Patents

Literature

127results about How to "Improve horizontal bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

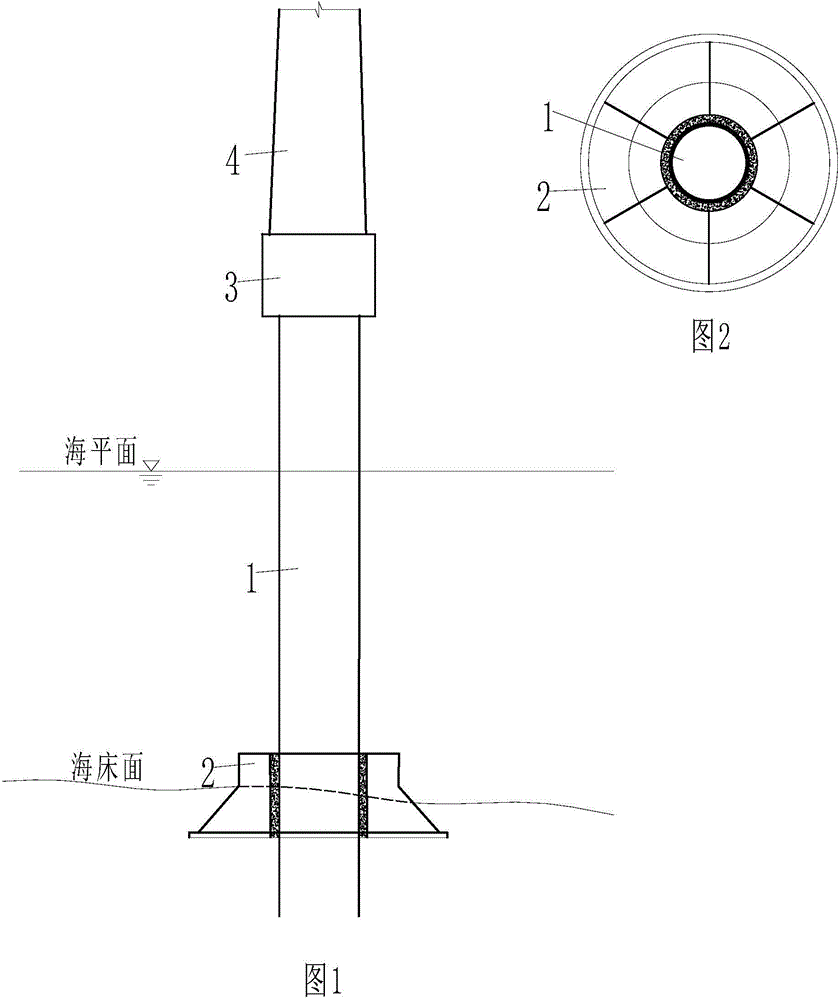

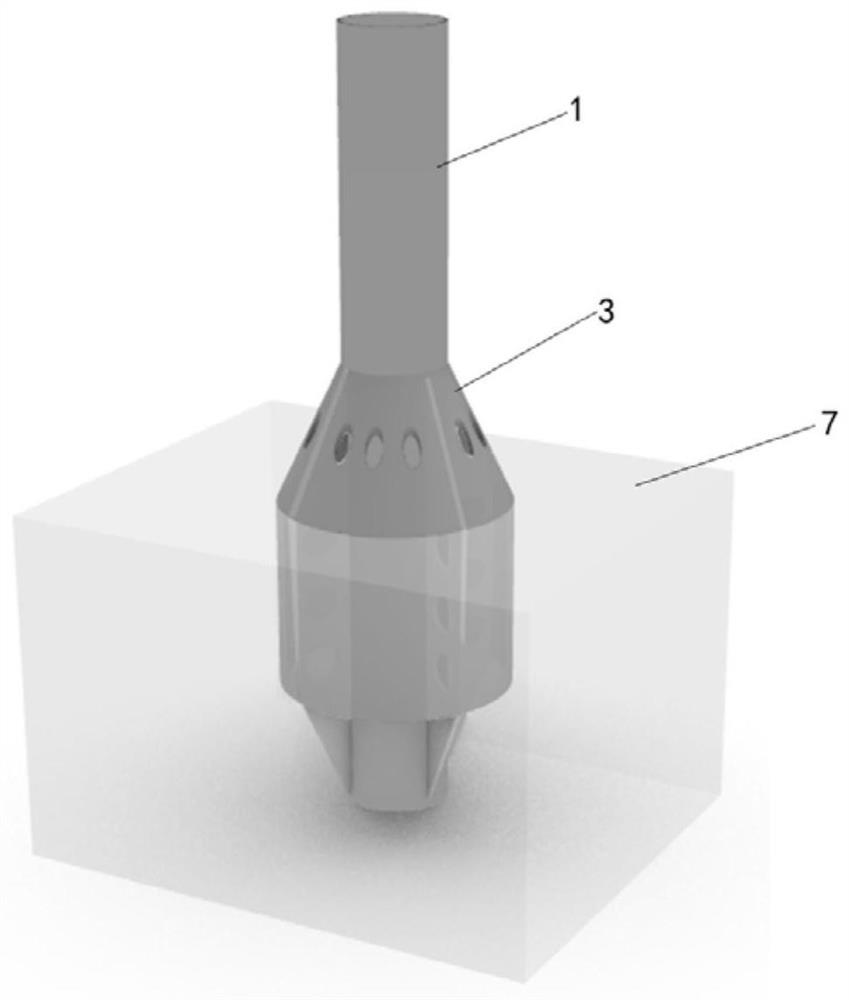

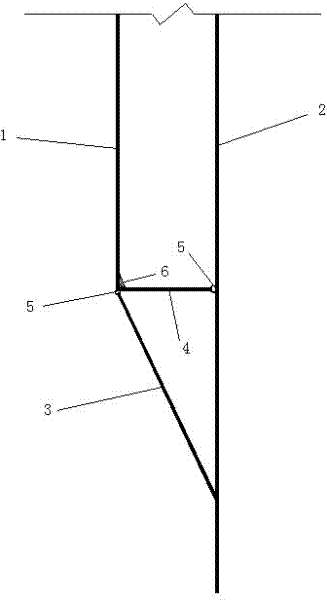

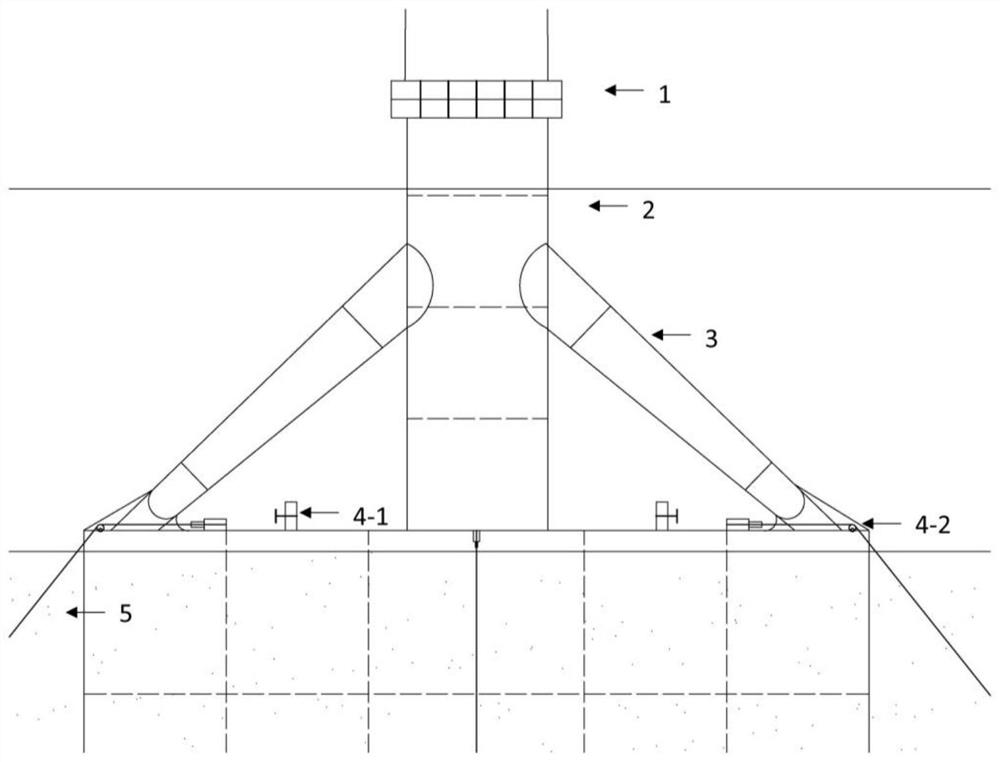

Single pile and gravity combined offshore wind power foundation

InactiveCN104818727AImprove anti-overturn performanceReduce horizontal displacementFoundation engineeringOffshore wind powerTower

The invention discloses a single pile and gravity combined offshore wind plant blower foundation. The foundation comprises a steel pipe pile vertically inserted to a seabed; the upper end of the steel pipe pile is connected with a transition section, and the upper end of the transition section is connected with a blower tower cylinder; the lower end of the steel pipe pile is anchored on the seabed by crossing through a gravity type foundation. The technical scheme of the single pile-gravity combined offshore wind plant blower foundation provides a novel foundation model formed by combining a single pile and the gravity; through adding an additional hollow gravity type foundation at the position of the steel pipe pile closing to the seabed, the rigidity of the single pile foundation closing to the seabed face is enhanced, advantages of two foundations are combined, and the using scale of a single-pile foundation is enlarged. The scheme increases the ability of resisting bending torque of the single-pile foundation, reduces the displacement of the pile body, and decreases the diameter and the thickness of the steel pipe pile.

Owner:FUJIAN YONGFU POWER ENG +1

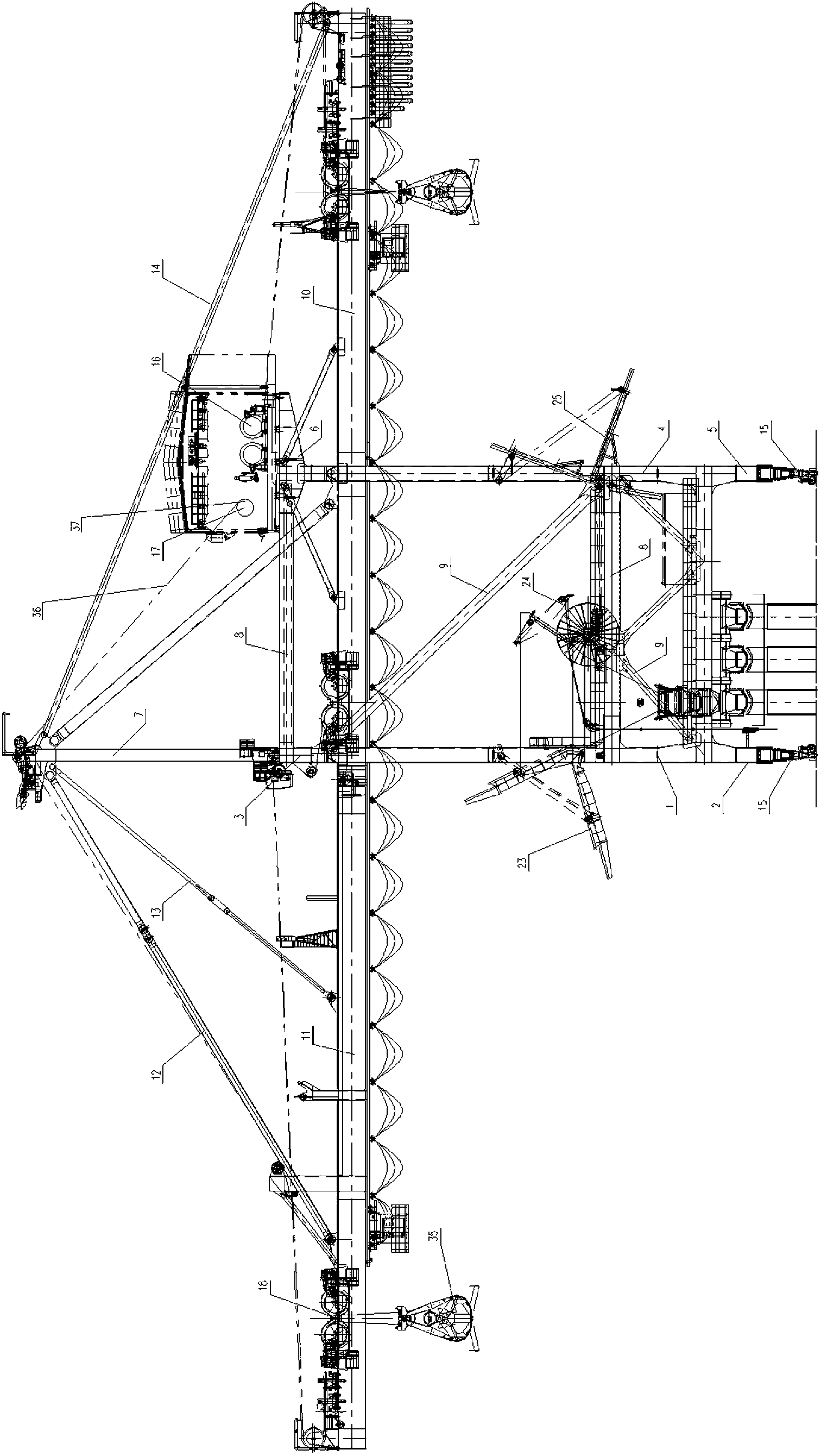

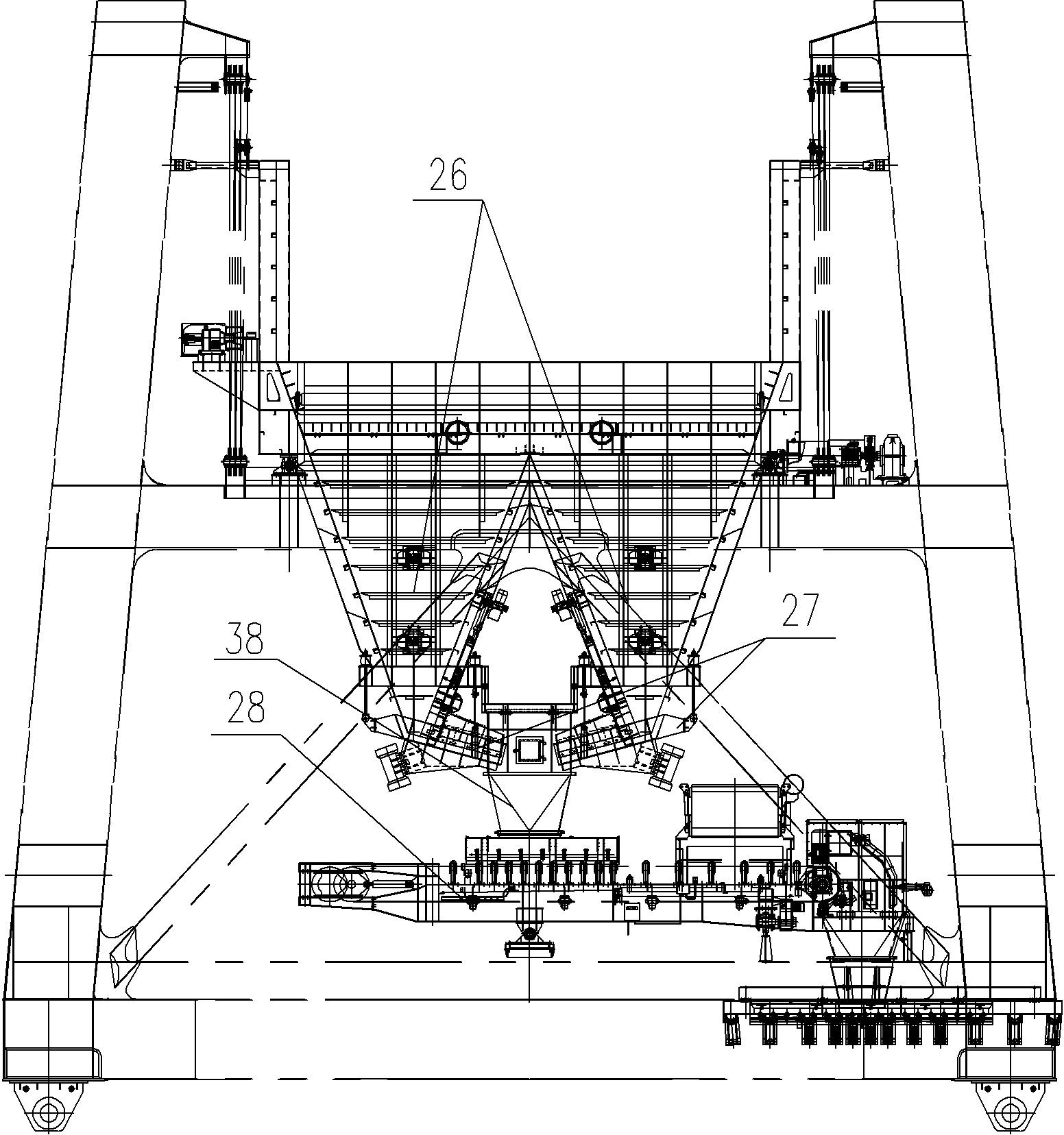

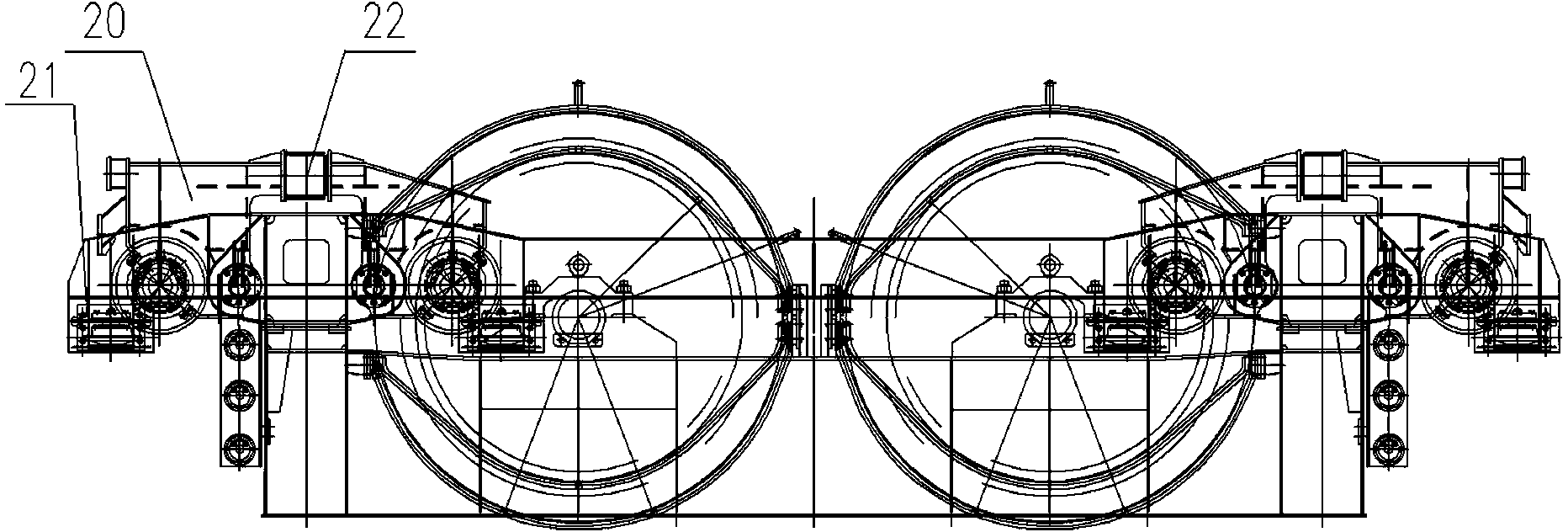

Bridge type grab bucket ship unloader

InactiveCN103287984ASuitable for berthing large shipsFulfil requirementsBase supporting structuresBraking devices for hoisting equipmentsDischarge efficiencyMarine engineering

The invention discloses a bridge type grab bucket ship unloader. The bridge type grab bucket ship unloader comprises a steel structure system, an operation system and an unloading system, wherein the steel structure system comprises a door frame structure, a rear girder, a front girder and a pull rod system; the door frame structure comprises a seat side vertical column, a sea side lower transverse beam, a sea side upper transverse beam, a land side stand column, a land side lower transverse beam, a land side upper transverse beam, a trapezoid frame, a connection beam and an inclined strut; the operation system comprises a walking mechanism, a hoisting, closing and trolley operation mechanism and a pitching mechanism; the walking mechanism is connected with the door frame structure; the unloading system comprises a material accepting plate system, hoppers and a feeding belt machine; and the pull rod system comprises a front pull rod, a middle pull rod and a rear pull rod. The bridge type grab bucket ship unloader disclosed by the invention has the advantages of high working efficiency and maximum yield; a manner that stretching-out distances of sea and land sides are great and three pull rods are used can meet the requirements of stopping large-size ship on a wharf and unloading materials in two directions of the sea and land sides; and the discharging efficiency of the double hoppers is high.

Owner:江苏海隆重机有限公司

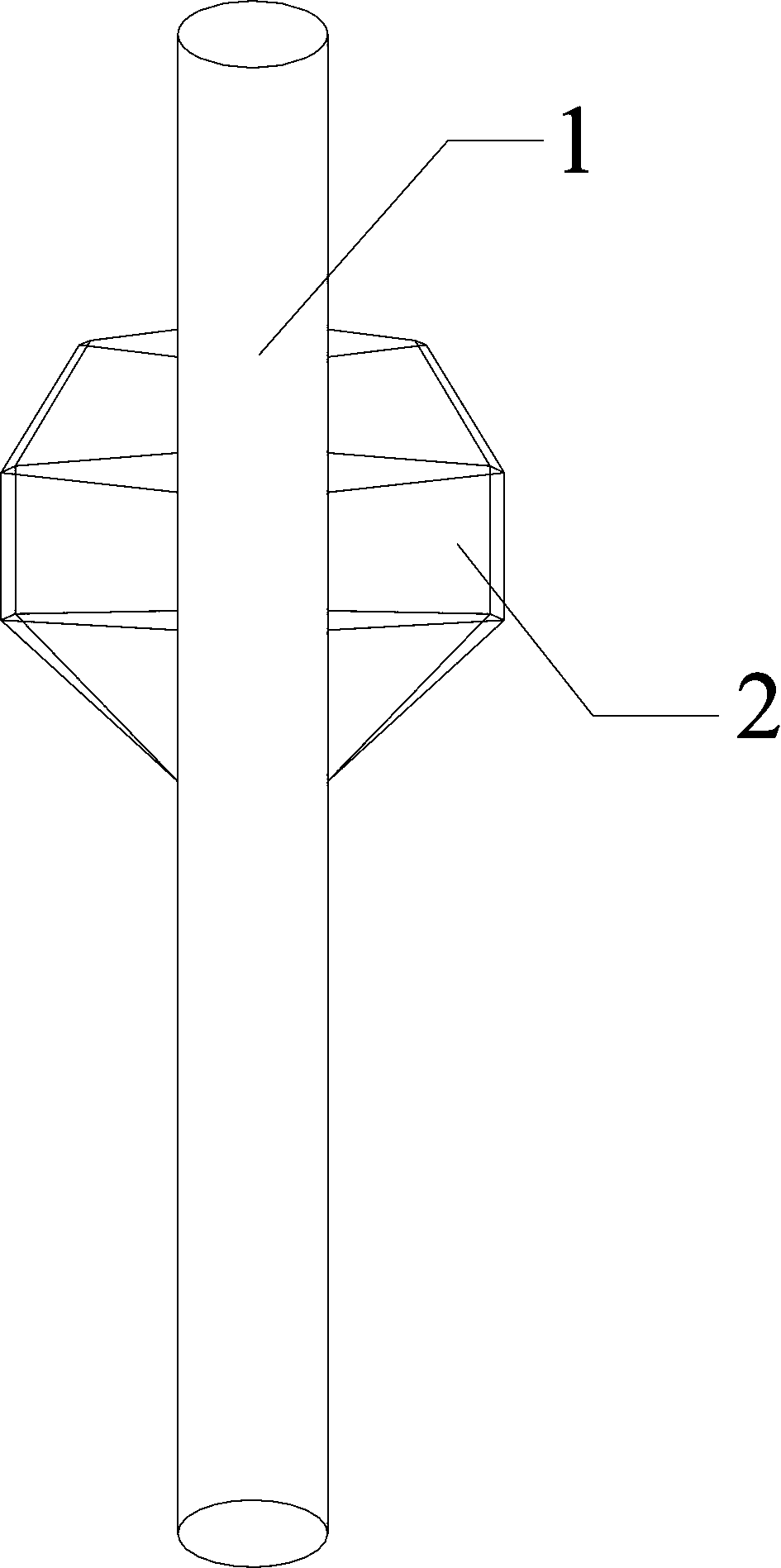

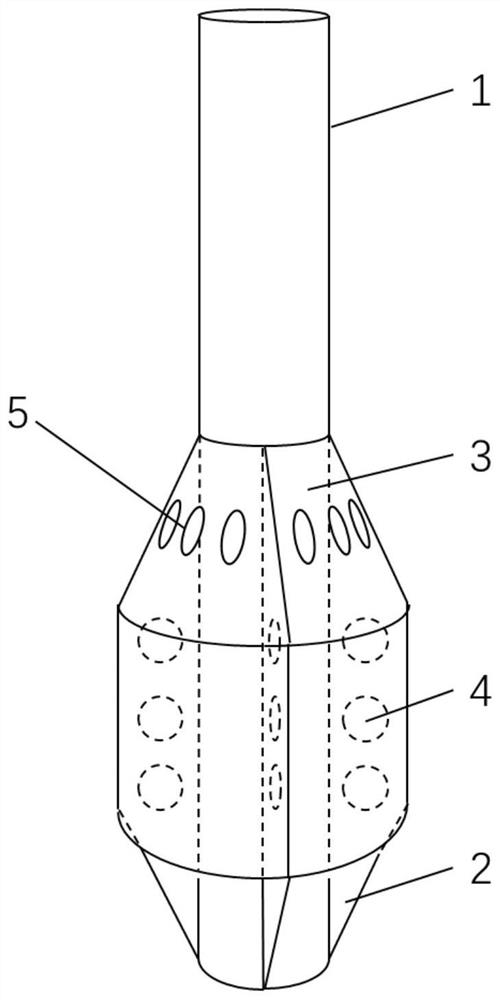

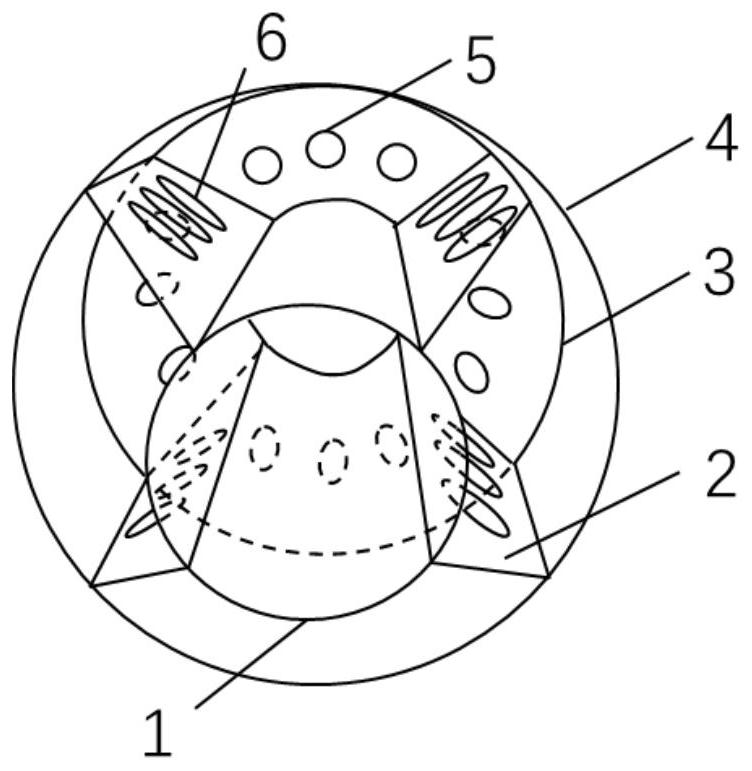

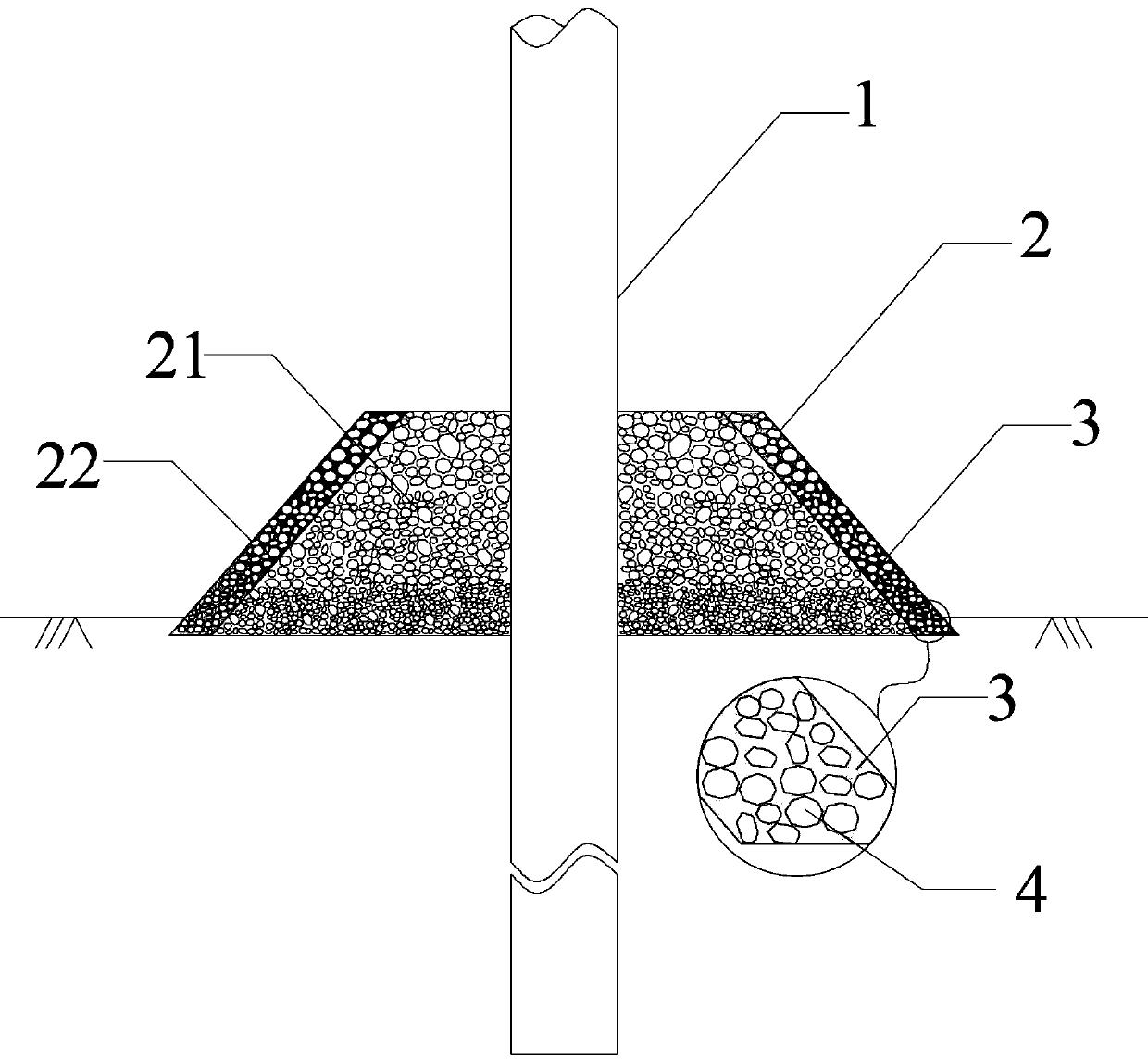

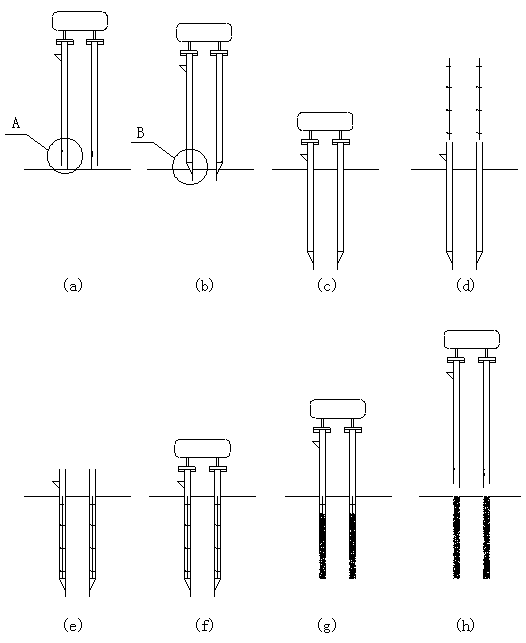

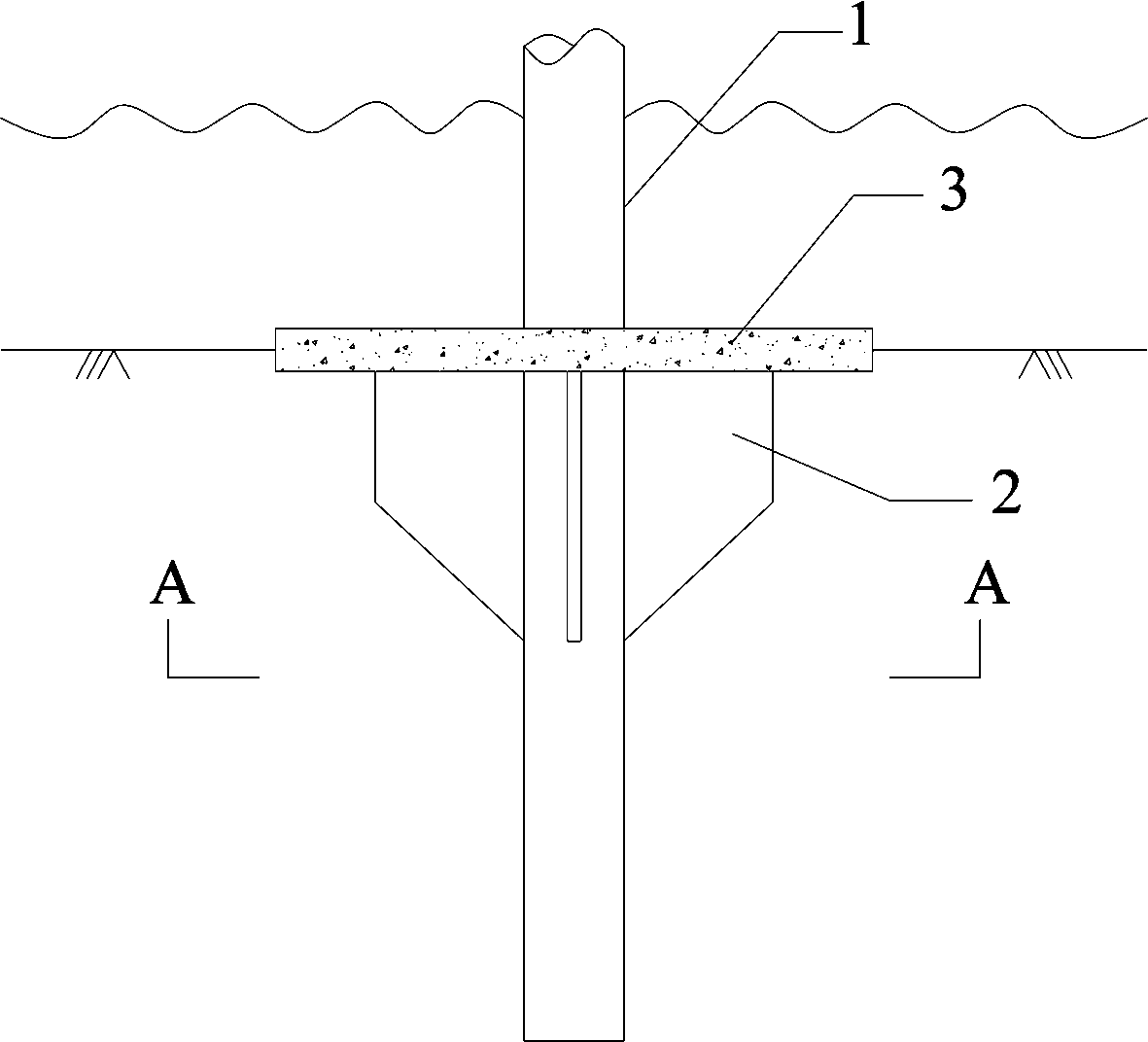

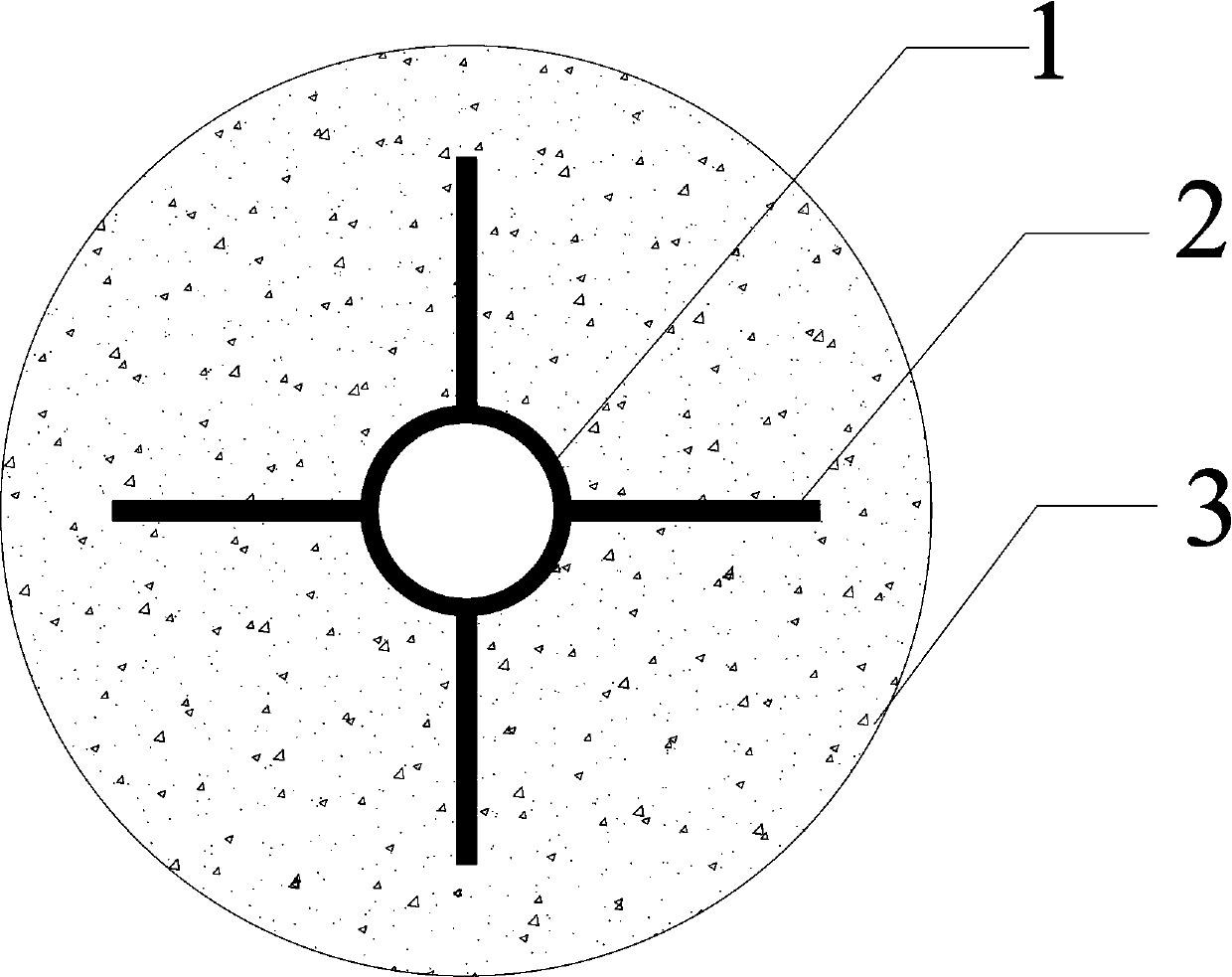

Offshore wind electricity single pile-wing plate-rockfill composite foundation and construction method thereof

PendingCN110984214AImprove carrying capacityFully mobilize resistanceFoundation engineeringRockfill materialStructural engineering

The invention discloses an offshore wind electricity single pile-wing plate-rockfill composite foundation and a construction method thereof. The foundation comprises a single pile, a wing plate and rockfill, the wing plate is of a conical structure, and is welded to the outer wall of a pile body, the rockfill is formed through dense stacking of the rockfill, the upper end of the wing plate is located in the rockfill, and the lower end of a pile wing is located on a seabed supporting layer. The construction method of the offshore wind electricity single pile-wing plate-rockfill composite foundation comprises the following steps of S1, determining the sizes of the single pile, the wing plate and the rockfill; S2, driving the single pile with the wing plate by the designed anchorage depth; and S3, stacking the rockfill on a seabed nearby the single pile. The problems of the low single pile bearing force, the large pile wing of the wing plate pile, serious foundation washing and the like can be solved, the single pile, wing plate and rockfill combination structure uses pile periphery soil resistance and rockfill friction force, the pile foundation bearing force can be improved, the pile foundation horizontal displacement can be reduced, the wing plate size is reduced, a wing plate stress mechanism is changed, washing of waves and ocean currents to seabed soil can be blocked, and safe and stable running of an offshore wind generation set can be ensured.

Owner:CHINA THREE GORGES CORPORATION

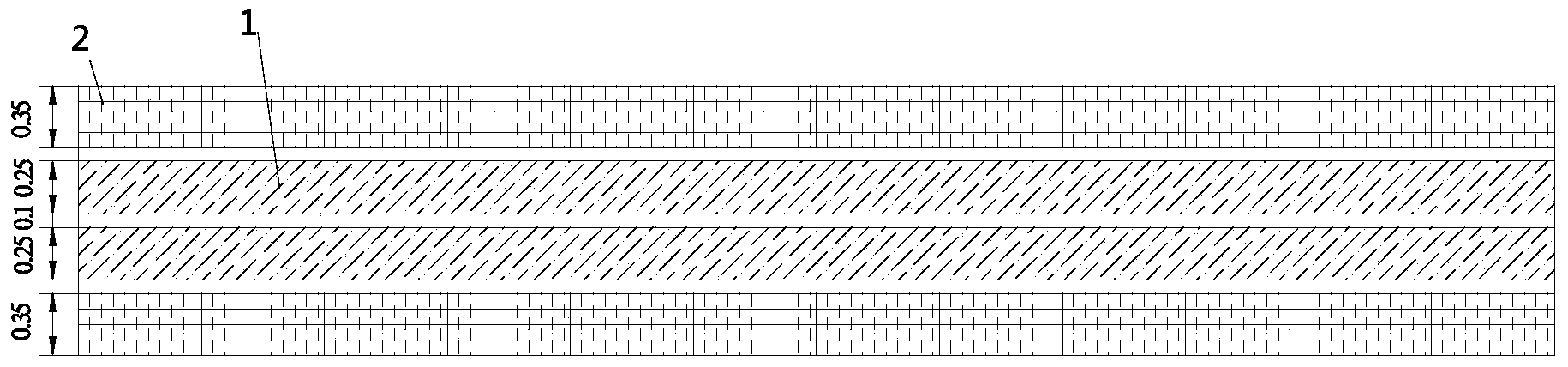

Construction method for non-prestressed centrifugal high-strength concrete pile planted pile

InactiveCN105421445AIncrease resistanceImprove pullout resistanceBulkheads/pilesHigh strength concreteSocial benefits

The invention provides a non-prestressed centrifugal high-strength concrete pile planted pile structure and a construction method thereof. The method comprises the construction steps that a pile planting machine is in place, the hole guiding operation is conducted, a bearing stratum is determined, base expansion is carried out, pile end cement paste is injected, pile periphery cement paste is injected and drill stems are pulled out, pile connection of pre-drilled holes is conducted, and non-prestressed centrifugal high-strength concrete piles are planted into pile holes. The pile planting construction method has the effects that damage to pile bodies is effectively reduced; the ductility of the pile bodies is improved more than 30%; the pile body cracking phenomenon is avoided; the whole performances of the pipe piles are improved more than 20%; the technique is simple, the cost is low and the cost performance is high; the centrifugal concrete piles which are high in vertical bearing capacity and horizontal pile foundation bearing capacity and capable of meeting the anti-seismic requirement can penetrate through a hard middle layer and a thick solidified layer and can be widely applied to foundation construction of various soil textures; it is ensured that the requirement of housing industrialization for quality is met; the pile planting construction method has good social benefits and popularization value.

Owner:TIANJIN JIANCHENGJIYE GRP

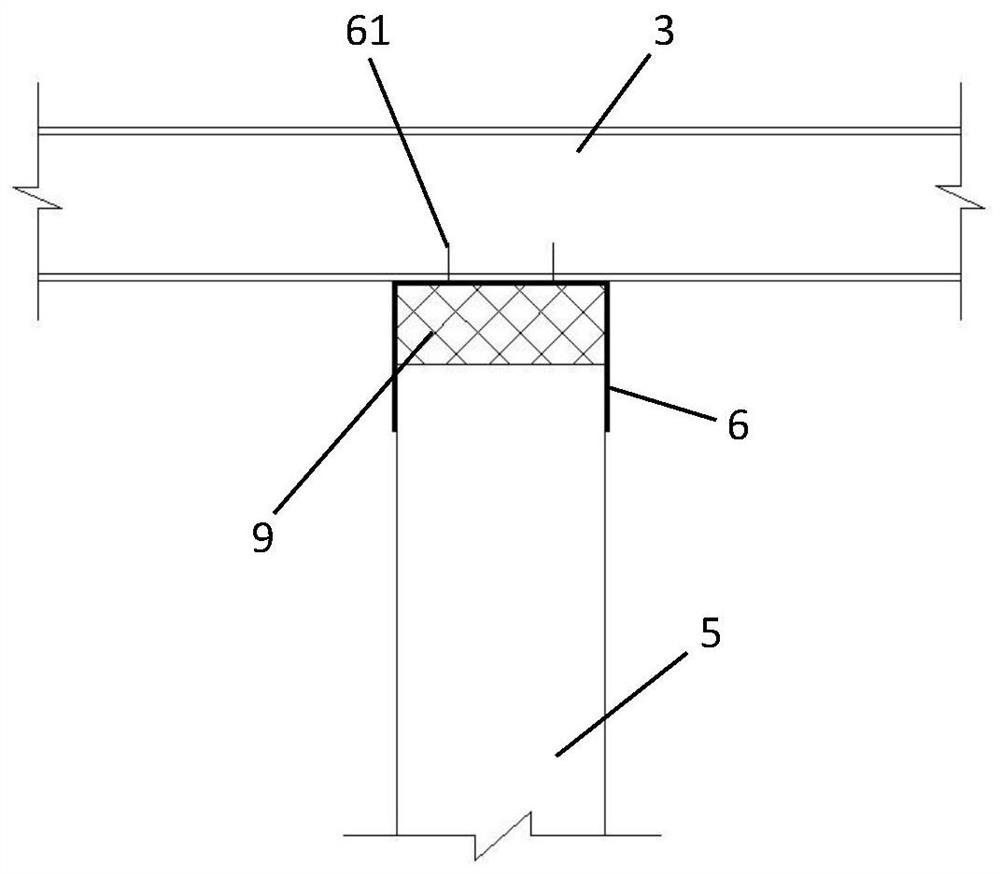

Offshore wind turbine tower foundation structure and installation method

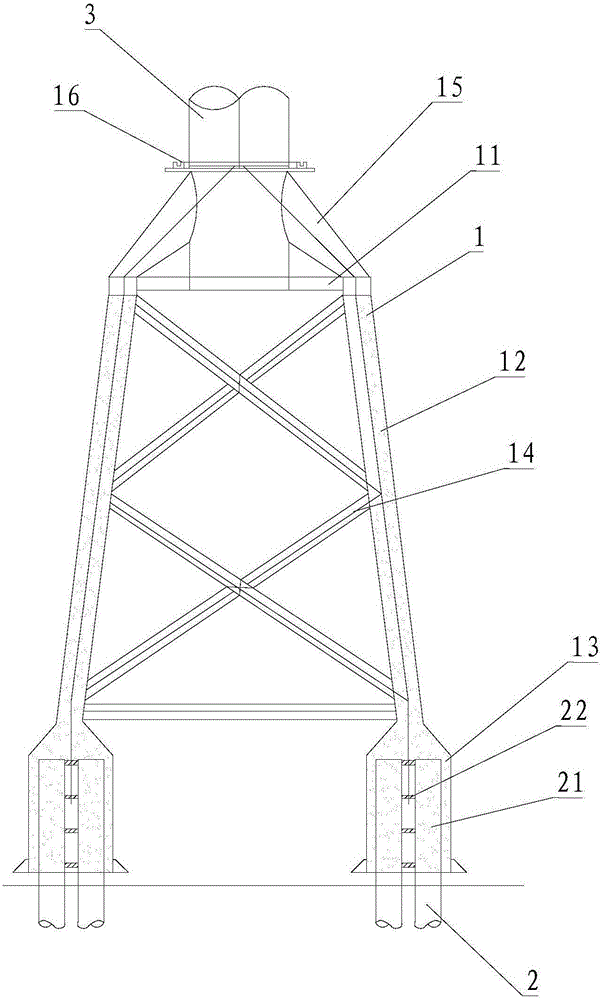

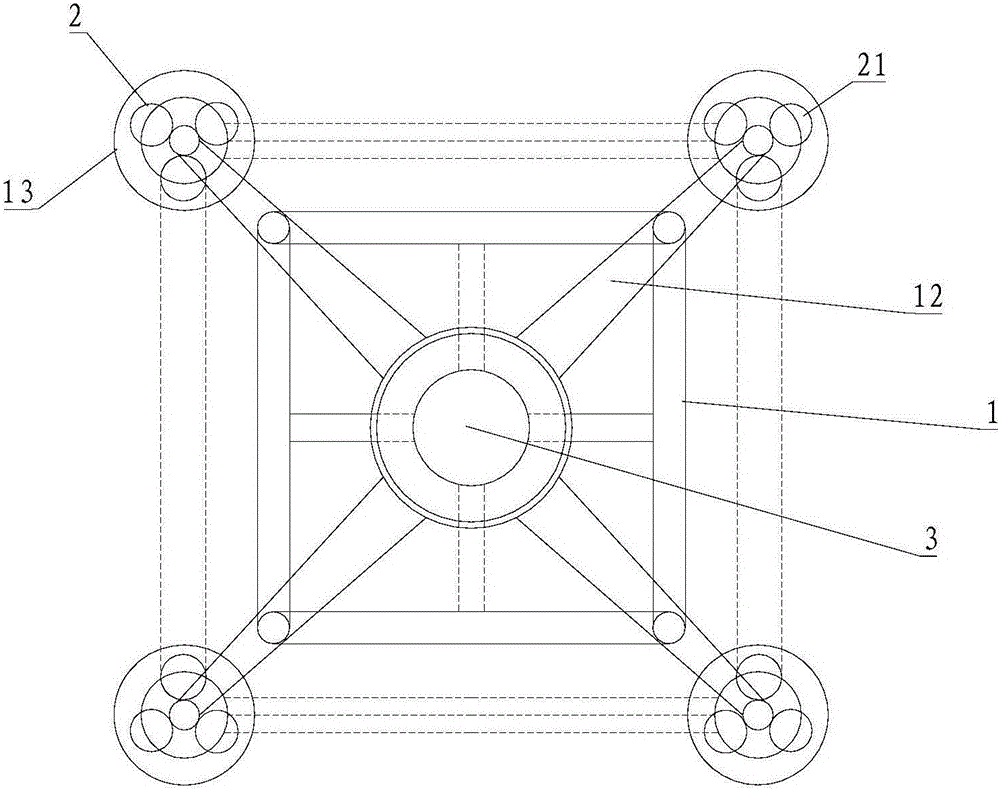

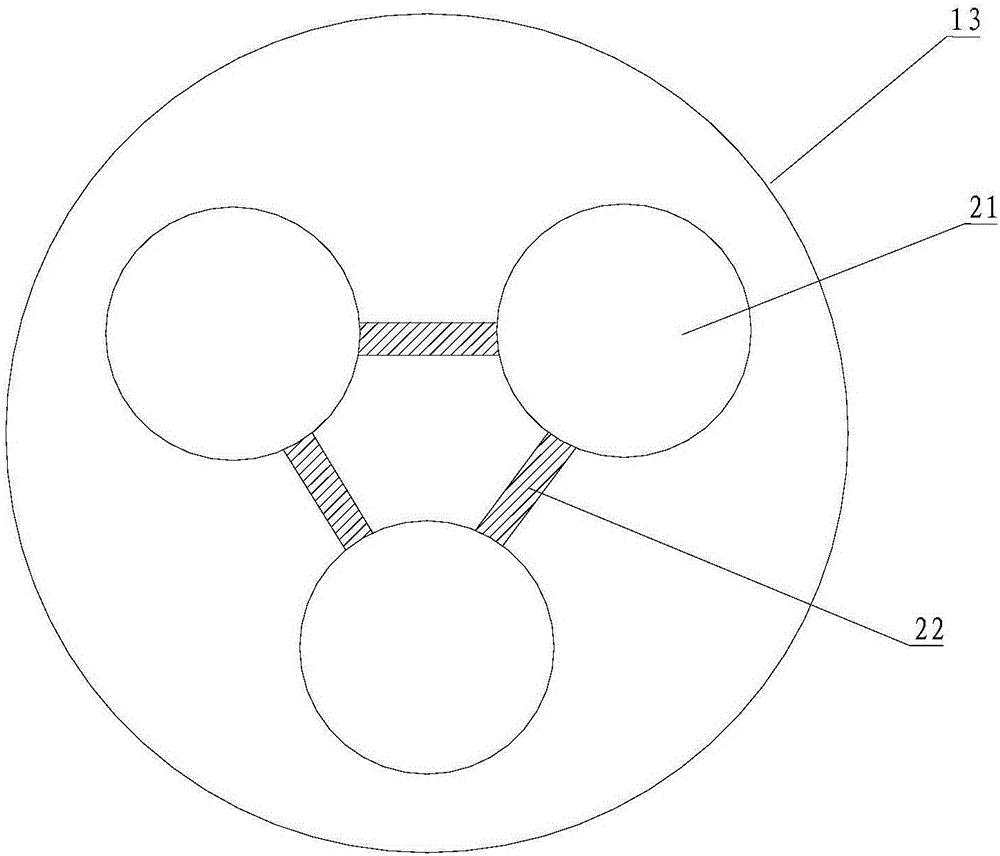

ActiveCN106013212AIncrease the moment of inertia of the structureEnhance overall rigidity and horizontal bearing capacityFoundation engineeringElectricityOffshore wind power

The invention relates to the field of offshore wind power mechanisms and aims to provide an offshore wind turbine tower foundation structure and an installation method. The offshore wind turbine tower foundation structure comprises an offshore jacket and a column pile component, wherein the offshore jacket comprises one or more cylinders arranged on the bottom, the column pipe component comprises one or more parallel column piles, the top of the column pile component is arranged in the cylinders, the portions, in the cylinders, of the column piles are connected through connectors, and the cylinders are grouted to enable the column pile component to be connected with the cylinders. The offshore wind turbine tower foundation structure has the advantages that the column piles can be small-diameter steel pipe piles, the multiple column piles are mutually connected through the connectors and connected with a sleeve on the bottom of a main conduit of the offshore jacket through grouting, so that a grid structure is formed by the column piles, structure inertia moment is increased, the overall rigidity and horizontal bearing capacity of the structure are improved, horizontal displacement of the bodies of the column piles is reduced, and the anti-topple capacity of a foundation is improved.

Owner:FUJIAN YONGFU POWER ENG

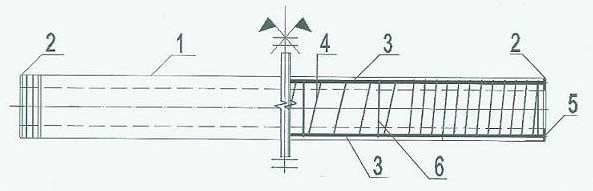

Offshore wind turbine single pile foundation with radial rib plates and anti-scouring cover

ActiveCN112177031AGuaranteed verticalitySimple structureProtective foundationElectric machineryStructural engineering

The invention provides an offshore wind turbine single pile foundation with radial rib plates and an anti-scouring cover. The offshore wind turbine single pile foundation comprises a tubular pile, a cylinder part and a conical cover body, wherein the tubular pile is a hollow cylinder; multiple rib plates are arranged on the outer side wall of the tubular pile, and are outwards distributed in a radial form along the outer side wall of the tubular pile; the cylinder part coats the outer sides of the rib plates, and is connected with the tubular pile through the rib plates; the inner wall of thecylinder part is connected with the upper edges of the rib plates to enhance the integrity of the single pile foundation; the conical cover body is used for preventing waves from scouring a seabed, coats the tubular pile, and is positioned above the cylinder part; a large end of the conical cover body is contacted with the cylinder part; the outer diameter of the large end of the conical cover body is matched with the outer diameter of the cylinder part; and the inner diameter of a small end of the conical cover body is matched with the outer diameter of the tubular pile. The offshore wind turbine single pile foundation improves the bearing capacity and the antiskid and anti-overturning stability of the single pile foundation, and meanwhile, can prevent scouring through setting the conicalcover body to improve the stability and the anti-scouring capacity.

Owner:SHANGHAI JIAO TONG UNIV

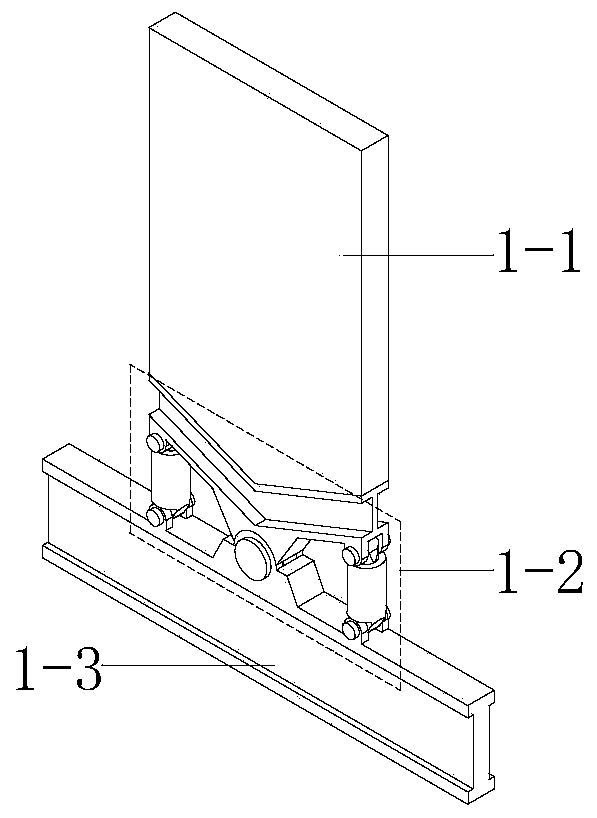

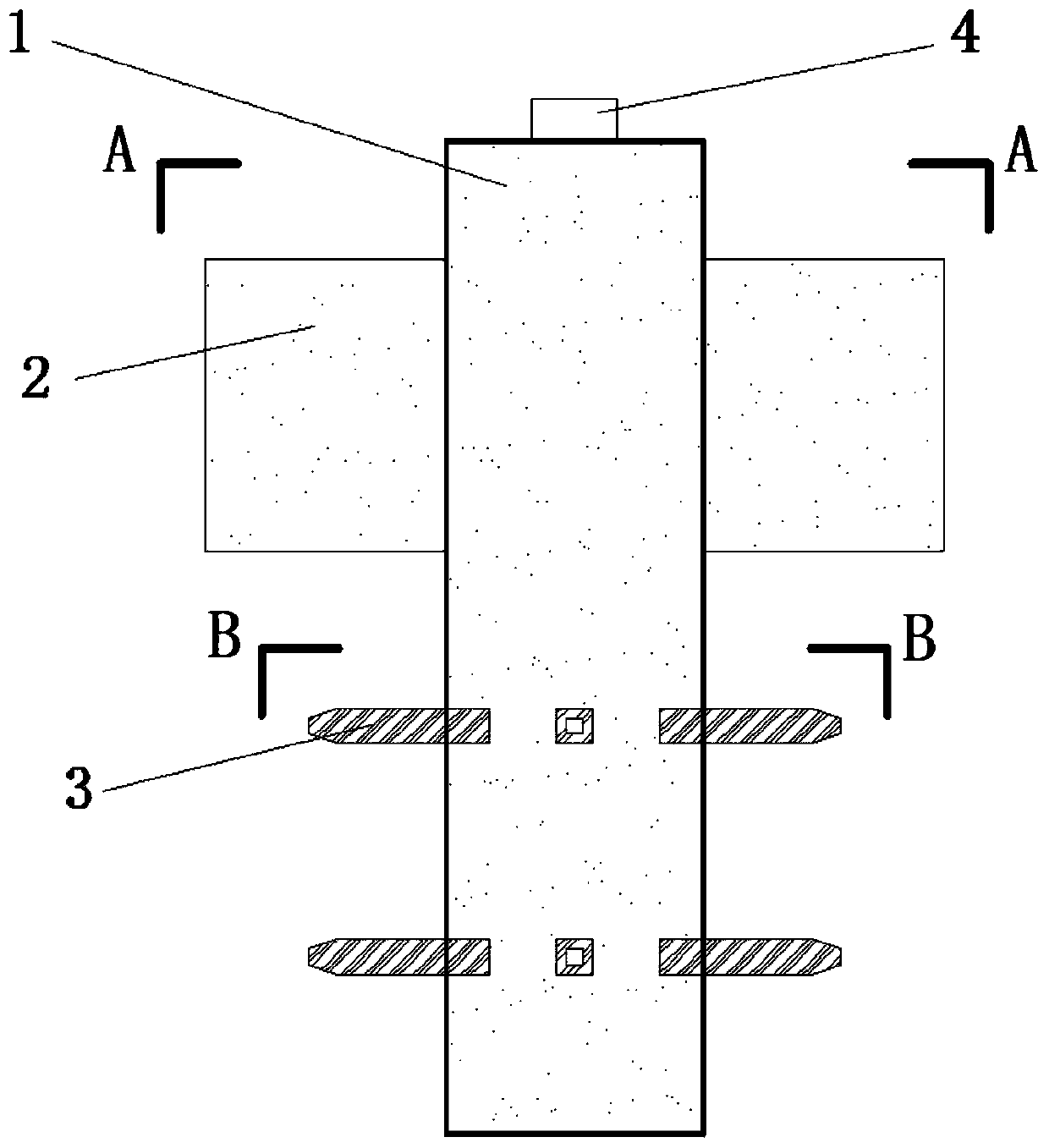

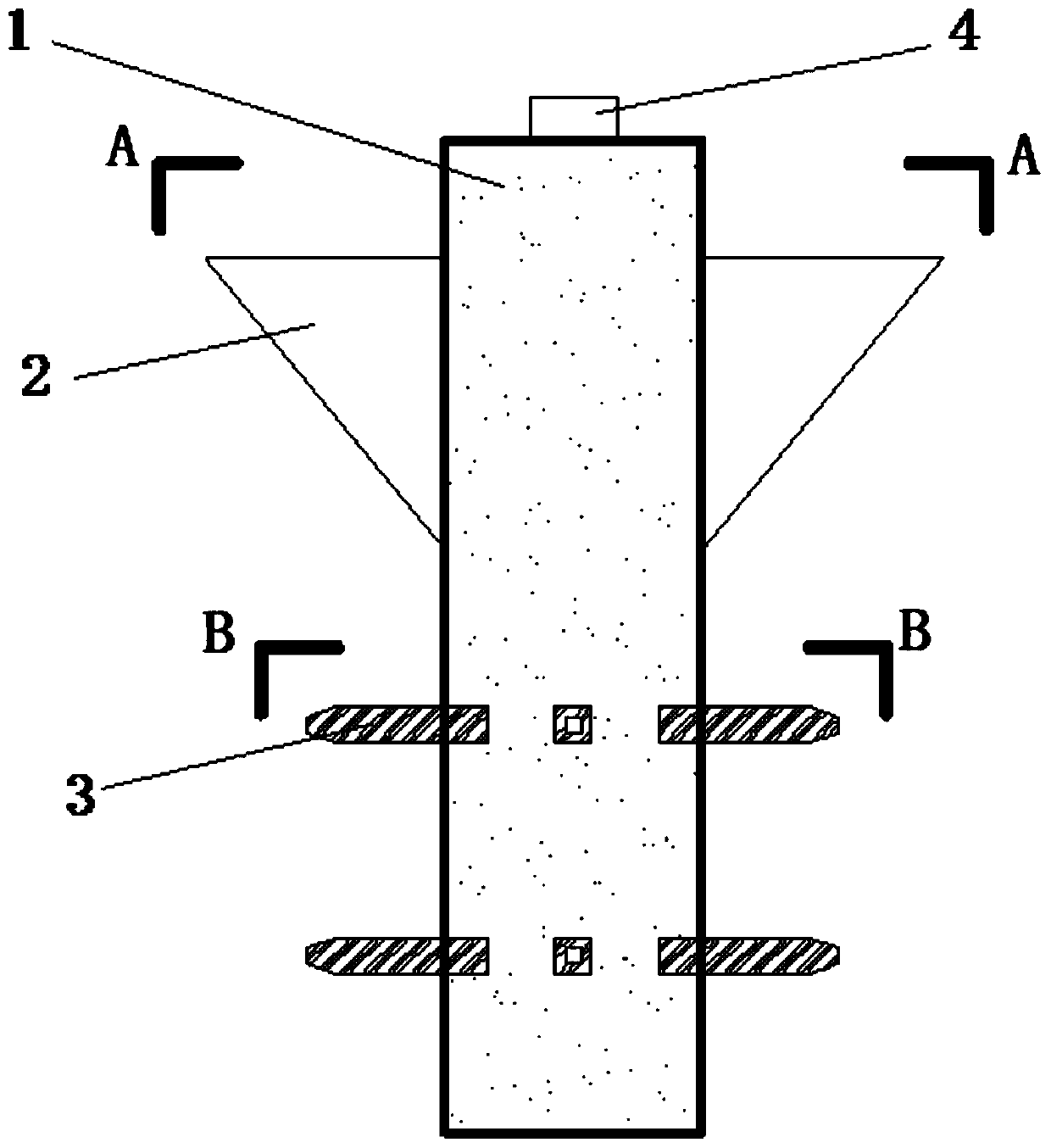

Bottom-hinged-supporting low-damage self-reset shear wall

ActiveCN110005091ANo plastic damageSection internal force does not surgeWallsProtective buildings/sheltersReinforced concreteRebar

The invention relates to a bottom-hinged-supporting low-damage self-reset shear wall. The bottom-hinged-supporting low-damage self-resetting shear wall comprises a reinforced concrete wall plate, a self-reset wall bottom and a foundation beam; the reinforced concrete wall plate is connected with the upper end of the self-reset wall bottom, the foundation beam is connected with the lower end of theself-reset wall bottom, a connecting plate is arranged in the middle of the upper surface of the foundation beam and provided with a connecting beam hinged joint, and self-reset short support hingedjoints II are arranged on the two sides of the connecting beam hinged joint correspondingly; the self-reset wall bottom comprises a connecting beam and a self-reset short support; an anti-shear key isarranged on the upper surface of the connecting beam, a foundation beam hinged joint is arranged in the middle of the lower surface of the connecting beam, and self-reset short support hinged jointsI are arranged on the positions, corresponding to the two self-reset short support hinged joints II, of the two ends of the lower surface of the connecting beam; and the self-reset short support comprises an inner pipe, an outer pipe, a disc spring and baffles, the disc spring is arranged in the outer pipe, the baffles are arranged at the two ends of the disc spring, the inner pipe penetrates through an inner hole of the disc spring and the baffles at the two ends and are capped at the two ends of the inner pipe through a stop block, and self-reset short support hinged joints III are arrangedat the two ends of the self-reset short support.

Owner:BEIJING JIAOTONG UNIV

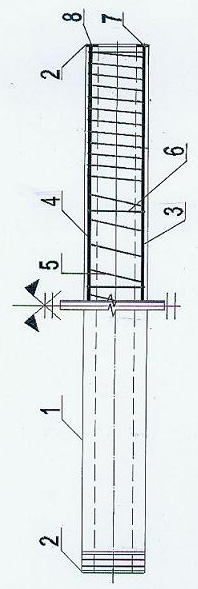

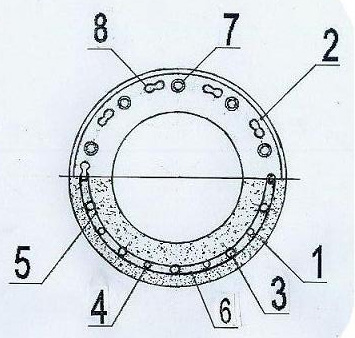

Toughening prestressed centrifugal concrete pile

InactiveCN102121246AImprove vertical bearing capacityImprove horizontal bearing capacityBulkheads/pilesRebarBearing capacity

The invention relates to a toughening prestressed centrifugal concrete pile which comprises a centrifugal concrete pile body, a prestressed main reinforcement, spiral hooping, two end plates and prestressed main reinforcement anchoring holes, and further comprises a non-prestressed main reinforcement and non-prestressed main reinforcement anchoring holes. Based on the reinforcement cage of the existing prestressed centrifugal concrete pile, the short anchoring reinforcements arranged on two end plates are changed into long non-prestressed main reinforcements capable of vertically passing through the whole frame so that the centrifugal concrete pile has the advantage of high bearing capacity because of the effect of the prestressed main reinforcement and the advantage of high horizontal bearing capacity because of the effect of the non-prestressed main reinforcement, therefore, the pile can replace the prefabricated solid square pile or on-site concreted pile used in area resisting eight-magnitude earthquake. Simultaneously, the structural design is reasonable, and the existing device and production method for producing the prestressed centrifugal concrete pile can be continue to use completely, therefore, the toughening prestressed centrifugal concrete pile is very easy for popularization, and a new variety is added for concrete piles.

Owner:宿迁市固丰管桩有限公司

Concrete filled steel tube composite pile foundation and construction method

ActiveCN109024651AEasy constructionGood anti-seismic performance of the structureBulkheads/pilesRebarSteel tube

The invention belongs to the technical field of bridge pile foundation engineering and relates to a concrete filled steel tube composite pile foundation and a construction method. The concrete filledsteel tube composite pile foundation comprises a concrete filled steel tube structural pile and a reinforced concrete structural pile. The concrete filled steel tube structural pile and the reinforcedconcrete structural pile are connected from top to bottom in sequence to form an integral pile foundation. The concrete filled steel tube structural pile is located above the zero point of the bending moment of the integral pile foundation. The reinforced concrete structural pile is located below the zero point of the bending moment of the integral pile foundation. The mark of concrete filled upin the reinforced concrete structural pile is lower than that of concrete filled up in the integral pile foundation. The concrete filled steel tube composite pile foundation and the construction method provided by the invention have the advantages that construction is convenient, the anti-seismic performance is good, the bearing capacity is high, and the construction difficulty and the construction cost can be lowered.

Owner:山西省交通科技研发有限公司

Vacuum preloading and soil body surface solidification combined processing technique

InactiveCN105064324ASolve the lack of carrying capacityImprove bearing capacitySoil preservationWork periodSurface layer

The invention discloses a vacuum preloading and soil body surface solidification combined processing technique. The vacuum preloading and soil body surface solidification combined processing technique includes the following steps that A, a vertical water discharging plate is arranged in a hydraulic reclamation mud / sludge / waste mud pit; the upper end of the vertical water discharging plate is connected with a water discharging pipeline; the water discharging pipeline is connected with the outside; sealing cloth coves the top of soil in a vacuum preloading water reduction pit and the water discharging pipeline; the edge of the sealing cloth is sealed through a sealing structure and soil; a vacuum pump is connected with the water discharging pipeline and used for pumping water in the soil; B, after vacuum preloading is finished, the vacuum sealing cloth on the surface is removed; C, curing agents are added to the soil body on the surface layer and evenly distributed in the soil body on the surface layer; D, after a period of time, the soil body is solidified. The soil body processed through the technique is high in dehydration rate, short in work period and higher in strength after the soil body is processed.

Owner:WENZHOU UNIVERSITY

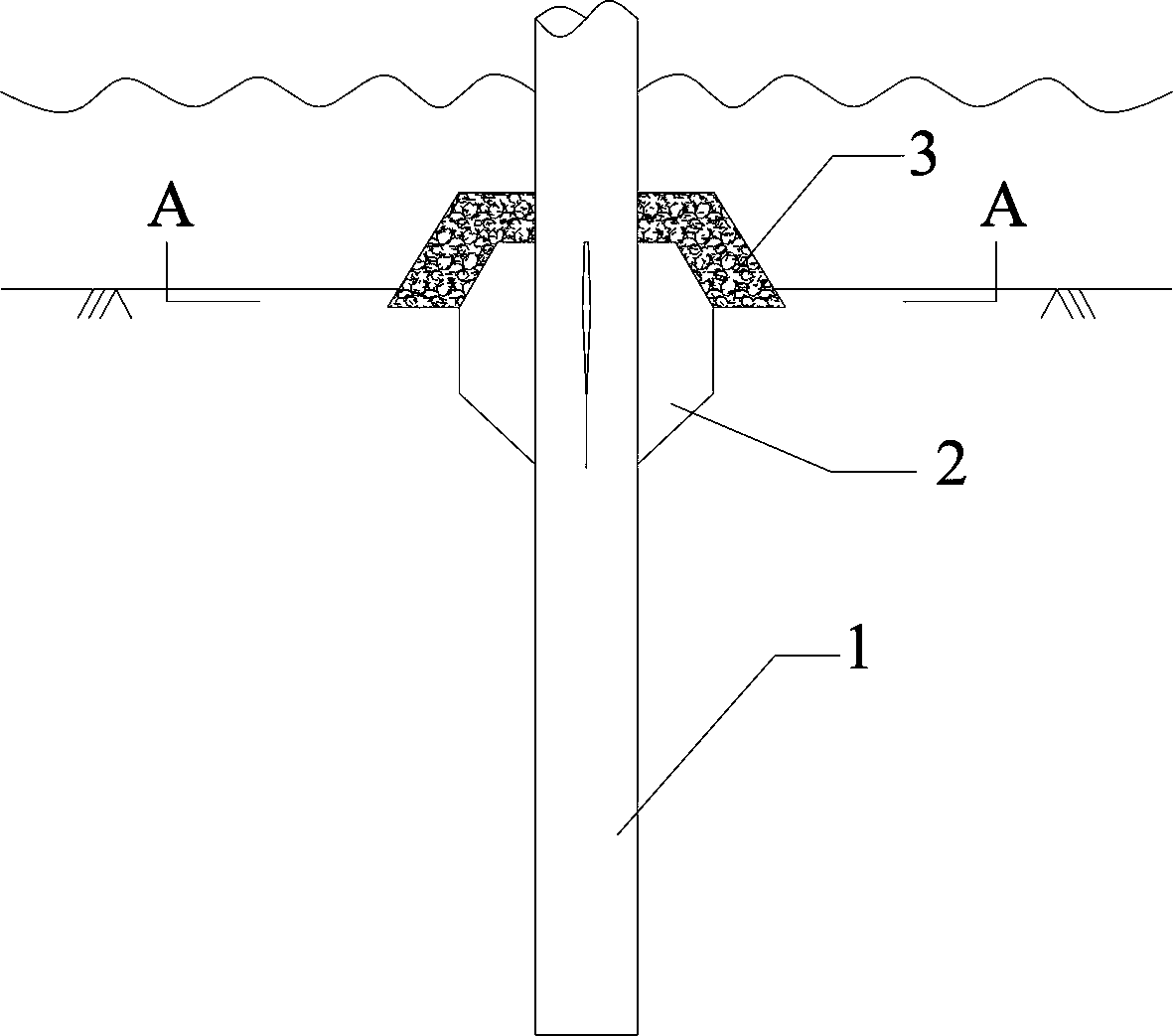

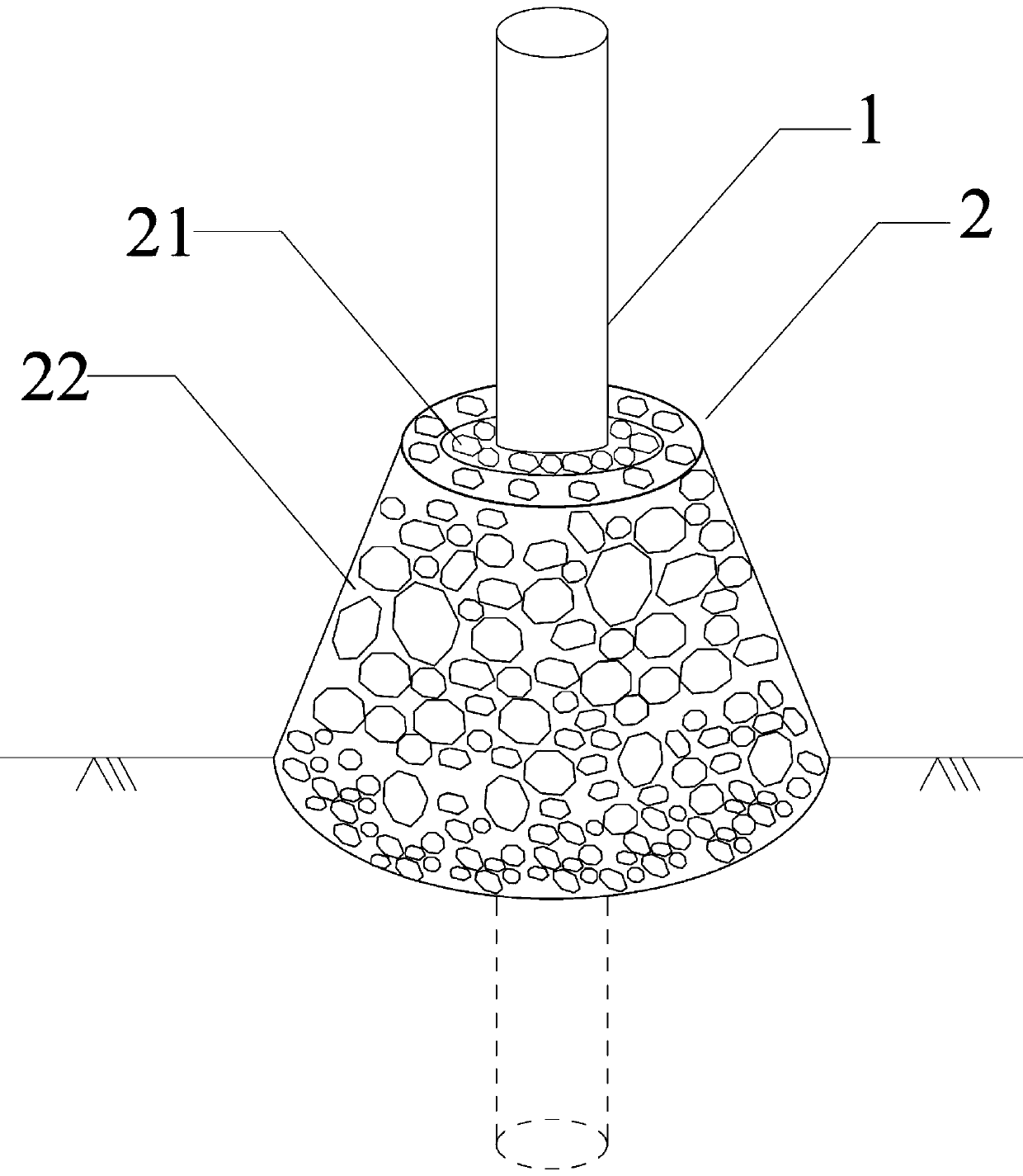

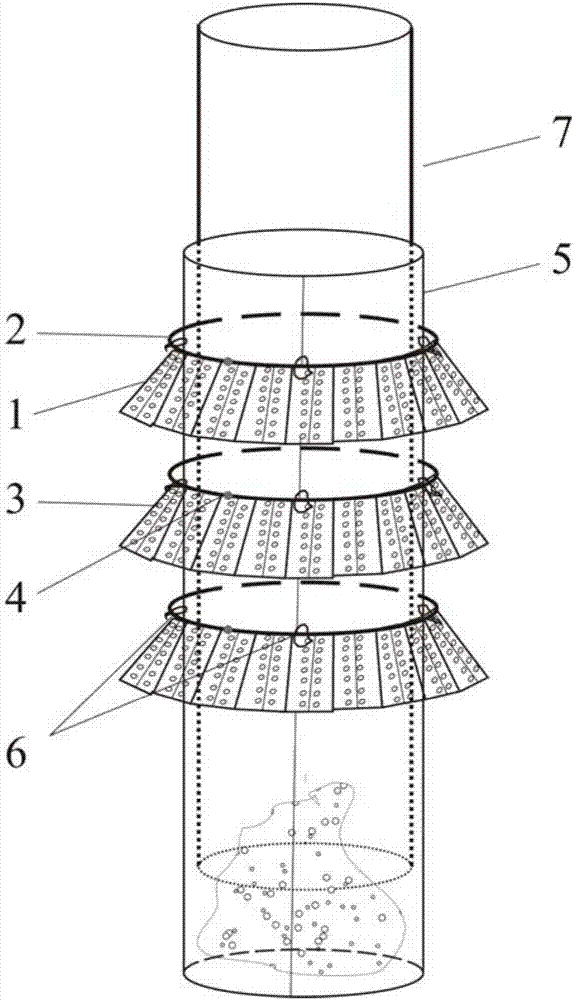

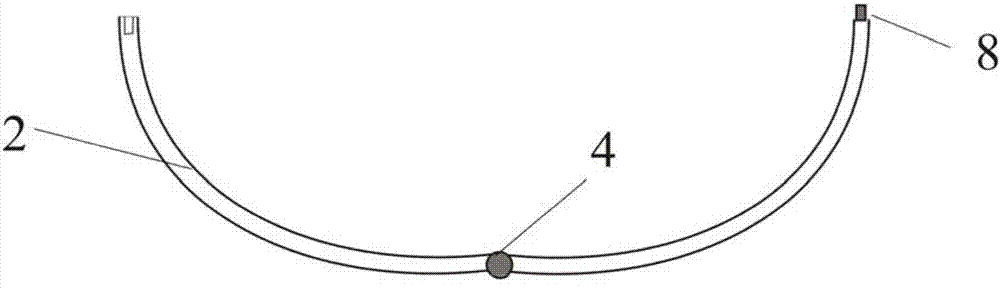

Offshore wind power single pile-friction cone composite foundation and construction method thereof

PendingCN110984213AImprove carrying capacityImprove bearing capacityFoundation engineeringCrushed stoneOffshore wind power

The invention discloses an offshore wind power single pile-friction cone composite foundation and a construction method thereof. The offshore wind power single pile-friction cone composite foundationcomprises a single pile and a friction cone, wherein a rock-fill body is arranged inside the friction cone, a cemented rock-fill body shell is arranged outside the friction cone, and the cemented rock-fill body shell is obtained by grouting and cementing the rock-fill body outside the friction cone. The construction method of the offshore wind power single pile-friction cone composite foundation comprises the following steps of 1, carrying out single pile construction by using pile sinking equipment; 2, stacking graded crushed stone materials on seabed around the single pile to form the friction cone; 3, placing a grouting device on the surface of the rock-fill body outside the friction cone; and 4, conveying underwater self-protection cementing materials through the grouting device, wherein the cementing materials fill gaps of the rock-fill body outside the friction cone to form a cemented rock-fill body. The offshore wind power single pile-friction cone composite foundation has the advantages of high horizontal bearing capacity, small pile body horizontal displacement, deformation and bending moment and the like, and has the characteristics of simple construction, high adaptability to geological conditions and the like.

Owner:CHINA THREE GORGES CORPORATION

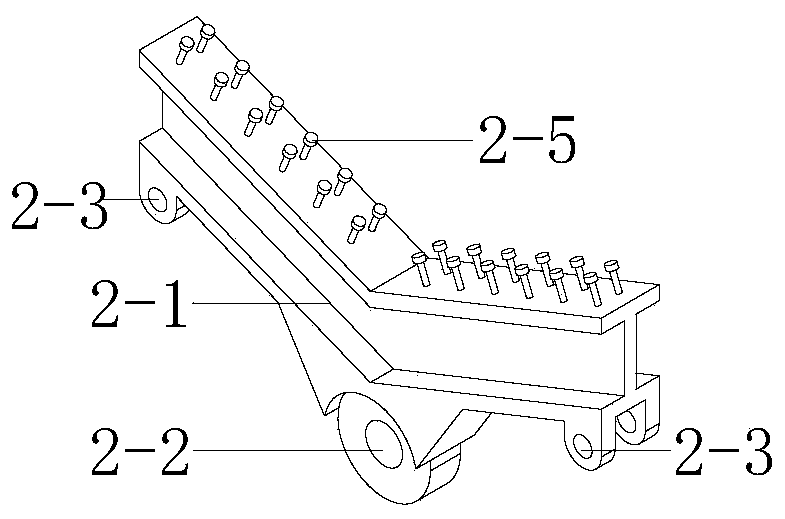

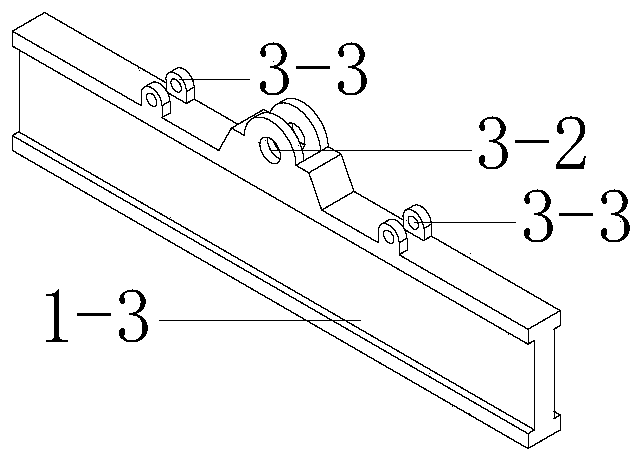

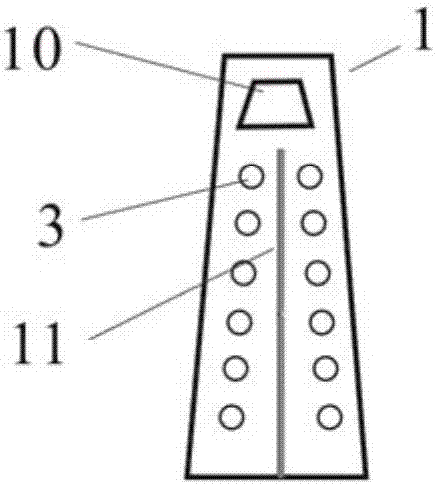

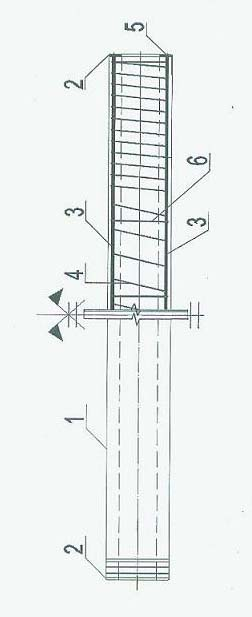

Horizontal bearing reinforcing body of soft foundation cast-in-place pile and construction method thereof

ActiveCN106988300AImprove horizontal bearing capacityImprove vertical bearing capacityBulkheads/pilesLong lastingSmall hole

The invention discloses a horizontal bearing reinforcing body of a soft foundation cast-in-place pile and a construction method thereof. The device comprises one group of wing plates with the same structure and size and a hoop, wherein the wing plates are uniformly arranged at the periphery of the hoop, and small holes are arranged in the wing plates; the wing plates are in a rounded-trapezoid-like shape, and clamping grooves are arranged in the short edges of the wing plates; projecting teeth are uniformly arranged in the hoop in the peripheral direction, the number of the projecting teeth is consistent with the number of the wing plates, and the wing plates are hinged to the hoop through the clearance fit of the clamping grooves and the projecting teeth; and the wing plates can rotate relative to the hoop in a 90-degree range. The long-lasting problems that the single dependence of the horizontal bearing capability improvement of the cast-in-place pile on the diameter increase of the pile causes cost wastes and a specially-shaped pile foundation has to depend on special construction equipment are solved. According to the method, the horizontal bearing reinforcing body is jointly formed by adopting the wing plates, the hoop and grouting concrete, the improvement of the horizontal bearing capability of the cast-in-place pile is realized, the vertical bearing capability is also enhanced, and special pile foundation construction equipment is not required; and the mounting method is simple, efficient and rapid.

Owner:SOUTHEAST UNIV

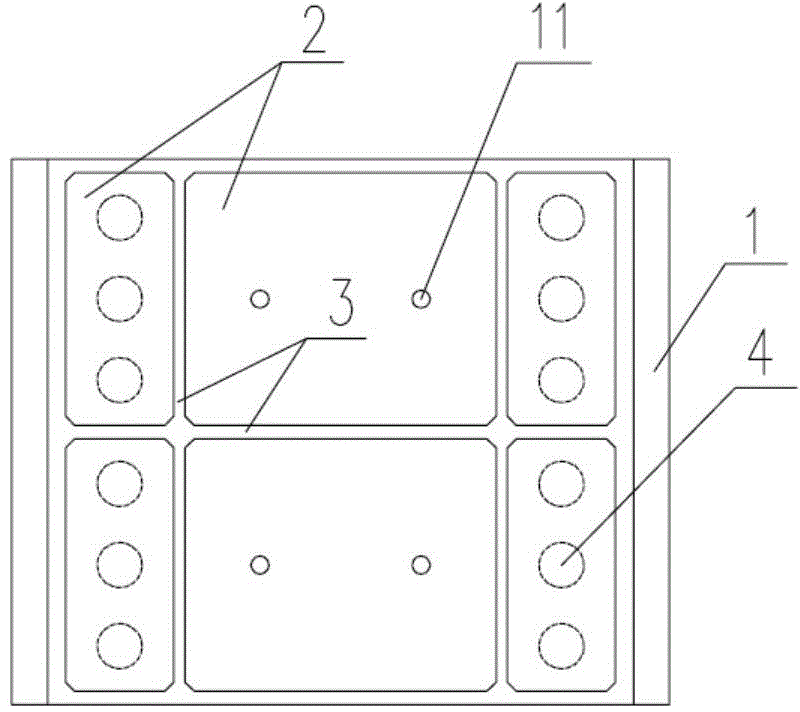

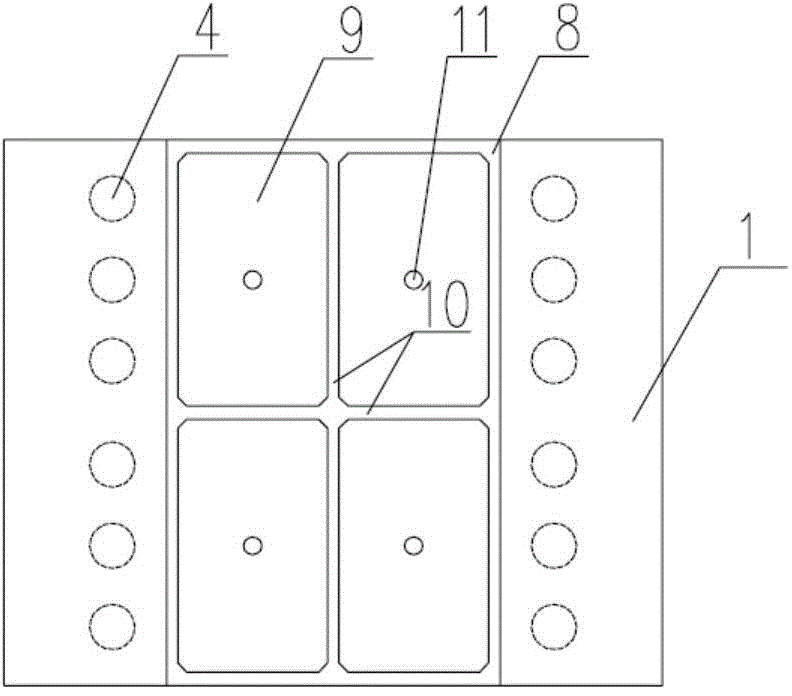

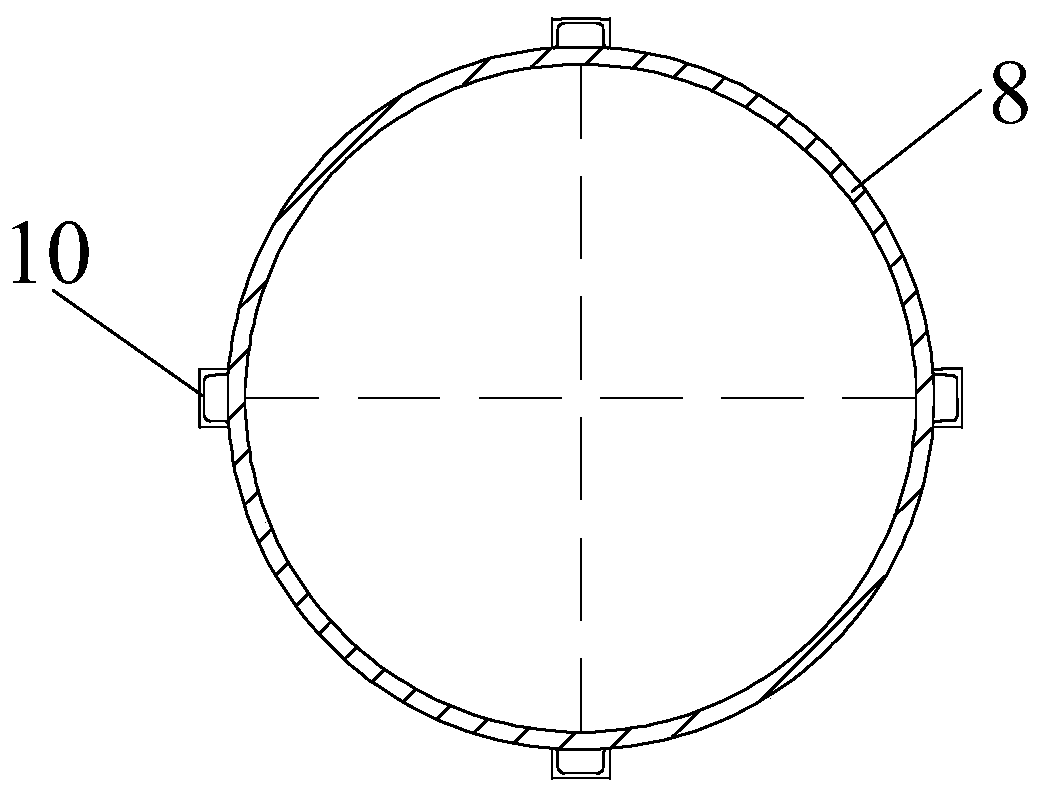

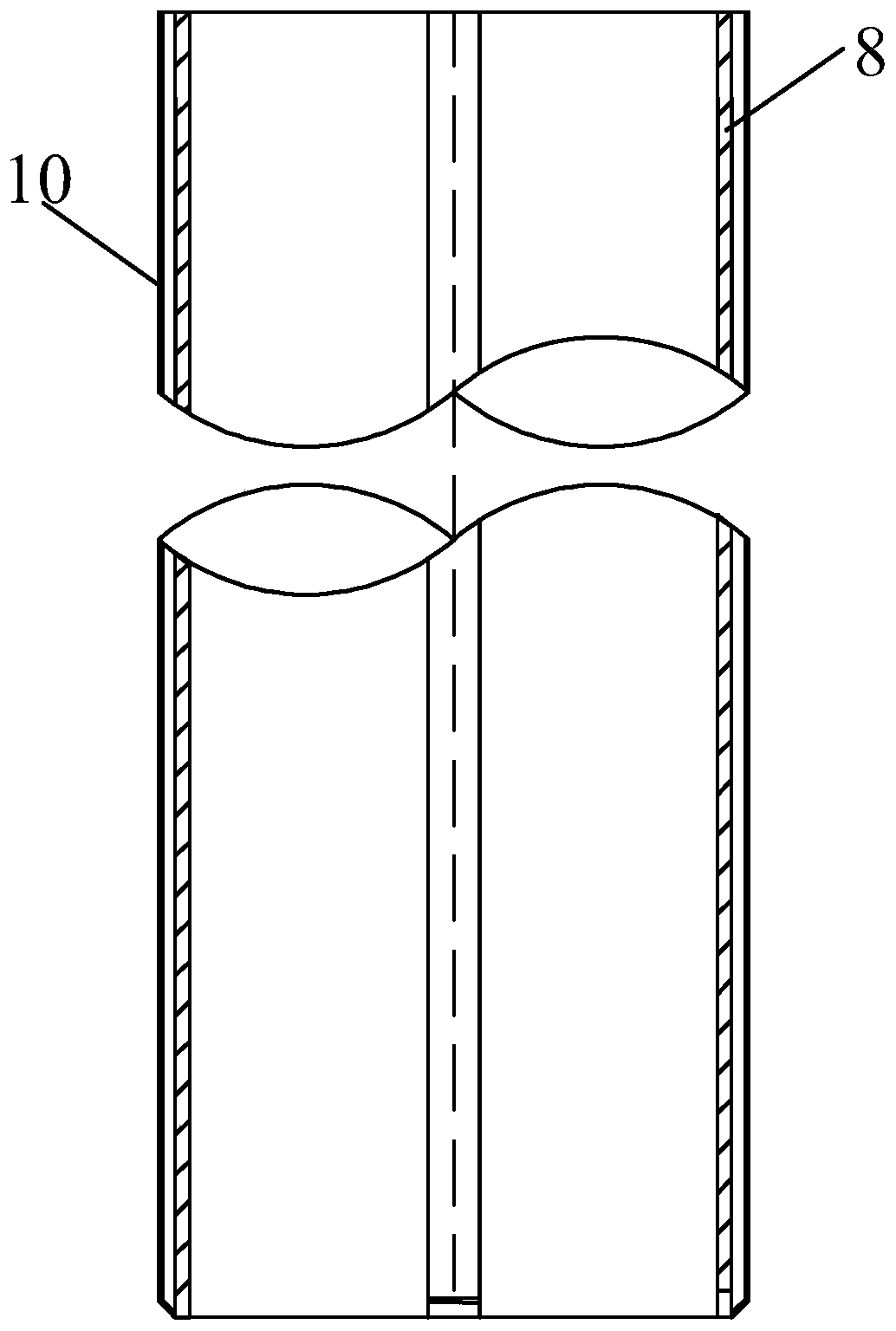

Construction method of breakwater in pile-supported cylindrical caisson structure

ActiveCN104314042AImprove stabilityImprove impact performanceBreakwatersQuaysEngineeringMulti segment

The invention relates to a construction method of a breakwater in a pile-supported cylindrical caisson structure. Connection of a multi-segment pile and sinking of thereof are finished by sinking a lower cylindrical caisson under negative pressure. The pile-supported cylindrical caisson structure comprises an upper cylinder with reserved pile holes, a lower cylinder with compartments and foundation piles; the foundation piles penetrate the reserved pile holes of the upper cylinder and are connected with the upper cylinder through concreting to form an integrated structure; a bottom plate of the upper cylinder is a cover plate of the lower cylinder; the cover plate is provided with reserved ducts for valve control. The construction method has the advantages that the advantages of the cylindrical caisson structure, the caisson structure and the foundation pile structure are given to full play; after the lower cylinder is sunk into the earth, horizontal bearing capacity of the foundation structure can be improved; the foundation pile structure allows higher vertical bearing capacity for a foundation; after the upper cylinder is filled with backfill, structural stability can be improved and wave impact resistance can be improved.

Owner:天津港航工程有限公司

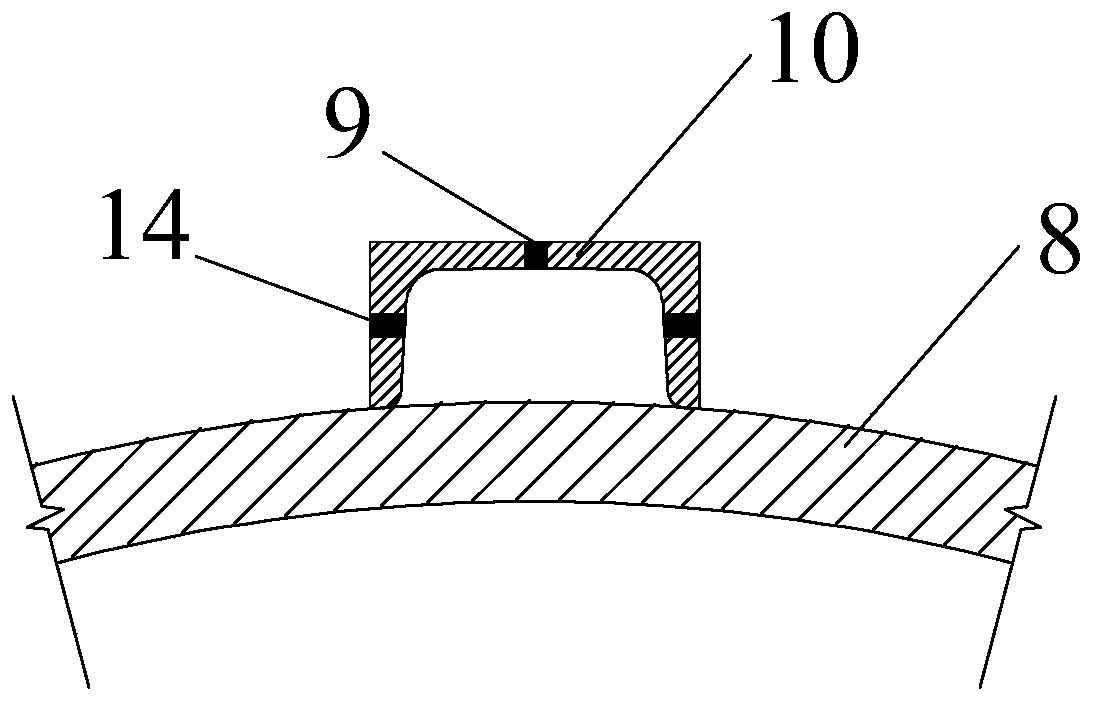

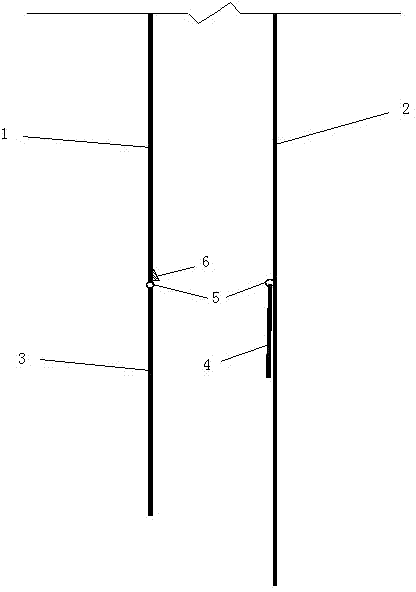

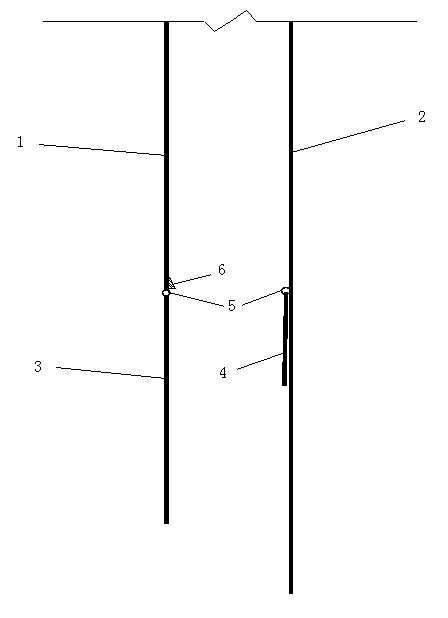

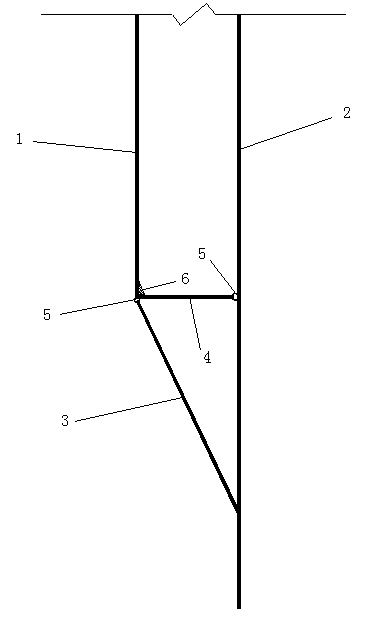

Offshore steel pipe distributed post-grouting device, air-type grouting assembly and construction method

InactiveCN111501761ARealization of groutingAdjustable grouting reinforcement rangeBulkheads/pilesSlurryPipe

The invention discloses an offshore steep pipe distributed post-grouting device, an air-type grouting assembly and a construction method. The air-type grouting assembly comprises a grouting pipe for being placed into a vertical square grouting channel, square rubber air bags which are wrapped on the outer side of the grouting pipe at upper and lower intervals, an upper air pipe connected with thesquare rubber air bag at the upper end to inflate the square rubber air bag, and a lower air pipe connected with the square rubber air bag at the lower end to inflate the square rubber air bag, and aplurality of slurry outlets are uniformly formed in the outside surface, avoiding the square rubber air bags at the upper and lower ends, of the grouting pipe; and the square rubber air bags are filled under the action of external air pressure, and the square rubber air bags at the upper and lower ends under the sufficient air state form a local closed space with the vertical square grouting channel. According to the air-type grouting assembly, a closed space is formed by using the square rubber air bags arranged up and down and the inner wall of the vertical square grouting channel under sufficient air state, and the local grouting in the vertical square grouting channel is achieved.

Owner:都城伟业集团有限公司 +1

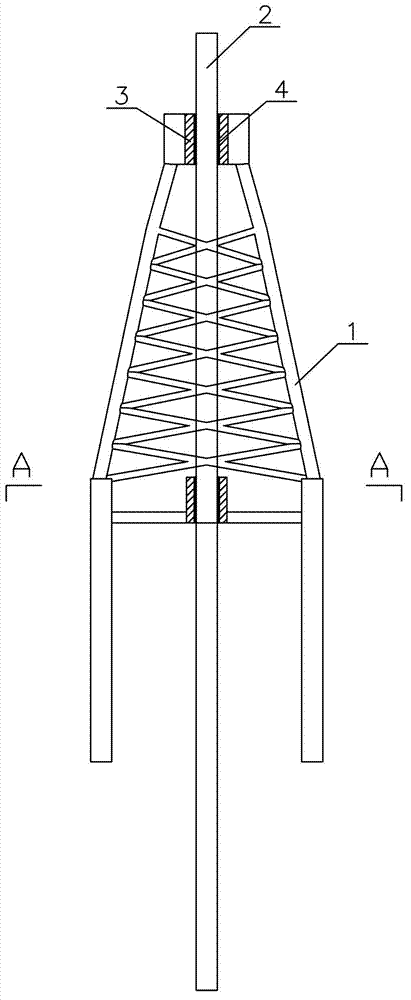

Composite pile foundation

InactiveCN102852155AIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringWind powerBearing capacity

The invention discloses a composite pile foundation. Tube-shaped connection sections are respectively arranged at the center of the top and the center of the bottom of a truss of a four-foot guiding pipe frame foundation, single-pile foundations are inserted on an upper connection section and a lower connection section and fixedly connected with the connection sections, and the connection can be specifically in a welding mode, in a grouting mode through a shear connector, in an elastic mode through an elastic member or the like. The composite pile foundation fully takes advantages of specific stress of the single-pile foundations, strong application capacity to a soil layer, convenient construction, good horizontal bearing capacity of the four-foot guiding pipe frame foundation and the like, is greatly improved in integral rigidity, horizontal load resisting, vertical load resisting and bending moment capacity compared with a single single-pile foundation or four-foot guiding pipe frame foundation, particularly changes the stress mode of the single-pile structure, effectively reduces bending moment load on the foundations caused by fan load, reduces horizontal displacement of a wind power structure and accordingly reduces pile length, pile diameter, wall thickness and penetration depth, remarkably reduces material cost, and is simple in construction process.

Owner:TIANJIN UNIV

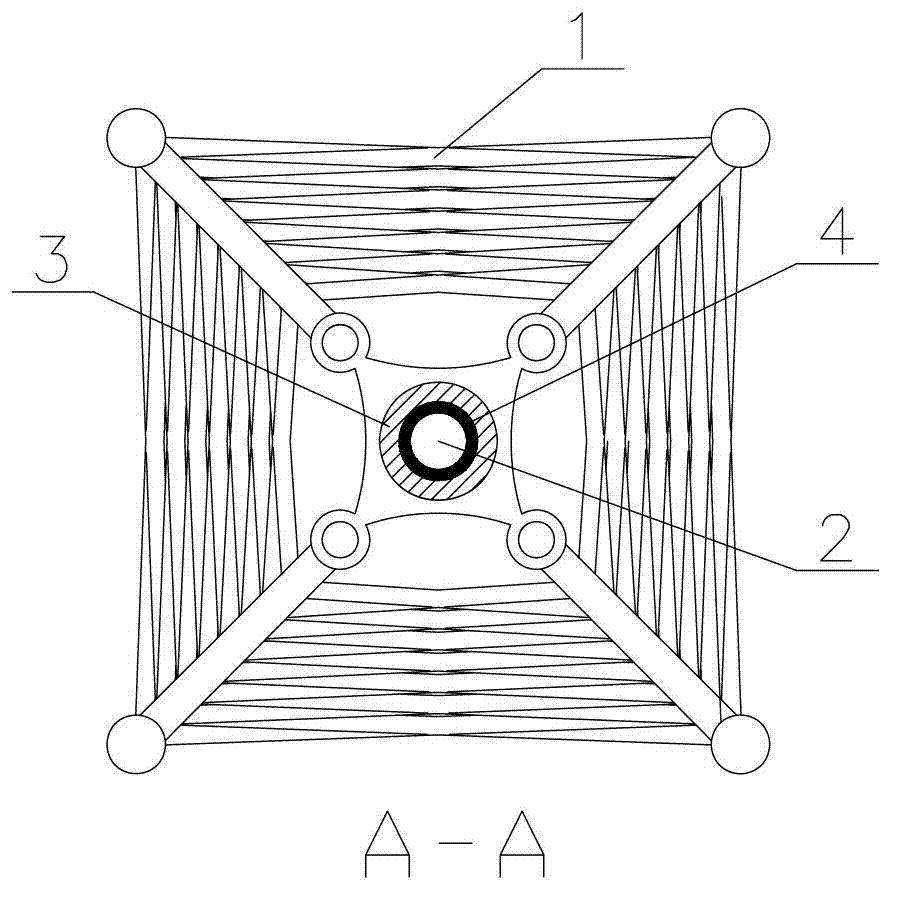

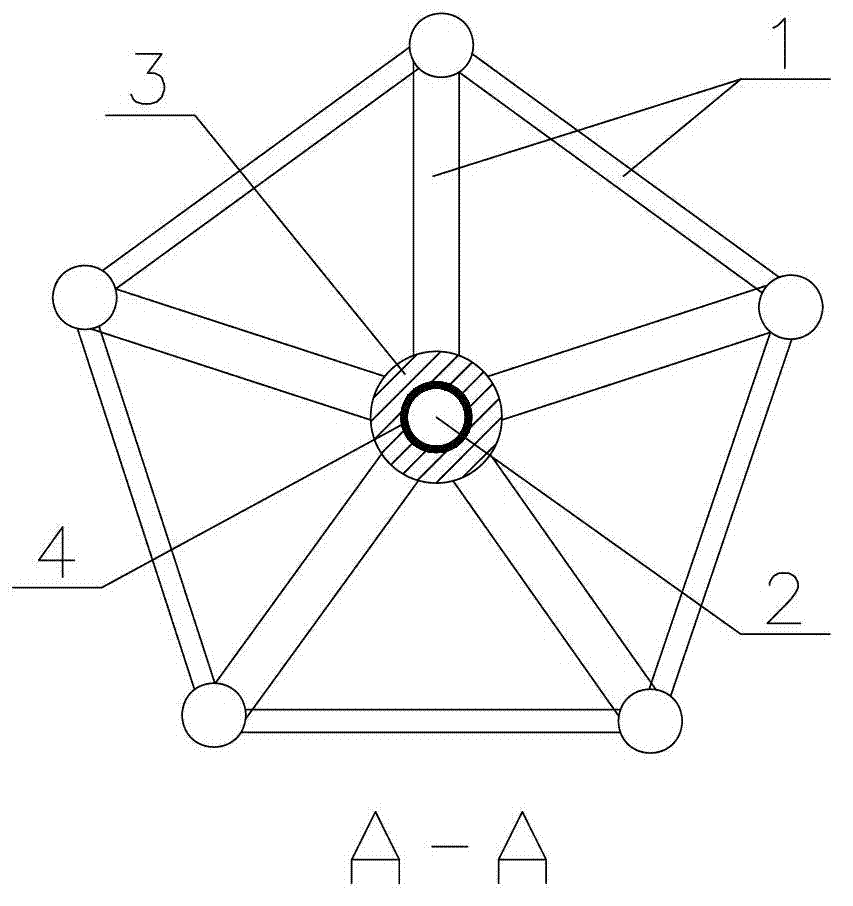

Composite pile foundation

InactiveCN102852154AIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityLoad resistance

The invention discloses a composite pile foundation. Cylindrical connecting sections are respectively arranged in the centers of the top and the bottom of a truss on the five-feet bracket type foundation; the upper and lower connecting sections are inserted into a single-pile foundation; the single-pile foundation is fixedly connected with the connecting sections; and welding, grouting connection through a shear key or elastic connection through an elastic body can be adopted. The advantages of definite stress of the single-pile foundation, high soil layer applicability, convenient construction, high horizontal bearing capacity of the five-feet bracket type foundation and the like are fully utilized, compared with the independent single-pile foundation or the five-feet bracket type foundation, the composite pile foundation has the advantages that the integral rigidity, horizontal load resistance, vertical load resistance and bending moment resistance are greatly improved, particularly the stress mode of the single-pile structure is changed, the bending moment load of the fan load on the foundation is effectively realized, and the horizontal displacement of the wind power structure is reduced, so that the pile length, the pile diameter, the wall thickness and the penetration depth of the pile foundation are reduced; and therefore, the material cost is greatly reduced, and the construction process is simple.

Owner:TIANJIN UNIV

Non-prestressed centrifugal concrete pile

InactiveCN102071701AImprove horizontal bearing capacityMeet the seismic requirementsBuilding reinforcementsBulkheads/pilesPre stressArchitectural engineering

The invention discloses a non-prestressed centrifugal concrete pile, which is characterized by comprising a centrifugal concrete pile body, a non-prestressed main bar, a spiral stirrup and two end plates, wherein the non-prestressed main bar is longitudinally distributed and is welded or bound on the spiral stirrup; and the two ends of the non-prestressed main bar are welded respectively or anchored on the two end plates through anchor holes. Based on the conventional non-prestressed centrifugal concrete pile, a prestressed main bar which is positioned on a reinforcement framework and can longitudinally pass through the entire framework is replaced by the non-prestressed main bar, a centrifugal molding process is used in a production process and a part of residual water is brought out centrifugally, so that concrete is more compact. The advantages of a centrifugal pile and a solid square pile are brought into full play, and the centrifugal concrete pile which has high vertical bearing capacity and high horizontal bearing capacity of a pile foundation and can meet a seismic resistance requirement is provided. Simultaneously, a prestress application process is eliminated, so that the non-prestressed centrifugal concrete pile is produced by a production method which is simpler than the conventional production method of a prestressed centrifugal concrete pile, and production efficiency is higher.

Owner:宿迁市固丰管桩有限公司

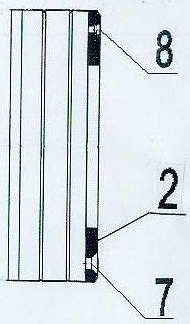

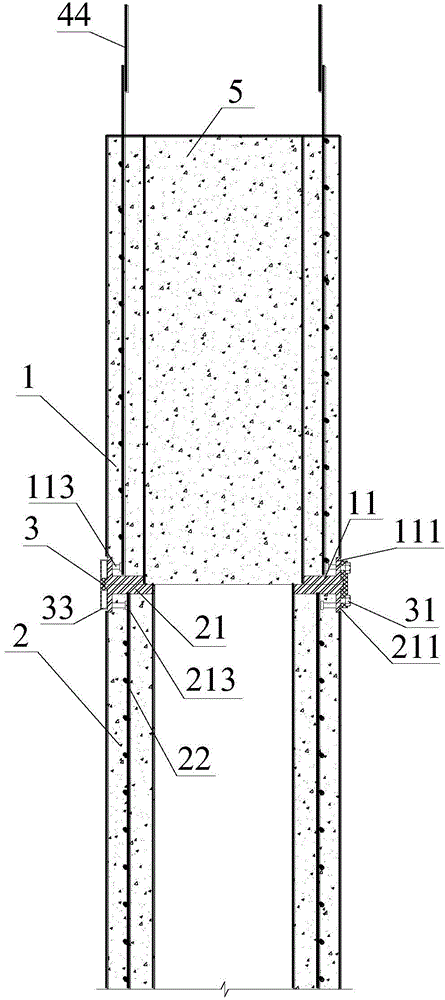

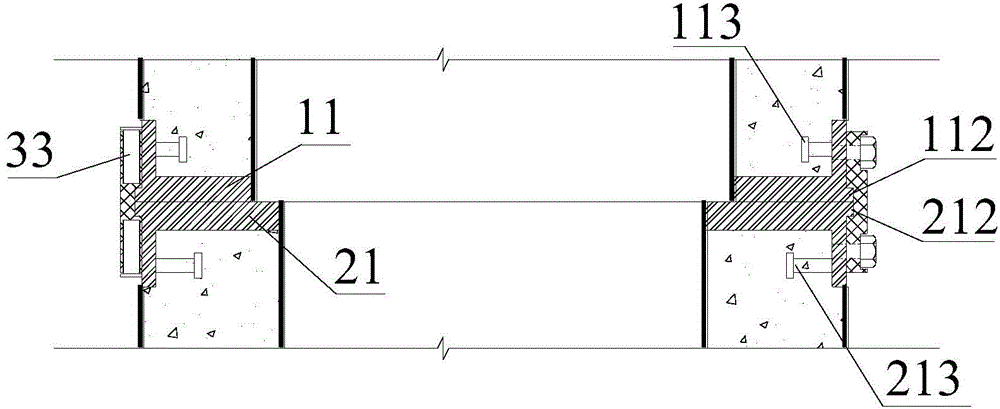

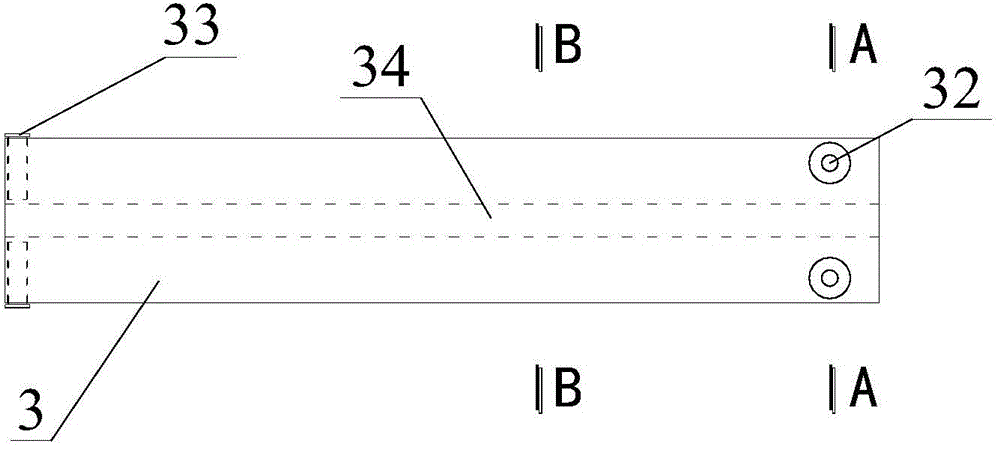

Prefabricated piles, connecting structure of prefabricated piles and construction method of connecting structure

ActiveCN109853527AImprove horizontal bearing capacityHigh pull-out capacityBulkheads/pilesEngineeringStructural engineering

The invention discloses prefabricated piles, a connecting structure of the prefabricated piles and a construction method of the connecting structure. The prefabricated piles include pile bodies and end head plates at the two ends, wherein a plurality of connecting cylinders are arranged in the end head plates in an embedded mode, and the two ends of a main rib penetrate through the connecting cylinders and extend outwards; the connecting cylinders are filled with colloids in a sealing mode, and the whole pile bodies have no metal materials; ribs and the pile bodies can be effectively preventedfrom being eroded by chloride ions in corrosive environments such as seawater; the connecting structure of the prefabricated piles comprises columnar connecting bodies tightly connected between the prefabricated piles, and sleeves are arranged on the columnar connecting bodies in a sleeving mode; and gaps between the sleeves and the side walls of the columnar connecting bodies and the connectingcylinders are all filled with the colloids, the connecting structure can be tightly connected between the two prefabricated piles, the connection is reliable, and the function of corrosion resistanceand high-strength connection can be realized. The construction method of the connecting structure comprises the steps that the columnar connecting bodies and the sleeves are installed, and the installation is convenient.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

Construction Method of Cast-in-situ Reinforced Concrete Large Diameter Pipe Pile

The invention discloses a construction method of a PCC (cast-in-place concrete large-diameter pipe) pile, which comprises the following steps: taking a pile driver in place; rotating movable inner supports to close to limiting stoppers; closing a valve pile tip; sinking a pile mould; moving a vibration head; placing a reinforcement cage; arranging the vibration head; pouring concretes; drawing a tube in a vibrating manner; opening the valve pile tip and the inner supports; punching the concretes and the reinforcement cage into a foundation; and extracting a formed pile from the pile mould. The three or more than three movable inner supports and the limiting stoppers are uniformly arranged along the pile mould. Transverse spacer bars are arranged on the reinforcement cage, two end of each of the transverse spacer bars are provided with a semicircular elbow respectively, each transverse cross section of the reinforcement cage is provided with three or more than three transverse spacer bars, and one group of the transverse spacer bars is arranged along the horizontal direction at an interval of 3-5m. The movable inner supports and the reinforcement cage with the transverse spacer bars are arranged skillfully, thus the problem of construction of the PCC pile is solved, the application range of the PCC pile is expanded, the cost is low, and the higher bearing capacity is obtained with the less concrete consumption.

Owner:HOHAI UNIV

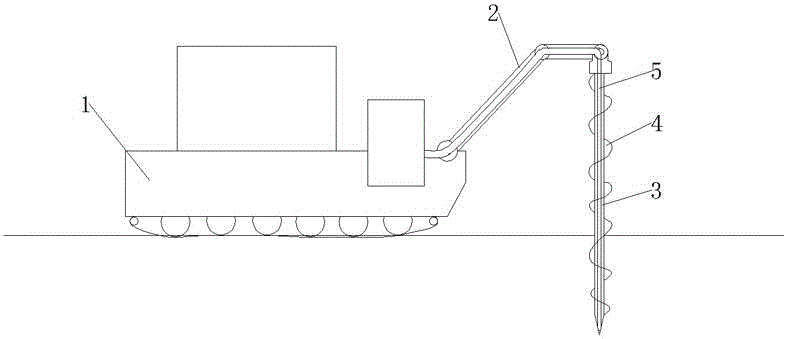

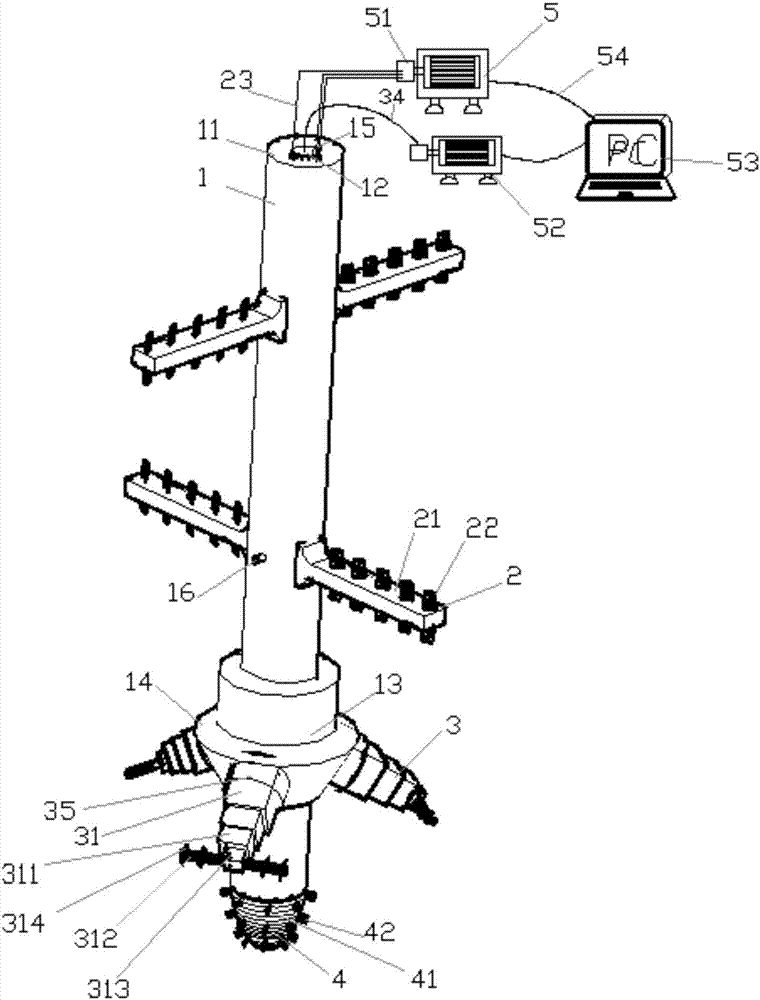

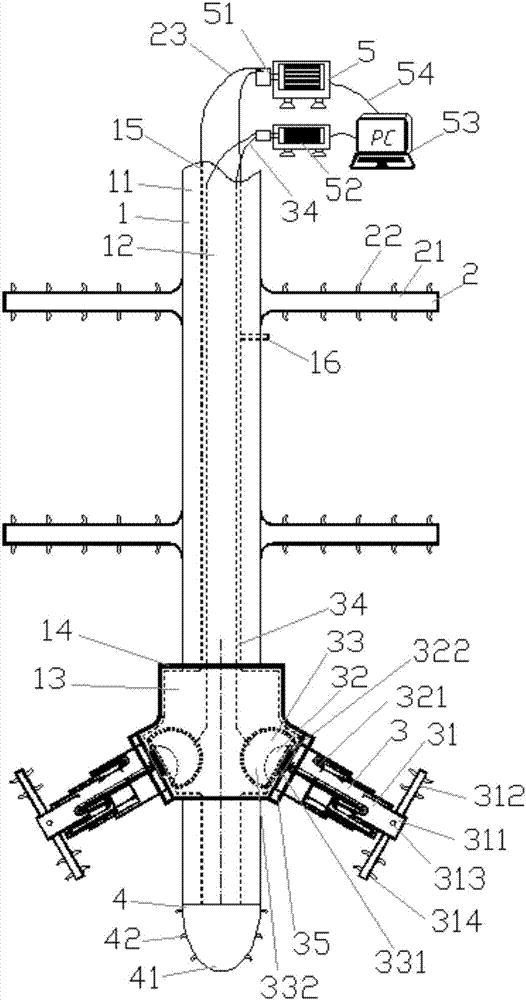

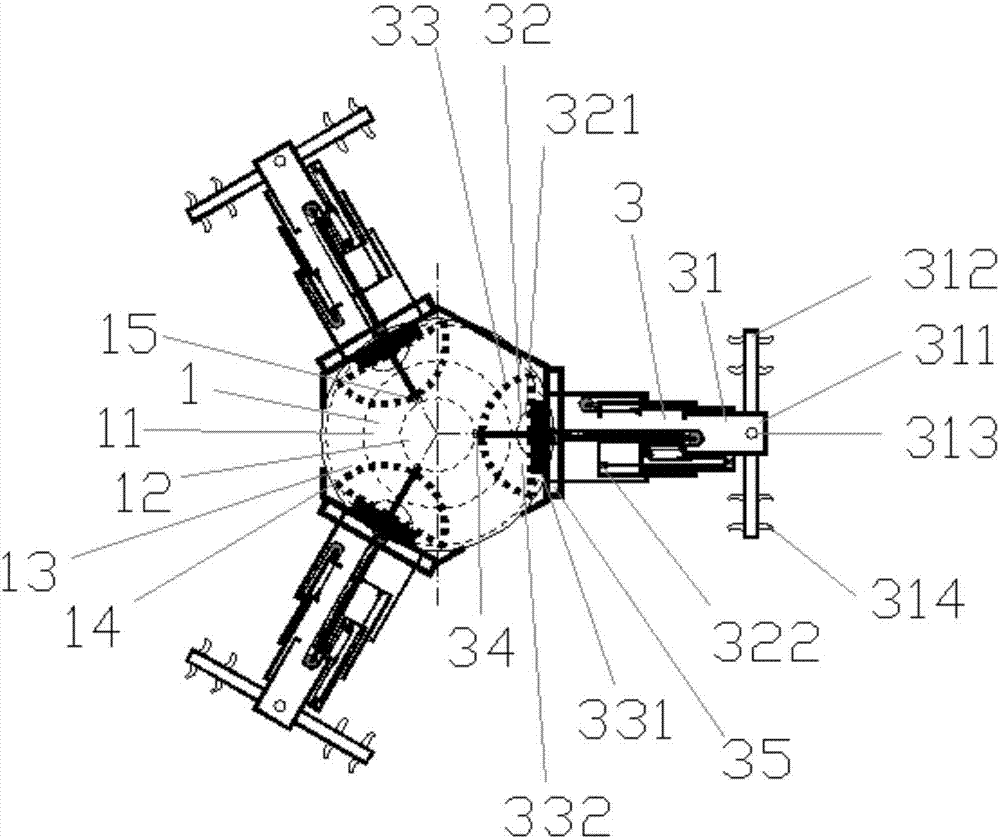

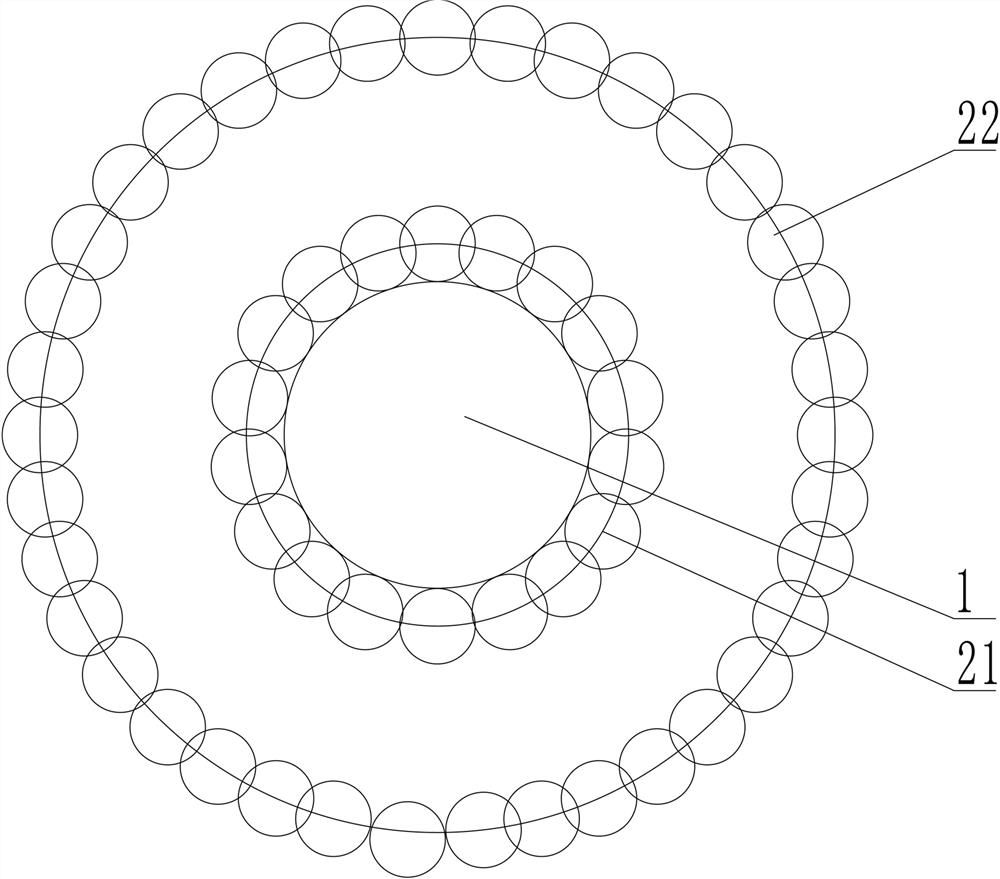

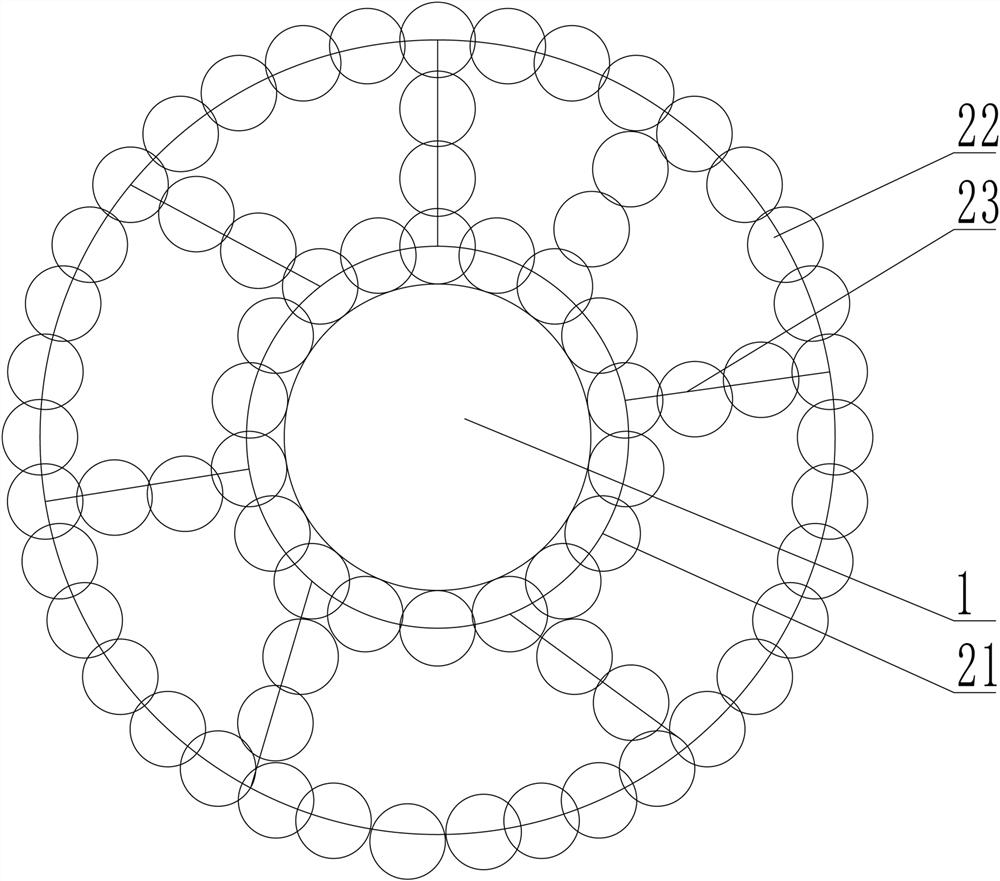

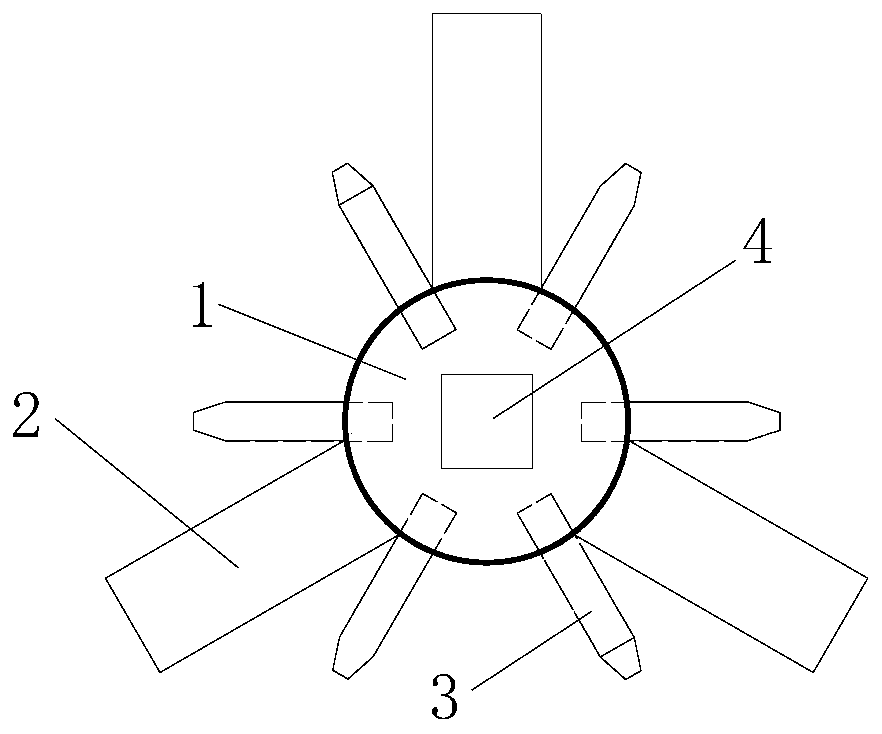

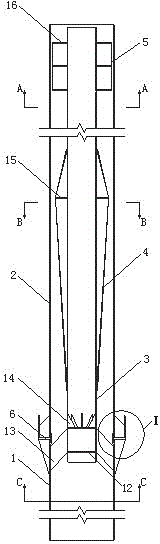

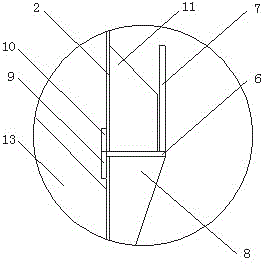

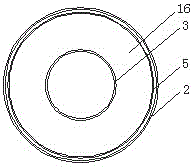

Drill bit system for root-shaped mixing pile

PendingCN106930702ASave investment in construction projectsSimple structureDrilling rodsDrilling casingsAutomatic controlDrill bit

The invention relates to a drill bit system for a root-shaped mixing pile. The system comprises a drill spindle, a common mixing structure, a telescopic mixing fulcrum bar structure, a drill bit top structure and a mixing spindle regulating power system; the common mixing structure is a common mixing rod-shaped structure arranged on the outside wall of the drill spindle, the telescopic mixing fulcrum bar structure is a telescopic mechanical-arm-shaped structure which is telescopic and can conduct rotary mixing, the telescopic mixing fulcrum bar structure is arranged on the outside wall of the drill spindle, the drill bit top structure is fixed to the lower end of the drill spindle, and the mixing spindle regulating power system is arranged outside the drill spindle and automatically controls and regulates mixing of the telescopic mixing fulcrum bar structure to generate the root-shaped mixing pile. The system has the advantages of fully intelligent control, novel and practical structure, and convenient and rapid construction, saving labor of construction staff, being convenient to manage and maintain, saving construction investment by a large margin and the like.

Owner:浙江省水利水电勘测设计院有限责任公司

Construction method of PCC (cast-in-place concrete large-diameter pipe) pile

The invention discloses a construction method of a PCC (cast-in-place concrete large-diameter pipe) pile, which comprises the following steps: taking a pile driver in place; rotating movable inner supports to close to limiting stoppers; closing a valve pile tip; sinking a pile mould; moving a vibration head; placing a reinforcement cage; arranging the vibration head; pouring concretes; drawing a tube in a vibrating manner; opening the valve pile tip and the inner supports; punching the concretes and the reinforcement cage into a foundation; and extracting a formed pile from the pile mould. The three or more than three movable inner supports and the limiting stoppers are uniformly arranged along the pile mould. Transverse spacer bars are arranged on the reinforcement cage, two end of each of the transverse spacer bars are provided with a semicircular elbow respectively, each transverse cross section of the reinforcement cage is provided with three or more than three transverse spacer bars, and one group of the transverse spacer bars is arranged along the horizontal direction at an interval of 3-5m. The movable inner supports and the reinforcement cage with the transverse spacer bars are arranged skillfully, thus the problem of construction of the PCC pile is solved, the application range of the PCC pile is expanded, the cost is low, and the higher bearing capacity is obtained with the less concrete consumption.

Owner:HOHAI UNIV

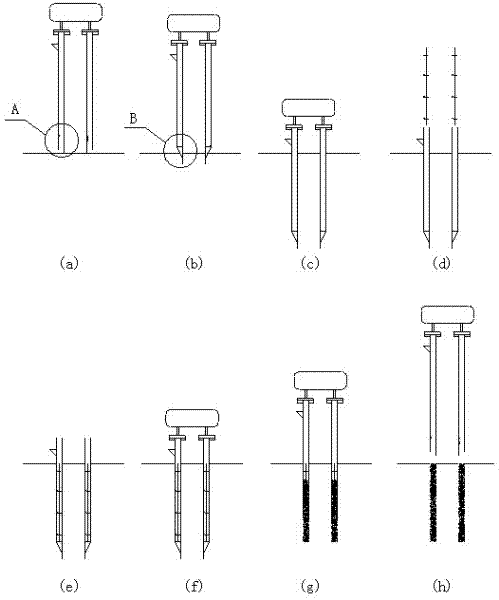

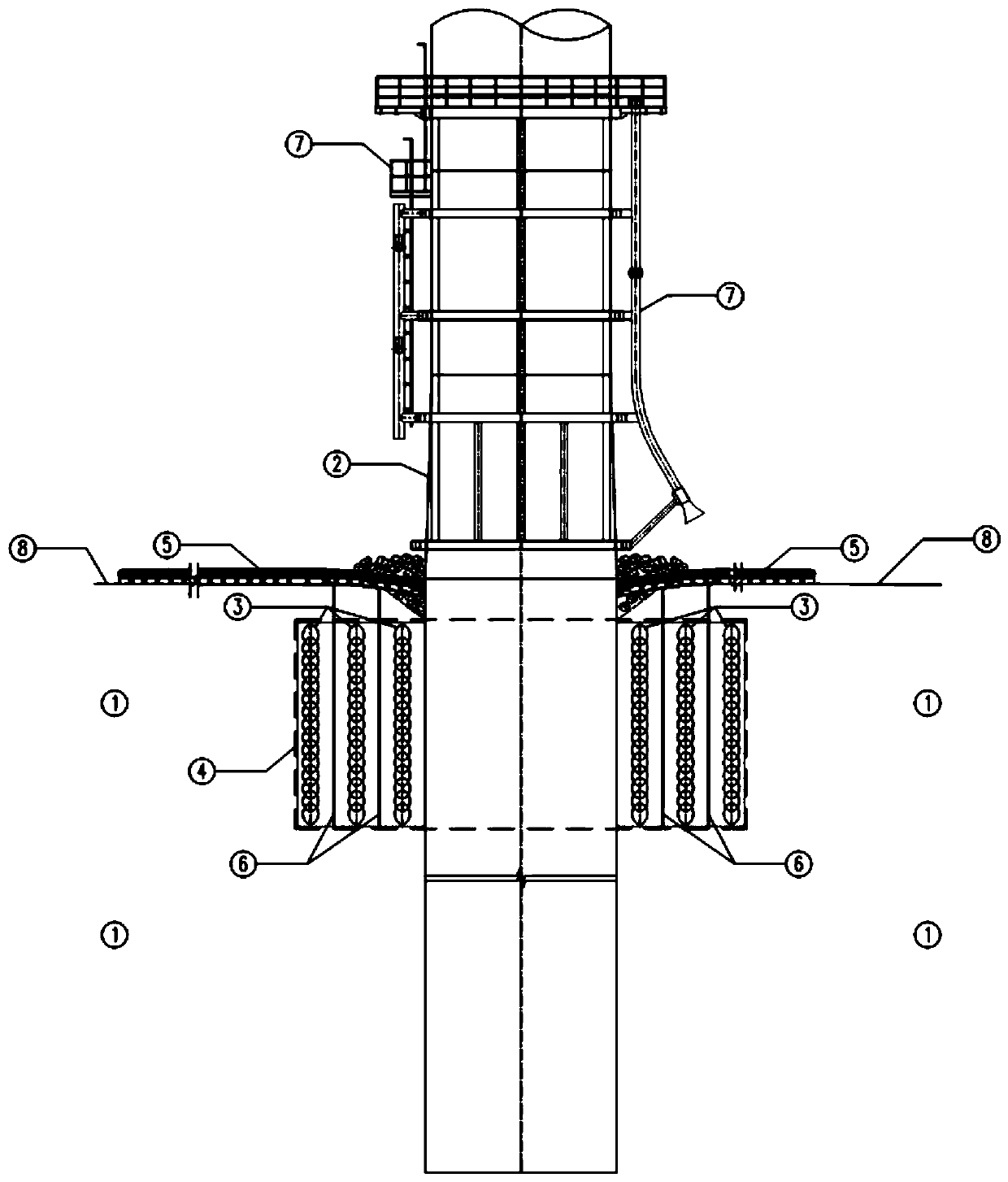

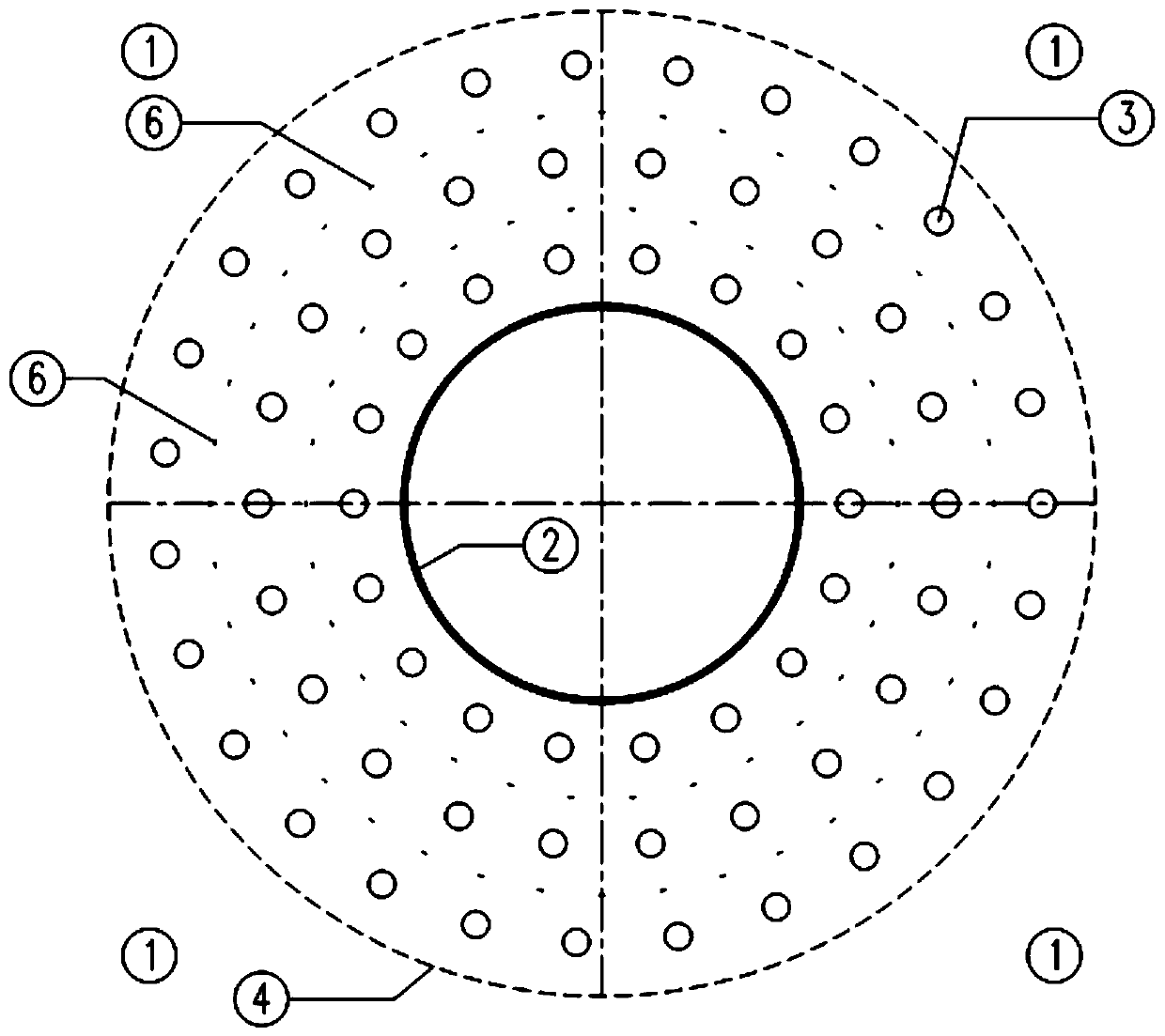

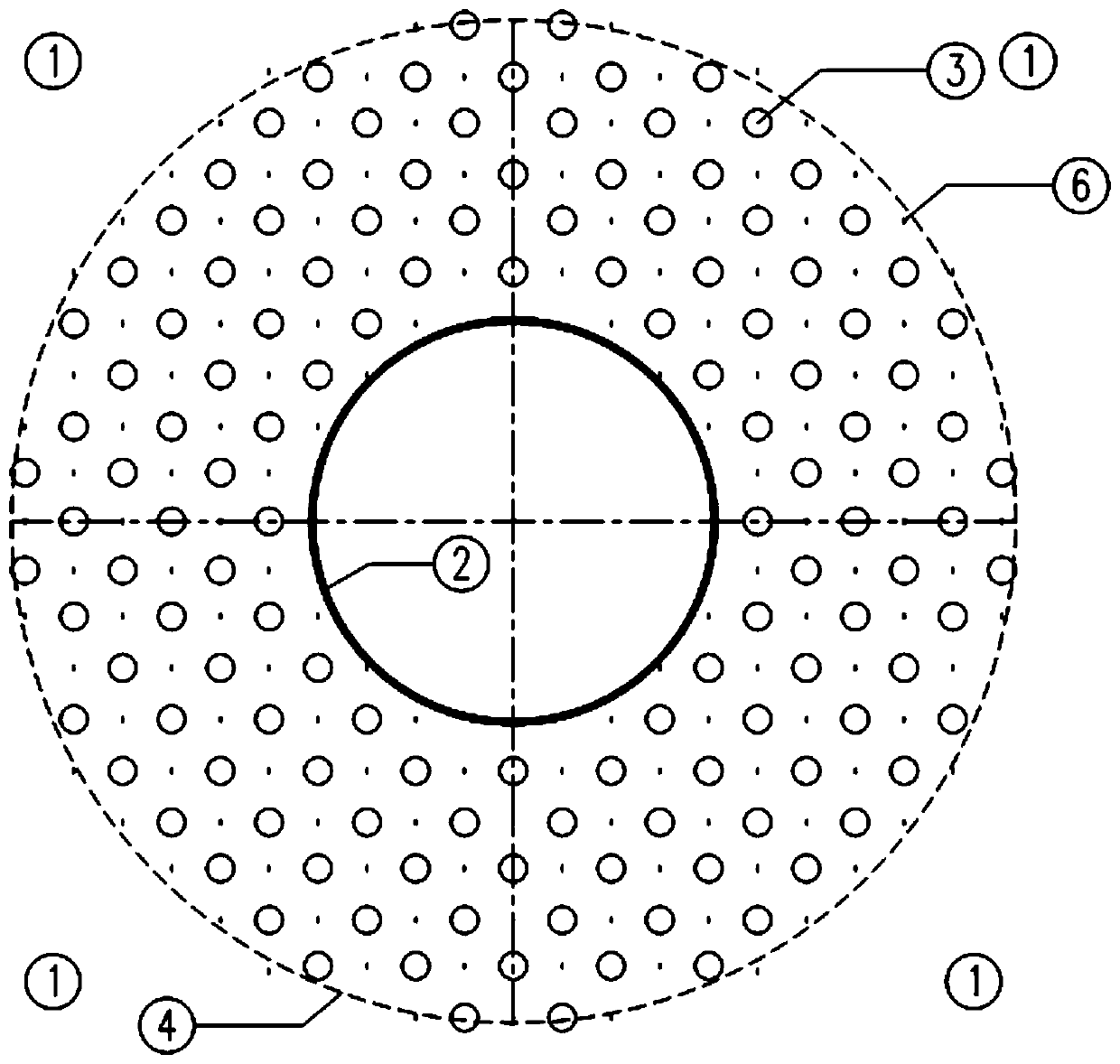

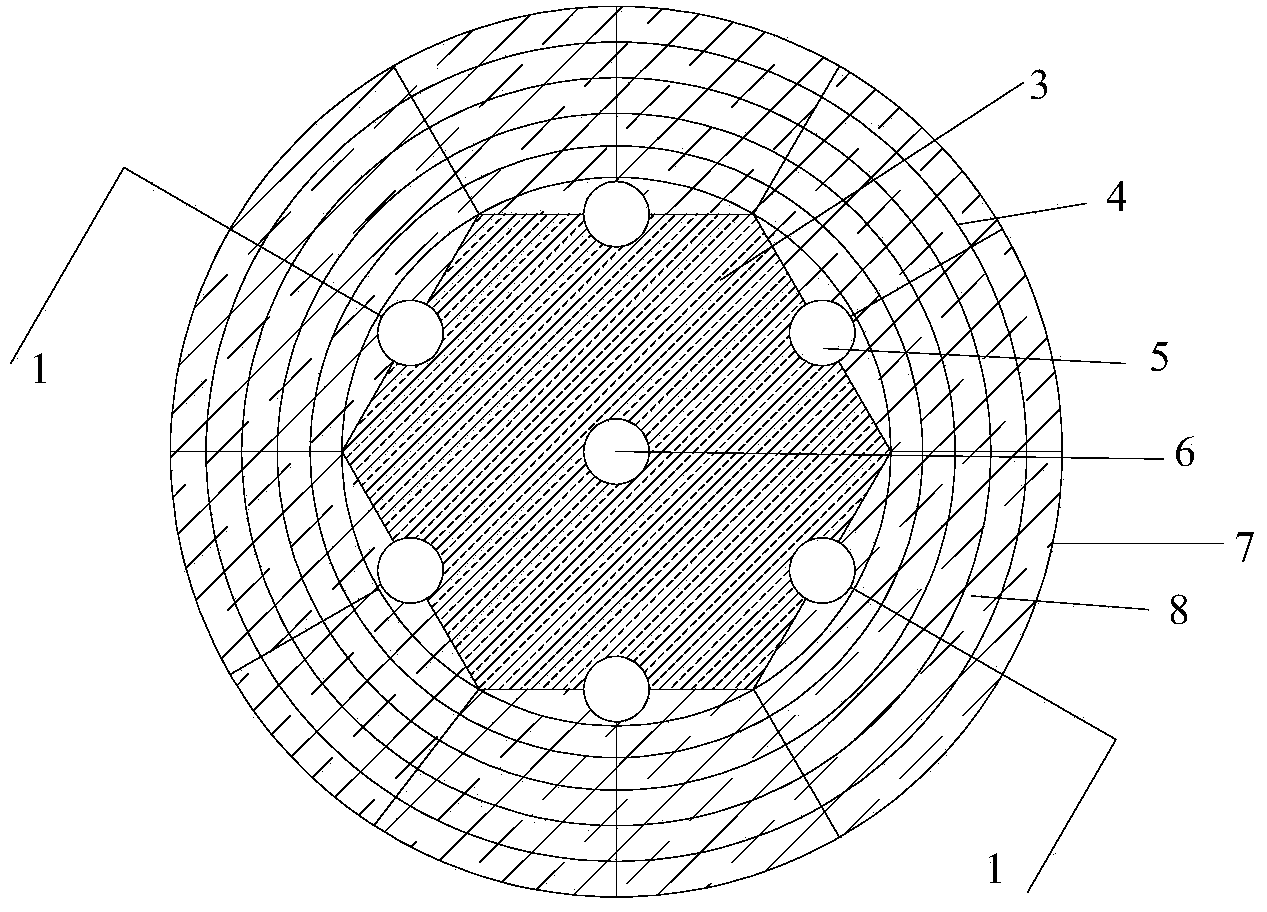

Single-pile foundation of offshore wind power vibroflotation cemented pile reinforced soft soil foundation and construction method

InactiveCN112922019AImprove carrying capacityImprove horizontal carrying capacityFinal product manufactureWind motor assemblyOffshore wind powerSeabed

The invention provides a single-pile foundation of an offshore wind power vibroflotation cemented pile reinforced soft soil foundation and a construction method. The single-pile foundation comprises a single pile and vibroflotation cemented piles, wherein the vibroflotation cemented piles are arranged around the single pile; the vibroflotation cemented piles are formed in a seabed soft soil layer and a supporting layer through a construction method of combining a deep sea gravel pile vibroflotation pile forming process and an underwater self-compacting cement-based cementing material self-flow grouting process; the vibroflotation cemented piles and soil bodies among the piles form a vibroflotation cemented pile composite foundation; and the pile body strength of the vibroflotation cemented piles in the composite foundation is sequentially increased from an outer ring to an inner ring and is sequentially decreased from the upper part to the lower part. The vibroflotation cemented piles effectively improve the bearing capacity of the soft soil layer, the applicability of the single-pile foundation in a shallow covering layer seabed and an offshore deep water wind power plant is expanded, meanwhile, a scouring structure does not need to be additionally arranged, and the single-pile foundation has the characteristics of being low in foundation manufacturing cost and construction cost, high in construction efficiency and easy and convenient to operate.

Owner:CHINA THREE GORGES CORPORATION +2

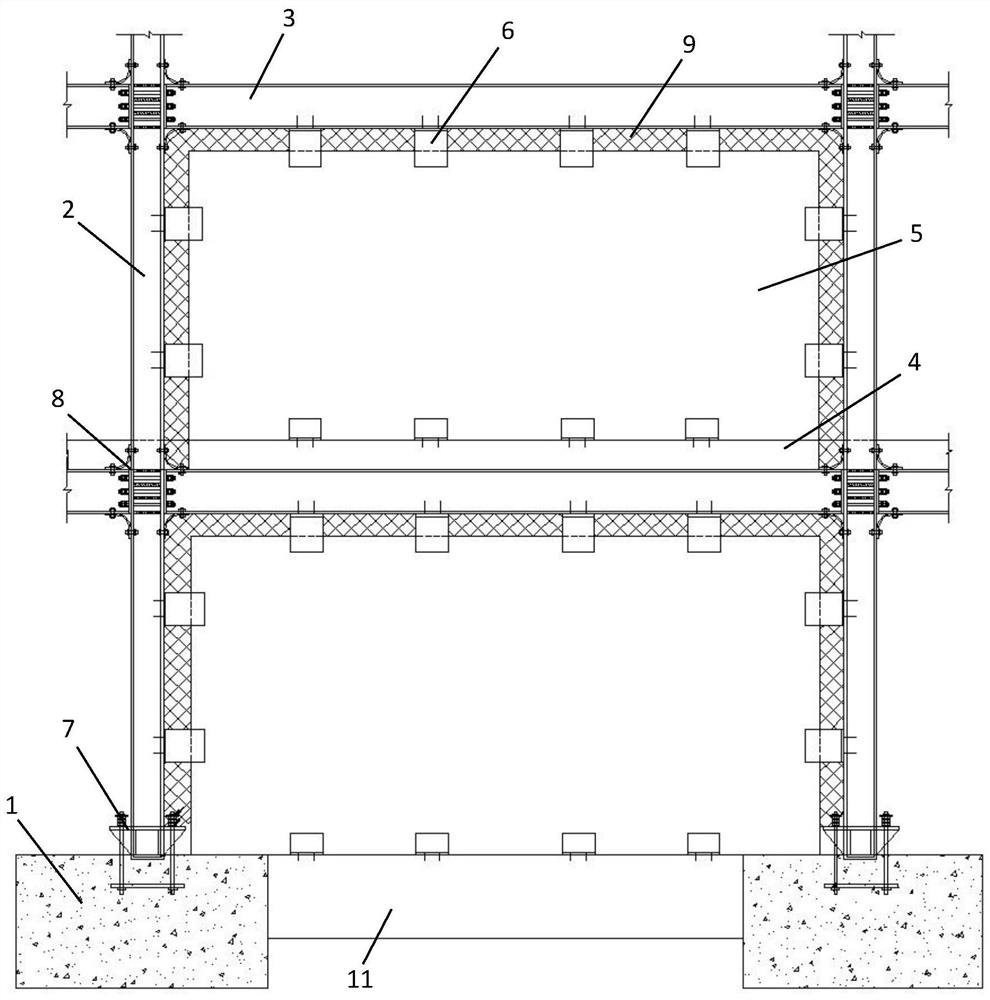

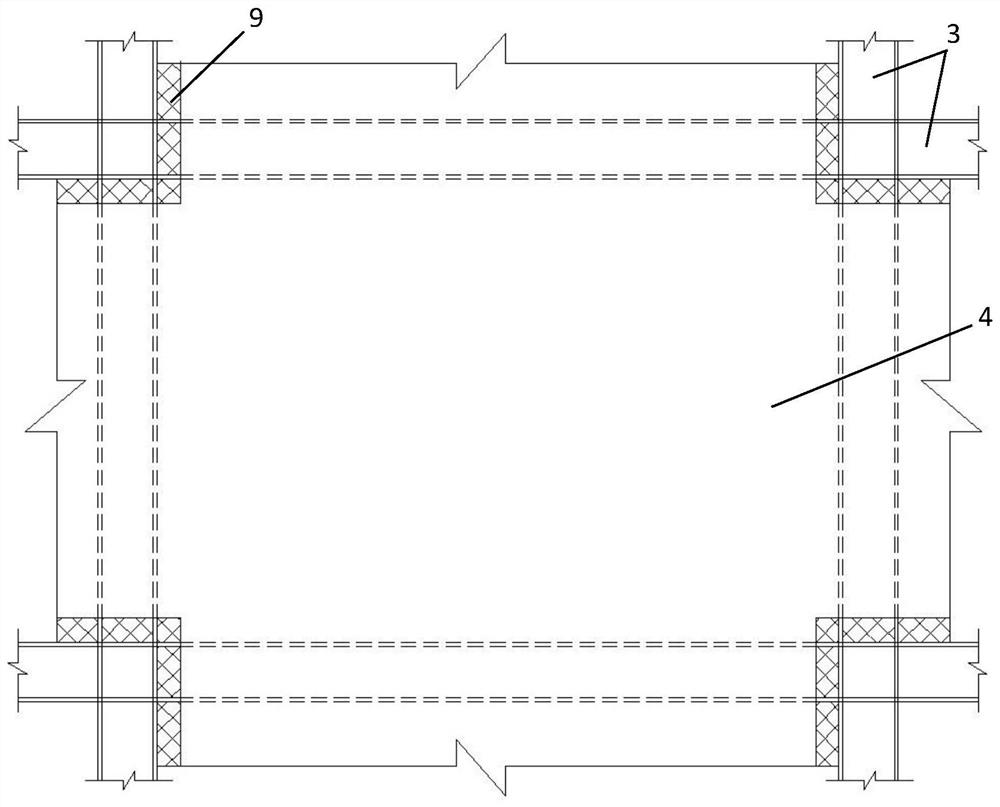

Prefabricated assembly type self-resetting frame integral structure

PendingCN111962659AImprove horizontal bearing capacityRealize energy consumptionProtective buildings/sheltersShock proofingFloor slabArchitectural engineering

The invention discloses a prefabricated assembly type self-resetting frame integral structure which comprises foundations, steel columns, cross beams, floor slabs, prefabricated filling wallboards andU-shaped clamps. The steel columns and the foundations form self-resetting column base structures; the steel columns and the cross beams connected with two sides thereof form self-resetting joint structures; when an earthquake comes, the self-resetting joint structures located at the beam-column joints dissipate earthquake energy firstly, and the horizontal bearing capacity of the structure is improved; secondly, the floor slabs and the prefabricated filling wallboards are not in direct contact with the steel columns; certain distances are reserved between the prefabricated filling wallboardsand the bottoms of the U-shaped clamps on the upper portion and the two sides, when the overall structure has the tendency of lateral overturning, the floor slabs and the prefabricated filling wallboards keep a normal stable state, it is guaranteed that the gravity center of the overall structure does not deviate substantially along with the earthquake action, and the overall structure has the self-resetting capacity after an earthquake. And finally, the self-resetting joint structures and the self-resetting column base structures play a role to jointly ensure that joints and column bases arenot greatly damaged, so that the energy consumption and the self-resetting function of the structure are realized.

Owner:HAINAN UNIVERSITY

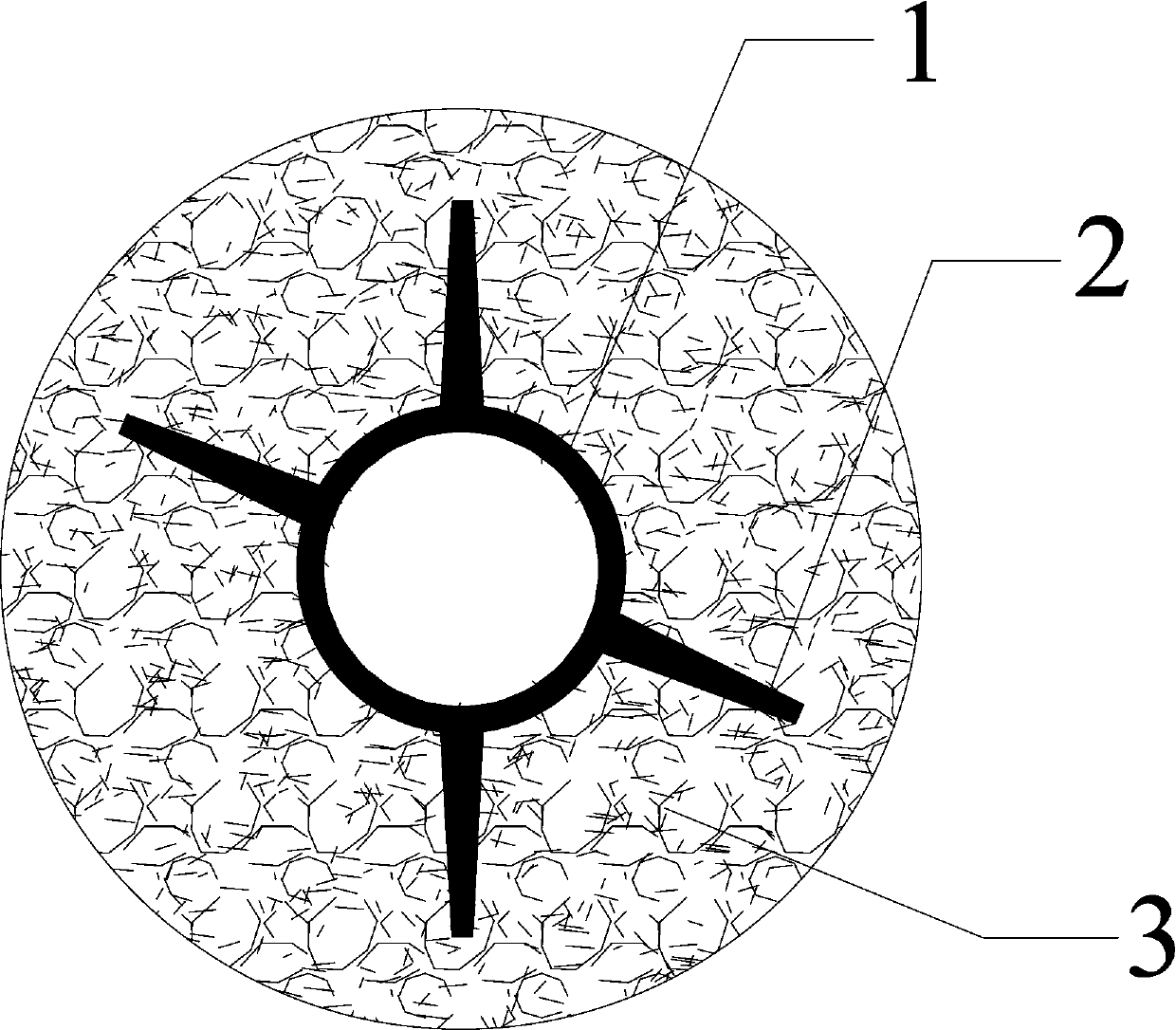

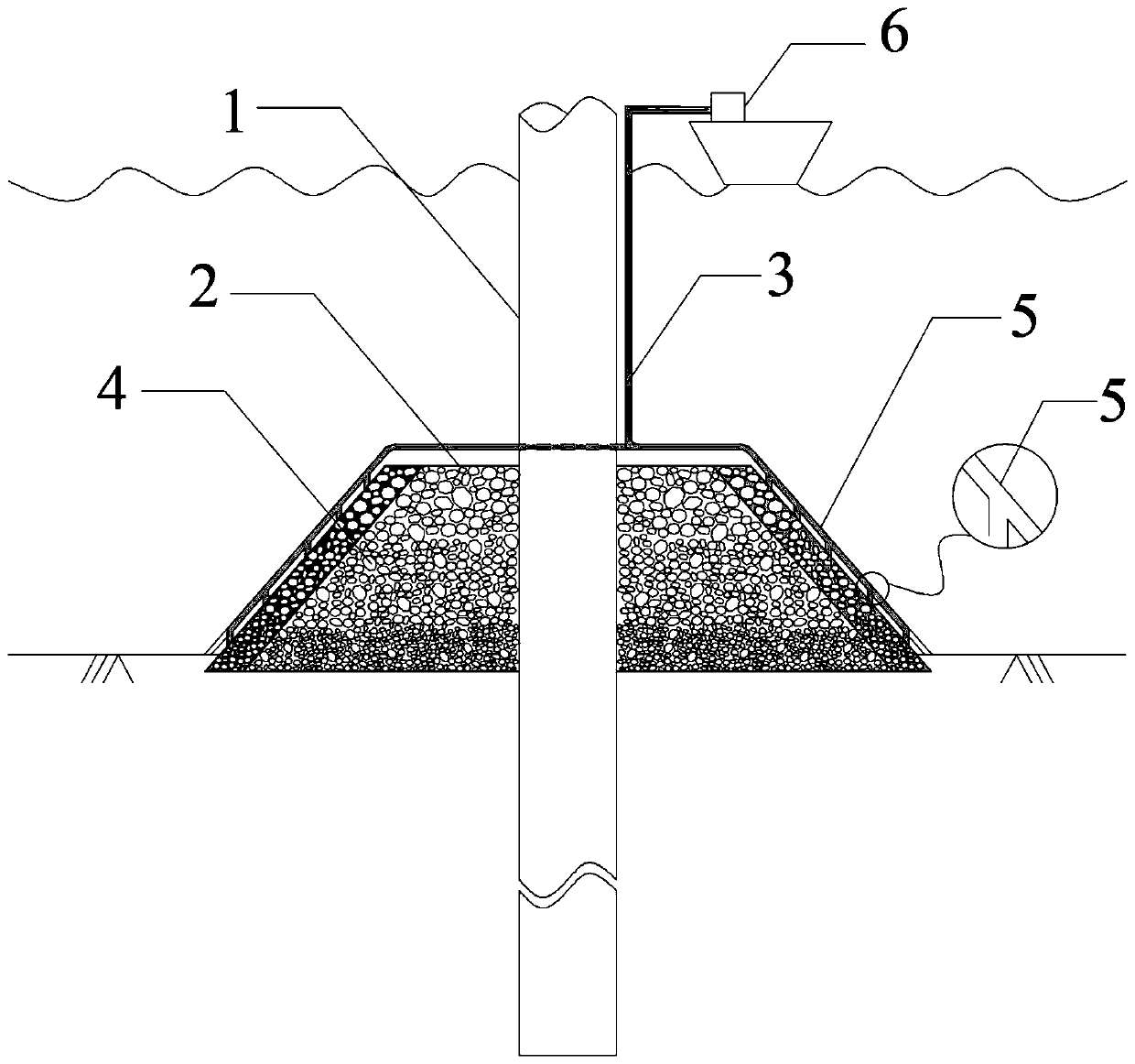

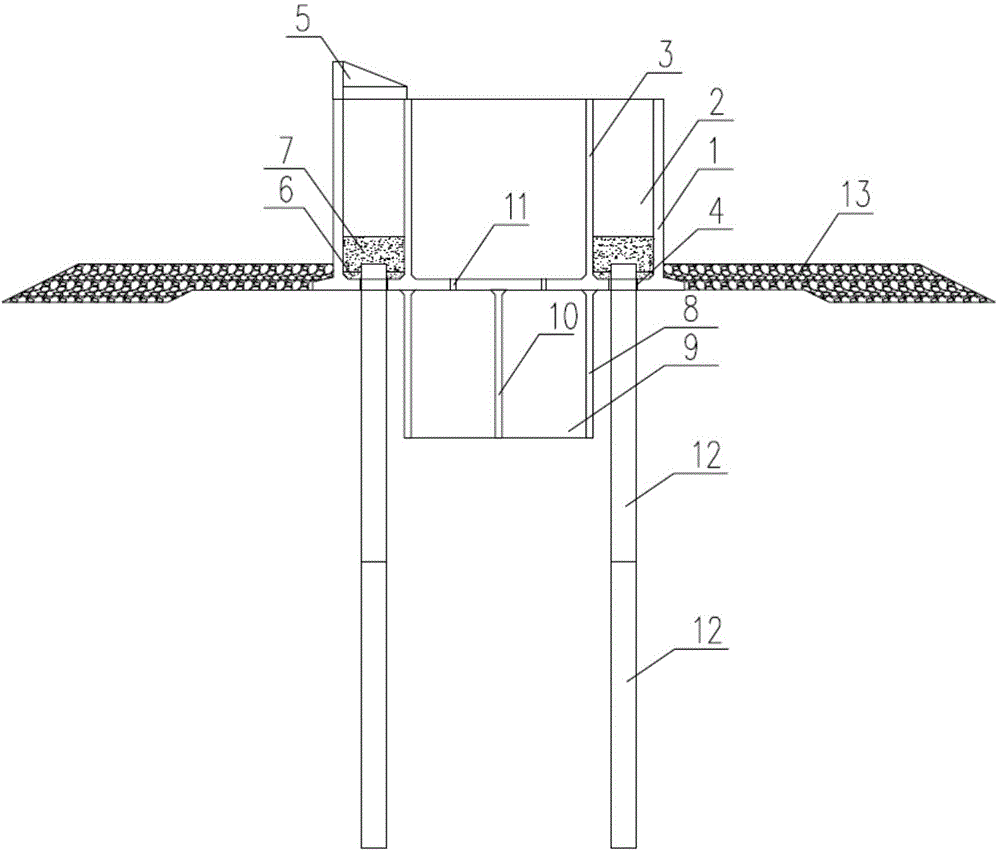

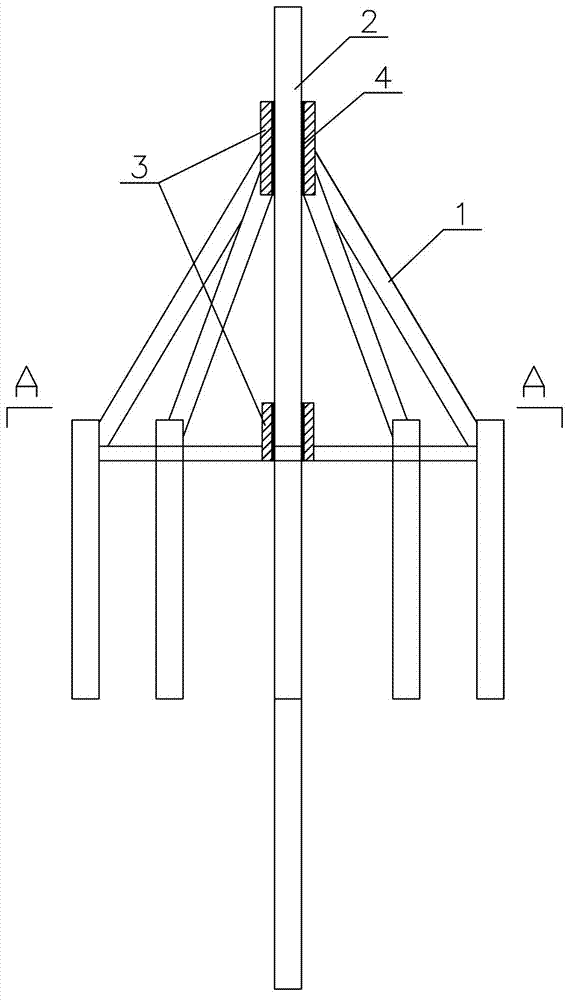

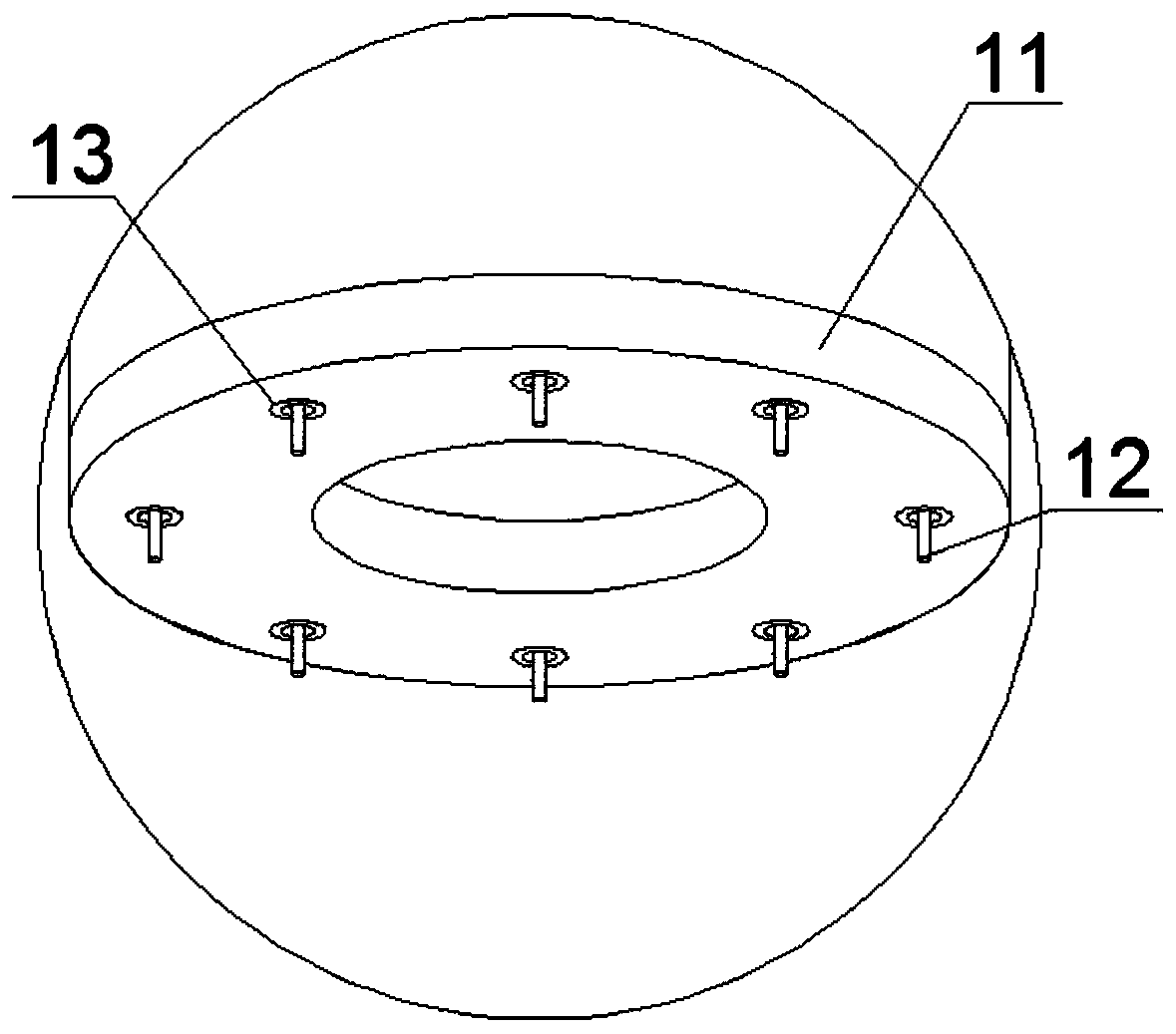

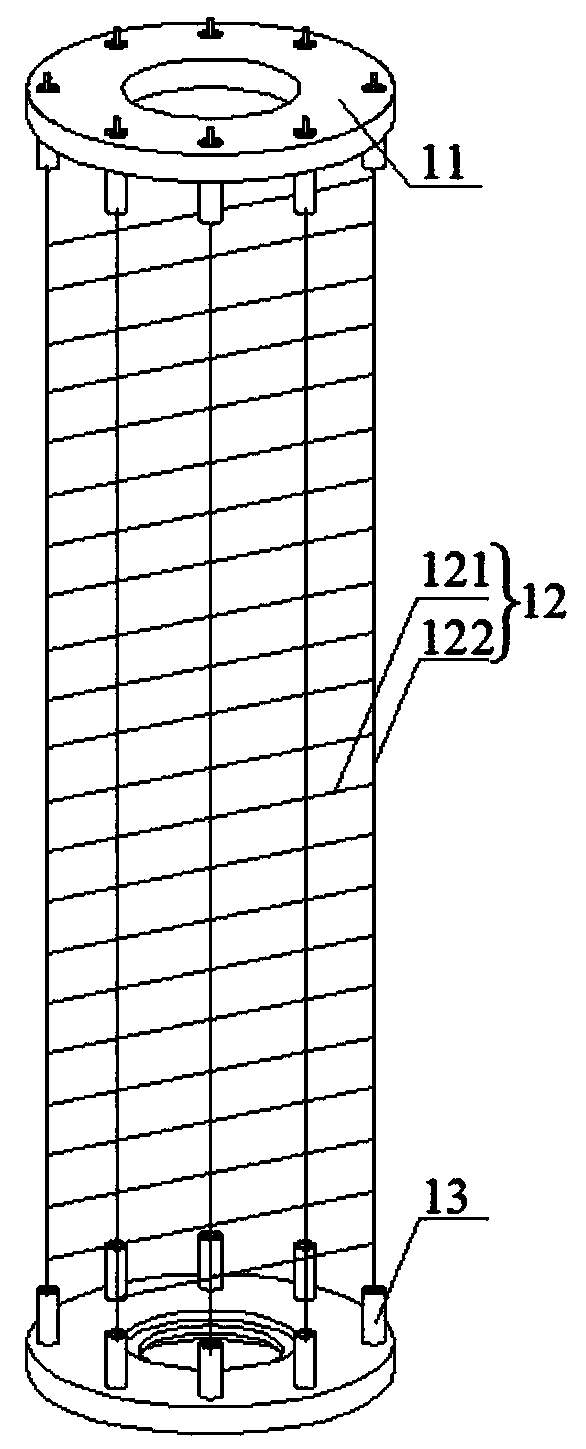

Offshore fan combination-type single pile foundation and construction method thereof

PendingCN110984212AImprove horizontal bearing capacityReduce horizontal and rotational displacementFoundation engineeringSeawaterGeotechnical engineering

The invention discloses an offshore fan combination-type single pile foundation and a construction method thereof. The offshore fan combination-type single pile foundation comprises a pile body, a pile wing and a gravity disc, the pile wing is located on the outer wall of the upper part of an anchoring section of the pile body, the gravity disc is located on the interface of a surrounding soil body of the pile body and seawater and is of a rigid structure, and the gravity disc and the pile body are fixedly connected or freely connected. The construction method of the combination-type single pile foundation comprises the following steps that S1, parameters of the pile body, the pile wing and the gravity disc are determined; S2, the pile body is driven to the designed anchoring depth throughpile sinking equipment; and S3, the gravity disc is hung on the mud-water interface near the pile body. Through the gravity disc, the pile surrounding soil body can be strengthened, the size of the pile wing can be decreased, stress of the pile wing can be improved, through the synergistic effect of a single pile, the pile wing and the gravity disc, the passive soil pressure and shearing resistance of the pile surrounding soil body can be fully mobilized, the horizontal carrying capacity of the pile foundation is improved, rotation and lateral displacement of the pile body are lowered, the bending moment of the pile body is reduced, then the diameter and the length of the pile body can be appropriately decreased, the construction cost is lowered, and the construction progress is accelerated.

Owner:CHINA THREE GORGES CORPORATION

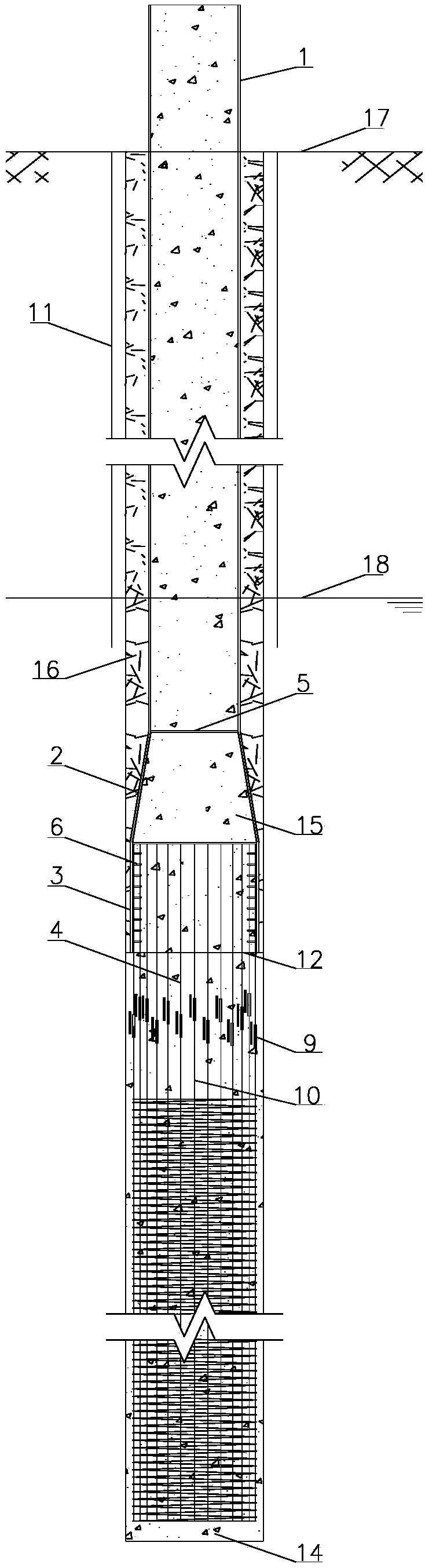

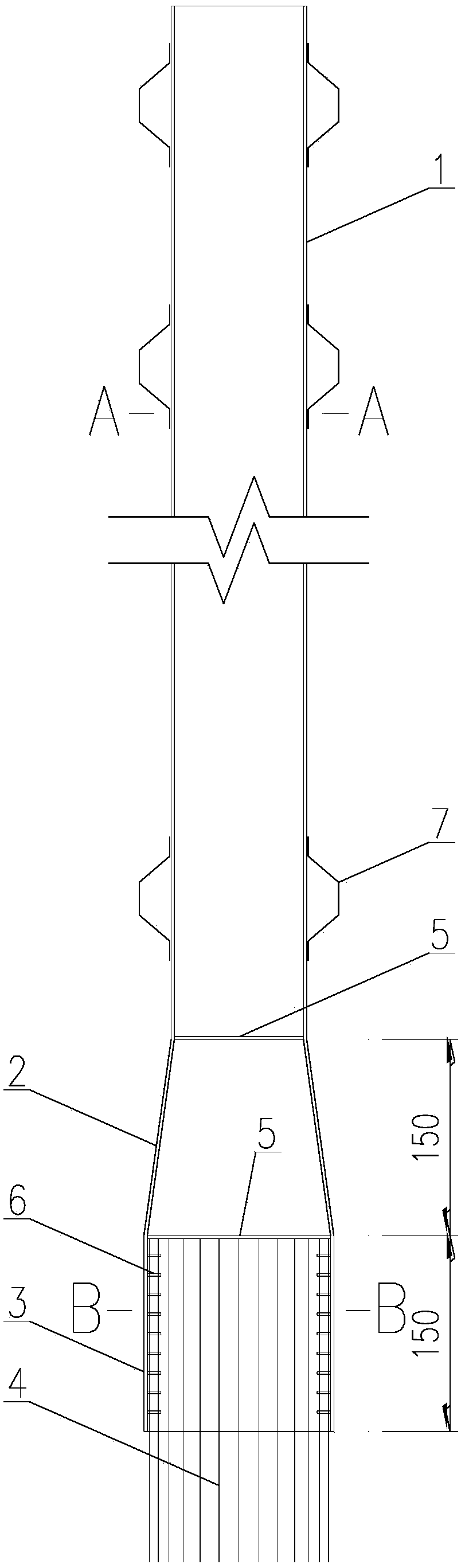

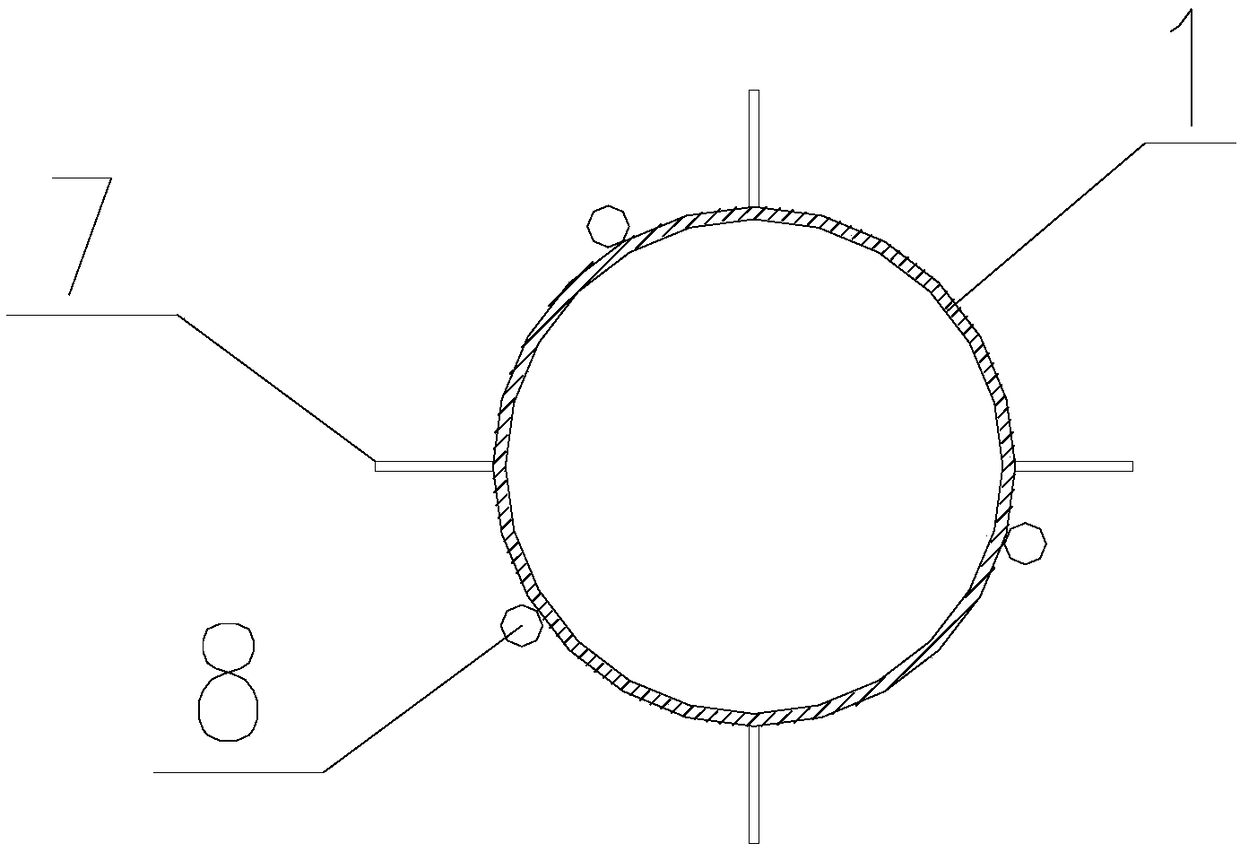

Fabricated pile and construction method thereof

The invention discloses a fabricated pile which comprises a lower pipe pile. A lower pipe pile reinforcing cage is arranged in the lower pipe pile, and an upper end plate is arranged at the upper end of the lower pipe pile. A top pipe pile is arranged at the upper end of the lower pipe pile, a lower end plate which is pressed on the upper end plate is arranged at the lower end of the top pipe pile, and the lower end plate and the upper end plate are connected. A top pipe pile reinforcing cage is arranged in the top pipe pile, composite stirrups shaped like a Chinese character 'jing' are arranged on the top pipe pile reinforcing cage every other 200-400 mm, and a post-poured concrete grouting core is arranged in the top pipe pile. The invention further discloses a construction method of the fabricated pile. According to the fabricated pile and the construction method of the fabricated pile, the upper fabricated pipe pile and the lower fabricated pipe pile are assembled together, and the advantages of the pipe piles and the advantages of cast-in-situ bored piles are fused together in the mode that the post-poured concrete grouting core is poured in the top pipe pile. The fabricated pile has the advantages that pile connection is simple, convenient and fast, the construction cost is low, construction is quick, the quality can be guaranteed easily, and the bearing capacity is high.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +2

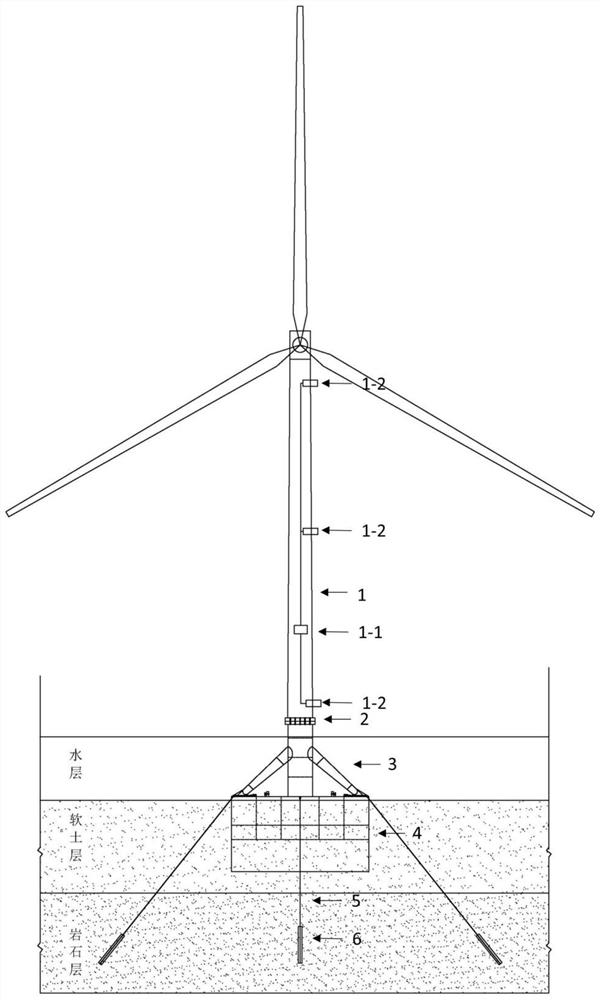

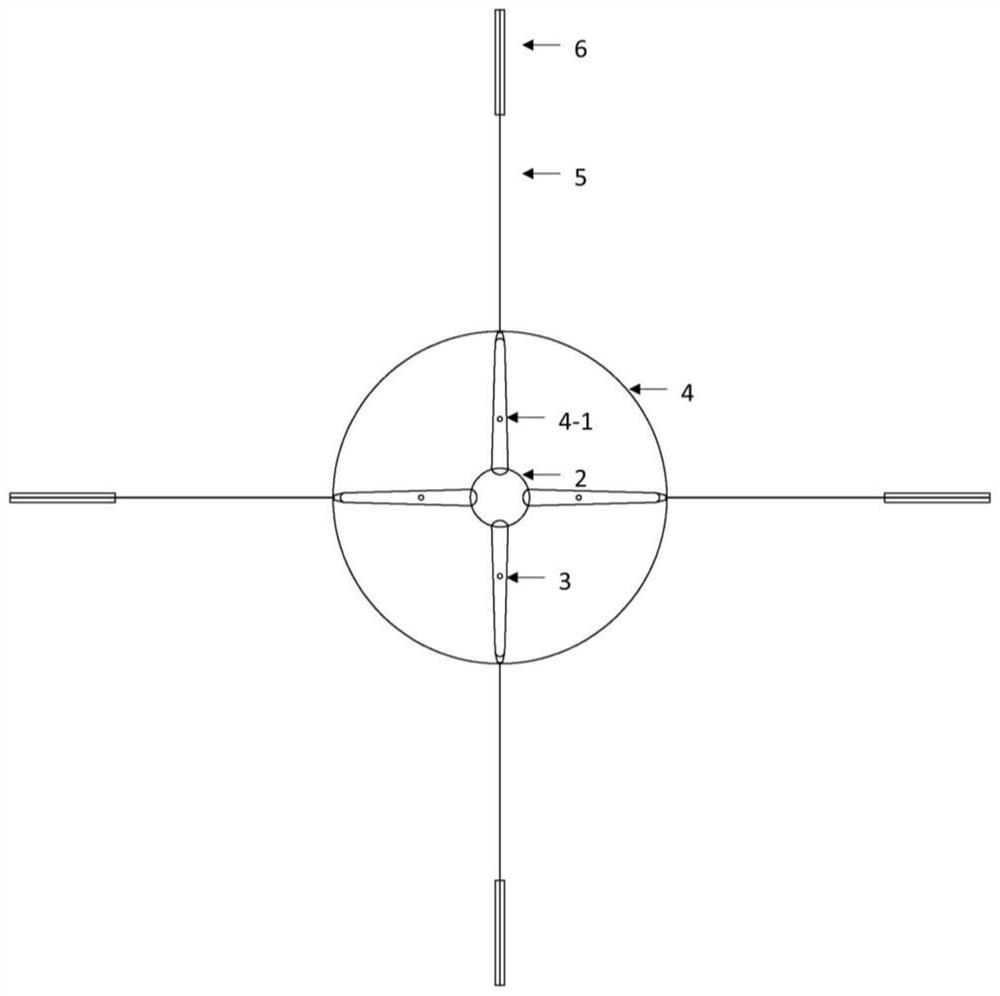

Offshore wind turbine composite skirt type foundation structure with active control system and construction method

ActiveCN113073672AEfficient and stable grid-connected power generationImprove power generation efficiencyBulkheads/pilesSuction forceMarine engineering

The invention relates to an offshore wind turbine composite skirt type foundation structure with an active control system and a construction method. The offshore wind turbine composite skirt type foundation structure comprises a wind turbine tower drum, a transition section tower drum, an inclined leg support and a skirt type suction bucket, a plurality of anchor rods which are uniformly distributed and embedded into a rock layer are annularly arranged on the skirt type suction bucket, prestress is applied to the anchor rods through an anchoring tensioning device mounted on the skirt type suction bucket, and therefore, the skirt type suction bucket is prevented from inclining; and an acceleration sensor and a main control device are installed on the wind turbine tower drum, the acceleration sensor is used for recording the acceleration of the wind turbine tower drum and transmitting a signal to the main control device, the main control device adjusts the pretension of the anchor rods by controlling the anchoring tensioning device after receiving the signal, and the overall stability of the foundation structure is ensured. According to the offshore wind turbine composite skirt type foundation structure with the active control system and the construction method, through an active control technology, the system rigidity and the natural vibration frequency of a wind turbine foundation are adjusted, efficient and stable grid-connected power generation of a wind turbine under the strong wind condition is achieved, the perpendicularity and displacement of the wind turbine are corrected in time, and the power generation efficiency of the wind turbine is improved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Offshore single pile foundation with compacted grouting reinforcement foundation

PendingCN110439022ALow costImprove power generation efficiencyBulkheads/pilesSoil preservationTurbineSeabed

The invention relates to an offshore single pile foundation with a compacted grouting reinforcement foundation in the pile foundation field of ocean engineering. According to the technical scheme, a steel pipe pile is sunk to a seabed, the seabed is a soft soil foundation, in the soft soil foundation, a reinforced foundation with compacted grouting technology is arranged on the periphery of the steel pipe pile, and the reinforced foundation includes a compacted grouting bubble, a drainage channel and soft soil between the compacted grouting bubble and the drainage channel; and the reinforced foundation is a rotating body coaxial with the steel pipe pile. The offshore single pile foundation has high horizontal bearing capacity, small pile top horizontal displacement, small pile body inclination and large foundation stiffness, adapts to the characteristics of large horizontal load of an offshore wind turbine, meets the strict requirements of the offshore wind turbine on foundation horizontal displacement and pile body inclination, and meets the requirements of 'structure + foundation' integral natural vibration frequency.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

Supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions

InactiveCN103967004AGood tensile performanceSlow to overcome hardeningExcavationsBulkheads/pilesPre stressHigh intensity

A supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions is composed of a pile core and a pile cylinder, wherein the pile cylinder is tightly pasted on the outer side of the pile core. The pile core is composed of a prefabricated prestressed pile, grouting pipes and a center grouting pipe, wherein the cross section of the prefabricated prestressed pile is orthohexagonal. Each side face of the prefabricated prestressed pile is provided with a groove in the axis direction. The grouting pipes are arranged in the grooves. A center grouting hole is formed in the prefabricated prestressed pile in the central axis direction. The center grouting pipe is arranged in the center grouting hole. The pile cylinder is composed of multiple layers of reinforcing steel bar cages and a grouting body. The reinforcing steel bar cage on the innermost layer tightly wraps the pile core, the reinforcing steel bar cage on the outermost layer is tightly attached to the hole wall, and the rest layers of reinforcing steel bar cages are evenly distributed. The reinforcing steel bar cages are wrapped in the grouting body. The concrete strength of the pile core reaches more than 80 MPa, and therefore the defects that the cast-in-place concrete hardening speed is low at a low temperature, and the quality is difficult to ensure are overcome; the tension resistance of the pile is greatly improved due to the prestress of the pile core and the reinforcing steel bar cages of the pile cylinder, and therefore the horizontal bearing capacity is improved, and larger anti-slide force can be provided by the supporting and protecting composite anti-slide pile.

Owner:BEIJING UNIV OF TECH

Construction method of prefabricated root key-type wing plate foundation

InactiveCN111485572AGood synergyGive full play to the role of bearingFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses a construction method of a prefabricated root key-type wing plate foundation. A main concrete structure is included, and comprises a column body, wing plates and prefabricatedroot keys; an embedded part is connected to the top of the column body; the wing plates are uniformly arranged on the column body, and the wing plates and the column body are vertically intersected and close to the top; and a plurality of prefabricated root keys are vertically connected to the outer side of the column body, and the prefabricated root keys extend from the inside to the outside of the column body. According to the prefabricated root key-type wing plate foundation, the vertical and horizontal bearing capacity and lateral stiffness of the foundation can be effectively improved, the pile length and diameter of the pile foundation are reduced, the expansion of the conventional foundation is canceled, so as to reduce the safety risk, construction difficulty and engineering quantity of the foundation construction, the concrete transportation engineering quantity in mountainous is reduced, and the purposes of safety and reliability, cost saving and environmental protection areachieved.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Variable-diameter steel tube built pile capable of reducing negative friction

InactiveCN104131550AReduce contact areaReduce negative friction effectBulkheads/pilesButt jointSoil surface

A variable-diameter steel tube built pile capable of reducing negative friction comprises a large-diameter steel tube pile arranged in a soil bearing layer. The top end of the large-diameter steel tube pipe is in butt joint with a pile driving sleeve, a small-diameter steel tube pile is arranged in the pile driving sleeve, a quadrilateral rib plate connected with the inner wall of the large-diameter steel tube pile is fixed to the outer wall of the bottom of the small-diameter steel tube pile, a reducing sleeve is arranged at the periphery of the small-diameter steel tube pile, a reinforcing plate is arranged in the reducing sleeve, the reducing sleeve is arranged under the middle of a soft soil layer, an expanded top barrel is arranged at the periphery of the upper portion of the small-diameter steel tube pile through a partition plate, the top of the expanded top barrel is aligned at the soil surface, a reinforcing ring is arranged at the top end of the large-diameter steel tube pile, an enclosing and blocking part is arranged at the tail end of the outer side of the reinforcing ring, a large triangular rib plate is arranged at the bottom of the reinforcing ring, an upper bottom plate and a lower bottom plate are arranged on the inner wall of the bottom of the small-diameter steel tube pile, and a small triangular rib plate is arranged on the inner wall of the small-diameter steel tube pile. The variable-diameter steel tube built pile capable of reducing negative friction can effectively reduce negative friction and optimize pile foundation level and vertical bearing performance.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com