Cemented soil composite pre-fabricated screwed pile and pile forming method thereof

A technology of cement-soil piles and threaded piles, which can be applied to sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of low strength and bearing capacity of composite piles, improve construction quality and efficiency, and avoid environmental pollution. , The effect of solving the difficulty of pile sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

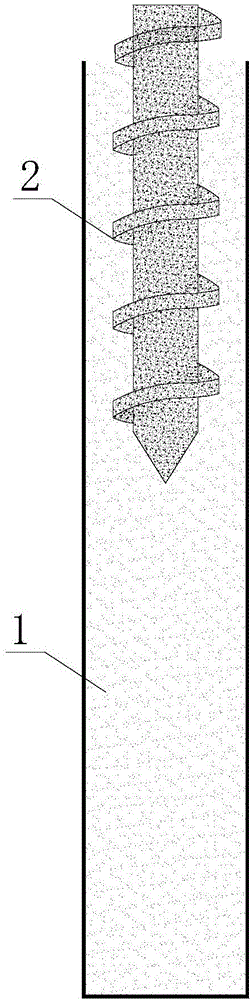

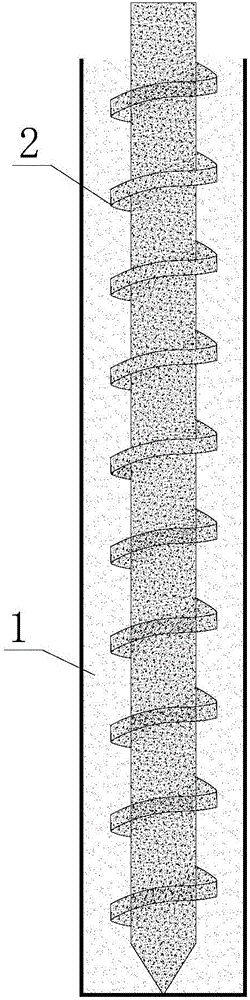

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention proposes a cement-soil composite prefabricated threaded pile, and the cement-soil composite prefabricated threaded pile includes: a cement-soil pile 1 and a prefabricated threaded pile 2 arranged in the cement-soil pile; the prefabricated threaded pile 2 After the cement-soil pile is formed into a pile 1, it is inserted into the cement-soil pile 1 by a drilling rig (the prefabricated threaded pile 2 is screwed into the cement-soil pile 1 by the drilling rig). Through the compaction effect of the prefabricated threaded piles on the cement-soil piles during the placement process, the confining effect of the soil around the prefabricated threaded piles and the cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com