Patents

Literature

48results about How to "Improve pile side friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

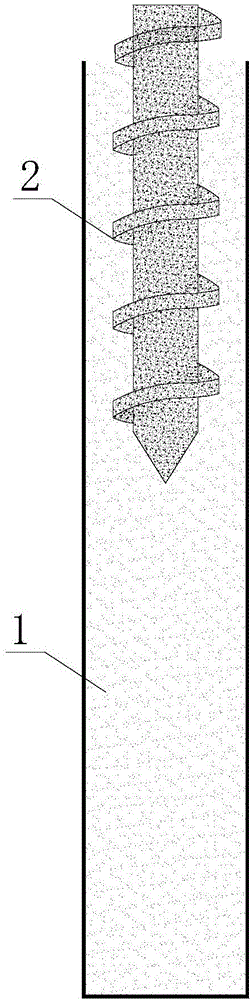

Cast-in-situ bored pile with wall protected through microorganism soil solidification and construction method

ActiveCN105386432AAvoid collapsing holesImprove pile side frictionBulkheads/pilesSoil preservationDrill holeBiology

The invention relates to a cast-in-situ bored pile with the wall protected through microorganism soil solidification and a construction method. The construction method includes the steps that a, a hole is drilled through a drilling rig, and meanwhile microorganism bacterium liquid is injected into the drilled hole and diffused into a foundation around the drilled hole; b, a separation plate is placed into the drilled hole; c, a cementing solution is injected into the drilled hole and diffused into the foundation around the drilled hole and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and soil around the drilled hole is solidified; d, after the separation plate sinks to the bottom of the hole, the separation plate is lifted out; and e, the step a, the step b, the step c and the step d are repeated until hole forming is completed. Mud is not used for protecting the wall in the construction process of the cast-in-situ bored pile with the wall protected through microorganism soil solidification, so that mud cakes and pollution are avoided, and pile side friction resistance is brought into full play; in addition, a microorganism solidified soil layer and a microorganism wall protecting cementing surface are formed by the reinforced soil around the pile and can not only prevent hole collapse but also bear loads in combination with the pile, and therefore the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

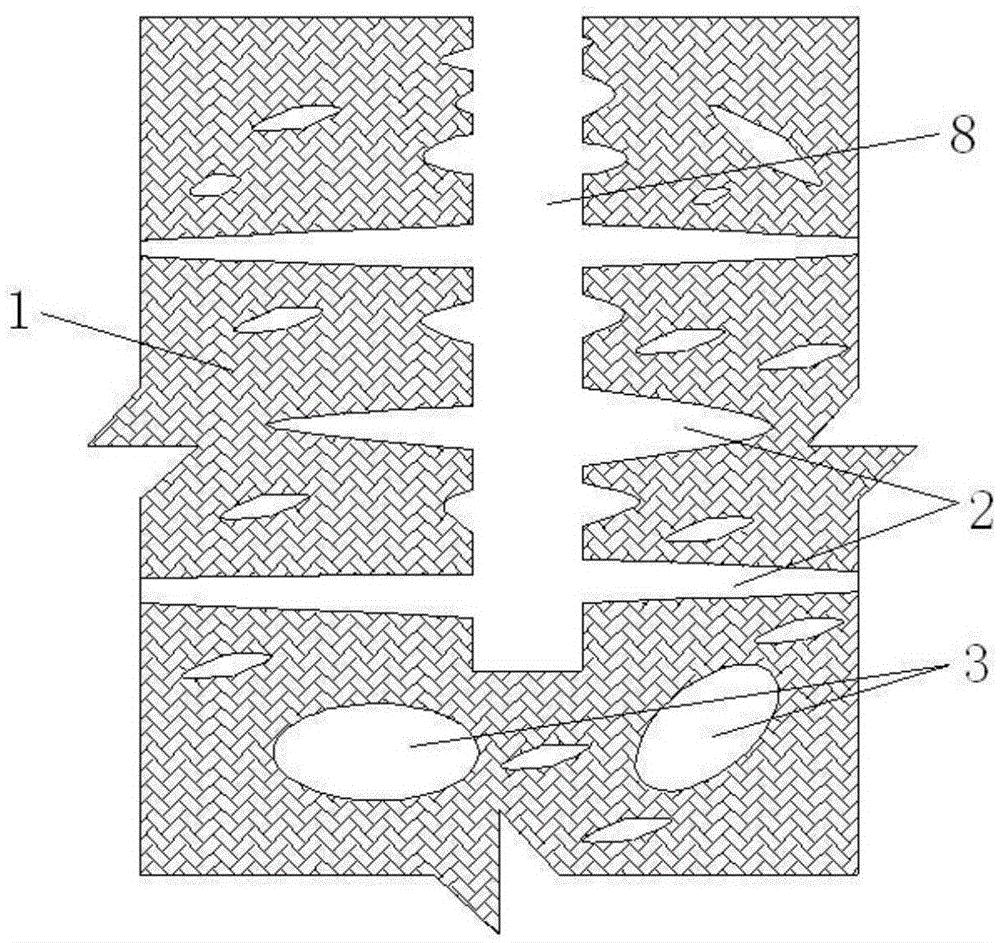

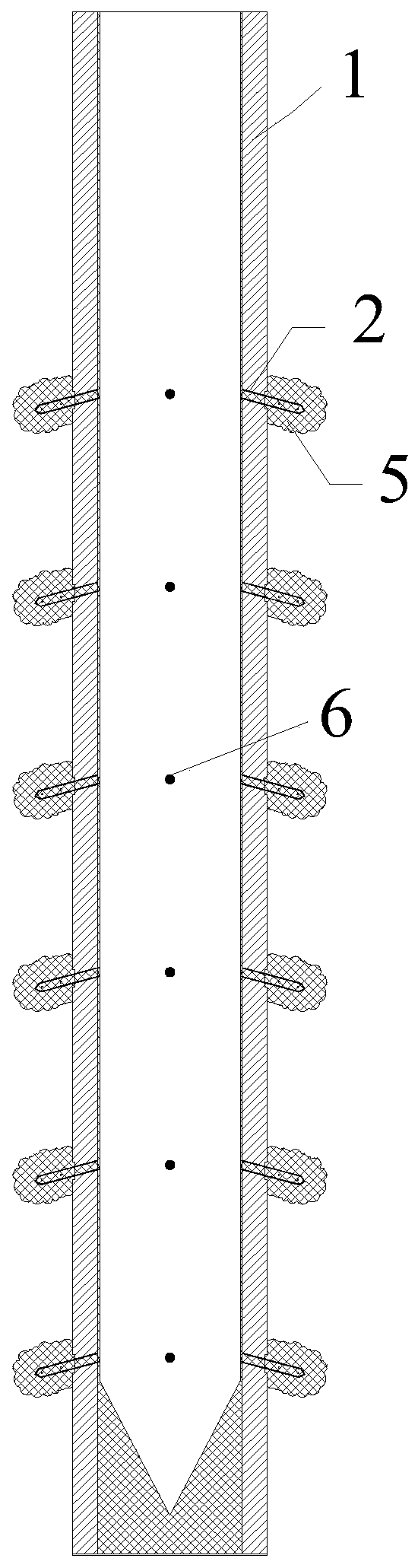

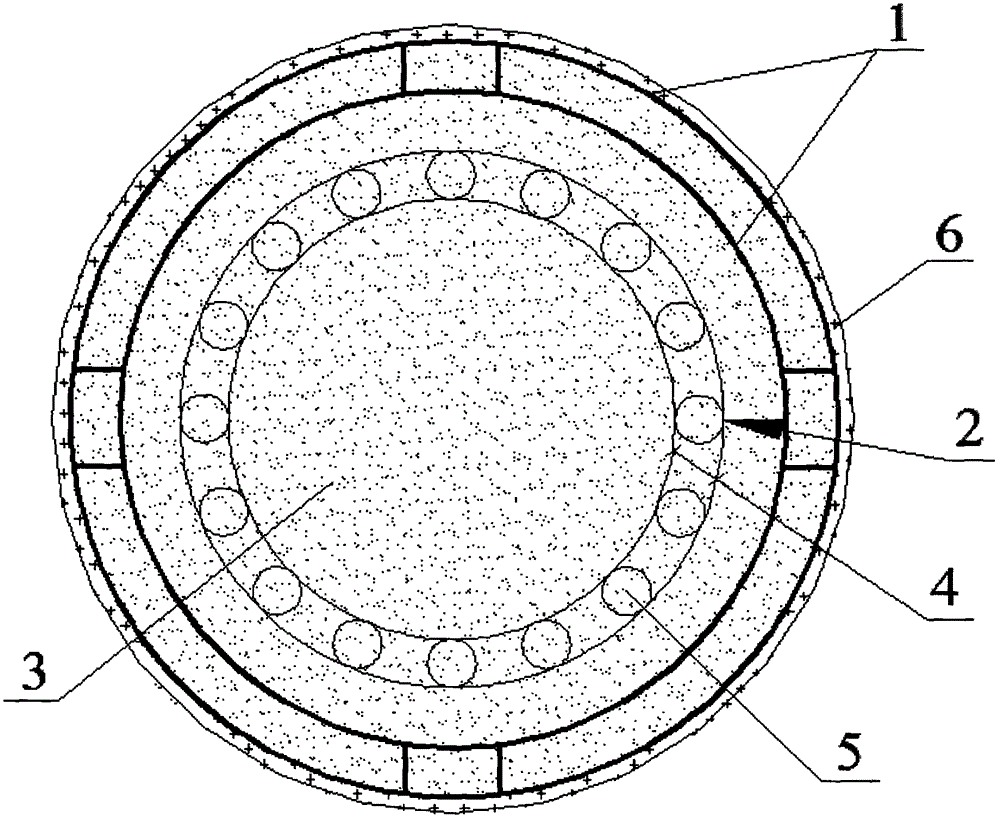

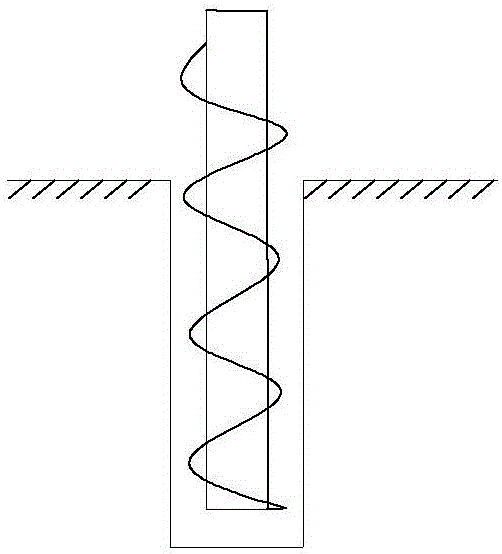

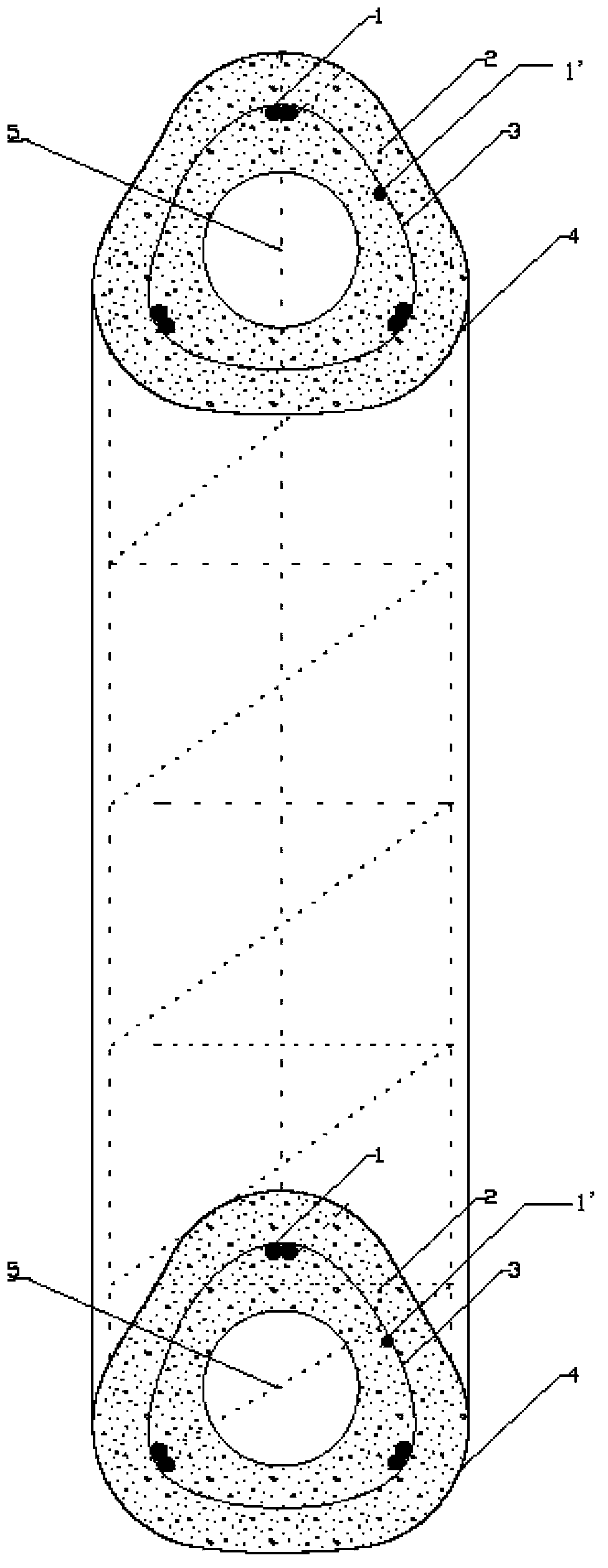

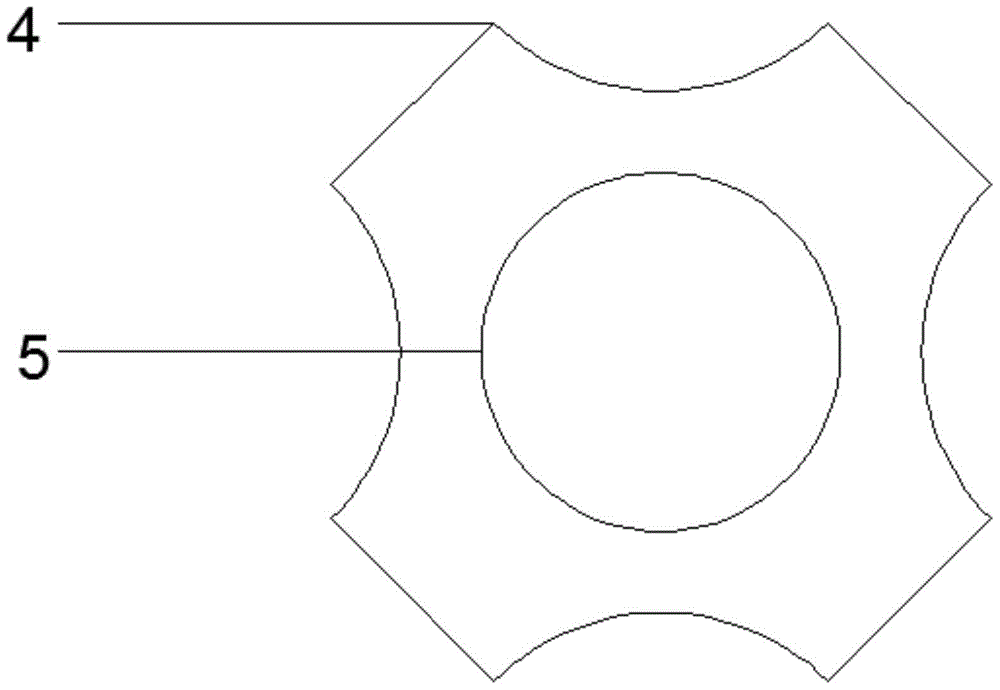

Bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and construction method

ActiveCN103485334BIncrease girthImprove mechanical performanceBulkheads/pilesReinforced concreteEngineering

The invention relates to a bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and a construction method. The pile is characterized by structurally comprising the inverted-arch cambered hollow special-shaped pile, a pile toe arranged at the bottom end of the special-shaped pile and fixed through fixing parts, and a precast reinforced concrete pile tip; a cemented soil layer is arranged on the outer side of a pile body; a cross section of the special-shaped pile is Y-shaped or X-shaped, and bushings with threads are arranged in a round hole in the center of the pile body and on the outer side of the pile body; a reinforcement cage, which is in the same shape as the pile body but slightly smaller than the pile body, is arranged in the pile body; horizontal and longitudinal tensile reinforcements are arranged in the reinforcement cage; and the fixing parts corresponding to the bushings and an immersed tube are arranged on the top face of the precast reinforced concrete pile tip. During construction, the pile toe and the inner bushing are fixed firstly, then the reinforcement cage and the outer bushing are sleeved, and concrete is poured between the inner bushing and the outer bushing as well as between the outer bushing and the immersed tube to respectively form a concrete pile core and a pile-side cemented soil layer. Area of the cross section of the pile body is small, consumption of building materials is reduced, bearing capacity is high, and the pile body is high in capability of resisting to environmental erosion.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

PHC pipe pile construction method

ActiveCN111691420AReduce the difficulty of penetratingImprove pile side frictionBulkheads/pilesArchitectural engineeringRebar

The invention relates to a PHC pipe pile construction method. The PHC pipe pile construction method comprises the following steps including the first step of construction preparation, the second stepof measuring, paying-off and pile distribution, the third step of long spiral drilling machine arrival, the fourth step of long spiral drilling machine hole drilling and guiding, the fifth step of drill rod elevating and soil cleaning, the sixth step of pile pressing, the seventh step of steel bar cage installing and the eighth step of grouting. By means of the PHC pipe pile construction method, the pipe pile injection difficulty can be lowered, meanwhile, the pipe pile bearing capability is improved, and the pipe pile injection difficulty and the pipe pile bearing capability are combined.

Owner:福建省华策建设集团有限公司

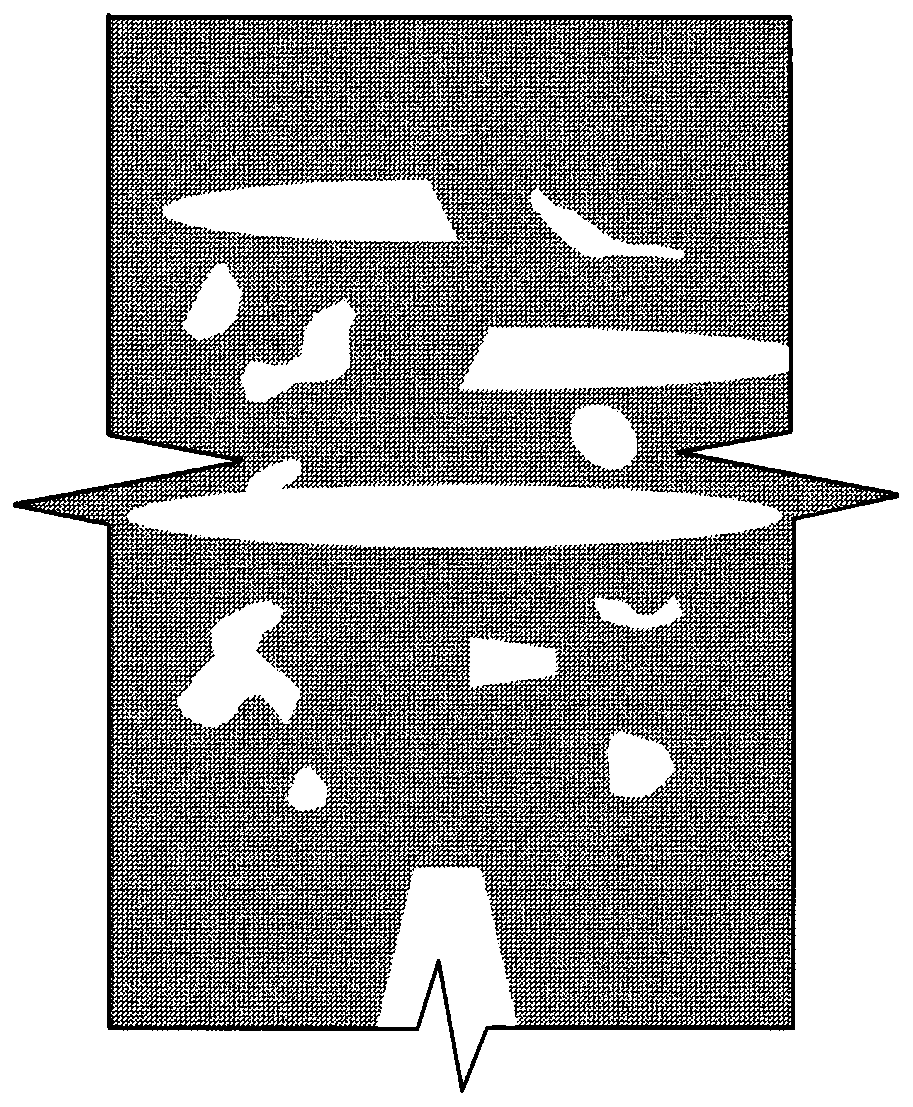

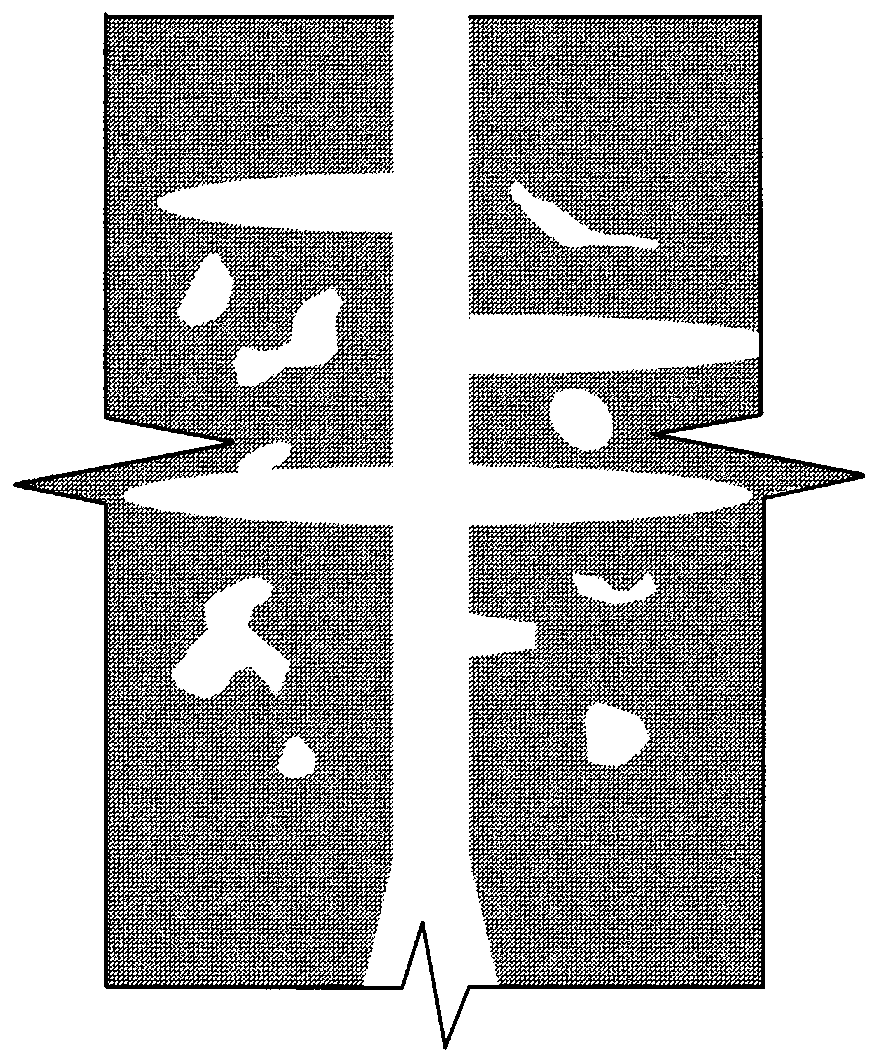

Bored cast-in-place pile suitable for karst areas with connectivity channels and pile forming method thereof

The invention relates to a bored cast-in-place pile suitable for karst areas with connectivity channels and a pile forming method thereof. The bored cast-in-place pile comprises a pile body and a wrapping piece, wherein the pile body at least comprises a concrete pile body and a reinforcing cage, the wrapping piece is a composite geotextile with a closed bottom and an open top, the wrapping piececoats the reinforcing cage before the pile body is formed into the pile, the wrapping piece is arranged around and lightly buckled on the reinforcing cage through an annular iron wire, concrete groutis injected into the reinforcing cage under high pressure, the high-pressure concrete grout pushes part of the wrapping piece to bulge towards the connectivity channels to form a dendritic structure in a branch-like form, and the pile is formed after the grout is solidified and hardened; and the diameter of the wrapping piece is larger than the diameter of the reinforcing cage, and the length of the wrapping piece is larger than the length of the reinforcing cage. The bored cast-in-place pile is provided with the wrapping piece to wrap grout, so that the phenomena of grout leakage, diameter shrinkage and the like in the process of manufacturing the bored cast-in-place pile in the karst areas are avoided, the pile forming quality is effectively guaranteed, the integrity of the pile and karst with the connectivity channels is improved, and the bearing capacity of the pile is greatly improved.

Owner:GUANGXI UNIV

Cast-in-place pile applicable to karst region having communicating channels

The invention discloses a cast-in-place pile applicable to a karst region having communicating channels. The cast-in-place is applicable to the karst region having the communicating channels, and comprises a pile body that is arranged in the karst region having the communicating channels, and a covering part that covers a steel reinforcement cage of the pile body before pile forming; a diameter of the covering part is greater than a diameter of the steel reinforcement cage of the pile body before pile forming, and a length of the covering part is greater than a height of the steel reinforcement cage of the pile body before pile forming; in a use state, the covering part extends into the communicating channels in the karst region, and the covering part extending into the communicating channels is filled with concrete slurry. The cast-in-place pile of the present invention is capable of better combining with integral rock in the communicating karst region for bearing together, and also capable of remarkably increasing the pile side frictional resistance of a pile foundation, thereby improving the integral bearing capability of the foundation.

Owner:GUANGXI UNIV

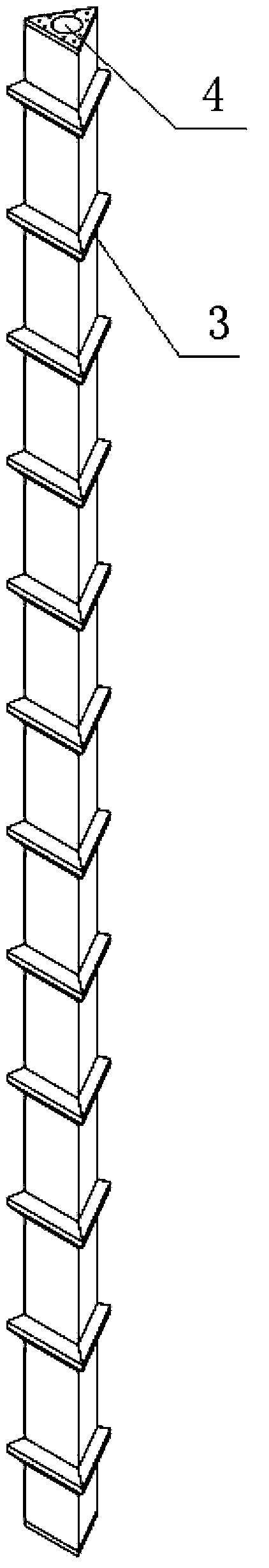

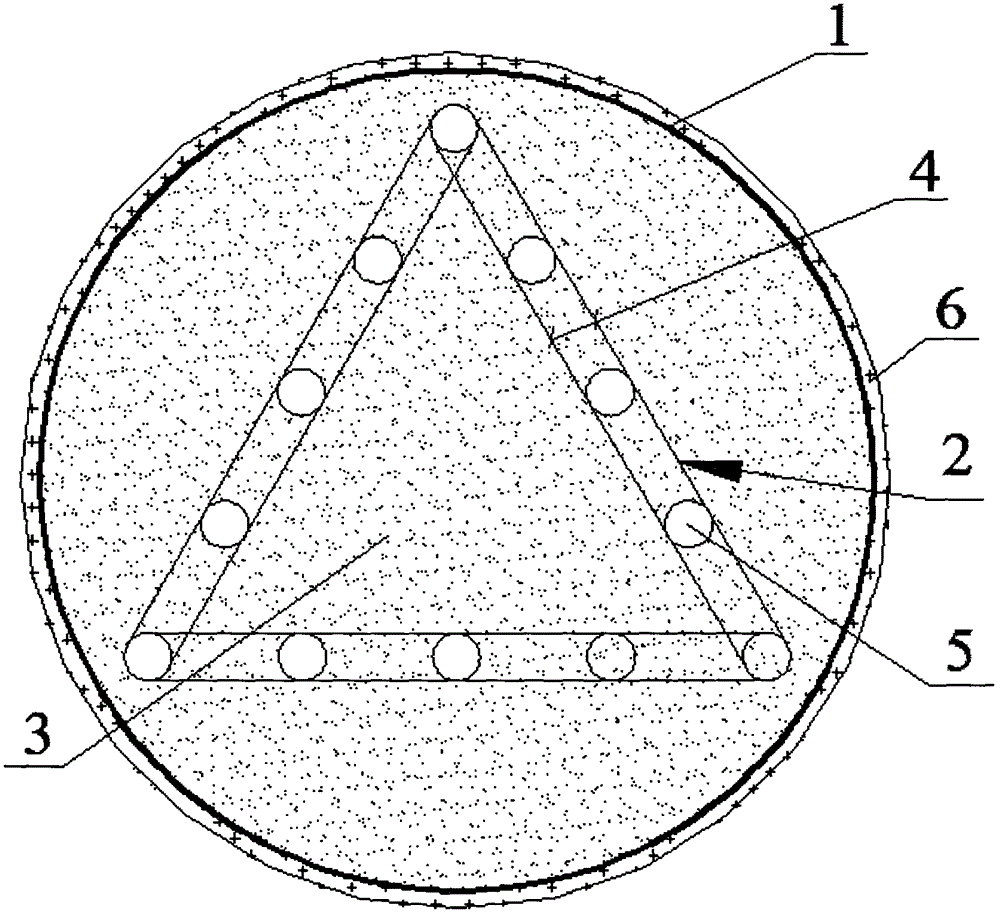

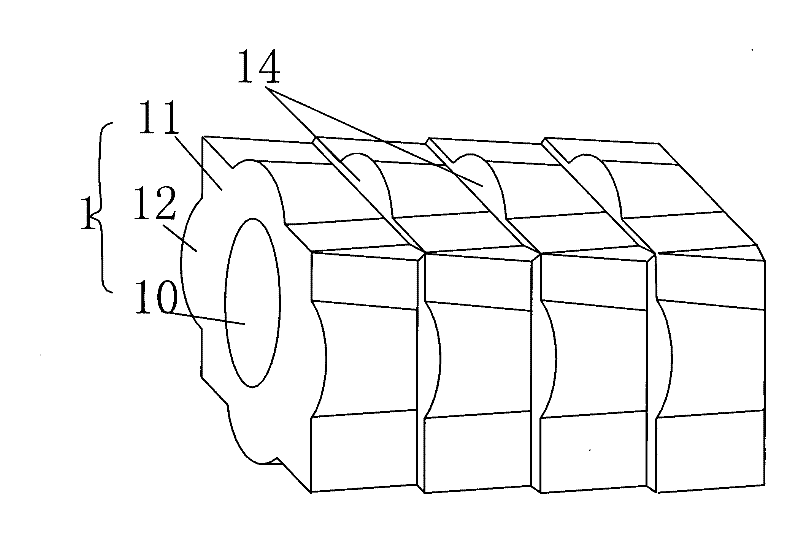

Partial prestressed concrete bamboo joint pile

InactiveCN103572752AHigh specific surface areaImprove pile side frictionBulkheads/pilesPre stressProtection layer

The invention relates to a partial prestressed concrete bamboo joint pile; a central through hole penetrating through the whole partial prestressed concrete bamboo joint pile is formed in the longitudinal axis direction; the cross section of the inner periphery of the partial prestressed concrete bamboo joint pile is round; the cross section of the outer periphery of the partial prestressed concrete bamboo joint pile is round-angle triangular, round-angle quadrangular and round-angle hexagonal; the partial prestressed concrete bamboo joint pile comprises main ribs extending along the length direction of the bamboo joint pile and hoop ribs spirally surrounding the main ribs; the main ribs comprise prestressed ribs and non-prestressed ribs; concrete protection layers are arranged inside and outside the hoop ribs; the outsides of the main ribs are connected by the hoop ribs through fixing, roll-welding or binding; the prestressed ribs and the non-prestressed ribs are all positioned at the angles and the edges of triangles, quadrangles and hexagons defined by the hoop ribs; the partial prestressed concrete bamboo joint pile is provided with horizontal bosses; reinforcing ribs are arranged in the horizontal bosses. The triangles, quadrangles and hexagons, defined by the hoop ribs, at the outer peripheries of the prestressed ribs and the non-prestressed ribs are connected by binding or welding.

Owner:SHANGHAI ZHONGJI PILE IND

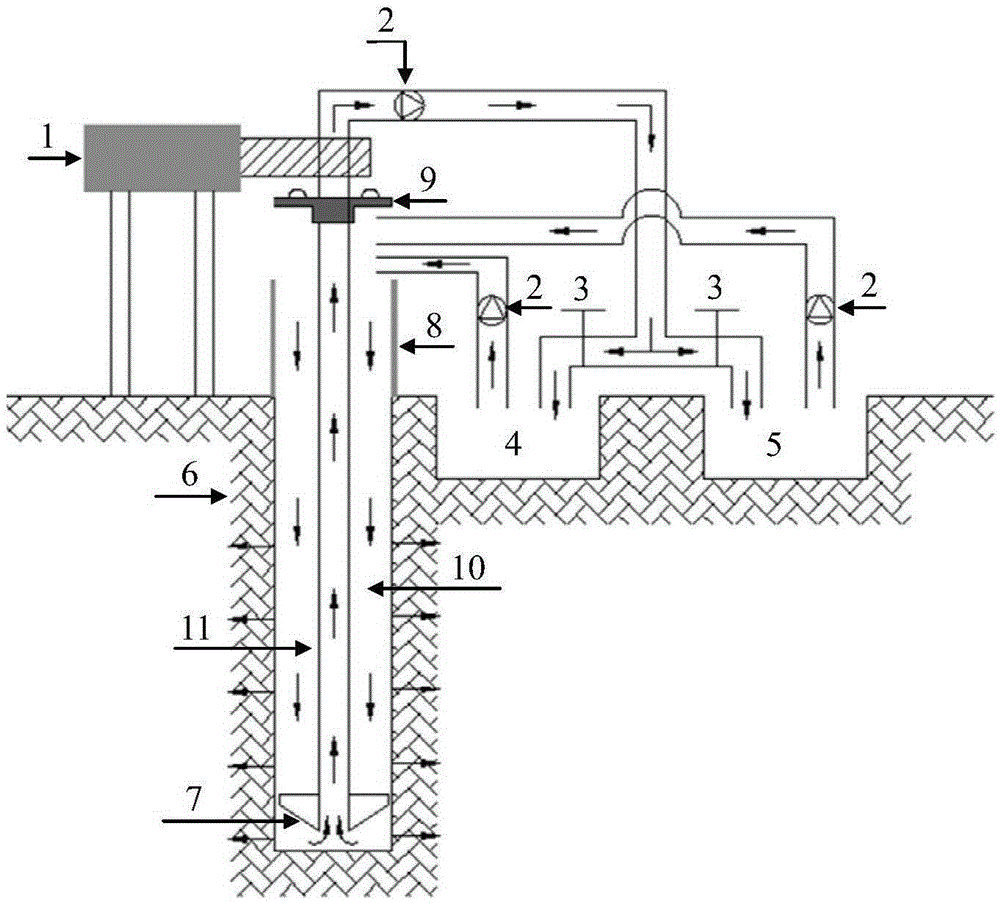

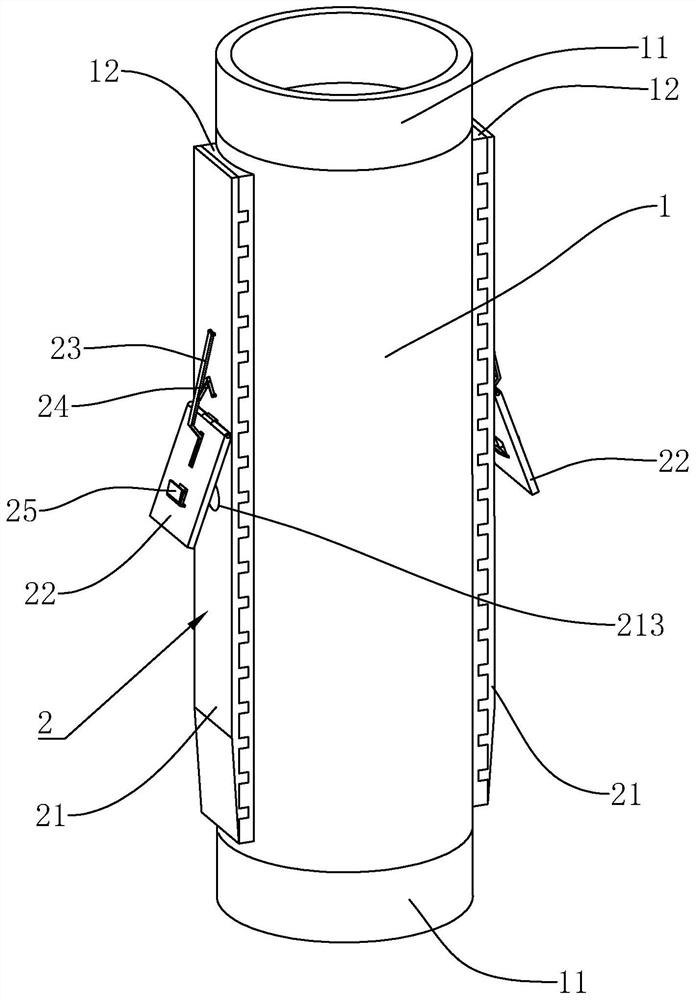

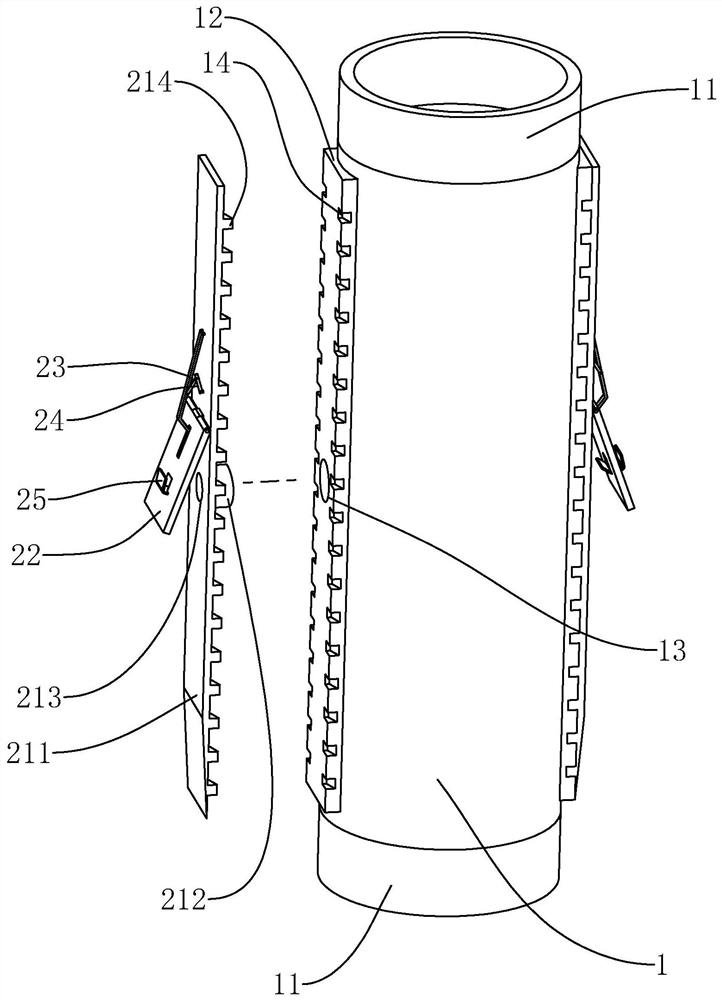

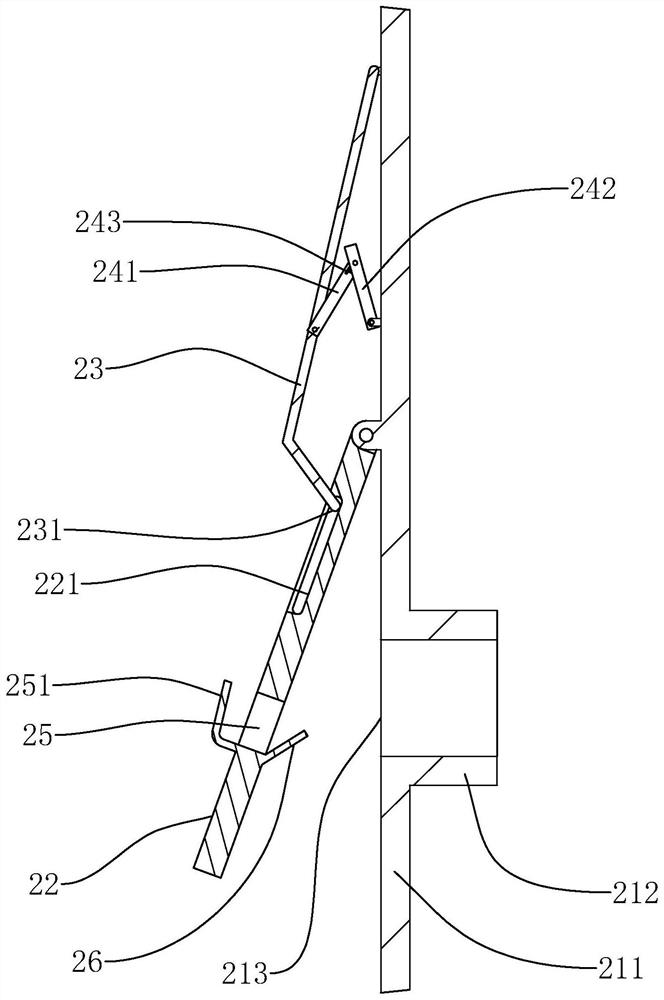

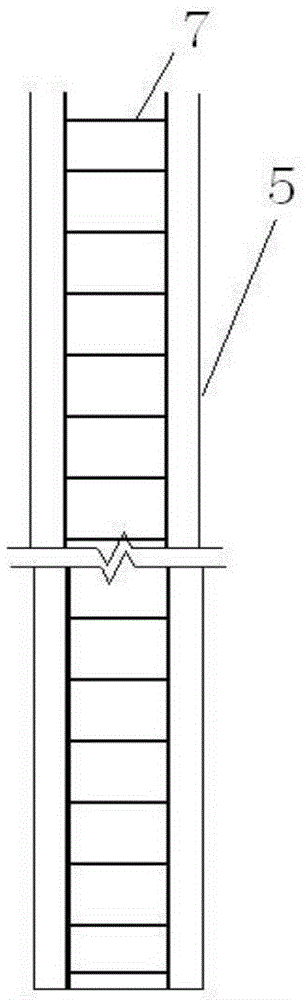

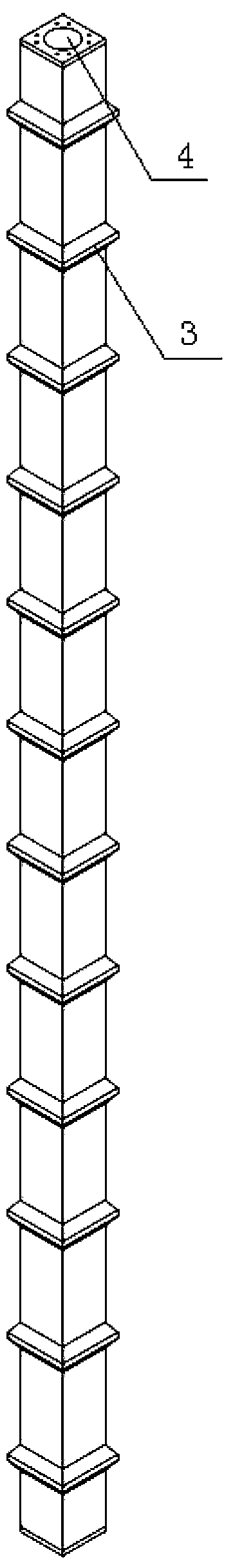

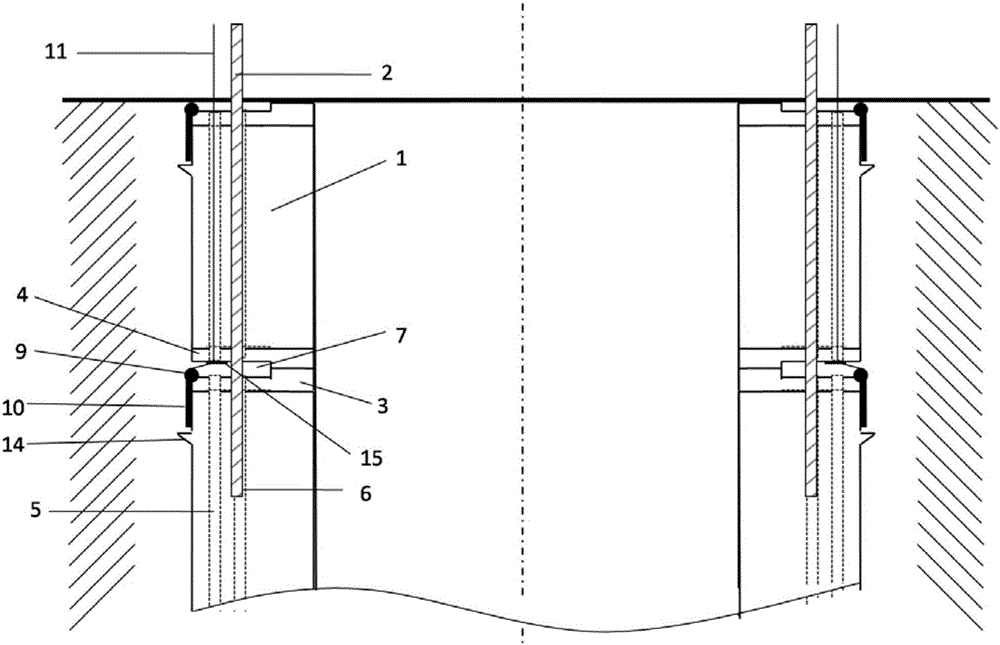

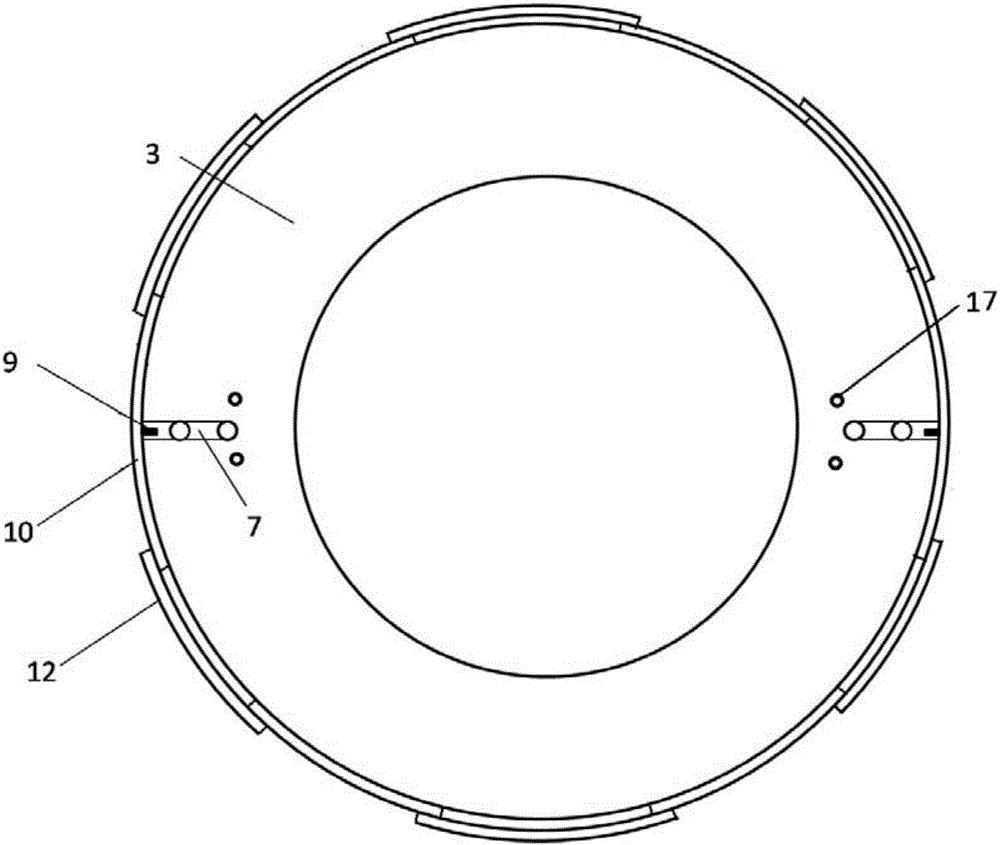

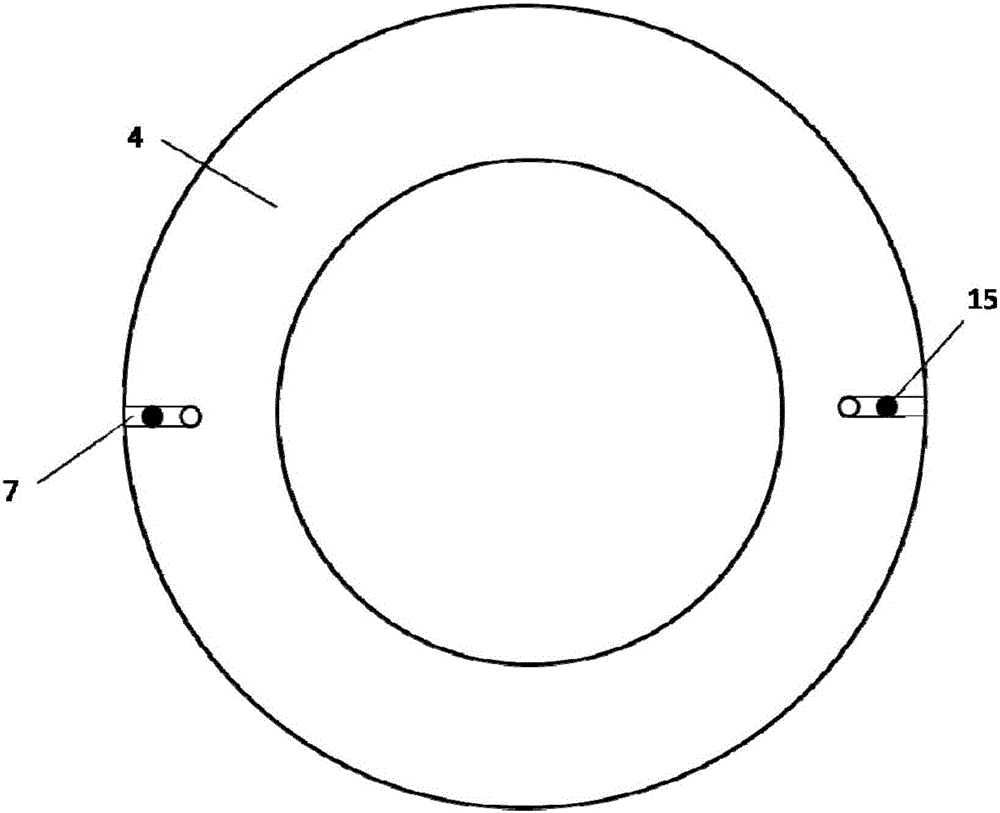

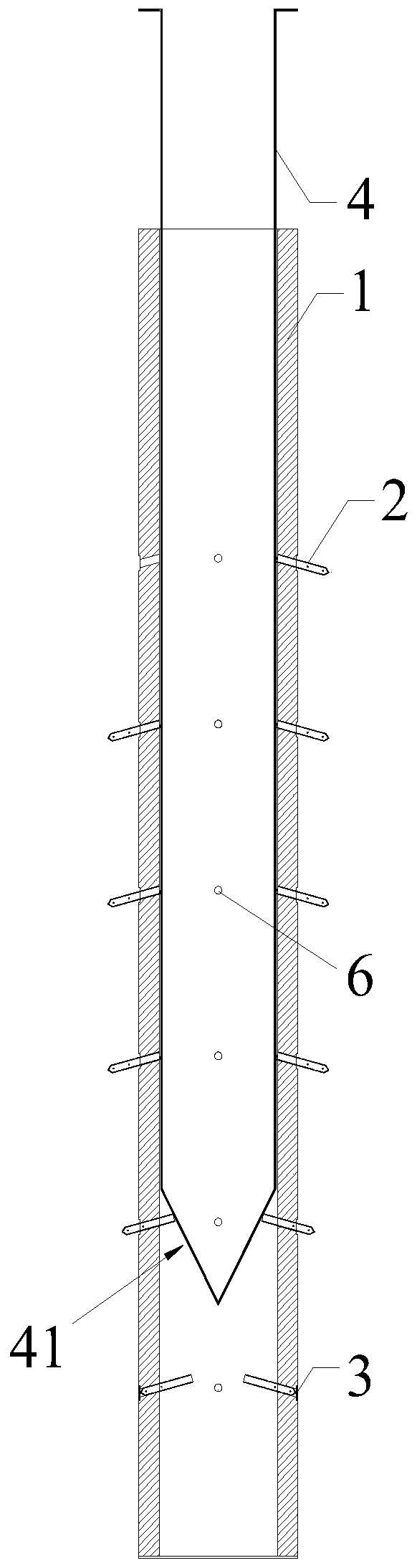

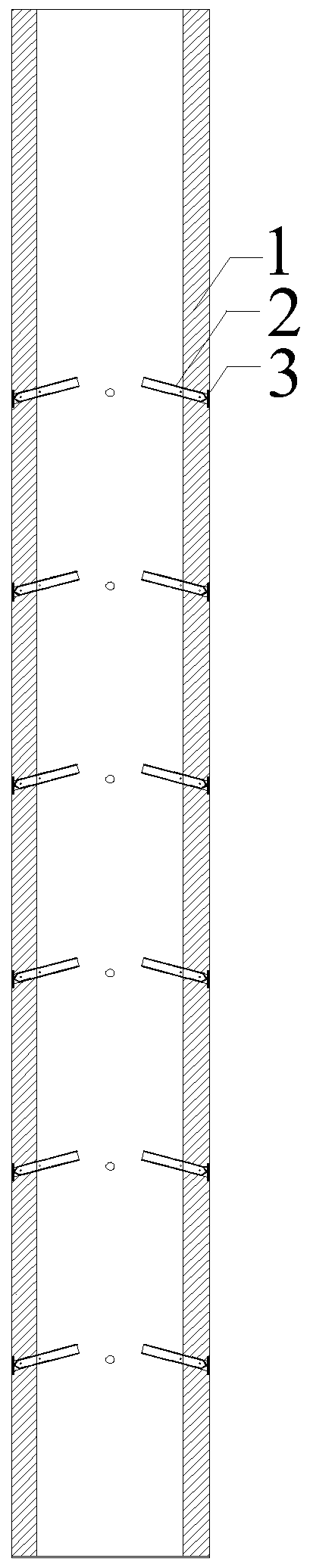

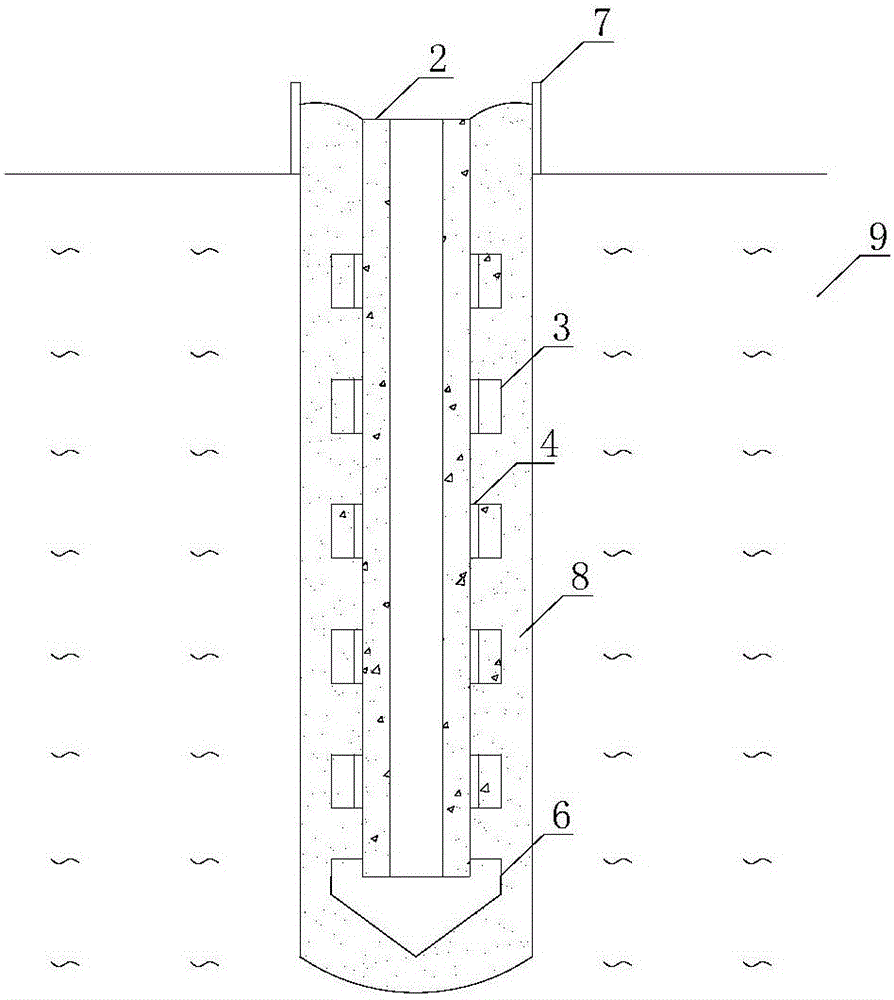

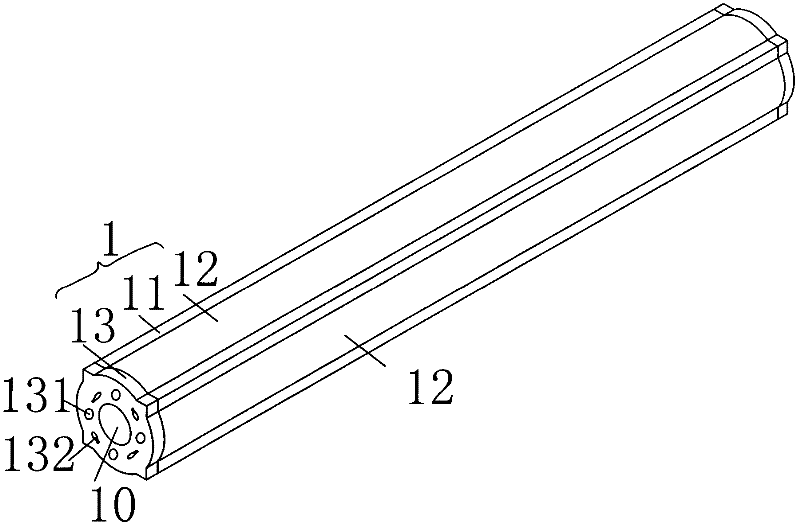

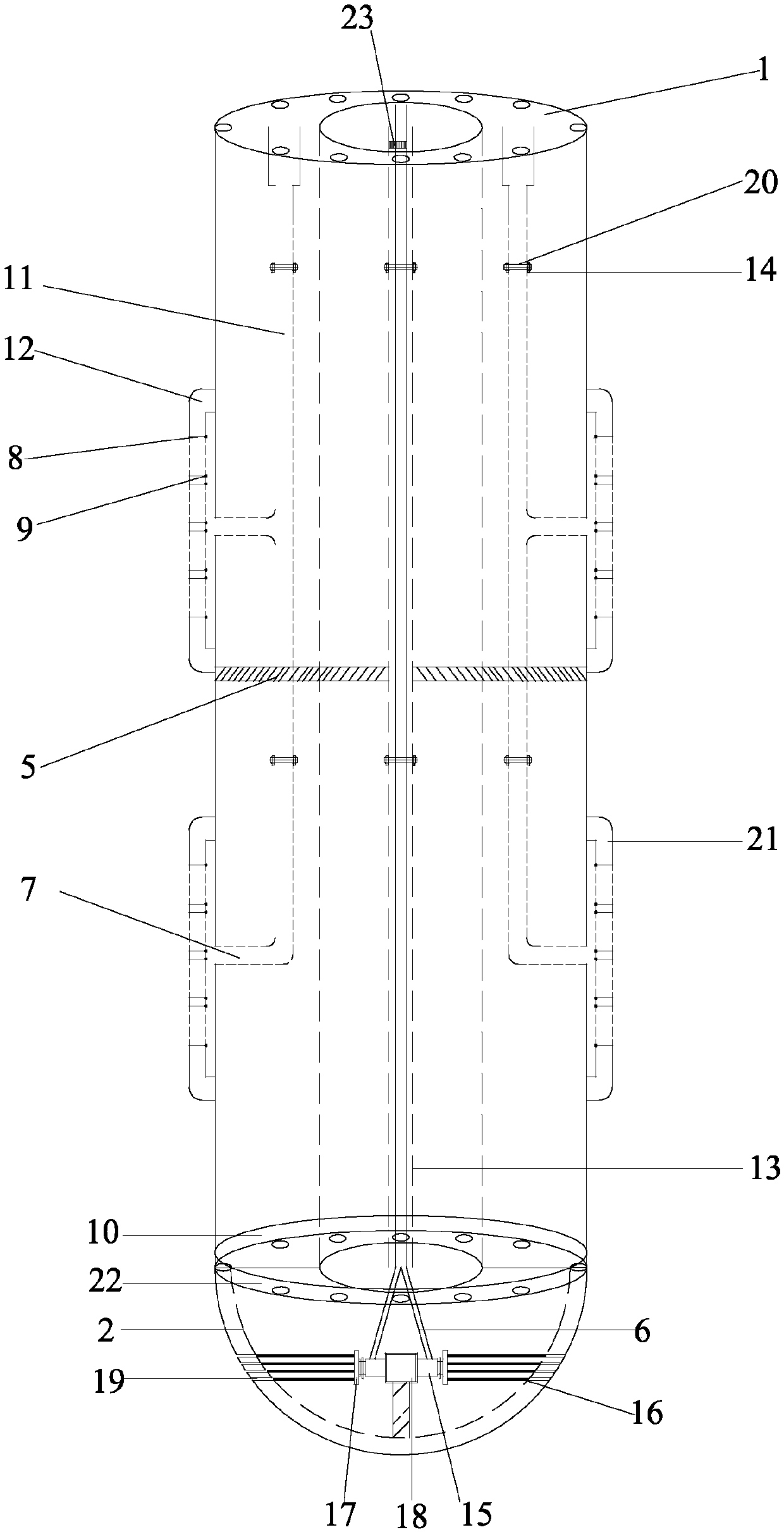

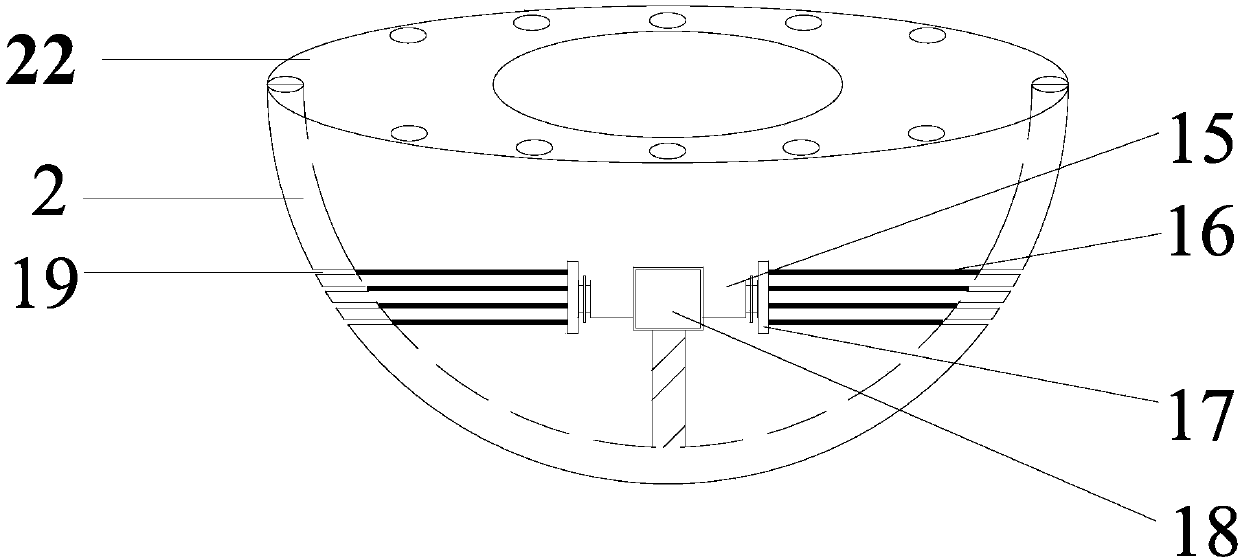

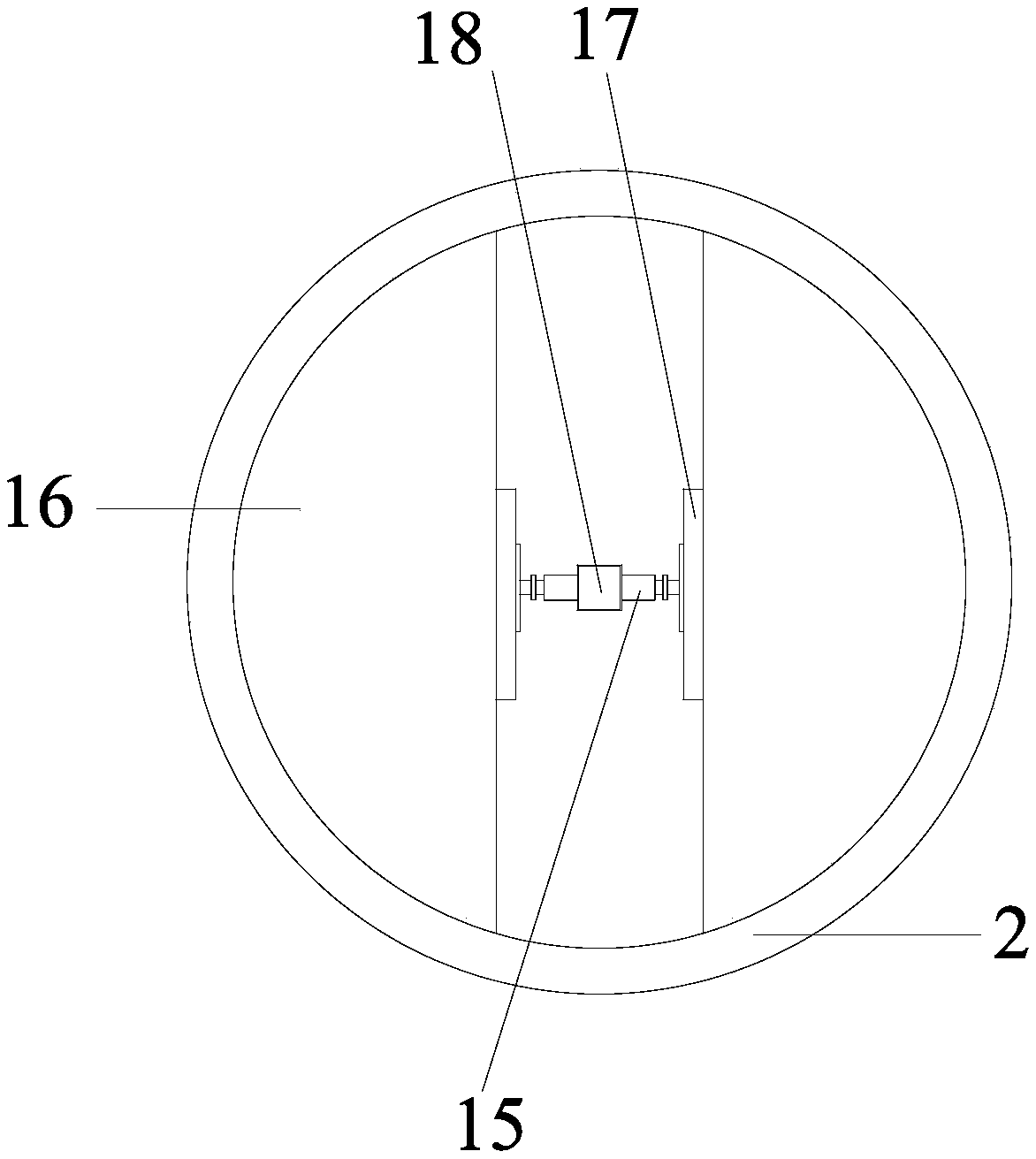

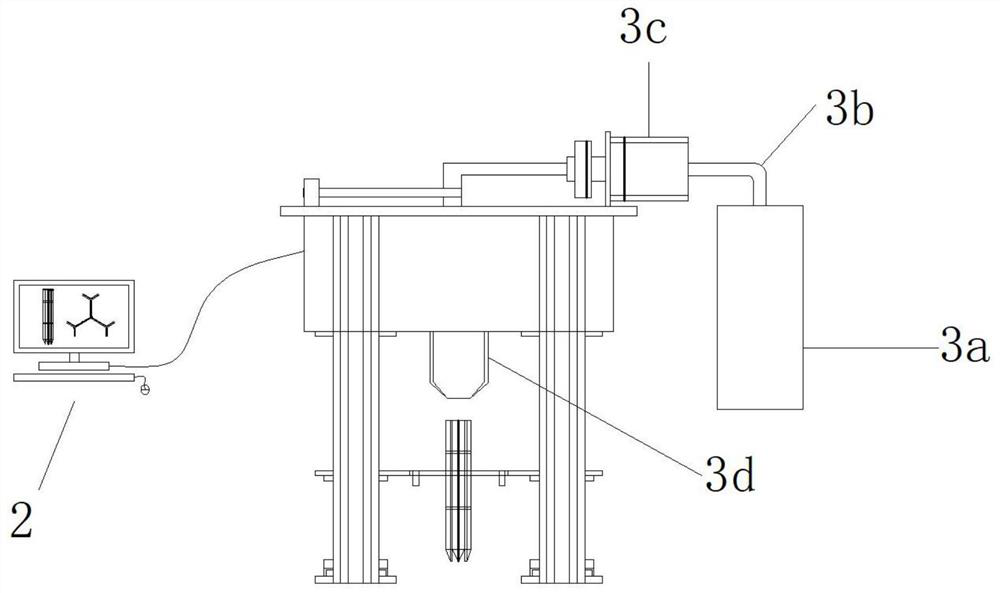

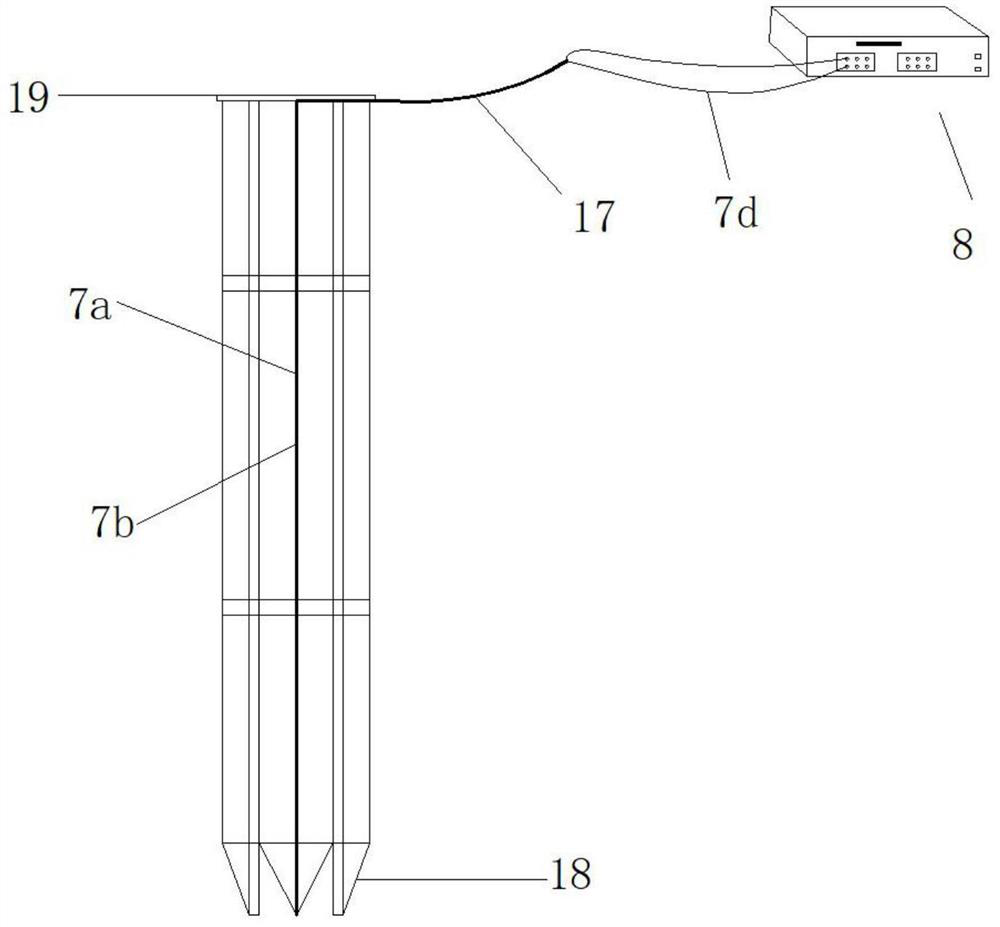

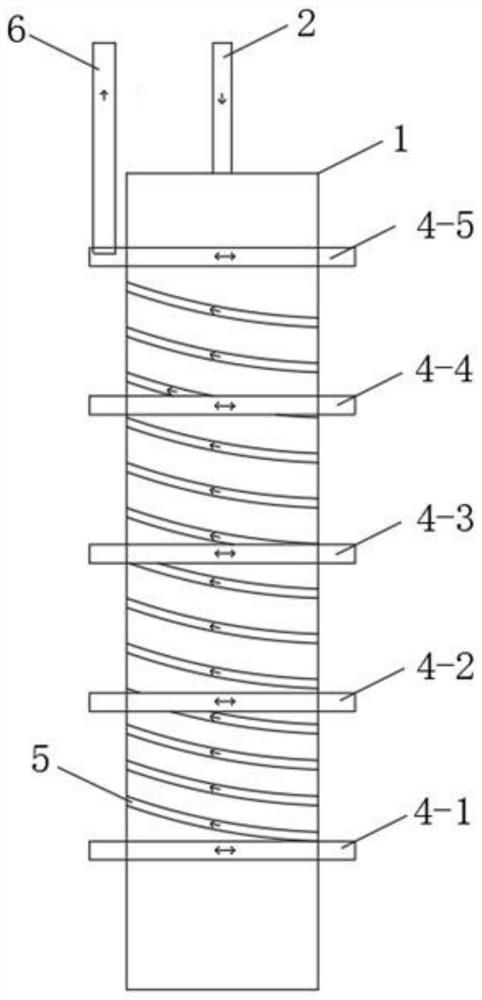

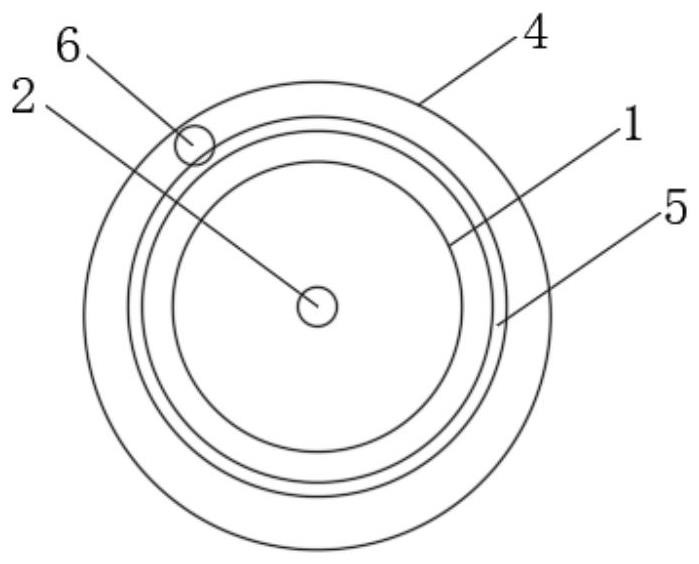

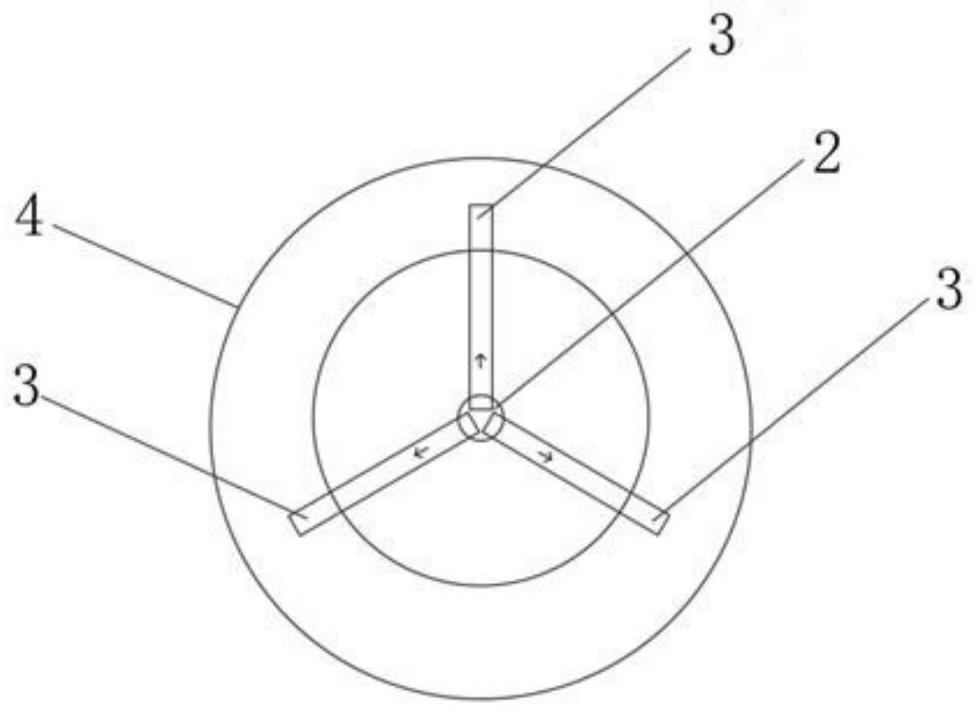

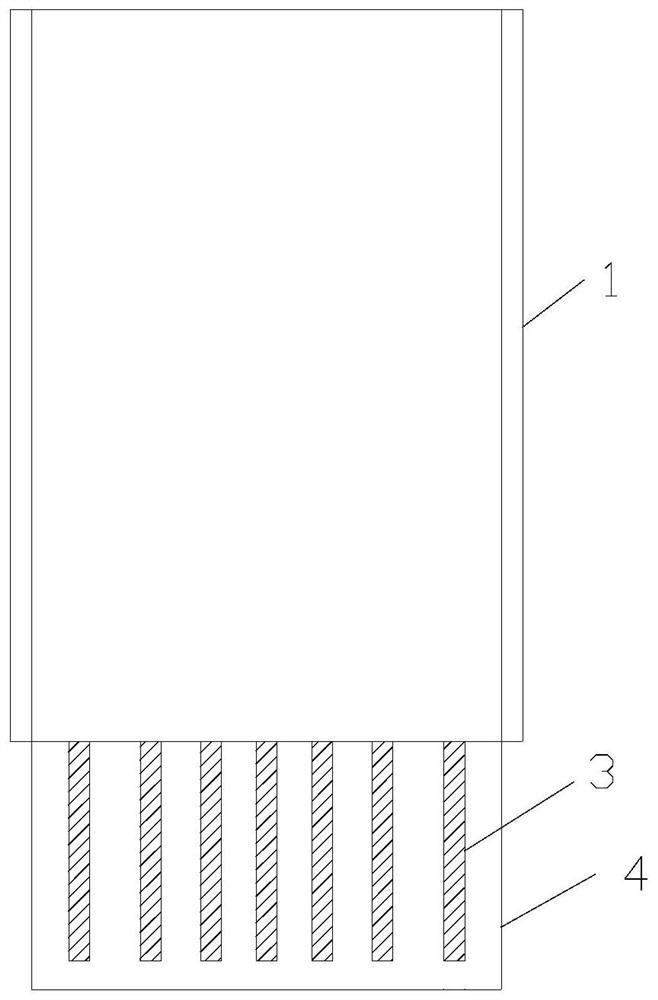

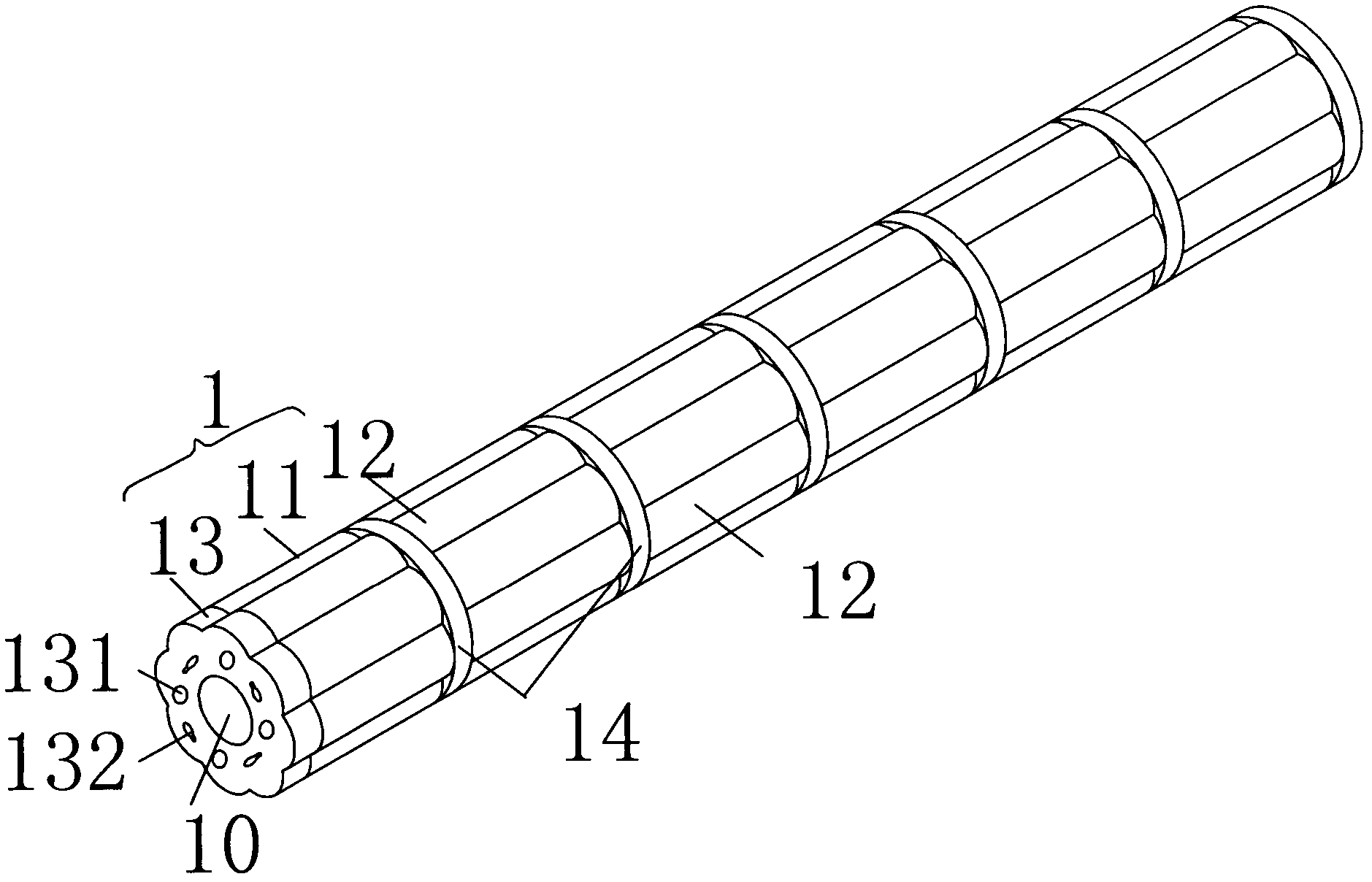

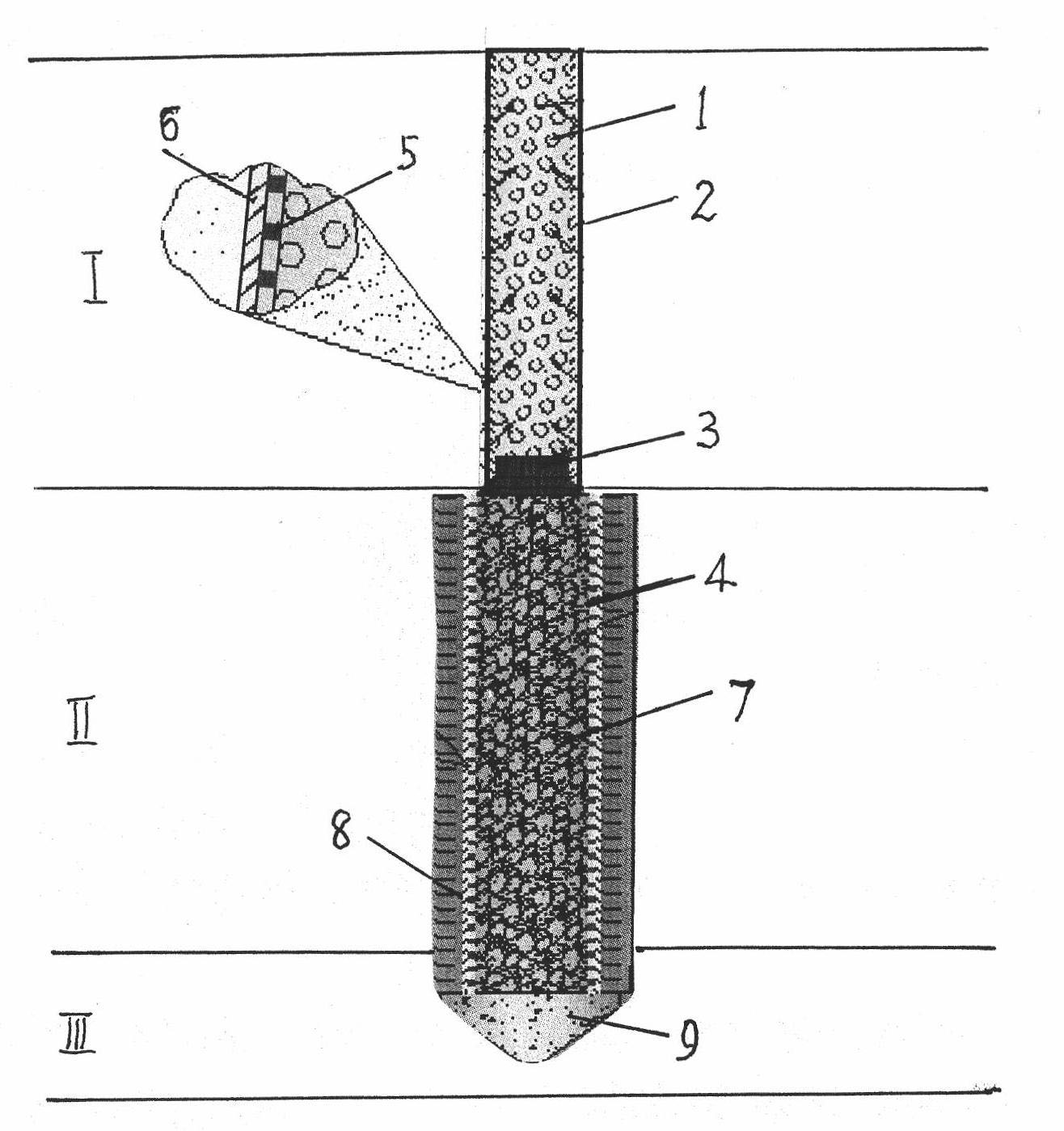

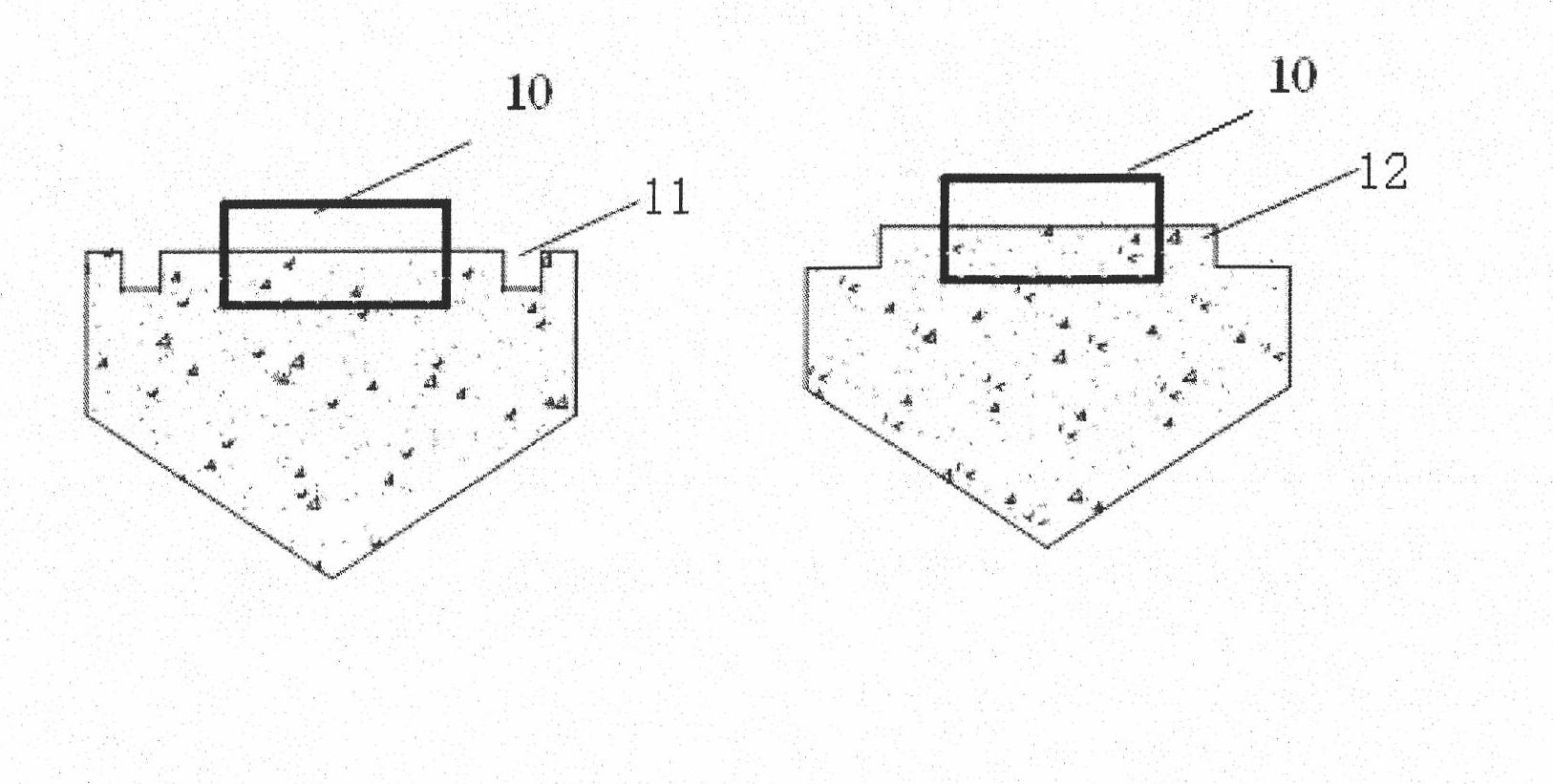

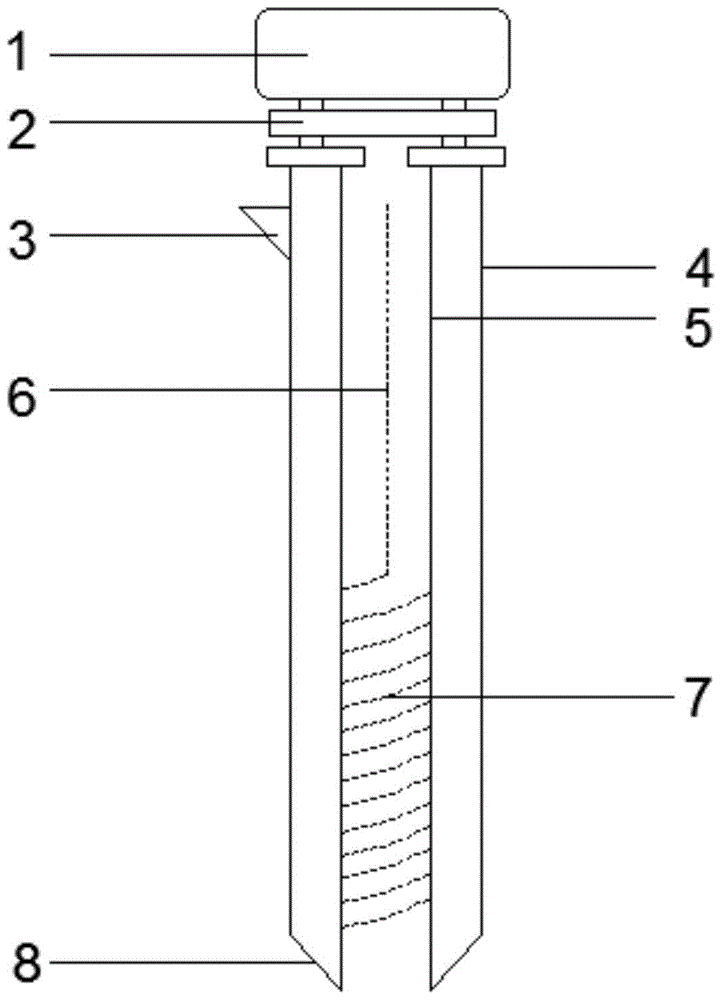

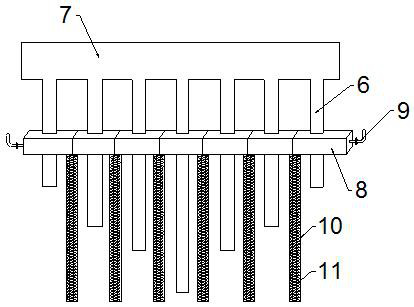

While-drilling casing pile side sectional high-pressure grouting system and method

ActiveCN105756065AImprove pile side frictionImprove load carrying capacityFoundation engineeringGroutPre stress

The invention discloses a while-drilling casing pile side sectional high-pressure grouting system and method. The grouting system comprises a prestress concrete tube pile, an upper end socket plate, a lower end socket plate, a grouting tube, a reserved tube and a baffle control structure, wherein the upper end socket plate and the lower end socket plate are arranged at the two ends of the prestress concrete tube pile. The upper end socket plate and the adjacent lower end socket plate are connected in a welded mode, and the upper end socket plate and the lower end socket plate are provided with connecting grooves which are formed in the radial direction of the prestress concrete tube pile and stretch out of the outer wall. A plurality of sealing baffles are movably arranged at the circumferential edge of the upper end socket plate. The grouting tube is inserted into the reserved tube. The grouting tube is provided with a grout outlet communicated with the connecting grooves. A plurality of through holes are formed in each of the upper end socket plate and the lower end socket plate. By means of the while-drilling casing pile side sectional high-pressure grouting system and method, high-pressure grouting is achieved, grout can enter peripheral rock and soil more deeply in a seepage or compaction or separation mode, a pile body and the periphery rock and soil are bonded, the friction resistance on the pile side is remarkably increased, and the bearing performance of the while-drilling casing pile is further improved.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

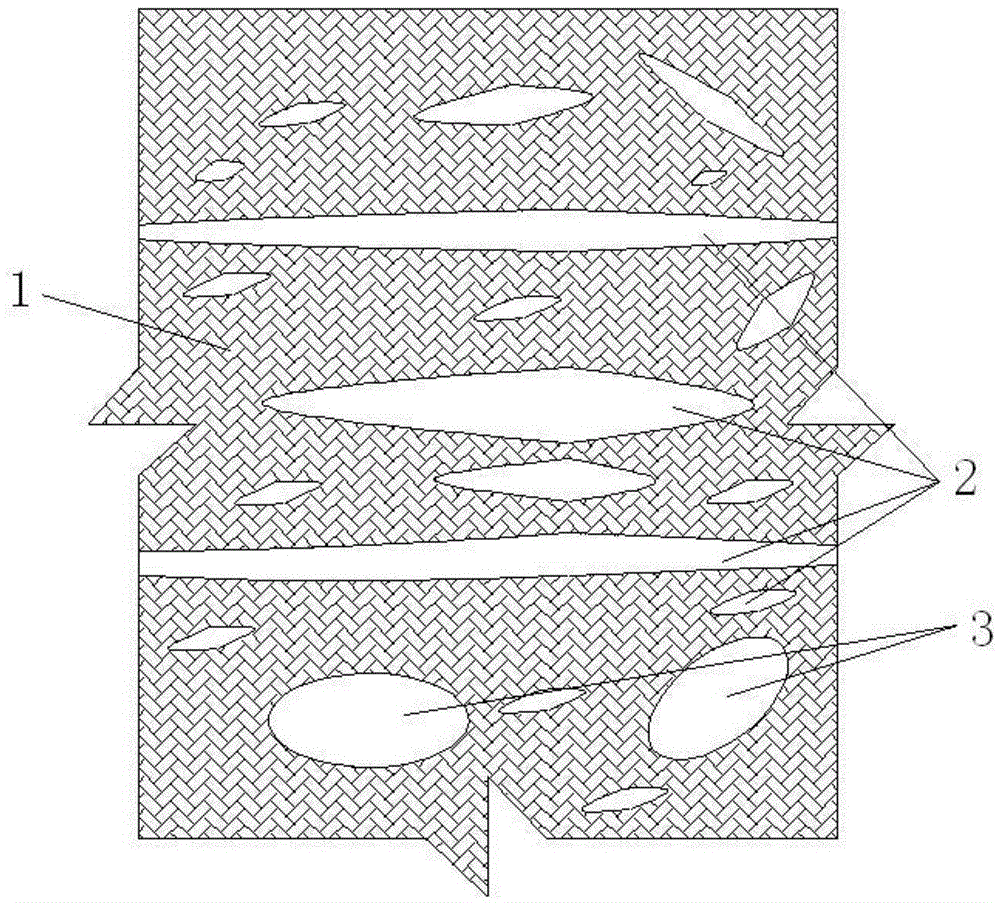

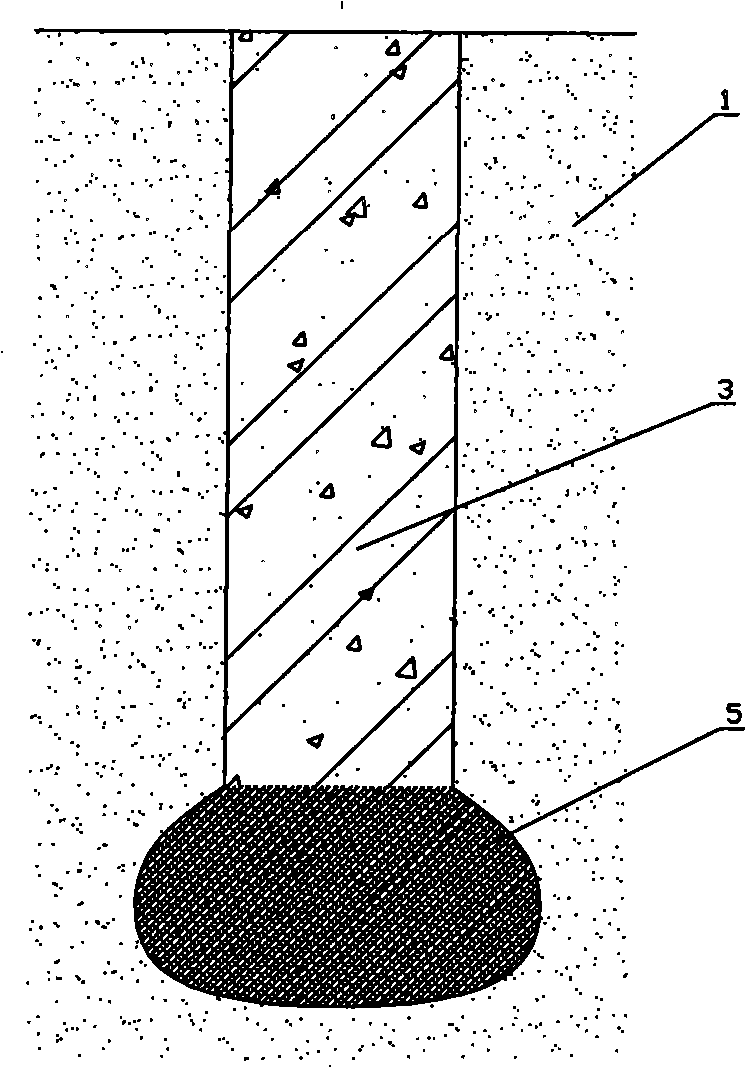

Concrete and induration formed composite type pile and its manufacture method

InactiveCN101260668AIncrease pile tip resistanceImprove pile side frictionBulkheads/pilesRebarReinforced concrete

The invention discloses a composite pile body formed by concrete and a concretion body and a construction method thereof; the composite pile body is formed by the different combination of the concrete pile body, a pile side concretion body formed by slurry sprayed from the pile side and a pile bottom concretion body formed by slurry sprayed from the pile bottom; the construction method comprises that: a hole is drilled to a preset depth by a driller; according to the need of a design proposal, the pile bottom concretion body is formed after slurry is sprayed from the pile bottom; the concrete is affused by lifting a drill stem, and the pile side concretion body with different shapes is formed by controlling the rotation of the drill stem and the spraying of the slurry; after the drill stem is lifted to the pile top and a height mark is designed, if the pile body is a reinforced concrete type composite pile body, a steel reinforcement cage also needs to be inserted to complete the construction of the composite pile body. The composite pile body formed by the concrete and the concretion body and the construction method can effectively improve the bearing capacity of the pile body and has high construction efficiency and high economical efficiency.

Owner:王力纬

Construction method of concrete pipe pile

ActiveCN109853528AImprove stress resistanceImprove pile side frictionBulkheads/pilesSlurryResistance force

The invention relates to the technical field of concrete pipe piles, and discloses a construction method of a concrete pipe pile. The construction method includes the steps that a hollow area is formed on the interior of the pipe pile in a surrounding mode, and a plurality of installing holes formed in the axial direction and at intervals are reserved in the side wall of the pipe pile; the inner end of a grouting floral pipe is inserted into the installing holes, and the pipe pile with the installed grouting floral pipe is arranged in a pile hole; a pushing steel pipe whose outer diameter is smaller than the inner diameter of the hollow area of the pipe pile, the pushing steel pipe is inserted into the hollow area and abuts against the outer end of the grouting floral pipe, and the inner end of the grouting floral pipe is pushed out of the installing holes and is embedded into the soil mass outside the pipe pile; when the pushing steel pipe is completely inserted into the hollow area of the pipe pile, then a grouting gap is arranged between the outer side wall of the pushing steel pipe and the inner side wall of the pipe pile, and the outer end of the grouting floral pipe is exposed in the grouting gap; grouting liquid is grouted into the grouting gap, and the grouting liquid is grouted into the soil mass outside the pipe pile through the grouting floral pipe to form a groutingliquid package wrapping the inner end of the grouting floral pipe, so that pile side friction resistance force of the pipe pile and the surrounding soil mass is increased.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD

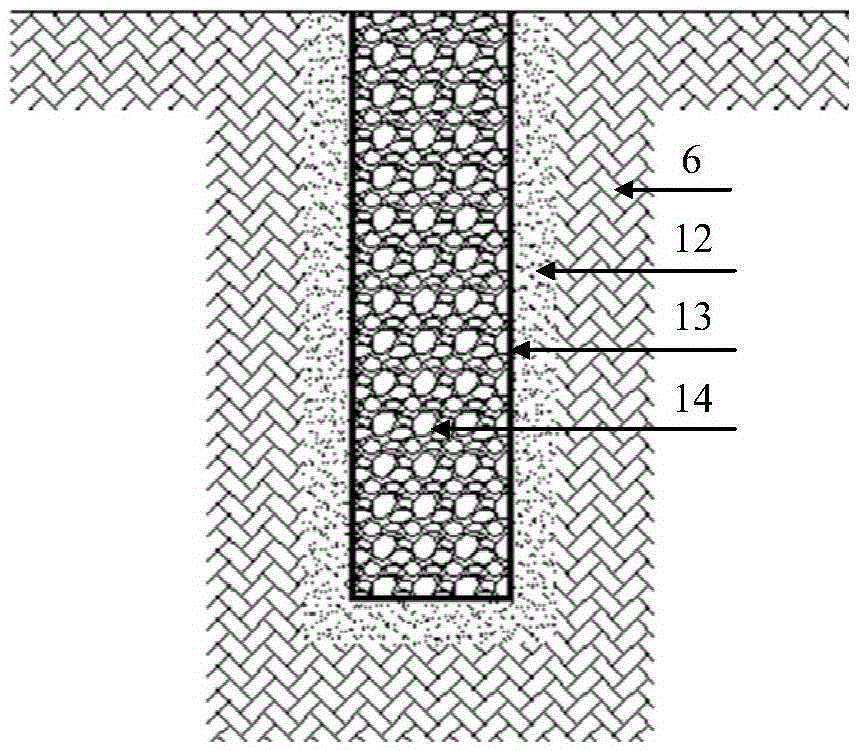

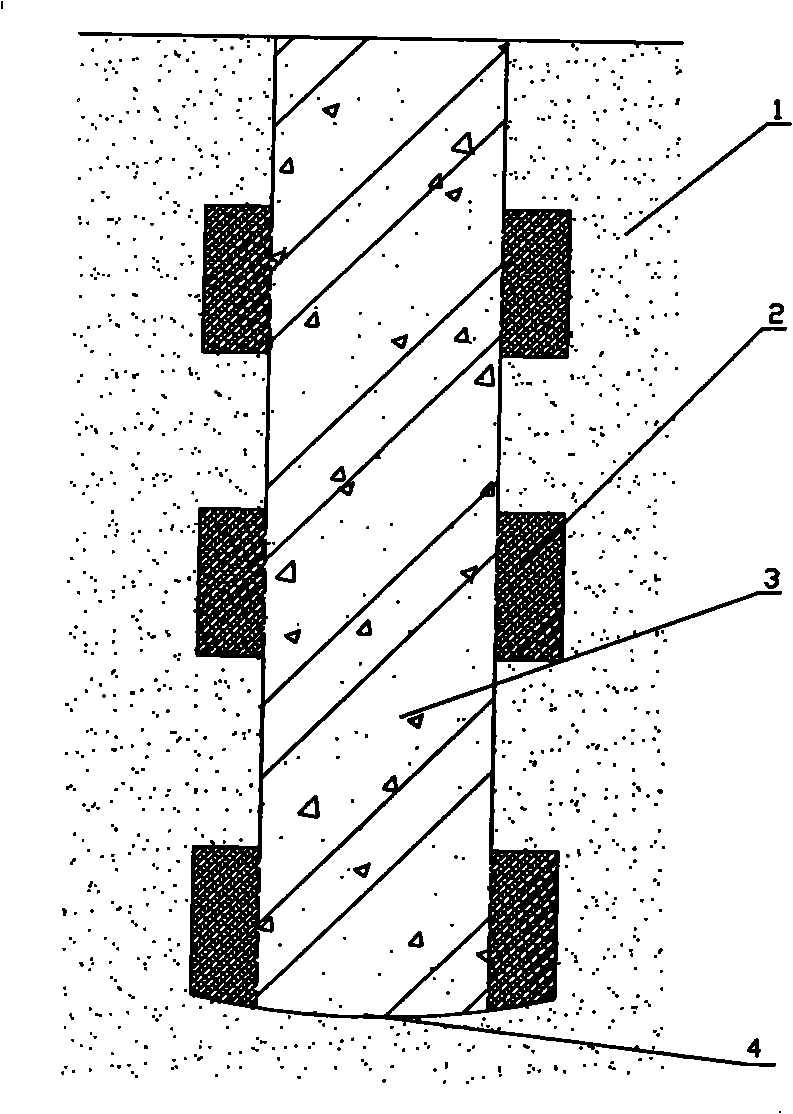

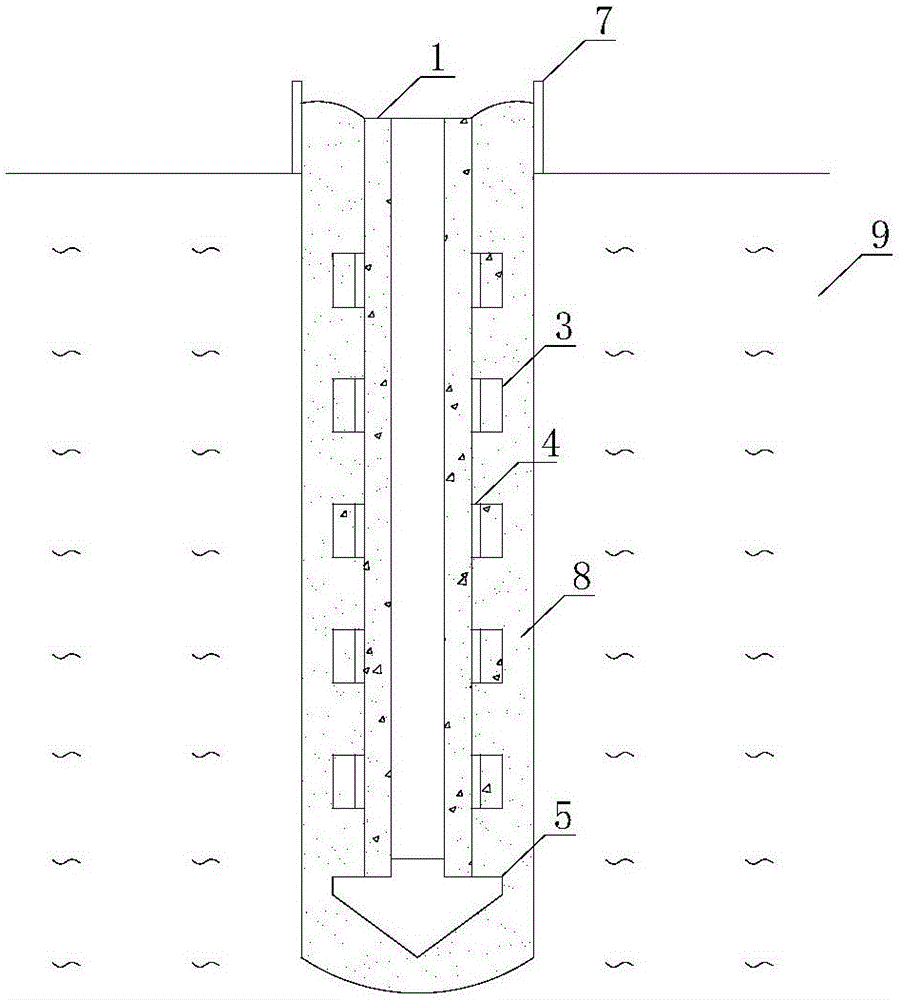

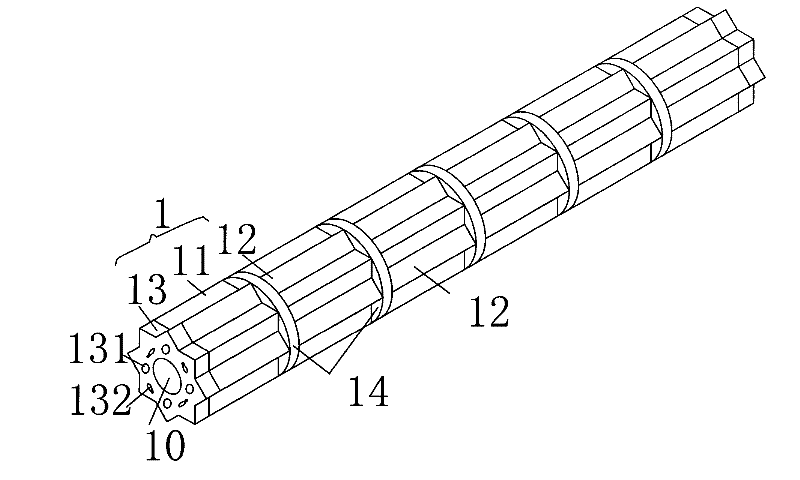

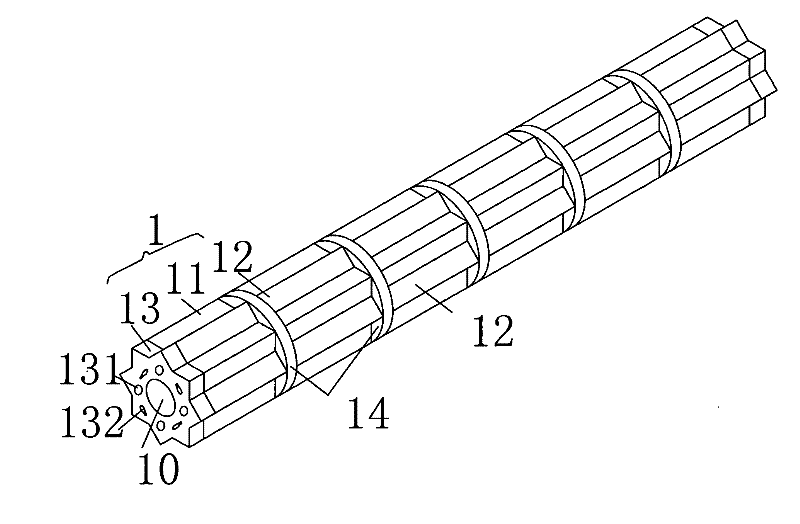

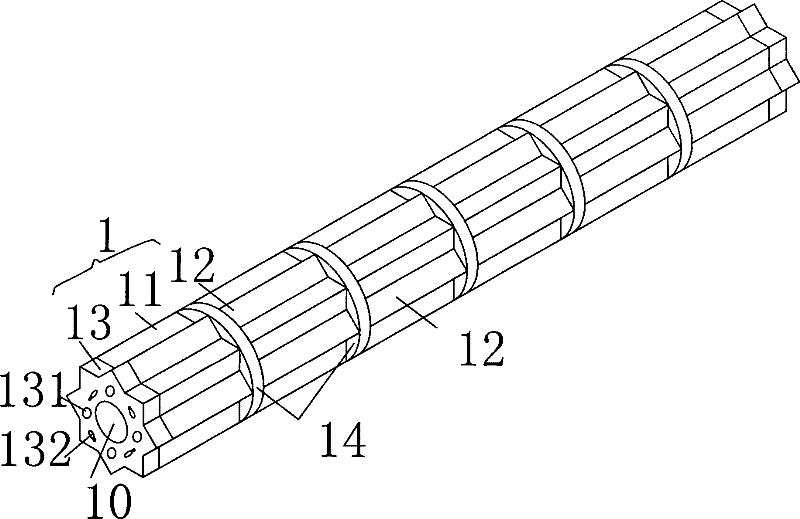

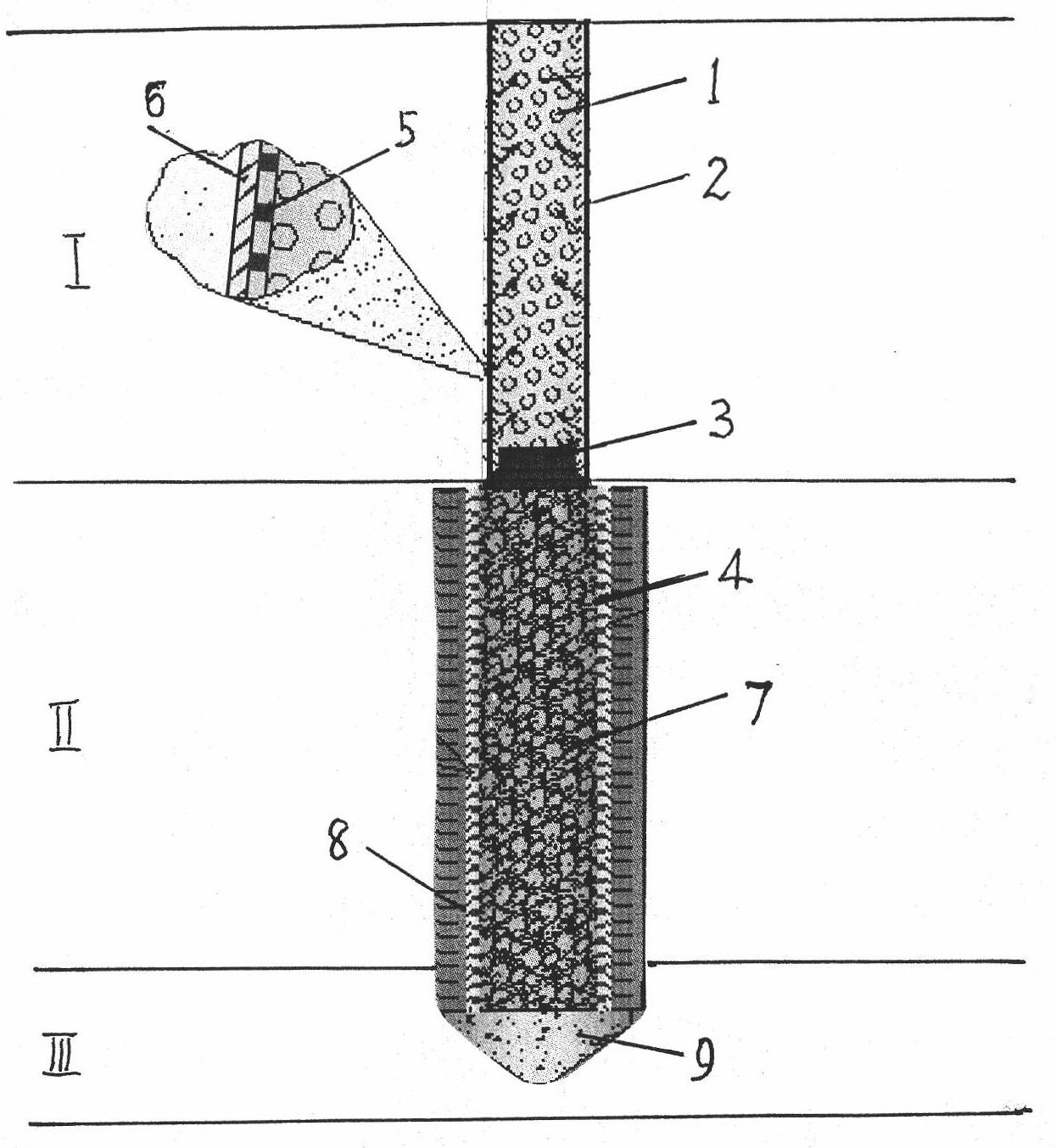

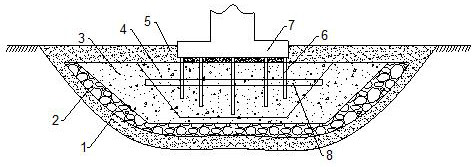

Prefabricated pile with external hoops and filled with sand-gravel aggregates, and construction method thereof

ActiveCN106592586ADissipate quicklyAccelerated consolidationBulkheads/pilesSoil preservationSoil massEconomic benefits

The invention discloses a prefabricated pile with external hoops and filled with sand-gravel aggregates, and a construction method thereof. A section-shaped spaced diameter-expanded pile body is formed through connecting the external diameter-expanding hoops of a pile body and pile-bottom-expanding pile tips with the pile body after the prefabricated pile is formed. The sand-gravel aggregates are filled in the periphery of the pile while the prefabricated pile with the external hoops is pressed or punched in foundation soil, and finally a composite foundation in which the prefabricated pile with the external hoops, the sand-gravel fillers in the periphery of the pile, and the foundation soil co-act is formed. In the method, the sand-gravel fillers in the periphery of the pile form a water drainage channel, a soil mass consolidation process is accelerated, and post-construction settlement after construction is completed is controlled; a larger soil mass internal friction angle of the sand-gravel aggregates provides higher pile side friction resistance of a pile foundation, thus the bearing capacity of the pile foundation can be improved; and each external hoop comprises a diameter-expanding hoop of the pile body and a pile-end-expanding pile tip. The equipment is simple, independent die customization is not required, and a fixing position on the pile body is adjustable, thus the prefabricated pile is adaptive to many designs and working conditions, and high in engineering adaptability; and the spaced diameter-expanded pile body is capable of providing bearing capacity higher than the bearing capacity of a prefabricated pile having an outer diameter which is the same as that of a diameter-expanded section, and capable of saving the manufacturing cost, thus achieving good economic benefits.

Owner:ZHEJIANG UNIV

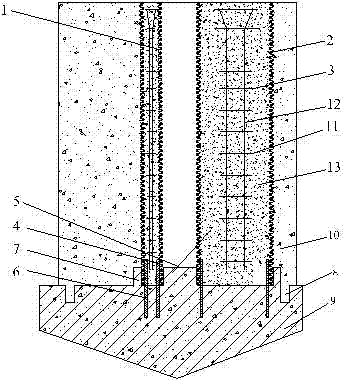

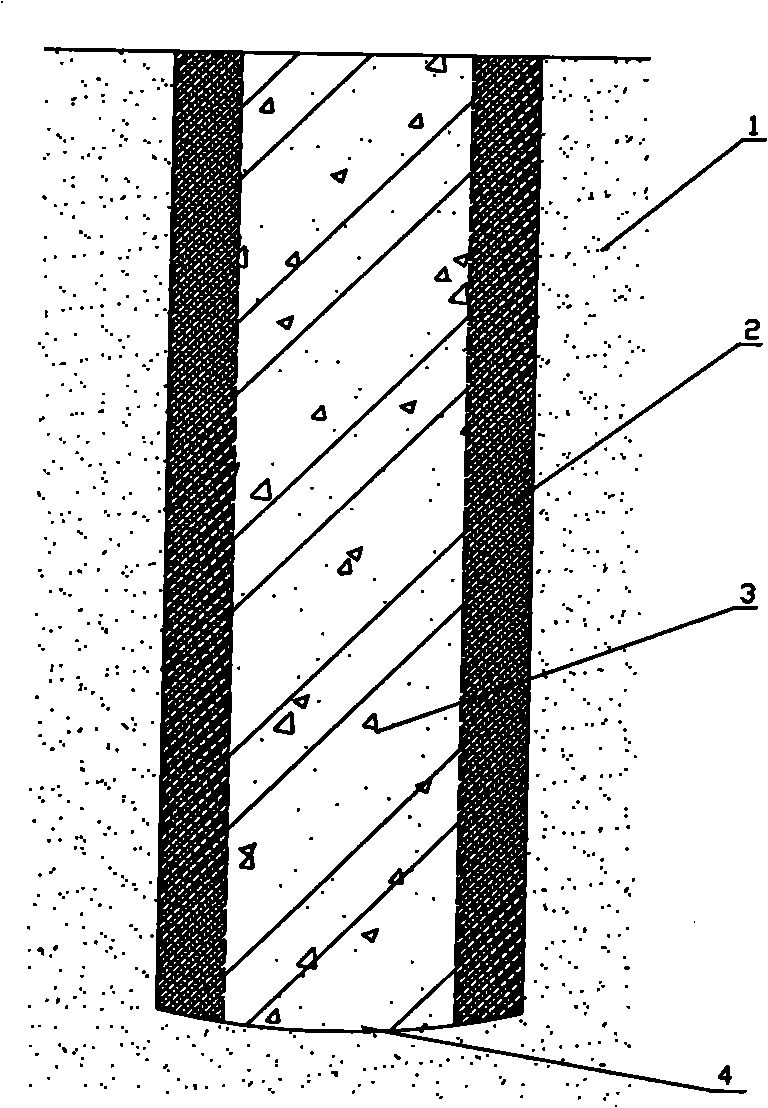

Plastic-sleeve bamboo-reinforcement cemented soil pile and construction method thereof

InactiveCN105839620ASimple construction methodImprove construction efficiencyBulkheads/pilesWaddingGeogrid

The invention discloses a bamboo-reinforced cement-soil pile with a plastic sleeve, which comprises a pile hole arranged in the soil body; a plastic sleeve is arranged in the pile hole, and a bamboo reinforcement cage is arranged inside the plastic sleeve; the plastic sleeve A grouting channel is provided in the pipe; cement soil is injected from the grouting channel, and the inner hole of the plastic casing is filled and the bamboo reinforcement cage is wrapped; a grouting filling is provided between the outer layer of the plastic casing and the pile hole. The construction method is construction preparation → pile driver in place → immersed pipe → hoisting into plastic casing → hoisting into bamboo reinforcement cage → pouring cement soil → vibrating pipe pulling → grouting or filling with sand and gravel → pile formation; construction method Simple, high construction efficiency, good construction quality and low project cost, can ensure the bearing capacity of the foundation of the project and meet the requirements of the construction period, effectively increase the pile side friction resistance, improve the bending and shearing resistance of cement-soil piles, and at the same time The pile body and the soft soil foundation are used to form a composite foundation with geogrid, which has high bearing capacity and can effectively solve the uneven settlement of the structure.

Owner:CHINA RAILWAY TIMES BUILDING DESIGIN INST CO LTD

Static drill squeezed branch and pipe pile combined pile type and construction method thereof

The invention discloses a static drill squeezed branch and pipe pile combined pile type. The static drill squeezed branch and pipe pile combined pile type comprises a pipe pile, a squeezed branch pile and an expanded pile, wherein the outer wall of the pipe pile is sleeved with the squeezed branch pile, and the expanded pile is connected with the end of the squeezed branch pile. The pipe pile is a hollow pipe. The pipe is filled with cement soil, and the solid pipe pile is formed. The squeezed branch pile comprises a squeezed branch pile body and squeezed branches distributed on the squeezed branch pile body at equal intervals in the axial direction. The squeezed branch pile is a cement soil pile. The expanded pile is an expanded concrete pile body. According to the static drill squeezed branch and pipe pile combined pile type, part of a soil body is extruded to the hole wall, the pile side friction is increased, discharge of an original soil body is reduced, meanwhile part of the residual soil body is dug out, a large-caliber pile foundation is formed, and the pile foundation bearing force is improved; then the squeezed branches are arranged, pre-pressure is applied to the side wall, the contact area of the combined pile and the soil is increased, the effective area of the pile body is increased, and the bearing force of the combined pile is improved; and then expansive concrete is pressed into a pile end expanded hole to form pre-pressure on the pile end, and the bearing capacity of the pile end is further improved.

Owner:SOUTHEAST UNIV

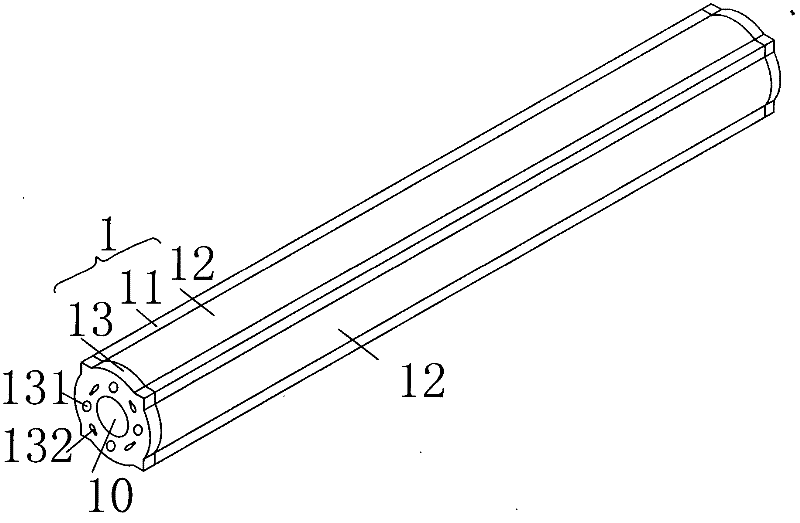

Square cylindrical pipe pile and processing method thereof

InactiveCN102359103AImprove the shape of the outer surfaceImprove pile side frictionMouldsBulkheads/pilesEngineeringFriction force

The invention discloses a square cylindrical pipe pile which at least comprises a square pile body; and a half-cylindrical outer surface is arranged on the outer surface on each side of the square pile body. The invention further discloses a processing method of the square cylindrical pipe pile. Due to the structural design of the half-cylindrical outer surfaces, the shape of the outer surface of the pipe pile is improved, the friction coefficient of the outer surface is increased and the pile side friction force of the pipe pile is improved. Simultaneously, due to the structural design of the half-cylindrical outer surfaces, the end area of the pipe pile is enlarged and the pile-end bearing capacity of the pipe pile is increased. Therefore, the square cylindrical pipe pile integrates the advantages of a circular pile and a square pile, simultaneously overcomes the inherent defects of the circular pile and the square pile, and has the characteristics of higher anti-compression friction force, higher anti-shearing performance, higher anti-pulling capacity, significant progress and beneficial effects.

Owner:SHANGHAI AOMI PHARMA EQUIP

Prestressed concrete pipe pile combining post grouting technology with expanding technology, and production method thereof

The invention relates to a prestressed concrete pipe pile combining a post grouting technology with an expanding technology. The prestressed concrete pipe pile comprises a prestressed concrete pipe pile body, a hemispheric pile head, a grouting hole, valves, hinges, a grouting pipe, line spray pipes, a hydraulic jack, a high-strength alloy blade, a blade fixing plate, a cubic thick steel cushion block, a blade outlet gap and spouting ports, wherein a grouting device is arranged in the prestressed concrete pipe pile body, the grouting device comprises a grouting pipe and the grouting hole, andthe grouting hole is formed in the outlet end of the grouting pipe; the line spray pipes are arranged at the two sides of the prestressed concrete pipe pile body; one spouting port is formed in each line spray pipe; one valve and one hinge are welded to each spouting port; and each valve is connected to the grouting hole through the corresponding hinge. The prestressed concrete pipe pile disclosedby the invention has the following beneficial effects: due to the adopted pile-side post grouting technology, the exertion level of pile-side friction resistance can be increased to a large extent; and moreover, compared with the traditional point grouting technology, the pile-side friction resistance is much easily increased due to line grouting, so that the bearing capacity of a pile body is improved.

Owner:NINGBO UNIV

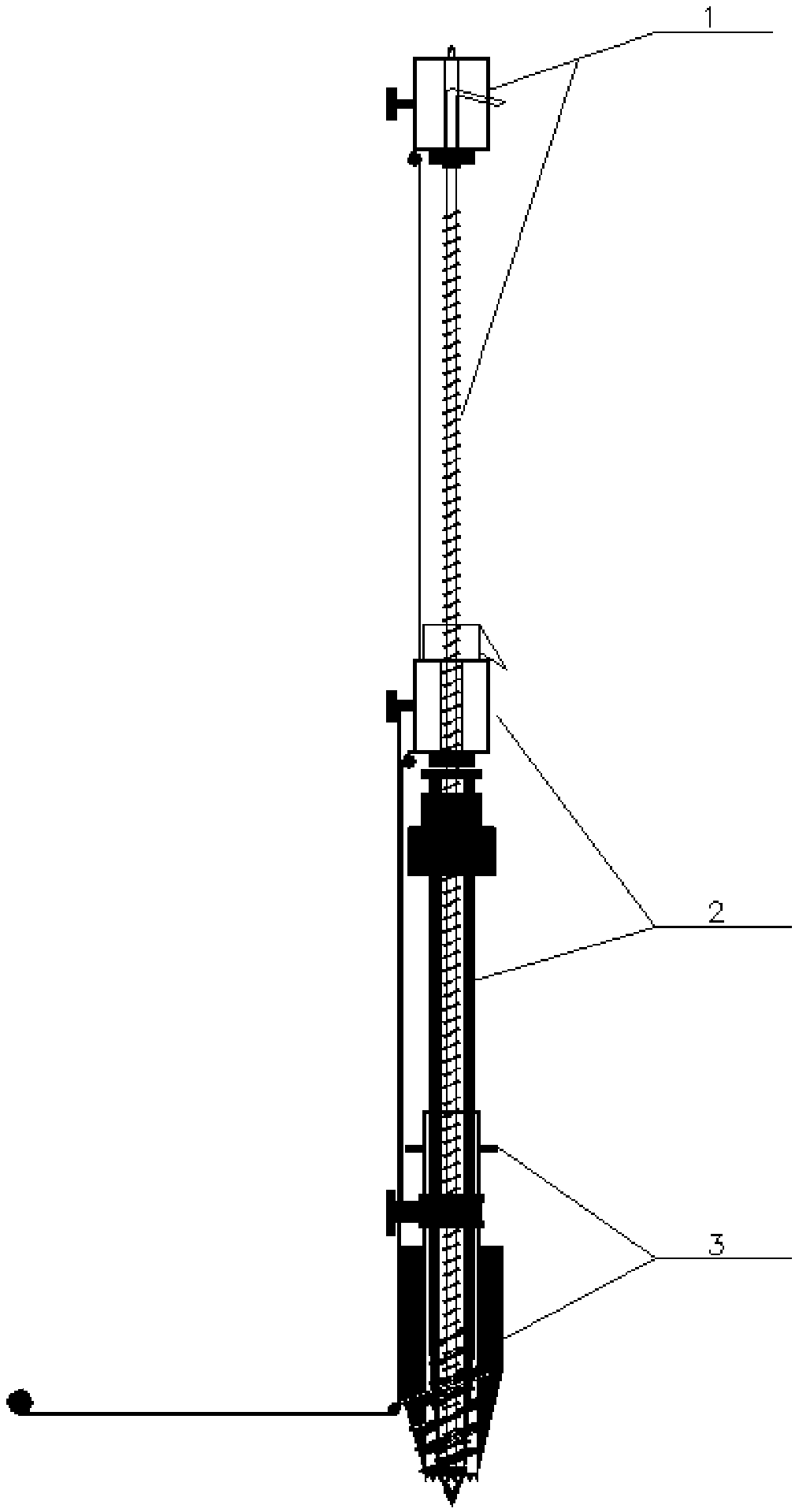

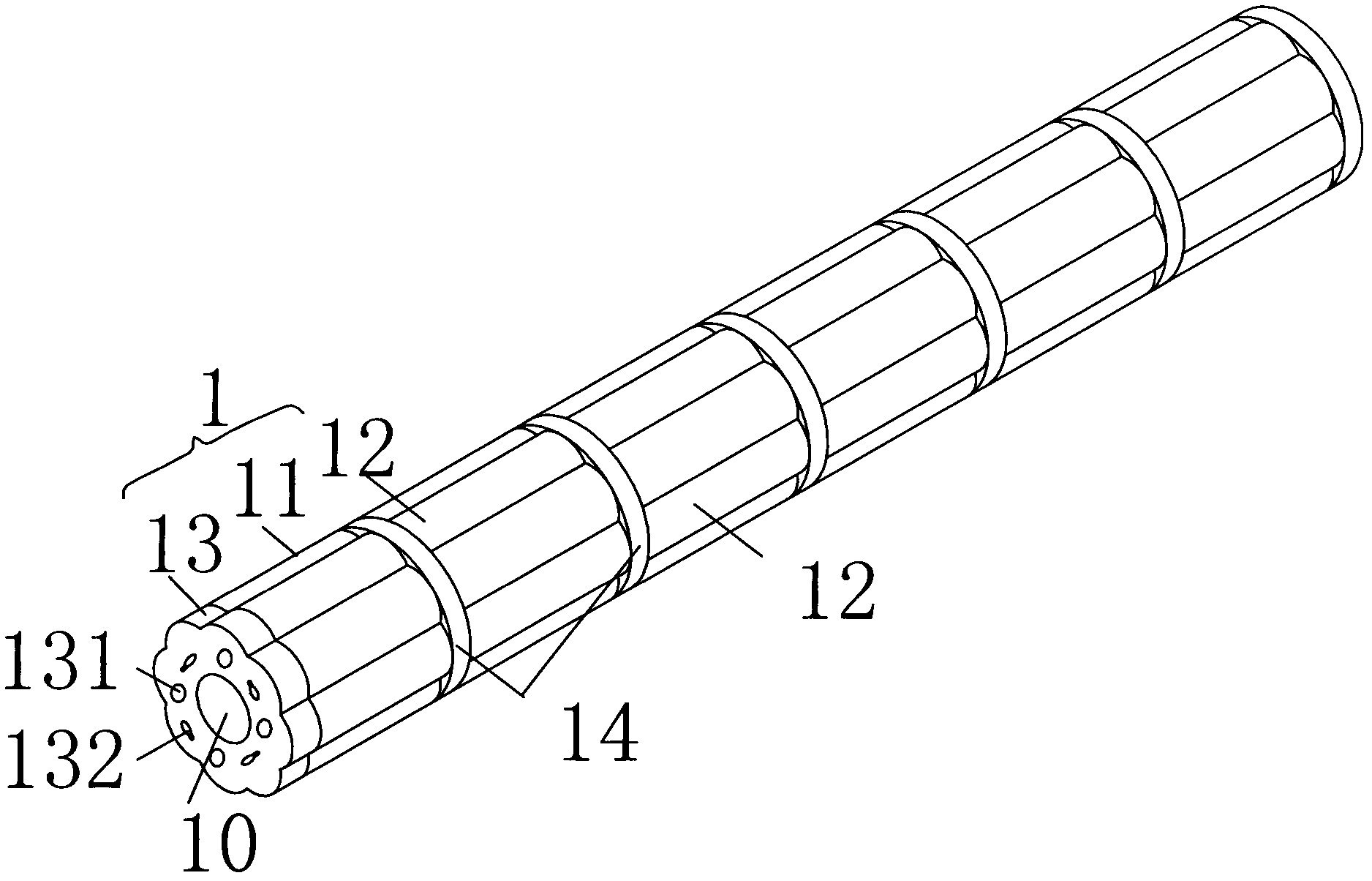

Multi-power guide linkage compound drilling tool, preparation method and pile type

PendingCN109025809AHigh degree of automationImprove ergonomicsDrilling rodsDrilling casingsComposite functionDrill

The invention relates to a technical field of civil engineering, in particular to a multi-power guide linkage compound drilling tool, a preparation method and a pile type. The drilling tool comprisesa guide linkage drilling tool, a middle power drilling tool and an upper power drilling tool arranged in turn with a shaft sleeve. The upper power drill and the middle power drill are respectively provided with a power mechanism. The guided drilling tool is provided with a guide device. At least one of the guide drilling tool, the middle power drilling tool and the upper power drilling tool is composed of a drilling tool body with function of squeezing and discharging soil. In construction, each drill tool is transformed from a traditional linkage mode to an active drive with linkage auxiliarymode. The squeezing and discharging of the soil, and the drilling and grouting concrete pilling can be achieved at the same time. The automation degree is high and the work efficiency is improved. The modified diameter of a pile and reasonable working method make the bearing capacity of single pile be further increased, thereby reducing cost. Comprehensive factors above shorten the duration of construction.

Owner:李广信

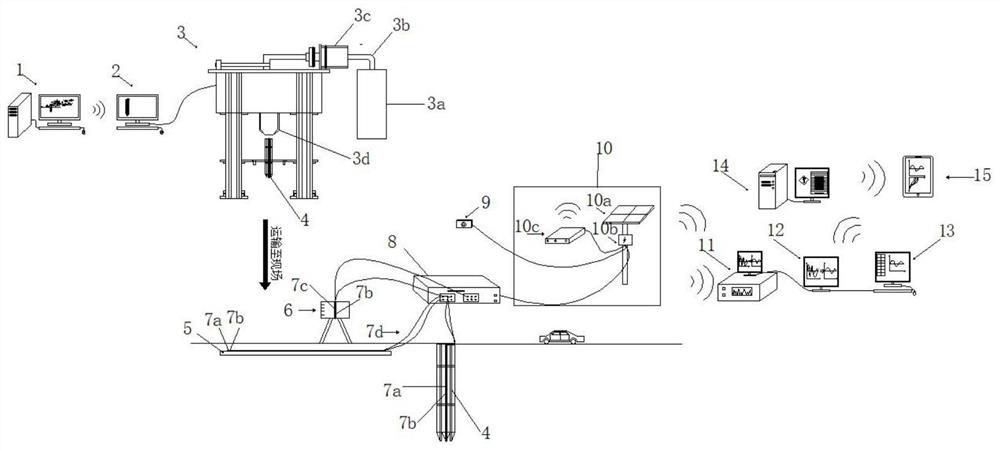

Expressway soft foundation intelligent processing and monitoring system and monitoring and early warning method

PendingCN111896049AImprove bearing capacityAccording to the law of stress diffusionProgramme controlBatteries circuit arrangementsSolar powerSnowflake

The invention discloses an expressway soft foundation intelligent processing and monitoring system and a monitoring and early warning method. The system comprises a highway soft foundation processingscheme cloud database module, , a snowflake-shaped steel sheet pile 3D printing module, a snowflake-shaped steel sheet pile deformation optical fiber sensing module, a roadbed settlement optical fibersensing module, a climate change optical fiber sensing module, an optical fiber data automatic acquisition and transmission module, an on-site road condition monitoring module, a solar power supply and data transmission module, an optical fiber data processing and analysis module, a monitoring result display module, a highway soft foundation processing effect evaluation module, a soft foundationprocessing effect cloud platform data management and early warning module and a mobile phone remote receiving module. During monitoring, 3D printing and snowflake-shaped steel sheet piles are used forrapid construction, BOTDR is used for monitoring roadbed settlement, snowflake-shaped steel sheet pile deformation and climate information, an evaluation result is displayed on a mobile phone mobileterminal in the form of a chart, and remote monitoring and long-term evaluation are realized for a road section secondary reinforcement scheme with an unsatisfactory processing effect.

Owner:HOHAI UNIV

Square cylindrical corrugated tube pile and processing method thereof

InactiveCN102359102AImprove the shape of the outer surfaceImprove pile side frictionMouldsBulkheads/pilesEngineeringBearing capacity

The invention discloses a square cylindrical corrugated tube pile which at least comprises a square cylindrical pile body. The outer surface of each edge of the square cylindrical pile body is of a corrugated shape. The invention also discloses a processing method of the square cylindrical corrugated tube pile. For the square cylindrical corrugated tube pile disclosed by the invention, due to the structure design of the corrugated outer surface, the shape of the outer surface of the tube pile is improved, the friction coefficient of the outer surface is increased, and the pile-side friction of the tube pile is improved. Meanwhile, due to the structure design of the corrugated outer surface, the end area of the tube pile is increased and the pile end bearing capacity of the tube pile is improved. Therefore, the square cylindrical corrugated tube pile disclosed by the invention combines the advantages of a round pile and a square pile, the respective inherent defects of the round pile and the square pile are also overcome, and the square cylindrical corrugated tube pile has higher compression resistance friction, higher shear resistance and higher pull-out resistance capability and has obvious progressive and beneficial effects.

Owner:SHANGHAI AOMI PHARMA EQUIP

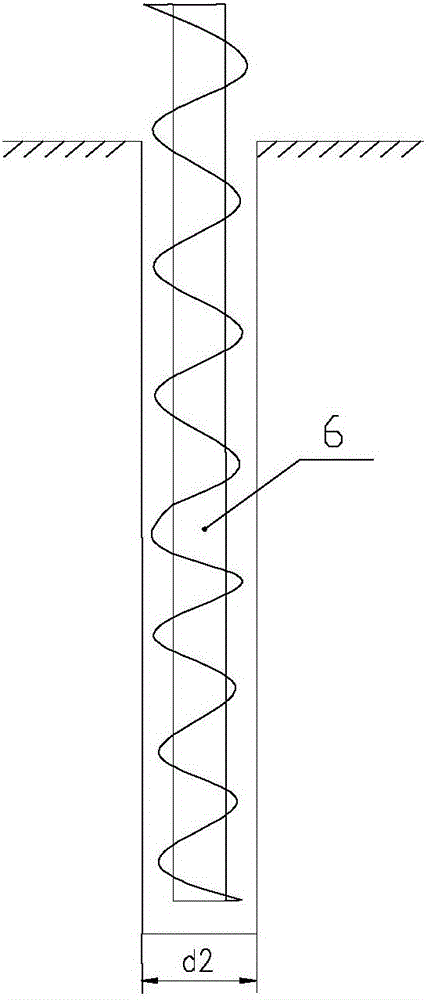

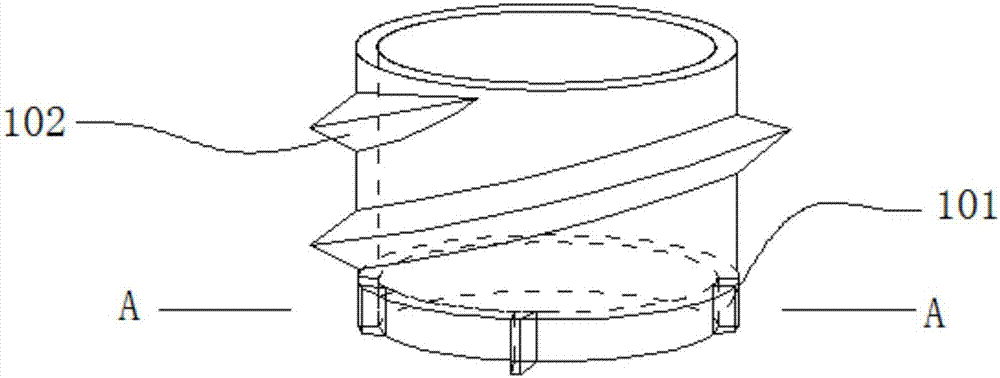

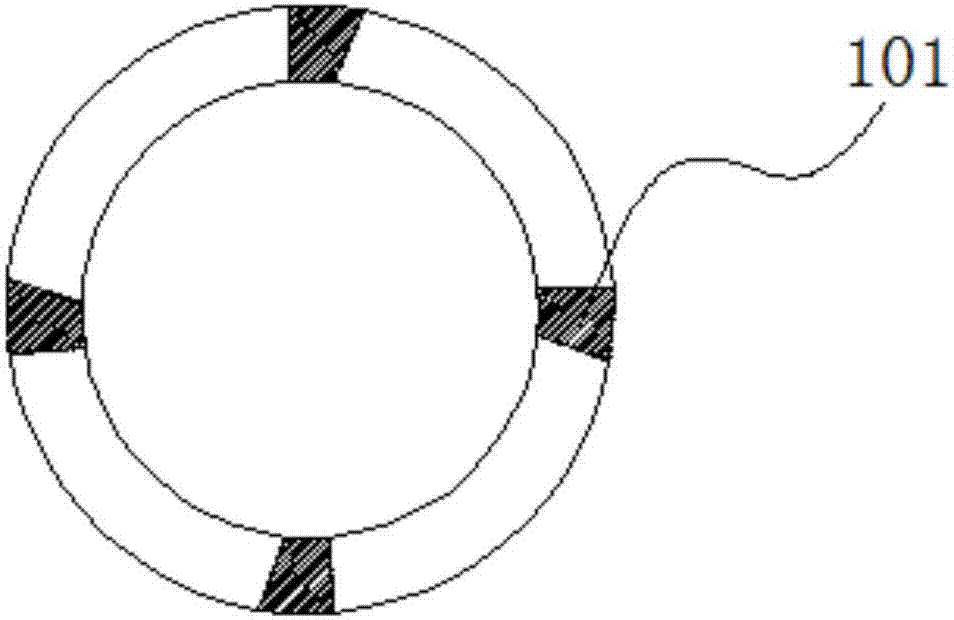

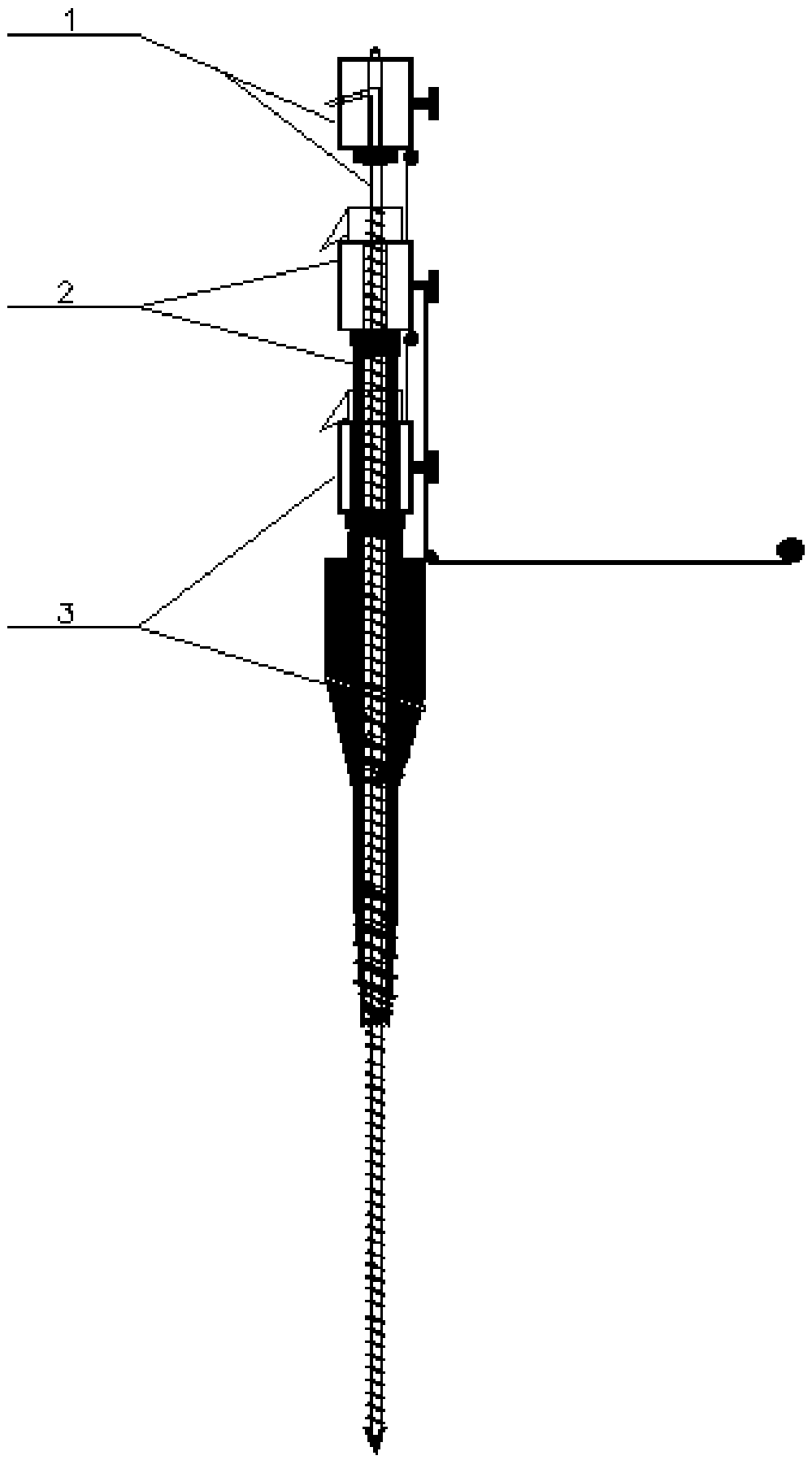

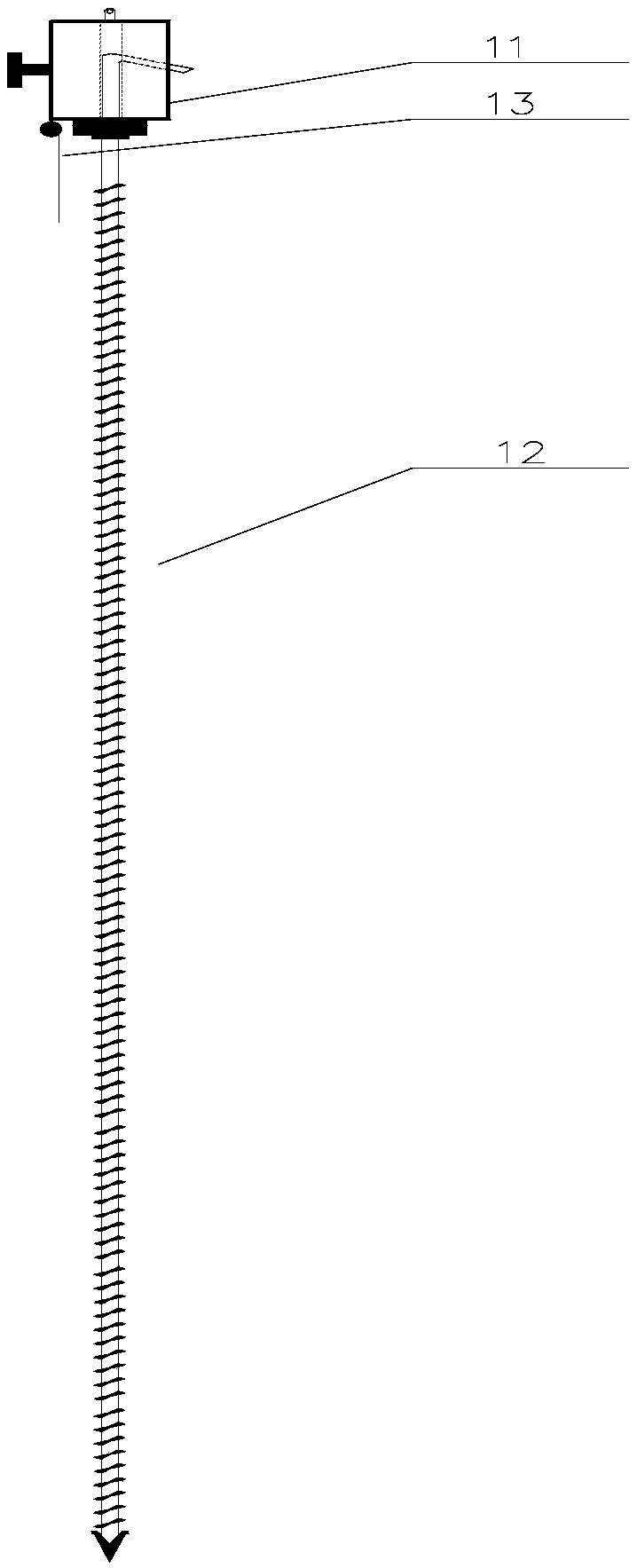

Socketed pile thread-like steel protecting cylinder capable of being drilled and using method thereof

InactiveCN107386282ASolve side slip problemImprove pile side frictionBulkheads/pilesStress concentrationHelical blade

The invention provides a socketed pile thread-like steel protecting cylinder capable of being drilled and a using method thereof. The steel protecting cylinder comprises a middle section, a drive section, a drill bit section and a thread section, wherein the drill bit section and the thread section can be embedded into a rock-soil body. At least three high-strength alloy block bodies are arranged on the outer periphery wall of the drill bit section. Helical blades I are further arranged on the outer periphery wall of the drill bit section. In the working process, the drive section, the middle section, the thread section and the drill bit section are sequentially arranged from top to bottom. The bottom face of the thread section is fixedly connected with the top face of the drill bit section. The bottom face of the middle section is fixedly connected with the top face of the thread section. The bottom face of the drive section is fixedly connected with the top face of the middle section. The using method of the steel protecting cylinder comprises the steps of assembling the steel protecting cylinder, locating the steel protecting cylinder, sinking the steel protecting cylinder, excavating a pile hole, clearing the hole and the like. The steel protecting cylinder solves the problems that due to the fact that the rock-in depth is too shallow, concrete overflows, and stress on a pile body at the bottom end of the steel protecting cylinder is concentrative, and has a wide application prospect.

Owner:CHONGQING JIAOTONG UNIVERSITY

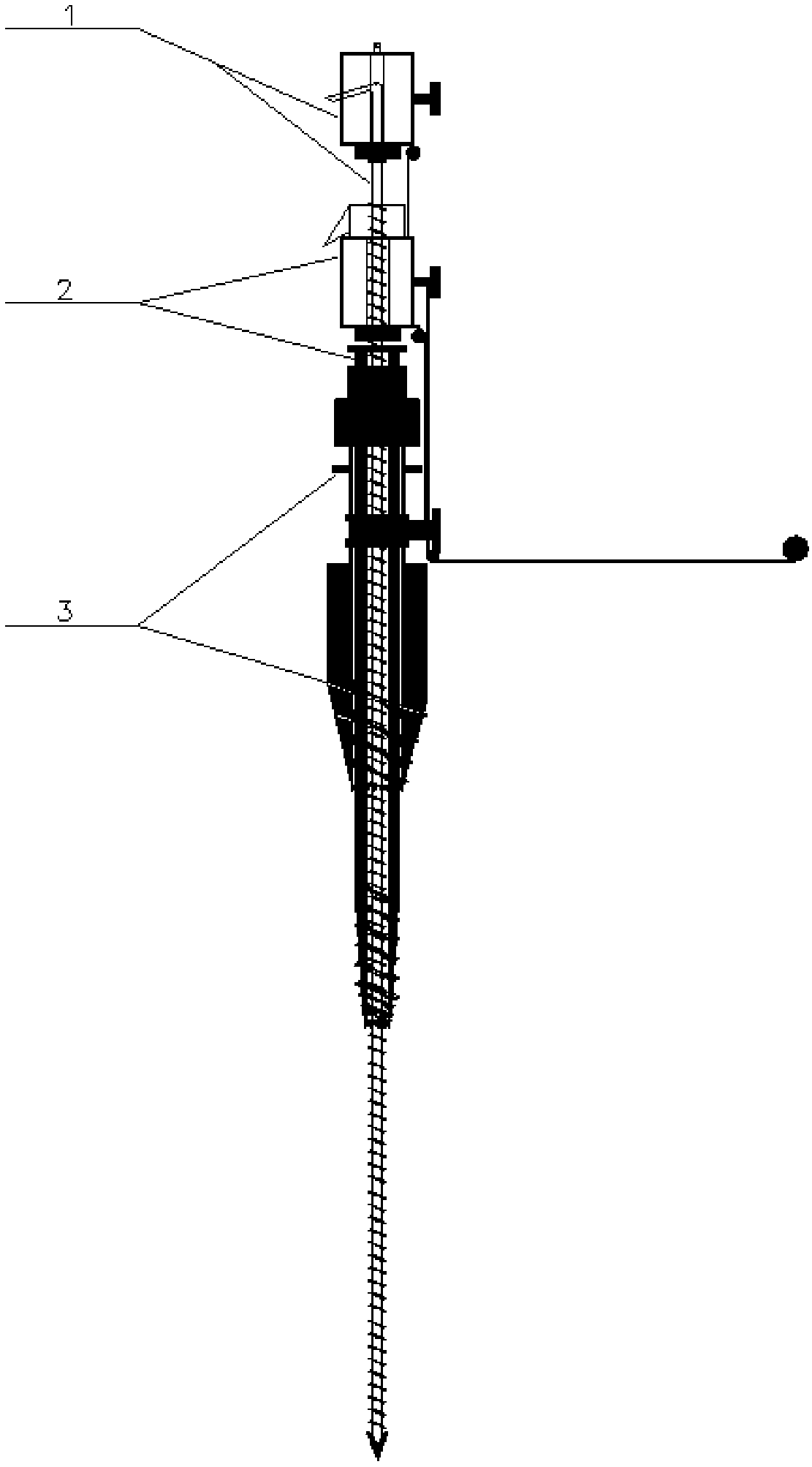

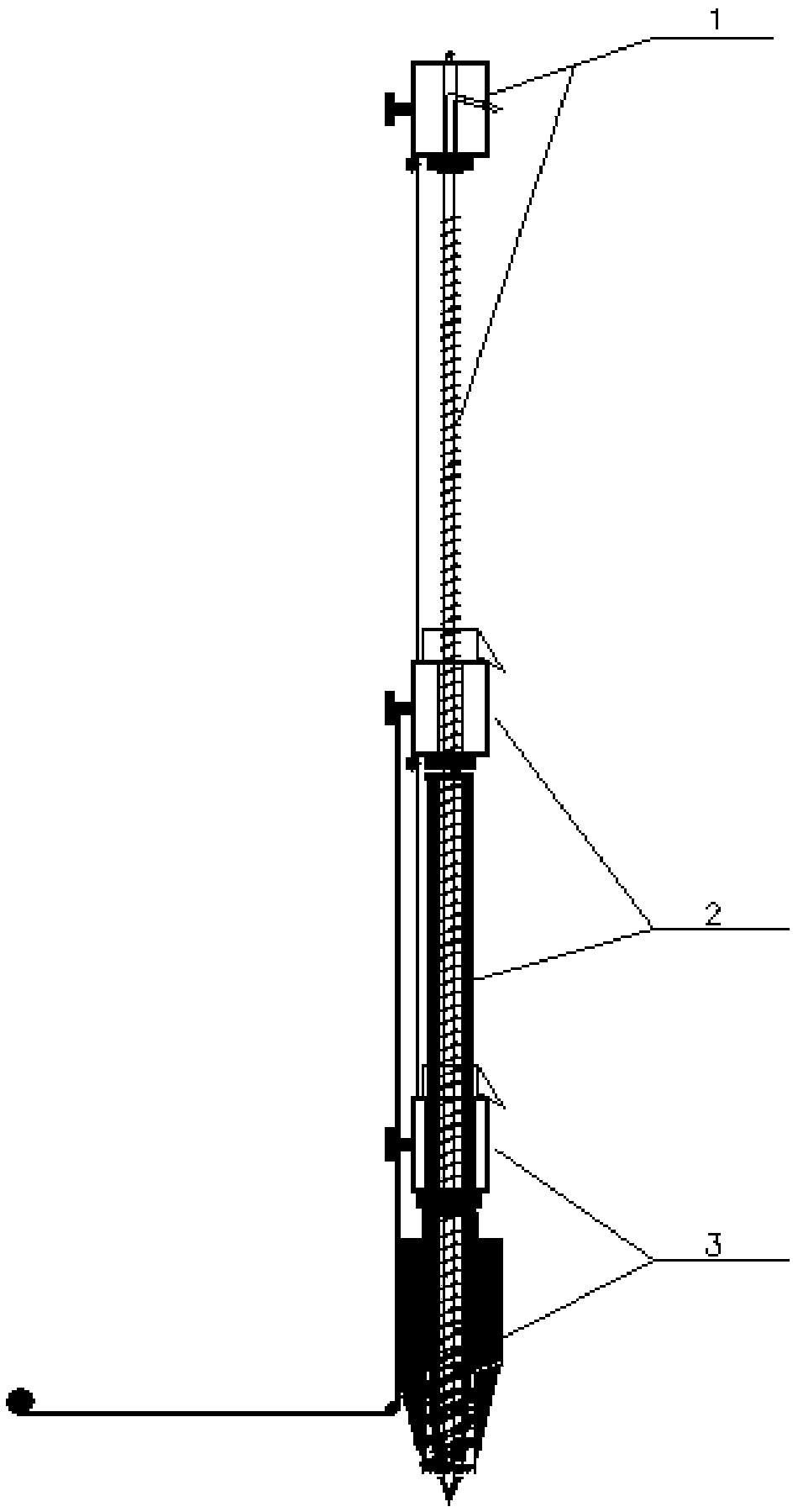

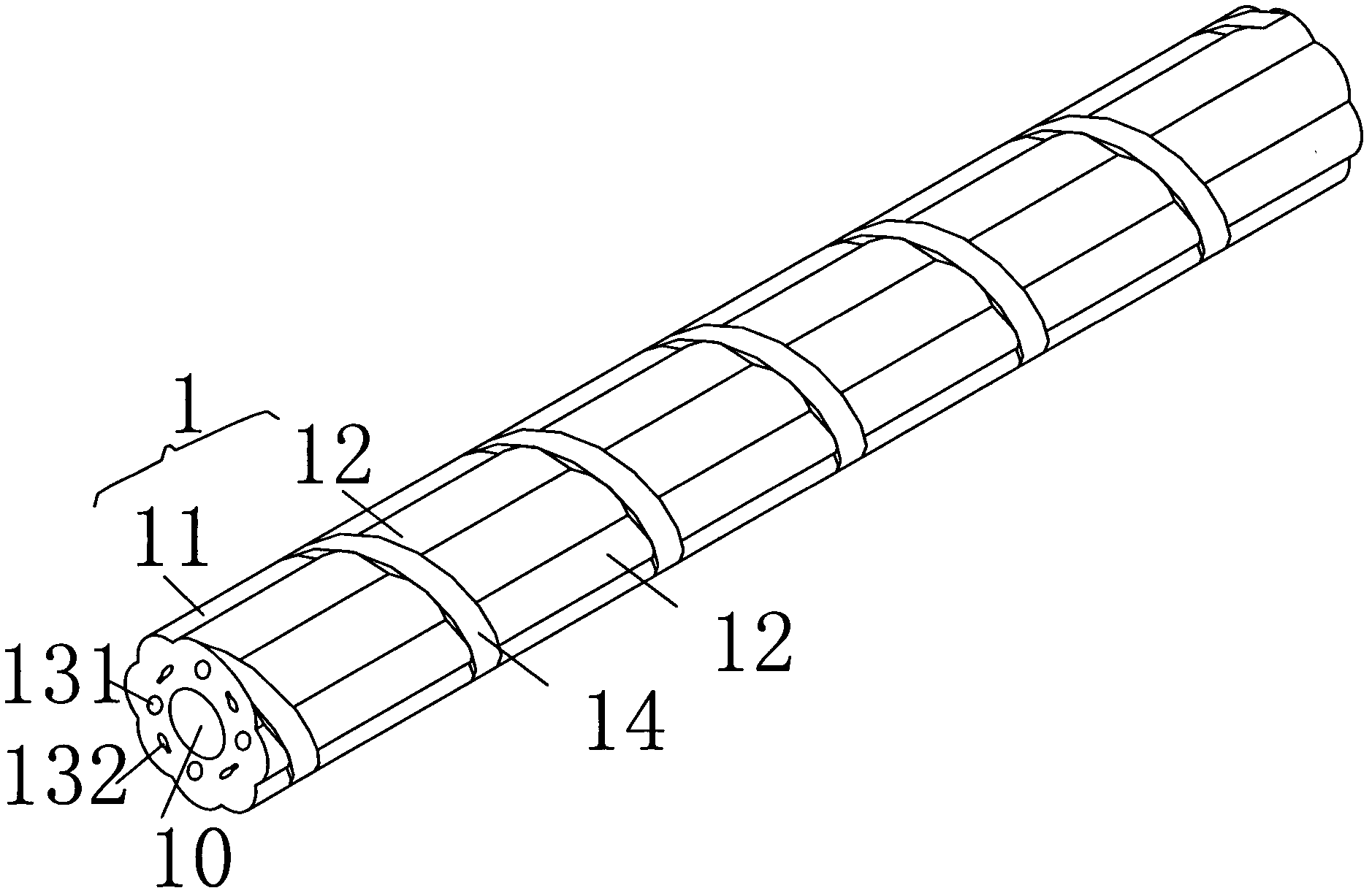

Multi-power compound drilling tool, production method thereof and pile

PendingCN109098655AHigh degree of automationImprove ergonomicsDrilling rodsDrilling casingsComposite functionPressure grouting

The invention relates to the technical field of civil engineering, in particular to a multi-power compound drilling tool, a production method thereof and a pile. The multi-power compound drilling toolcomprises a lower power drilling tool body, a middle power drilling tool body and an upper power drilling tool body which sleeve a same shaft sequentially, each of the three power drilling tool bodies is equipped with a power mechanism, and at least one of the three power drilling tool bodies comprises a drilling tool main body integrating soil squeezing and removing functions. The multi-power compound drilling tool has the advantages that when the multi-power compound drilling tool is used for construction, every drilling tool body is converted into active driving from traditional linkage tosqueeze and remove soil simultaneously and complete drilling and pressure grouting of the concrete pile once, and accordingly the automation degree is high and the work efficiency is improved; the single pile is provided with a variable-diameter pile body and formed according to a reasonable construction method, thereby being higher in bearing capacity and lower in cost; the construction period is shortened.

Owner:李广信

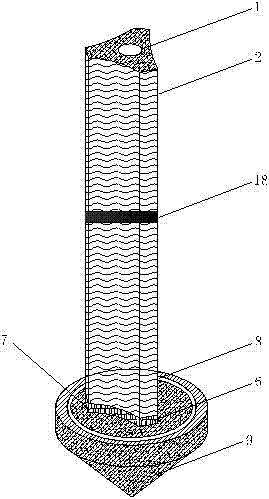

Covering type energy pile buried pipe heat exchanger structure

PendingCN114383331AReduce lossesSufficient heat exchangeCollector components/accessoriesLighting and heating apparatusStructural engineeringMechanics

The invention discloses a covering type energy pile buried pipe heat exchanger structure which comprises a concrete pile body and a pipeline system, and the pipeline system comprises a water inlet pipe arranged in the concrete pile body and a plurality of outer circular pipes fixed to the periphery of the concrete pile body in an embedded mode. A plurality of inner connecting pipes are communicated between the bottom of the water inlet pipe and the outer circular pipe at the lowermost end of the concrete pile body, a spiral heat exchange pipe is communicated between every two adjacent outer circular pipes, the spiral heat exchange pipes are embedded in the periphery of the concrete pile body, and the spiral directions of all the spiral heat exchange pipes are the same; the outer circular pipe arranged at the uppermost end is also communicated with a water outlet pipe; according to the structure, the heat exchange performance and heat exchange efficiency of the energy pile can be improved, and the pile body stress, the pile side friction force, the pile top settlement and the ultimate bearing capacity of the pile are improved by reducing the temperature change of the surface of the concrete pile body; and the spiral heat exchange pipe is arranged outside the concrete pile body, so that the flowing distance of cold (hot) water in the pipe is increased, and the heat exchange performance and the heat exchange efficiency of the energy pile are improved.

Owner:CHINA UNIV OF MINING & TECH

Pre-bored hole static blasting and manual pile digging auxiliary construction method for hard-rock stratum

InactiveCN111705815AEasy to determineGuaranteed diameter uniformityExcavationsBulkheads/pilesDrill holeBearing capacity

The invention is applicable to the technical field of manual pile digging construction, and provides a pre-bored hole static blasting and manual pile digging auxiliary construction method for a hard-rock stratum. A plurality of pre-bored holes are bored in the depth direction of a pile hole in the radial range of the pre-designed pile hole in the hard-rock stratum, expansion cement is injected into the pre-bored holes, the pre-bored holes are then injected with water and closed, and after the hard rock is expanded and cracked under the action of the expansion force of the expansion cement, thepile hole is excavated in the hard-rock stratum in the crack depth range to form a pile hole section. A pre-bored hole static blasting method is adopted, the influence on the environment is small, the blasting range is easy to determine, the diameter uniformity and the pile length of a pile body can be better guaranteed, improvement of the pile-side friction resistance and the single-pile bearingcapacity is facilitated, the single-pile bearing capacity and the overall settlement uniformity are ensured, and the construction cost is saved.

Owner:SANMING UNIV

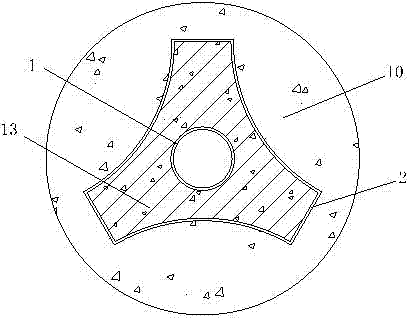

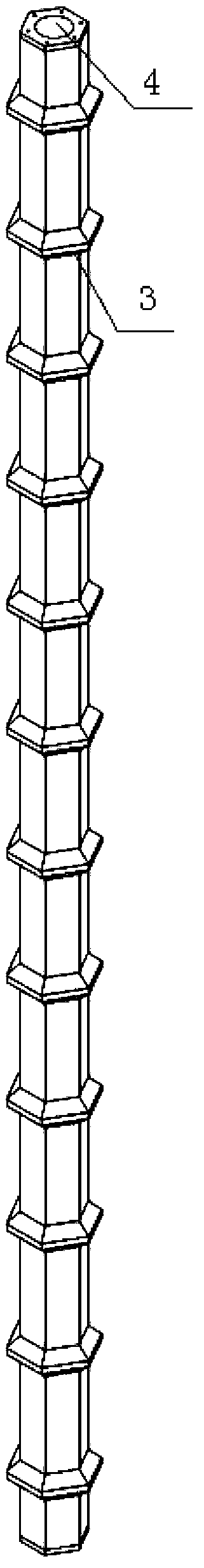

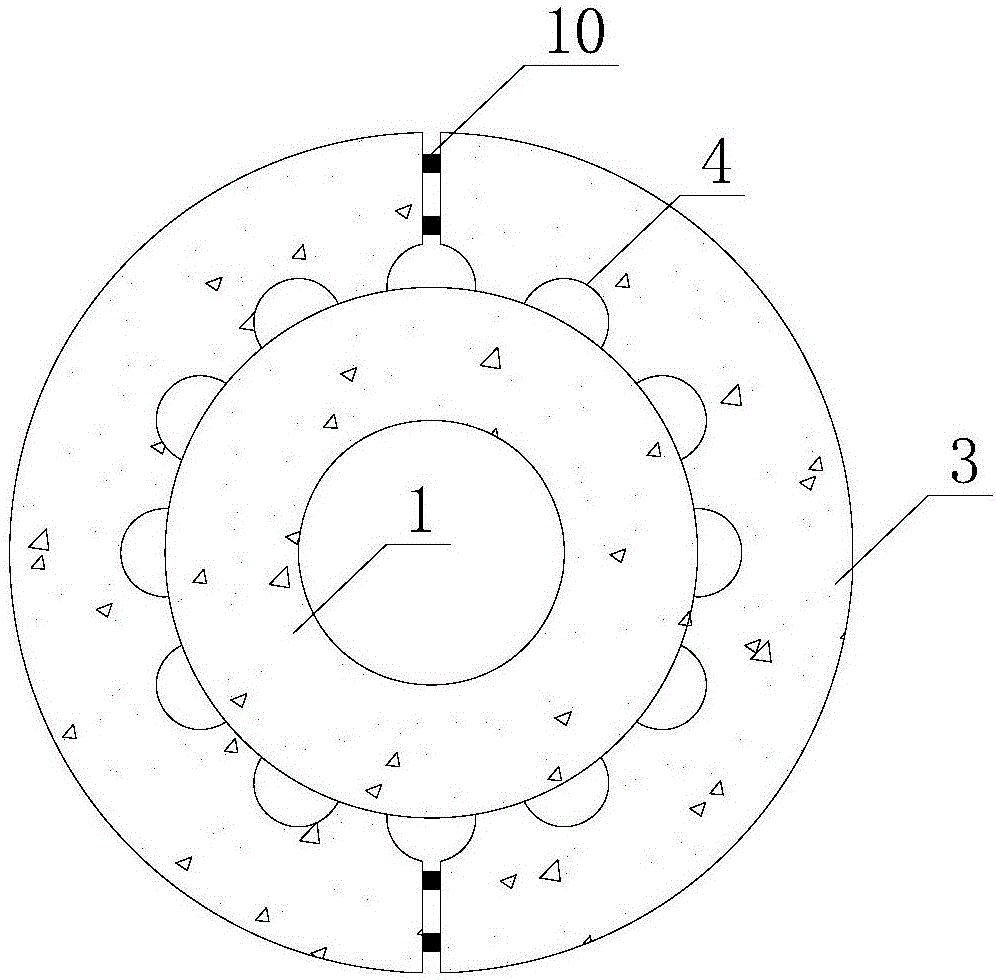

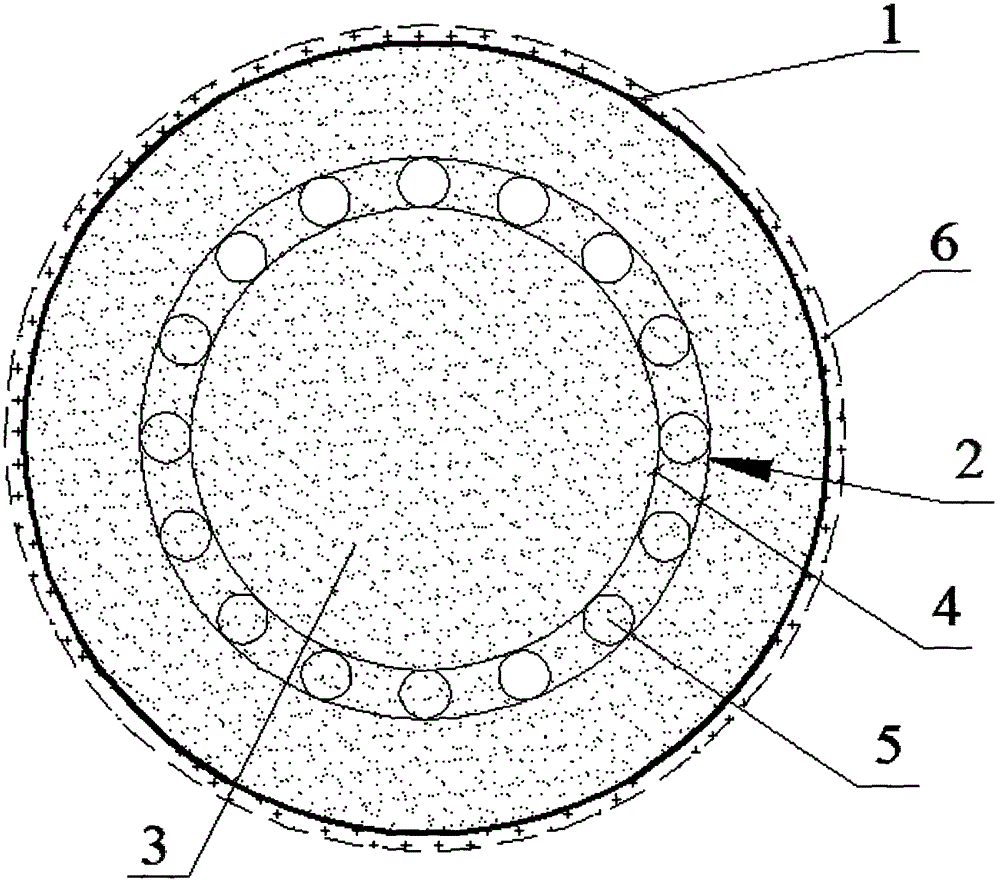

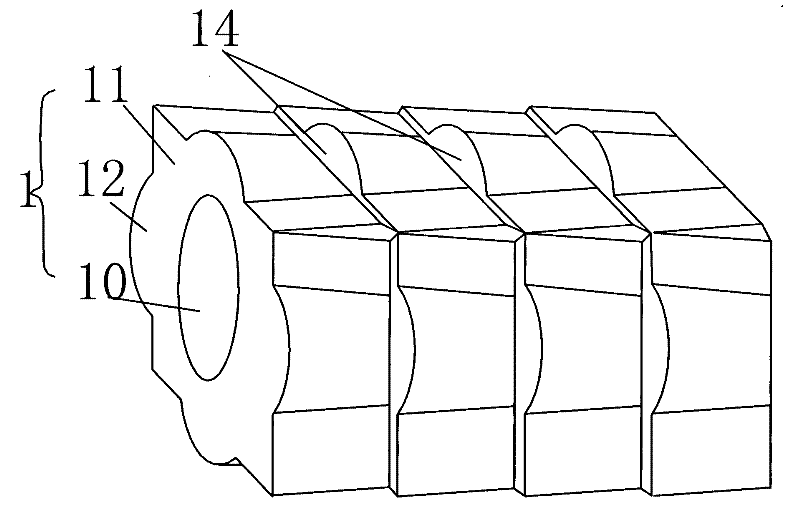

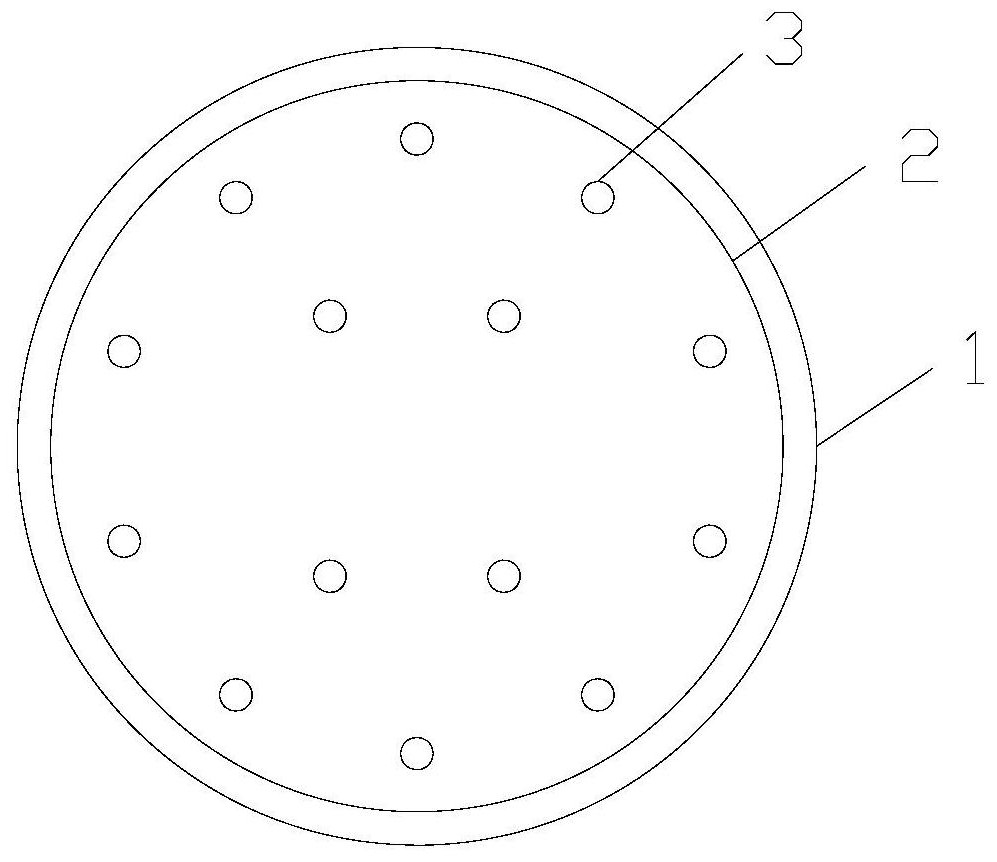

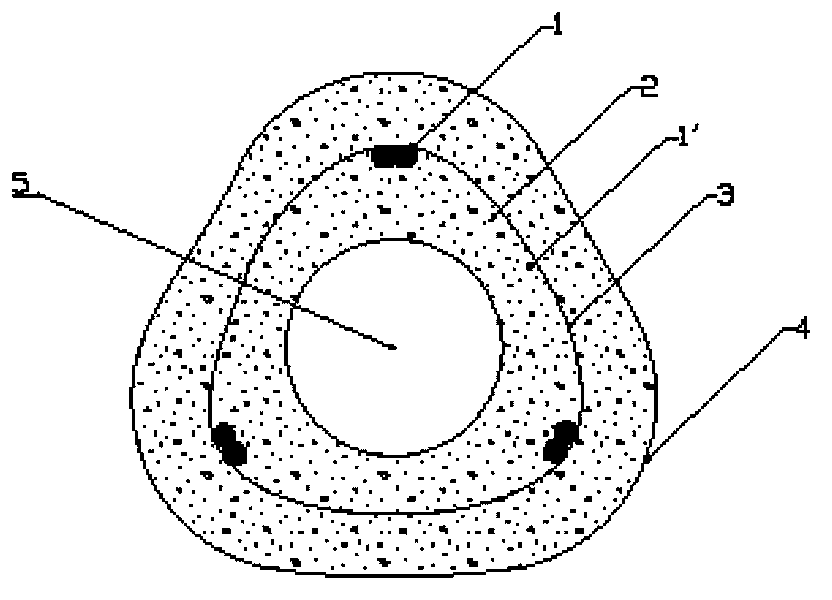

Partial prestressed concrete hollow triangular pile

InactiveCN103572753ALarge specific surface areaImprove pile side frictionBulkheads/pilesPre stressEngineering

The invention relates to a partial prestressed concrete hollow triangular pile; a central through hole penetrating through the whole partial prestressed concrete hollow triangular pile is formed in the longitudinal axis direction of the partial prestressed concrete hollow triangular pile; the cross section of the inner periphery of the partial prestressed concrete hollow triangular pile is round; the cross section of the outer periphery of the partial prestressed concrete hollow triangular pile is triangular; the geological dimensions of the cross sections of the inner periphery and the outer periphery of the partial prestressed concrete hollow triangular pile are same in the whole longitudinal axis direction; the partial prestressed concrete hollow triangular pile comprises main ribs extending along the length direction of a hollow square pile and hoop ribs spirally surrounding the main ribs; the main ribs comprise prestressed ribs and non-prestressed ribs; concrete protection layers are arranged inside and outside the hoop ribs; the outsides of the main ribs are connected by the hoop ribs through fixing, roll-welding or binding; the prestressed ribs and the non-prestressed ribs are all positioned at the angles and the edges of triangles defined by the hoop ribs.

Owner:SHANGHAI ZHONGJI PILE IND

Quincunx-shaped reinforced pipe pile and fabrication method thereof

InactiveCN102418338AImprove the shape of the outer surfaceImprove pile side frictionShaping reinforcementsBulkheads/pilesQuincunxEngineering

The invention discloses a quincunx-shaped reinforced pipe pile, which at least comprises a pile body and is characterized in that the cross section of the pile body is quincunx-shaped. The invention additionally discloses a fabrication method of the quincunx-shaped reinforced pipe pile. Since the design of a semicircular quincunx-shaped structure is adopted, the exterior shape of the pipe pile is improved, the friction coefficient of the exterior surface is increased and the pile side friction of the pipe pile is improved. Moreover, also since the design of the semicircular quincunx-shaped structure is adopted, the end area of the pipe pile is increased and the pile end bearing capacity of the pipe pile is improved. Therefore, the quincunx-shaped reinforced pipe pile disclosed by the invention has the advantages of a circular pipe and a square pipe, overcomes the inherent defects of the circular pipe and the square pipe at the same time, has higher anti-pressing friction, higher anti-shearing performance and a higher anti-pulling ability, and makes an obvious progress and a beneficial effect.

Owner:SHANGHAI AOMI PHARMA EQUIP

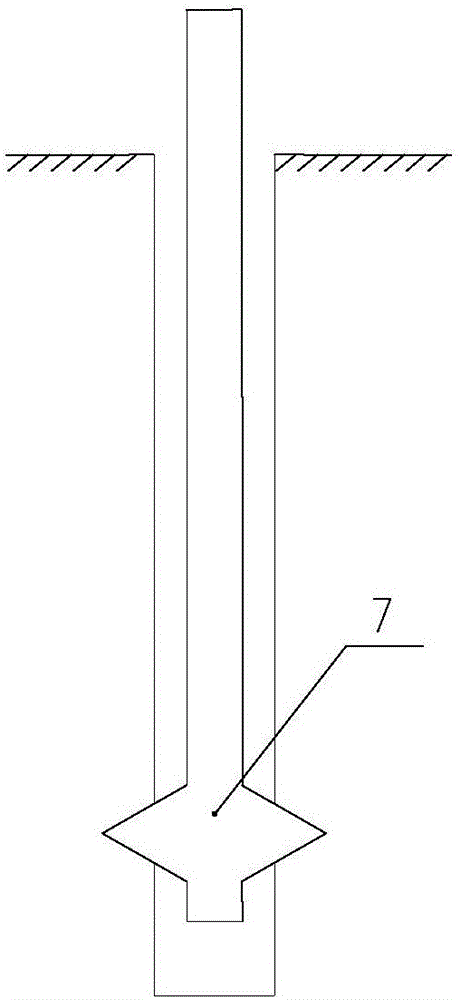

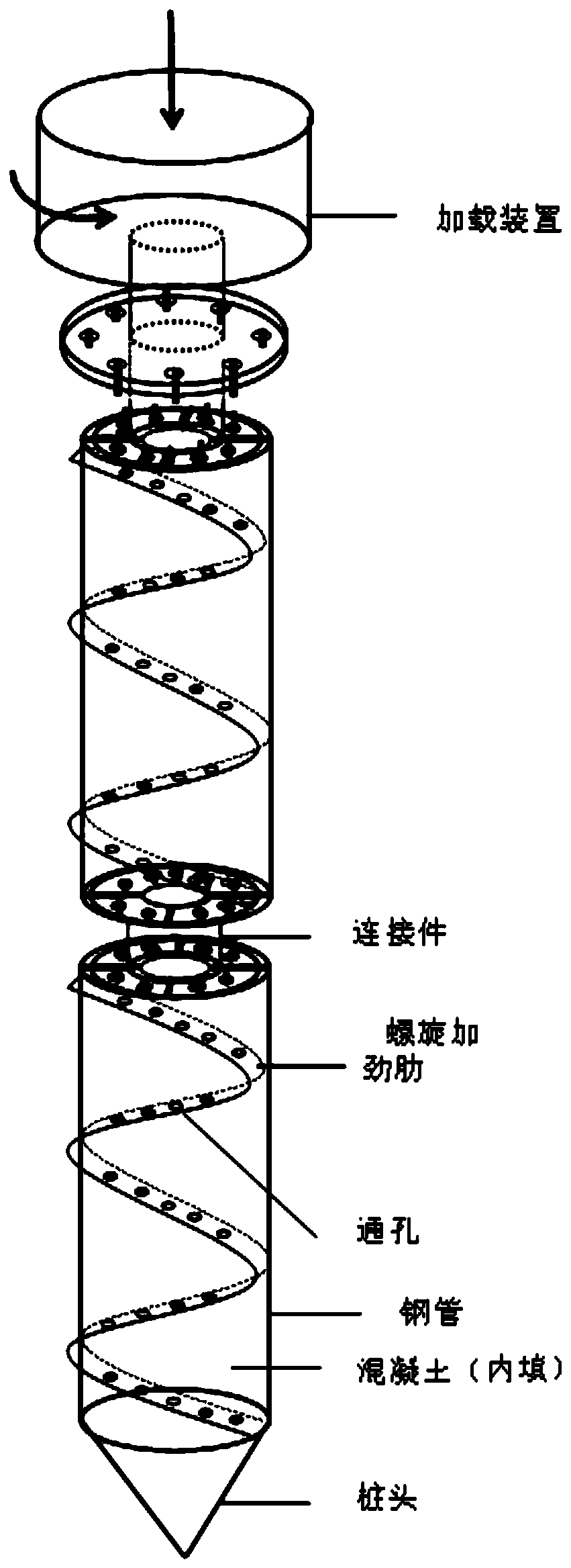

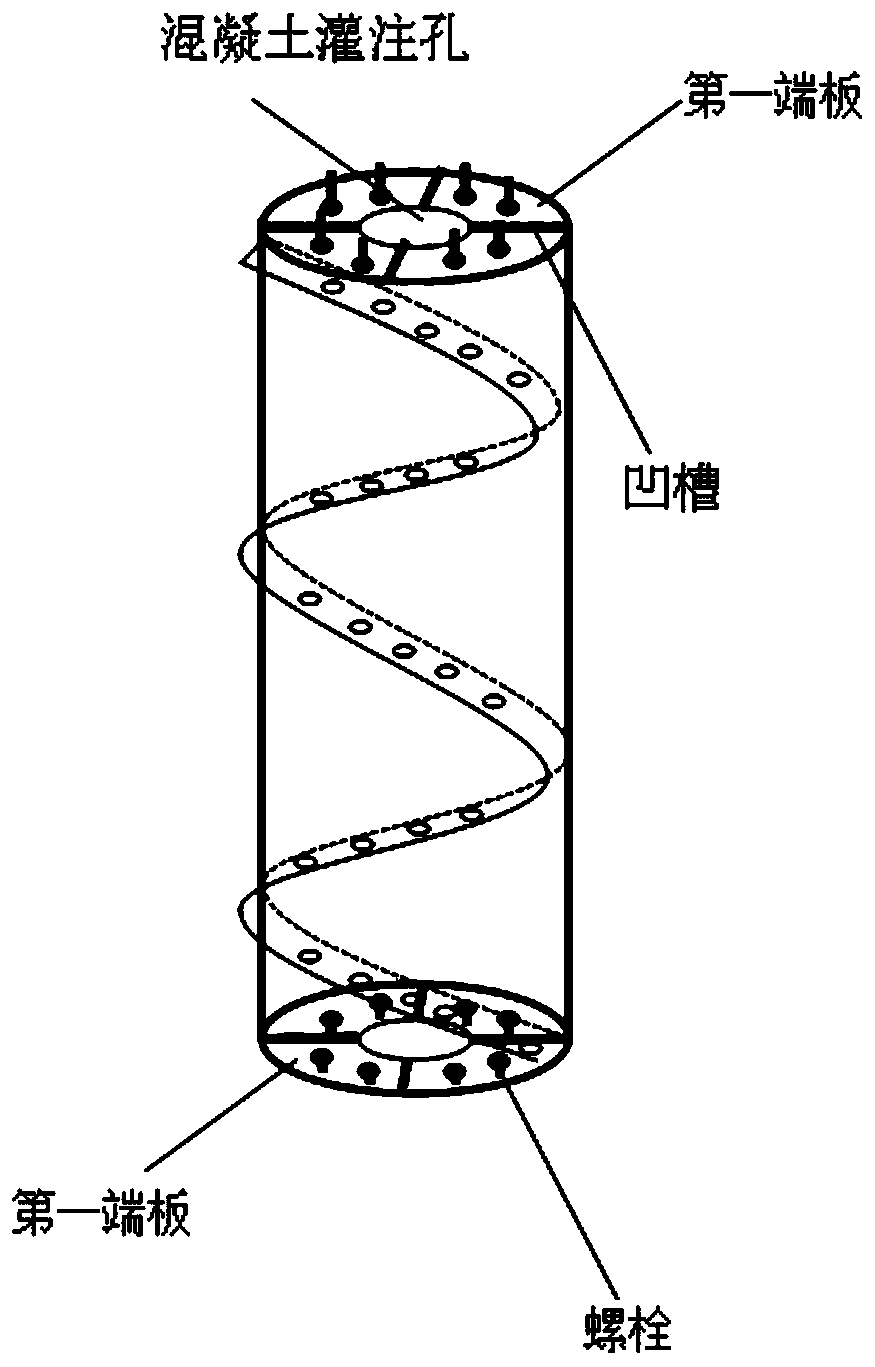

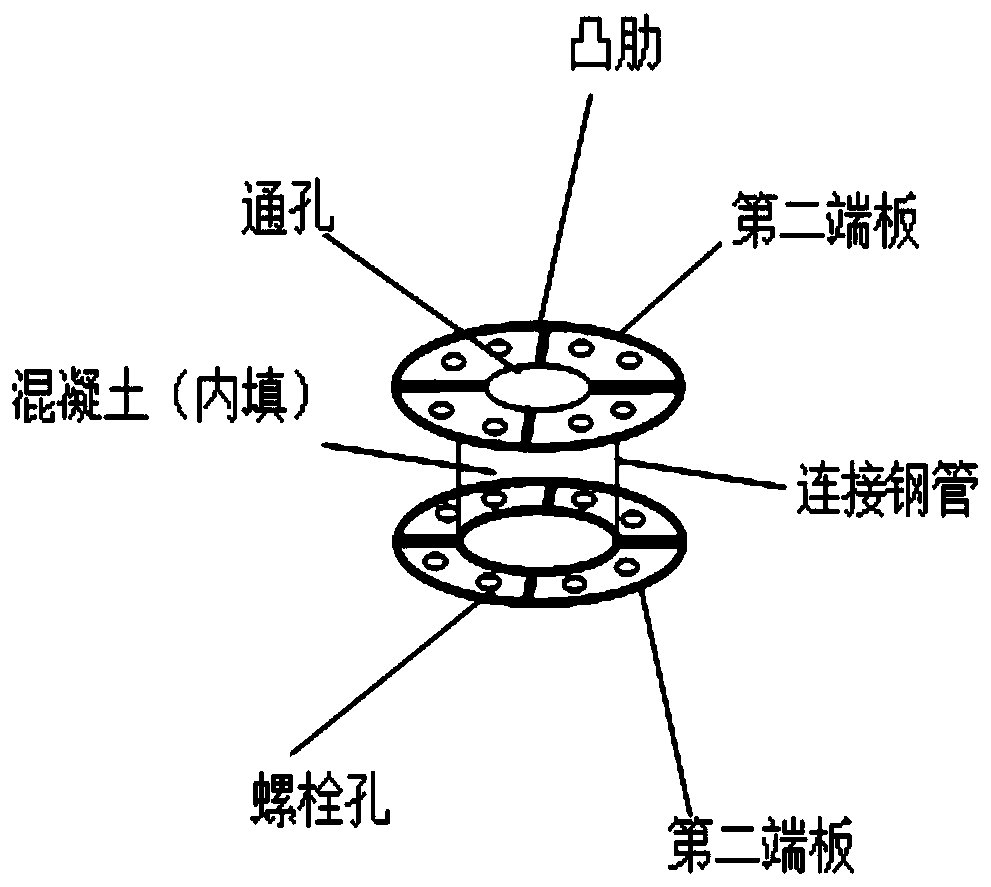

Concrete filled steel pipe pile and manufacturing method thereof

ActiveCN110091431AImprove pile side frictionFast constructionCeramic shaping apparatusBulkheads/pilesSteel tubeBearing capacity

The invention discloses a concrete filled steel pipe pile. The concrete filled steel pipe pile comprises multiple steel tubes. Each steel tube is filled with concrete. The heads and ends of the multiple steel tubes are connected through connecting pieces to form a pile body. The top end of the pile body is connected with a loading device through connecting pieces. The loading device drives the pile body to be pressed into a soil body. The bottom end of the pile body is fixedly connected with a tapered pile head to fix the pile body. The outer wall of each steel tube is fixedly connected a spiral stiffening rib from one end to the other end in the circumferential direction. The spiral stiffening ribs on the pile body formed by the multiple steel tubes are connected in the same rotating direction. According to the other scheme, the invention provides a manufacturing method of the concrete filled steel pipe pile. Through the concrete filled steel pipe pile and the manufacturing method thereof, the problems that the bearing capacity of a pile body is not enough due to small pipe side friction of an existing concrete filled steel pipe pile, the traditional welding connection speed is low, traditional welding connection is easily affected by the weather and the welding connection quality is not easy to ensure are solved.

Owner:XIAN UNIV OF TECH

Square-prism-reinforced pipe pile and machining method thereof

InactiveCN102337740AImprove the shape of the outer surfaceImprove pile side frictionShaping reinforcementsBulkheads/pilesPrismFriction force

The invention discloses a square-prism-reinforced pipe pile, which at least comprises a square pile body. A prismatic outer surface is arranged on the outer surface at each side of the square pile body, and a reinforcing rib is also arranged on the outer surface of the square pile body. Furthermore, the invention discloses a machining method of the square-prism-reinforced pipe pile. Due to the structural designs of the prismatic outer surface and the reinforcing rib, the square-prism-reinforced pipe pile provided by the invention is improved in outer surface shape, increased in friction coefficient of the outer surface and enhanced in pile-side friction force. Simultaneously, due to the structural designs of the prismatic outer surface and the reinforcing rib, the square-prism-reinforced pipe pile is also increased in end area and improved in pile-end bearing capacity. Therefore, the square-prism-reinforced pipe pile provided by the invention has the advantages of a round pile and a square pile, simultaneously also overcomes the respective inherent disadvantages of the round pile and the square pile and is higher in pressure-resistant friction force, higher in shear performance, higher in pullout resistance, and obvious in improvement and beneficial effect.

Owner:SHANGHAI AOMI PHARMA EQUIP

Variable diameter plastic sleeve mixed pile for reinforcing thick-covering and deep-burying soft soil layer and piling method

The invention discloses a variable diameter plastic sleeve mixed pile for reinforcing a thick-covering and deep-burying soft soil layer and a piling reinforcing method. The upper part of a mixed pile body in a thick covering is filled with a scattered material by a small-diameter sleeve to form granular piles of an upright draining body, the lower part of the pile body in the soft soil layer is filled with the scattered material by a large-diameter sleeve and grouted to form a rigid pile with a grouted scattered material pile body, the large sleeve and the small sleeve are connected by a variable diameter joint, the lower part of the large sleeve is connected with a pile tip, the wall of the sleeve is provided with an opening hole and wrapped with geotextile, and a grout scattering area is formed at the periphery of the pile body. The pile-forming reinforcing method comprises: measuring the depth of the soft soil layer at the covering layer, preparing the lengths of the large sleeve and the small sleeve, connecting the lower part of the large sleeve with the pile tip, beating the large sleeve to the pile depth by a beating machine, leaving the sleeve and the pile tip in the foundation, filling the scattered material in the large sleeve, then grouting the large sleeve to form a fixed pile body, and forming the grout scattering area or a gourd pile body at the periphery of the pile. The mixed pile has a reasonable structure, is economic and practical, effectively improves the performance of the soil around the pile, and improves the bearing performance of the pile body.

Owner:HOHAI UNIV

Pile mold and construction method of a cast-in-place X-shaped large-diameter hollow directional steel fiber concrete pile

ActiveCN104790390BOvercome the shortcomings of not being able to exert due shear resistanceIncrease girthBulkheads/pilesTube drawingDie casting

The invention discloses a pile mould of cast-in-place X-shaped large-diameter hollow orientated steel fiber reinforced concrete and a construction method. The pile mould is composed of an X-shaped pile mould outer tube and a round pile mould inner tube. A DC coil is wound in a spiral groove in the outer side of the round pile mould inner tube, and the positive pole and the negative pole of the coil are connected with a DC stabilized power supply through two linear grooves. The construction method comprises the following steps that a pile machine is on place, and a valve pile shoe is closed; the pile mould is submerged; steel fiber reinforced concrete is poured; the DC power supply is connected, and an axial magnetic field along a pile is generated in a cavity structure of the pile mould; vibration tube drawing is conducted; the pile mould is pulled out of the ground, and a complete pile body is formed. According to the pile mould of the cast-in-place X-shaped large-diameter hollow orientated steel fiber reinforced concrete and the construction method, the electromagnetic induction principle is ingeniously utilized to enable steel fibers to form an orientated distribution state that the steel fibers and the pile are distributed in parallel in the axial direction, so the horizontal bearing force of the pile is remarkably improved, the construction process is simple, the operability is high, and the application range of the construction method is greatly enlarged.

Owner:HOHAI UNIV

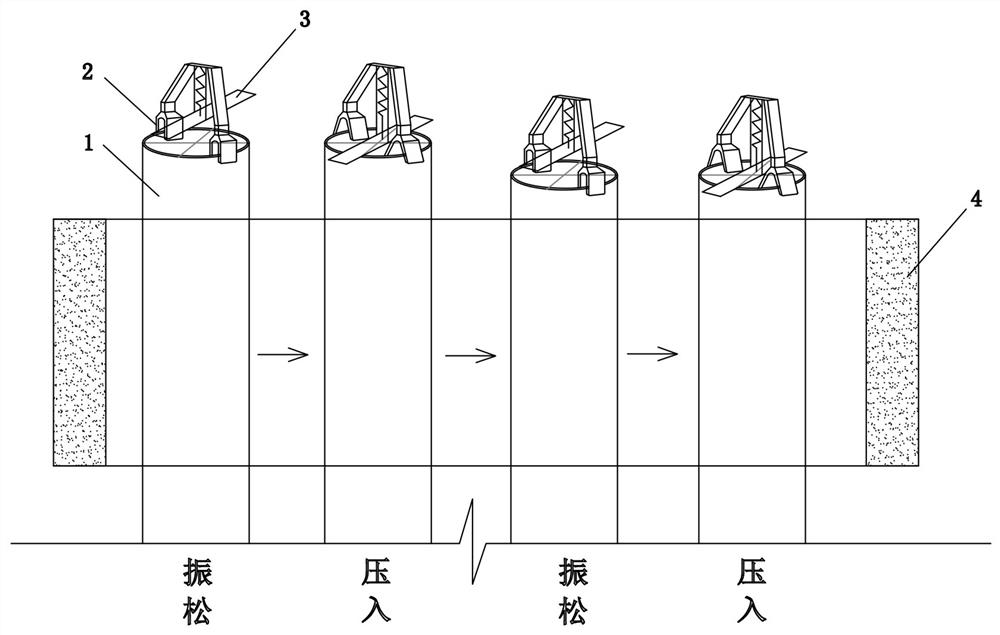

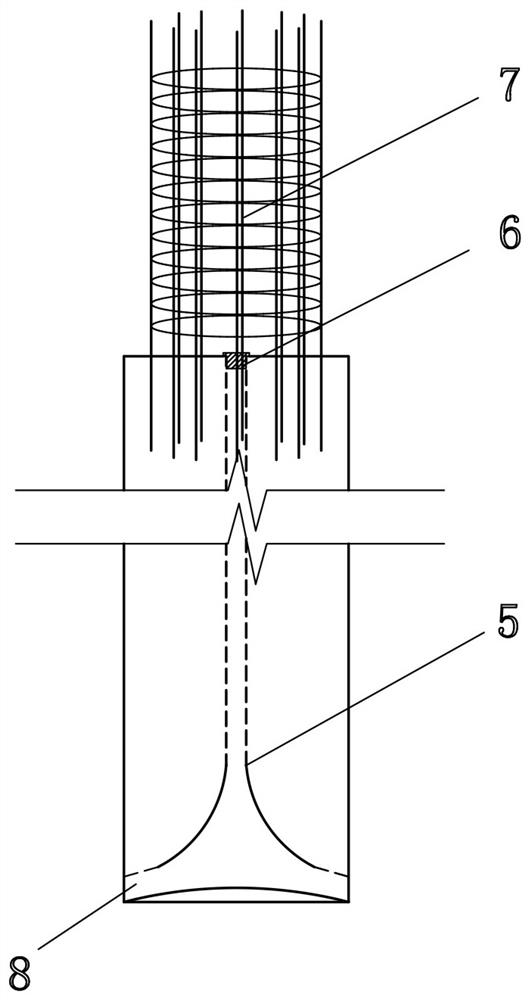

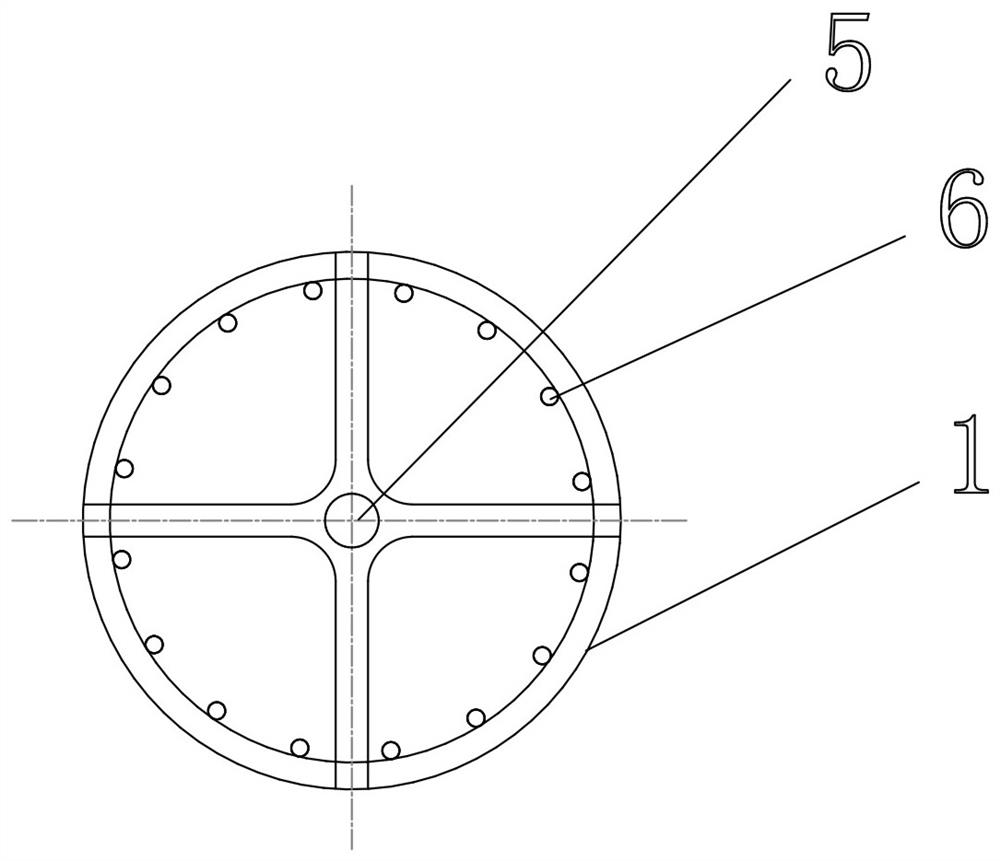

A construction method for hole forming and side wall grouting of cast-in-situ piles for coral sand foundation

The invention discloses a cast-in-place pile hole forming and side wall grouting construction method for a coral sand foundation. The method is characterized in that construction of hole forming of acast-in-place pile casing pipe is carried out by adopting a vibration and static pressure alternate operation method, pile side grouting is carried out while the steel casing pipe is pulled out, and specific construction comprises the steps of hole forming, hanging and placing a reinforcement cage, grouting the casing pipe, secondary hole cleaning, cast-in-place pile pouring, pulling out the steelcasing pipe, side wall grouting and the like. Compared with the prior art, the method has the advantages that the pile forming reliability and the pile foundation bearing capacity are high, the soilbody disturbance is effectively reduced, the particle crushing degree is reduced, the pile side friction resistance is improved, the problems of hole forming difficulty and low side resistance of thecoral sand foundation are well solved, the steel casing pipe can be recycled, the engineering cost is greatly reduced, and the method is green and environment-friendly, and has good environmental protection benefits and popularization prospects.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Settlement prevention method for bridge pile foundation

InactiveCN113653086AReduce additional stressImprove radial support and torsion resistanceFoundation engineeringBearing capacityCivil engineering

Owner:薛人芳

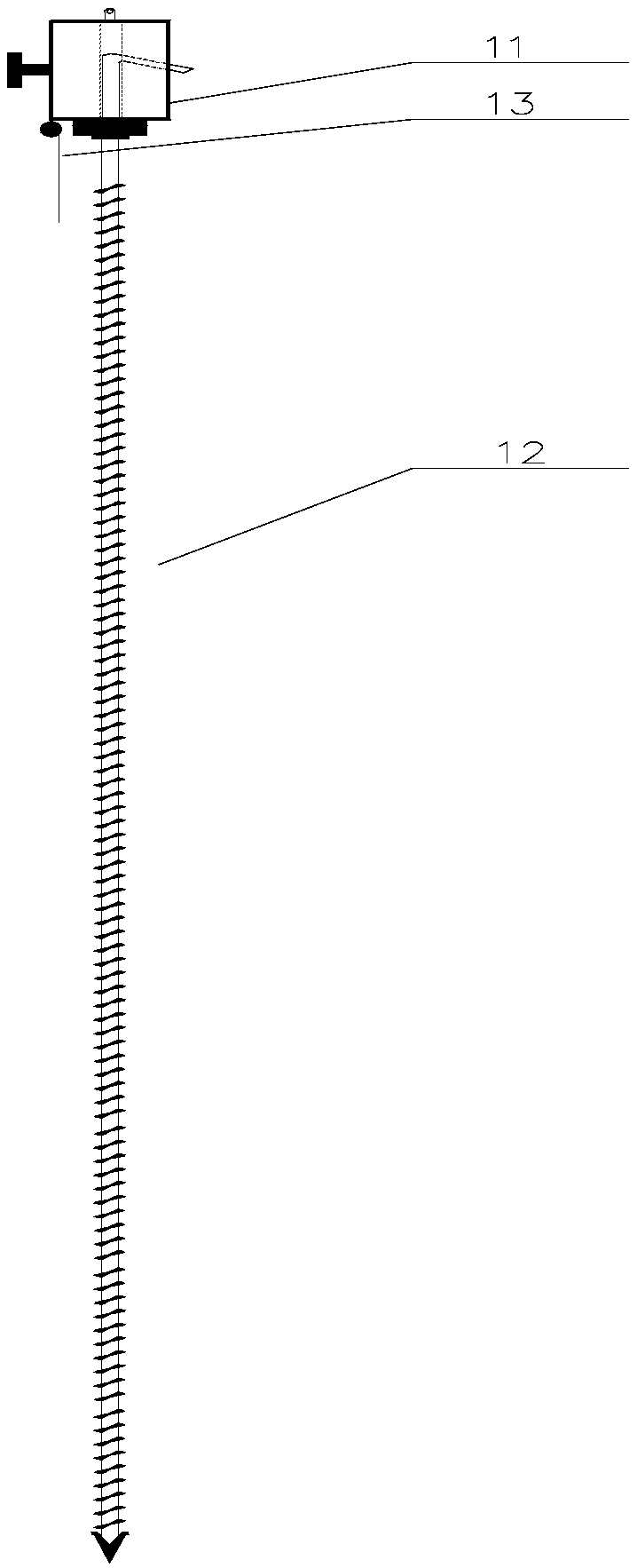

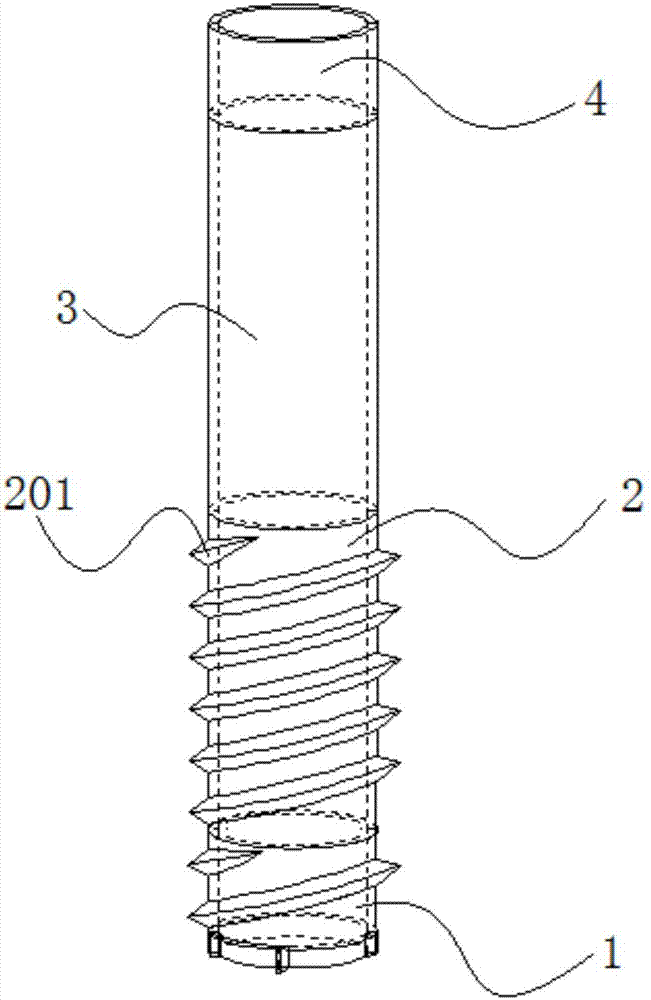

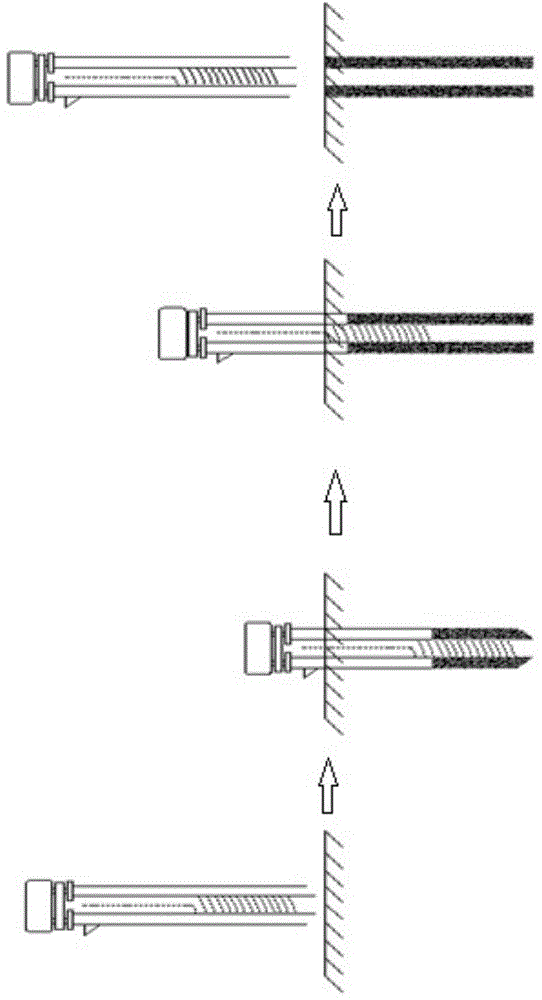

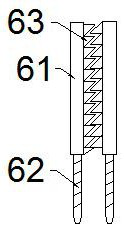

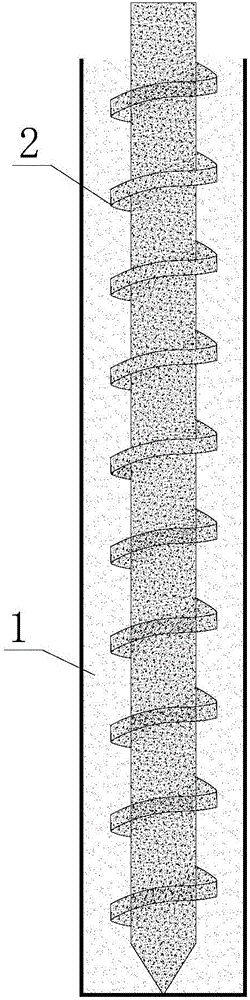

Cemented soil composite pre-fabricated screwed pile and pile forming method thereof

InactiveCN107178080AImprove pile side frictionEnhanced confinementBulkheads/pilesEngineeringDrilling machines

The invention provides a cement-soil composite prefabricated threaded pile and a pile forming method thereof. The cement-soil composite prefabricated threaded pile includes: a cement-soil pile and a prefabricated threaded pile arranged in the cement-soil pile; the prefabricated threaded pile is inserted into the cement-soil pile by a drilling machine after the cement-soil pile is piled. inside the pile. The method for forming a cement-soil composite prefabricated threaded pile includes the following steps: step A: first forming a cement-soil pile; step B: using a drilling rig to place the prefabricated threaded pile into the cement-soil pile to form a cement-soil composite prefabricated threaded pile. The present invention enhances the side-limiting effect of the soil around the prefabricated threaded pile and the cement-soil, increases the pile side frictional resistance of the prefabricated threaded pile, thereby forming a cement-soil composite prefabricated threaded pile with higher vertical compression resistance, pull-out resistance and horizontal bearing capacity .

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com