Pneumatic steady flame center staged combustor

A central grading and combustion chamber technology, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as complex mechanical structure, achieve simple geometric configuration, improve ignition performance, processing technology and simple mechanical installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

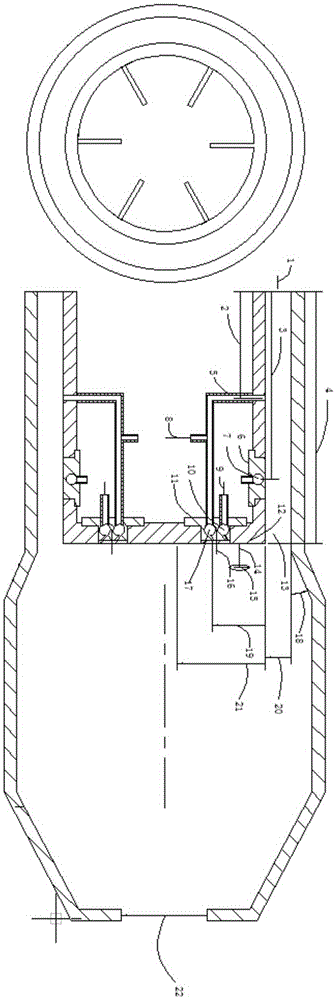

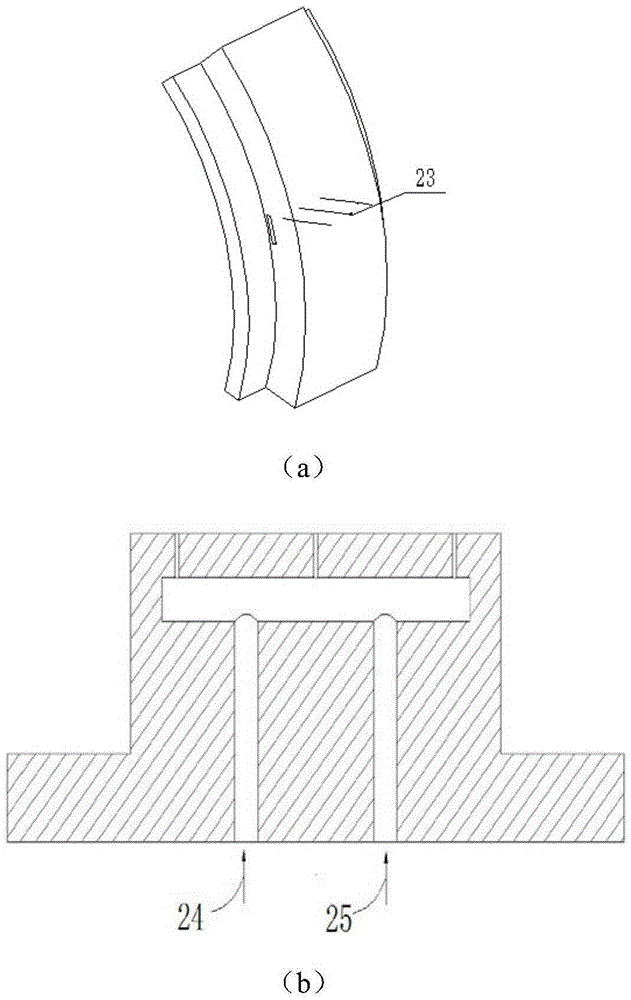

[0026] Such as figure 1 As shown, the embodiment of the present invention is an aerodynamic flame stabilizing center staged combustor, which is mainly composed of main combustion stage flow channel 13, back step pre-combustion stage 12, main combustion stage direct injection nozzle 6, pre-combustion stage airflow induced trapped vortex nozzle 11 Constitute with spark igniter 15. The direct injection nozzle 6 of the main combustion stage is composed of a No. 1 oil inlet 24 , a No. 2 oil inlet 25 , an oil collecting chamber 7 and an injection hole 23 . The pre-combustion level airflow induced trapped vortex nozzle 11 has two independent gas collection chambers and two rows of nozzle holes, namely the nitrogen gas collection chamber 10 and the premix gas collection chamber 17 , and the nitrogen gas injection holes 26 and the premix gas injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com