Bottom-hinged-supporting low-damage self-reset shear wall

A self-resetting, low-damage technology, applied in the direction of walls, building components, earthquake-proof, etc., can solve the problems of easy loss of pre-tension, easy formation of plastic hinges at the bottom of the wall, insufficient ductility, etc., and achieve the effect of large elastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1~4 The present invention is described in further detail.

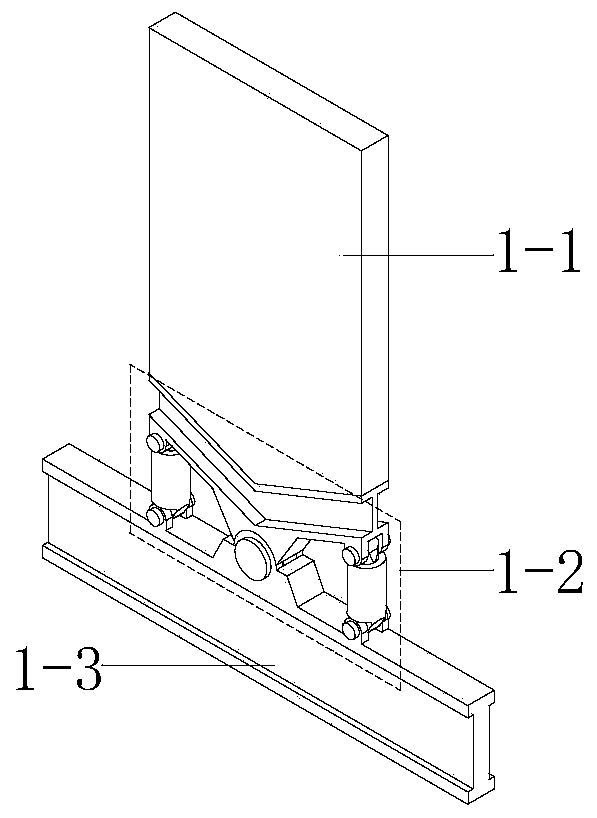

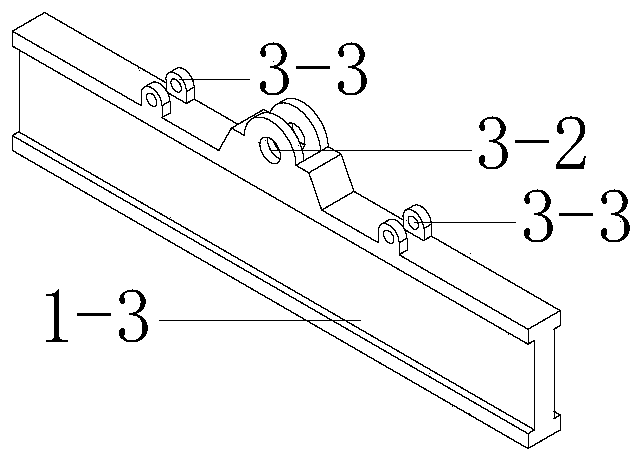

[0039] The present invention is a low-damage self-resetting shear wall hinged at the bottom, and the structural diagram of the present invention is as follows figure 1 As shown, the bottom hinged low-damage self-resetting shear wall includes a reinforced concrete wall panel 1-1, a self-resetting wall bottom 1-2 and a foundation beam 1-3. The reinforced concrete wall panel 1-1 can be designed according to the current specification, and made by pouring concrete after binding the steel mesh. The foundation beams 1-3 can be made of steel or concrete under the condition that the anchorage requirements are met. Self-resetting wall bottom 1-2 includes connecting beam 2-1, self-resetting short support 4-4;

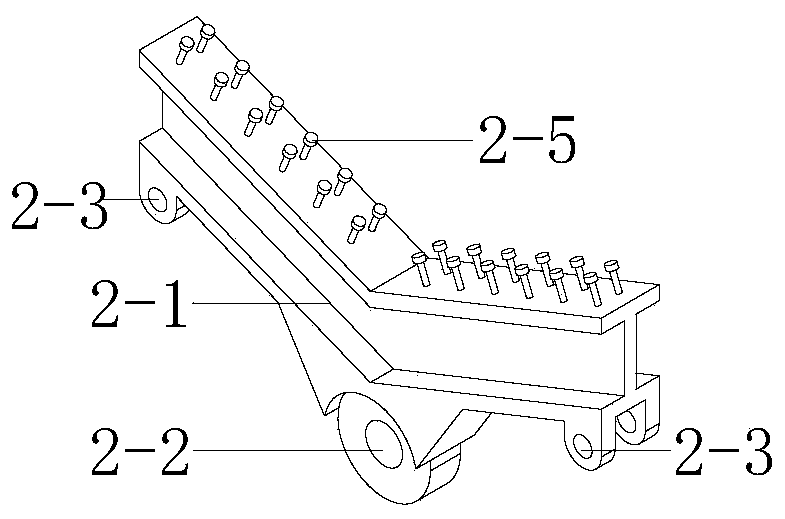

[0040] Connecting beam 2-1 such as figure 2 As shown, the connecting beam 2-1 is used to bear and transmit the internal force transmitted from the upper reinforced concrete wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com