Shell, preparation method thereof and electronic equipment

A shell and prepolymer technology, applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, and other household appliances, can solve the problem of satisfying consumers' high pursuit of product appearance and texture, hardness, gloss, and texture There is a large gap, the preparation method needs to be improved, etc., to achieve the effect of excellent mechanical properties, simple preparation method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

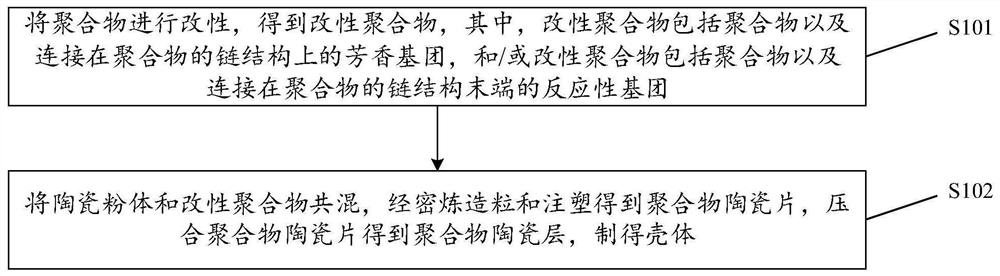

[0023] see figure 1 , is a flow chart of the preparation method of the housing provided in an embodiment of the present application, including:

[0024] S101: Modify the polymer to obtain a modified polymer, wherein the modified polymer includes a polymer and an aromatic group connected to the chain structure of the polymer, and / or the modified polymer includes a polymer and an aromatic group connected to A reactive group at the end of a polymer chain structure.

[0025] S102: blending the ceramic powder and the modified polymer, performing banbury granulation and injection molding to obtain a polymer ceramic sheet, and pressing the polymer ceramic sheet to obtain a polymer ceramic layer to obtain a casing.

[0026] In the present application, the modified polymer is used to improve the mechanical properties of the shell 100 and prolong the service life of the shell 100, which is beneficial to the application of the shell 100; the preparation method of the shell 100 is simple...

Embodiment 1

[0084] In the preparation process of the shell, zirconia and modified polyphenylene sulfide (PPS) are blended, and the shell is obtained after banburying, granulation, injection molding and pressing. Among them, the mass proportion of zirconia in the shell is 75%, and the mass proportion of modified PPS is 25%. The modified PPS is a PPS with naphthalene groups grafted on the side chain. The structural formula is as follows:

[0085]

Embodiment 2

[0087] Roughly the same as Example 1, the difference is that the modified PPS is a PPS grafted with amino end groups at the end of the main chain, and the structural formula is as follows:

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com