Bridge type grab bucket ship unloader

A bridge-type grab and ship unloader technology, applied in the direction of walking bridge cranes, cranes, traveling mechanisms, etc., can solve the problems of not meeting the loading and unloading requirements of the wharf, and achieve the advantages of small operating impact, reducing rail gnawing, and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

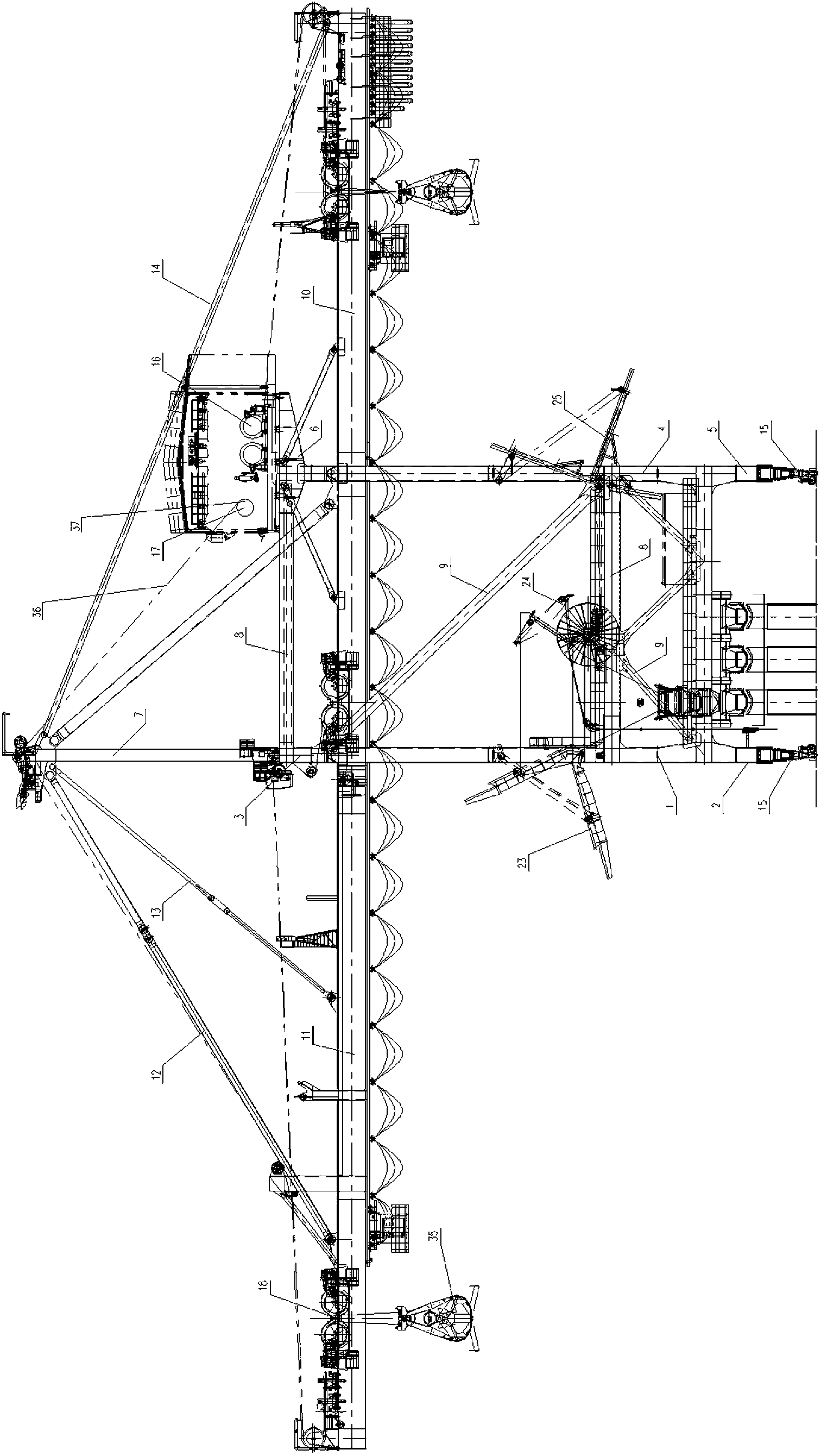

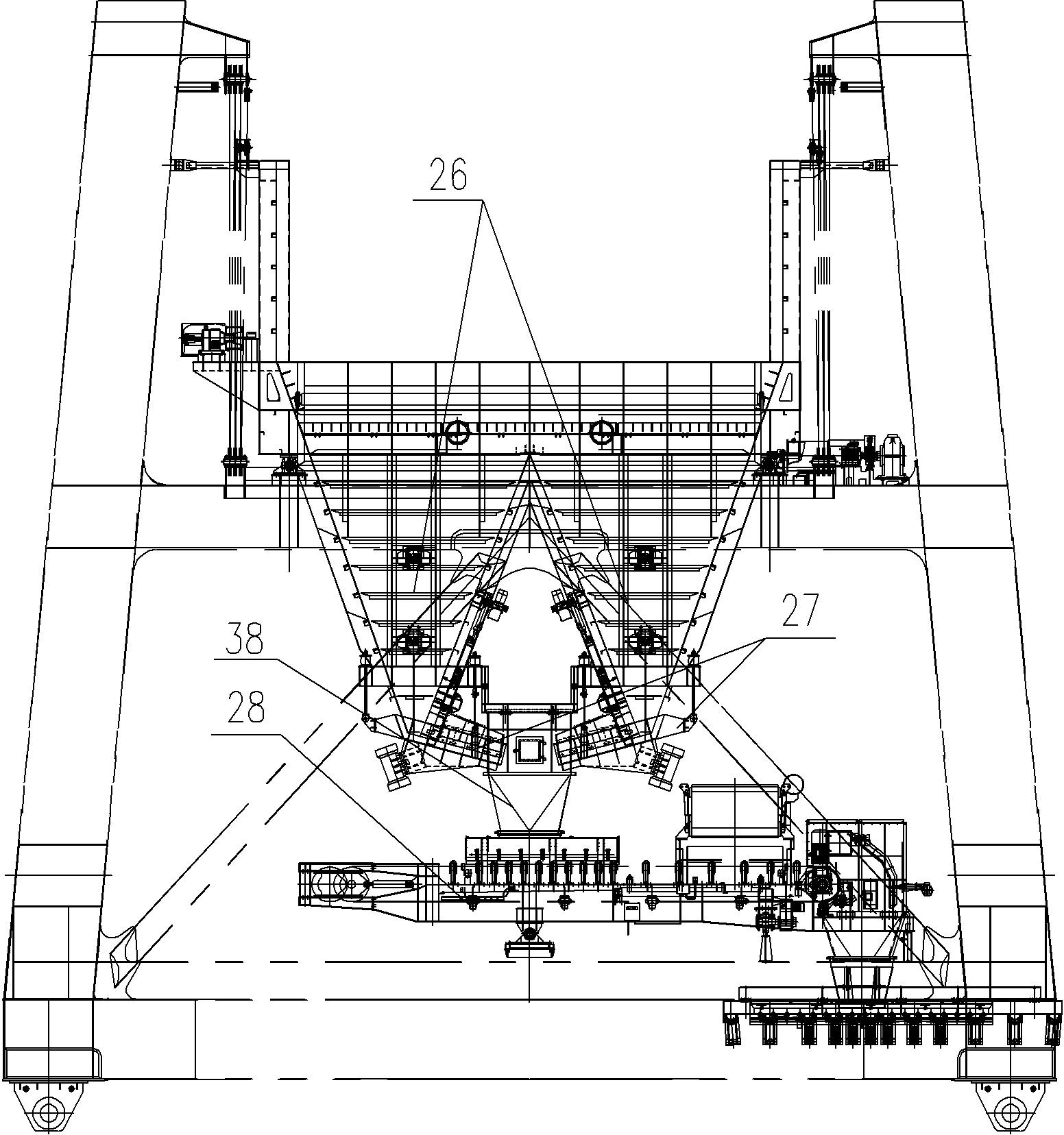

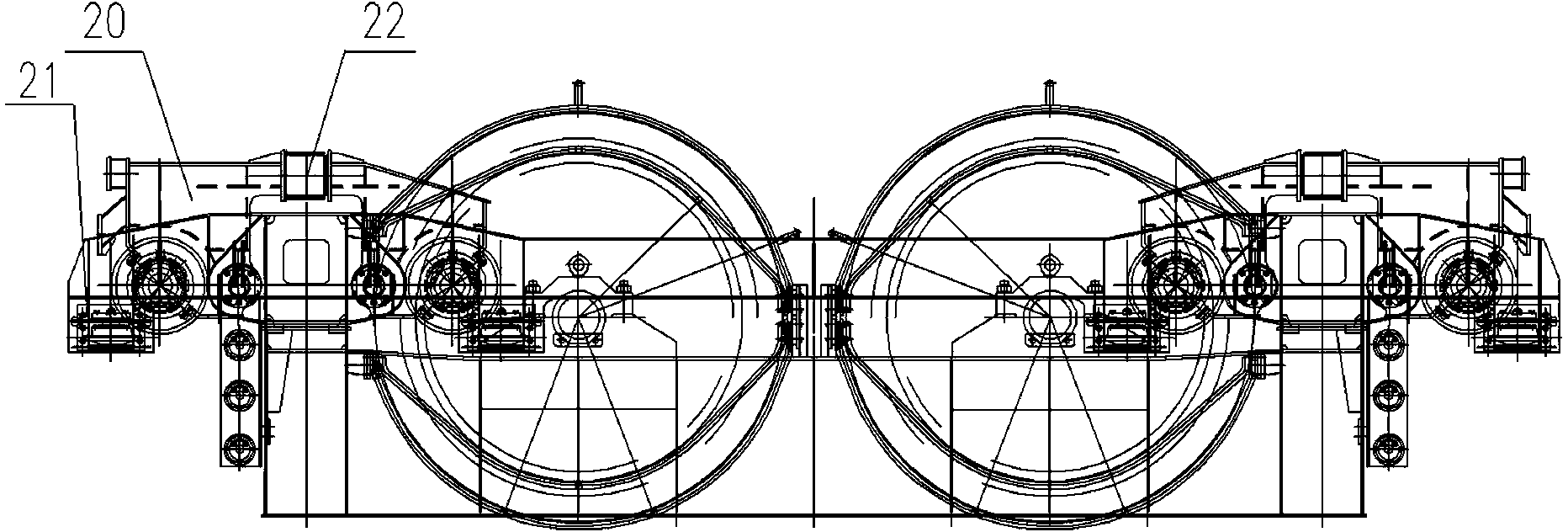

[0022] Such as Figures 1 to 5 As shown, the bridge-type grab ship unloader of the present invention includes a steel structure system, an operating system and an unloading system. The steel structure system includes a door frame structure, a rear girder 10, a front girder 11 and a tie rod system. The door frame structure includes a seaside column 1. The sea side lower beam 2, the sea side upper beam 3, the land side column 4, the land side lower beam 5, the land side upper beam 6, the ladder frame 7, the connecting beam 8 and the diagonal brace 9, the door frame structure includes the sea side door frame And the land side door frame, the sea side door frame is formed by connecting the sea side upper beam 3 and the sea side column 1, usually by bolts, the lower end of the sea side column 1 is welded with the sea side lower beam 2, and the land ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com