Partial prestressed concrete bamboo joint pile

A technology of bamboo piles and concrete, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problem of not overcoming the bending resistance, bending resistance, shear resistance, and bearing specifications of the pile body. Get overall strengthening and other issues to achieve the effects of increasing rescue time, enhancing mechanical properties, and good deformation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

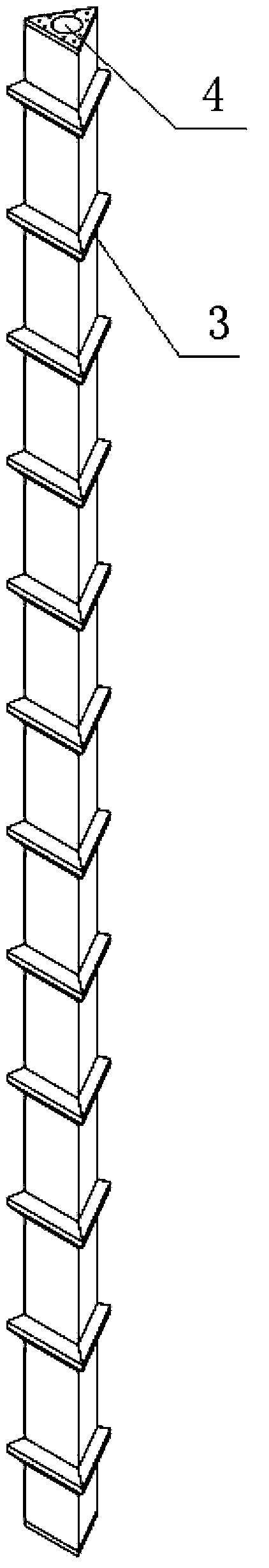

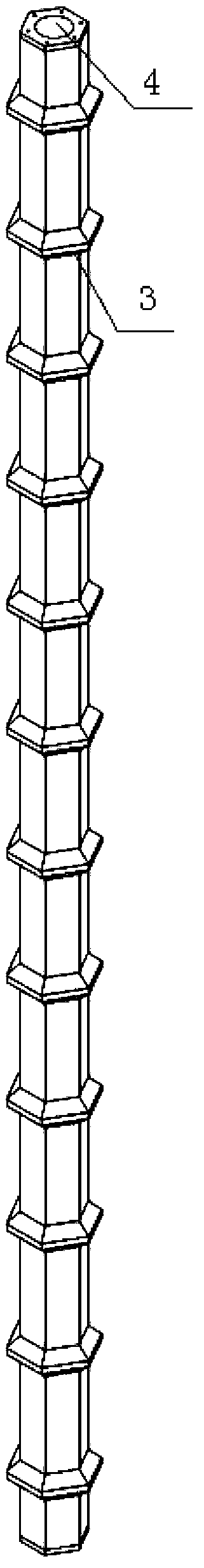

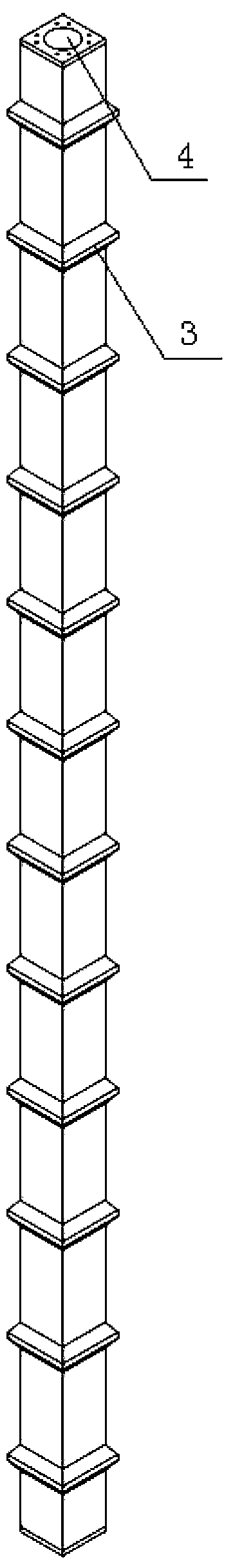

[0028] figure 1 It is one of the three-dimensional views of the present invention, figure 2 It is the second perspective view of the present invention, image 3 It is the third perspective view of the present invention, Figure 4 for the invention figure 1 sectional view of Figure 5 for the invention figure 2 sectional view of Image 6 for the invention image 3 cross-sectional view. Such as Figure 1~6 As shown: the longitudinal axis of the partially prestressed concrete bamboo pile is provided with a central through hole 4 that runs through the entire partially prestressed concrete bamboo pile, and the inner peripheral cross section of the partially prestressed concrete bamboo pile is circular. The outer peripheral cross section of the partially prestressed concrete bamboo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com