Construction method of breakwater in pile-supported cylindrical caisson structure

A construction method and pile-supported technology, which is applied in the field of port engineering, can solve the problems of poor vertical compression resistance and settlement deformation of the box, so as to improve the ability to resist wave impact, improve stability, and save construction time and construction cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows: embodiment

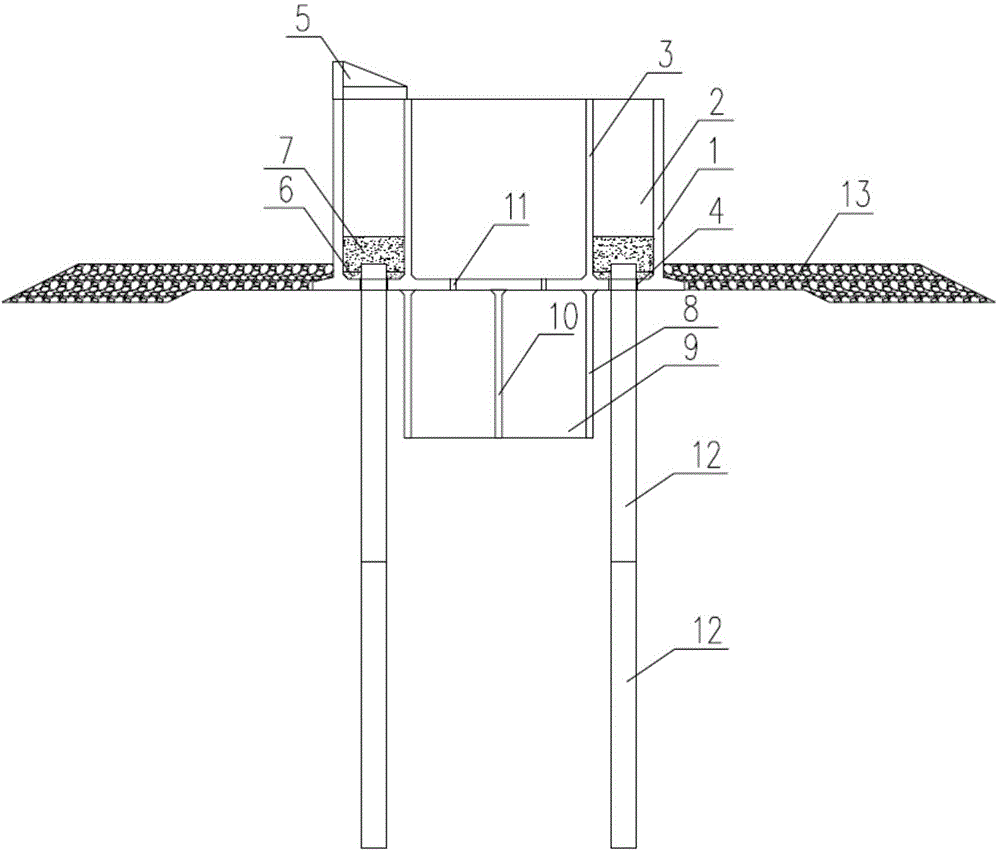

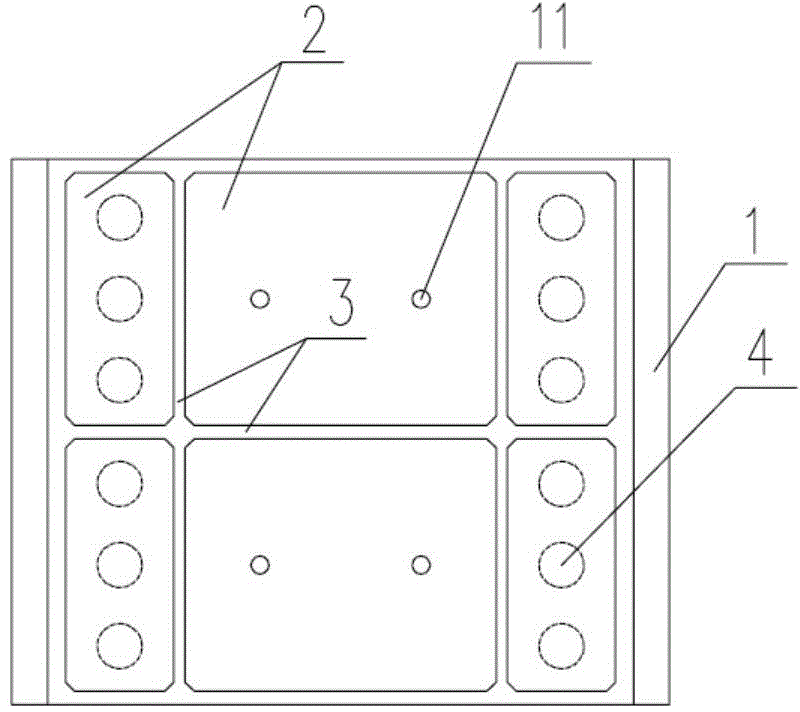

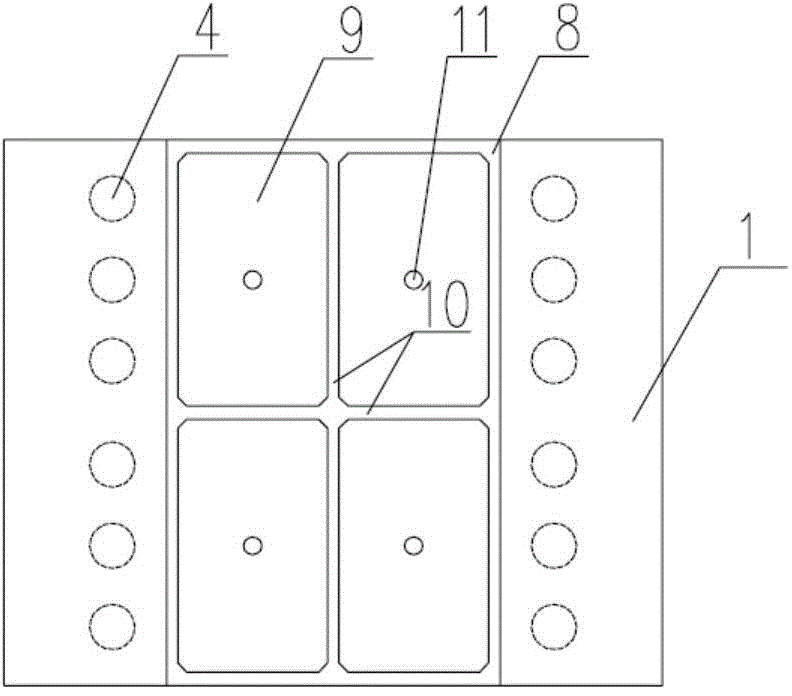

[0036] see attached Figure 1-4 , the present embodiment provides a method for constructing a breakwater using a pile-supported box-tube structure, comprising the following steps:

[0037] (1) Clearing and leveling the seabed mud surface at the installation position of the pile-supported box-tube breakwater;

[0038] (2) After the assembly of the pile-supported box structure is completed, the floating dock or slide to the auxiliary launch for air flotation haulage, inflate the lower cylinder 8, close the valve on the reserved channel 11 after completion, and adjust the compartments of the lower cylinder At the same time, ballast water is added to the upper tank 1 compartment to control the levelness of the pile-supported box-tube structure, and the pile-supported box-tube structure is towed to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com