PHC pipe pile construction method

A technology of PHC pipe piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve pipe pile side friction resistance and weakening of pile end resistance, uneven thickness of multi-layer silty clay, and soil squeezing effect Loss and other problems, to reduce the difficulty of penetration, increase the density and quantity of the skeleton, and increase the quantity and density of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

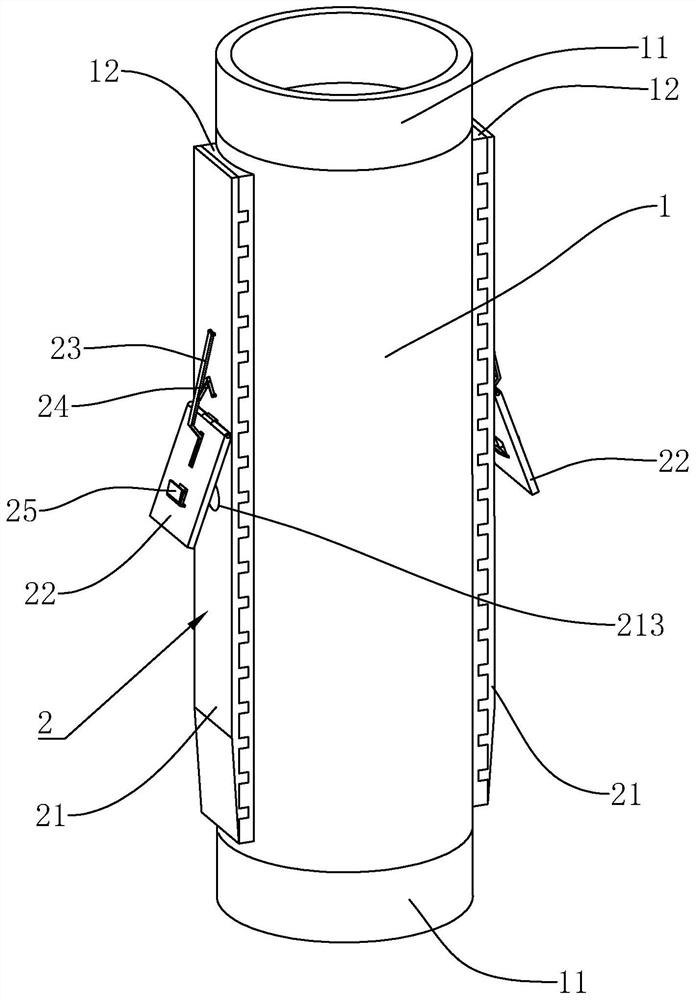

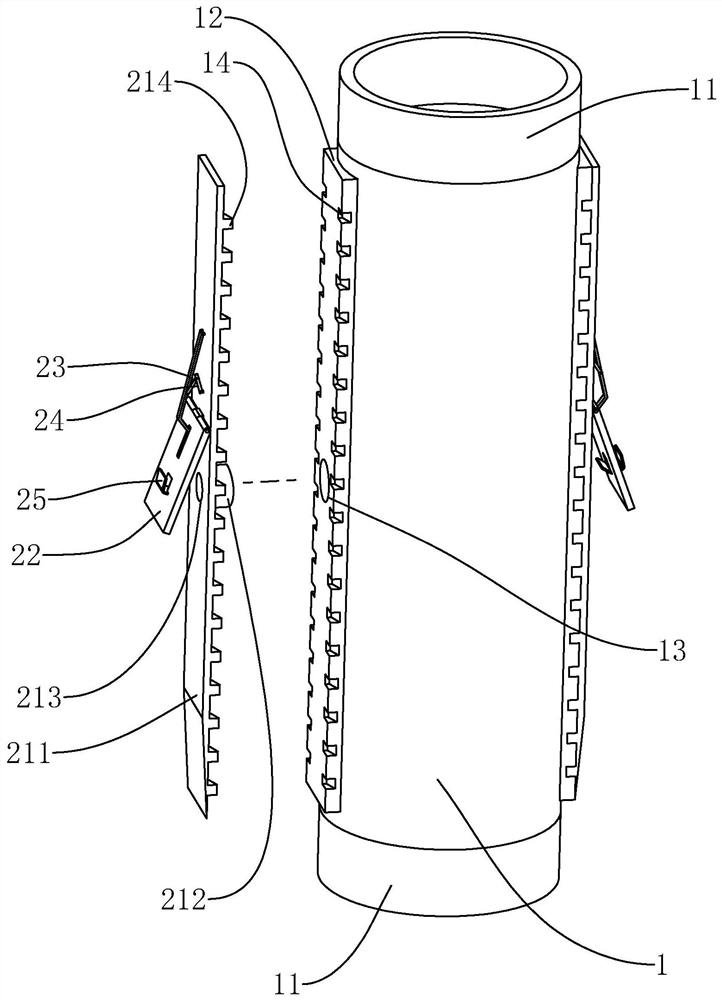

[0056] Embodiment 1: as figure 1 As shown, it is a PHC pipe pile structure disclosed by the present invention, which includes a pipe pile 1 and a metal skeleton assembly 2 installed on the pipe pile 1; wherein the upper and lower ends of the pipe pile 1 are provided with pile head caps 11 .

[0057] Such as figure 1 As shown, the outer peripheral surface of the pipe pile 1 is protrudingly configured with a plurality of plane platforms 12, the length direction of the plane platforms 12 is arranged along the axial direction of the pipe pile 1, and each plane platform 12 is evenly arranged along the circumference of the pipe pile 1; the plane platforms 12 A grout hole 13 connected to the inner cavity of the pipe pile 1 is opened through it.

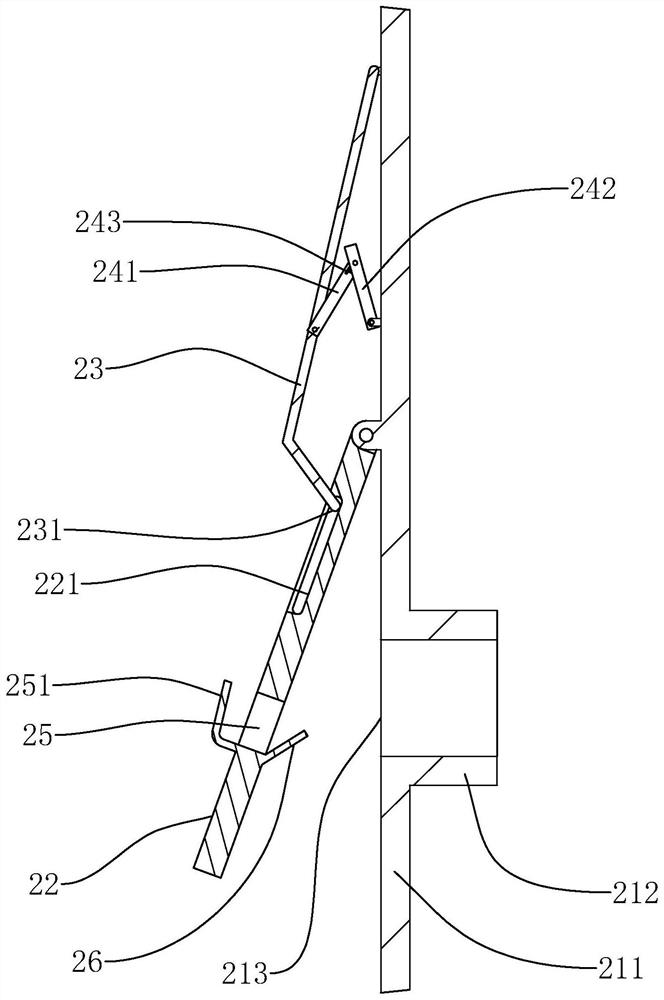

[0058] Such as figure 1 , figure 2 As shown, the skeleton assembly 2 includes a carrier body 21, a flap plate 22, a skeleton rod 23 and a linkage frame 24; the carrier body 21 includes a fixed plate 211 and a fixed sleeve 212, the fixed ...

Embodiment 2

[0066] Embodiment 2: The difference with Embodiment 1 is that, as Image 6 As shown, there are two flip plates 22, and the flip plates 22 are arranged symmetrically up and down along the through hole 213. The free end of flip plate 22 is positioned at the outside of top flip plate 22, and the outer side of the extension end 251 of the louver hole 25 of top flip plate 22 blocks the entrance end of the louver hole 25 of the flip plate 22 below, and the flip below The end of the deflector 26 of the plate 22 abuts against the outer surface of the extension end 251 of the louver hole 25 of the flip plate 22 above; The escape groove 222 of the plate 26.

[0067] During pile pressing, the louver hole 25 of the lower flap 22 is closed, so that the pile side soil is difficult to enter through the louver hole 25 of the lower flap 22, and in the initial stage of pile pressing, the pile side soil is more likely to block the lower flap 22. The louver hole 25, that is, the pile side soil ...

Embodiment 3

[0069] Embodiment 3: a kind of construction method based on embodiment 1 or embodiment 2 structure disclosed by the present invention, comprises the following steps:

[0070] S1. Construction preparation:

[0071] S1.1. Technical preparation, familiarize yourself with and review construction drawings and relevant technical documents; master geological survey data and technical and economic data; prepare construction organization design, determine construction plan, and propose measures to save labor and materials and reduce process costs.

[0072] S1.2. Preparation of construction materials, determine the demand for materials, construction machinery, equipment, tools, etc. at each stage, and arrange transportation and entry in time to meet the needs of continuous construction.

[0073] S1.3. According to the geological exploration information, a grout hole 13 is opened at a specific position of the pipe pile 1, and the specific position is the part of the pipe pile 1 where the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com