Static drill squeezed branch and pipe pile combined pile type and construction method thereof

A technology of squeezing and expanding the support disk and support disk pile, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problem of high requirements for hole cleaning and concrete pouring, inability to make full use of the original soil, and inconvenient mud treatment. and other problems, to achieve the effect of fast construction, saving steel and concrete, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

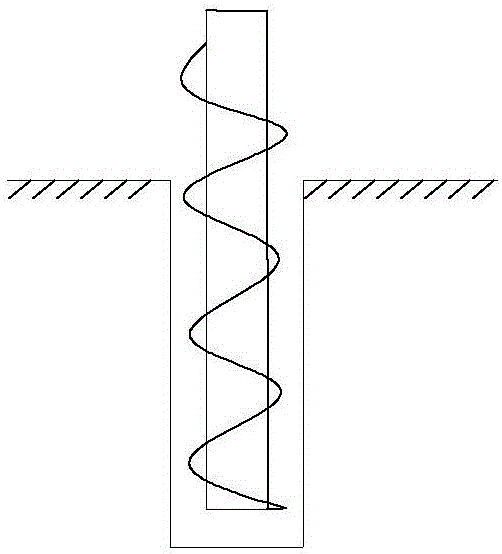

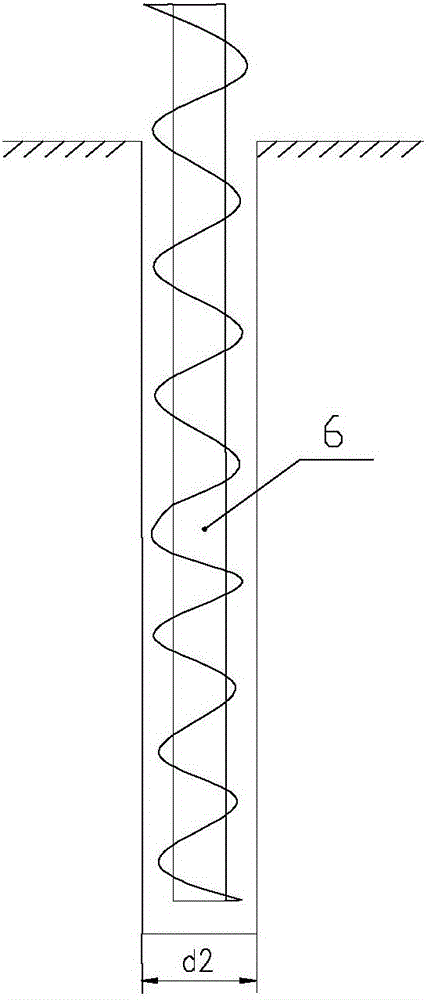

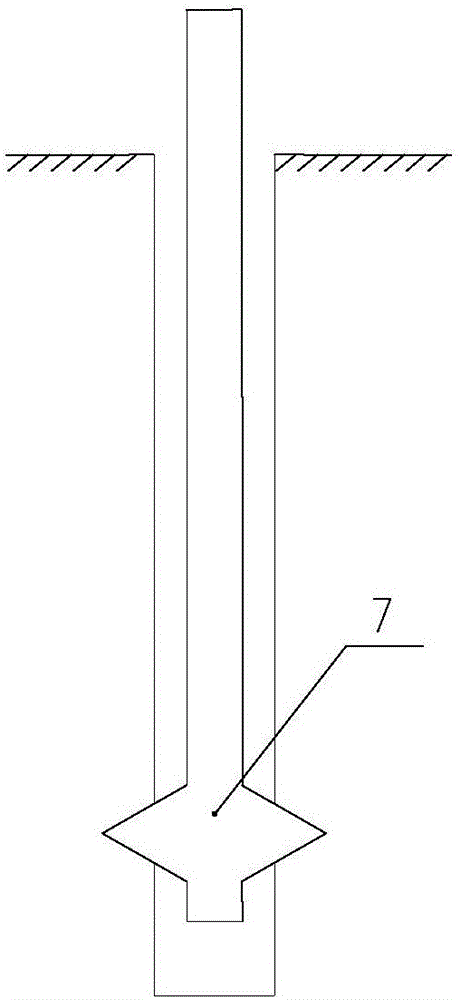

[0030] Such as Figure 7 As shown, a combined pile type of a static drilling, extrusion expansion support plate and pipe pile of the present invention includes a pipe pile 1, a support plate pile 2 and an expansion pile 3. Among them, the support plate pile 2 is sleeved on the outer wall of the pipe pile 1, and the end of the support plate pile 2 is connected with an enlarged pile 3; wherein the pipe pile 1 is a hollow pipe, and the outer diameter d1 of the prefabricated pipe pile 1 is slightly smaller than the diameter d2 of the pile hole. Pile 1 inner diameter can be put into pile bottom reaming equipment.

[0031] The pipe is filled with cement and soil to form a solid pipe pile; the support disc pile 2 includes a support disc pile body 4 and support discs 5 distributed at equal intervals along the axial direction of the support disc pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com