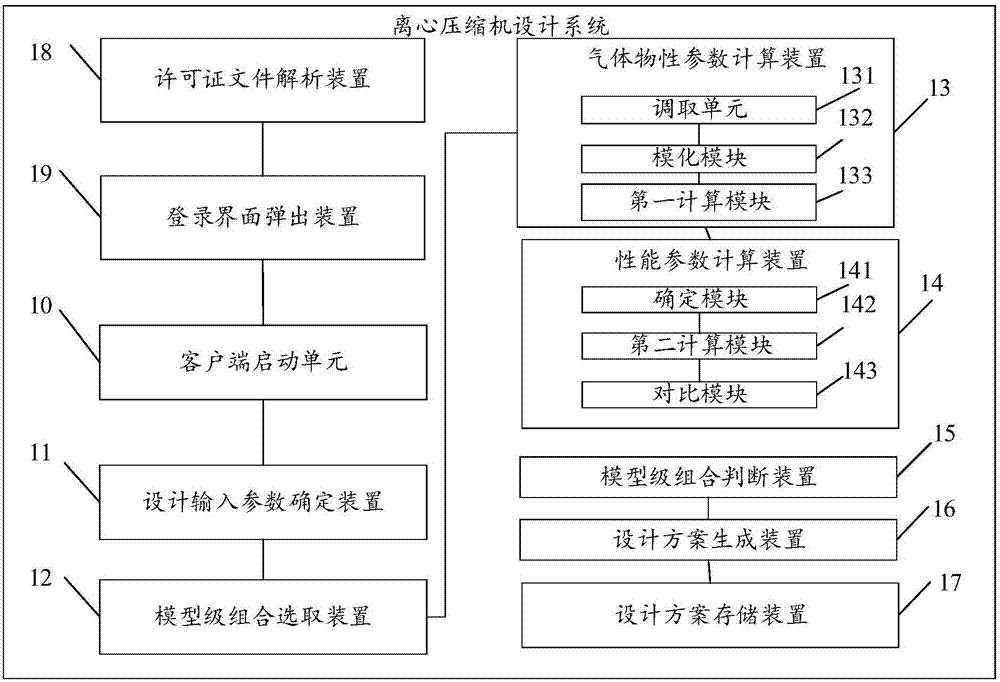

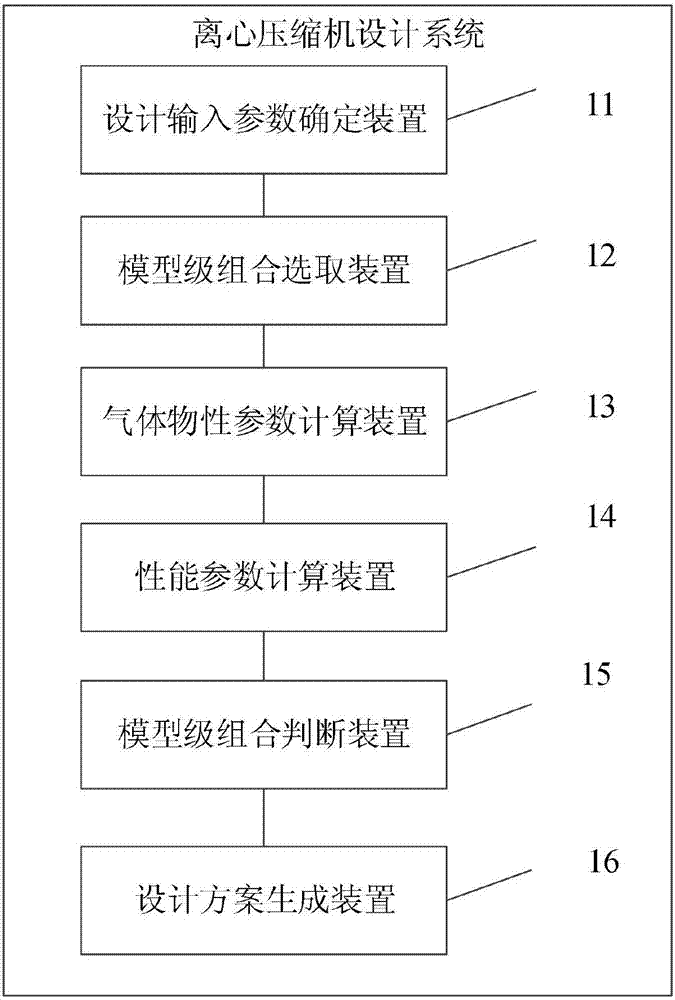

Centrifugal compressor design system

ActiveCN108009382AImprove efficiencyEliminate limitationsGeometric CADDesign optimisation/simulationCentrifugal compressorDesign systems

The invention discloses a centrifugal compressor design system and relates to the field of centrifugal compressor design. The system mainly aims to eliminate the limitation of selecting a model levelaccording to experience, improve the efficiency of a designed centrifugal compressor and expand a working condition range. The system comprises a design input parameter determination device, a model level combination selection device, a gas physical parameter calculation device, a performance parameter calculation device, a model level combination judgment device and a design scheme generation device. Through the devices, a model level combination can be selected from a preset model level database according to design input parameters, and gas physical parameters corresponding to all-level inlet and outlet states of the centrifugal compressor in model level combination modeling are iteratively calculated according to the model level combination and modeling rules; whether the model level combination meets a preset optimal rule is judged according to performance parameters; if yes, a design scheme of the centrifugal compressor is generated; and if not, a model level combination is reselected according to the design input parameters till the preset optimal rule is met.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

Dry low-emission burner

ActiveCN109611891ATaking into account stabilityWell mixedContinuous combustion chamberCombustorPulp and paper industry

The invention belongs to the technical field of burner design, and particularly relates to a dry low-emission burner. The dry low-emission burner includes a venturi tube, a premixing outdoor cylinder,a premixing indoor cylinder, a nozzle body, a main combustion premixing spraying rod and a precombustion premixing spraying rod, wherein the outlet end of the premixing outdoor cylinder is connectedwith the inlet end of the venturi tube, the premixing indoor cylinder is arranged on the inner side of the premixing outdoor cylinder to form a main combustion level premixing channel with the premixing outdoor cylinder, and the nozzle body is arranged on the inner side of the premixing indoor cylinder, and a precombustion premixing level channel is formed between the nozzle body and the premixingindoor cylinder; the nozzle body is internally provided with a precombustion diffusion channel, the precombustion diffusion channel penetrates through the nozzle body in the axial direction, the end,close to the venturi tube, of the precombustion diffusion channel is provided with a precombustion diffusion nozzle hole, and the other end, close to the venturi tube, of the precombustion diffusionchannel communicates with a fuel source; and the inlet end of the main combustion premixing spraying rod communicates with the fuel source, the outlet end is arranged at the inlet end of the main combustion premixing level channel, the outlet end of the main combustion premixing spraying rod is provided with a main combustion premixing nozzle hole, the inlet end of the precombustion premixing spraying rod communicates with the fuel source, the outlet end is arranged at the inlet end of the precombustion premixing level channel, and the outlet end of the precombustion premixing spraying rod isprovided with a precombustion premixing nozzle hole.

Owner:AECC SHENYANG ENGINE RES INST

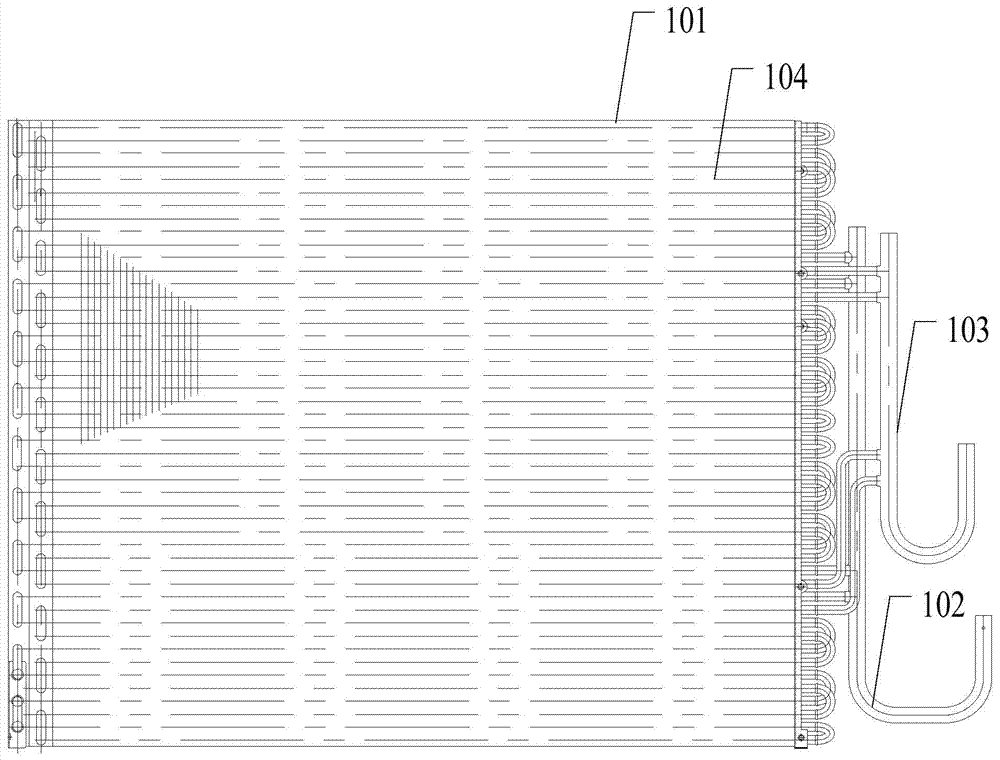

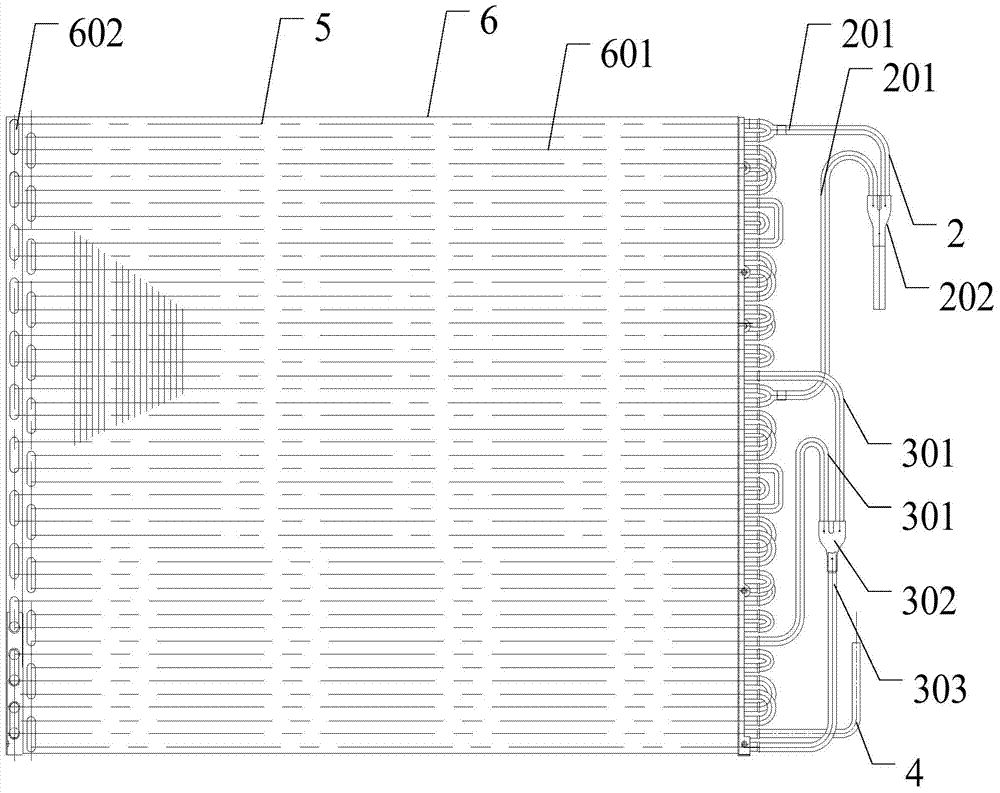

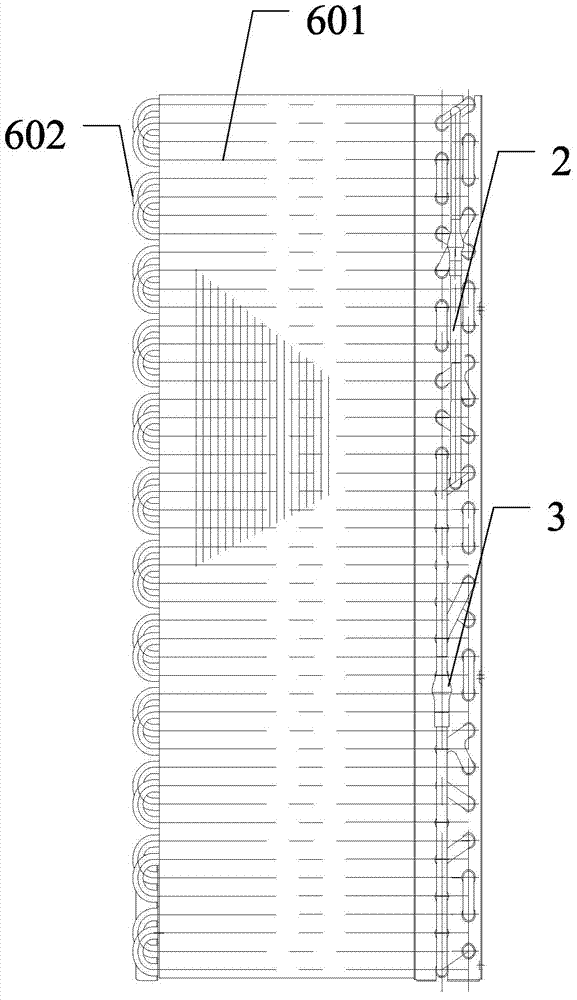

Contraction type heat exchanger

ActiveCN103673402AFully utilize the heat exchange areaGuaranteed to match the volume changeEvaporators/condensersEngineeringHeating effect

The invention discloses a contraction type heat exchanger, which comprises a body, wherein the body is provided with a heat exchange pipe assembly and is provided with an air inlet pipe assembly, a current collecting pipe assembly and a main liquid outlet pipe, the air inlet pipe assembly comprises a plurality of air inlet pipes and a multi-way pipe, one end of each air inlet pipe is connected with the corresponding heat exchange pipe assembly, in addition, a plurality of branches are formed, the other end of each air inlet pipe is collected at the multi-way pipe, the current collecting pipe assembly comprises a liquid outlet branch pipe, a multi-way pipe and a current collecting pipe in arrangement corresponding to each branch, the liquid outlet branch pipe comprises a first liquid outlet branch pipe and a second liquid outlet branch pipe, the first liquid outlet branch pipe realizes the current collection to the current collecting pipe through the multi-way pipe, the second liquid outlet branch pipe is used for liquid outlet, and the main liquid outlet pipe is connected with the current collection pipe through the heat exchange pipe assembly. The contraction type heat exchanger has the advantages that a heat exchanger flow path can be enabled to be anastomotic with the volume change of condensing agents, the heat exchange area of a condenser is sufficiently utilized, the use work condition range of an air conditioner is expanded, the refrigeration and heating effects of the air conditioner are improved, and the comfort degree of the air conditioner is improved, so the use efficiency is maximized.

Owner:GUANGDONG CHIGO AIR CONDITIONING

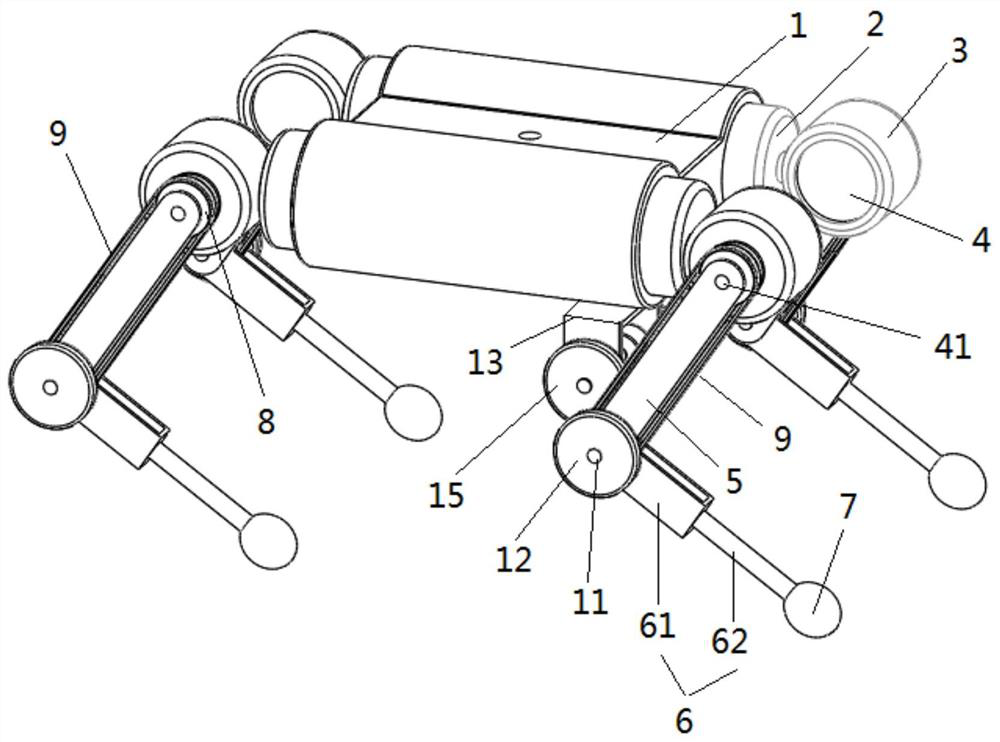

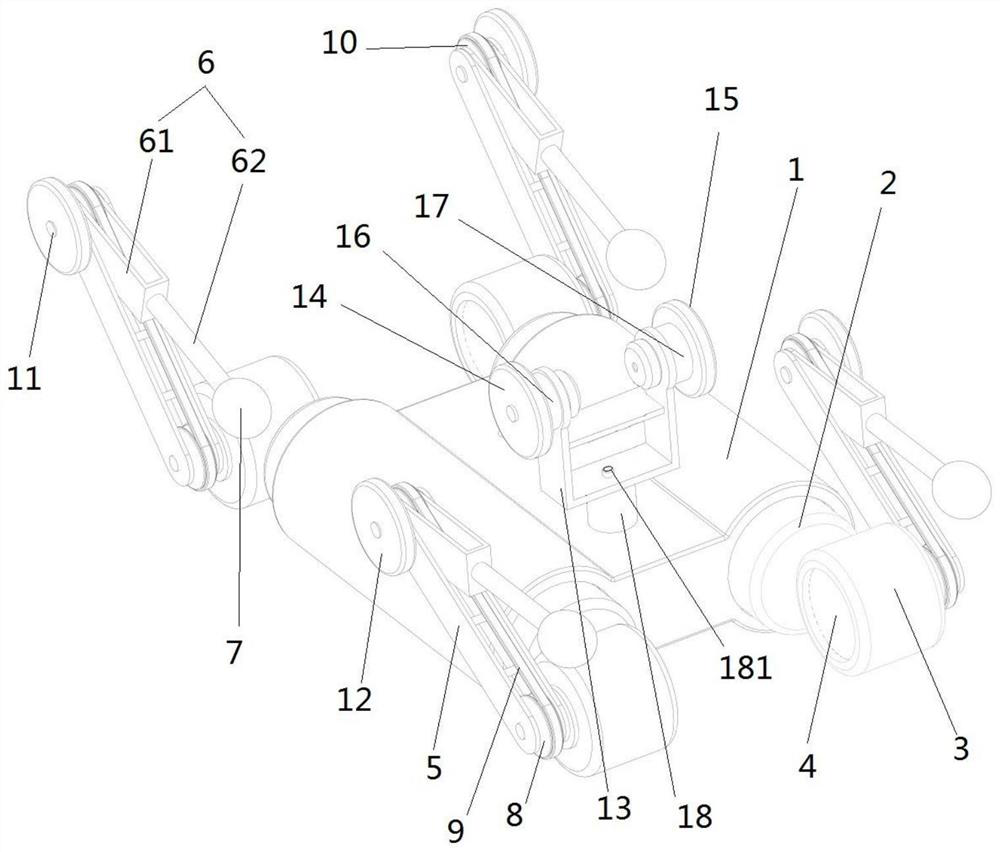

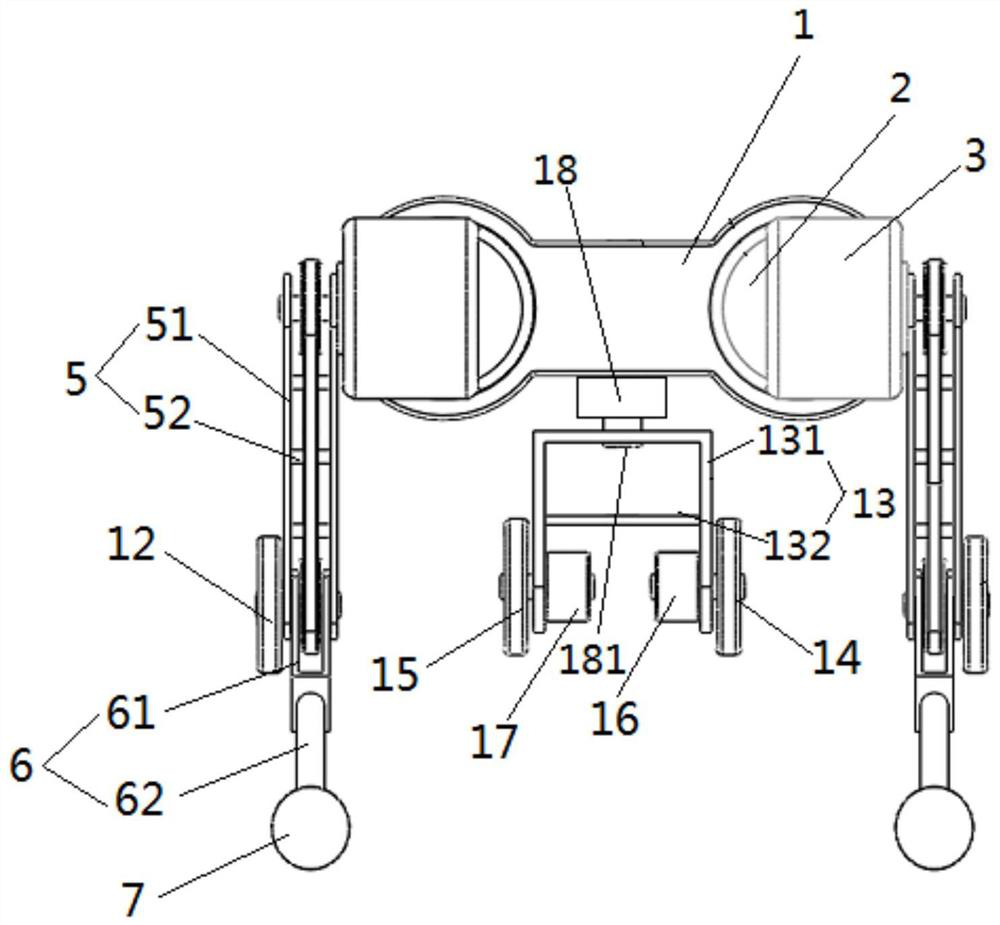

Wheel-foot hybrid robot

PendingCN112519916AImproved location transfer efficiencyGuaranteed working radiusVehiclesPhysical medicine and rehabilitationDrive wheel

The invention provides a wheel-foot hybrid robot. The wheel-foot hybrid robot comprises a robot body, first leg modules and a second leg module. each first leg module comprises a foot part and a supporting wheel; the second leg module comprises a steering motor, a first driving wheel and a second driving wheel; the leg module has two working modes: a foot mode and a wheel mode; in the wheel mode,the supporting wheels assist in supporting the robot body, the first driving wheel and the second driving wheel drive the wheel-foot hybrid robot to move together, and steering of the wheel-foot hybrid robot is achieved through steering of the steering motor. In the foot mode, the second leg module and the supporting wheels are suspended, and the feet of the first leg modules alternately touch theground so as to drive the wheel-foot hybrid robot to move. Compared with the prior art, the position transfer efficiency is greatly improved. In addition, in the foot mode, rapid steering of the wheel-foot hybrid robot can be achieved.

Owner:THE 21TH RES INST OF CHINA ELECTRONIC TECH GRP CORP

Centrifugal radial flow turbine

ActiveCN106089306ANo need to increase RPMIncrease output powerBlade accessoriesStatorsEngineeringTurbine

The invention provides a centrifugal radial flow turbine, compared with a traditional centripetal radial flow turbine, the rotation rate does not need to be increased under the same flow, the output power can be increased and the requirement of the output power of a turbine can be met as long as the level number of the turbine is added; a high speed bearing, a motor and a speed change mechanism do not need to be assembled, the equipment cost can be effectively reduced, the equipment operation safety can be improved, which is conducive to the reliability and stability of equipment; compared with an axial-flow turbine, the centrifugal radial flow turbine is compact in structure, small in size, can well adapt the small flow work condition, and expand the working condition range of the turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

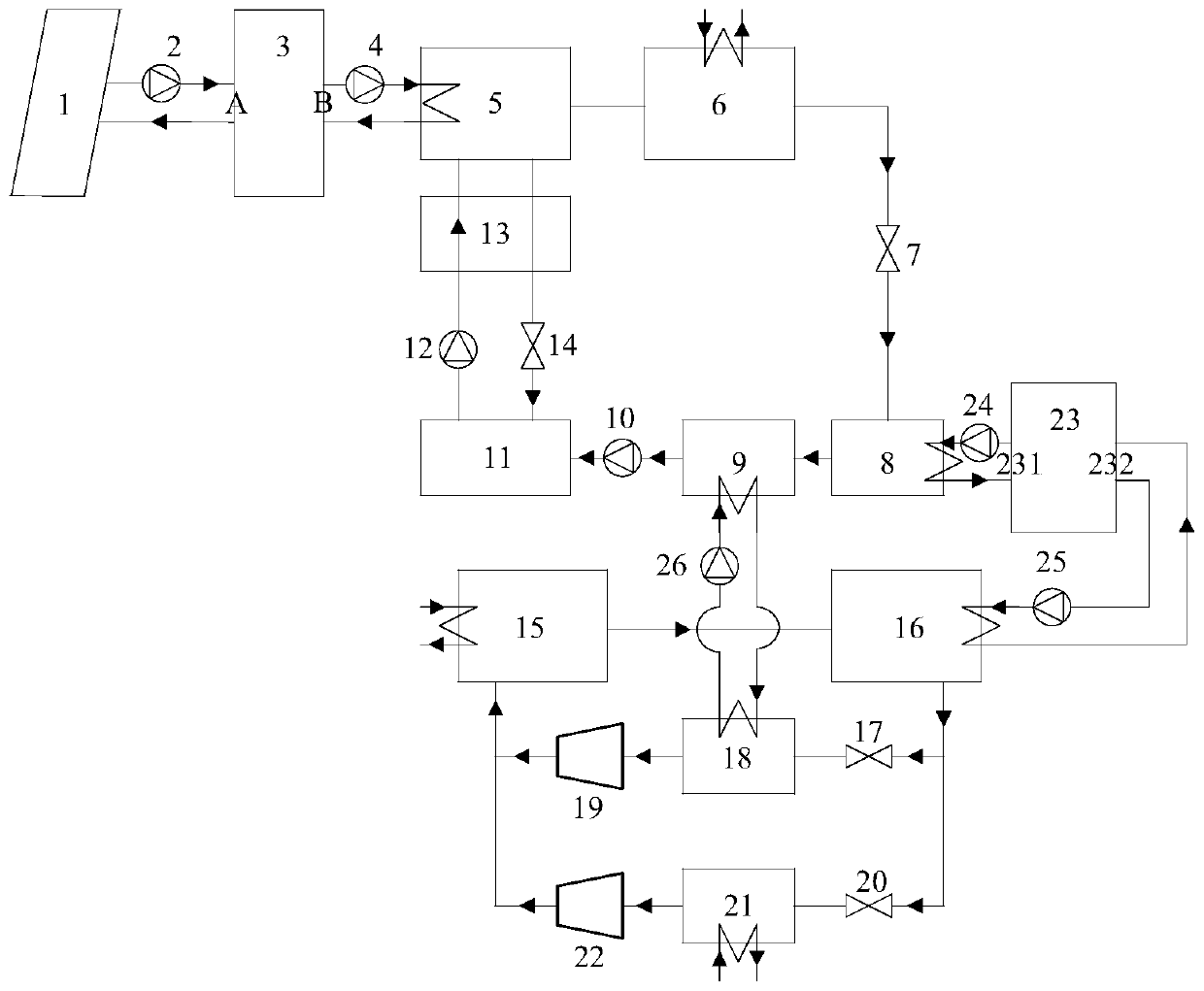

Refrigerating system and method based on secondary condensation pressurization absorption and supercooling compression

ActiveCN110906582AImprove the performance of low-temperature heat source conditionsReduce economic costsMechanical apparatusBoiler absorbersPhysicsCollector device

The invention discloses a refrigerating system and method based on secondary condensation pressurization absorption and supercooling compression. A heat collector is sequentially connected with a first hot water pump and a heat storage tank; the heat storage tank is sequentially connected with a second hot water pump and a generator; the generator is sequentially connected with an absorption circulating condenser, an absorption circulating throttle valve, an absorption circulating evaporator, a secondary condenser, a booster pump, an absorber, a solution pump, a solution heat exchanger and a solution throttle valve; a main-stage circulating compressor is sequentially connected with a condenser, a subcooler, a main-stage throttle valve and a main-stage evaporator; a secondary circulating compressor is sequentially connected with the condenser, the subcooler, a secondary throttle valve and a secondary evaporator; a cold storage tank is sequentially connected with an absorption circulating chilled water pump and an absorption circulating evaporator; and the cold storage tank is sequentially connected with a supercooling pump and the subcooler. According to the system, secondary condensation and the booster pump are combined to replace a large water vapor compressor to achieve pressurization absorption, and therefore, a heat source working condition range is widened, and the low-temperature heat source working condition performance of the system is remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

Tellurium beryllium copper alloy and preparation method thereof

The invention discloses a tellurium beryllium copper alloy. The tellurium beryllium copper alloy comprises the following components in percentage by weight: 0.2-2.1wt.% of beryllium Be, 0.1-0.7wt. / % of tellurium Te, other elements: cobalt Co, nickel Ni, lead Pb, rare earth elements and impurity elements, and the balance of Cu, wherein lead Pb is smaller than or equal to 0.6wt.% and the sum of other elements is smaller than or equal to 4wt.%. A preparation method comprises the following steps: a, proportioning, feeding, smelting and casting the components in percentage by weight to obtain ingotblanks; and b, carrying out homogenization heat treatment, hot processing process, cold processing process and annealing, solid solution and aging heat treatment successively on the ingot blanks obtained in the step a to obtain the tellurium beryllium copper alloy. By adding tellurium into the tellurium beryllium copper alloy, tellurium and a copper matrix form a compound Cu2Te. The tellurium beryllium copper alloy is more excellent in heat processing property than that of a beryllium copper alloy, and also has the physical, mechanical and anti-corrosive properties of the beryllium copper alloy. By adding tellurium, the machinability of the beryllium copper alloy can be improved on the premise of environment-friendliness.

Owner:KINKOU SUZHOU COPPER IND CO LTD

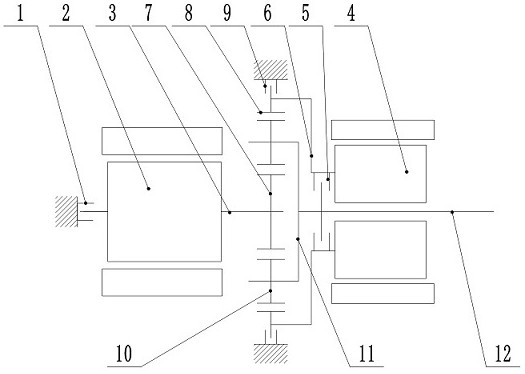

Dual-motor drive system for electric vehicle

InactiveCN112549940AExpand the range of working conditionsAvoid normal workElectric propulsion mountingControl devicesElectric machineryElectric vehicle

The invention relates to a dual-motor drive system of an electric vehicle. The dual-motor drive system is provided with a first motor, a second motor and a planetary mechanism, and stepless speed change is achieved. According to the electric vehicle, by arranging the double motors and a continuously variable transmission, the working condition range of the electric vehicle is expanded, and the economical efficiency is improved.

Owner:派腾奥普科技服务(北京)有限公司

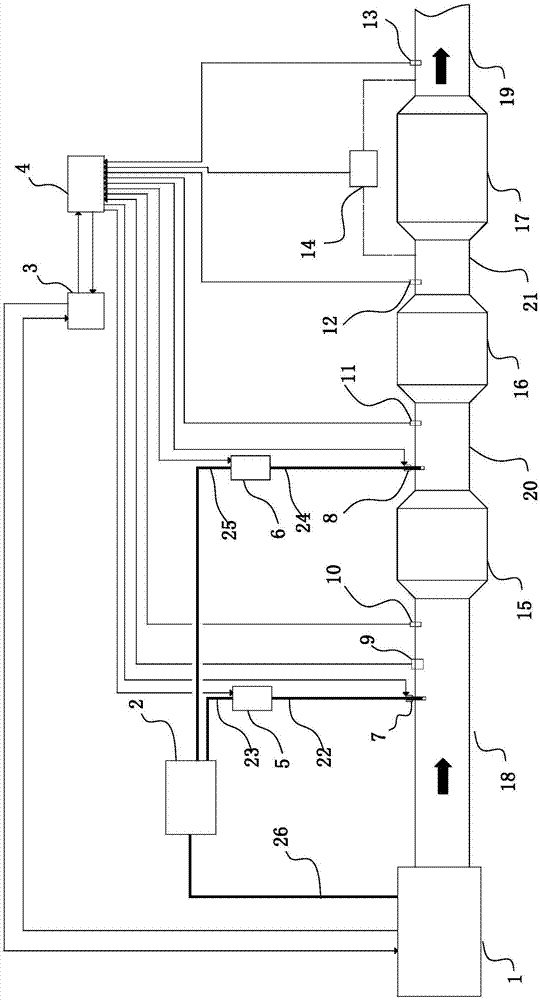

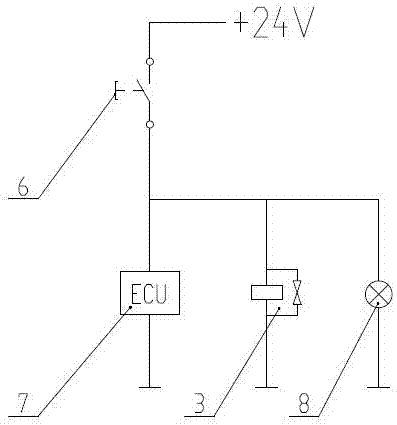

Double evaporation type DPF regeneration system for light vehicle

PendingCN107237663AIncrease temperatureReduce the impactInternal combustion piston enginesExhaust apparatusParticulatesFuel tank

The invention relates to a DPF regeneration system, in particular to a double evaporation type DPF regeneration system for a light vehicle, and belongs to the technical field of diesel engine tail gas treatment. The double evaporation type DPF regeneration system comprises a diesel engine, a fuel tank, an ECU, a DCU, a primary evaporation type fuel injection device, a secondary evaporation type fuel injection device, a primary oxidation catalytic converter and a secondary oxidation catalytic converter. The exhaust end of the diesel engine is connected with the air inlet end of the primary oxidation catalytic converter through an exhaust manifold, the air outlet end of the primary oxidation catalytic converter is connected with the air inlet end of the secondary oxidation catalytic converter through a first middle exhaust pipe, the primary evaporation type fuel injection device is arranged between the diesel engine and the primary oxidation catalytic converter, and the secondary evaporation type fuel injection device is arranged between the primary oxidation catalytic converter and the secondary oxidation catalytic converter. Exhaust gas of the diesel engine is heated twice, and the working condition range of the engine capable of carrying out particulate matter trap regeneration can be greatly enlarged.

Owner:WUXI WEIFU HIGH TECH CO LTD

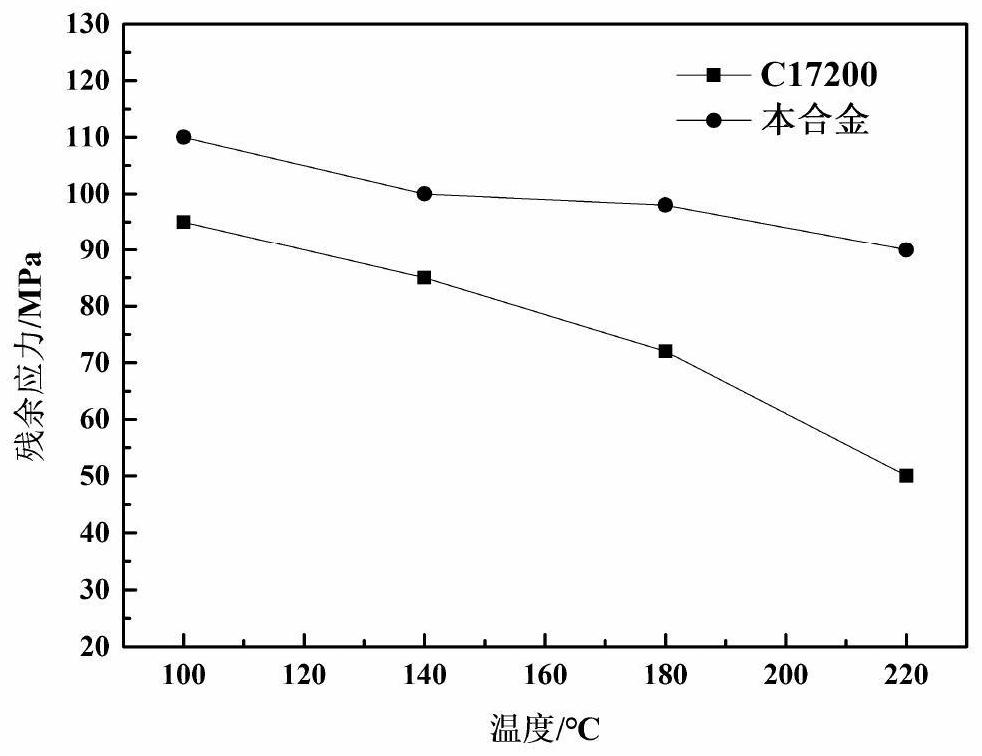

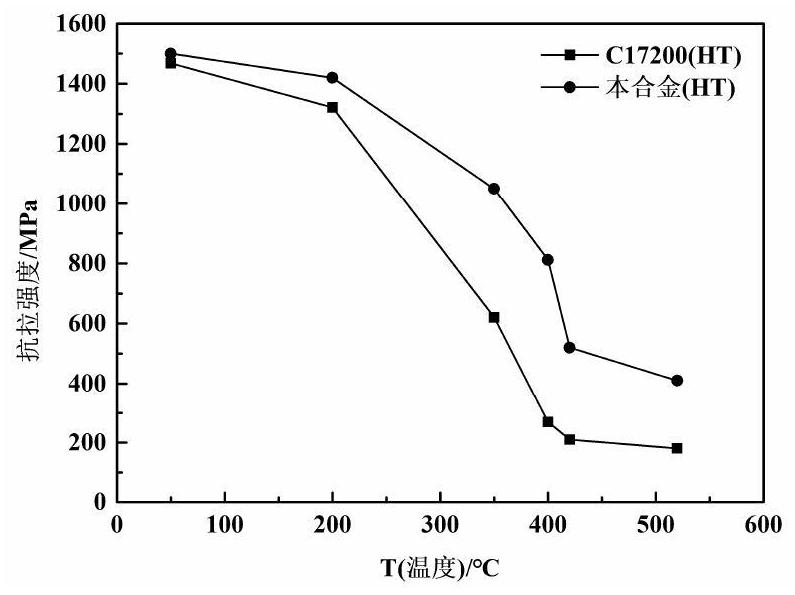

Preparation method of easy-for-turning Be-Cu alloy resistant to high-temperature softening and stress relaxation

The invention discloses a preparation method of an easy-for-turning Be-Cu alloy resistant to high-temperature softening and stress relaxation. The easy-for-turning Be-Cu alloy comprises 0.2-2.1 wt.% of Be, 0.1-0.7 wt.% of Te, more than 0.2 wt.% of Co and Ni, less than 0.7 wt.% of Co, Ni and Fe, no more than 4 wt.% of the sum of impurity elements, and the balance Cu. The preparation method comprises the following steps: a, carrying out blending, feeding, smelting and spray deposition according to the weight percentage, so as to obtain an ingot blank; and b, subjecting the ingot blank obtained in the step a to homogenizing heat treatment, hot machining technology, cold working technology as well as annealing, solid solution and aging heat treatment, so as to obtain the easy-turning Be-Cu alloy. Compared with that of a traditional high-Be Be-Cu alloy, the high-temperature softening temperature point of the the easy-for-turning Be-Cu alloy is improved by 75 DEG C + / - 10 DEG C; compared with that of a traditional low-Be Be-Cu alloy, the high-temperature softening temperature point of the the easy-for-turning Be-Cu alloy is improved by 90 DEG C + / - 10 DEG C; compared with that of a traditional Be-Cu alloy, the stress relaxation resistance of the easy-for-turning Be-Cu alloy is improved by 30%; and the Be-Cu material application working condition range is enlarged.

Owner:KINKOU SUZHOU COPPER IND CO LTD

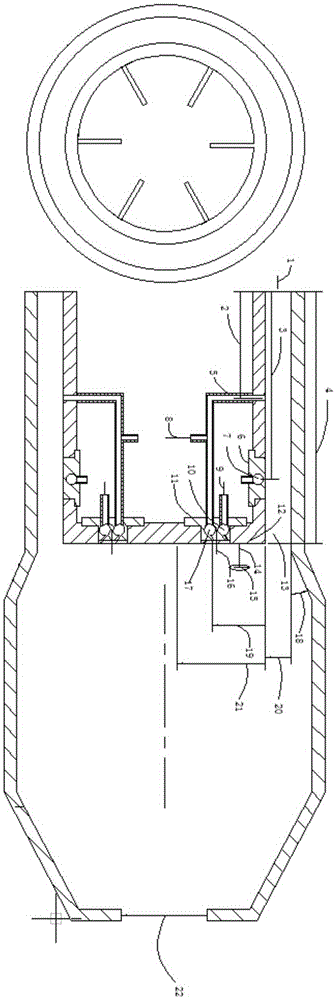

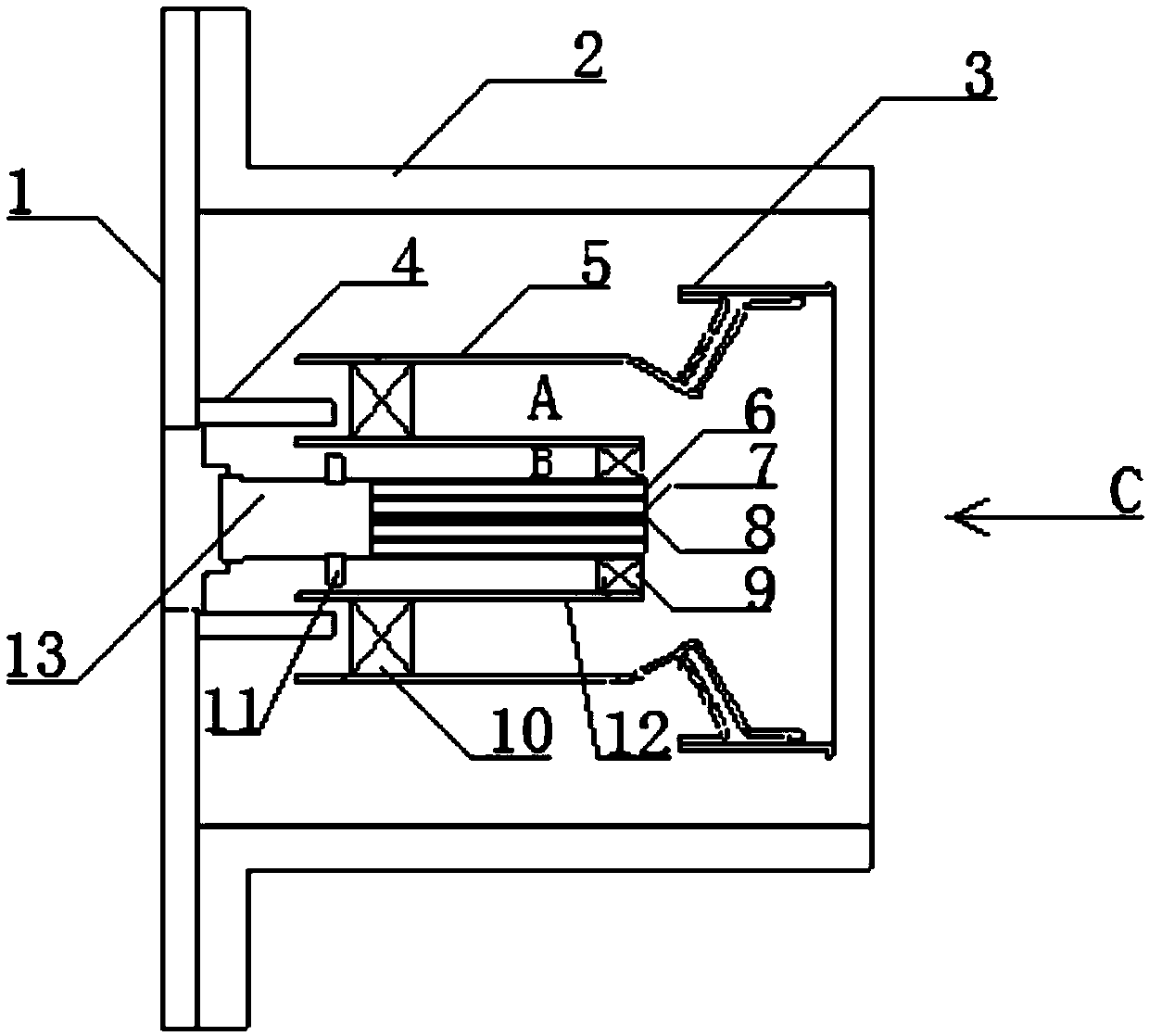

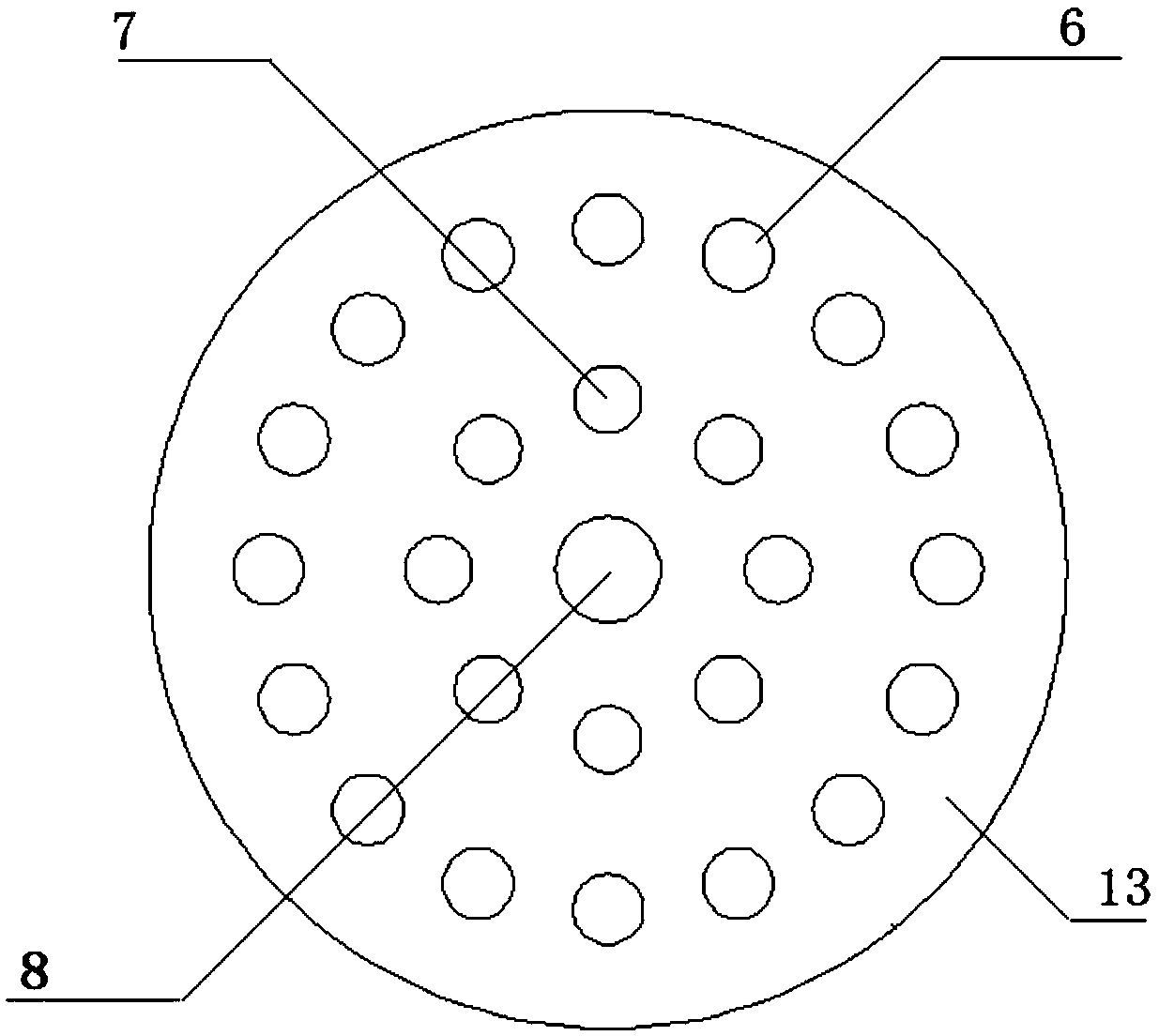

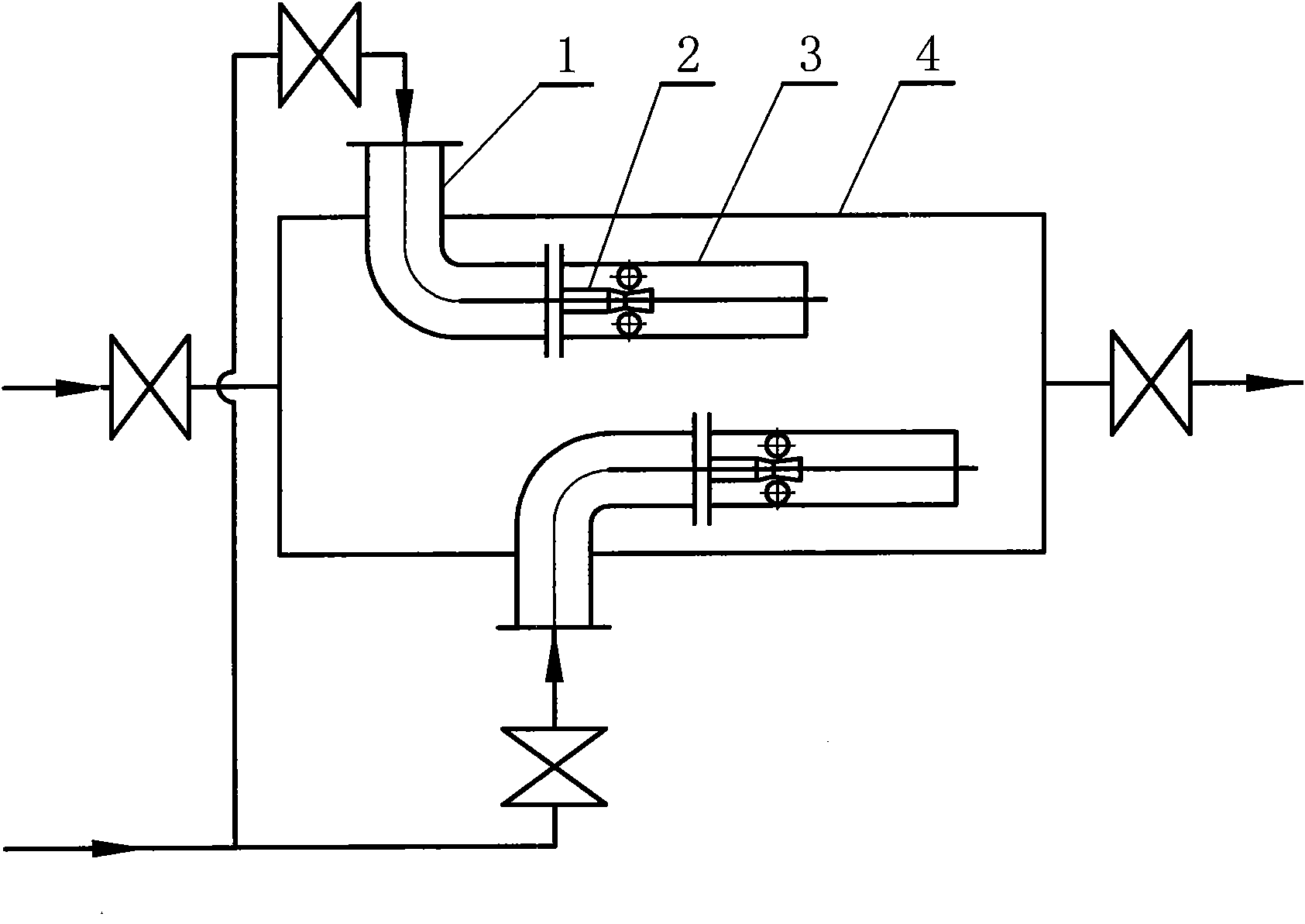

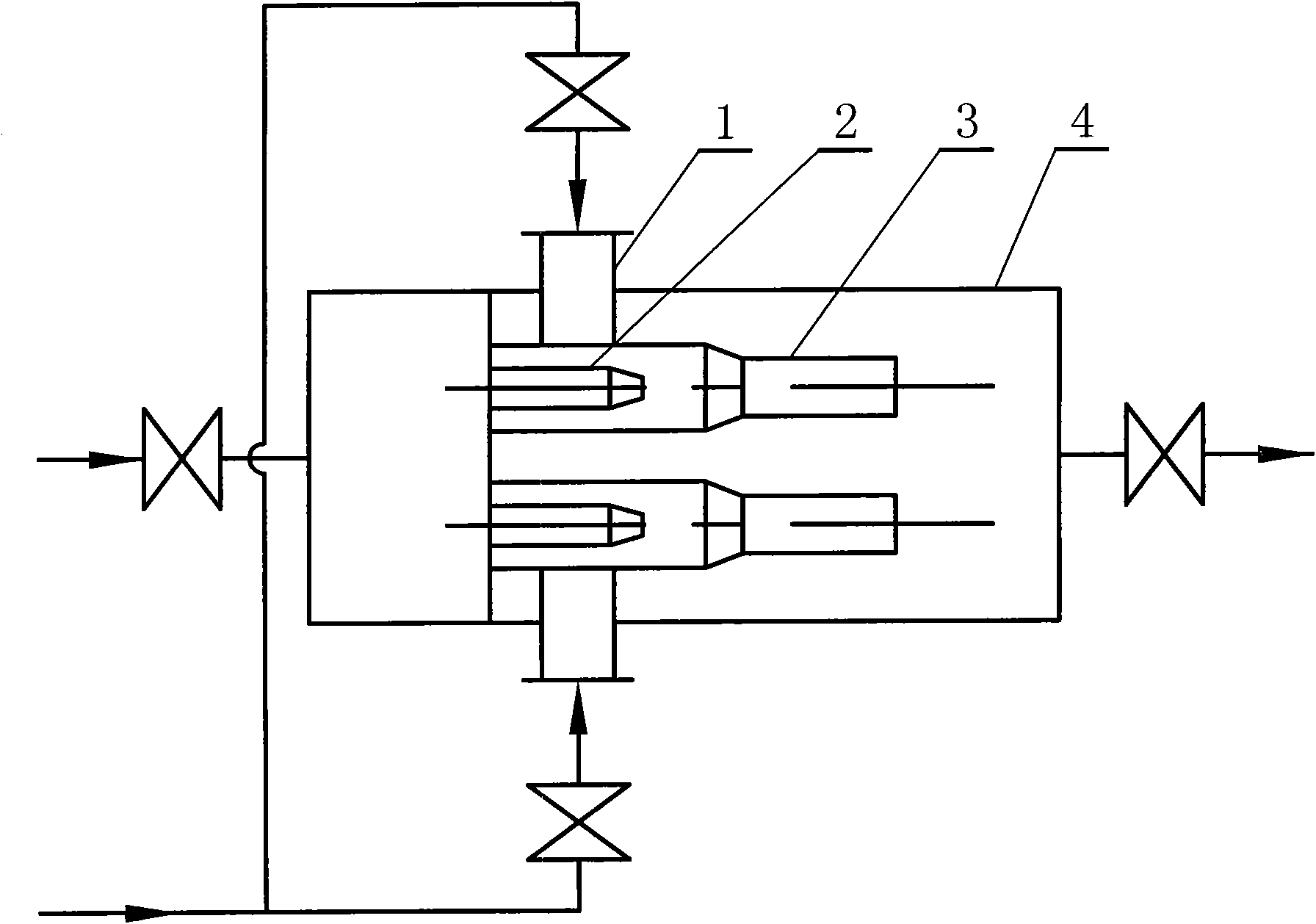

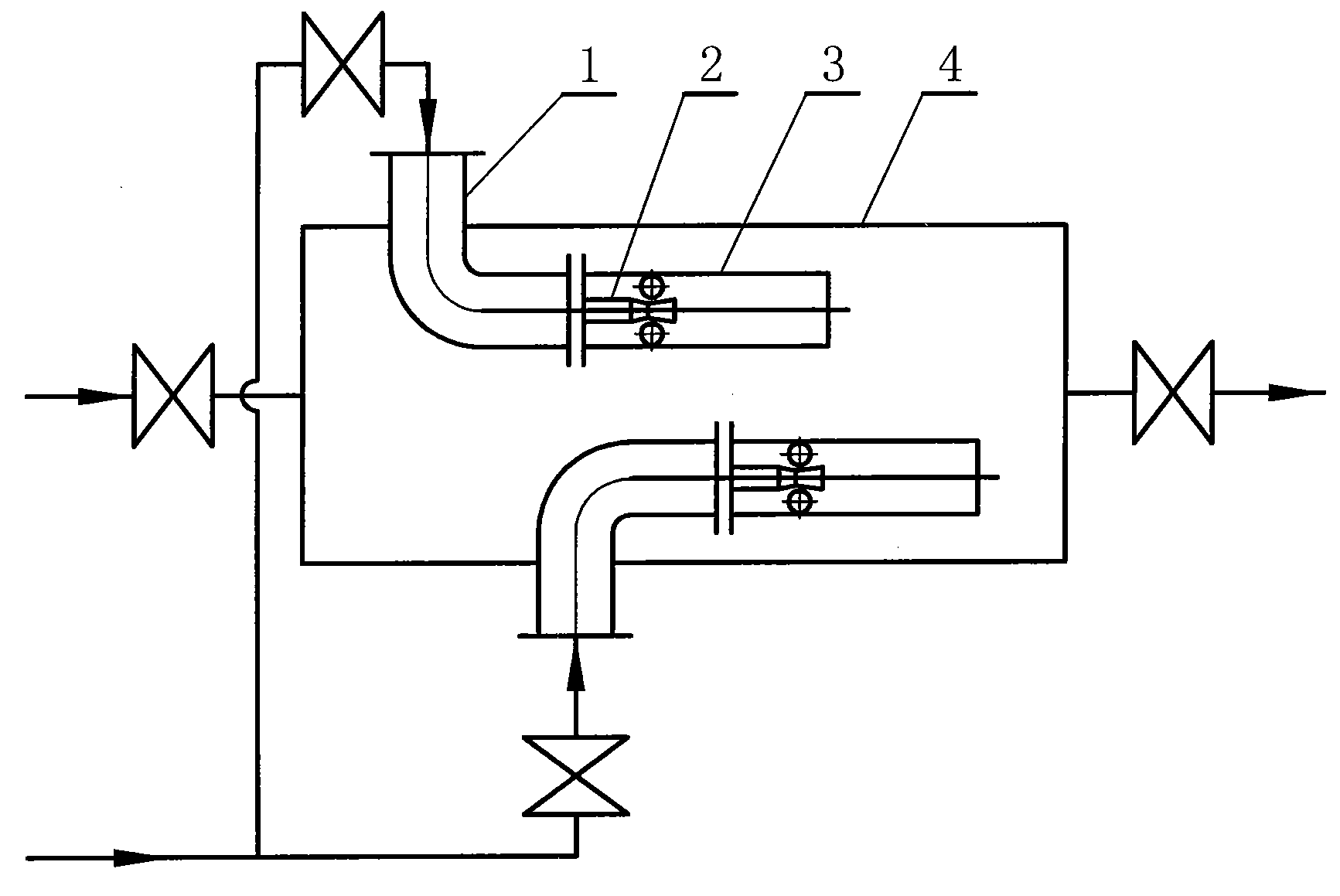

Multi-nozzle and multi-channel heater of steam-water two phase flow mixed type

The present invention discloses a heater, especially discloses a multi-nozzle and multi-channel heater of a steam-water two phase flow mixed type. The multi-nozzle and multi-channel heater of the steam-water two phase flow mixed type comprises a heater shell (4) and a plurality of channels, wherein each channel comprises a steam inlet (1), a nozzle (2) and a mixing tube (3). The heater provided in the invention reduces the flow rate of each channel, thereby decreasing the noise of steam-water mixing, and can close an individual channel without influencing the hydraulic operating condition of other channels when load reduces, being able to work steadily and enlarge the changing scope of heater operating condition and maintain steam bubble rate and slip speed changeless, thereby solving the problem of water hammer.

Owner:王汝武

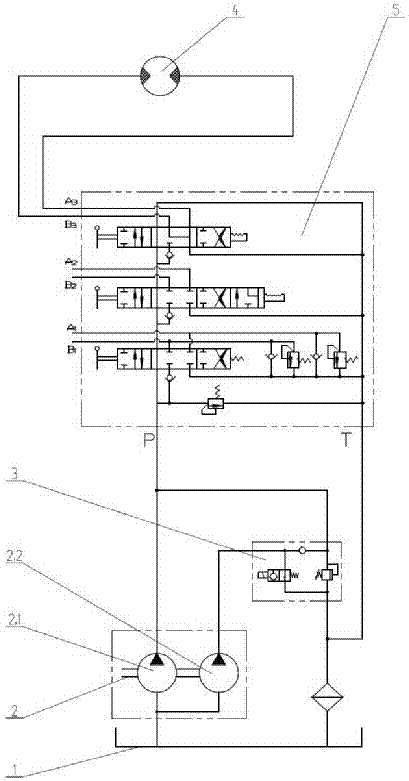

Wheeled loader capable of being configured with travelling working machine tool

ActiveCN107119741AExpand the range of working conditionsWill not affect the efficiency of transition operationsSoil-shifting machines/dredgersSolenoid valveHydraulic pump

The invention discloses a wheeled loader capable of being configured with a travelling working machine tool and belongs to the technical field of engineering machinery. An engine is provided with two working curves, namely the standard working curve and the machine tool mode curve; A hydraulic pump is a double pump; an oil outlet of a main pump body is connected with a multi-channel valve connected with a machine tool motor; an oil outlet of an auxiliary pump body is connected with a solenoid valve; the solenoid valve comprises two oil outlets; and one oil outlet of the solenoid valve is connected to the multi-channel valve, and the other oil outlet of the solenoid valve is connected to a hydraulic oil tank. When an electronic control button is in a natural state, an engine ECU is in the standard working curve state, and at this time, the main pump body independently supplies oil to a whole hydraulic system; when the electric control button is pressed down, the main pump body and the auxiliary pump body jointly supply oil to the whole hydraulic system; and therefore, a flow supplied to the machine tool motor by the hydraulic pump is increased, furthermore, the travelling speed of the loader and the proportional coefficient of the flow output by the hydraulic pump of the loader to the machine tool motor are decreased, and the function of travelling working is realized.

Owner:XCMG CONSTR MACHINERY

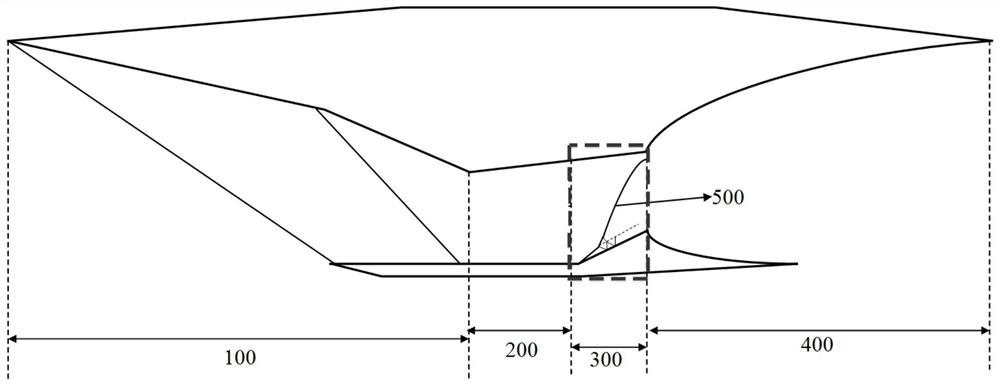

Detonation combustion chamber, scramjet engine and hypersonic aircraft

ActiveCN113048516AReduce the temperatureRelieve pressureIntermittent jet plantsExplosive combustion chamberRamjetCombustion chamber

The invention provides a detonation combustion chamber, a scramjet engine and a hypersonic aircraft. The detonation combustion chamber is characterized in that a slope is arranged in the combustion chamber, the slope is obliquely arranged upwards from the inlet end of the combustion chamber to the outlet end of the combustion chamber, a suction hole is formed in the surface of the slope, the suction hole communicates with a suction device or a vacuum cavity, a suction valve is arranged in the suction hole, and the position of the suction valve is lower than the slope surface; when the suction valve is closed, the suction hole above the suction valve forms a concave cavity in the surface of the slope, and a post-wave product can be sucked when the suction valve is opened. According to the detonation combustion chamber, through the design of the suction hole and the suction valve, the concave cavity and wall surface suction are applied to the slope at the same time, the purposes of promoting oblique detonation wave detonation and restraining oblique detonation wave forward transmission are achieved, and therefore the stationary range of oblique detonation waves can be widened.

Owner:NAT UNIV OF DEFENSE TECH

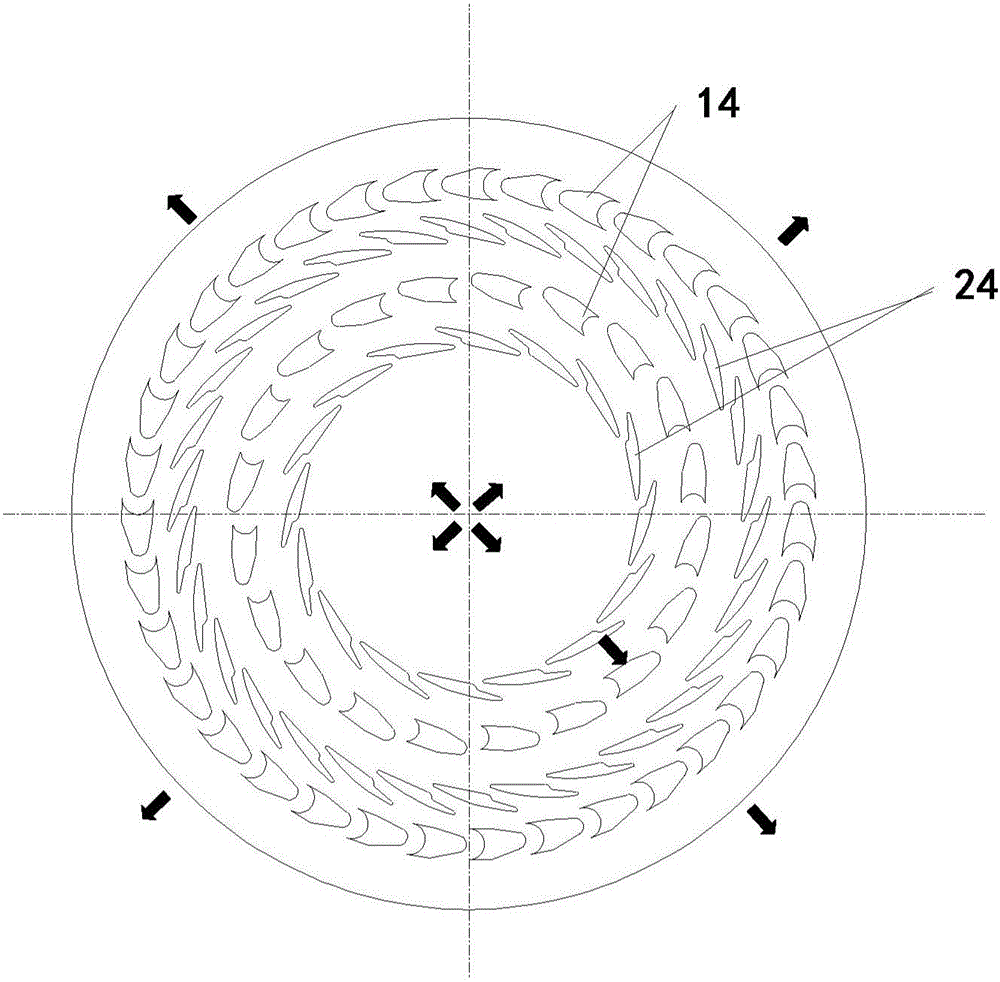

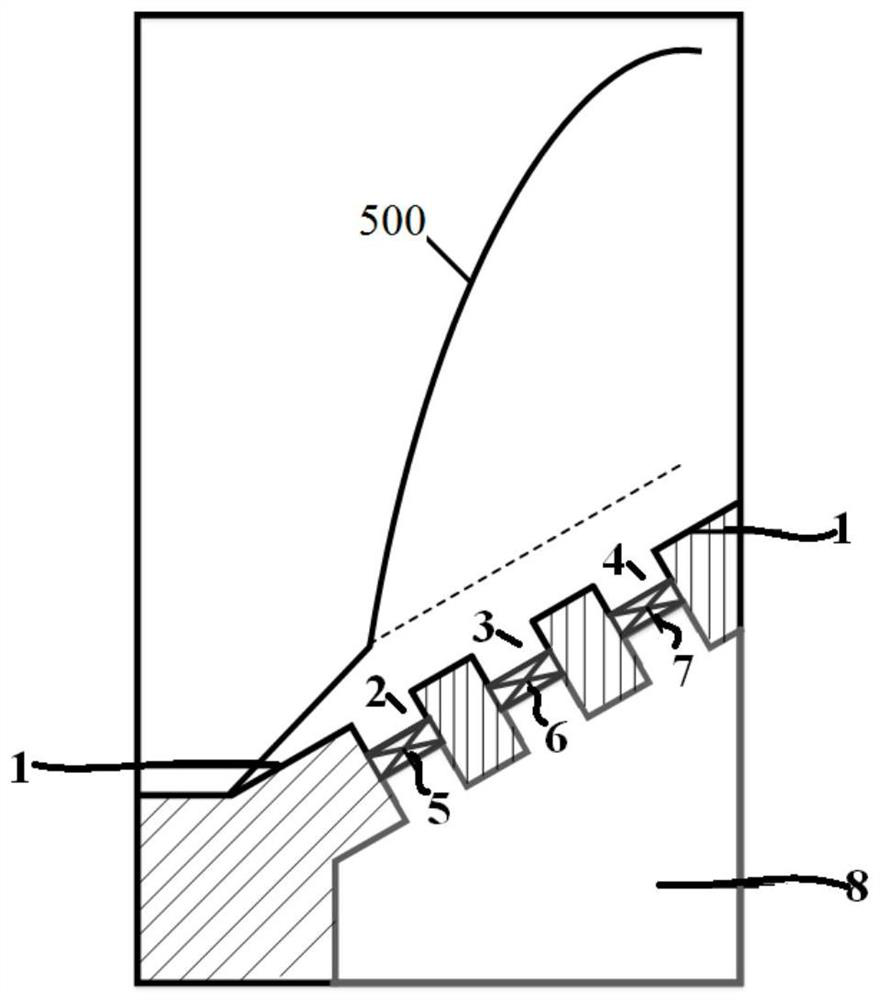

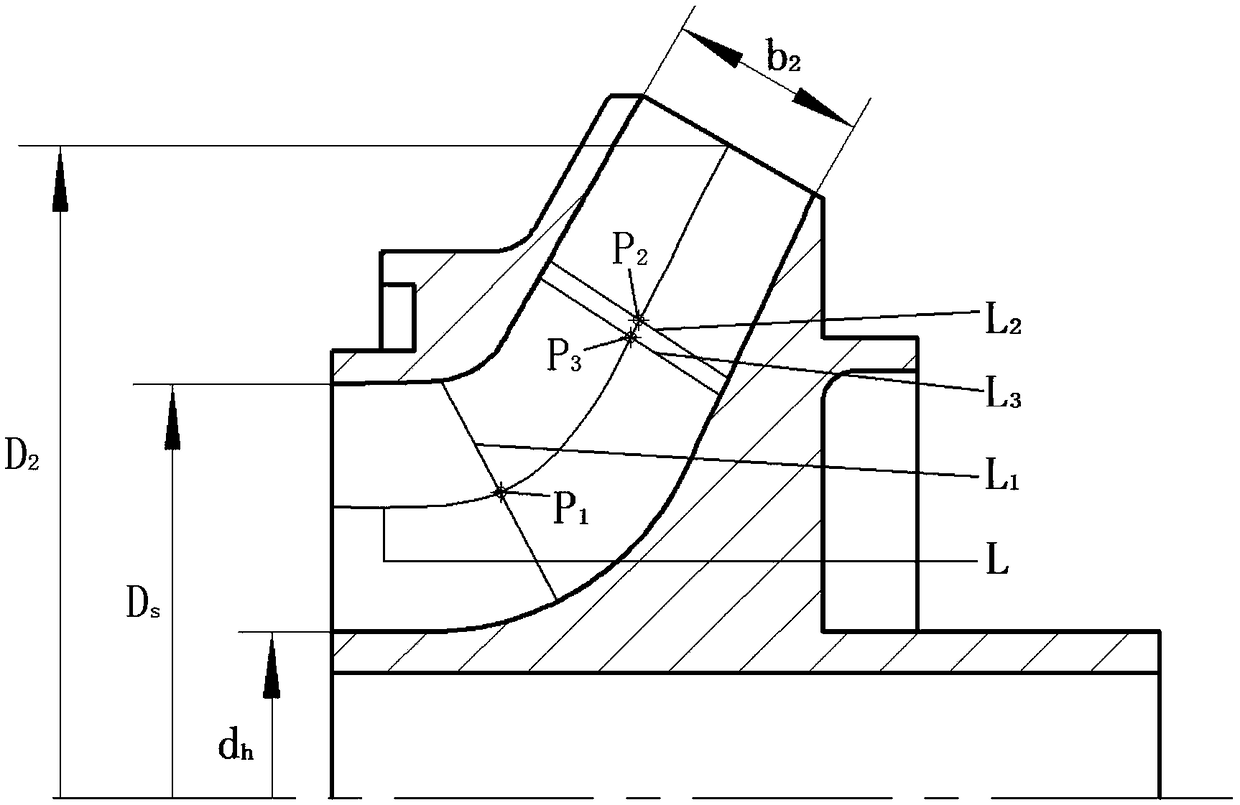

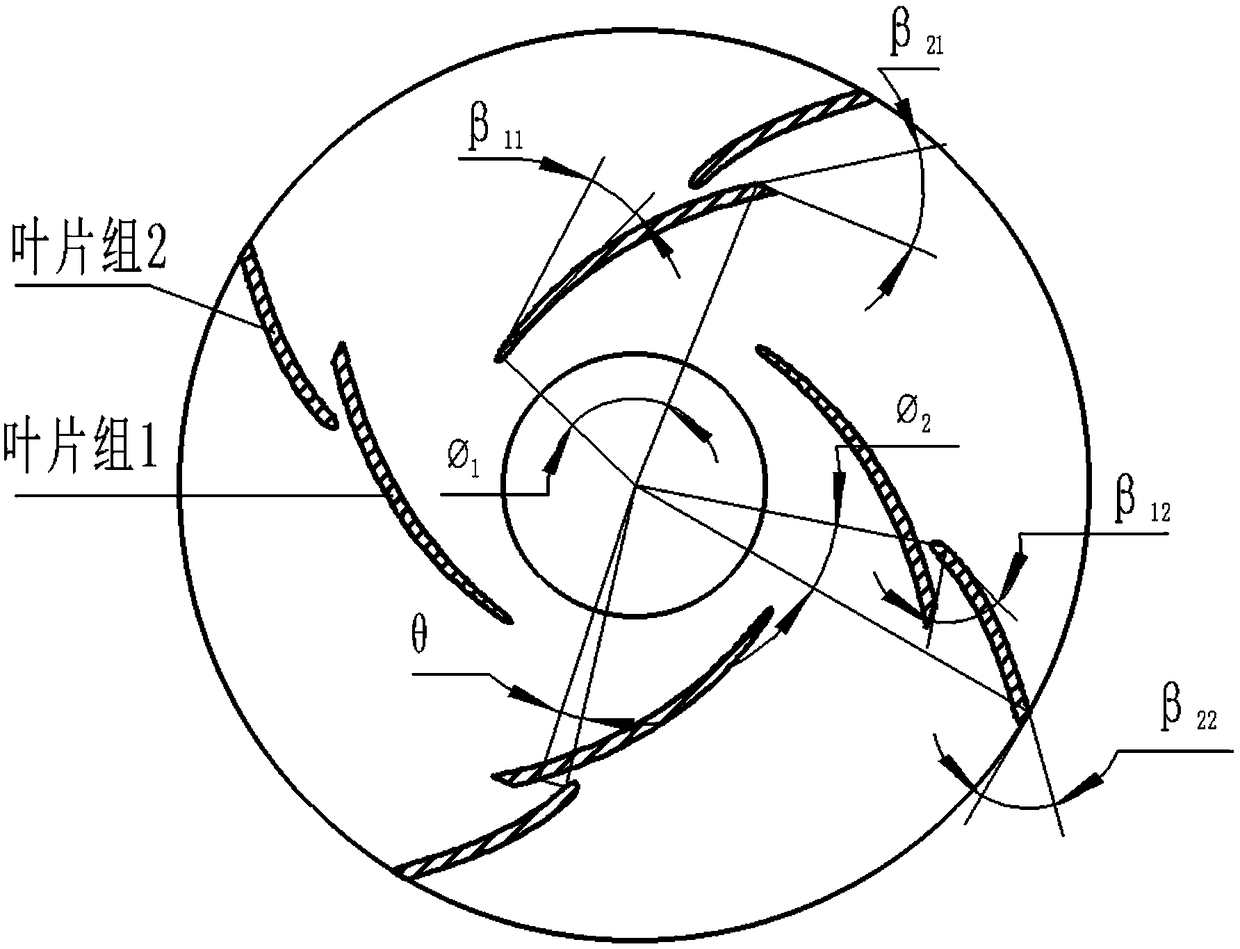

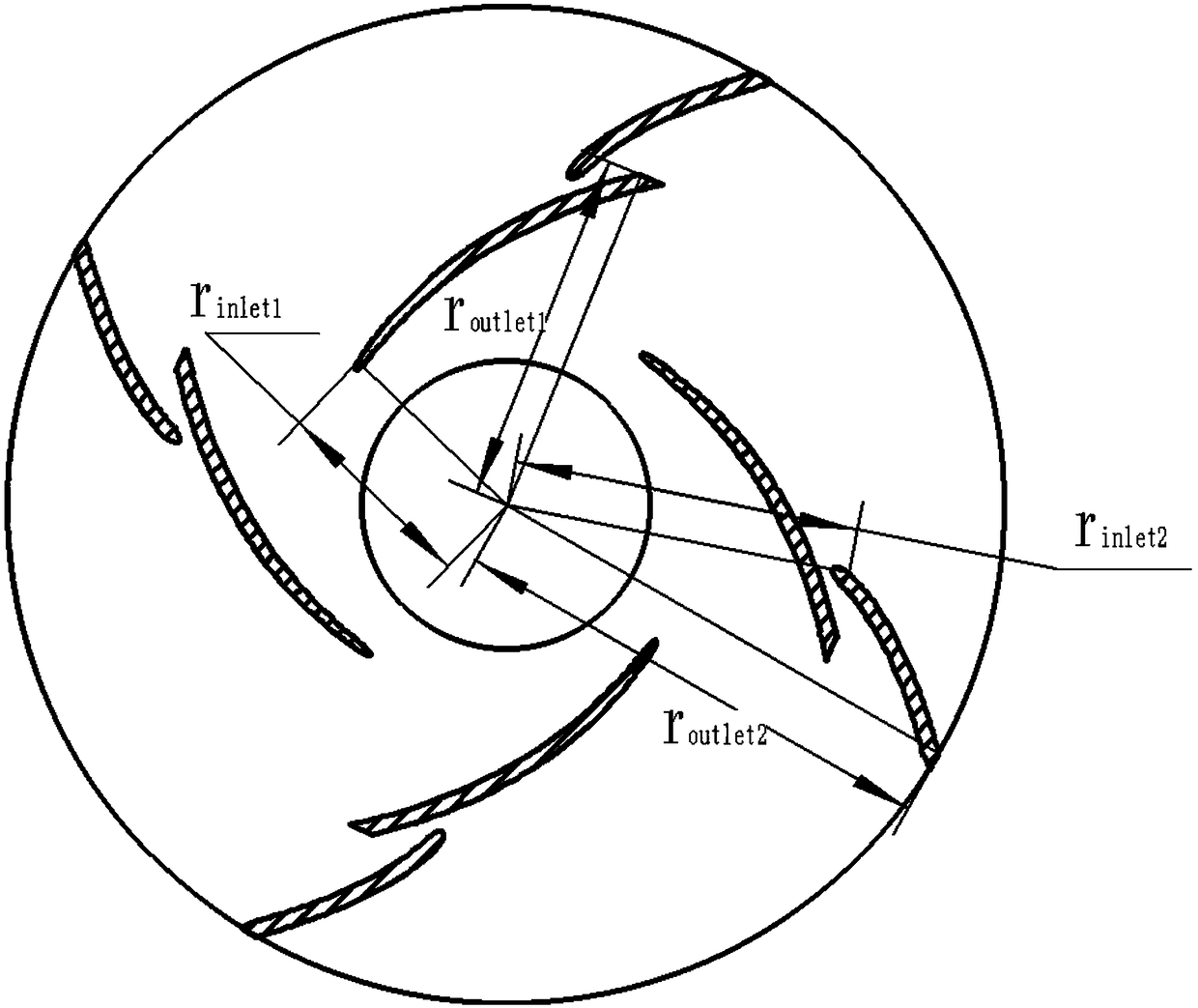

A design method of submersible pump impeller with wide-width characteristics is presented

PendingCN109359415AExpand the range of working conditionsSafe and stable operationGeometric CADSpecial data processing applicationsImpellerOil well

The invention provides the designed head H3 / 4 and the rated speed n parameter at the designed head H1 / 2, 3 / 4Qmax at the designed maximum flow rate Qmax and 1 / 2Qmax at the design head H1 / 2, 1 / 4Qmax, and the geometric parameters of the impeller are adjusted. , impeller outlet diameter D2, impeller inlet diameter Ds, impeller outlet width b2, first group vane inlet side L1, second group vane inlet side L3, first group vane outlet side L2, first set of vane inlet mounting angle beta11, A set of blade exit angles beta 21, a first set of blade wrap angle Phi 1, a second set of blade inlet angles beta12, a second set of blade exit angles beta22, a second set of blade wrap angle Phi 2, and a circumferential relative between the two sets of blades Angle theta. The invention can adapt the submersible electric pump to the variable oil well productivity and ensure the long-term safe and stable operation of the submersible electric pump.

Owner:JIANGSU UNIV

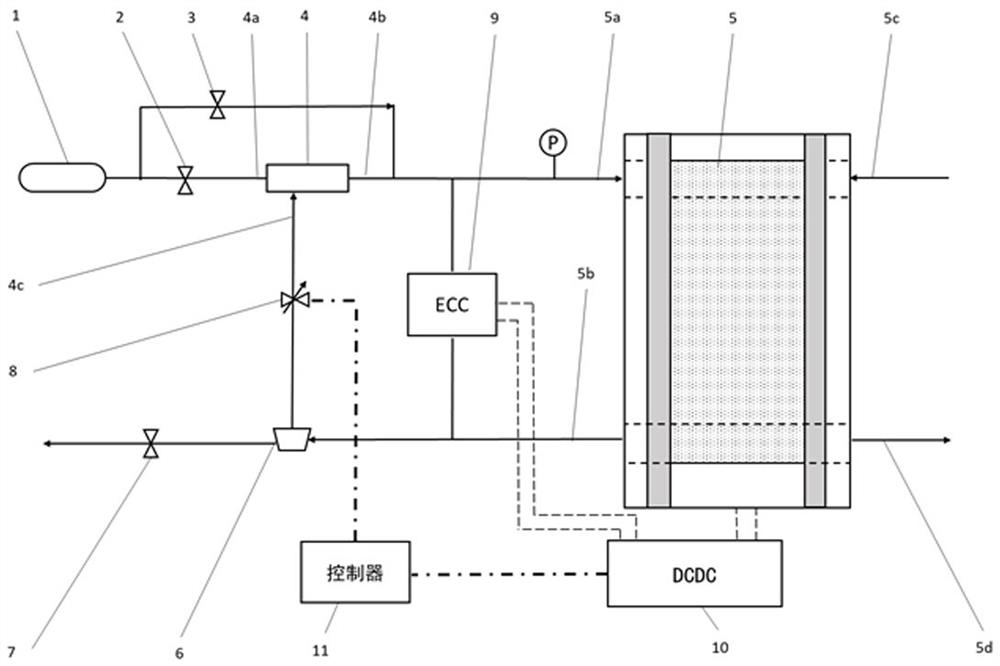

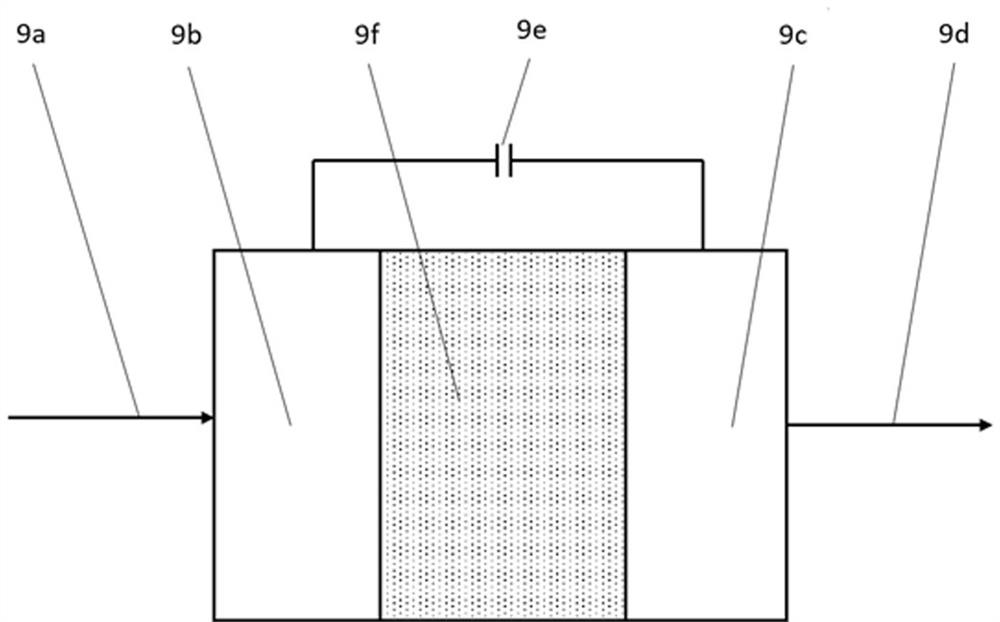

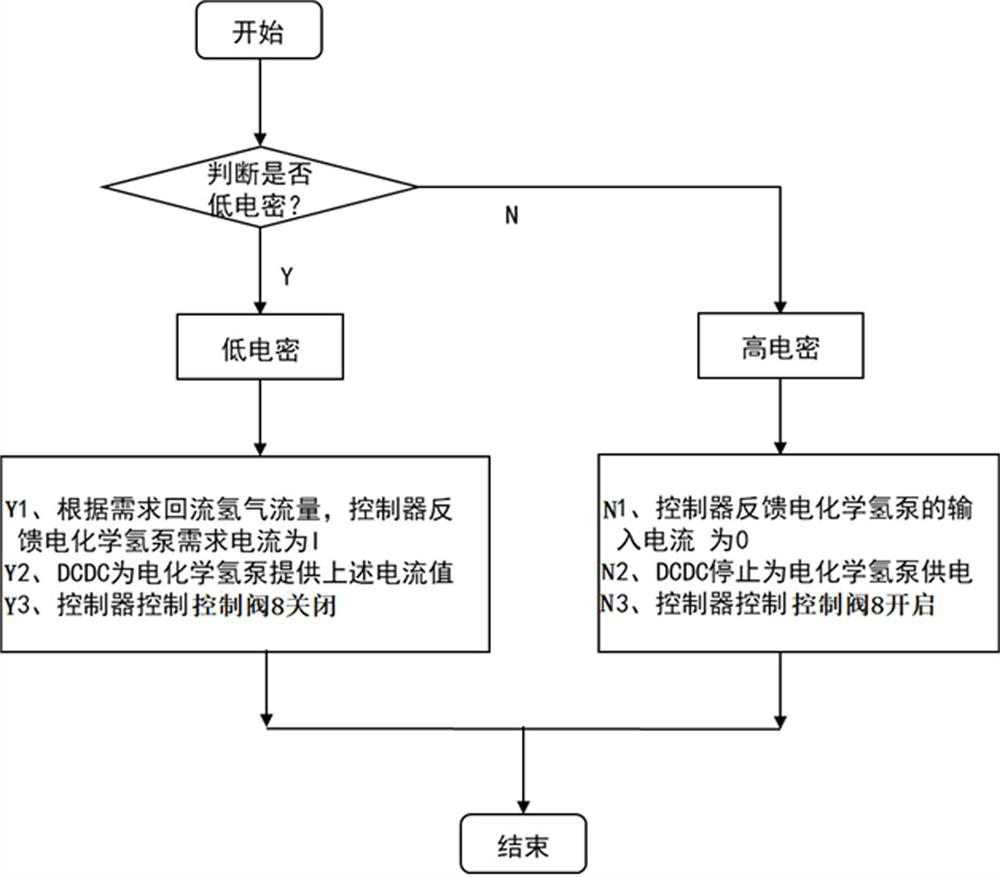

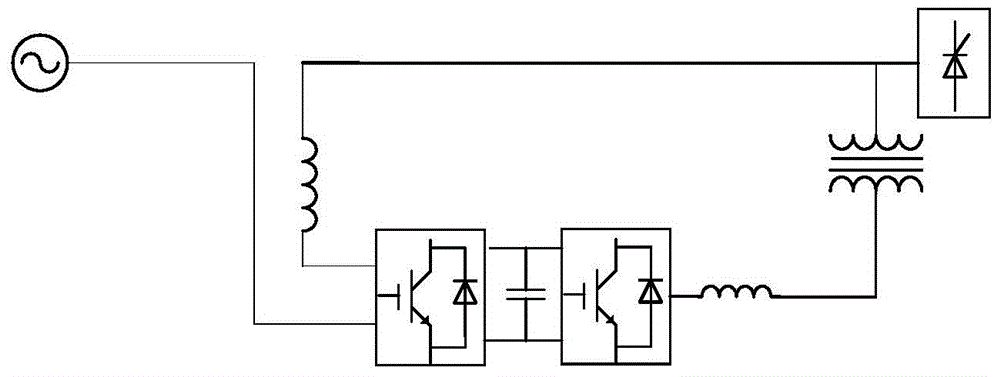

Fuel cell anode circulation system and control method thereof

The invention belongs to the technical field of fuel cells, and relates to a fuel cell anode circulating system and a control method thereof.The system comprises a hydrogen tank, an electric pile, an ejector, a water segregator, an electrochemical hydrogen pump, a controller and a DCDC; the ejector is arranged between the hydrogen tank and the galvanic pile anode inlet to form a gas inlet passage; a reflux inlet of the ejector, the water segregator and an anode outlet of the galvanic pile are connected to form a hydrogen circulation path; the electrochemical hydrogen pump and the ejector are arranged in parallel; and the controller is used for controlling the ejector and / or the electrochemical hydrogen pump to work according to the working condition. The low working condition range of the fuel cell anode system in idling and the like is widened; the controller adjusts the current of the electrochemical hydrogen pump to adjust the backflow flow of hydrogen; the electrochemical hydrogen pump filters nitrogen to improve the concentration of backflow hydrogen; and the regulation and control mode is simple and flexible.

Owner:BEIJING SINOHYTEC

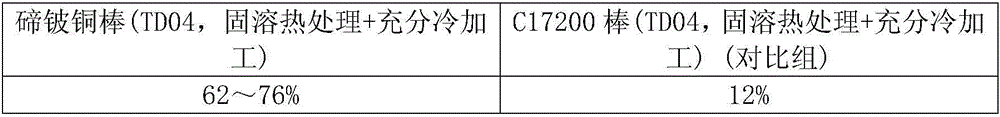

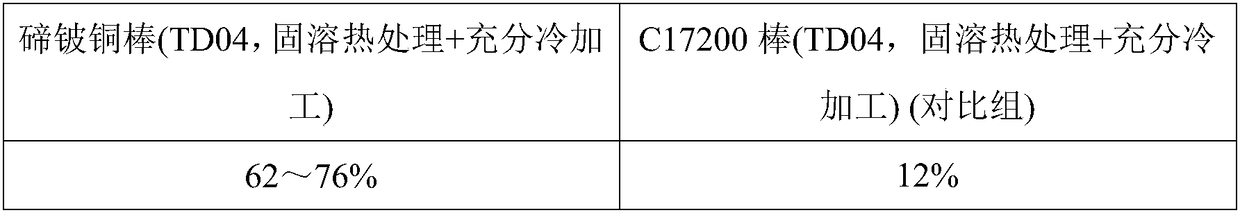

Tellurium-beryllium-copper alloy for manufacturing rods and wires as well as preparation method of tellurium-beryllium-copper alloy

The invention discloses a tellurium-beryllium-copper alloy for manufacturing rods and wires as well as a preparation method of the tellurium-beryllium-copper alloy. The tellurium-beryllium-copper alloy comprises beryllium, tellurium, cobalt, nickel, boron, copper and rare earth elements mainly comprising lanthanum, cerium and praseodymium. The preparation method comprises the specific steps that burdening, feeding and smelting are carried out according to the weight percentage, a horizontal continuous casting coil is continuously extruded through a continuous extruder to obtain a hot working plastic deformation metallographic structure, then solid solution, drawing and aging heat treatment processes are sequentially carried out, and the tellurium-beryllium-copper alloy rods and wires are obtained through machining. The boron element added into the alloy has a strong deoxidizing effect and a grain refining effect, and after rods and wires are subjected to a hot extrusion process throughthe continuous extruder, the wires are dynamically recrystallized, so that the tellurium element is not only distributed on the original grain boundary, but also enters the grains from the grain boundary, and the dispersity is further crushed, so that the dispersion distribution is better, and the turning performance is improved to 70%-80% from the original 62%-76%.

Owner:KINKOU SUZHOU COPPER IND CO LTD

A large-capacity unified power quality controller and its control method

ActiveCN103618310BStable DC side voltageRealize functionPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionOrthogonal coordinatesTransformer

The invention relates to a unified power quality controller UPQC for flexible power transmission and distribution in a power system, in particular to a large-capacity unified power quality controller UPQC and a control method thereof. The structure of the unified power quality controller using the secondary side of the multi-winding transformer connected to the H-bridge converter is applied to the parallel side of the UPQC. The three-phase parallel side is equivalent to three single-phase rectifiers modeled across the line voltage. Since each H-bridge rectifier is independently controlled, it is not affected by the unbalanced three-phase voltage, which is beneficial to the stability of the DC side voltage of the UPQC when the grid voltage fluctuates, and a control method based on virtual orthogonal coordinate transformation is adopted to make the parallel side of the UPQC The single-phase rectifier device is equivalent to a three-phase rectifier model, which has the functions of controllable power factor and harmonic suppression of the three-phase rectifier, and can fully realize all the functions of the three-phase rectifier under the condition of symmetrical system voltage.

Owner:STATE GRID CORP OF CHINA +1

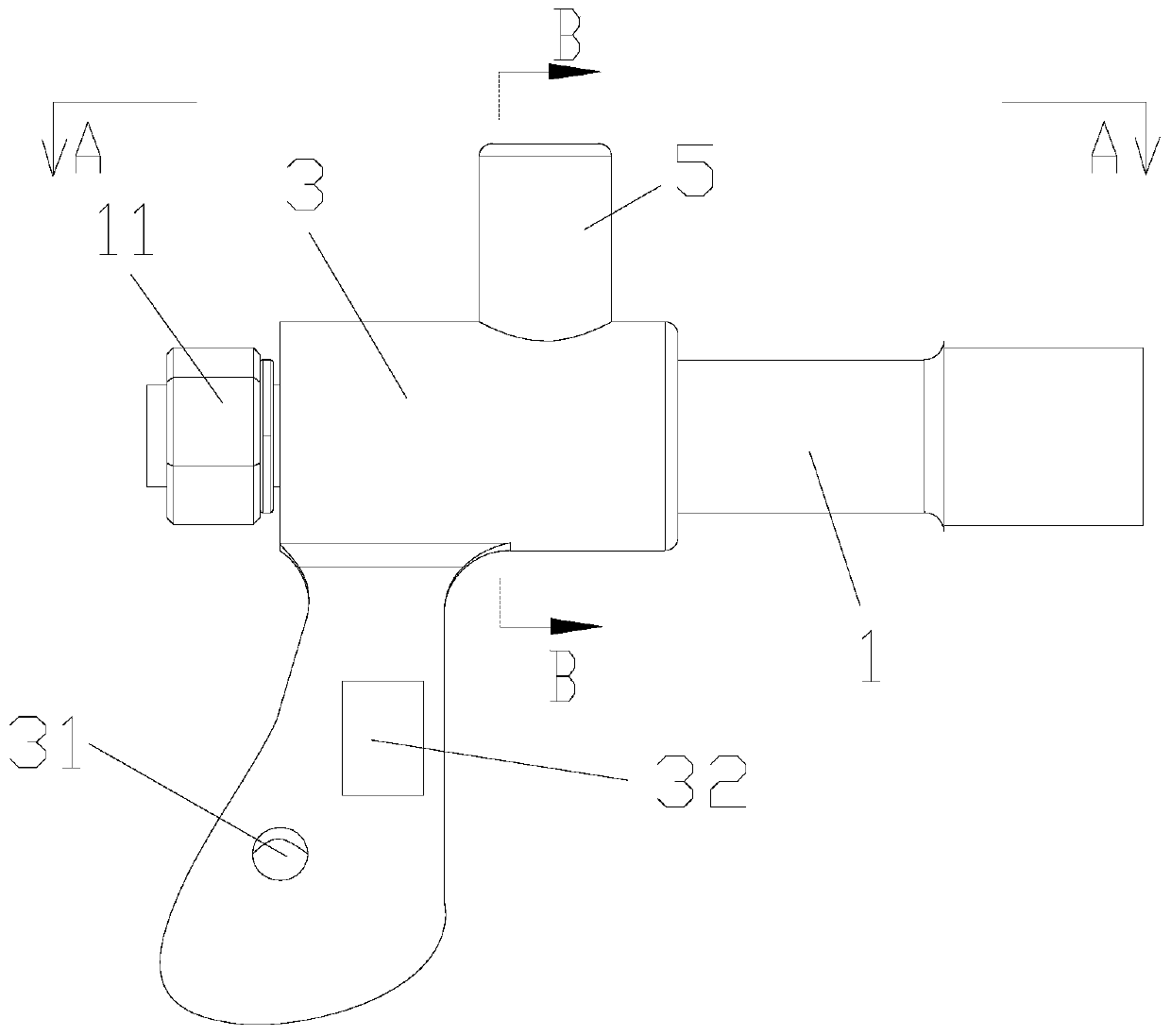

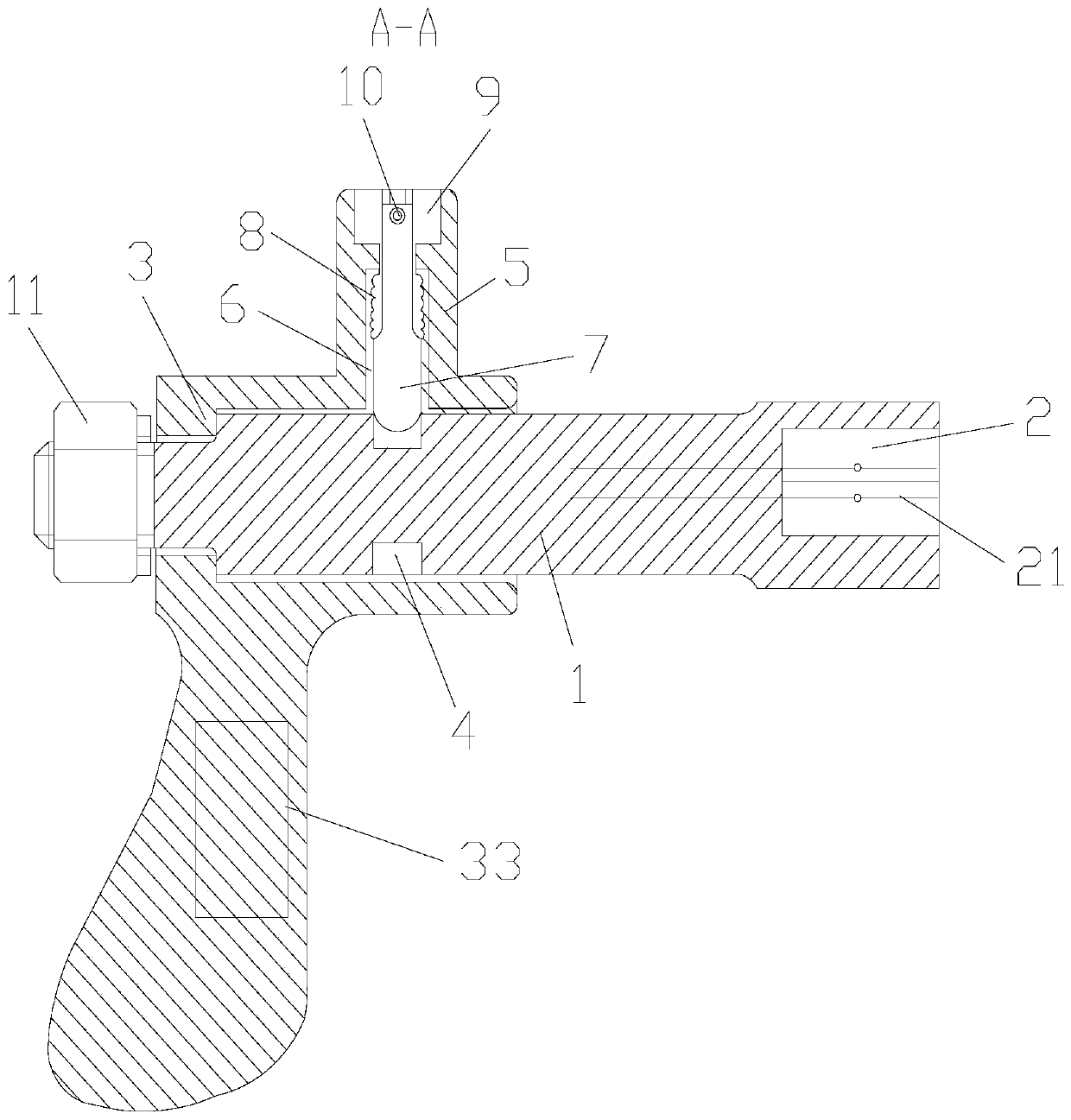

Novel triangular key and using method thereof

PendingCN110924752AChange the direction of forward and reverseReduce safety incidentsKeysIndividual entry/exit registersStructural engineeringAnnular array

The invention provides a novel triangular key and a using method thereof. The triangular key comprises a key rod; a triangular hole matched with a triangular cylinder of an elevator landing door is formed in one end surface of the key rod; outside threads are formed in the left end of the peripheral side wall of the key rod; the key rod is provided with a jacket in a sleeved manner and freely rotates in the jacket; the cross section of the key rod is circular; multiple first grooves are formed in the peripheral side wall of the key rod in an annular array by taking the center of a circle of the key rod as the center; a positioning rod is connected to the jacket; a cylindrical cavity is formed in the positioning rod and is internally provided with a cylindrical pin matched with the first grooves; the bottom surface of the cylindrical pin is obliquely arranged; the cylindrical pin is provided with a compression spring in the sleeved manner; and a second groove is formed in the upper surface of the positioning rod. By adopting the novel triangular key provided by the invention, the limitation of a human arm structure can be solved so that continuous rotation can be performed in a small corner range to realize unlocking, and the problem that the elevator landing door can be opened by irrelevant personnel at will in the prior art can be solved.

Owner:福建省特种设备检验研究院漳州分院

Fuel on-site mixing and compressed ignition internal combustion engine and control method

InactiveCN100557219CWide adaptabilityExpand the range of working conditionsElectrical controlMachines/enginesInternal combustion enginePower performance

The invention provides a fuel field mixing compression ignition internal combustion engine and a control method thereof, in particular relates to fuel preparation, supply and combustion control of a combustion engine. The invention adopts a high-octane and high-cetane fuel field mixing and auxiliary ignition technology, and can meet the requirement that the internal combustion engine makes use of the fuel of different octane numbers under different loads, namely, more high-cetane fuel is mixed in the high-octane fuel under low load or ignition is assisted in, to improve the ignition property of the mixed fuel so that the mixed fuel can be fired reliably under low load and temperature with the firing time controllable. The quantity of high-cetane fuel to be mixed in is reduced under medium load; a signal high-octane fuel is adopted under large load to avoid engine detonation. By adopting the fuel field mixing compression ignition combustion mode, not only an even premixing compression ignition engine is prevented from being on fire under low load, but also the working condition range under large load can be widened. In addition, the power performance of the engine is improved. In this way, the even premixing compression ignition engine is practical.

Owner:BEIJING UNIV OF TECH

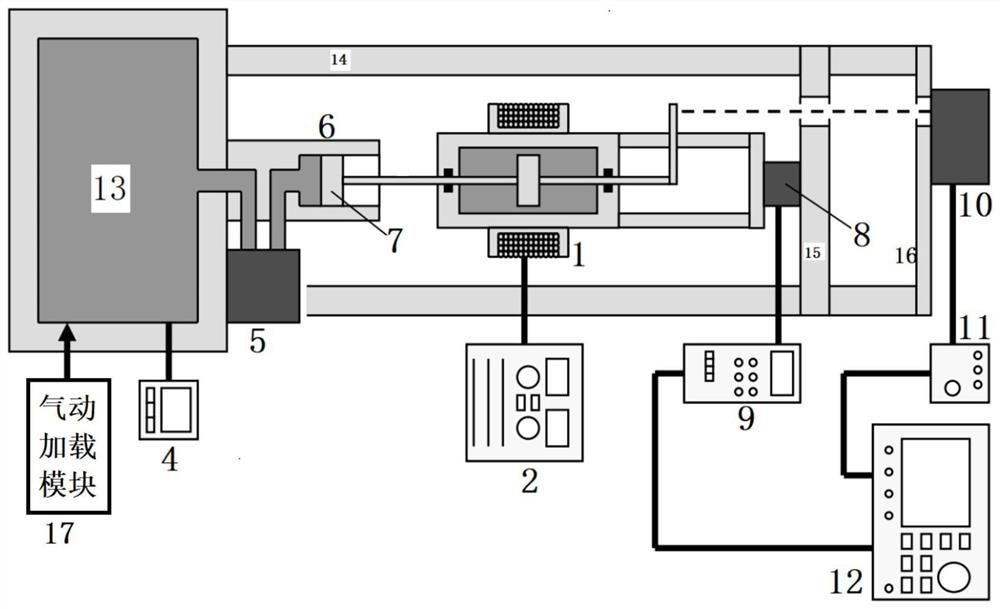

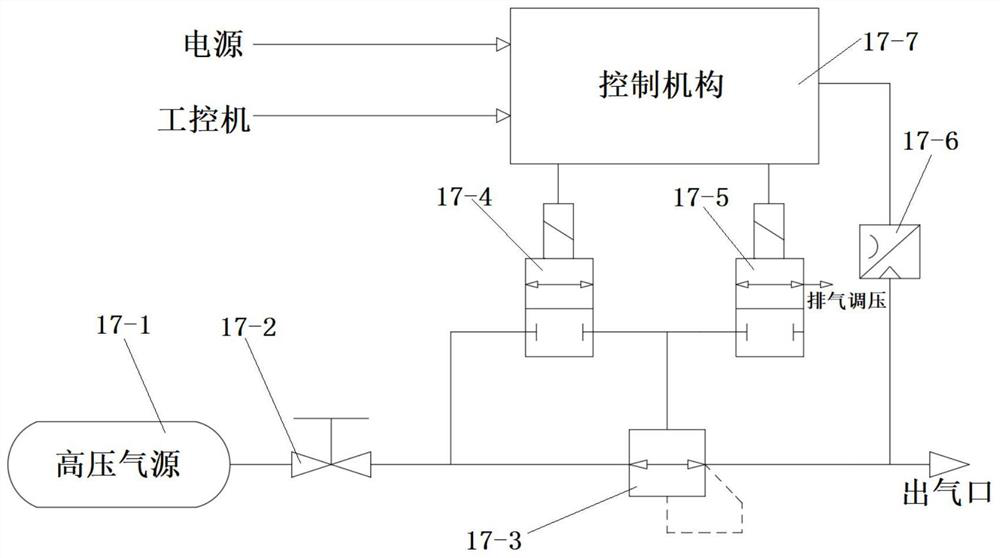

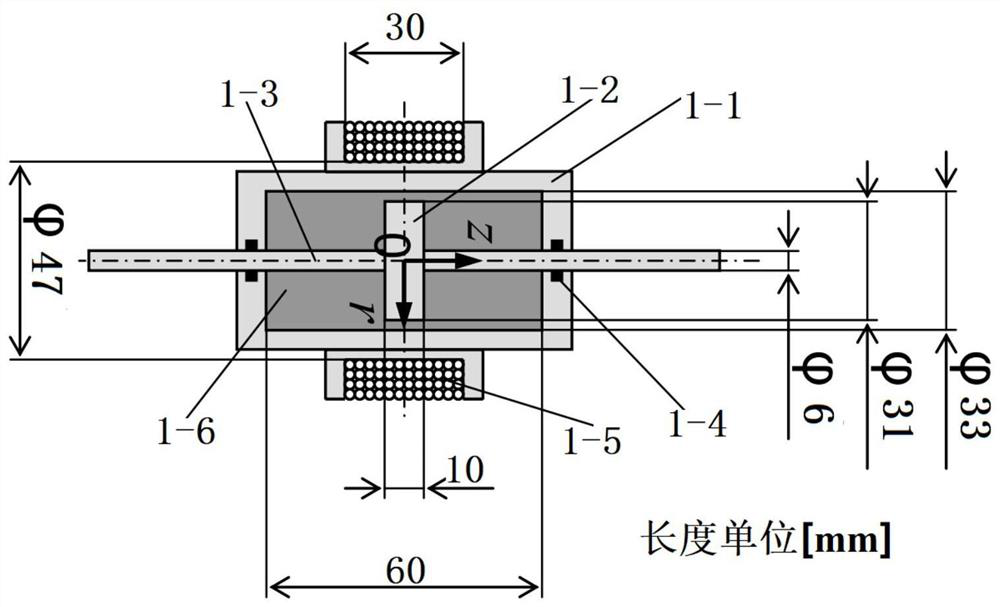

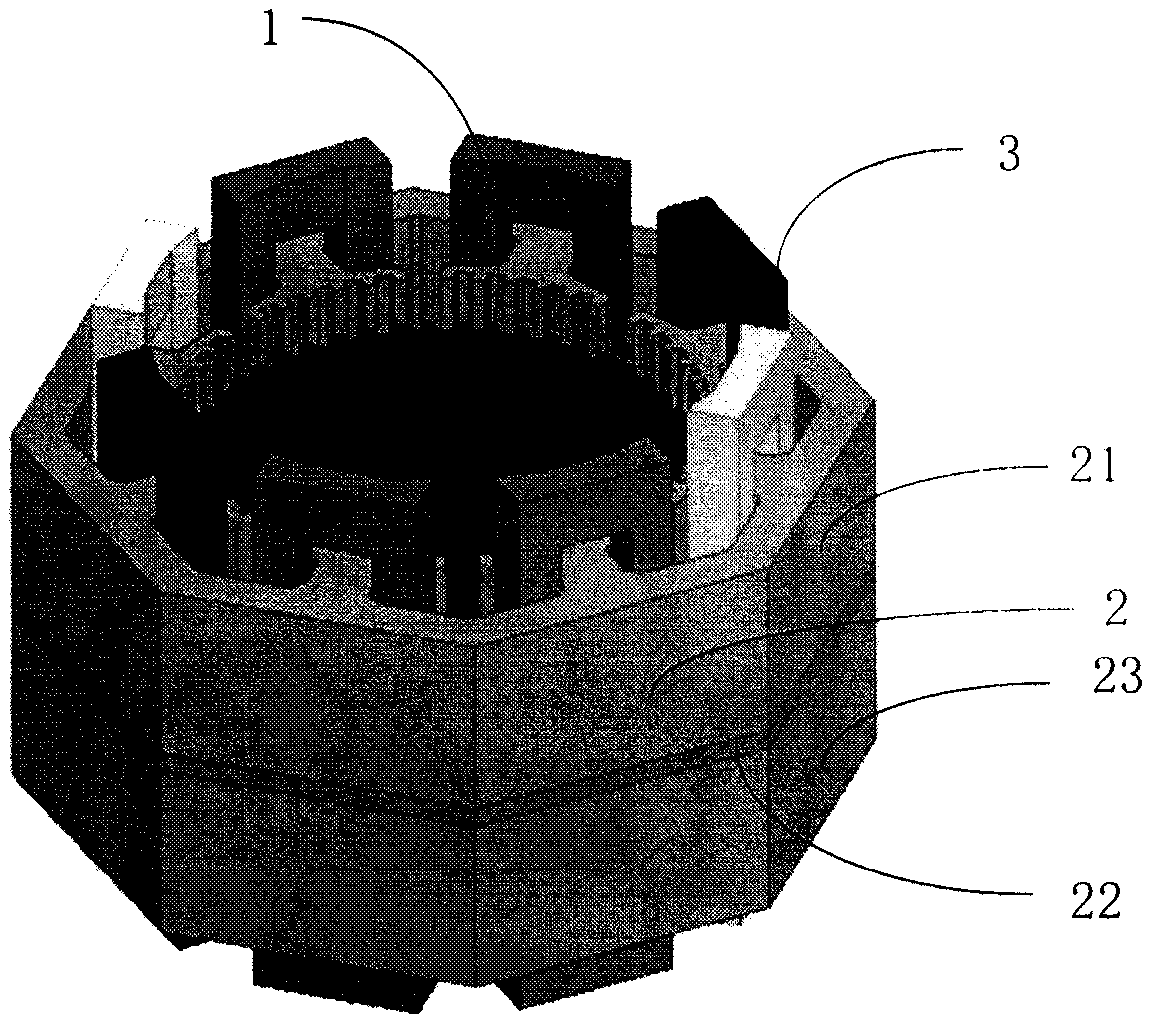

Test bed

PendingCN112255579AImprove technical effectFacilitates automated analysisOptical rangefindersMagnetic property measurementsInlet valveClassical mechanics

The invention relates to a test bed which is specially used for testing the resistance characteristic of a shock absorber of a magnetic functional fluid containing micron-scale and nano-scale magneticparticles, namely, testing the influence of different mixing ratios, electromagnetic field intensities and loading loads of micron-scale and nano-scale magnetic particles in the magnetic functional fluid of the shock absorber on the shock absorption resistance of the shock absorber. The test bed measures position change of a measured object in a non-contact mode through using a laser displacementsensor, and achieves the technical effects of high measurement precision, high sensitivity and accurate and efficient signal transmission for the micro displacement change of a shock absorber piston;and a test result is directly displayed through an oscilloscope and is more visual and faster. A pneumatic loading module is designed, through the design of a control mechanism, an air inlet valve, an air outlet valve and a pilot pressure regulating valve, the test bed realizes pneumatic loading, pressure maintaining and automatic adjusting control over loading loads, guarantees the loading accuracy and stability, and has large adjustable range of the loading loads, so that the testable working condition range of the test bed is larger.

Owner:XIHUA UNIV

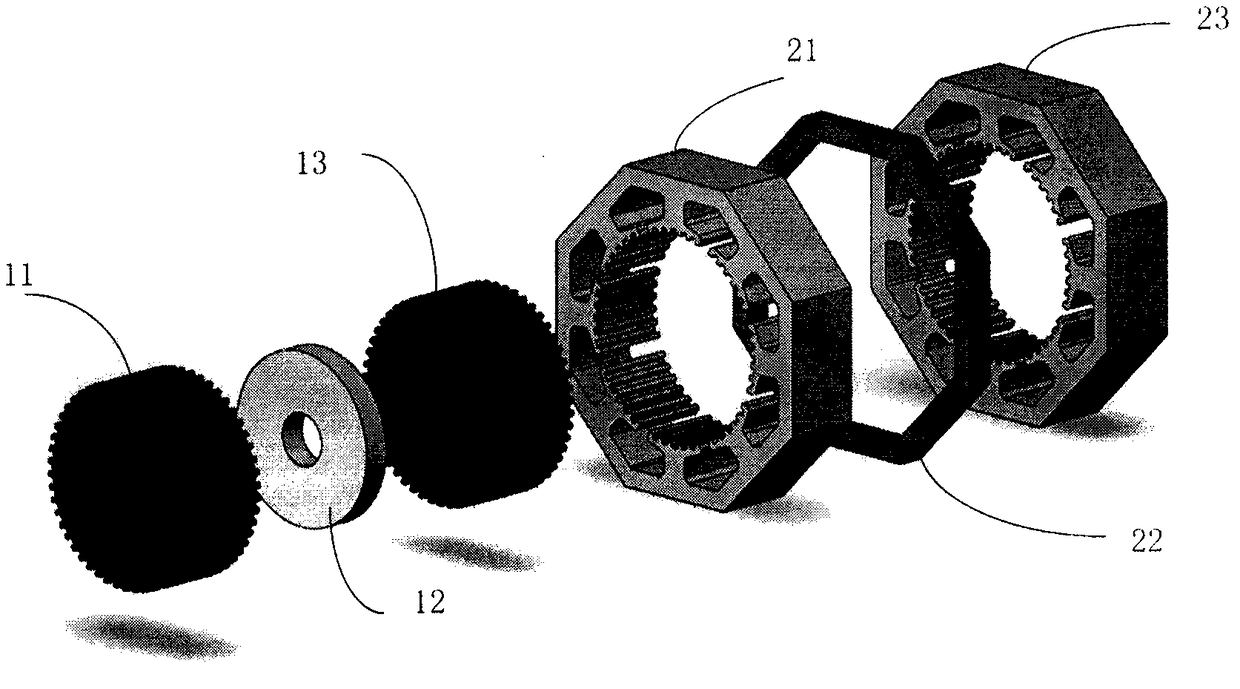

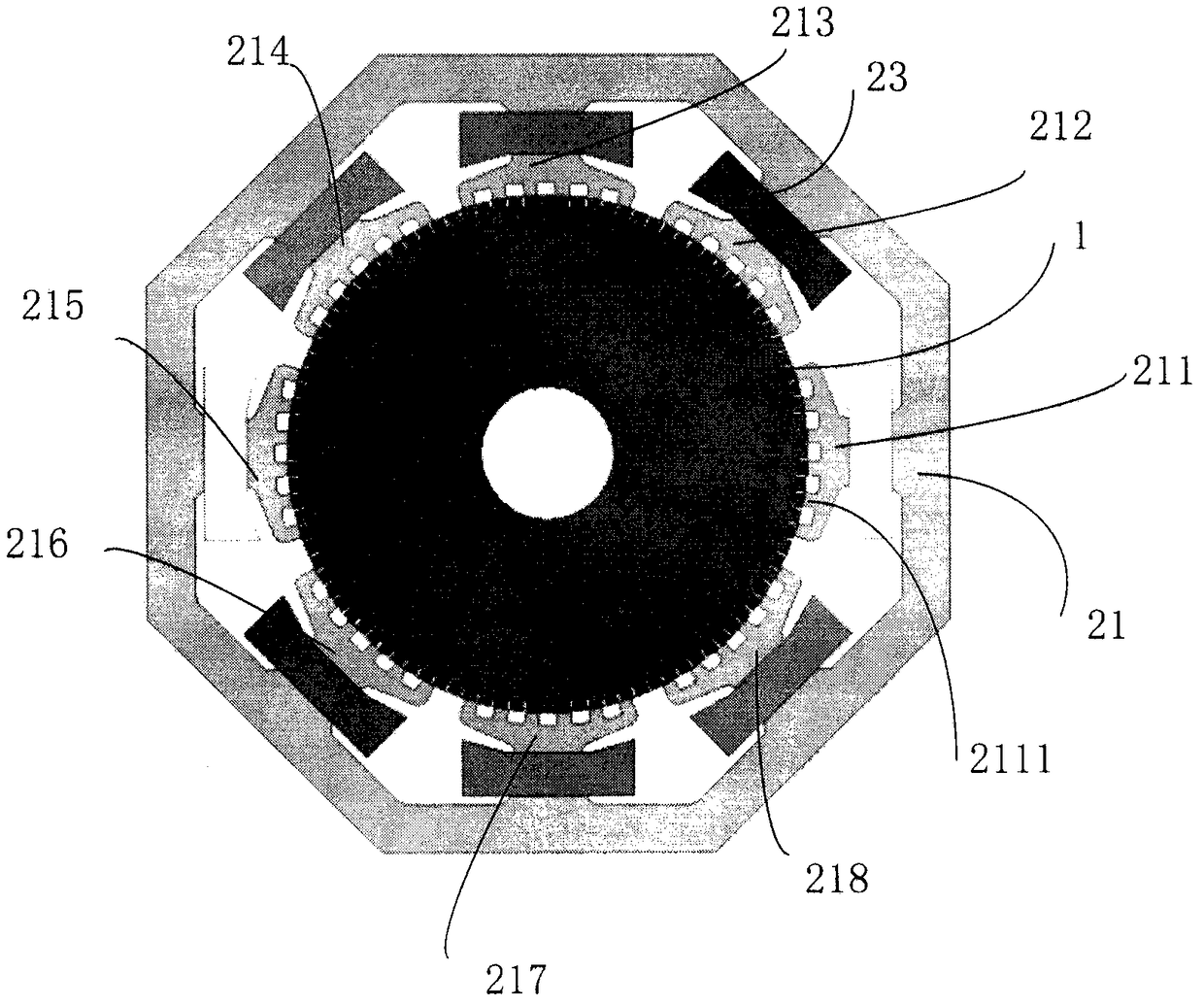

Hybrid stepping motor

InactiveCN108768127AImprove reliabilityExpand the range of working conditionsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention discloses a hybrid stepping motor which contains a rotor, a stator and windings. The rotor is arranged in the stator, the stator is provided with multiple magnetic poles, the windings are arranged on the magnetic poles, and permanent magnet steel is embedded into the stator. According to the hybrid stepping motor, the no-load flux linkage and the no-load back electromotive force bothpresent sine rule changing, besides that the advantages of being high in precision and torque and the like are achieved, the structure of the rotor is greatly simplified, the strength and the stability of the rotor are enhanced, therefore, the reliability of the hybrid stepping motor is improved, and the application working condition and the application range of the motor are expanded.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com