Multi-power compound drilling tool, production method thereof and pile

A technology of power drilling tools and compound drilling, applied in drilling equipment and methods, drilling equipment, drill pipes, etc., can solve the problems of low single pile bearing capacity, low degree of automation, and single construction method, and achieve single pile bearing capacity The effect of improving, improving work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

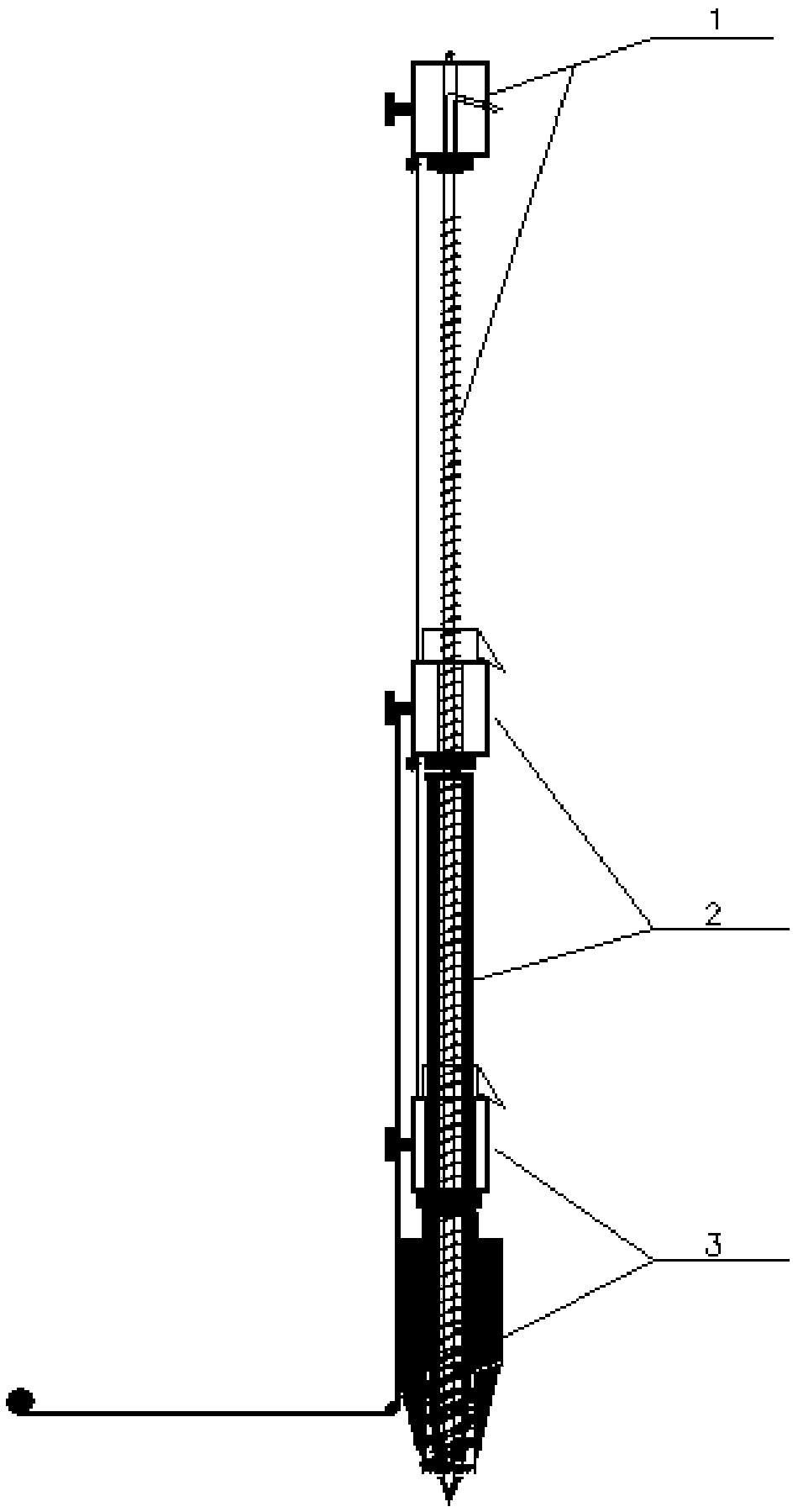

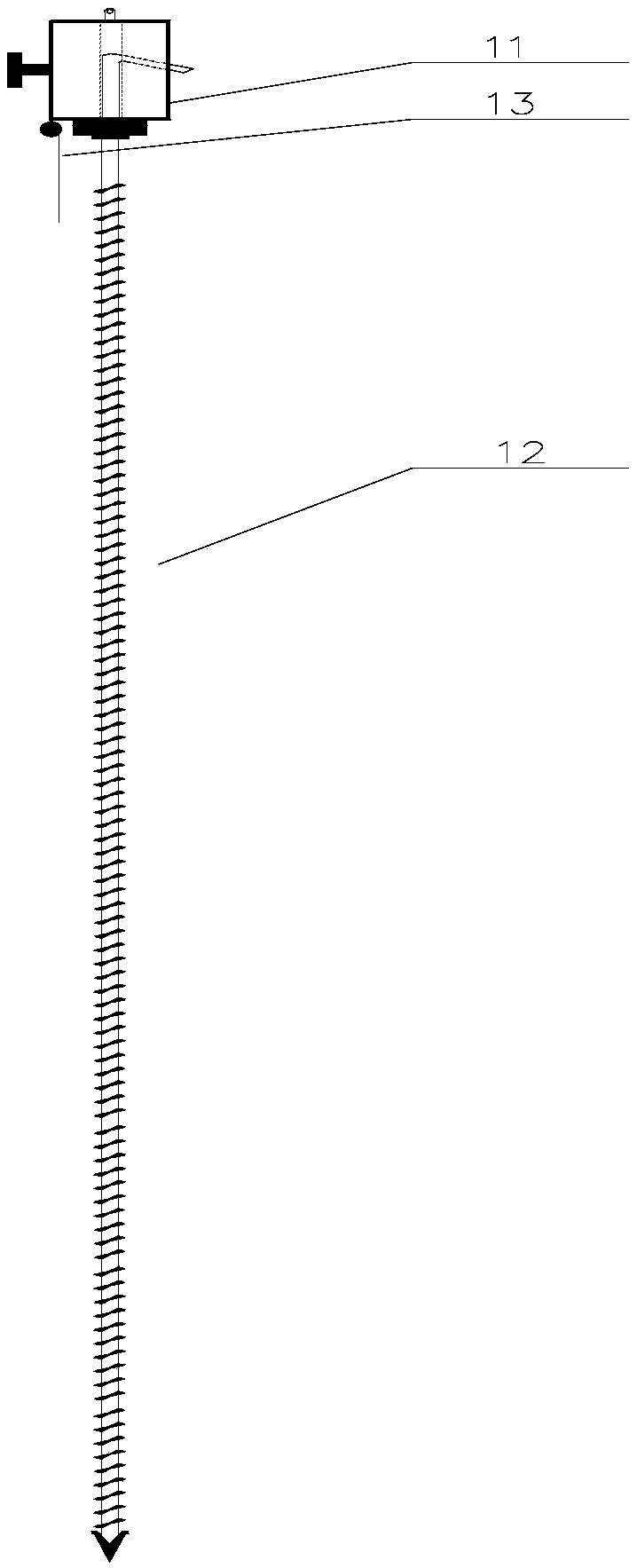

[0043] This embodiment provides a multi-power composite drilling tool, which includes: a lower power drilling tool, a middle power drilling tool and an upper power drilling tool coaxially set in sequence; the lower power drilling tool, the middle power drilling tool and the upper power drilling tool The drilling tools are respectively equipped with a power mechanism, and the power mechanism can independently drive the corresponding drilling tools to rotate; the lower power drilling tool, the middle power drilling tool and the upper power drilling tool are constructed according to the design depth of the pile body and the soil softness in the ground. According to the degree of hardness and distribution, adopt the appropriate construction method and match the corresponding drilling tools for combination.

[0044] If the ground soil within the depth of the pile body is medium-hard ground soil (or most of it is medium-hard ground soil), the combined drilling tools are soil-discharg...

Embodiment 2

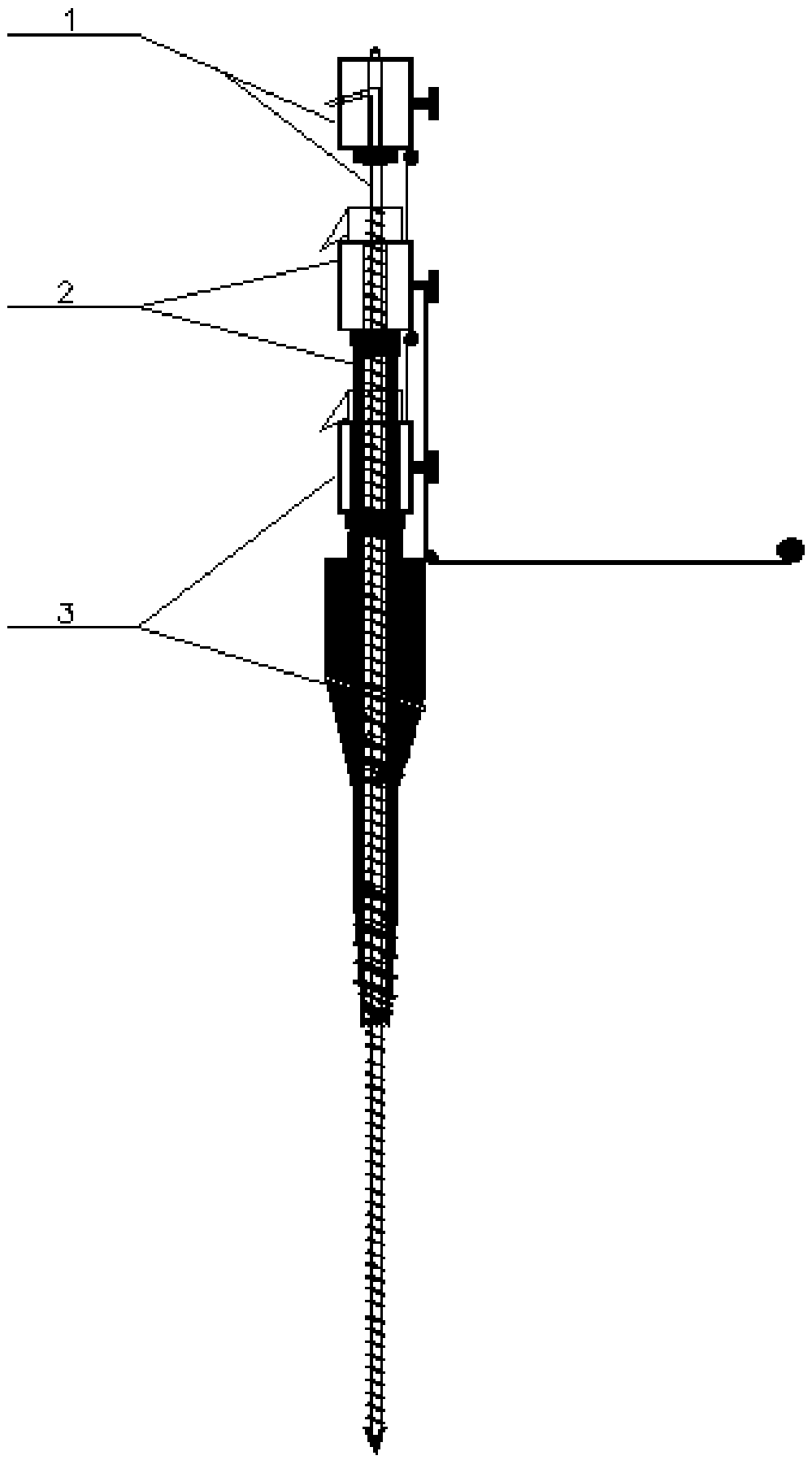

[0075] combine Figure 11 to Figure 26 As shown, the second embodiment provides a method for preparing the pile 4 according to the multi-power composite drilling tool, which includes: according to the requirements of the stratum for the construction method, the upper power drilling tool 1 and the middle power drilling tool 2 and the lower power drilling tool 3 successively drill to their respective design depths; start the concrete pump 5, start to press the concrete, and while pressing the concrete, successively lift the upper power drilling tool 1, the middle power drilling tool 2 and the lower power drilling tool 3, Until the bottom ends of each power drilling tool are flush in turn, the elevation of the hole is raised synchronously, and the concrete is also poured into piles to the design elevation at the same time.

[0076] In the treatment of soft foundations such as building structures or railways and highways, the foundation soil that needs to be treated can be general...

Embodiment 3

[0108] combine Figure 27 to Figure 36 As shown, this embodiment also provides a type pile 4 prepared according to the multi-power composite drilling tool, which includes: a main pile body 41; the main body pile body 41 is provided with at least two inverted conical stepped bodies 42 ; The range of the included angle between the extension line of the inclined plane at the variable diameter of the inverted tapered stepped body 42 and the central axis of the main pile body 41 is: 5°-90°. For example: the reduced diameter of the inverted cone stepped body 42 is located at the shallow part of the pile body, and the included angle between the extension line of the inclined plane where the reduced diameter of the inverted cone stepped body 42 is located and the central axis of the main pile body 41 The range value should be 30°~45°. Another example: the reduced diameter of the inverted tapered step-shaped body 42 is located in the deep part of the pile body, and the included angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com