Patents

Literature

51results about How to "Simple mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-salt high-alkali Medium-low-level radioactive liquid waste cement solidified body and preparation method thereof

InactiveCN102169737AStrong adsorption capacityIncrease retention capacityRadioactive decontaminationSlagCoal

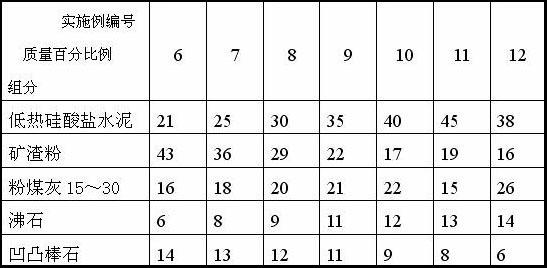

The invention discloses a high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body which is composed by mixing the following components: high-salt high-alkali medium-low-level radioactive liquid waste and, solidification material, water glass and cellulose ether, wherein the high-salt high-alkali medium-low-level radioactive liquid waste to the solidification material is 0.55-0.75: 1 in mass proportion; the modulus of the water glass is 2.5-3.5 based on Na2O in the water glass and the mass of the solidification material is 1-3% of the mass of the water glass ; the mass of the solidification material is 0.05-0.5% of the mass of the cellulose ether; the component mass percent of the solidification material is as follows: 20-40% of low-heat Portland cement, 15-50% of slag powder, 15-30% of coal ash, 5-15% of zeolite and 5-15% of attapulgite; and the cement solidification body with various properties meeting the requirements is obtained by carrying out normal-temperature maintenance on the mixed slurry which obtained by mixing and stirring. The high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body is suitable for the solidification of the medium-low-level radioactive liquid waste, which has the total salt concentration being 100-400g / L, the pH value being larger than 13 and the nuclide being 90Sr or / and 137 Cs.

Owner:SOUTHWEAT UNIV OF SCI & TECH

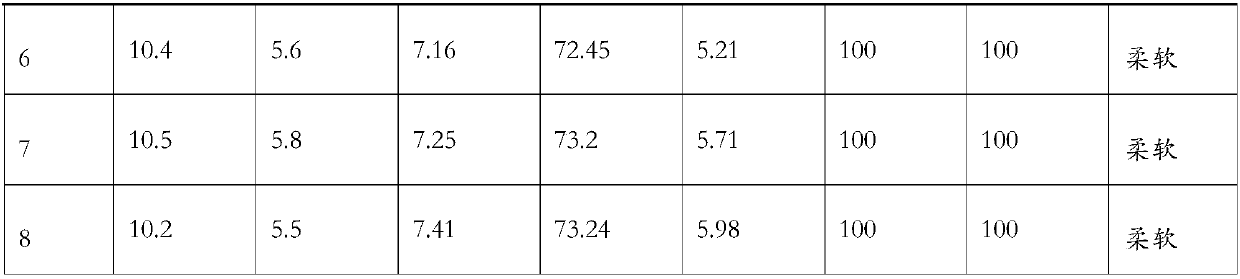

Rapid solidification construction method for sea mud on large-area coastal beach

ActiveCN108468325AConstruction technology and machinery are simpleConstruction progress is fastSoil preservationSubgradeSilt

The invention relates to a rapid solidification construction method for sea mud on a large-area coastal beach. The rapid solidification construction method specifically comprises the following steps of performing construction partition, performing mud excavation, mud piling and draining, spreading an HAS sea mud curing agent, stirring the HAS sea mud curing agent and the sea mud uniformly, performing enclosing material solidification on the mixed soil to obtain a sea mud consolidated body and performing layered and blocked / segmented backfilling and compaction on the sea mud consolidated body.The method has the beneficial effects that the foundation bearing capacity, compaction degree, deflection value and the like after the sea mud is cured by the HAS sea mud curing agent in situ can meetcorresponding standards, uneven settlement can be reduced after layered backfilling, the foundation bearing capacity can reach more than 110 kPa, and common foundation requirements such as field-leveling foundation, building foundation and road subgrade can be met.

Owner:GEZHOUBA ZHONGGU TECH CO LTD

Preparation method of crack self-repairing material for concrete

The invention relates to a preparation method of a crack self-repairing material for concrete, belonging to the technical field of building materials. The crack self-repairing material for the concrete is prepared by adding epoxy resin coated urea-formaldehyde resin microcapsules, epoxy resin has strong adhesive force to the concrete and can effectively prevent the fracture of the concrete from expanding, an epoxy resin adhesive is a solid after curing and does not react with a urea-formaldehyde resin coating layer and the concrete, the epoxy resin adhesive-containing urea-formaldehyde resin microcapsules and a catalyst are dispersed in a composite material matrix, when the material generates a crack, stress concentration at the top of the crack causes the microcapsules to crack, a repairagent migrates to the crack by capillary siphon phenomenon to fill the crack and meet the catalyst added to the material, the core material undergoes physical and chemical changes to form good adhesion to complete the repair. Therefore, the self-repair polymer with the repair agent coated by the microcapsules can improve the service life of the concrete.

Owner:游雪花

Pneumatic steady flame center staged combustor

InactiveCN105402772ASimple geometryImprove flame stabilityContinuous combustion chamberCombustion chamberLiquid fuel

The invention discloses a pneumatic steady flame center staged combustor. A main combustion stage annular direct-injection type nozzle consists of a first oil inlet, a second oil inlet, an oil collecting cavity and an injection hole; a pre-combustion stage nozzle is provided with two independent gas collecting chambers and two rows of spray orifices which respectively spray nitrogen and methane / air premixed gas; and after entering an inlet of an annular combustion chamber, air is distributed into different flows which respectively enter a main combustion stage annular flow path and a pre-combustion stage pre-mixing channel. The main combustion stage direct-injection type nozzle transversely sprays liquid fuel oil into the main combustion stage annular flow path, and then the liquid fuel oil is mixed with main combustion stage air flow. The methane / air premixed gas and the nitrogen are obliquely and upwards sprayed into a backward-facing step pre-combustion stage by pre-combustion stage air flow; an electric spark igniter is positioned on a methane / air premixed gas injection track, and ignition starting of the pre-combustion stage is realized; and then high-temperature fuel gas of the pre-combustion stage ignites a main combustion stage. Mechanical components of the pneumatic steady flame center staged combustor are simple, stable and reliable in structure, and the liquid fuel oil can be efficiently and stably combusted in a wider incoming flow working condition range.

Owner:BEIHANG UNIV

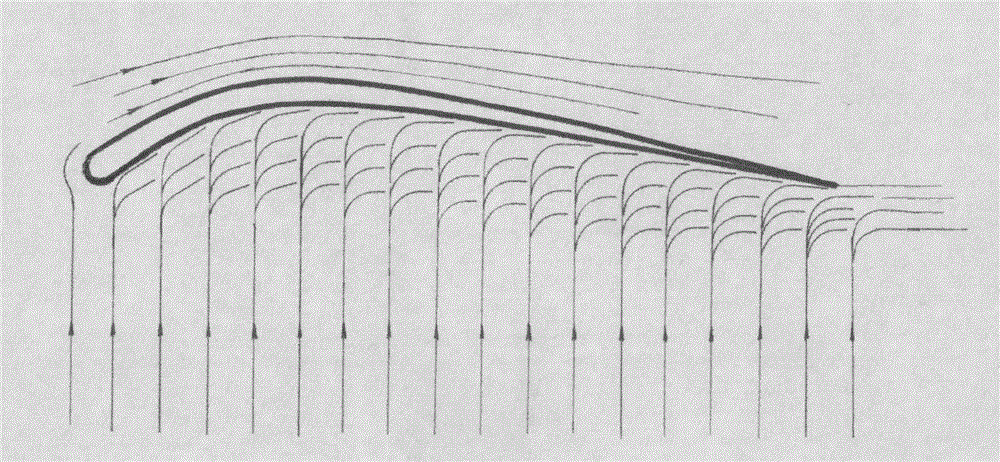

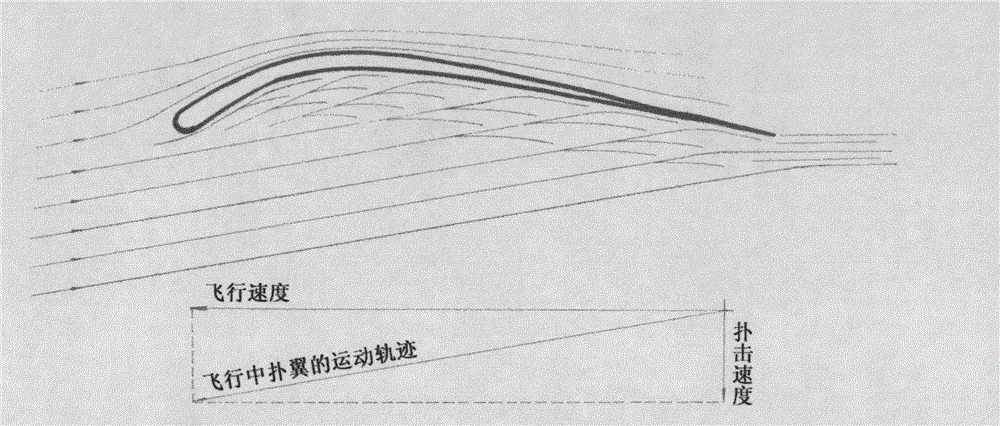

Dual-rotor coaxial helicopter with wing-shaped rotors

The invention relates to a dual-rotor coaxial helicopter with wing-shaped rotors, and the helicopter belongs to B64C 27 / 04. helicopters according to international patent technology classification. The general layout adopts a mashup design of a dual-rotor coaxial helicopter and a fixed wing aircraft with preposed canard wings. An elevator is preposed, and horizontal wings and ailerons for lateral control are disposed at the rear. A control surface that is responsible for yaw control is positioned behind ducted propellers that are disposed at the rear and used for providing thrust. Fans are arranged below the fuselage on the left and the right so as to retreat or horizontally and slightly adjust the fuselage hovering position or make the fuselage revolve. Due to the wing shape change, when an engine encounters in-flight shut-down, the helicopter continuously suffers height loss, so that air and the rotors interact to convert the potential energy of the helicopter into kinetic energy, which makes the rotors continue to rotate according to the rotation direction of the engine during working hours. Consequently, a lifting force can be generated, and fall can be changed to a safe landing. The helicopter provided in the invention can solve or improve the problems of small speed, short flying range, low flight height, great vibration and noise, poor reliability, high cost and use fee in helicopters in active service.

Owner:顾惠群

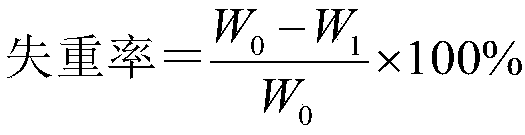

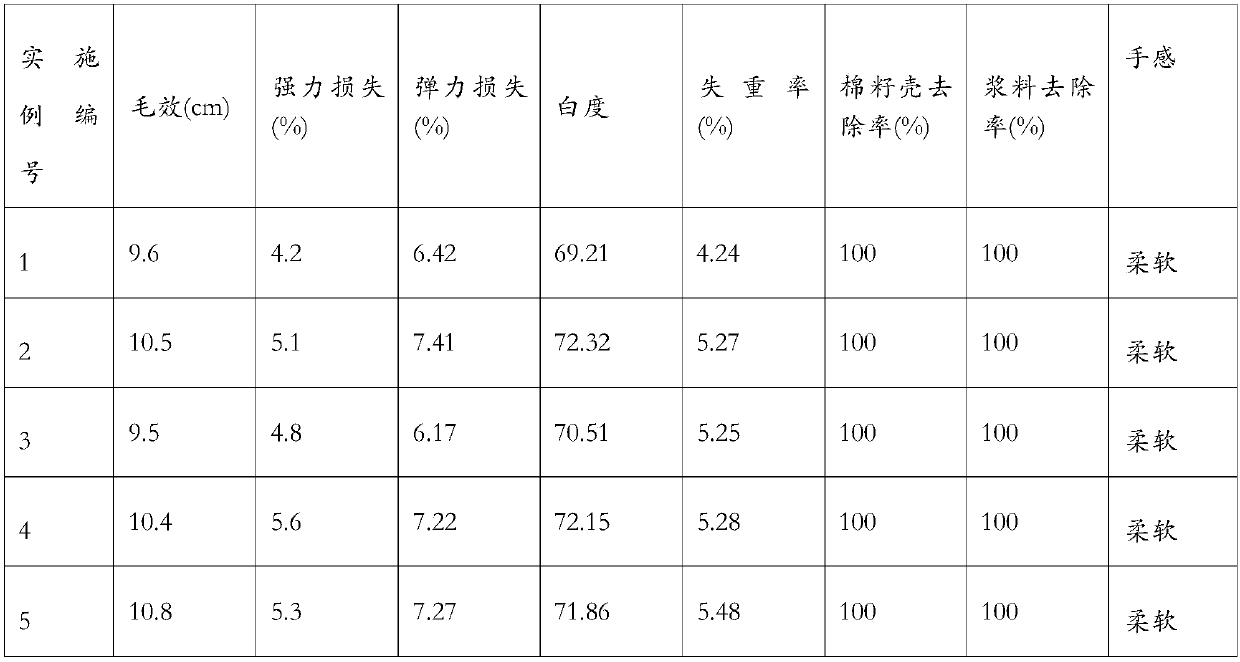

Short-flow pre-treatment method for pure cotton heavy fabrics

PendingCN109576975ASimple processWater saving and energy saving production costVegetal fibresChemistryDyeing

The invention discloses a short-flow pre-treatment method for pure cotton heavy fabrics and belongs to the technical field of dyeing and finishing pre-treatment. The short-process pre-treatment methodfor pure cotton heavy fabrics comprises the steps of padding a singed pure cotton heavy gray fabric with scouring and bleaching liquid, then piling up the fabric at room temperature, executing steaming and washing, executing slight rinsing with a dilute aqueous solution of hydrogen peroxide, finally executing low-alkali mercerizing, and then executing full washing to complete the pure cotton heavy fabric pre-treatment process. The process is good in treatment effect, has the advantages of small fabric strength damage, high quality, soft handfeel, high hair effect and good glossiness, also creates the high color yield condition for subsequent dyeing and printing processing and is simple in technological operation and strong in controllability. In addition, the treatment wastewater, chemical agent use amount and energy consumption of the process are far lower than those of a traditional strong alkali scouring process, and the burden of sewage treatment of enterprises is greatly reduced.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

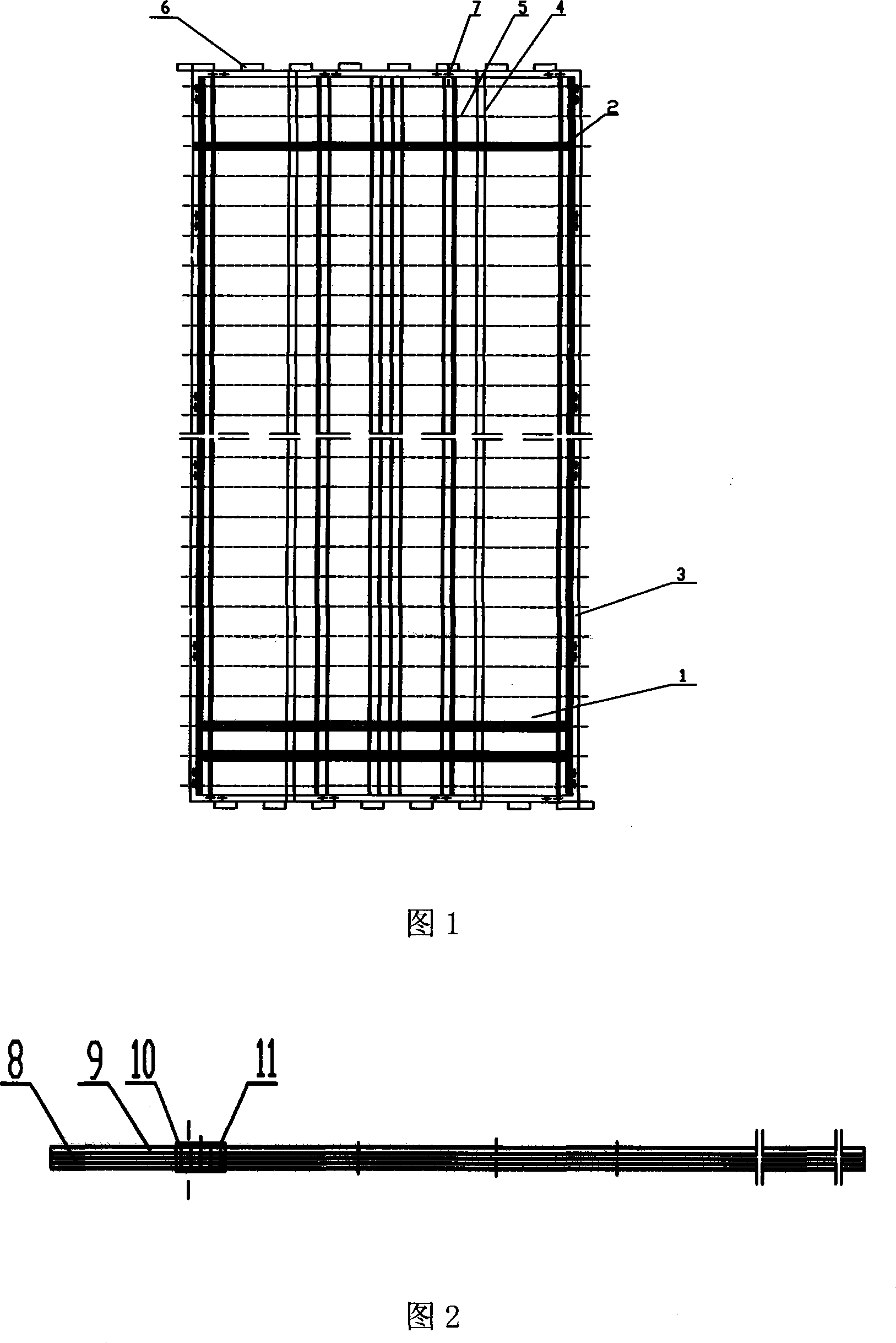

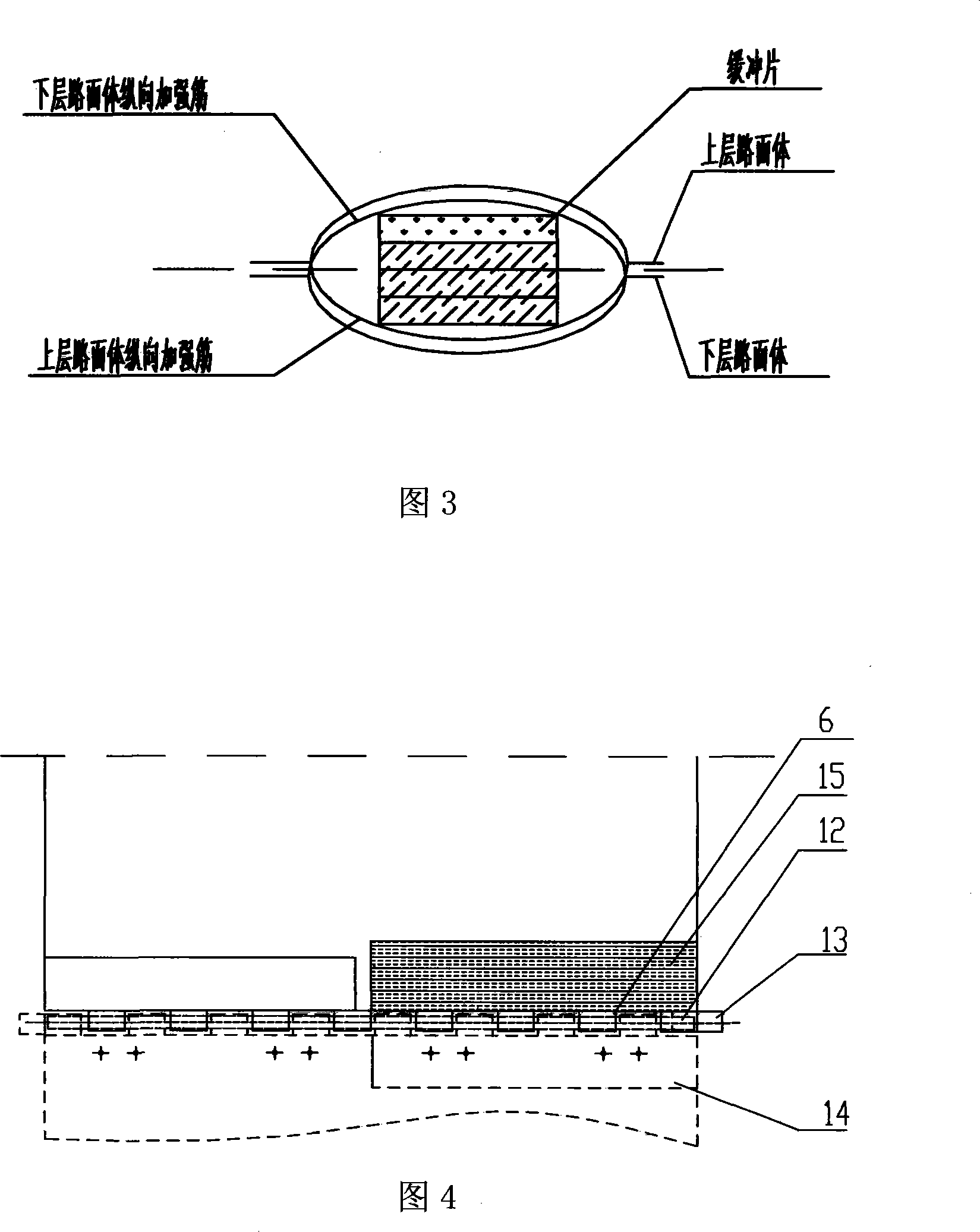

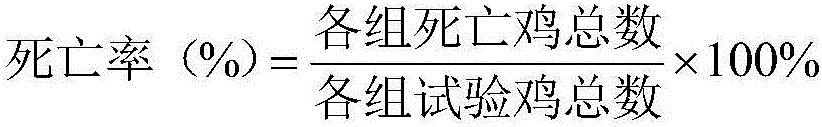

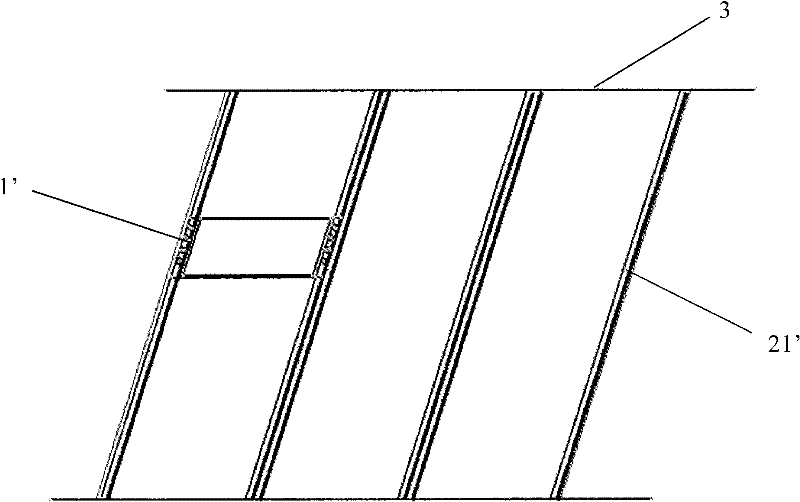

Lightweight high-strength pavement equipment

The invention disclose a light high strength pavement device, comprising a pavement base, a tie down device, a plurality of struts and a pavement segment piecing device; wherein, the pavement base is double-layer bursiform fabric braided by fiber; the struts are inserted into the pavement base horizontally in a certain spacing distance; the piecing device comprises a plurality of piecing hinge ears and a piecing bar. The piecing hinge ears are sewed on both ends of the pavement base. The ternary conjugated structure of the double-layer bursiform fabric and the strut form in braided complex mode can improve the bearing capacity, and the effective width is no less then four meters, and the pavement can be longitudinally spliced or disassembled quickly via the jointing device. The light high strength pavement device has the advantages of light weight, small diameter after folding, convenient transportation and operation of laying and withdrawing, excellent wear resistance and anti-slip performance.

Owner:中国人民解放军南京军区司令部工程科研设计所 +2

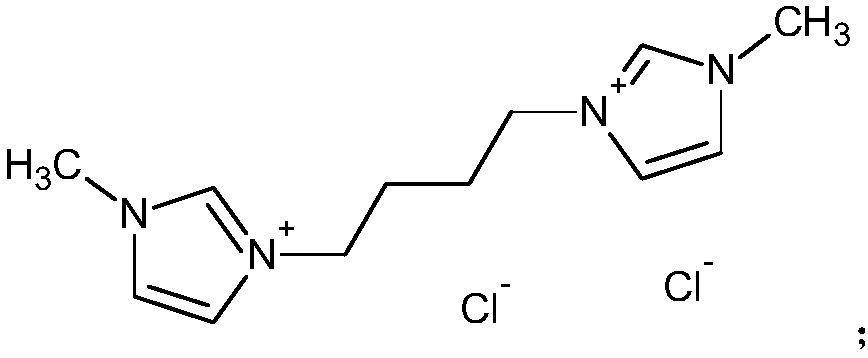

Preparation method of cellulose casein composite fibers

ActiveCN108624983AAchieve low temperature dissolutionIncrease contentConjugated cellulose/protein artificial filamentsArtifical filament manufactureCelluloseFiber

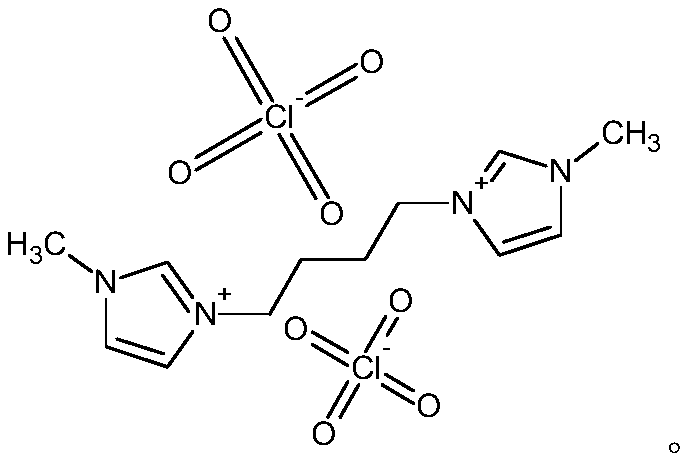

The invention discloses a preparation method of cellulose casein composite fibers. The method comprises the following steps: (a) dissolving casein and cellulose into an aqueous solution of ionic liquid to prepare a homogeneous phase mixed spinning dope; (b) filtering the obtained spinning dope, spinning, solidifying, stretching, washing, bleaching, oiling, and drying to obtain the cellulose caseincomposite fibers; the ionic liquid is obtained by mixing 90-110 parts by mass of 1-butyl-3-methylimidazolium chloride with 5-15 parts by mass of bi-1,4-bis[1-(3-methylimidazole)]butyl dichloride and5-15 parts by mass of bi-1,4-bis[1-(3-methylimidazolyl)]butyl diperchlorate. The method realizes the industrial production of the composite filters prepared by co-dissolving and co-producing the casein and the cellulose, thus having a higher practical value.

Owner:龙丝(上海)新材料科技有限公司

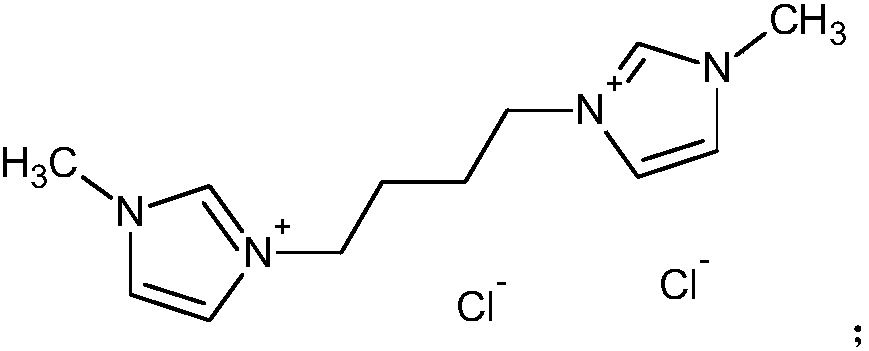

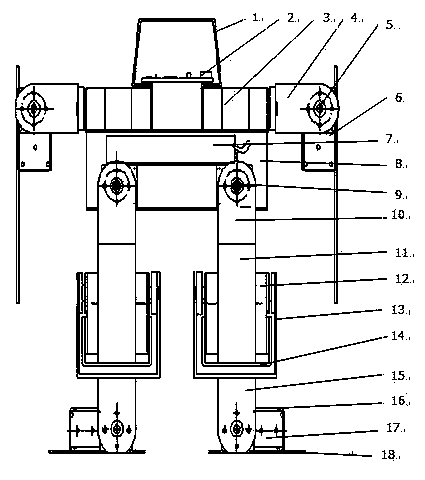

Dustproof and explosion-proof pelleting and drying equipment for oily sludge

PendingCN108558164ANo mechanical actionReduce productionSludge treatment by de-watering/drying/thickeningGranulation in rotating drumsSludgeCombustible gas

The invention discloses dustproof and explosion-proof pelleting and drying equipment for oily sludge. The equipment comprises a pelleting cabin and a drying cabin, multiple roller cylinders are horizontally installed in the pelleting cabin, and a motor A is installed at the exterior of the pelleting cabin; a feeding port is formed in the upper portion of the pelleting cabin, and a thermometer A and a pressure gauge A are installed at the feeding port; a rotation shaft is vertically installed in the drying cabin, a motor B is connected to the bottom of the rotation shaft, and a small heating disc and a large heating disc are alternatively installed on the rotation shaft; multiple rake arms are distributed on the small heating disc and the large heating disc from the center to the exterior,multiple rake blades are vertically installed on the rake arms, and a discharging port is formed in the lower end of the drying cabin; a thermometer B, a pressure gauge B and a combustible gas concentration detection meter are installed on the side wall of the drying cabin; communicated steam pipes are arranged in the pelleting cabin and the drying cabin. The dustproof and explosion-proof pelleting and drying equipment has the advantages that the safety is high, the running maintenance cost is low, the low-quality heat source can be used, the products are good in quality, and the water treatment amount in the later period and the water demand amount are small.

Owner:JIANGSU LV CHUAN ENVIRONMENTAL PROTECTION TECH

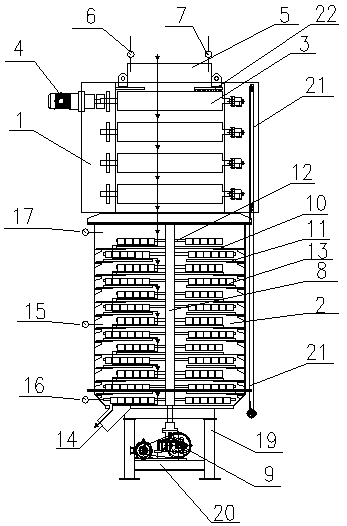

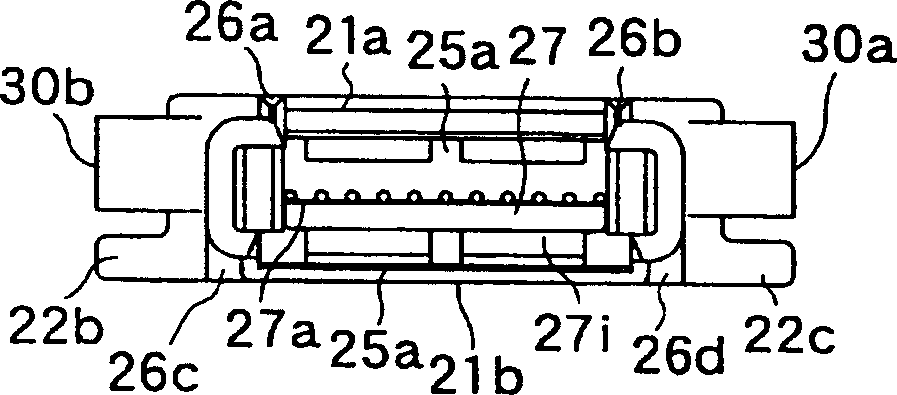

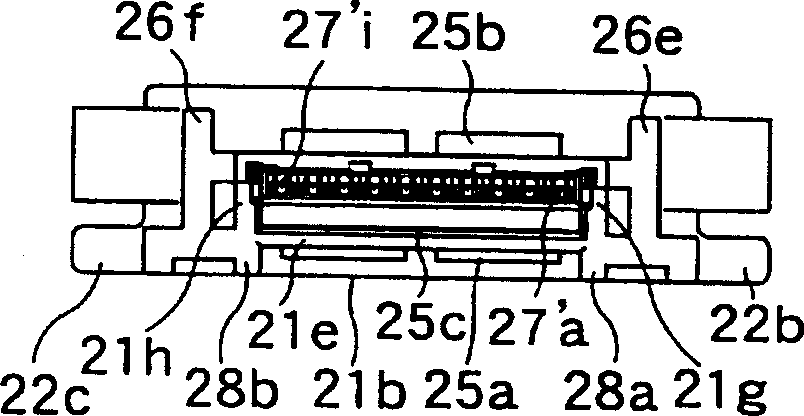

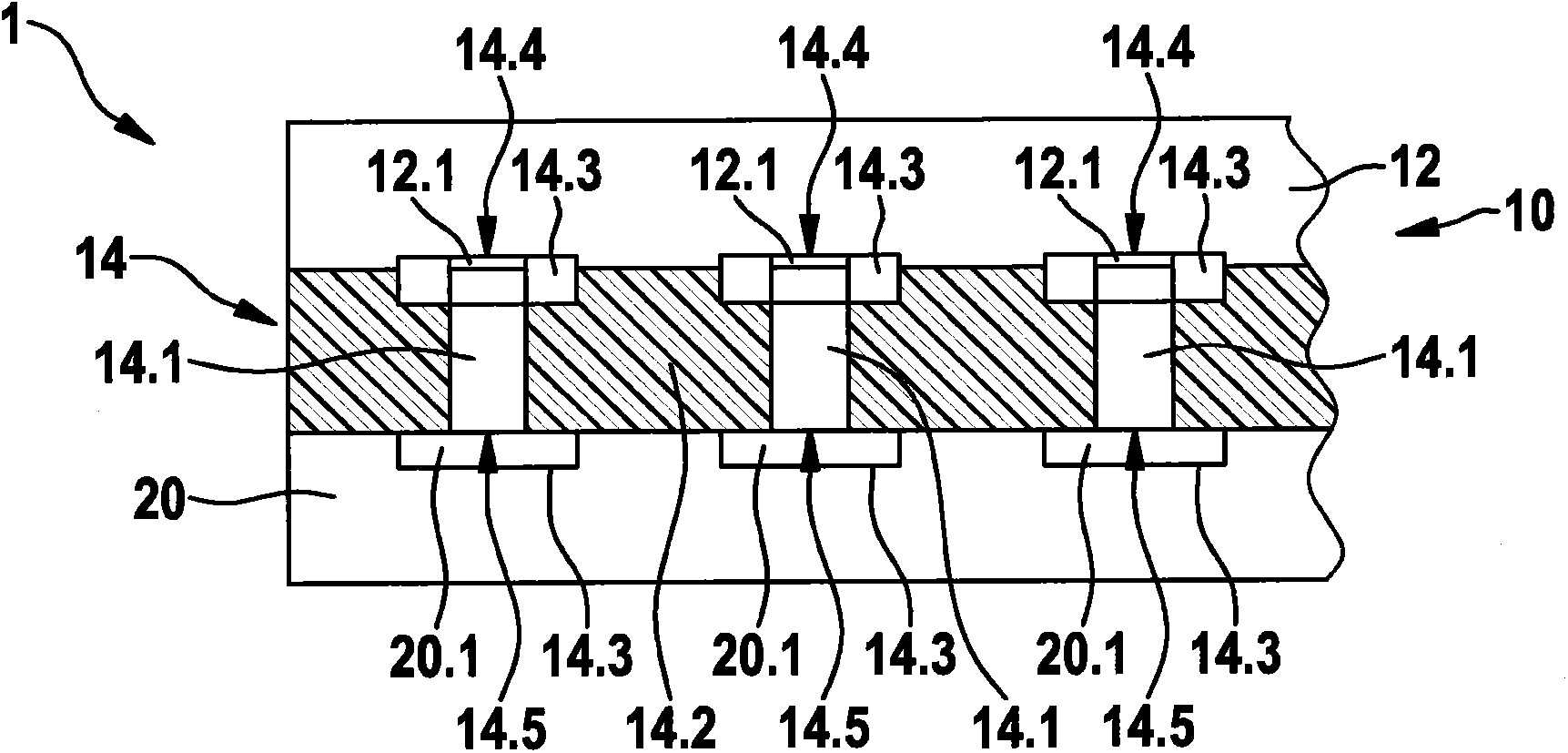

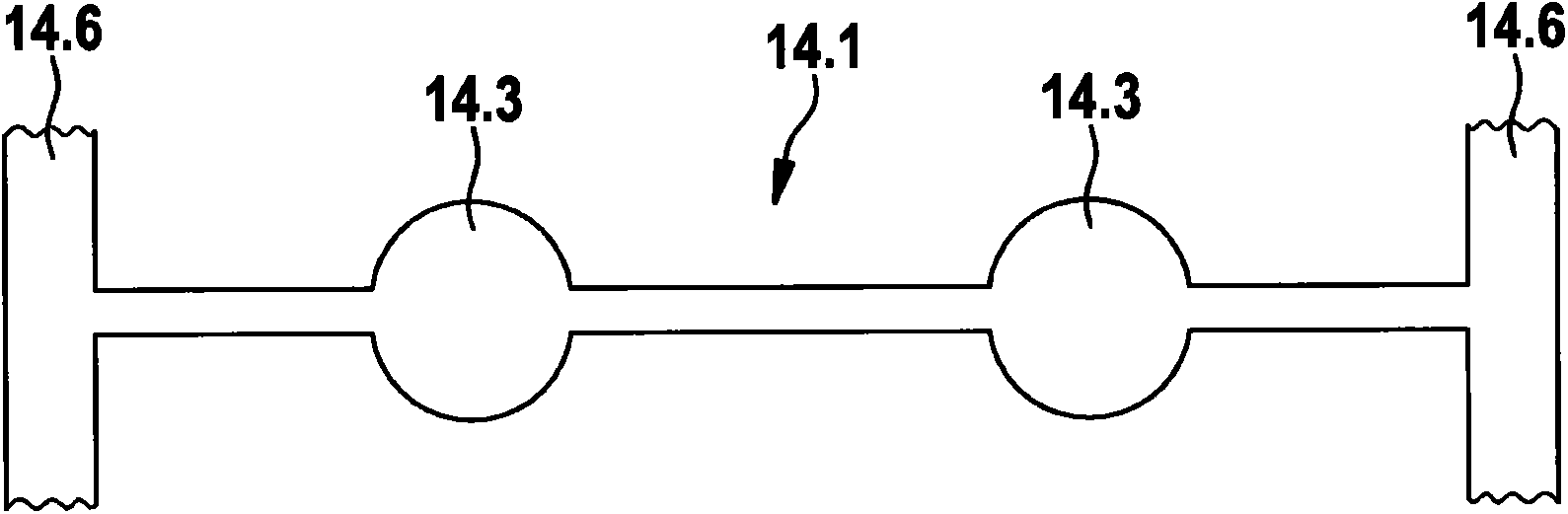

Connector for linking panel and panel-linking method using said connector

InactiveCN1428900AEasy to removeWill not affect the soldering partCoupling parts mountingFlangeElectrical and Electronics engineering

A connector for coupling panels which does not influence upon an electrically connected part of a connector to be attached to a panel even if an external force is applied to the panel. The connector for coupling panels comprises an insulating housing(20) having a through hole(25) therein through which connector terminals are fitted therein, flanges (22a) orthogonal to a direction of insertion and removal through the insulating housing and projected outwardly from at least one wall face of the insulating housing, comprising front and back faces, respectively, and a pair of retainer members (30a, 30b) having flexibility, fixedly attached to both side ends or both up-down ends of the insulating housing, respectively, wherein the retainer members are provided with a pair of retainer stepped parts(34a, 35a / 34b, 35b), facing each other, and there is a gap for allowing fixture of the panel between the front and back faces of the respective flanges and the respective retainer stepped parts of the retainer members.

Owner:JST MFG CO LTD

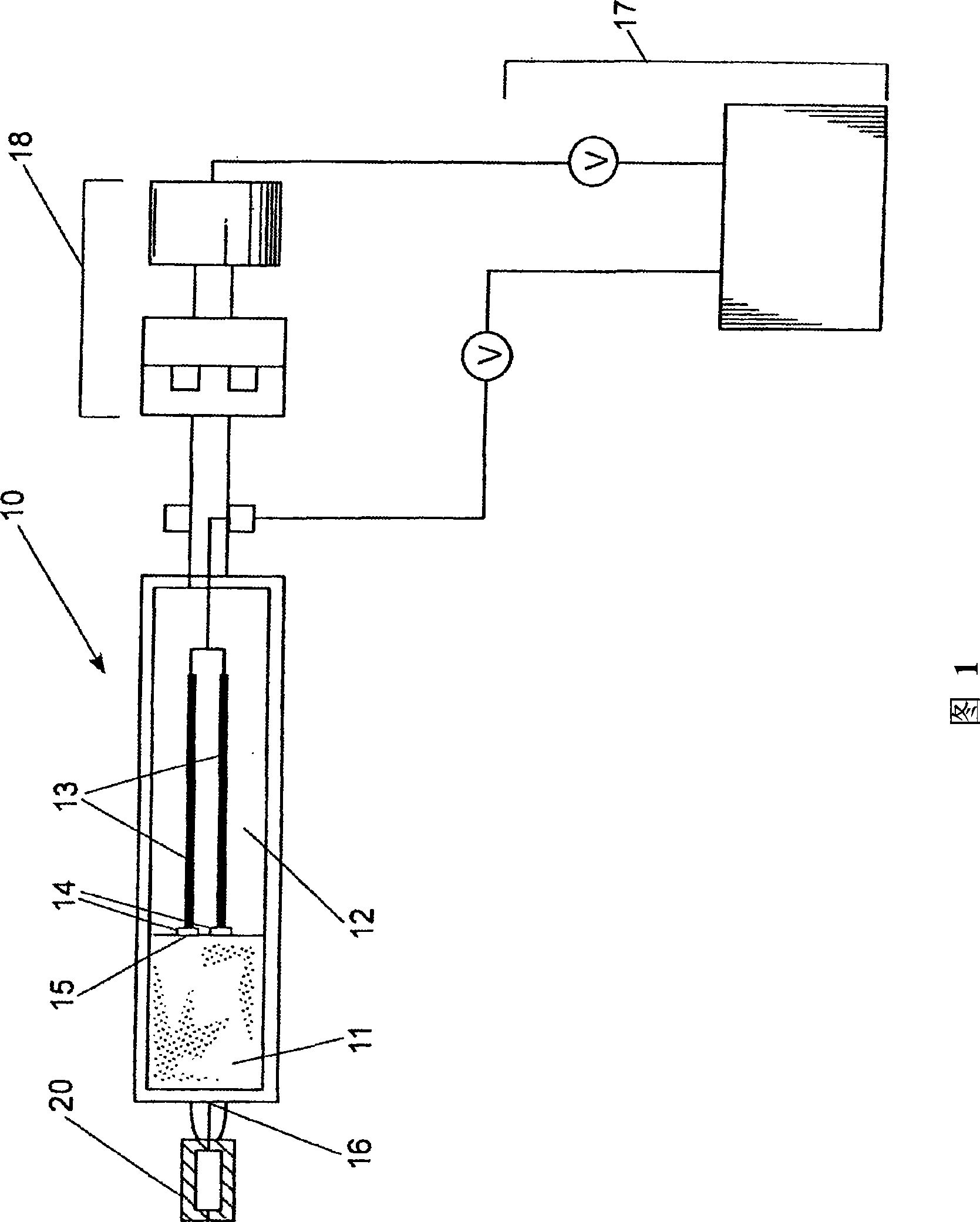

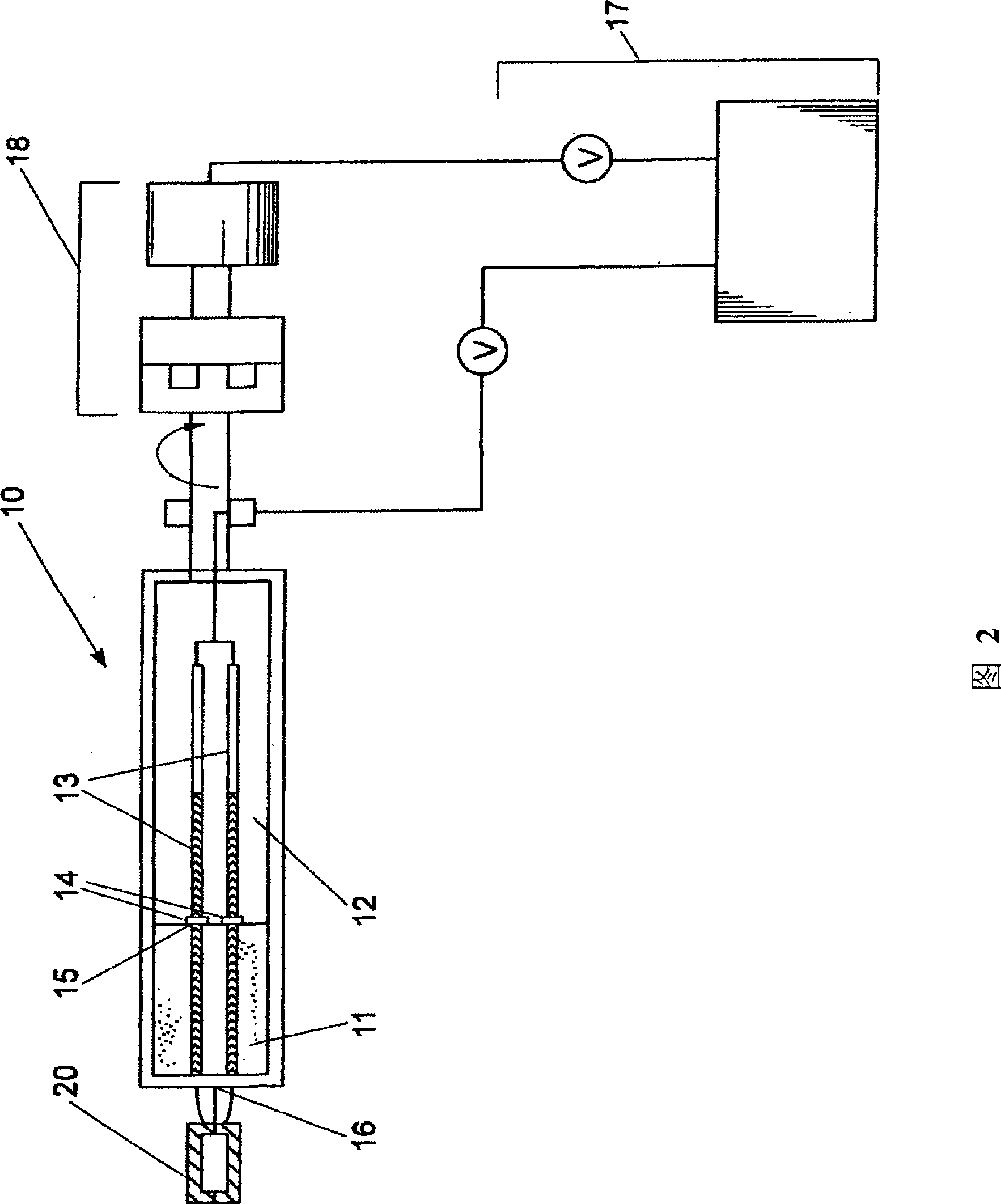

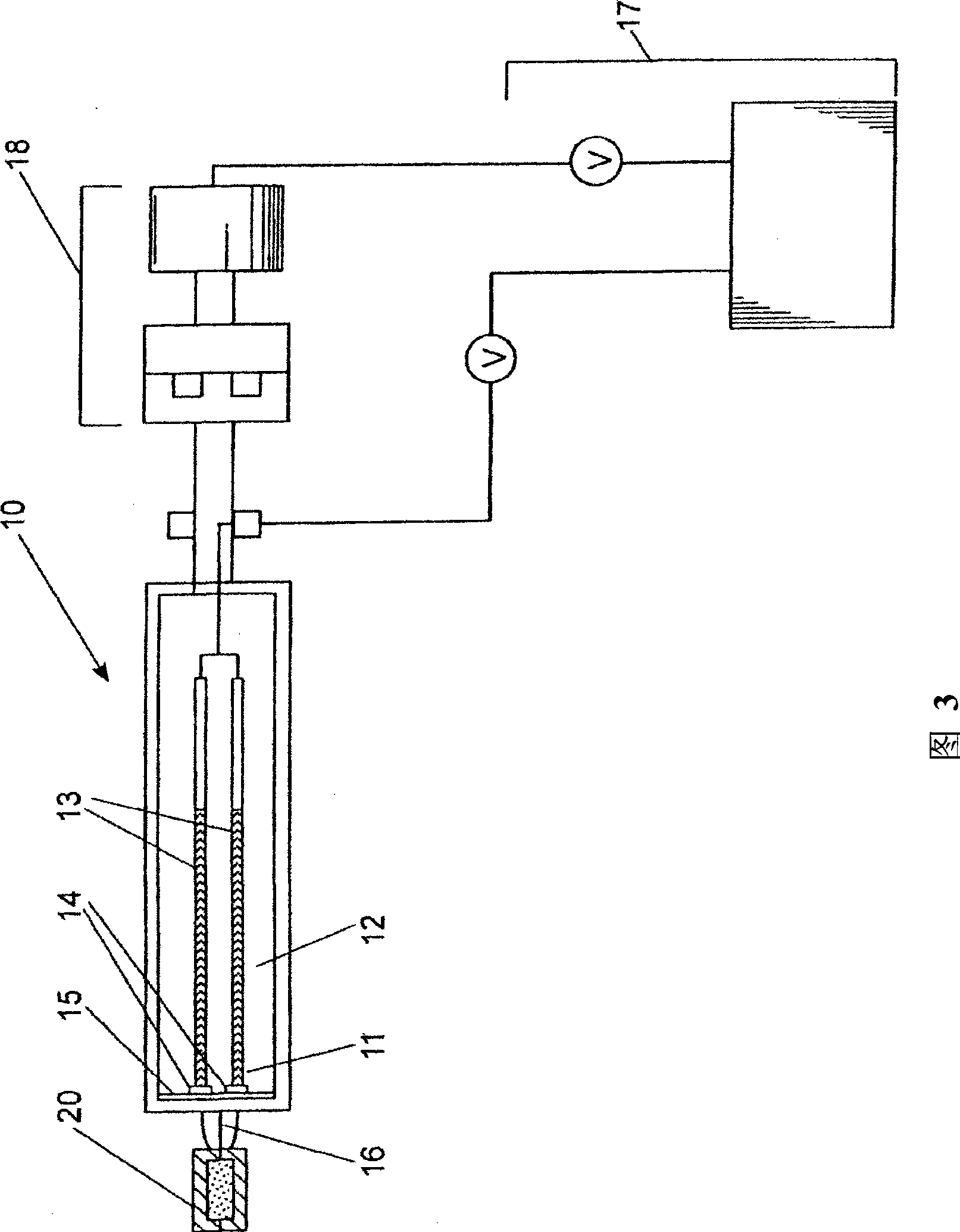

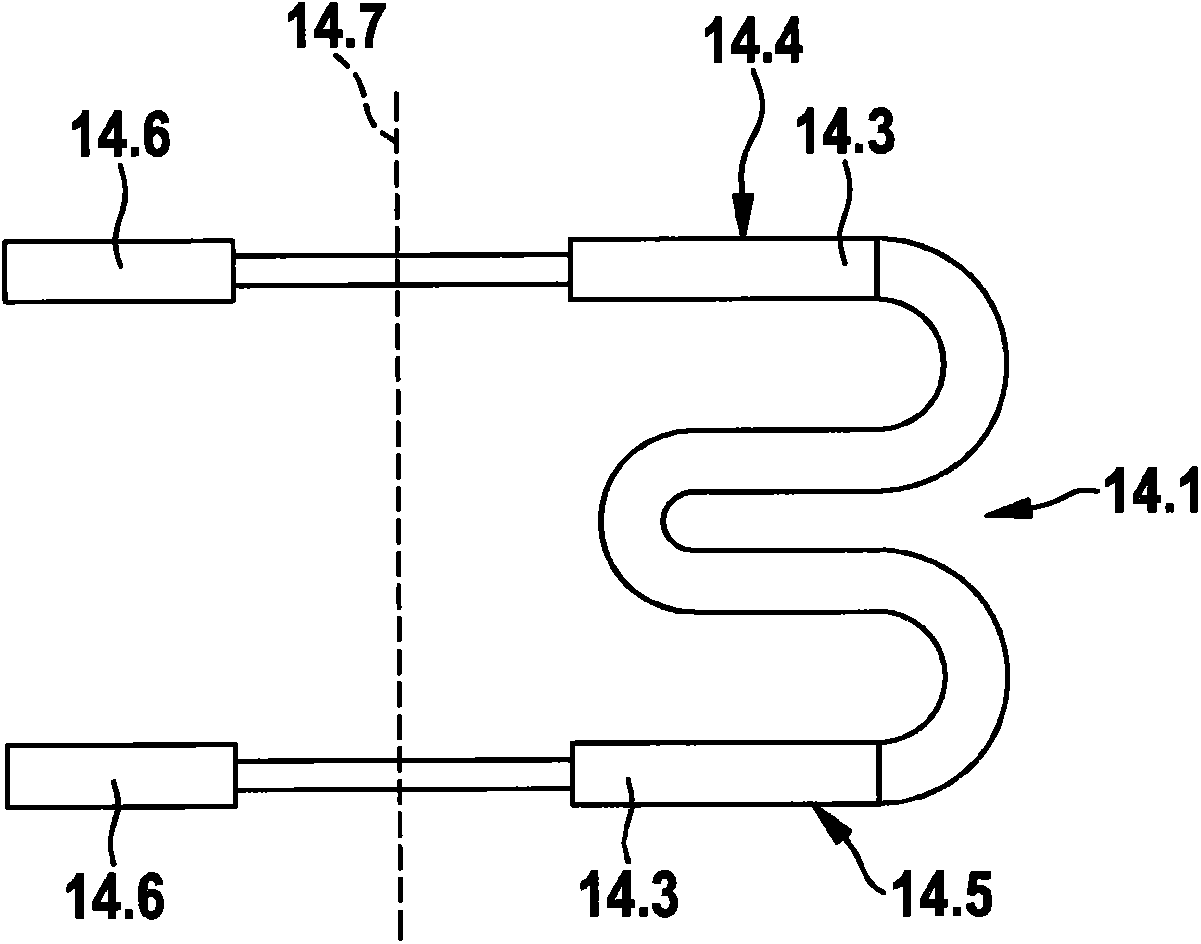

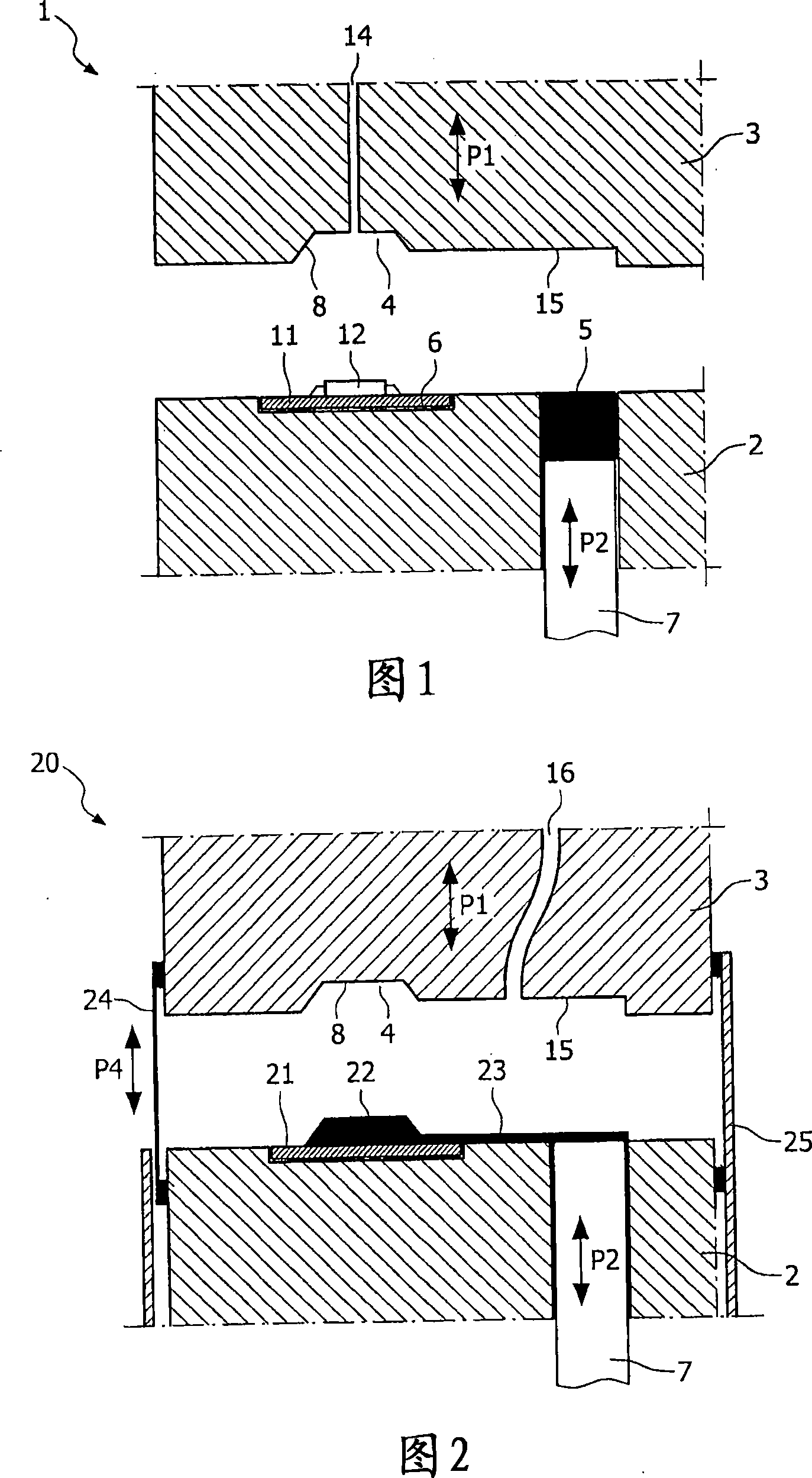

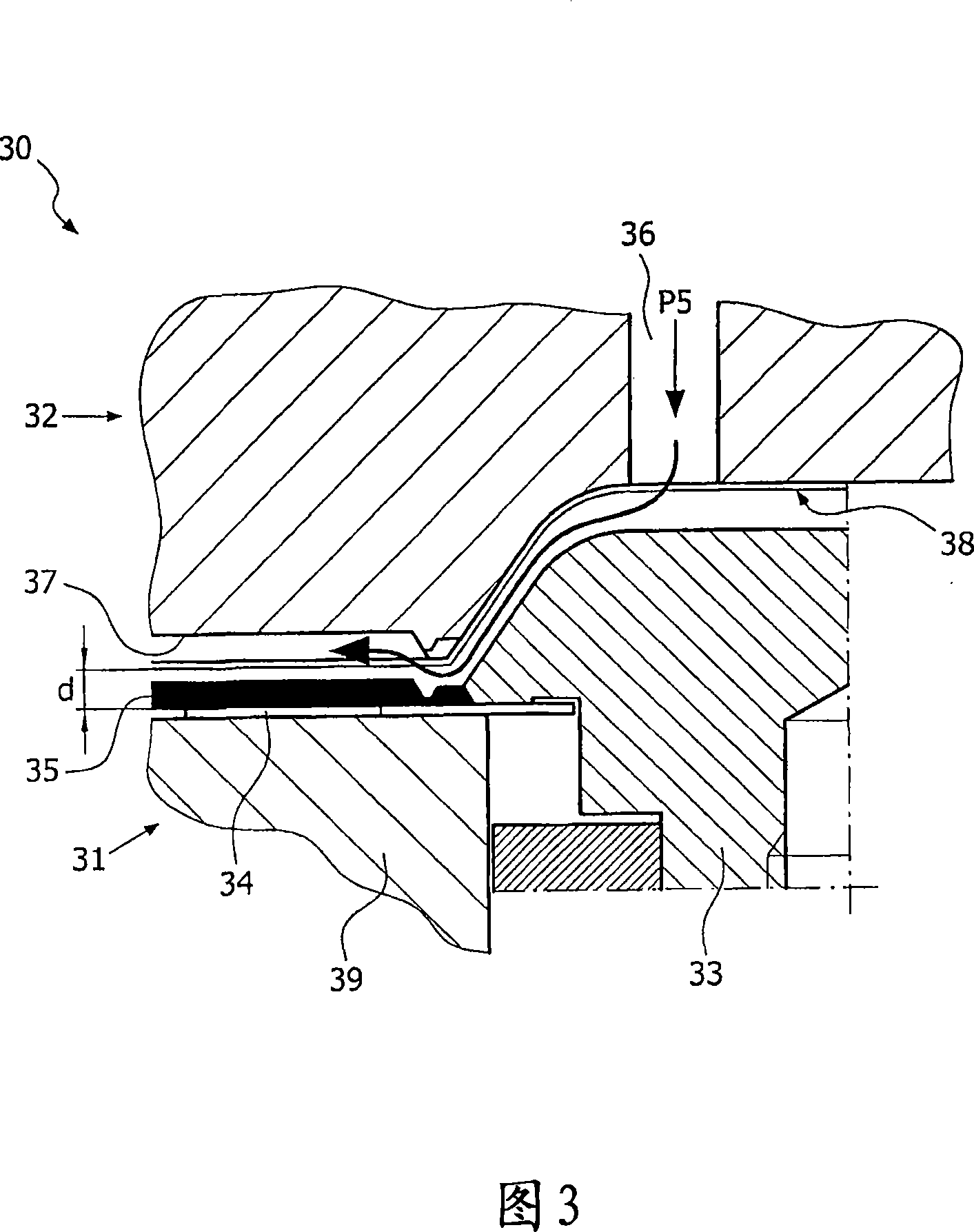

Retractable pin mixing sample forming device

InactiveCN101415483AEasy to recycleChange sizeShaking/oscillating/vibrating mixersTransportation and packagingMulti materialEngineering

The invention is a device for processing materials comprising a mixing chamber having a valve (16) for removal of the material from the mixing chamber and a piston (12) which fits within the mixing chamber in a manner such that the piston can be moved to remove substantially all material from the mixing chamber via the valve; at least one, preferably at least two, retractable mixing element(s) (13) wherein each of such elements is movable in and out of the mixing chamber through a port wherein the element and port are configured such that during mixing and when the element is withdrawn from the mixing chamber substantially no material is removed from the mixing chamber via the port. The invention is also a method of using such a device and a system comprising use of such devices in an automated or partially automated array.

Owner:DOW GLOBAL TECH LLC

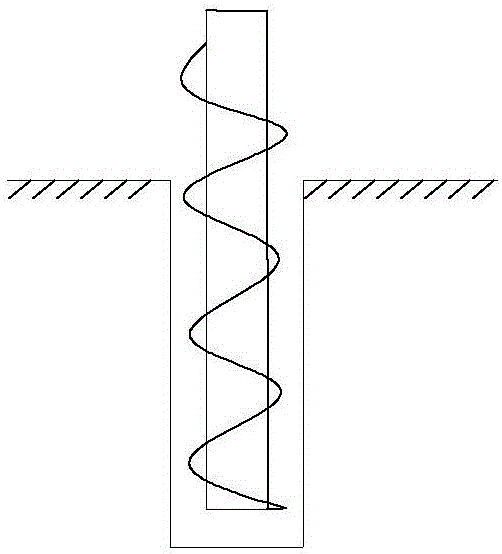

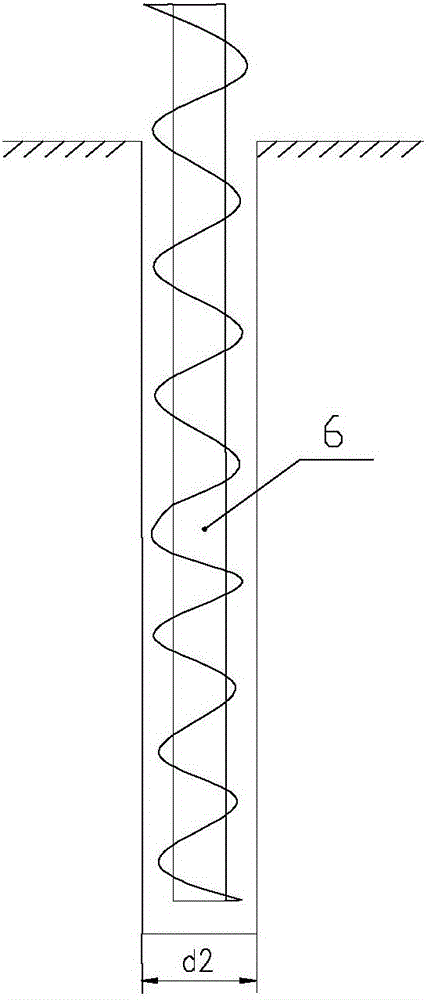

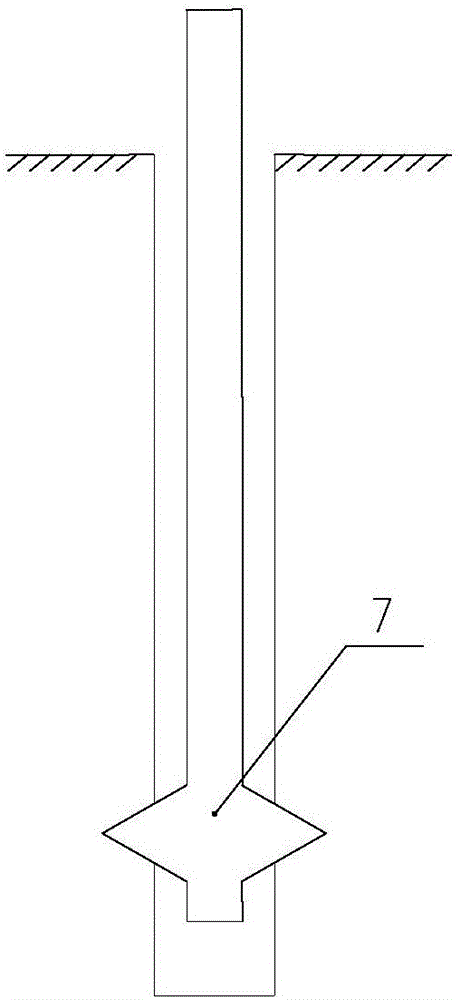

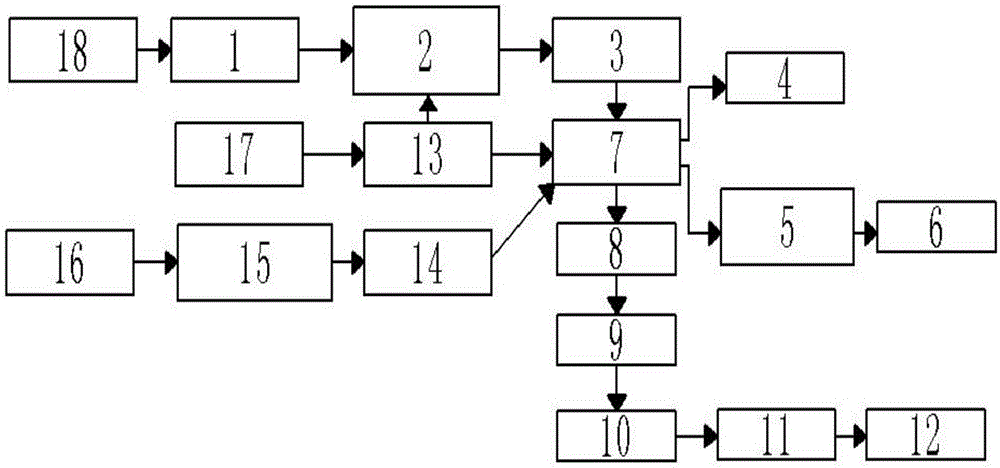

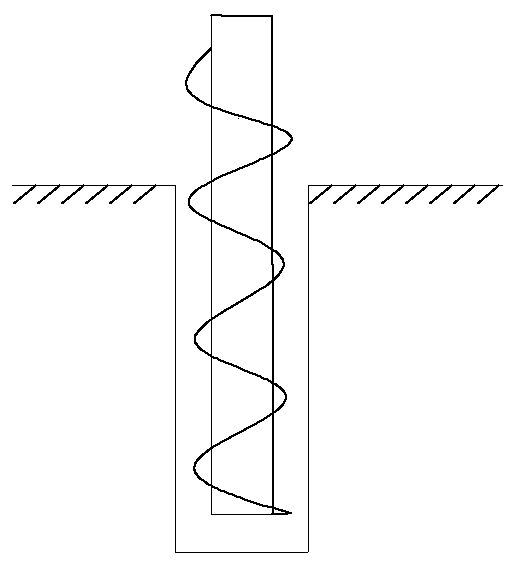

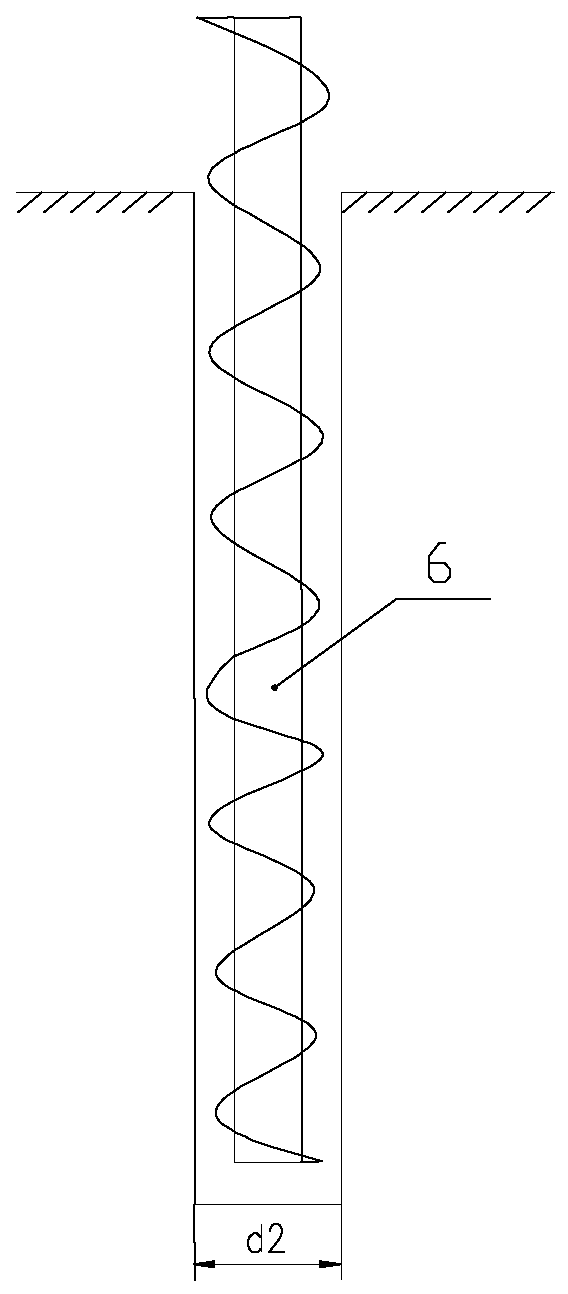

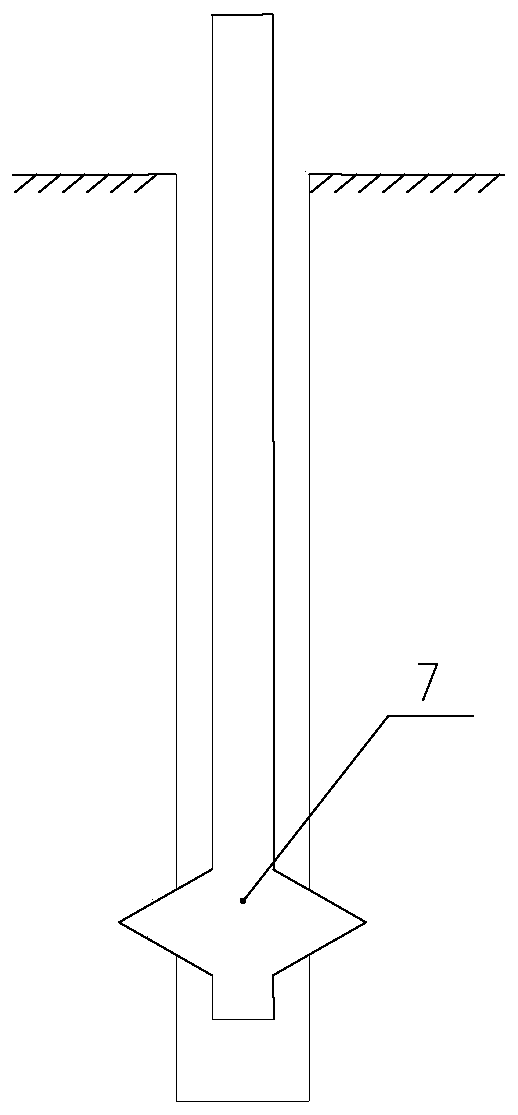

Static drill squeezed branch and pipe pile combined pile type and construction method thereof

The invention discloses a static drill squeezed branch and pipe pile combined pile type. The static drill squeezed branch and pipe pile combined pile type comprises a pipe pile, a squeezed branch pile and an expanded pile, wherein the outer wall of the pipe pile is sleeved with the squeezed branch pile, and the expanded pile is connected with the end of the squeezed branch pile. The pipe pile is a hollow pipe. The pipe is filled with cement soil, and the solid pipe pile is formed. The squeezed branch pile comprises a squeezed branch pile body and squeezed branches distributed on the squeezed branch pile body at equal intervals in the axial direction. The squeezed branch pile is a cement soil pile. The expanded pile is an expanded concrete pile body. According to the static drill squeezed branch and pipe pile combined pile type, part of a soil body is extruded to the hole wall, the pile side friction is increased, discharge of an original soil body is reduced, meanwhile part of the residual soil body is dug out, a large-caliber pile foundation is formed, and the pile foundation bearing force is improved; then the squeezed branches are arranged, pre-pressure is applied to the side wall, the contact area of the combined pile and the soil is increased, the effective area of the pile body is increased, and the bearing force of the combined pile is improved; and then expansive concrete is pressed into a pile end expanded hole to form pre-pressure on the pile end, and the bearing capacity of the pile end is further improved.

Owner:SOUTHEAST UNIV

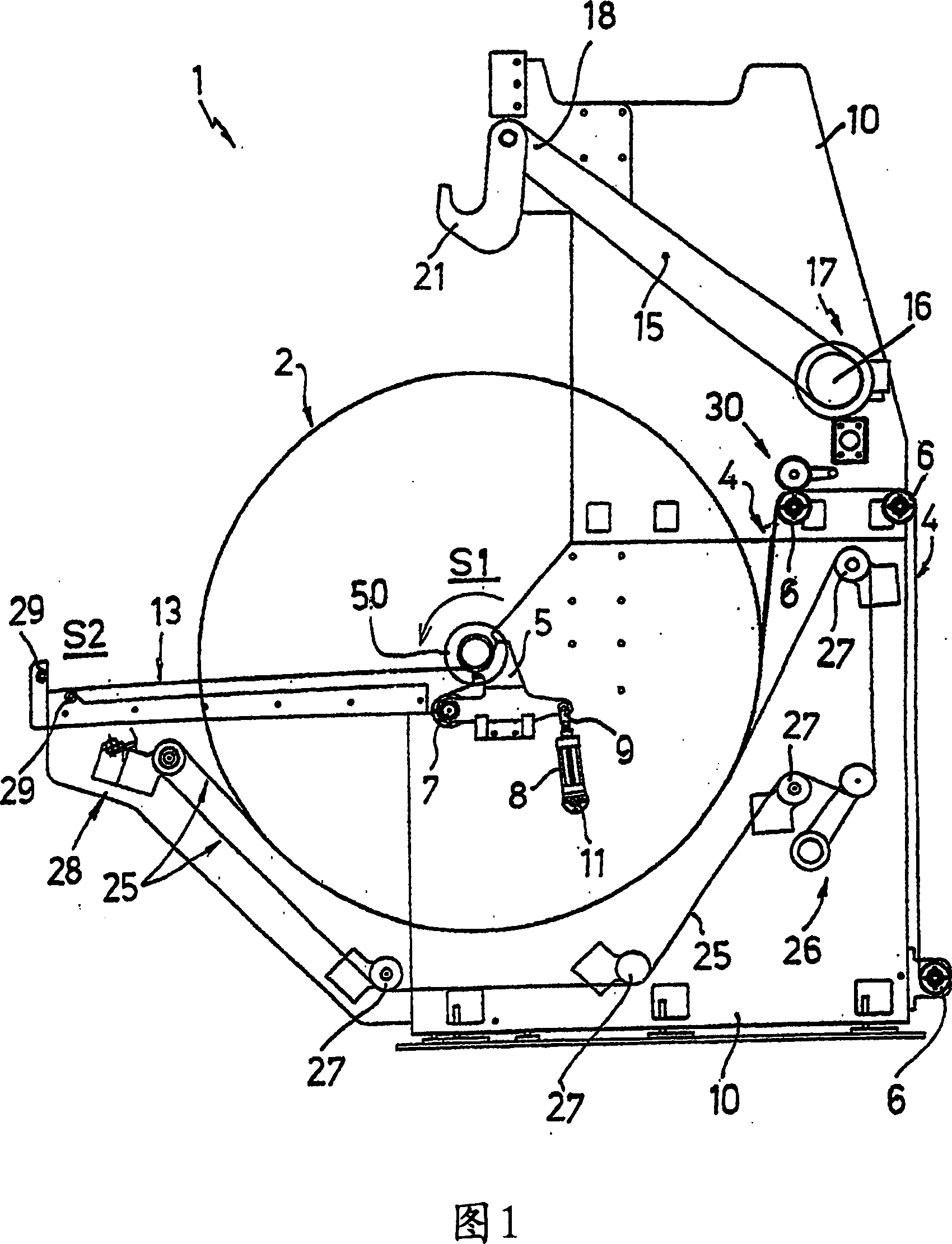

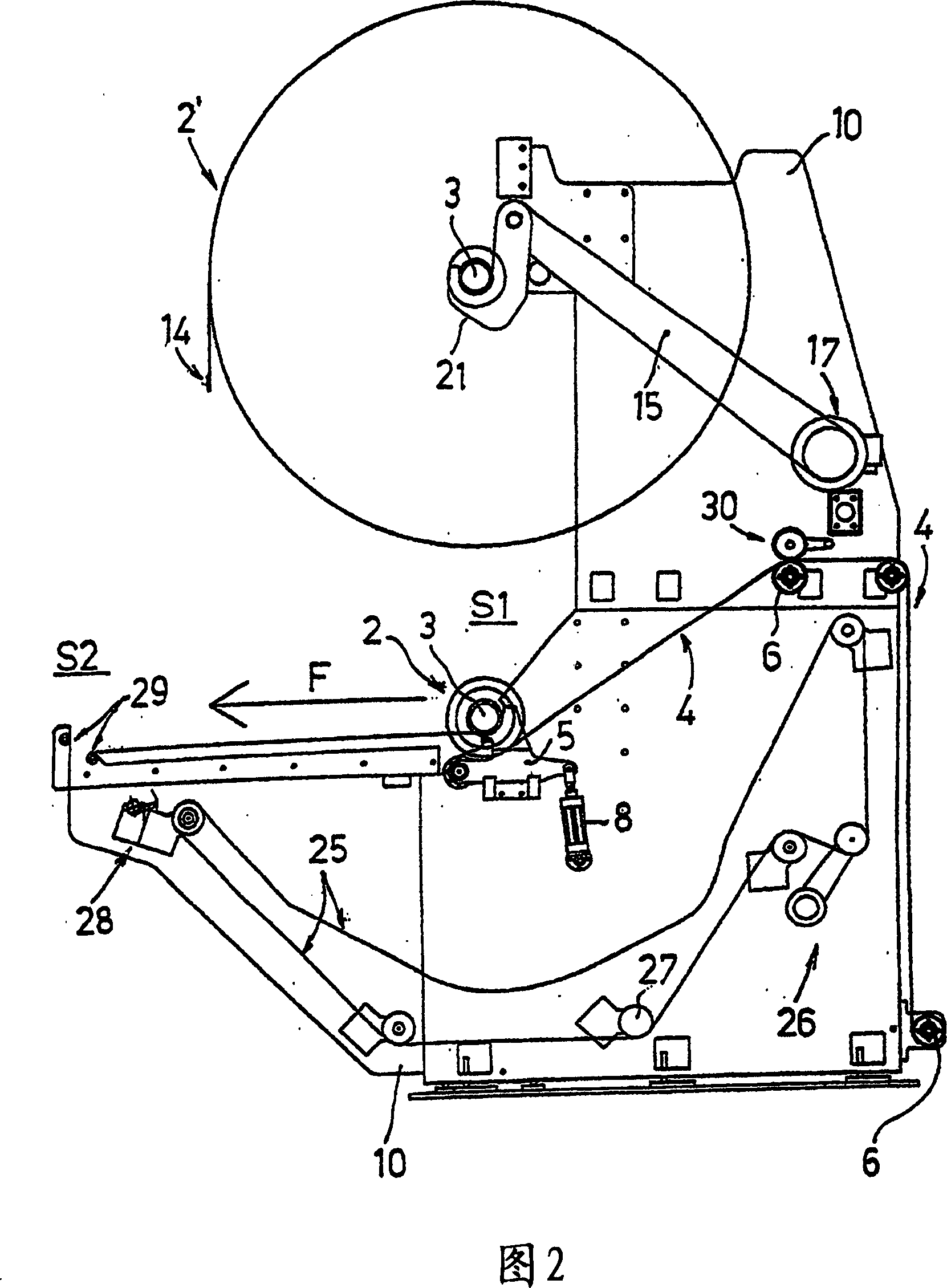

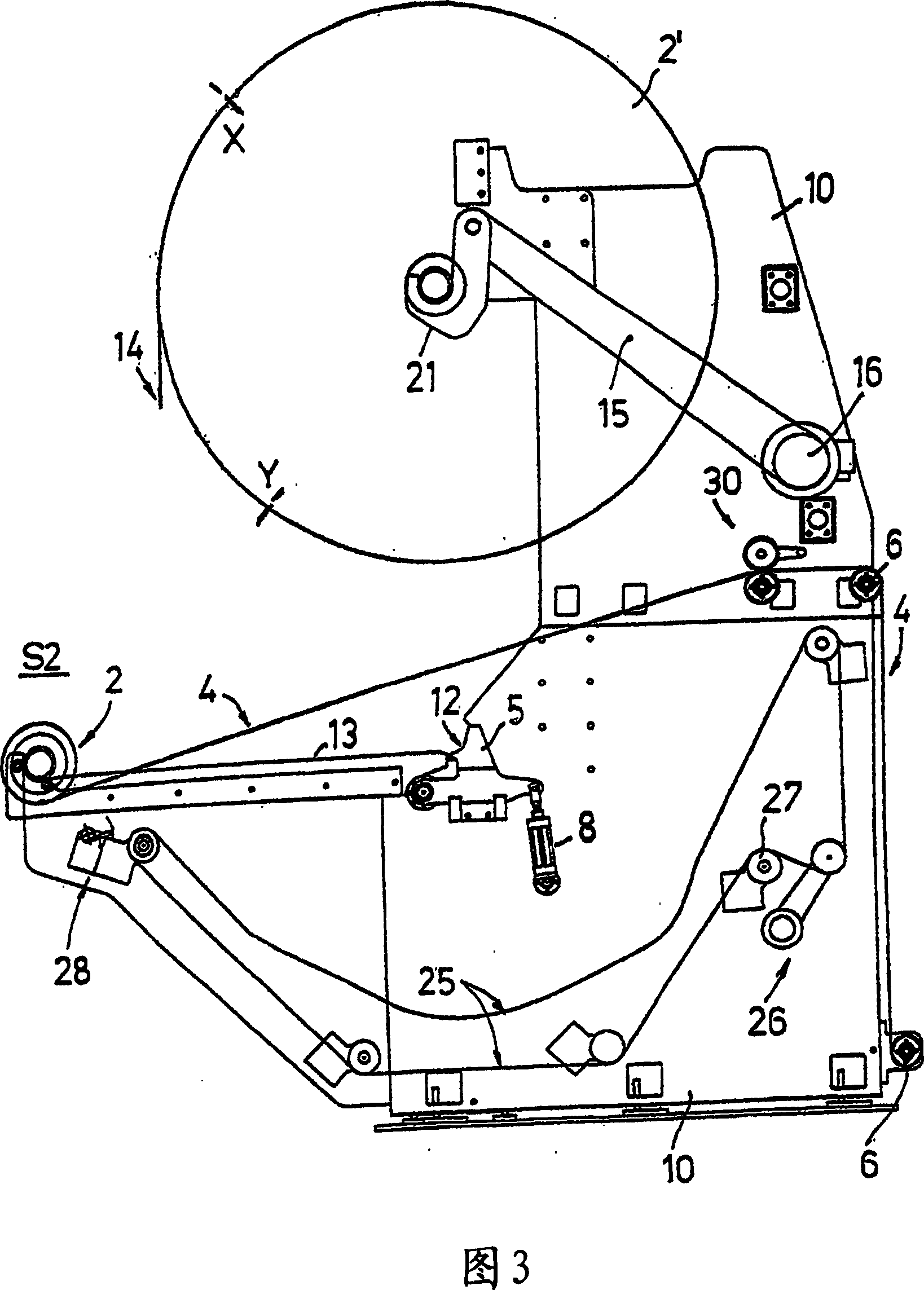

Device and method for changing the reel in an unwinder

The invention is to obtain the automatic change of the reel in an unwinder, in particular for reels of paper and other materials in web form, operation in which a reel (2) that is nearly empty is replaced with a new reel (2'), wherein provision is made to connect a tail portion (LC) of the web of the nearly empty reel (2) to the head portion (LT) of the web of the new reel (2') after overlapping of said ends (LC) and (LT), said overlap step begins along the surface of the new reel 2', right next to the latter.

Owner:FUTURA SPA

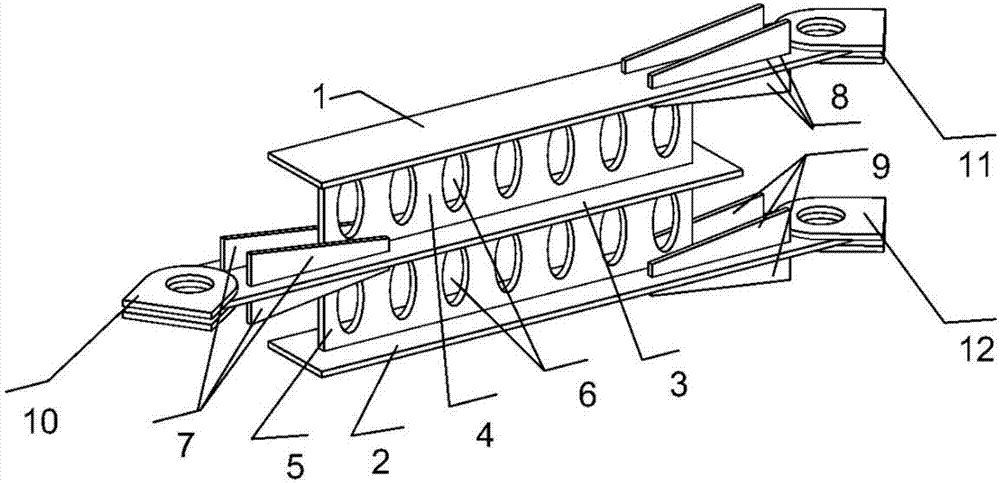

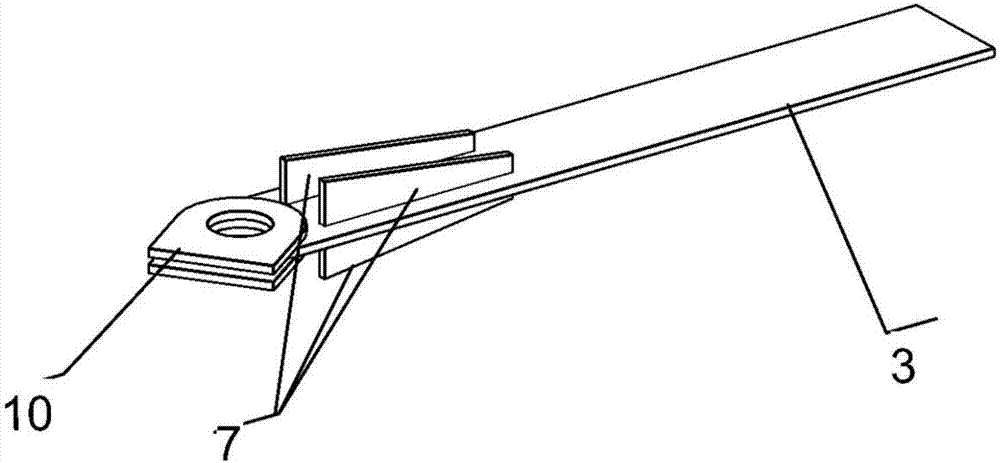

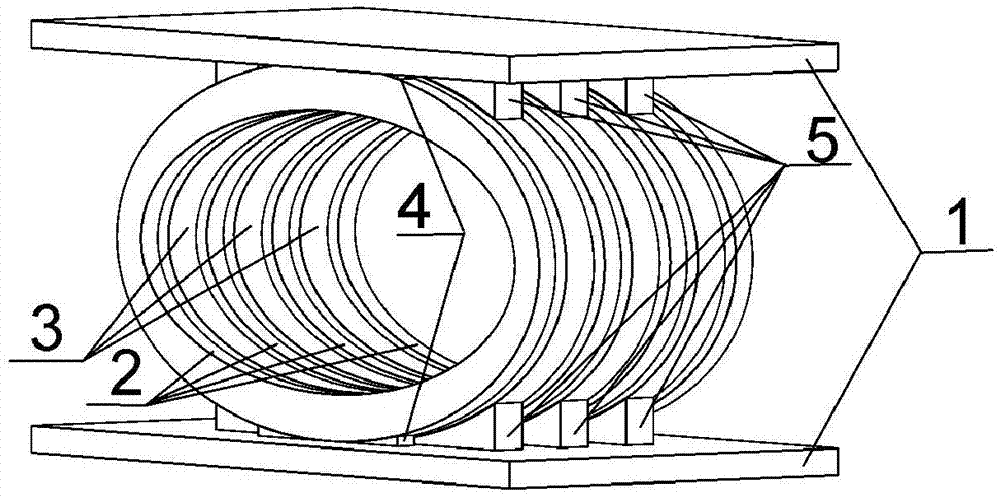

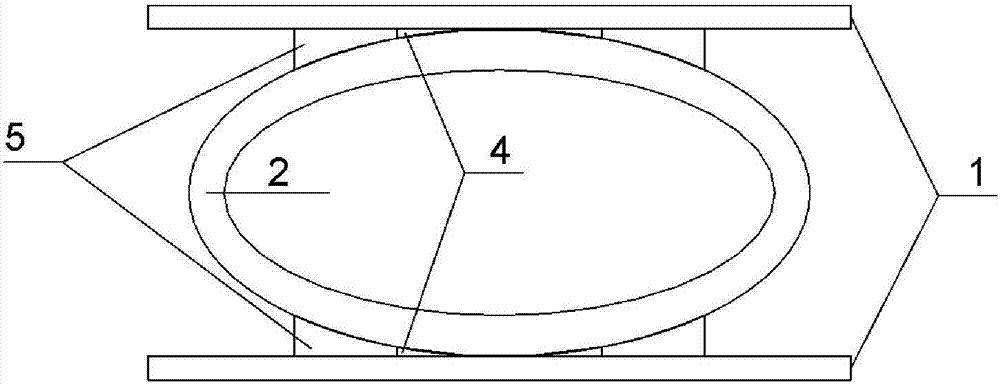

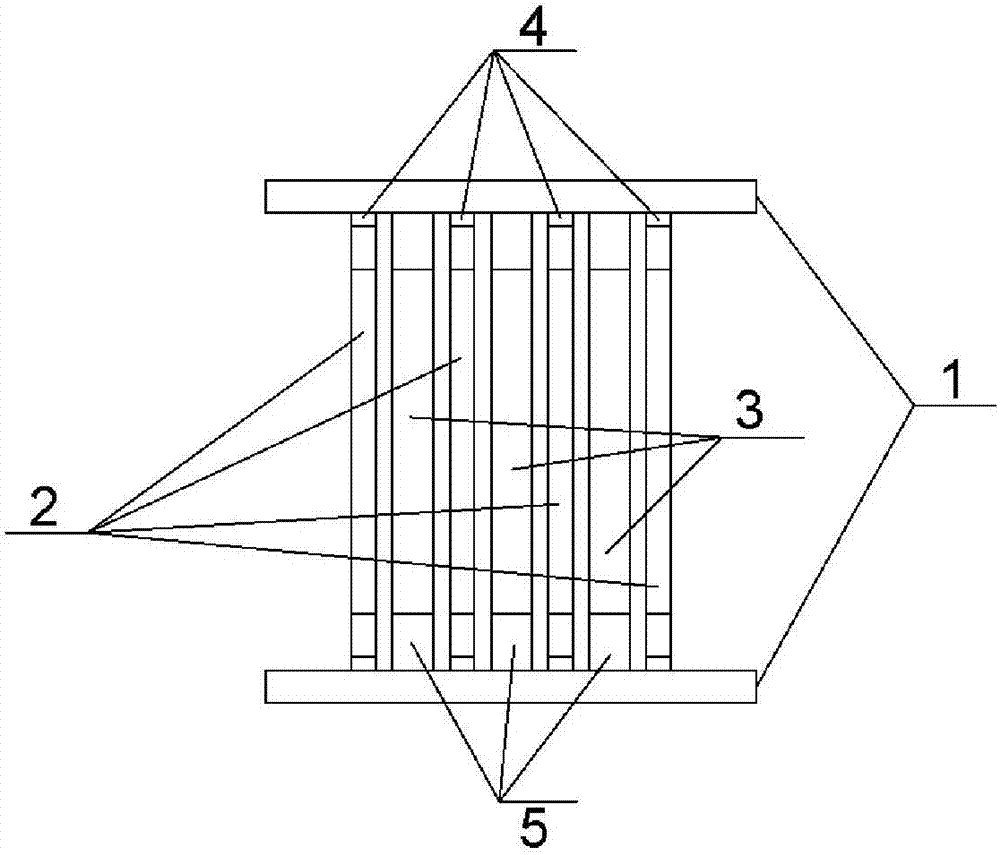

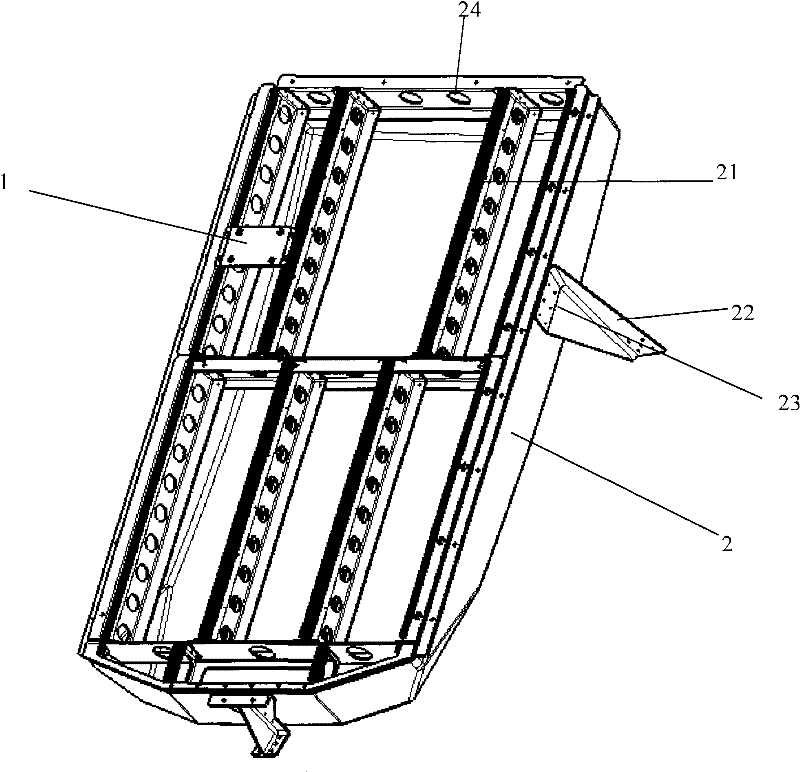

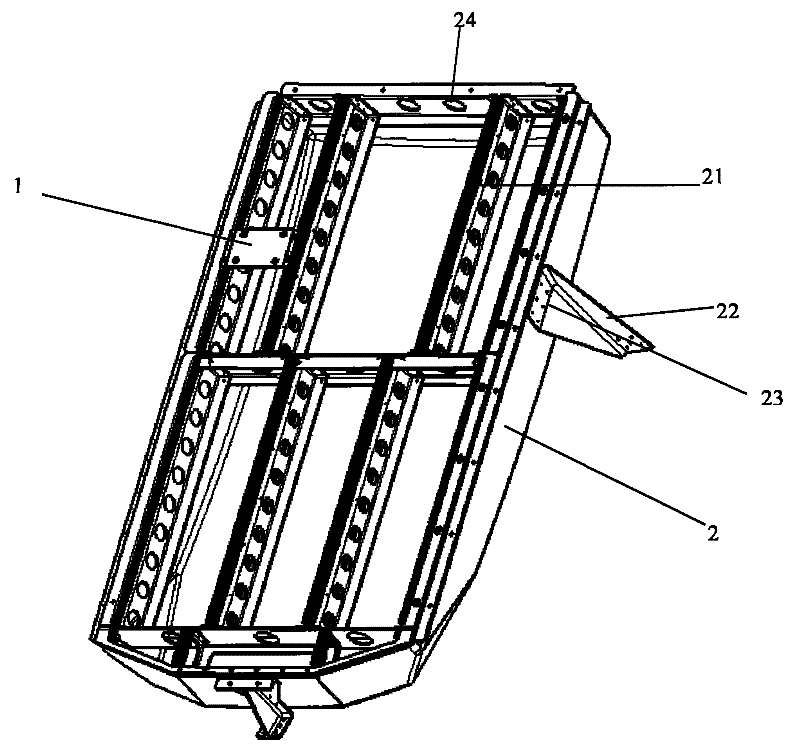

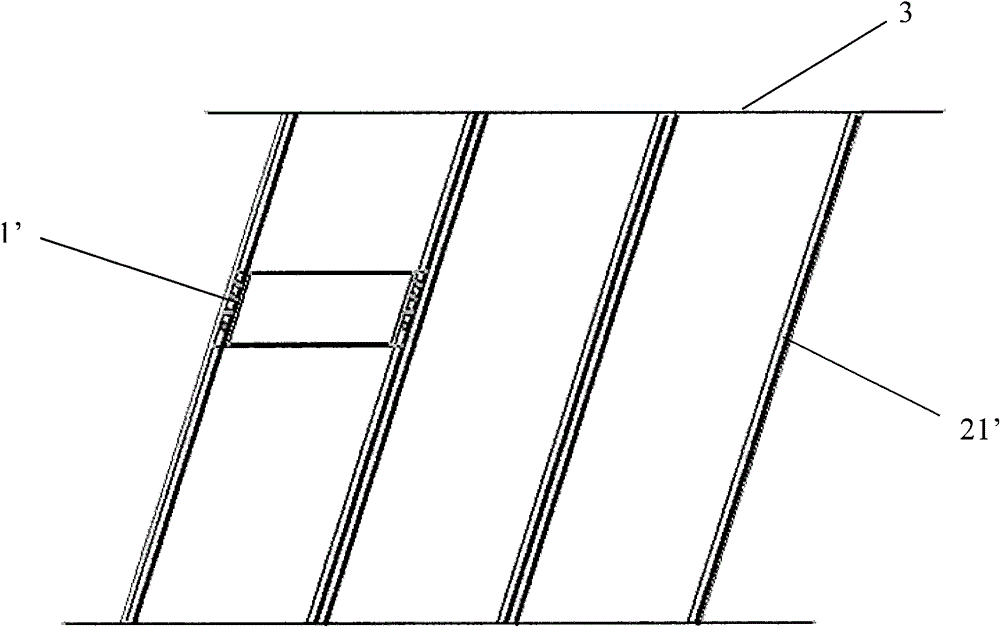

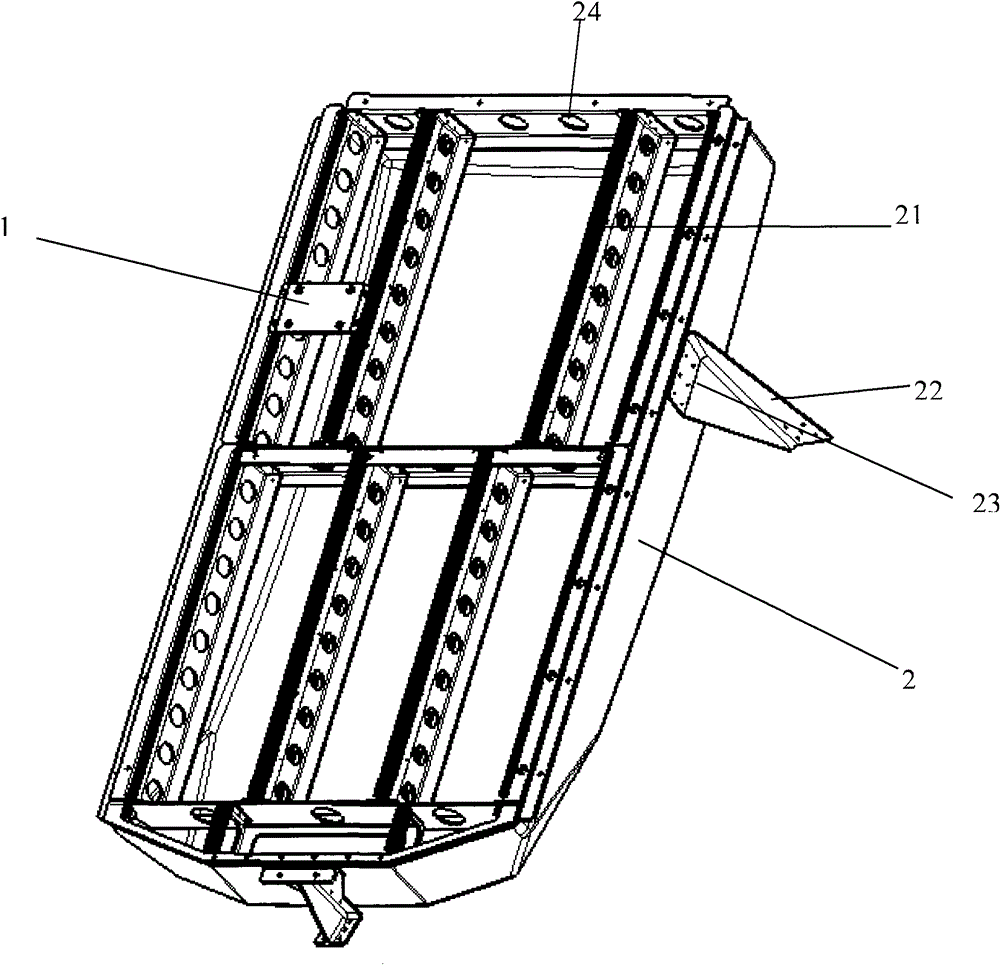

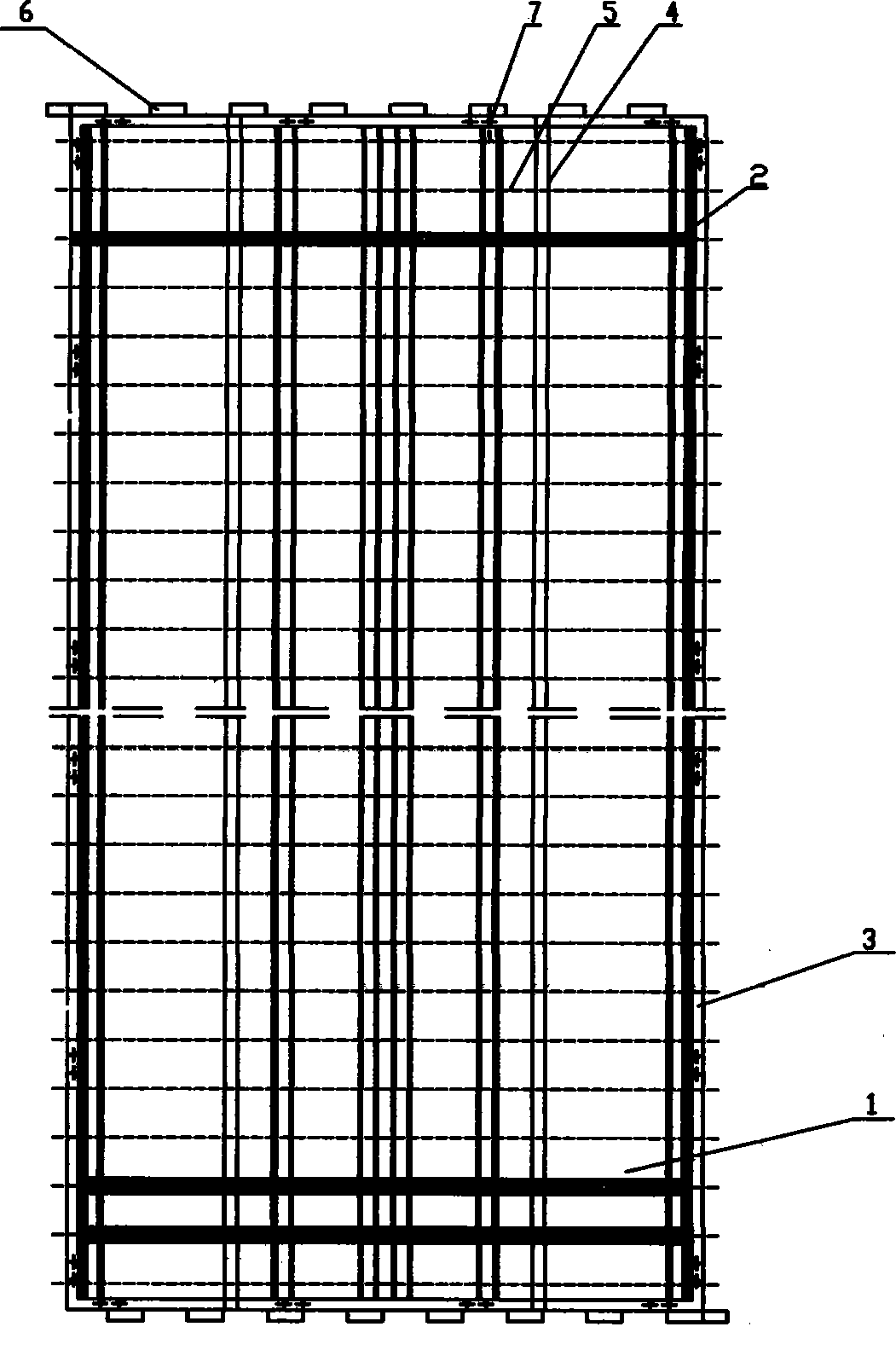

Novel supporting type metal damper

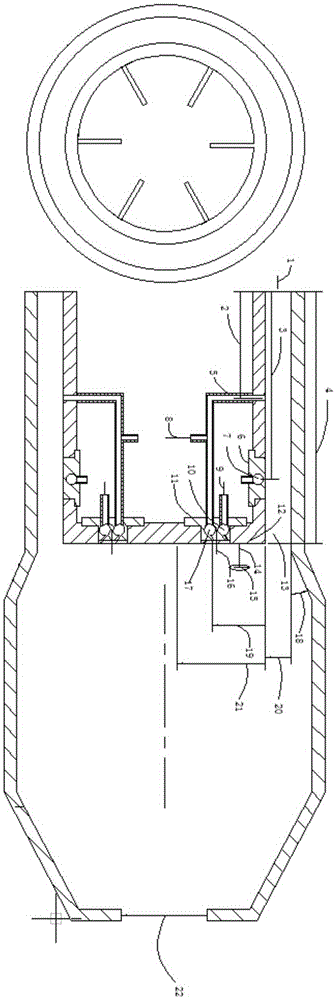

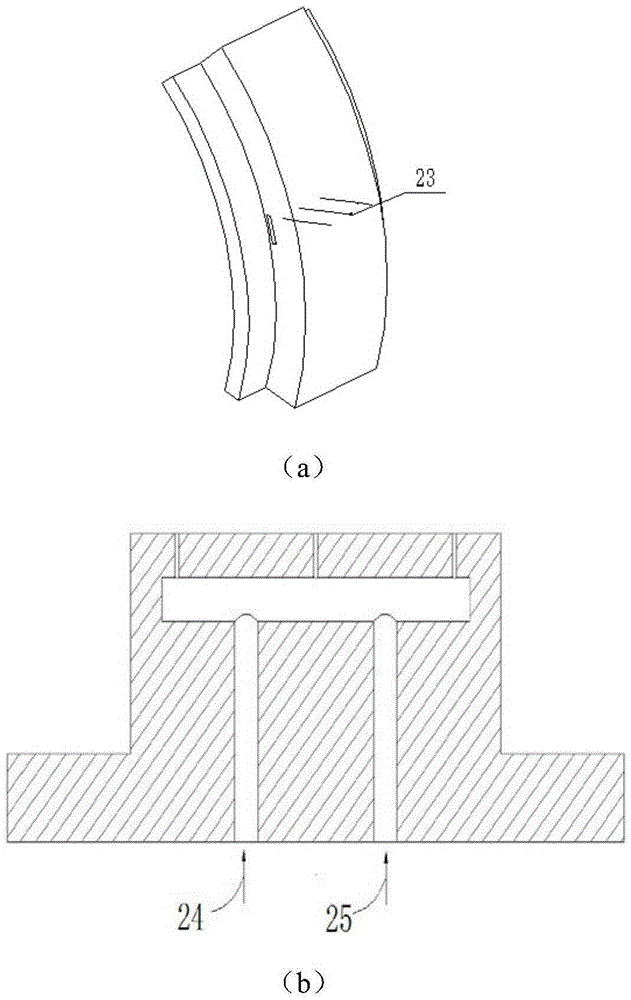

InactiveCN107327039ASimple mechanical propertiesEasy to installProtective buildings/sheltersShock proofingSteel platesType metal

The invention relates to the field of energy-dissipation components of building structures, in particular to a supporting type metal damper which is simple in mechanical property, convenient to mount and stable in energy dissipation. The novel supporting type metal damper comprises a connecting component and an energy dissipation component. The connecting component comprises a first connecting plate, a third connecting plate and a second connecting plate, wherein the first connecting plate, the third connecting plate and the second connecting plate are sequentially placed in parallel from top to bottom. The energy dissipation component comprises a first shearing energy-dissipation steel plate and a second shearing energy-dissipation steel plate, wherein the first shearing energy-dissipation steel plate is fixedly arranged between the lower plate surface of the first connecting plate and the upper plate surface of the third connecting plate, and the second shearing energy-dissipation steel plate is fixedly arranged between the lower plate surface of the third connecting plate and the upper plate surface of the second connecting plate. The supporting type metal damper is arranged between a beam and a column in an obliquely-supported mode, and hinge steel plates used for being connected with a beam-column frame of a building are arranged at the ends of the connecting plates correspondingly. The novel supporting type metal damper is simple in mechanical property, convenient to mount and stable in energy dissipation; and besides, the supporting type metal damper is simple and easy to transform, the construction period is short, and the apparent characteristics can be easily checked.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Sensor, sensor unit, and method for producing sensor unit

ActiveCN103748434AWill not corrodeLow costAcceleration measurementSpeed/acceleration/shock instrument detailsEngineering

Owner:ROBERT BOSCH GMBH

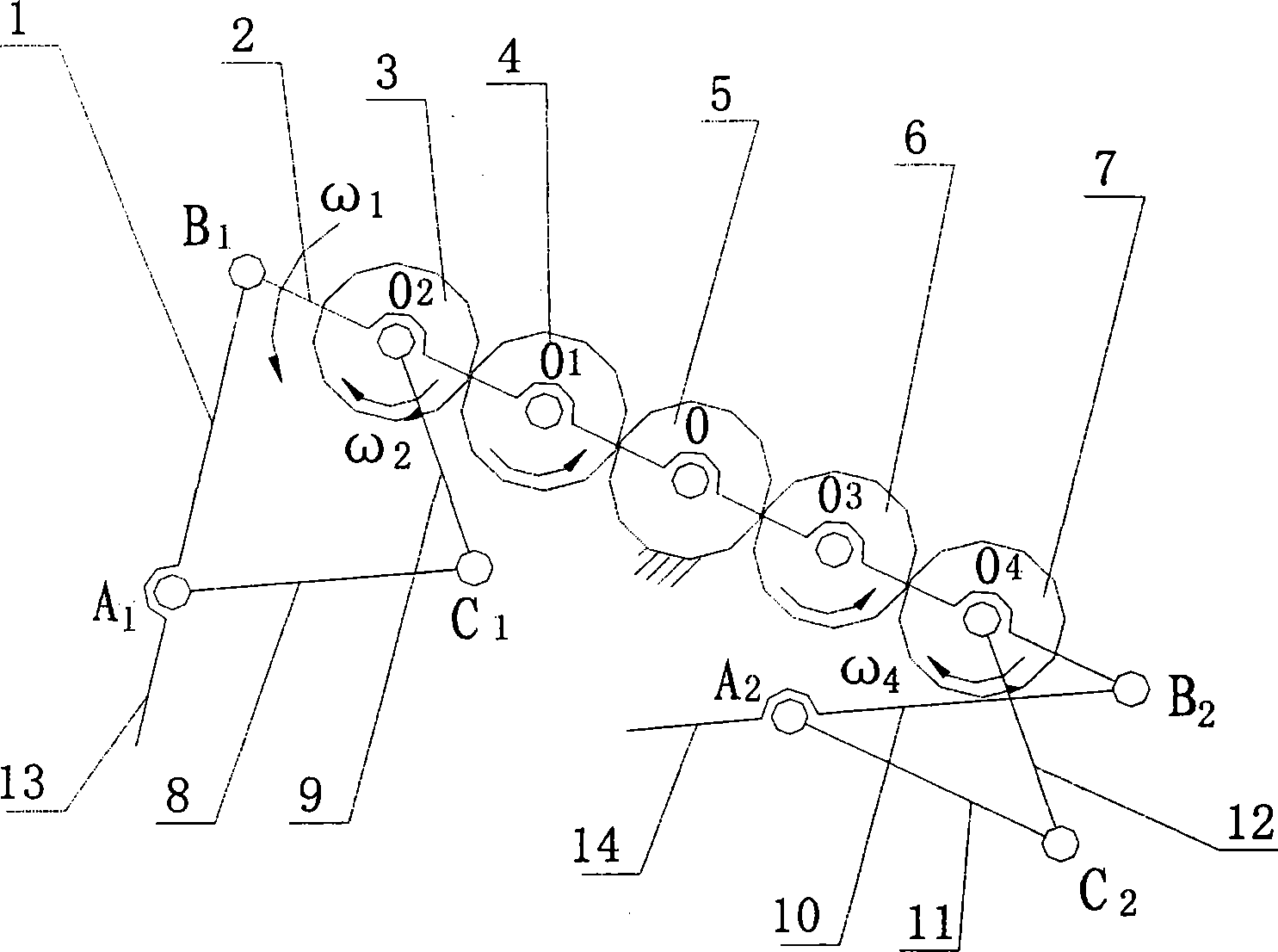

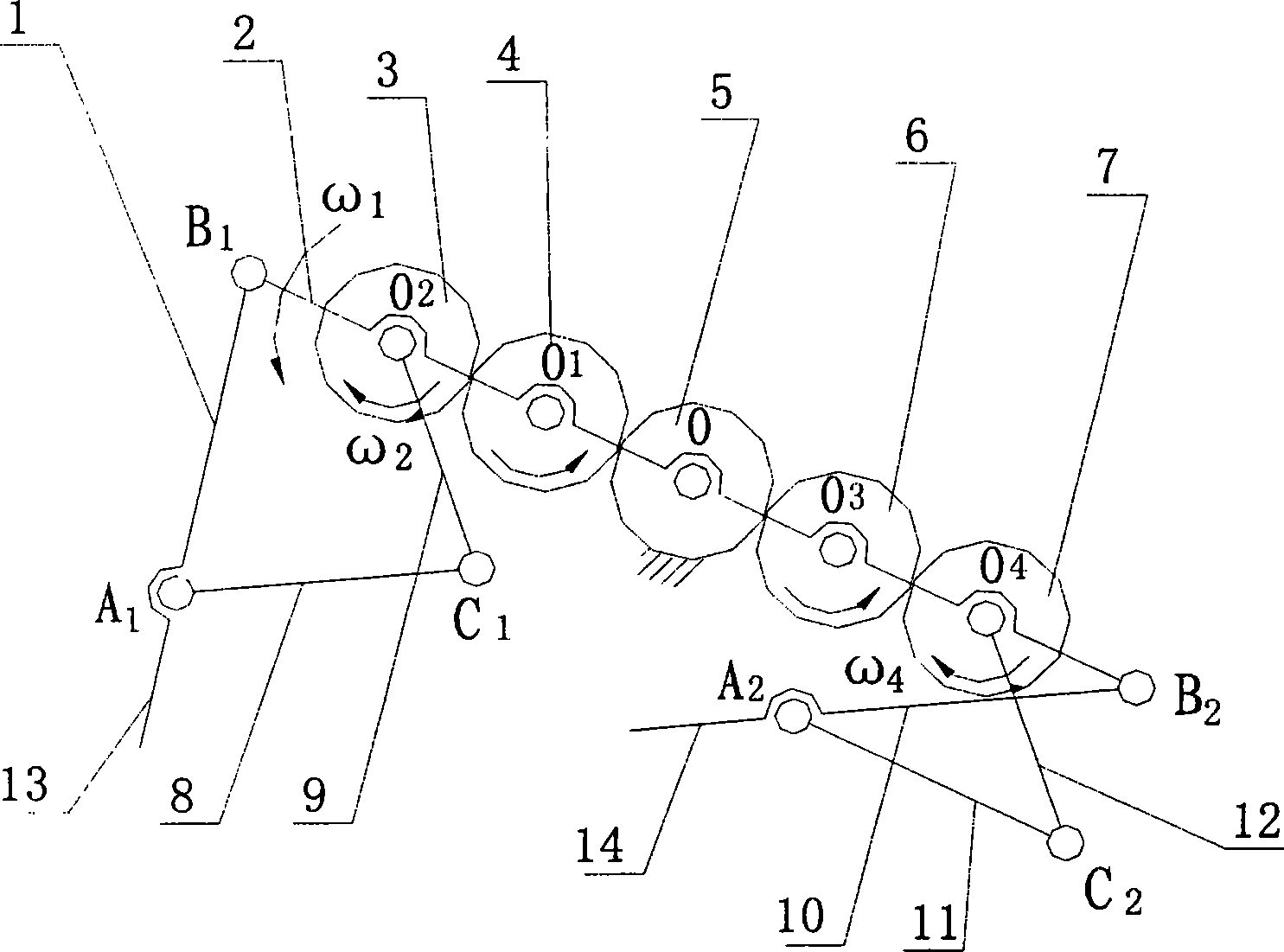

Rotary type double crank insert division mechanism

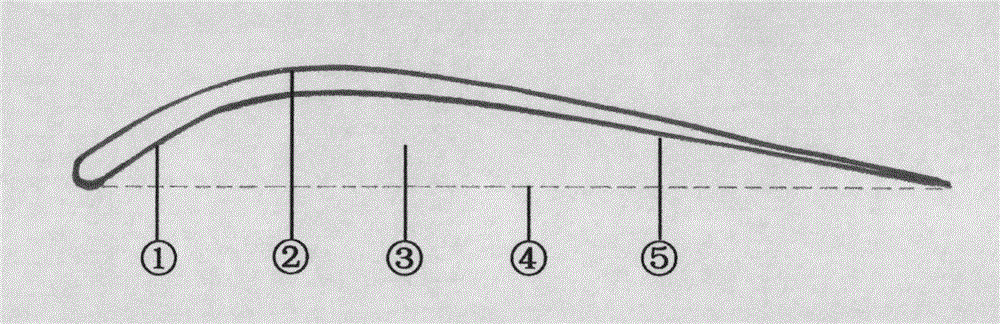

The invention discloses a revolving double-crank transplanting mechanism of a seedling planting machine. A planet carrier rotates around the center of fixed cylindrical gears; a transplanting mechanism consisting of two double-crank mechanisms are mounted on the two ends of the planet carrier; the frame of the double-crank mechanisms is the planet carrier; the cranks of the double-crank mechanisms are driven to rotate by two cylindrical gears; the mechanism which is composed of the cylindrical gears and a plurality of member bars has no non-circular gears, thus realizing two seeding actions for one rotation around the planet carrier, and the track of seedlings meets the requirements of agricultural technology.

Owner:ZHONGJI SOUTHERN MACHINERY

10-DOF floor exercise robot

InactiveCN103659818ASimple structureSimplified weightManipulatorPhysical medicine and rehabilitationElectric machinery

The invention discloses a 10-DOF floor exercise robot comprising a head part, shoulder U-shaped members, arm racks, a trunk support, waist U-shaped members, sinuous fixing clamps, leg U-shaped members, U-shaped fixing clamps, foot U-shaped members, right-angled fixing members, sole plates, motors, a controller, and a battery. The 10-DOF floor exercise robot can do many humanoid acts, such as forward roll, backward roll, handstand, split, and push-up. Double-shaft motor control is adopted, the acting process has stable power transmission, and control is simple, handy, and well stable. The size and weight of the robot is controlled in the certain range, the parts are fixedly connected, the shape of the robot is fully utilized, and fewer parts for fixation are used.

Owner:NORTHWEST A & F UNIV

Method and device for encapsulating electronic components with a conditioning gas

Owner:BESI NETHERLANDS BV

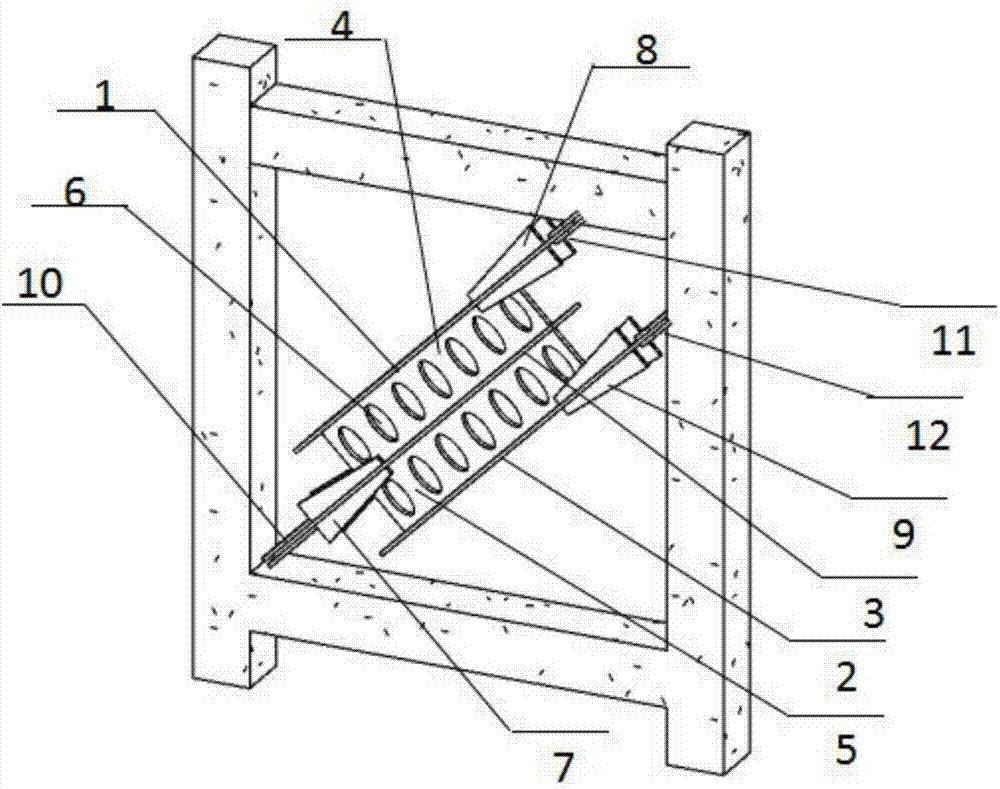

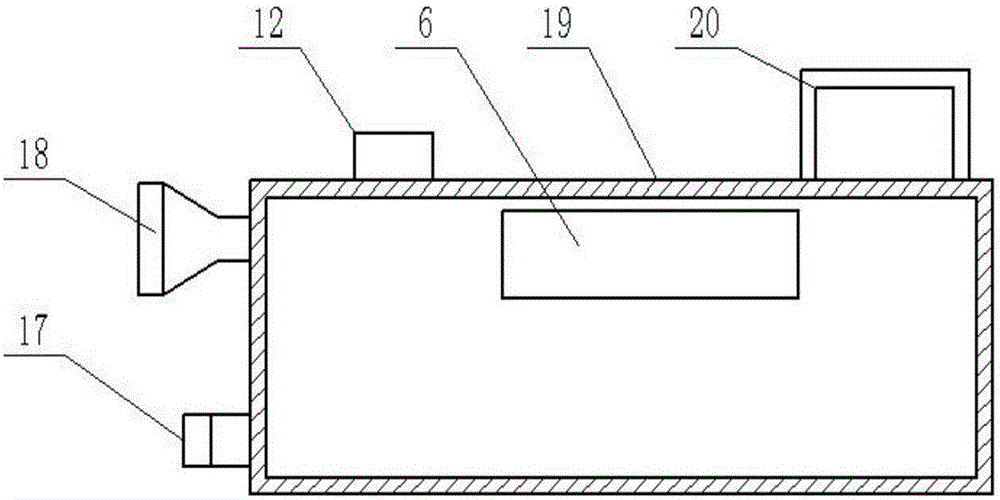

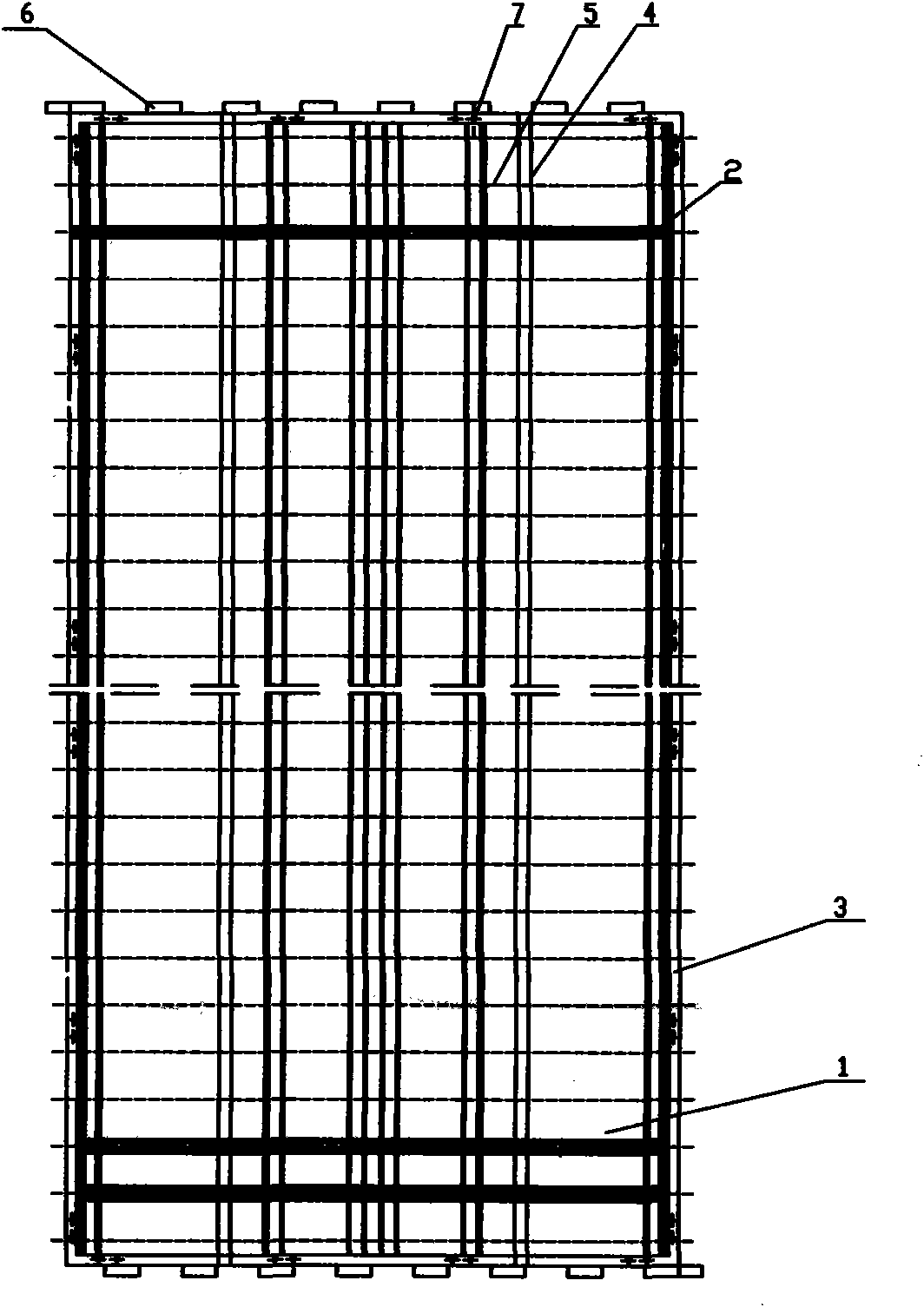

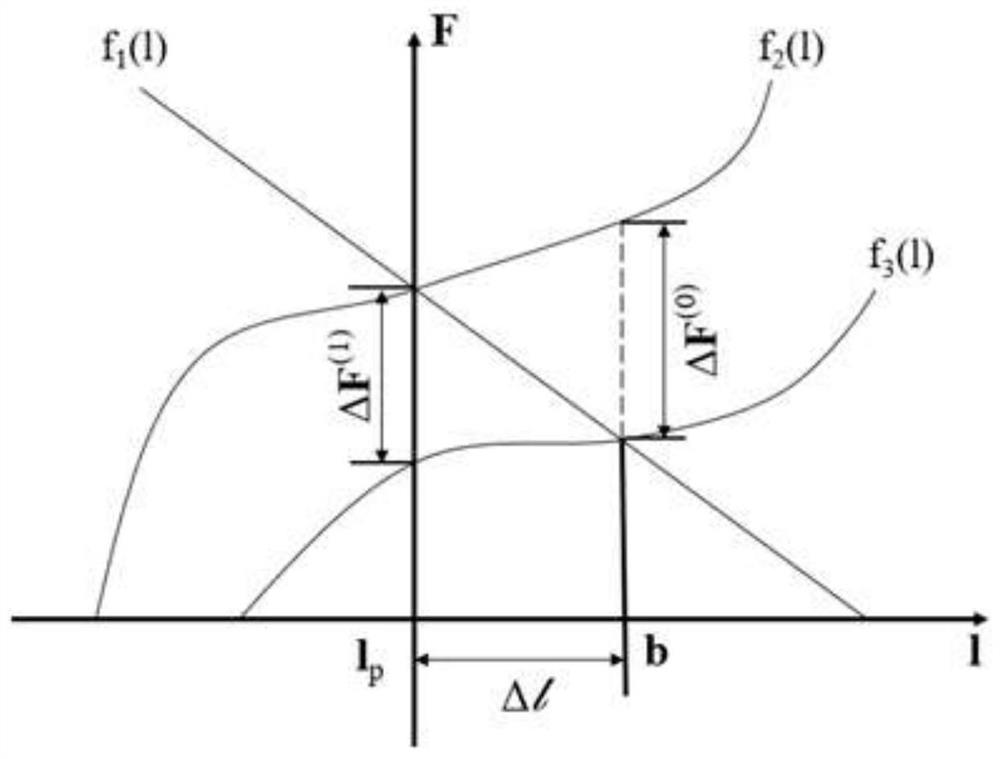

Damper achieving staged yielding

InactiveCN107035017AEasy to installStable energy consumptionProtective buildings/sheltersShock proofingEnergy stabilityMaterials science

The invention provides a staged yield damper, comprising: upper and lower connecting plates (1), a first energy dissipation steel plate (2), a second energy dissipation steel plate (3), the first energy dissipation steel plate (2) and The second energy-dissipating steel plates (3) are arranged between the upper and lower connecting plates (1), wherein the first energy-dissipating steel plates (2) and the second energy-dissipating steel plates (3) are alternately arranged. In the present invention, by installing alternately arranged first energy-dissipating steel plates and second energy-dissipating steel plates between the upper and lower connecting plates, the stages of different yield degrees formed by the first energy-dissipating steel plates and the second energy-dissipating steel plates damper. The staged yield damper in the invention has simple mechanical properties, convenient installation, stable energy consumption, and can meet the energy consumption requirements of wind vibration, small earthquake and large earthquake at the same time.

Owner:SHANGHAI INST OF TECH

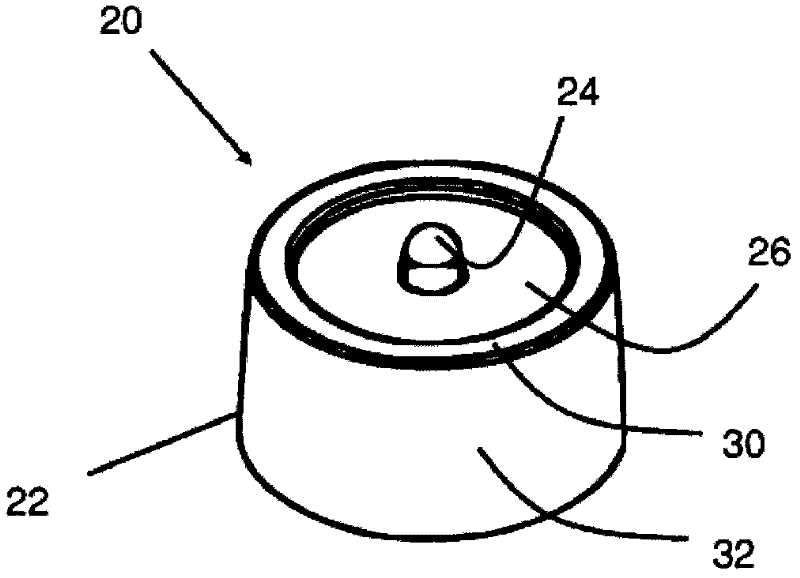

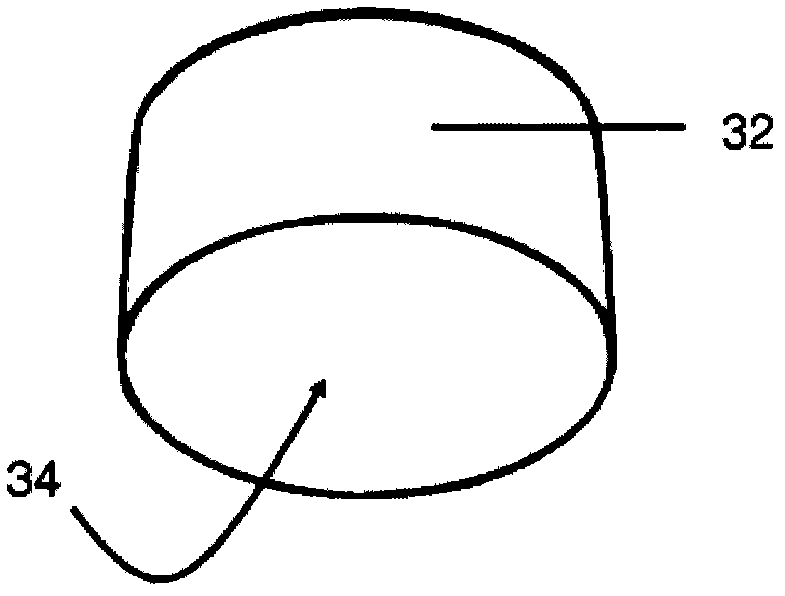

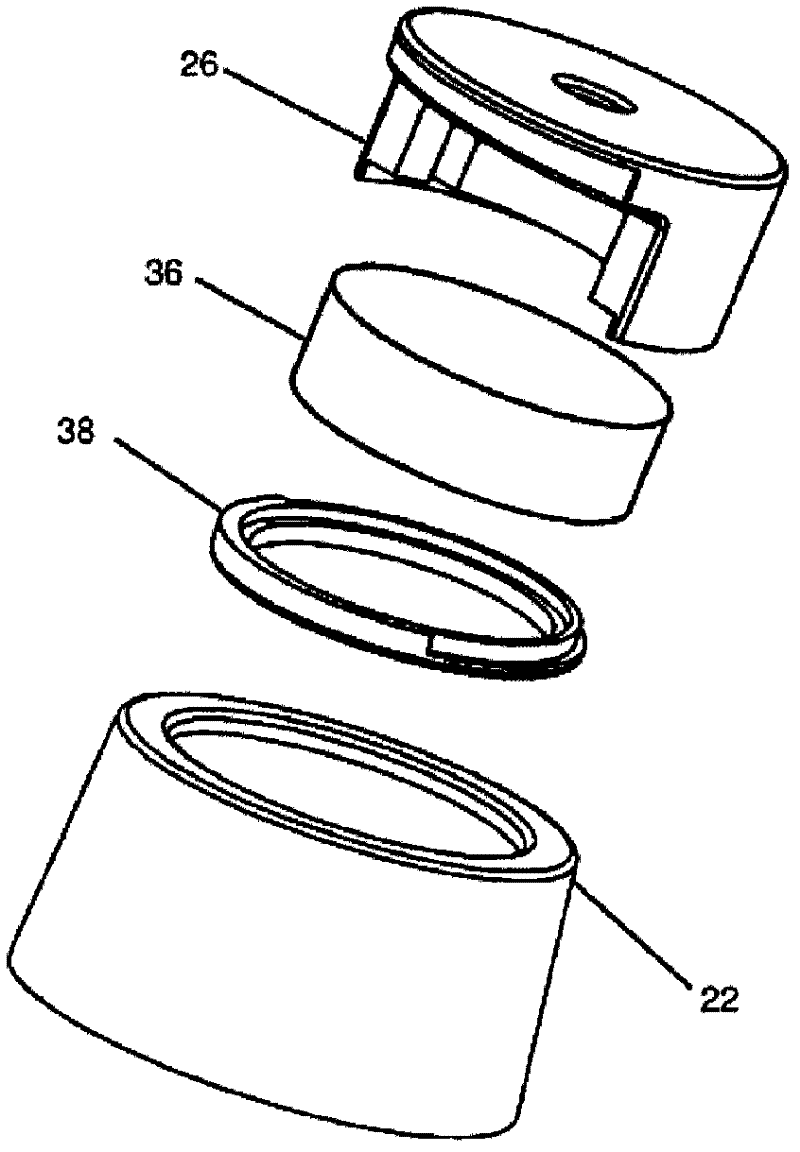

Liquid illuminator and assembly thereof

InactiveCN102245062AEasy to insertEasy to insert and fixContainer decorationsLevel indicationsCouplingBottle

An illuminator (20) and a liquid container assembly including the illuminator are disclosed. The illuminator (20) includes a light source (24), a power source and a coupling portion (22). The coupling portion (22) is flexibly compressible such that the illuminator (20) is easily inserted and secured within a space of a suitable size provided on the surface of the liquid container. The illuminator (20) can be used in combination with various liquid container such as drinking glass or liquid bottle to provide illumination to the liquid in the container.

Owner:PULZ

Preparation method of surface coating treating agent capable of improving strength of phosphate strengthened quartz fiber composite material and coating treatment method

The invention relates to a preparation method of a surface coating treating agent capable of improving the strength of a phosphate strengthened quartz fiber composite material and a coating treatment method, and relates to a preparation method of a surface coating treating agent for phosphate strengthened quartz fiber composite material and a coating treatment method. In order to solve the problems that the phosphate strengthened quartz fiber composite material prepared by using coating anticorrosive treatment in the existing method is bad in mechanical properties at normal temperature and high temperature, the treating agent is prepared by dissolving thermosetting phenolic resin in ethanol so as to obtain the surface coating treating agent. The preparation method comprises the following steps of: immerging quartz fiber in the surface coating treating agent for soaking; and airing after taking out so as to complete the coating treatment. The preparation method of the treating agent is simple, and the coating treatment method is simple; for the phosphate strengthened quartz fiber composite material prepared by taking the quartz fiber after being treated as a base material, the bending strength at the normal temperature reaches to 300MPa, and reaches to 124MPa at 500 DEG C; and the phosphate strengthened quartz fiber composite material can be applied to the high temperature resistance fields of aviation, aerospace, and the like.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

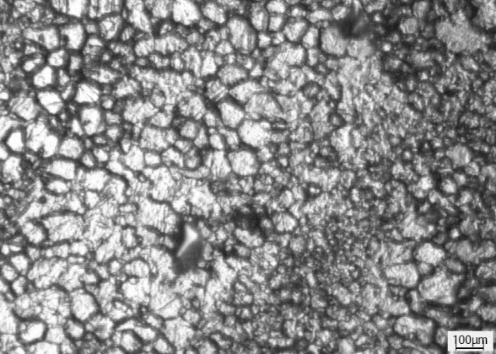

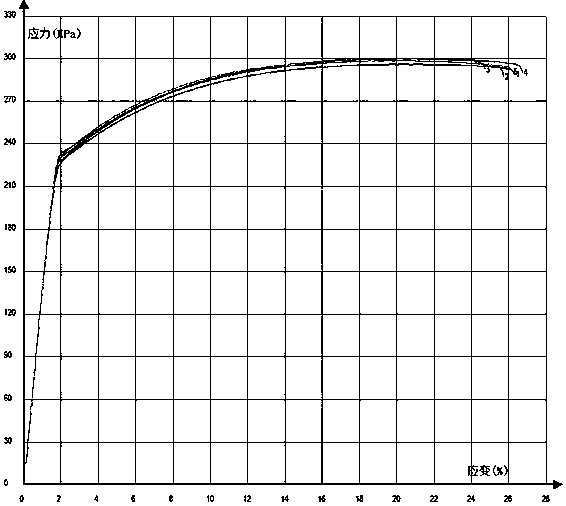

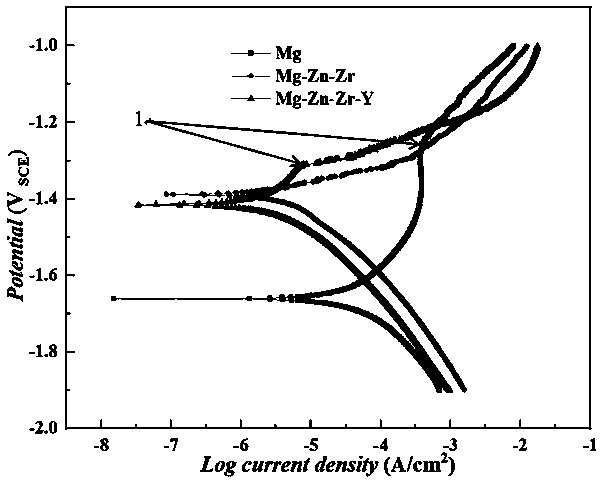

Degradable biomedical forging-state magnesium alloy and preparation method thereof

ActiveCN110144505AExtensive sources of raw materialsRaw material source is easy to getRepair materialImplant material

The invention provides a degradable biomedical forging-state magnesium alloy, and belongs to the field of degradable biomedical materials. The degradable biomedical forging-state magnesium alloy is prepared from the components in percentage by mass: 3.3 to 9 percent of Zn, 0.1 to 0.6 percent of Zr, 0.75 to 2 percent of Y, and the balance Mg, wherein the mass ratio of Zn / Y is larger than 4.38 and smaller than 6. The magnesium alloy not only has a favorable magnesium alloy and good corrosion resistance, but also has favorable biocompatibility, is suitable to be used as bone repair materials suchas a porous magnesium alloy material, a plastic surgery department material, an oral cavity oral cavity implant material and a bone lamella nail, and is particularly suitable to be used as a cardiovascular stent material and a bone repair material.

Owner:NANYANG NORMAL UNIV

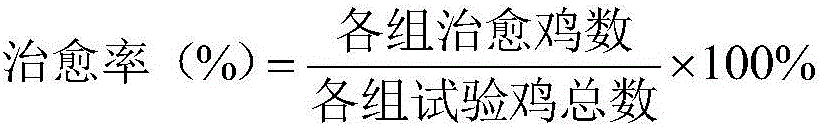

Amoxicillin superfine powder water-soluble preparation and preparation method thereof

InactiveCN106309374ALarge specific surface areaHigh dissolution rateAntibacterial agentsPowder deliverySalpingitisMedicine

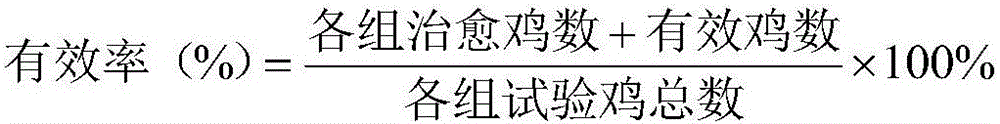

The invention discloses a formulation and a preparation method of an amoxicillin superfine powder water-soluble preparation and belongs to the technical field of veterinary medicine preparation. The amoxicillin superfine powder water-soluble preparation is soluble powder and comprises, by mass, 15-35% of amoxicillin, 15-35% of PVPK30, 15-35% of PEG6000, 5-20% of L-arginine and 1-5% of Tween-80. The amoxicillin superfine powder water-soluble preparation is non-degradable, specific surface area is increased, the preparation can be dispersed well and is easier to absorb, dissolution rate of amoxicillin is increased greatly, and the preparation is low in water content and impurity content. Acceleration experiments and long-time experiments show that the preparation has high stability. Pharmacological experiments find that the preparation has treatment effect on chicken salpingitis obviously better than common amoxicillin soluble powder, healing rate reaches 85.3%, and effective rate reaches 91.0%.

Owner:XIAN LUCKYROAD BIOLOGICAL TECH

Top control panel for aircraft cockpit and installation method thereof

The invention relates to a top control panel for an aircraft cockpit and an installation method thereof. The top control panel comprises a shell and a plurality of control panels, wherein the shell is provided with a guide rail positioned in the shell, and an installation angle sheet, a connector interface and a ventilation opening which are positioned on the shell; the plurality of control panels are arranged on the guide rail in the shell in a quick connection mode; and the plurality of control panels are arranged in the shell, so that the top control panel has an integrated structure. The invention also relates to a method for installing the top control panel for the aircraft cockpit.

Owner:COMAC +1

Aircraft cockpit top control panel and installation method thereof

The invention relates to a top control panel for an aircraft cockpit and an installation method thereof. The top control panel comprises a shell and a plurality of control panels, wherein the shell is provided with a guide rail positioned in the shell, and an installation angle sheet, a connector interface and a ventilation opening which are positioned on the shell; the plurality of control panels are arranged on the guide rail in the shell in a quick connection mode; and the plurality of control panels are arranged in the shell, so that the top control panel has an integrated structure. The invention also relates to a method for installing the top control panel for the aircraft cockpit.

Owner:COMAC +1

Laser range finding level ruler with positioning and voice reading functions

InactiveCN106443689AHigh precisionEasy to findSatellite radio beaconingElectromagnetic wave reradiationPhysicsLoudspeaker

The invention discloses a laser range finding level ruler with positioning and voice reading functions, and relates to the technical field of laser range finding. The level ruler comprises a ruler body, the top and bottom of the left side of the ruler body are provided with a laser receiver and a laser emitter respectively, the top center position of the surface of the ruler body is provided with a display, the left and right sides of the top of the ruler body are provided with a loudspeaker and a handle respectively, and the output end of the laser receiver is electrically connected with the input end of the a reception control circuit. The display is an LCD with backlight, the surface of the display is provided with a PVC protective film, the LCD with backlight can display patterns, use at night is enabled, the PVC protective film prevents a screen from being scratched, the service life of the display is prolonged, and the ruler is simple in the optical system and mechanical structure, high in precision, low in errors, low in cost, and stable and reliable.

Owner:ZHEJIANG MGS LEVEL IND CO LTD

Combined Pile Type and Construction Method of Static Drilling, Extrusion Expansion Disc and Pipe Pile

The invention discloses a combined pile type of a static drilling extruded expanded branch plate and a pipe pile, including a pipe pile, a branch pile sleeved on the outer wall of the pipe pile, and an enlarged pile connected to the end of the branch pile; The pipe pile is a hollow pipe, and the pipe is filled with cement soil to form a solid pipe pile; the support plate pile includes a support plate pile body and support plates distributed at equal intervals along the axial direction of the support plate pile body, and the support plate piles are The cement-soil pile body and the enlarged pile are expanded concrete pile bodies. The combined pile type of the static drilling squeeze expansion support plate and the pipe pile squeezes part of the soil to the hole wall, improves the pile side friction resistance, reduces the discharge of the original soil, and at the same time excavates the excess soil to form a large-diameter The pile foundation is improved, and the bearing capacity of the pile foundation is improved; secondly, a plurality of support plates are set to apply pre-pressure to the side wall, expand the contact area between the combined pile and the soil, increase the effective area of the pile body, and improve the bearing capacity of the combined pile ; Then press the expansive concrete through the pile end reaming to form a preload on the pile end, further improving the bearing capacity of the pile end.

Owner:SOUTHEAST UNIV

Lightweight high-strength pavement equipment

Owner:中国人民解放军南京军区司令部工程科研设计所 +2

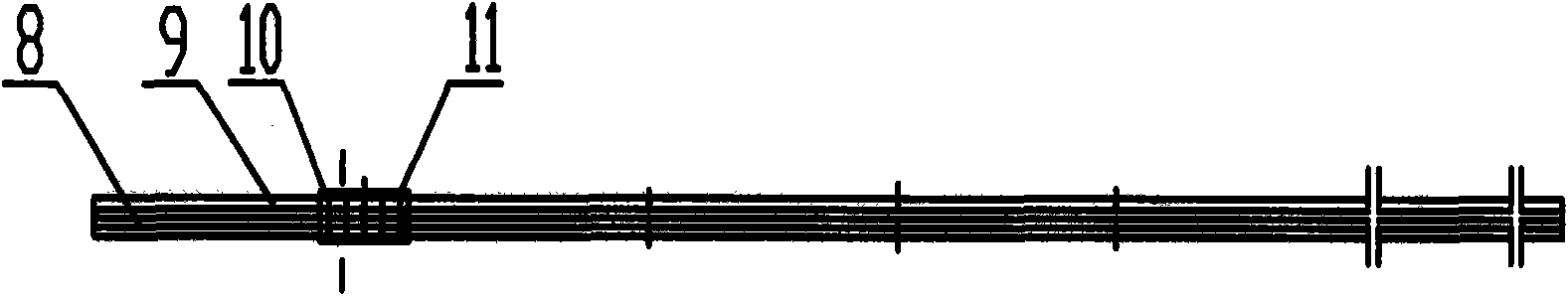

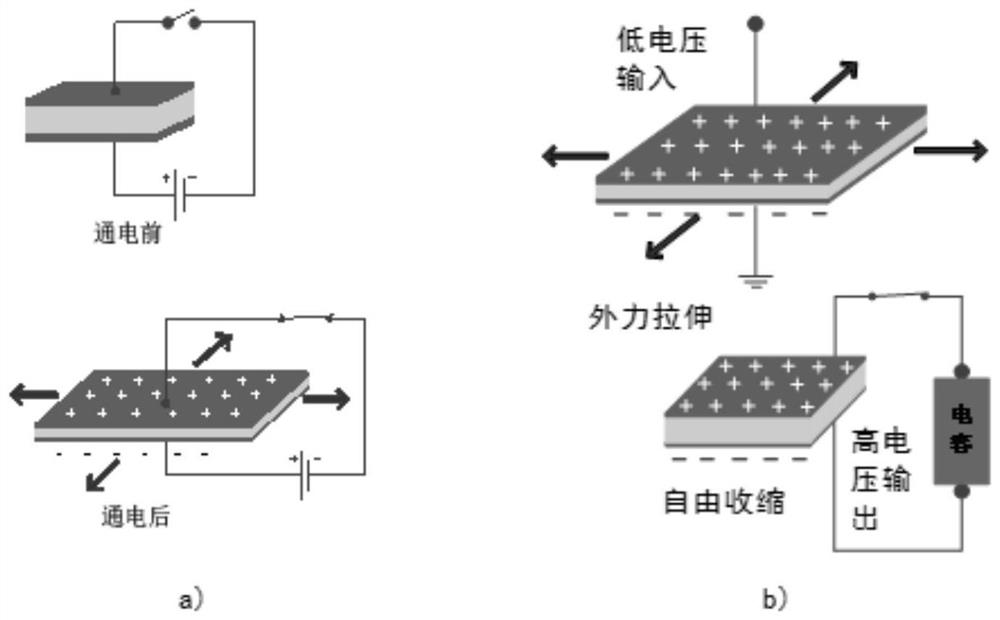

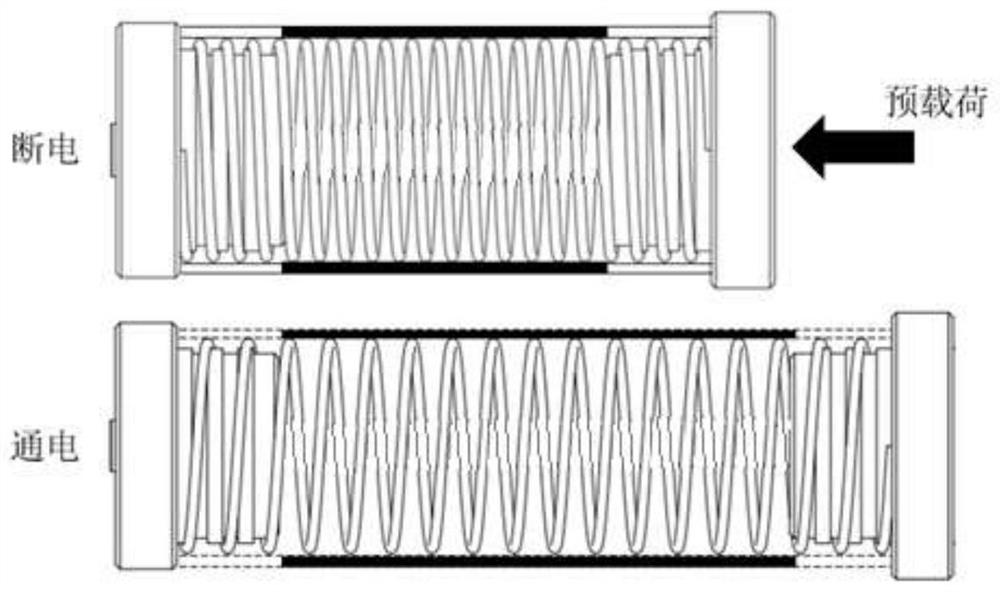

Joint unit, finger device and gripper

ActiveCN112571440BTroubleshoot technical issues with small workspacesIncrease exerciseJointsGripping headsDrive by wireControl engineering

The application discloses a joint unit, a finger device and a gripper. The cylindrical EAP driver and the SMA driver are combined through a connecting piece, and the linear drive of the cylindrical EAP driver is used to realize the freedom of movement of the joint unit, and the SMA driver is used to realize the joint The degree of freedom of rotation of the unit solves the technical problem that the working space of the mechanical fingers driven by EAP and SMA is small in the prior art, and at the same time, because the application connects the cylindrical EAP driver and the SMA driver in the form of end-to-end series , when the joint unit is used to execute the position, movement and mechanical inverse calculation of the end, the operation is simple, which is beneficial to provide a reaction speed.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

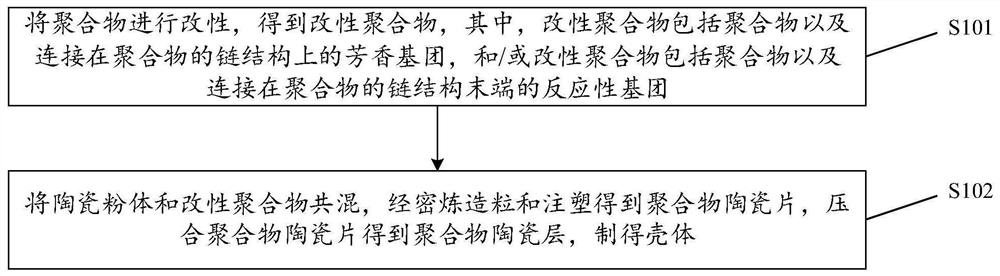

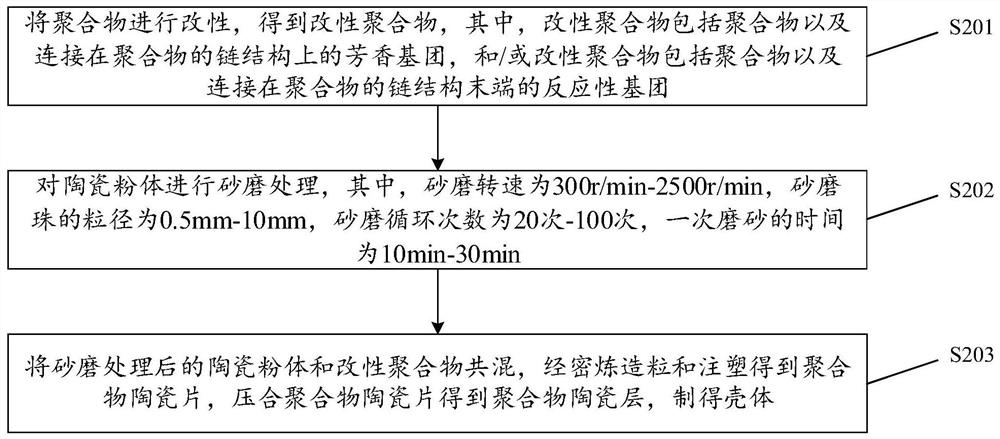

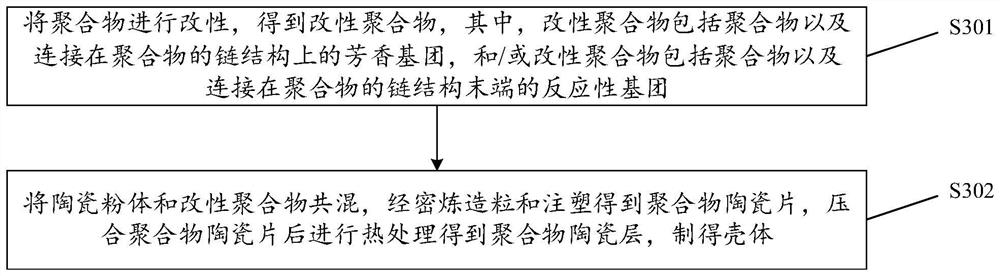

Shell, preparation method thereof and electronic equipment

ActiveCN113478855AEasy to prepareImprove mechanical propertiesCasings/cabinets/drawers detailsDomestic articlesPolymer scienceChain structure

The invention provides a shell preparation method. The shell preparation method comprises the following steps that a polymer is modified to obtain a modified polymer, the modified polymer comprises the polymer and an aromatic group connected to a chain structure of the polymer, and / or the modified polymer comprises the polymer and a reactive group connected to the tail end of a chain structure of the polymer; ceramic powder and the modified polymer are blended, a polymer ceramic sheet is obtained through banburying granulation and injection molding, the polymer ceramic sheet is pressed to obtain a polymer ceramic layer, and a shell is obtained. The preparation method is simple and easy to operate, the shell with excellent performance can be prepared, and the application of the shell is facilitated. The invention further provides another shell preparation method, the shell and electronic equipment.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com