Patents

Literature

48results about How to "Enhanced out-of-plane stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

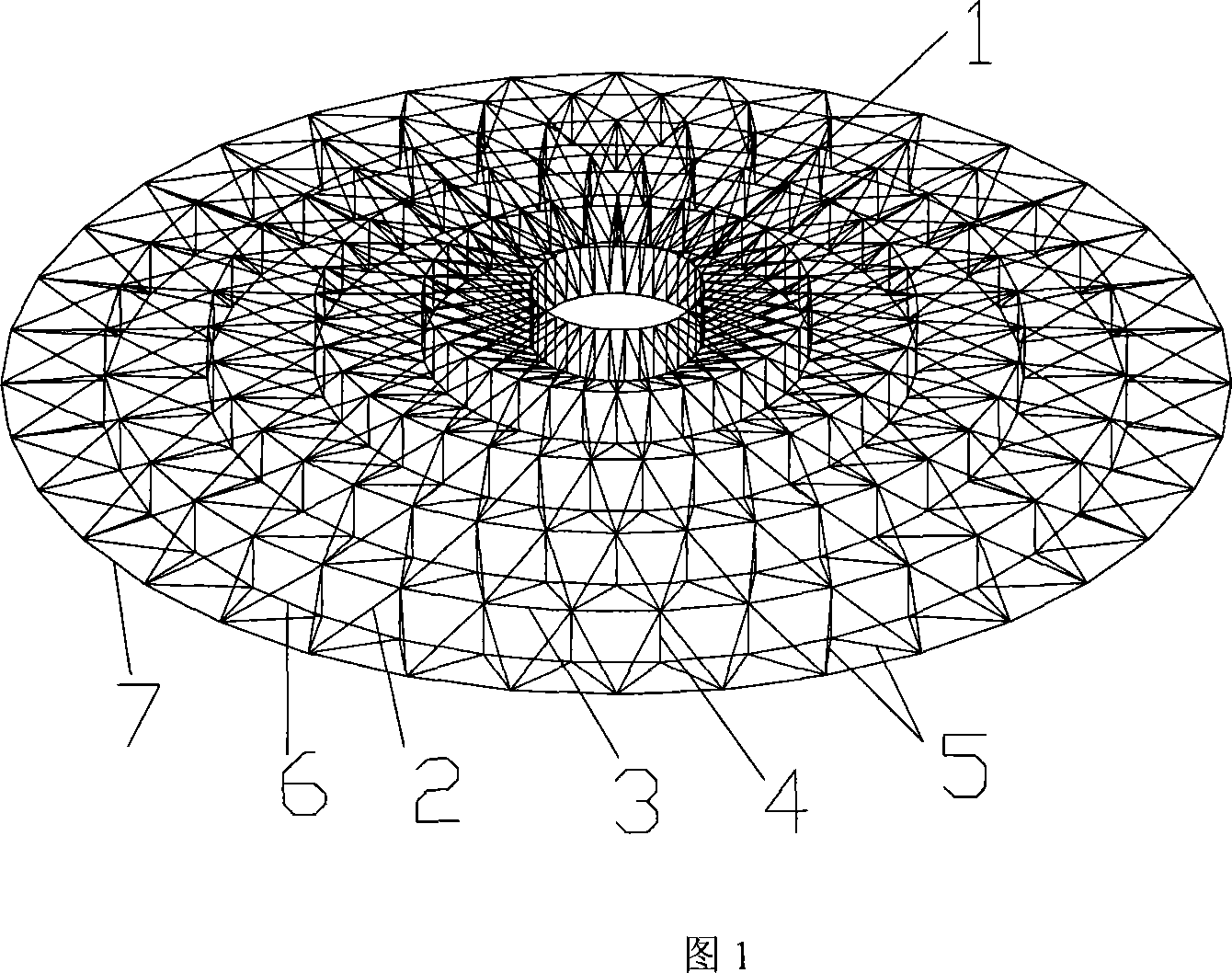

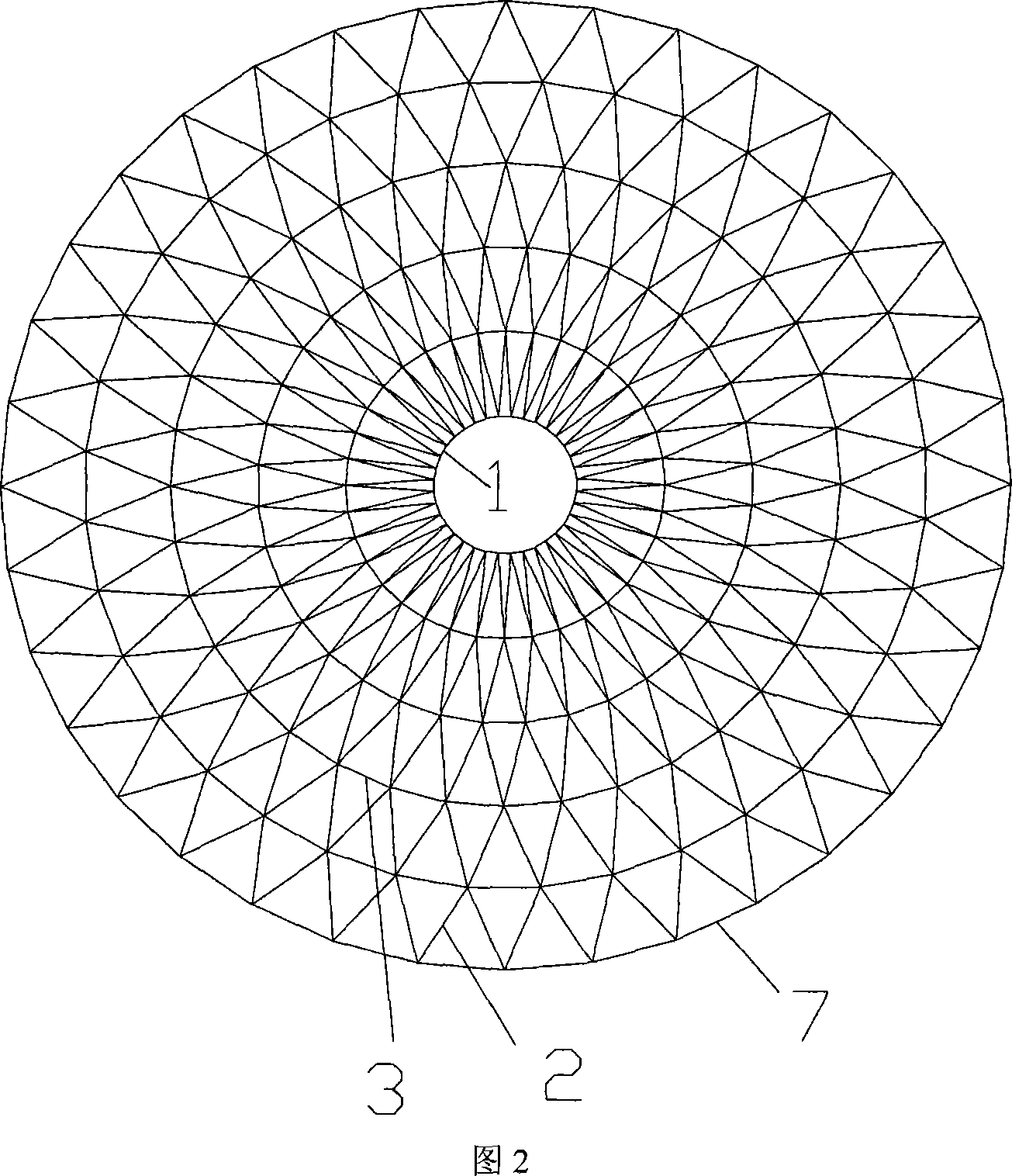

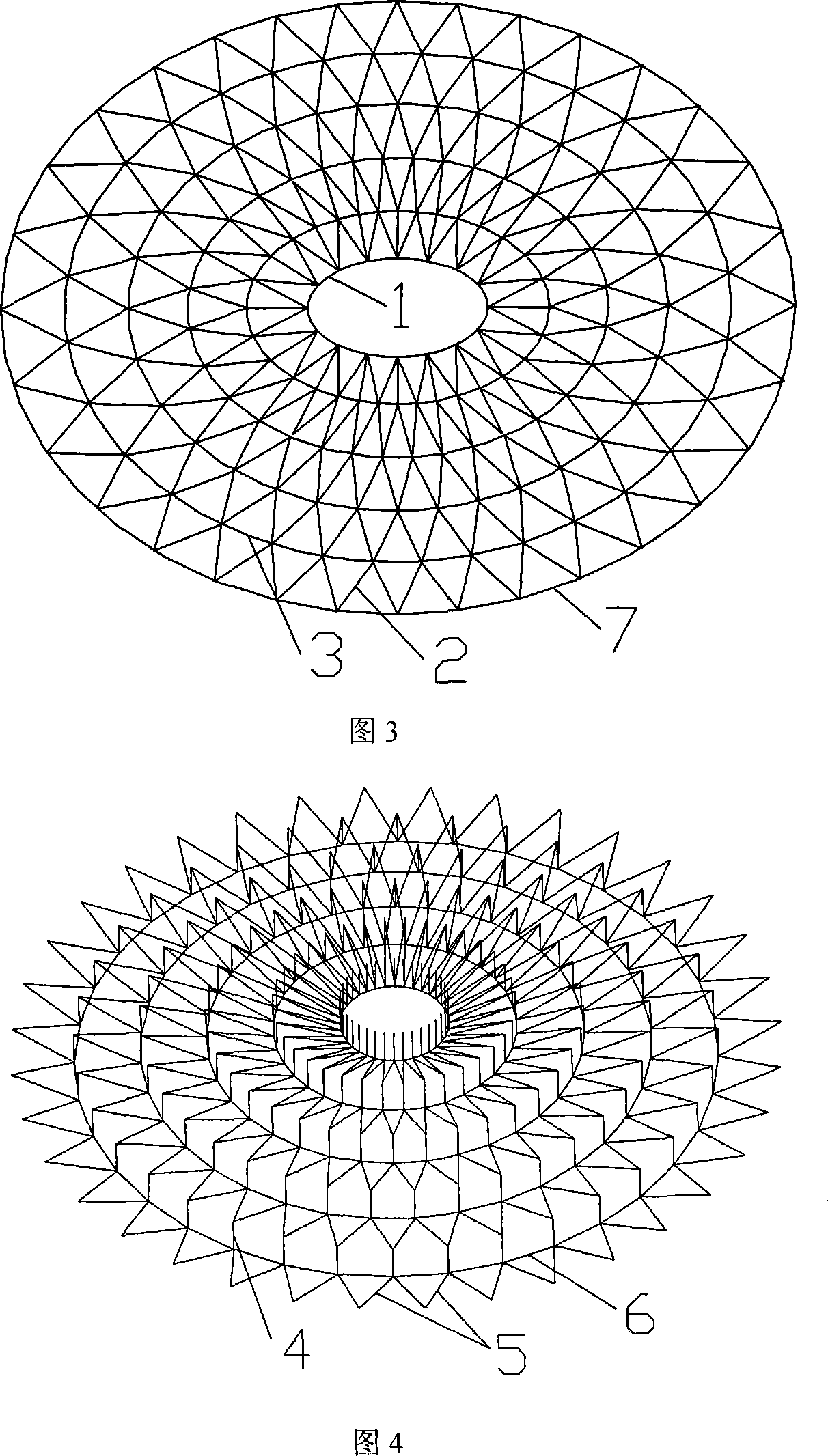

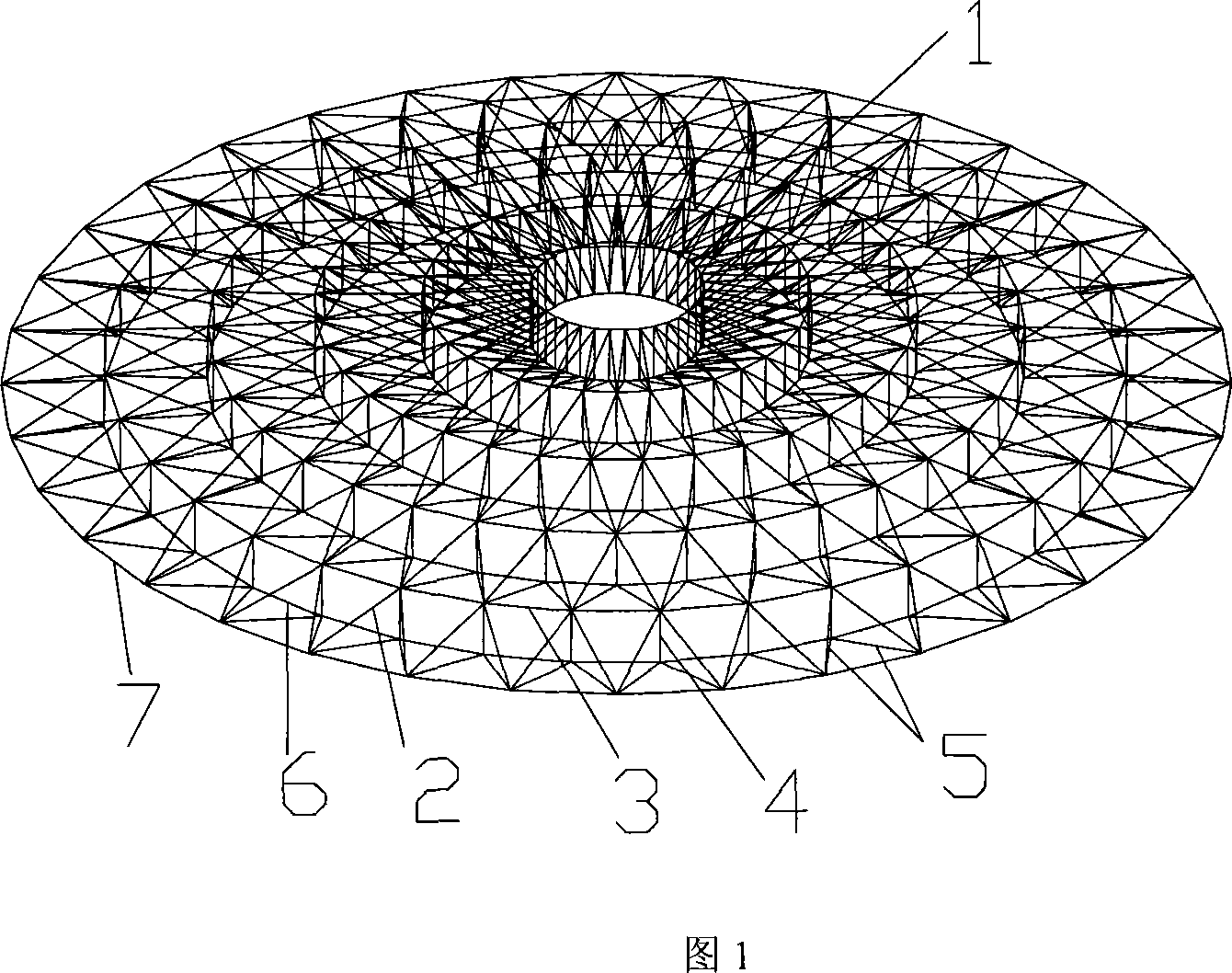

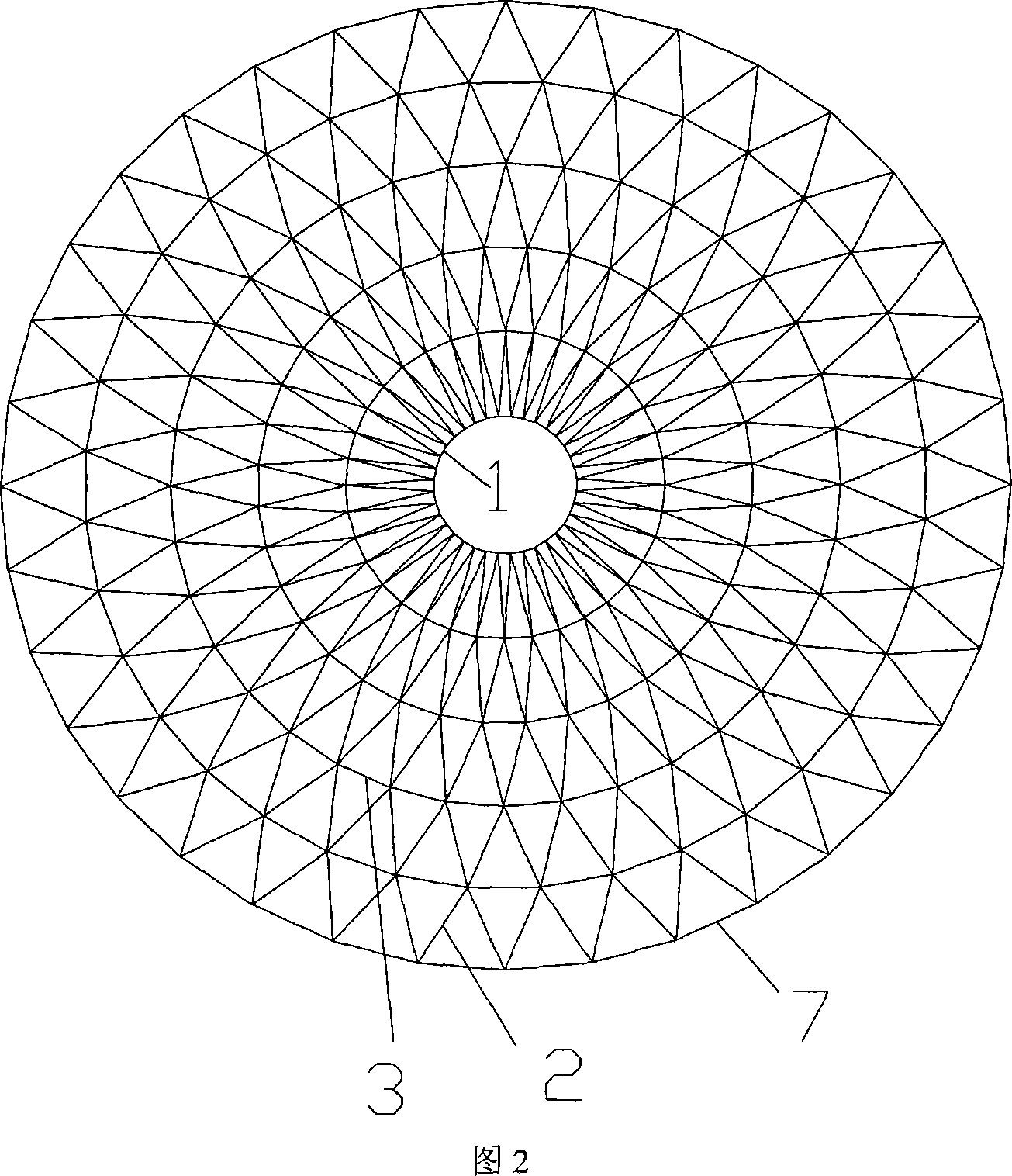

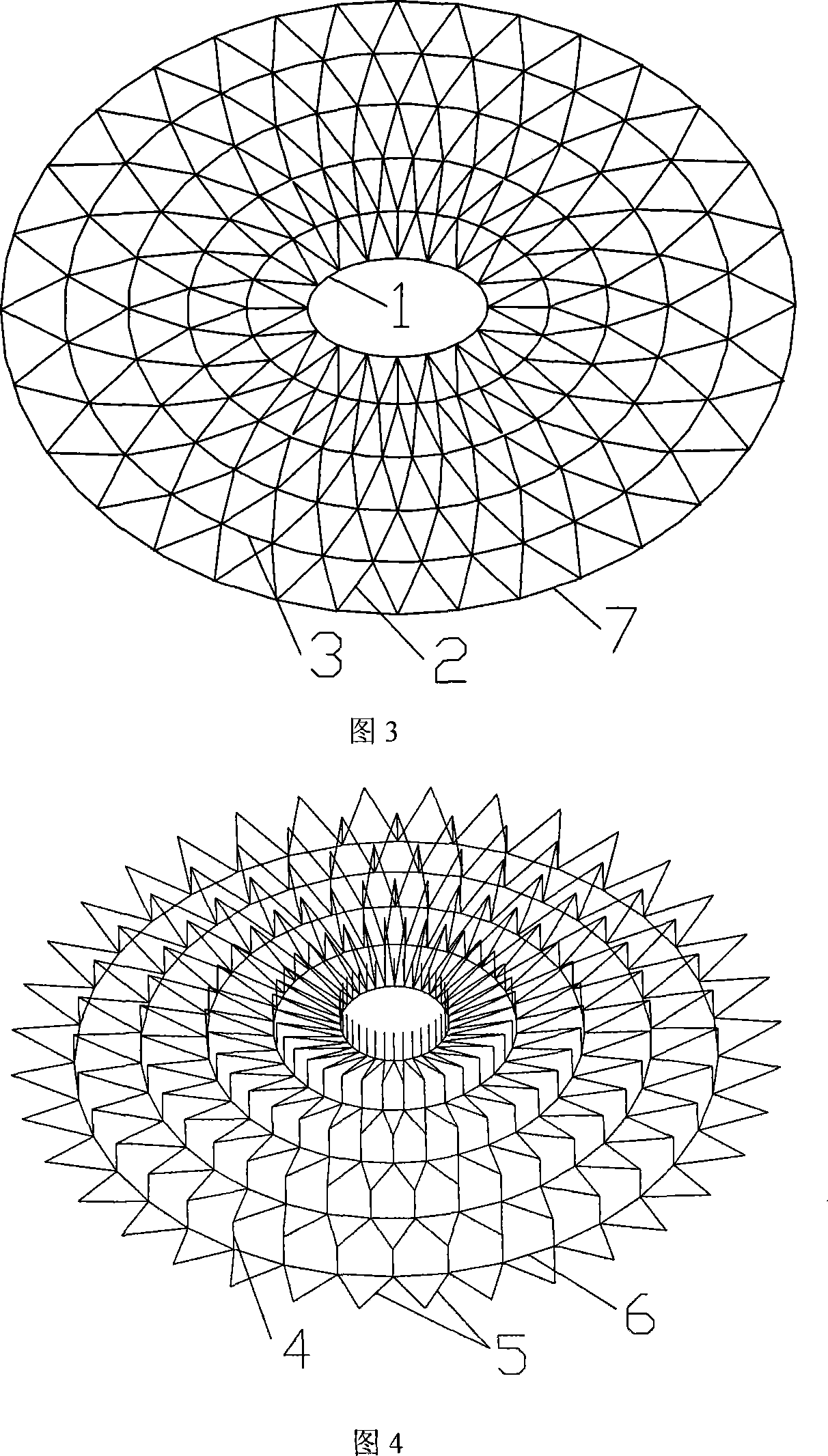

Suspended-dome multi-time prestressed construction method

InactiveCN101158195APower transmission is simpleReduce pressure peaksBuilding roofsInstabilityPre stress

The invention discloses a suspend dome structure multi-prestressed construction method used in construction field. The construction method is that: firstly, a central pressure ring, an upper radial bar and edge elements are arranged on an upper layer; secondly, a lower radial rope, a lower ring rope and a strut are arranged on a lower layer; thirdly, prestress is applied in the structure by stretching the lower ring rope or stretching the lower radial rope or adjusting the length of the strut; fourthly, a ring bar is arranged; fifthly, an external load is applied on the structure. Compared with the structure formed by a traditional method, the suspend dome structure formed by the invention reduces peak pressure of elements with concise force, even changes a part of elements from a pressure bar to a tension bar, avoids instability of elements, at the same time enhances the entire stability of the whole structure and enlarges the ultimate bearing capacity. Furthermore, the invention leads a more even distribution of internal force of the upper layer network shell bar elements, is helpful to the unity of the elements and convenient for design and construction, at the same time, the invention reduces the applied prestress value and reduces construction difficulty.

Owner:BEIJING UNIV OF TECH

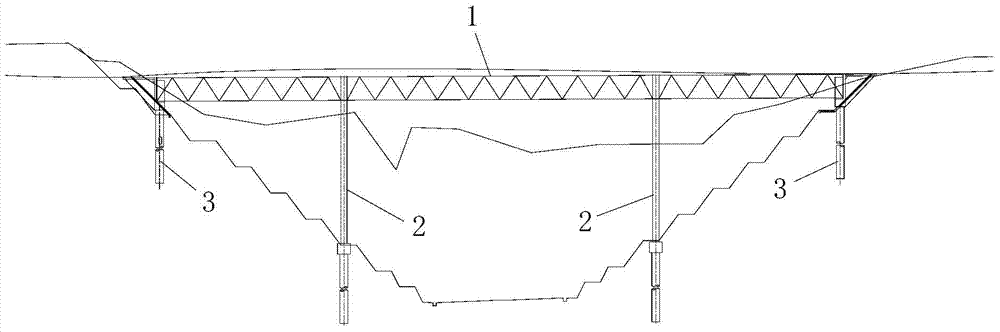

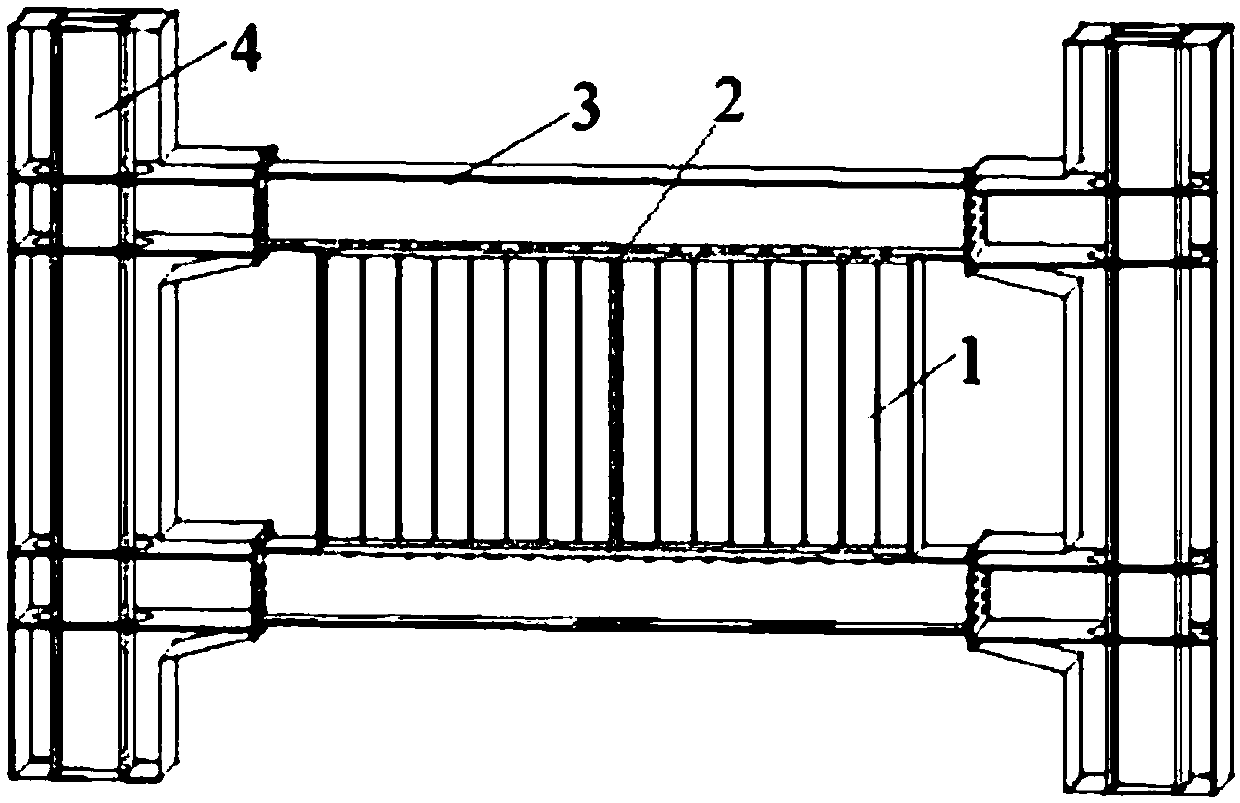

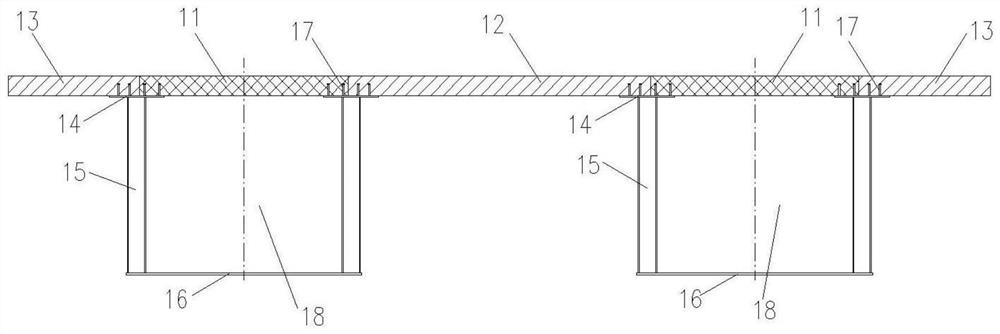

Continuous rigid frame bridge based on steel truss-concrete slab composite beam

InactiveCN103669194ALight weightImprove leaping abilityTruss-type bridgeBridge structural detailsSheet steelBridge deck

The invention discloses a continuous rigid frame bridge based on a steel truss-concrete slab composite beam. The continuous rigid frame bridge comprises a bridge substructure and the steel truss-concrete slab composite beam supported by the bridge substructure. The steel truss-concrete slab composite beam comprises a steel truss and a concrete bridge deck which is laid over the steel truss. The steel truss comprises one or more steel truss units; each steel truss unit is an inverted-triangle truss girder, wherein the inverted-triangle truss girder is composed of two upper chords, a lower chord, a left line of diagonal web members and a right line of diagonal web members, each upper chord comprises a first horizontal steel plate and a plurality of first vertical perforated steel plates evenly laid on the first horizontal steel plate, an upper chord transverse connecting system connected between the two upper chords comprises a plurality of upper chord transverse connecting pieces, and each upper chord transverse connecting piece comprises a second horizontal steel plate and a plurality of second vertical perforated steel plates evenly laid on the second horizontal steel plate. The continuous rigid frame bridge is simple in structure, reasonable in design, convenient to construct, good in stress performance, good in using effect and capable of effectively solving various problems existing in an existing continuous rigid frame bridge.

Owner:CHANGAN UNIV

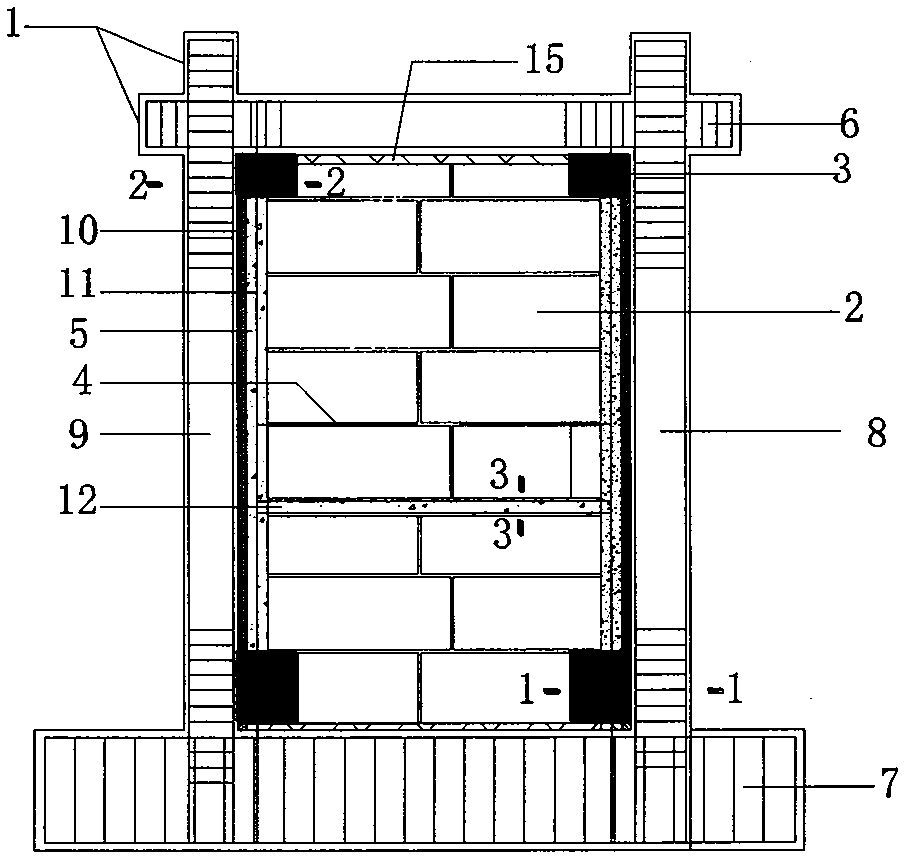

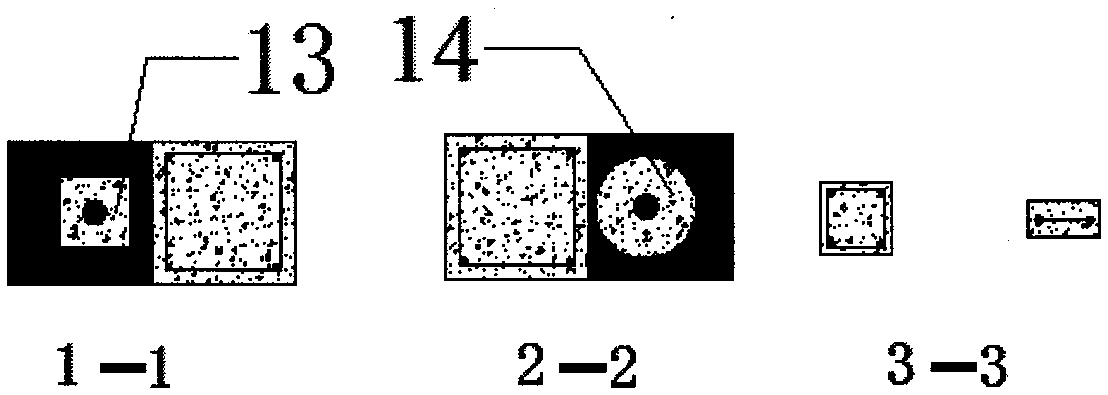

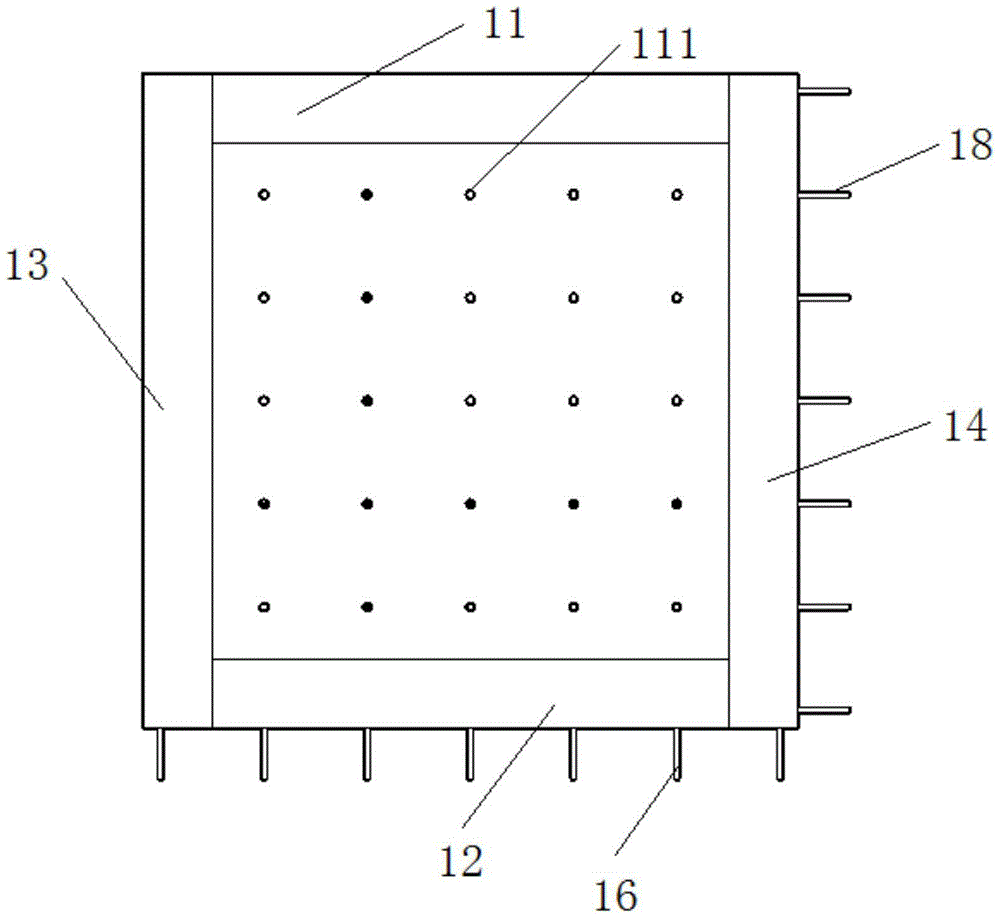

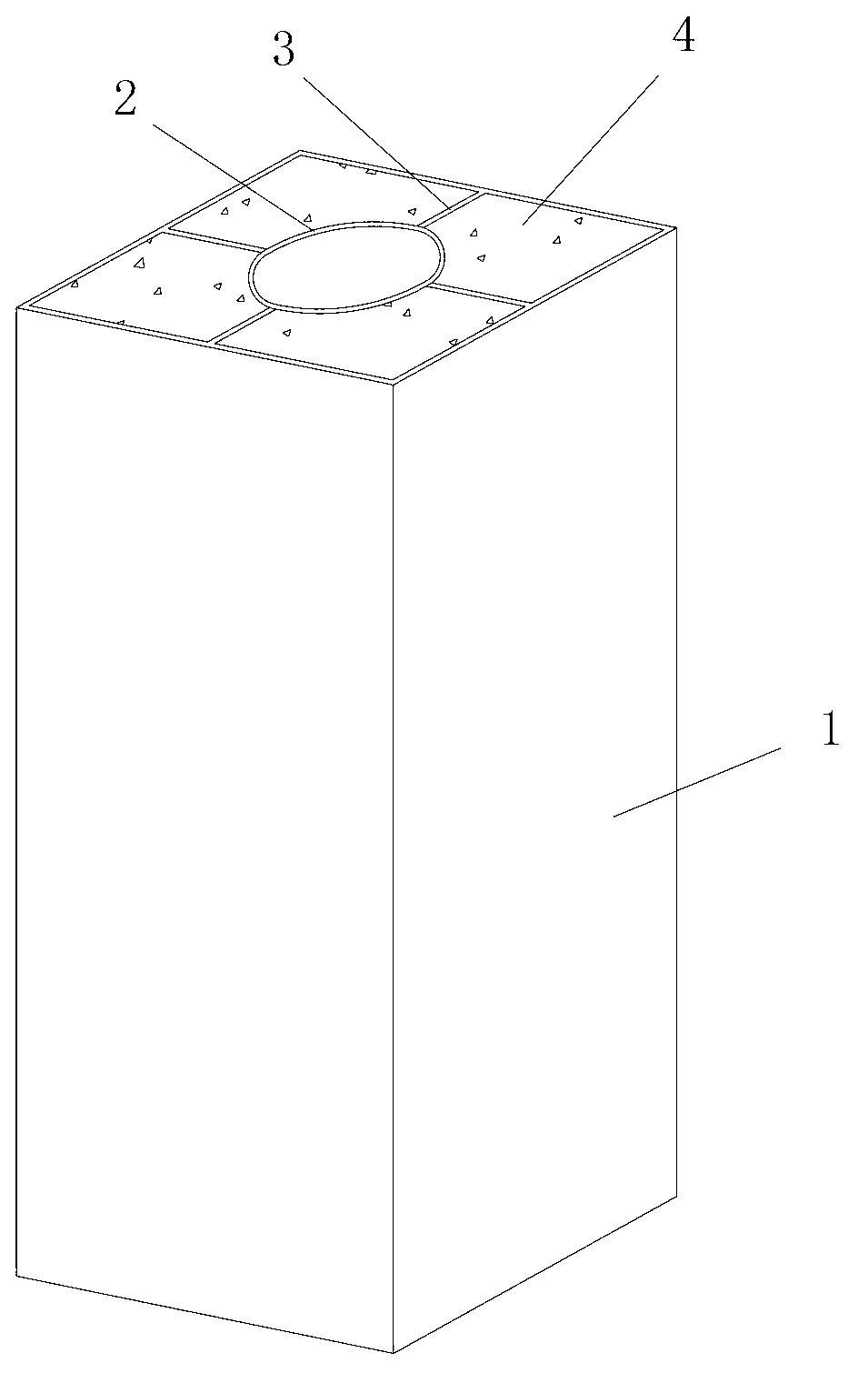

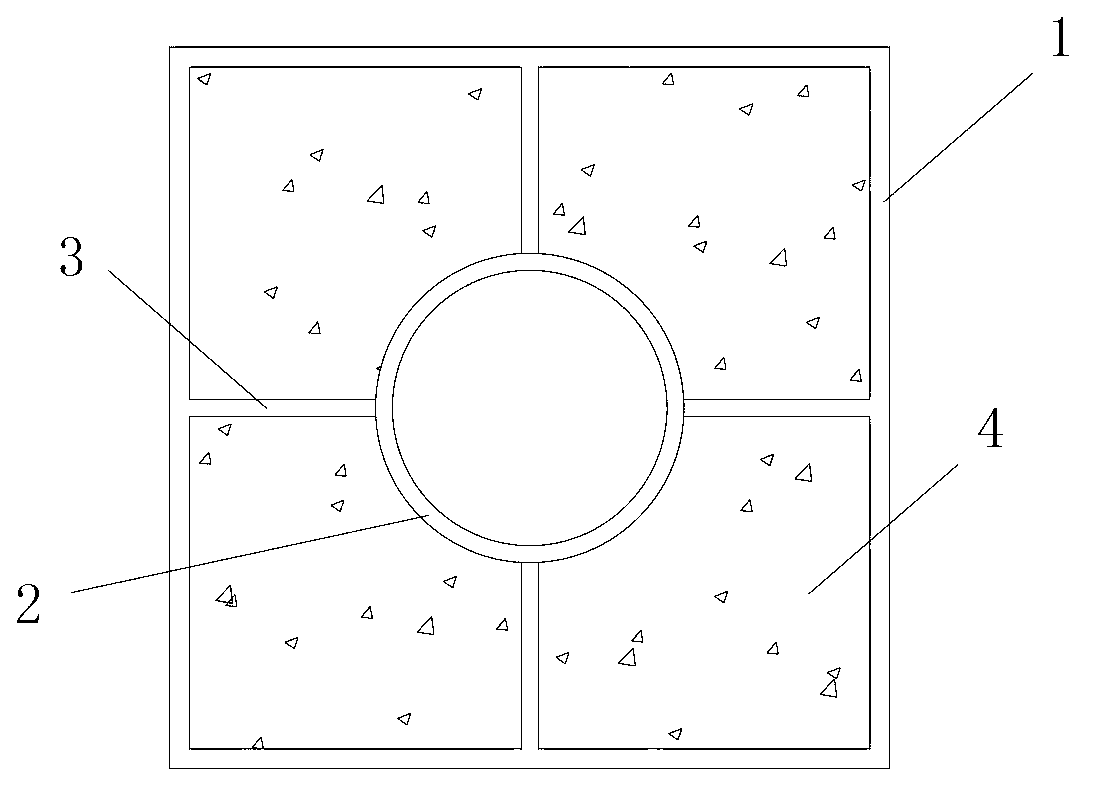

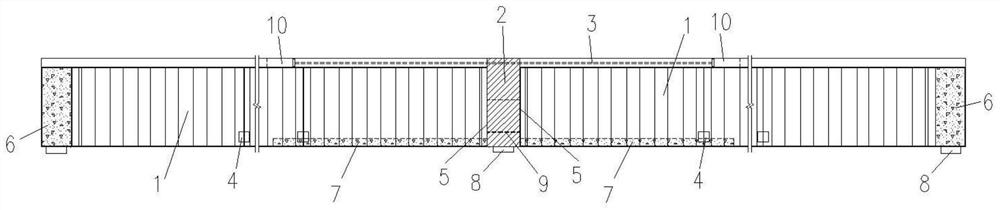

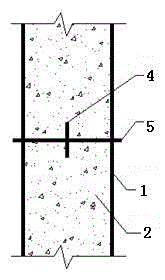

Deformation-controllable frame filling wall and construction method thereof

InactiveCN105507454AReduce earthquake forceProtection securityWallsShock proofingRebarDeformation control

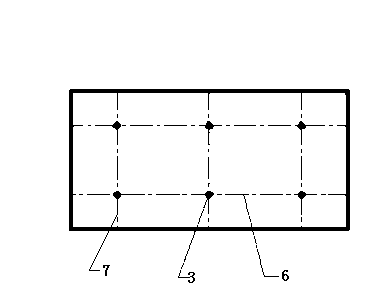

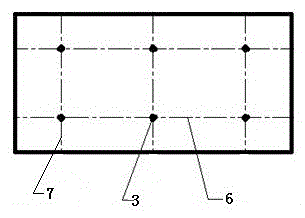

The invention discloses a deformation-controllable frame filling wall which is mainly composed of a frame 1, a filling wall 2, deformation control parts 3, horizontal tie bars 4, restraint columns 5 and horizontal connection beams 12. The deformation-controllable frame filling wall is characterized in that the frame 1 is composed of a frame upper beam 6, a frame lower beam 7, a frame left column 8 and a frame right column 9, the filling wall 2 is a brickwork filling wall which is built by bricks (clay bricks and hollow bricks) or concrete building blocks, the deformation control parts 3 are arranged at positions where four corners of the filling wall contact with joints of the frame, the filling wall 2 is connected with the frame left column 8 and the frame left column 9 through a flexible material 10, and connected with the frame upper beam 6 and the frame lower beam 7 through an elastic connection material 15, the restraint columns 5 are arranged at positions where the filling wall 2 is connected with the flexible material 10, and the horizontal tie bars 4 which are arranged in the height direction of the filling wall are connected with the restraint columns. When the height of the filling wall is large, horizontal tie beams 12 can be arranged in the filling wall, and two ends of the horizontal tie beams 12 are connected with the restraint columns 5.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs

InactiveCN102979251ALight structureImprove seismic performanceArched girdersStrutsMechanical propertyStructure based

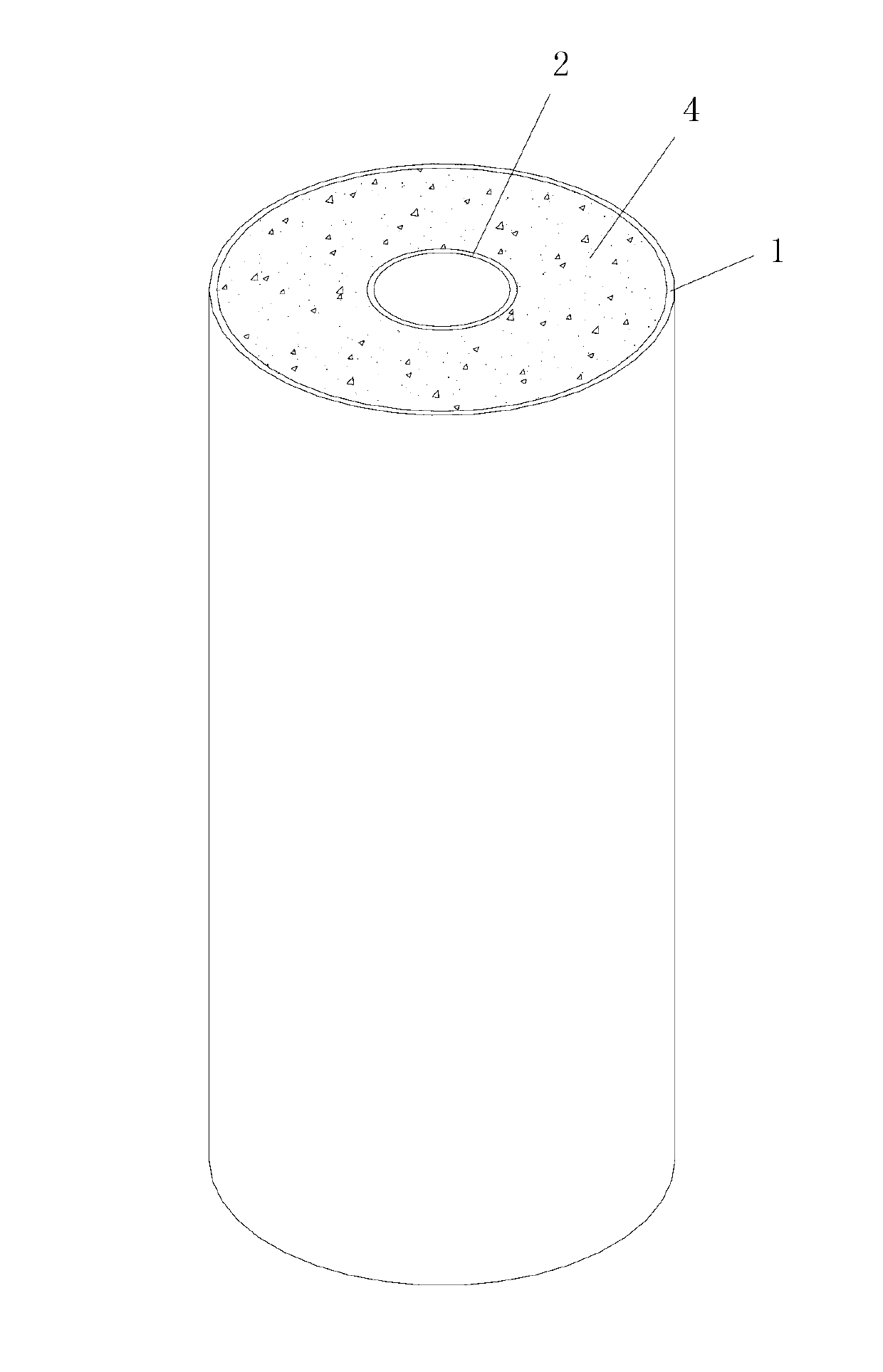

The invention discloses an SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of PBL stiffening ribs arranged between the outer steel tube and the inner steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube, the inner steel tube and the plurality of PBL stiffening ribs are equal in longitudinal length; the plurality of PBL stiffening ribs are arranged along the peripheral direction of the inner steel tube; the inner lateral wall of each PBL stiffening rib and the inner lateral wall of the inner steel tube are fastened and connected into a whole, and the outer lateral wall and the outer lateral wall of the outer steel tube are fastened and connected into a whole. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

Integral casting process for reinforced concrete wastewater tank in predrilling engineering

ActiveCN103015719AShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

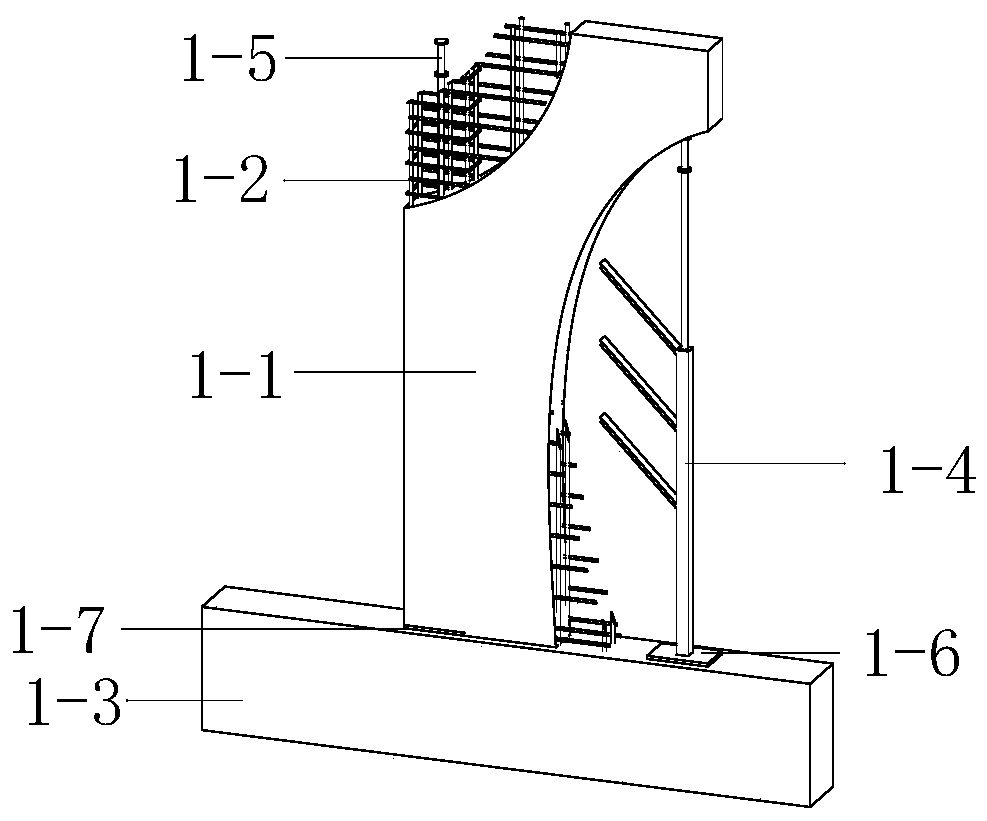

Bottom-hinged-supporting low-damage self-reset shear wall

ActiveCN110005091ANo plastic damageSection internal force does not surgeWallsProtective buildings/sheltersReinforced concreteRebar

The invention relates to a bottom-hinged-supporting low-damage self-reset shear wall. The bottom-hinged-supporting low-damage self-resetting shear wall comprises a reinforced concrete wall plate, a self-reset wall bottom and a foundation beam; the reinforced concrete wall plate is connected with the upper end of the self-reset wall bottom, the foundation beam is connected with the lower end of theself-reset wall bottom, a connecting plate is arranged in the middle of the upper surface of the foundation beam and provided with a connecting beam hinged joint, and self-reset short support hingedjoints II are arranged on the two sides of the connecting beam hinged joint correspondingly; the self-reset wall bottom comprises a connecting beam and a self-reset short support; an anti-shear key isarranged on the upper surface of the connecting beam, a foundation beam hinged joint is arranged in the middle of the lower surface of the connecting beam, and self-reset short support hinged jointsI are arranged on the positions, corresponding to the two self-reset short support hinged joints II, of the two ends of the lower surface of the connecting beam; and the self-reset short support comprises an inner pipe, an outer pipe, a disc spring and baffles, the disc spring is arranged in the outer pipe, the baffles are arranged at the two ends of the disc spring, the inner pipe penetrates through an inner hole of the disc spring and the baffles at the two ends and are capped at the two ends of the inner pipe through a stop block, and self-reset short support hinged joints III are arrangedat the two ends of the self-reset short support.

Owner:BEIJING JIAOTONG UNIV

SCS (structure cabling system) encased structure based on longitudinal stiffening ribs

InactiveCN102979250ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The invention discloses an SCS (structure cabling system) encased structure based on longitudinal stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of longitudinal stiffening ribs arranged at the inner lateral wall of the outer steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube and the inner steel tube are coaxially arranged; the plurality of longitudinal stiffening ribs are arranged along the peripheral direction of the inner steel tube; the outer steel tube, the inner steel tube and the plurality of longitudinal stiffening ribs are equal in the longitudinal length, and the transverse width of each longitudinal stiffening rib is the distance between the outer steel tube and the inner steel tube at the arranged positions. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

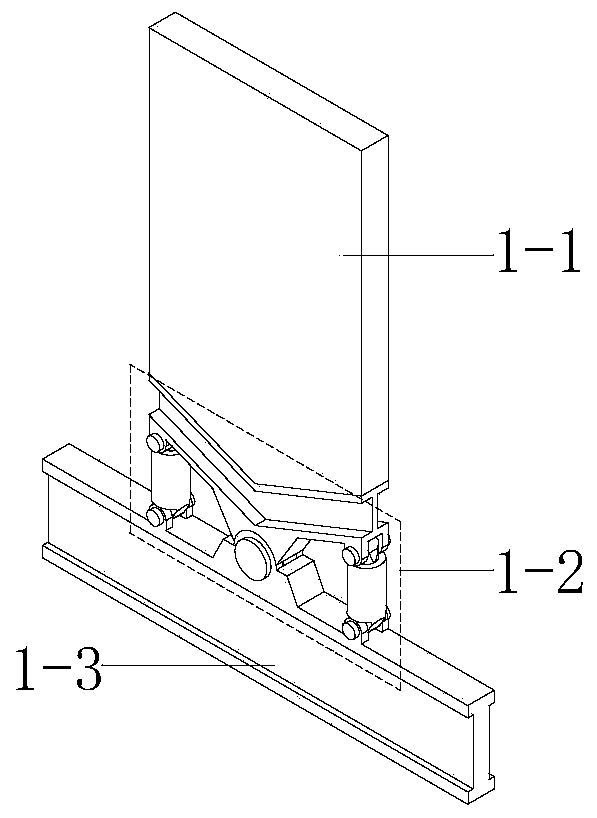

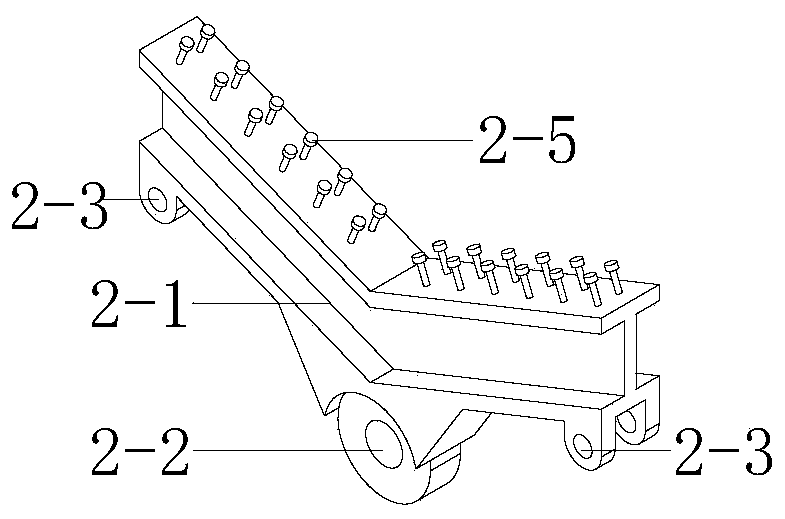

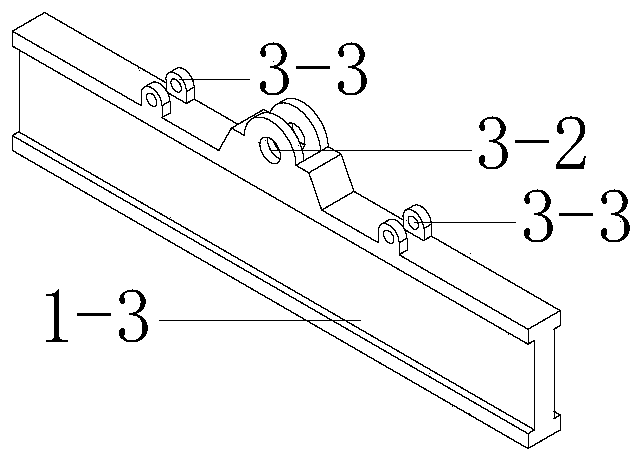

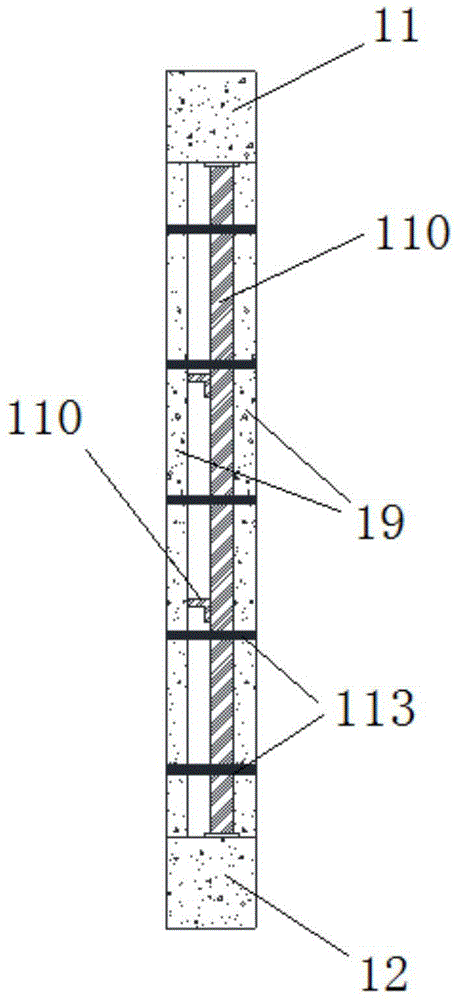

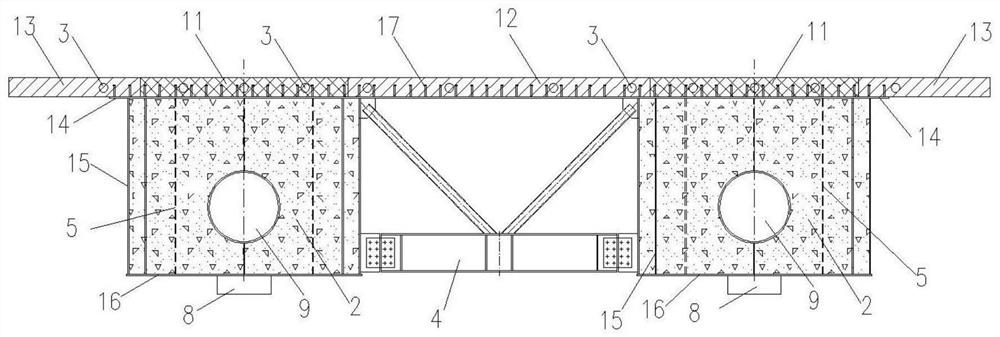

Energy dissipation shear wall with built-in trusses and construction method of shear wall

ActiveCN104612285APlay a stiffening roleHigh lateral stiffness against earthquakeWallsShock proofingEngineeringRebar

The invention discloses an energy dissipation shear wall with built-in trusses and a construction method of the shear wall. The energy dissipation shear wall comprises shear wallboards, the trusses are arranged between the shear wallboards, an edge frame is arranged on the peripheries of the shear wallboards, the trusses are fixedly connected with the edge frame, the edge frame comprises an upper edge frame beam, a lower edge frame beam, a left edge frame column and a right edge frame column, grouting sleeves are pre-buried on the left side of the upper edge frame beam and the left side of the left edge frame column, the right edge frame column is provided with transverse steel ribs extending out of the right edge frame column, and vertical steel ribs are extending out of the lower edge frame beam are arranged on the lower edge frame beam. The trusses are arranged in the steel rib concrete shear wallboards to have a certain reinforcing function on the shear wallboards, anti-seismic lateral rigidity is larger than that of a conventional steel rib concrete shear wall, and good energy-dissipation and anti-seismic functions are achieved. The built-in trusses divide the shear wallboards into a plurality of small wall columns, during large earthquakes, energy is dissipated through local yielding, stability outside the whole plane is enhanced, and the shear wallboards are moved through the trusses to achieve the anti-seismic function as a whole.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

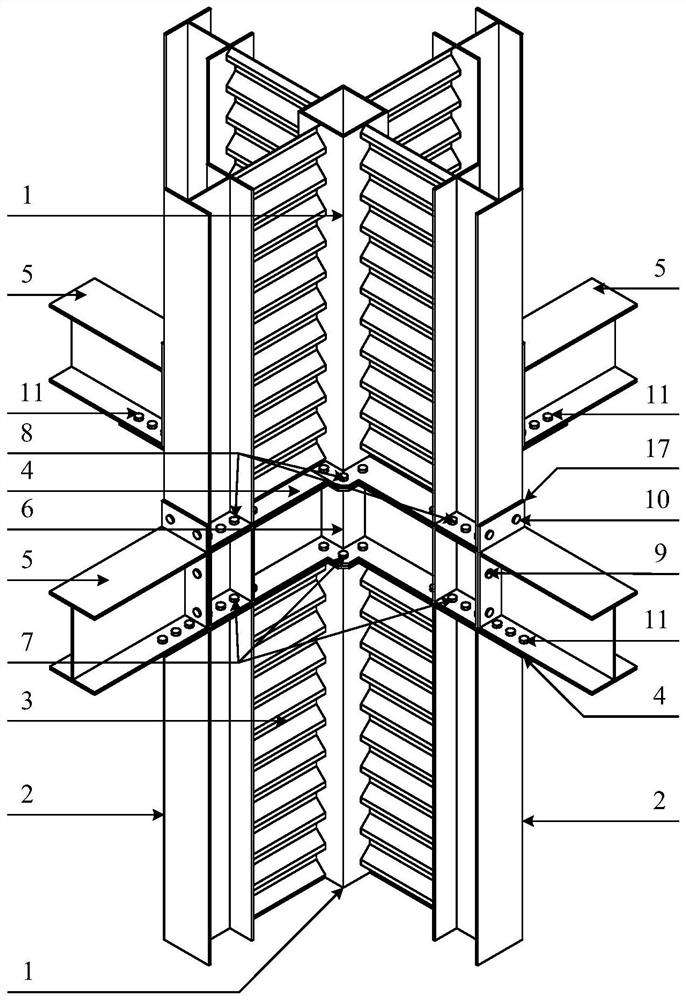

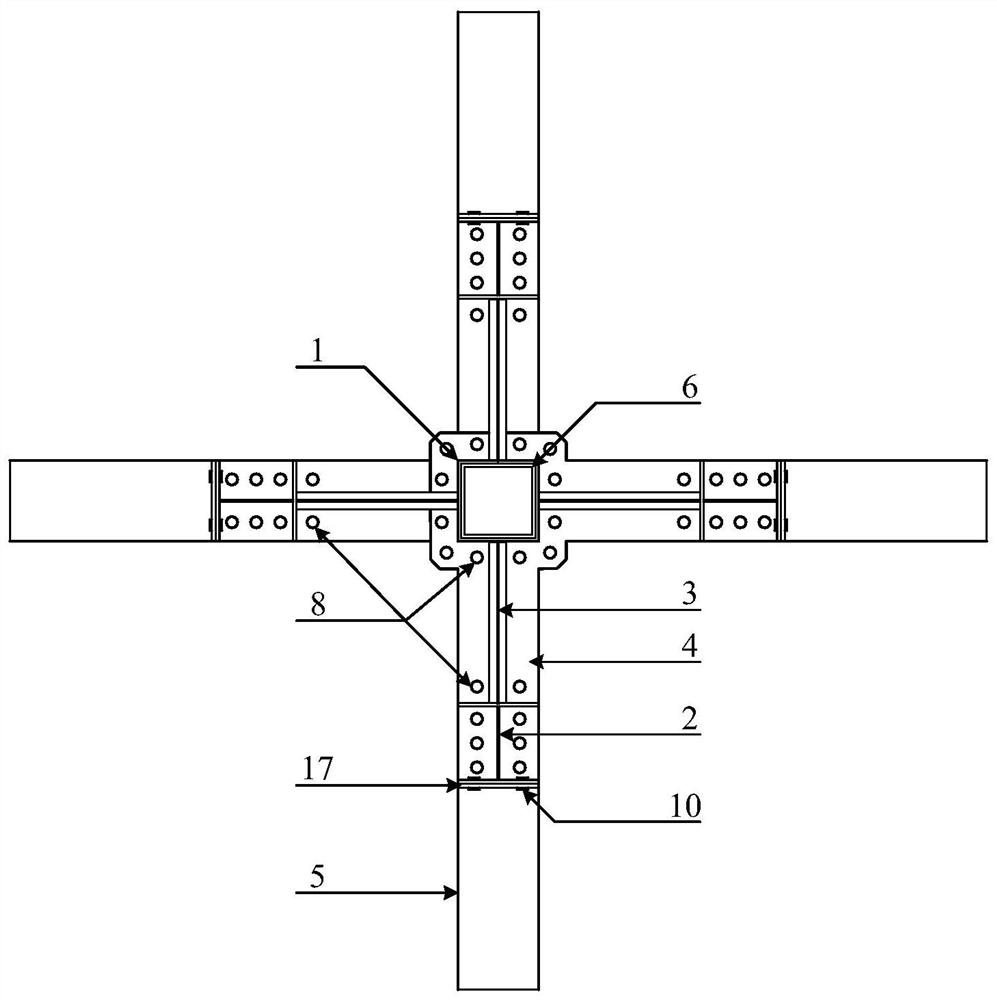

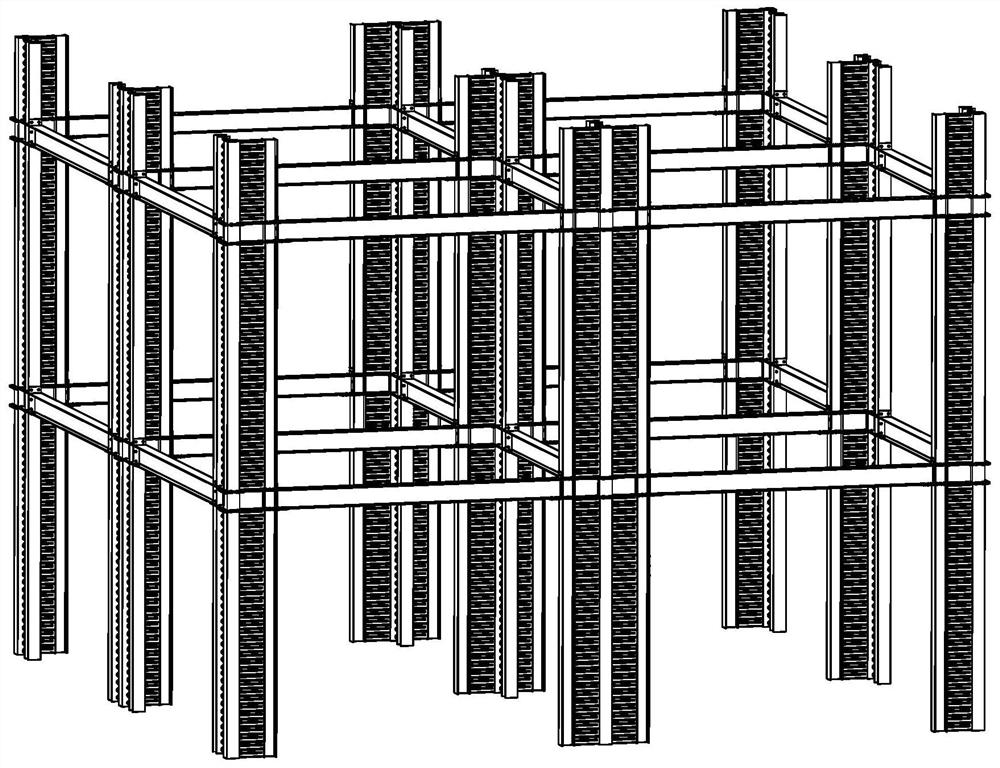

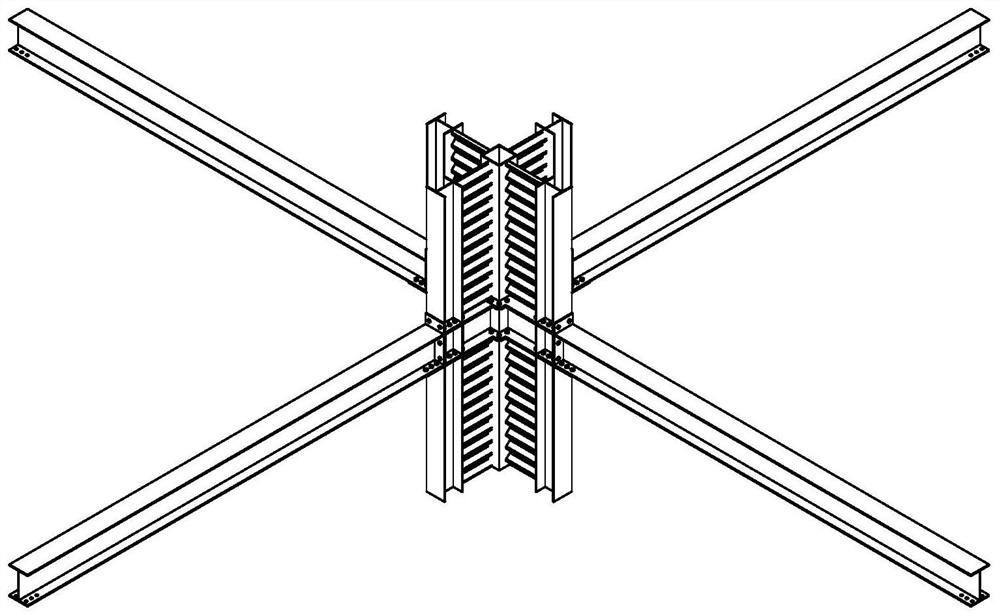

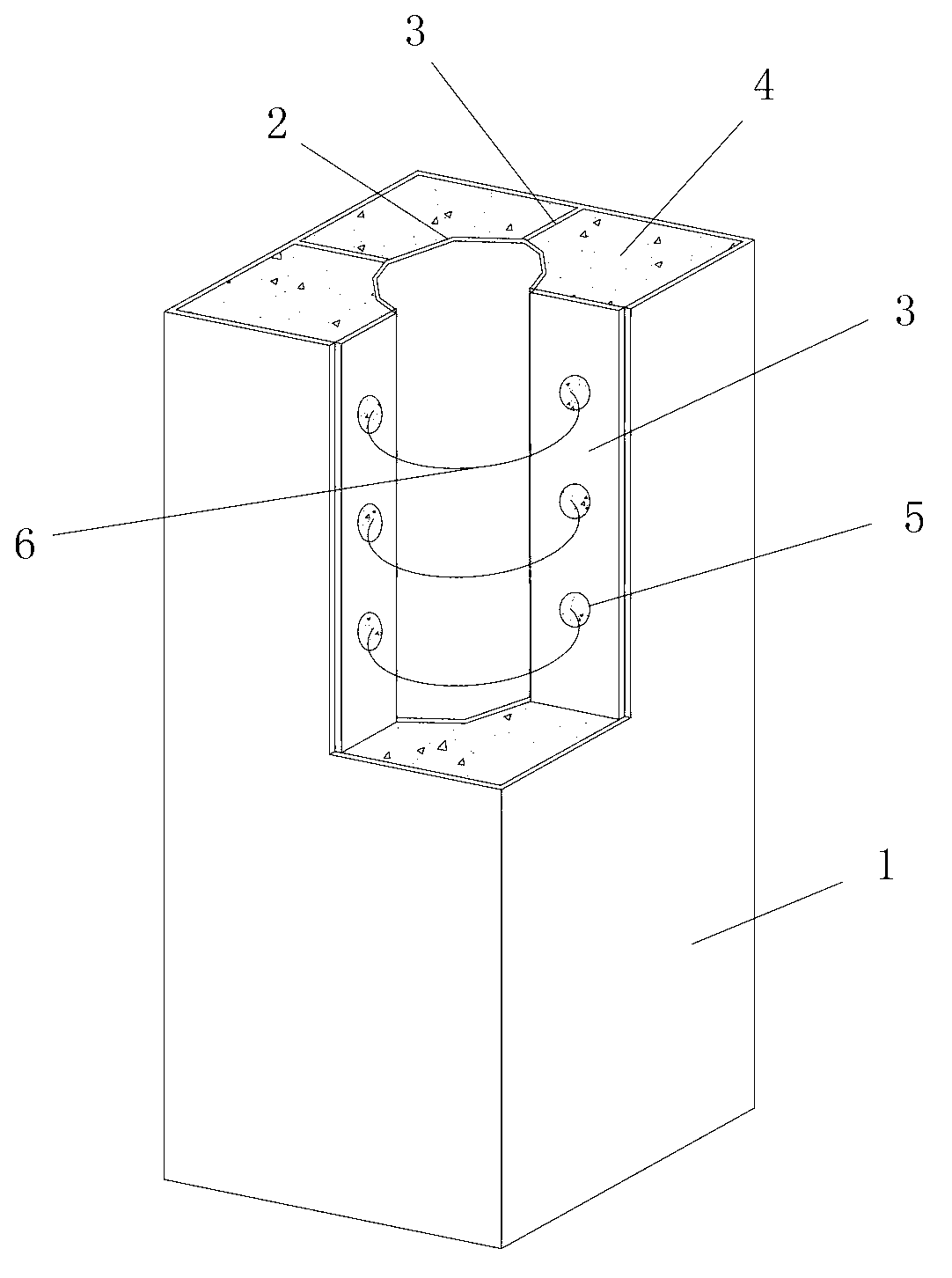

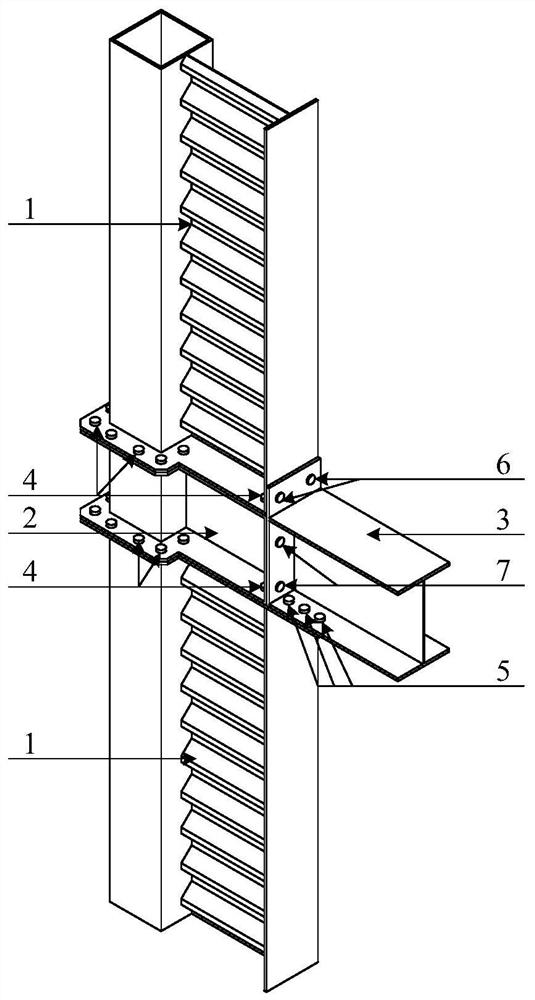

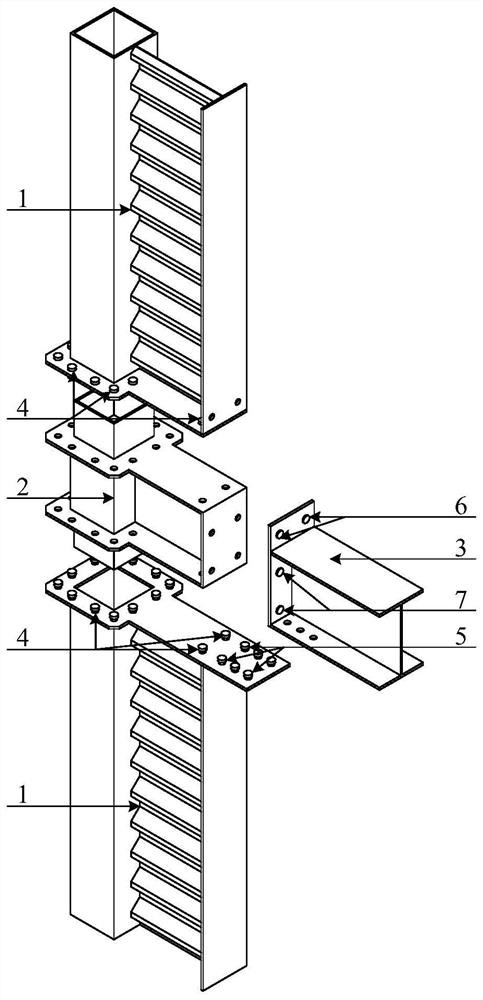

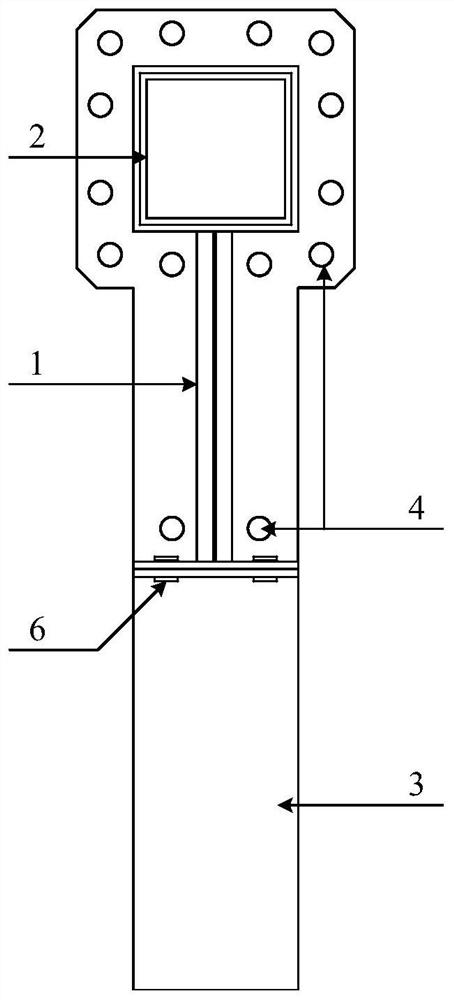

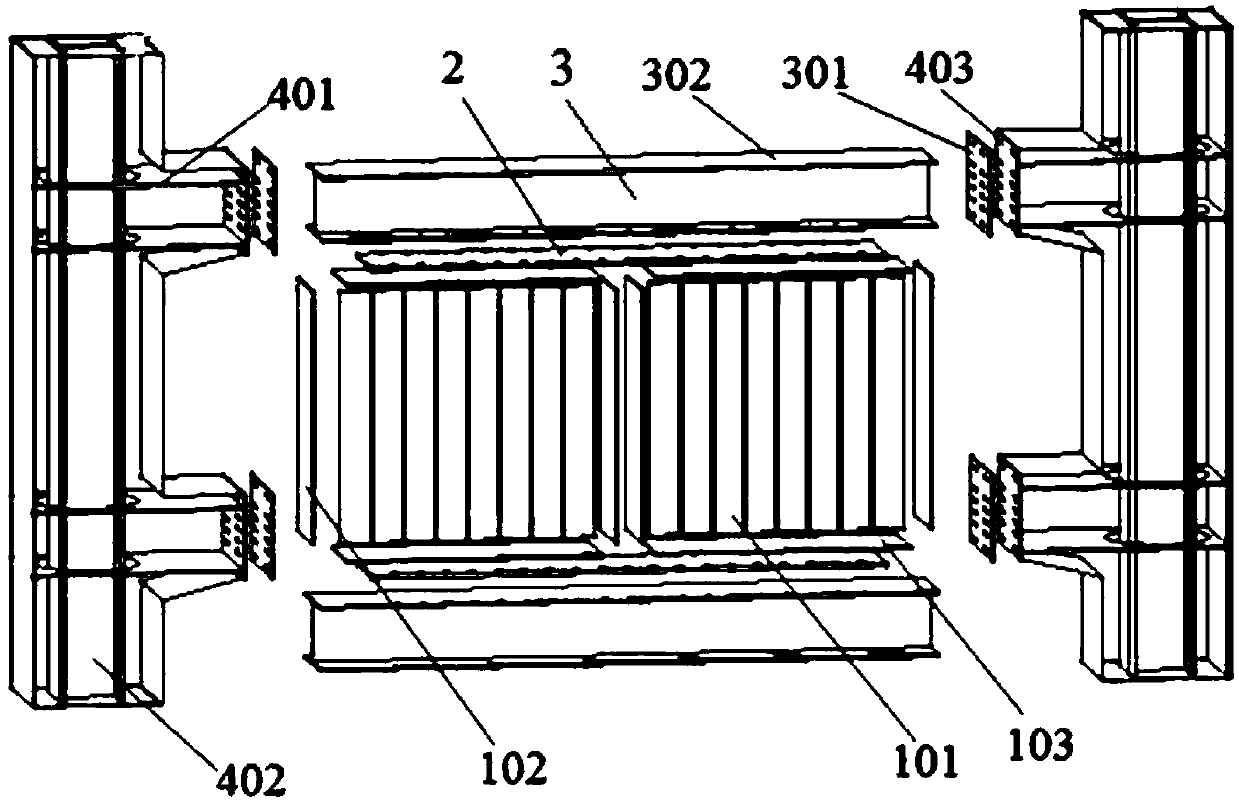

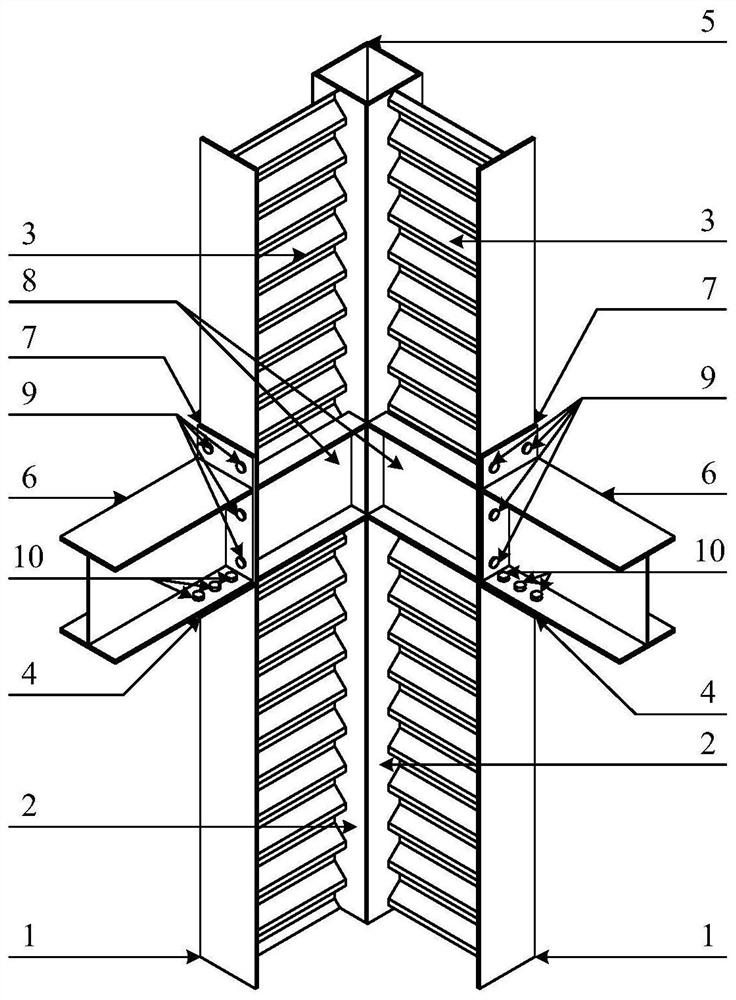

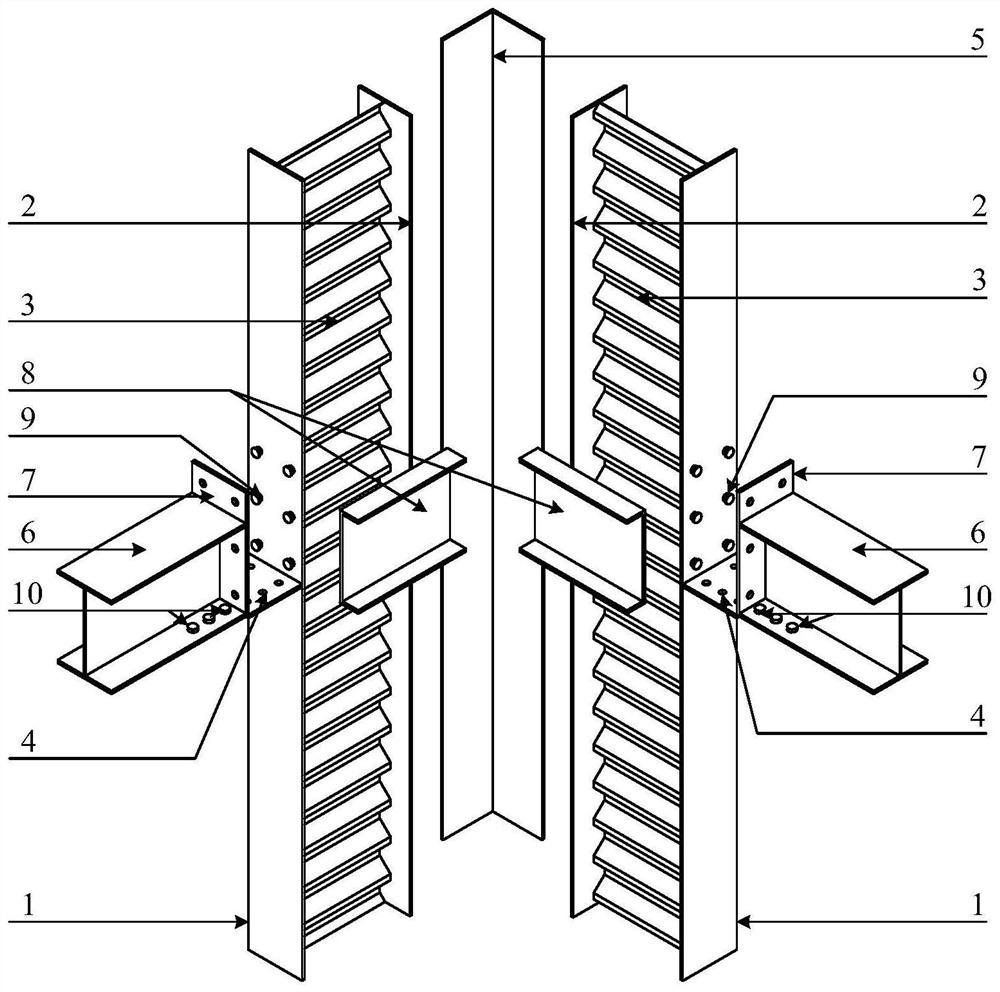

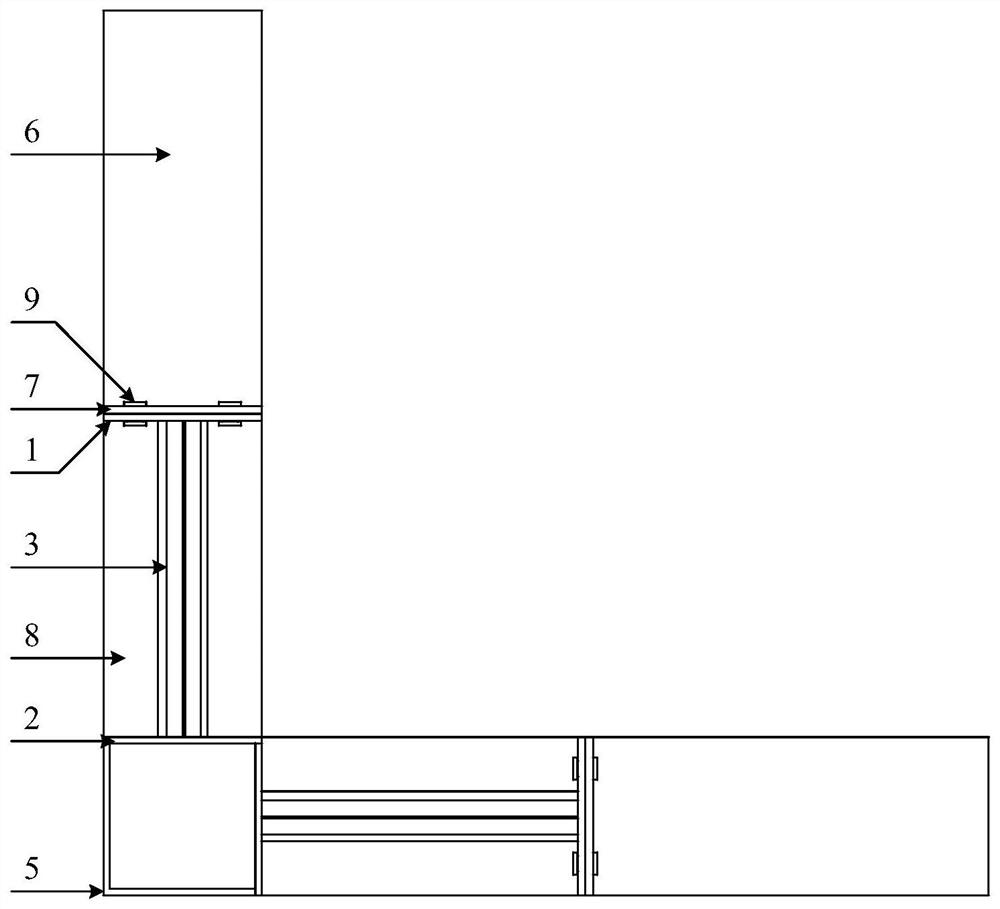

Fabricated beam-column connecting joint based on corrugated plate lateral-resistant special-shaped column

PendingCN112160419AReasonable power flow transmissionClear forceStrutsPillarsEarthquake resistantBolted joint

The invention discloses a fabricated beam-column connecting joint based on a corrugated plate lateral-resistant special-shaped column, and belongs to the technical field of structural engineering. Thebeam-column connecting joint is composed of a special-shaped column, an I-shaped beam with an end plate and a beam column-column connecting piece with a protruding column. Manufacturing and welding of steel components are completed in a factory, and welding and component quality are easy to control; only steel components need to be hoisted and connected through high-strength bolts on a construction site, and the construction efficiency is high. The connecting joint has the advantages of mechanical property and practical property at the same time, in the aspect of the mechanical property, thebearing capacity and the lateral-resistant stiffness of the special-shaped column are fully utilized, and the connecting joint has good anti-seismic property; and in the aspect of practical performance, the rapid assembly concept is emphatically achieved, and the protruding column problem in a house is solved.

Owner:BEIJING UNIV OF TECH

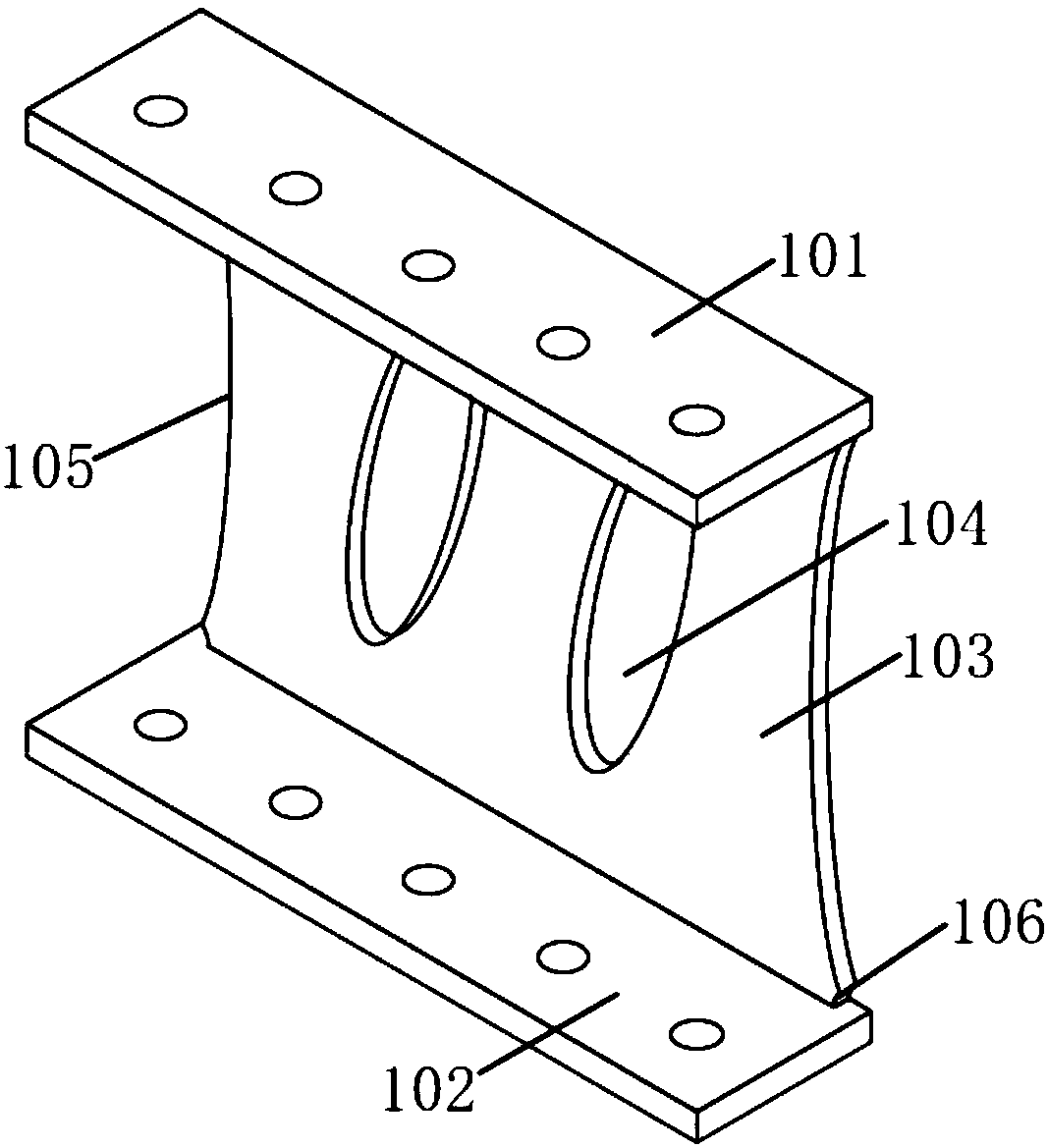

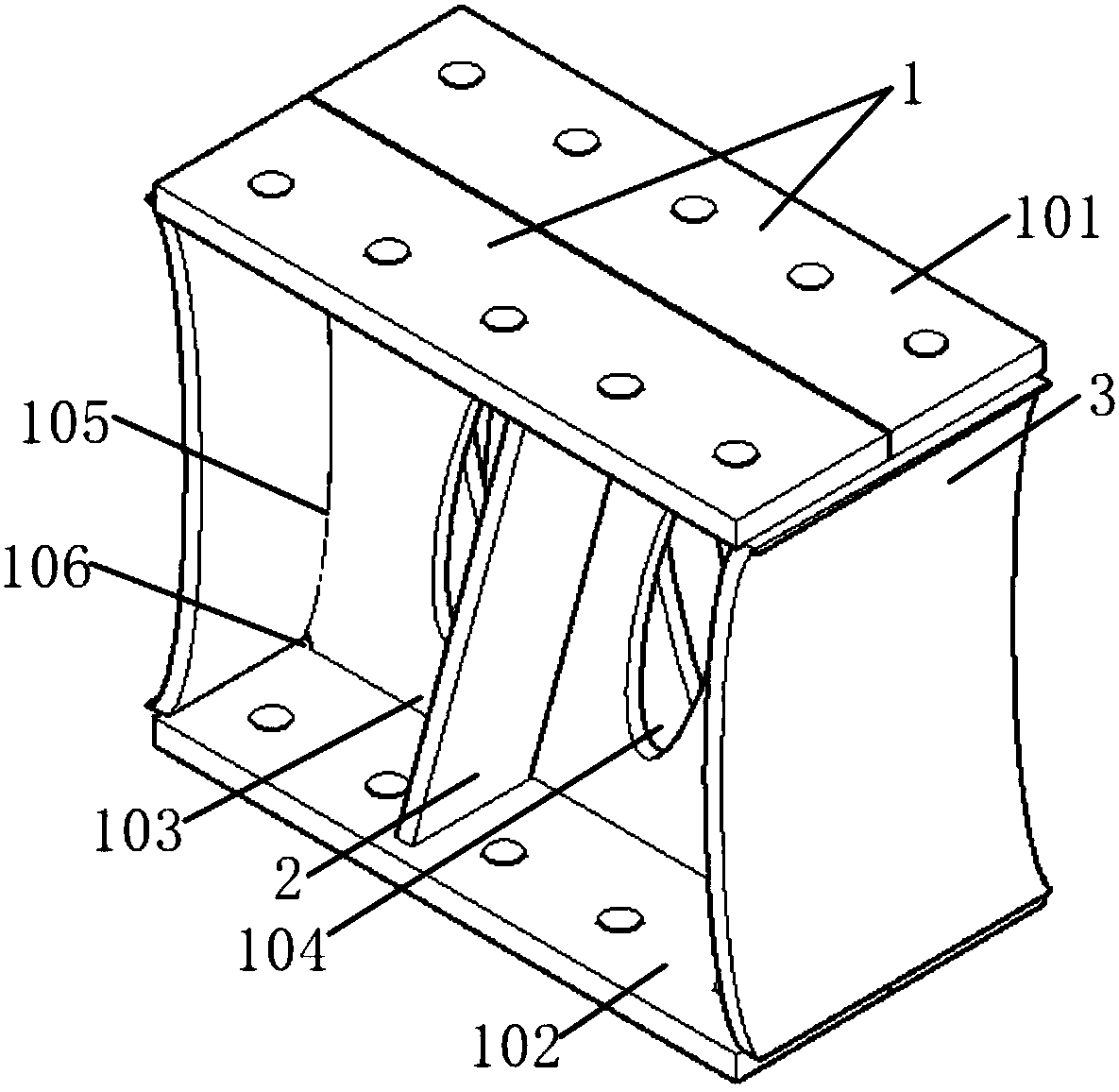

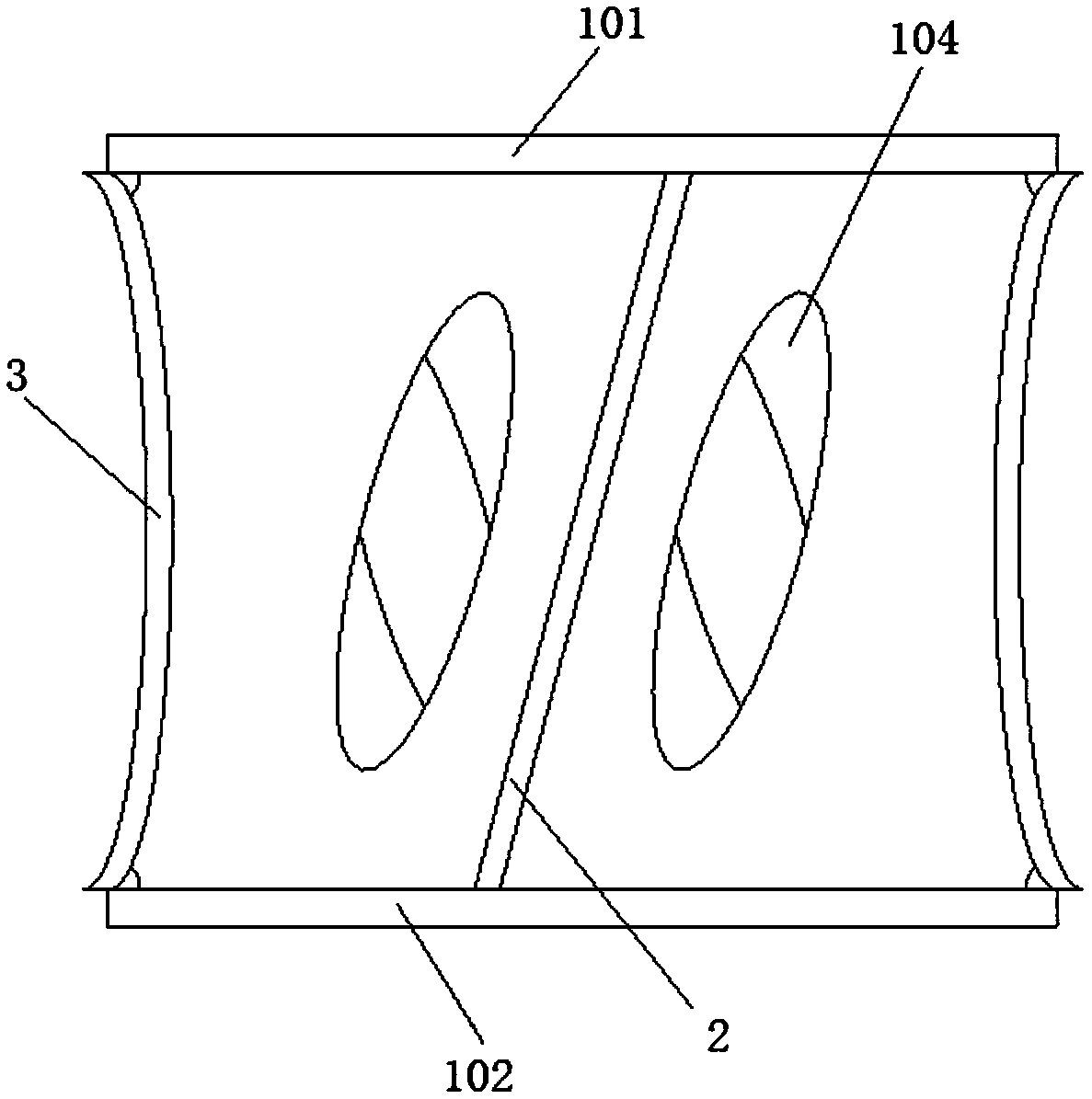

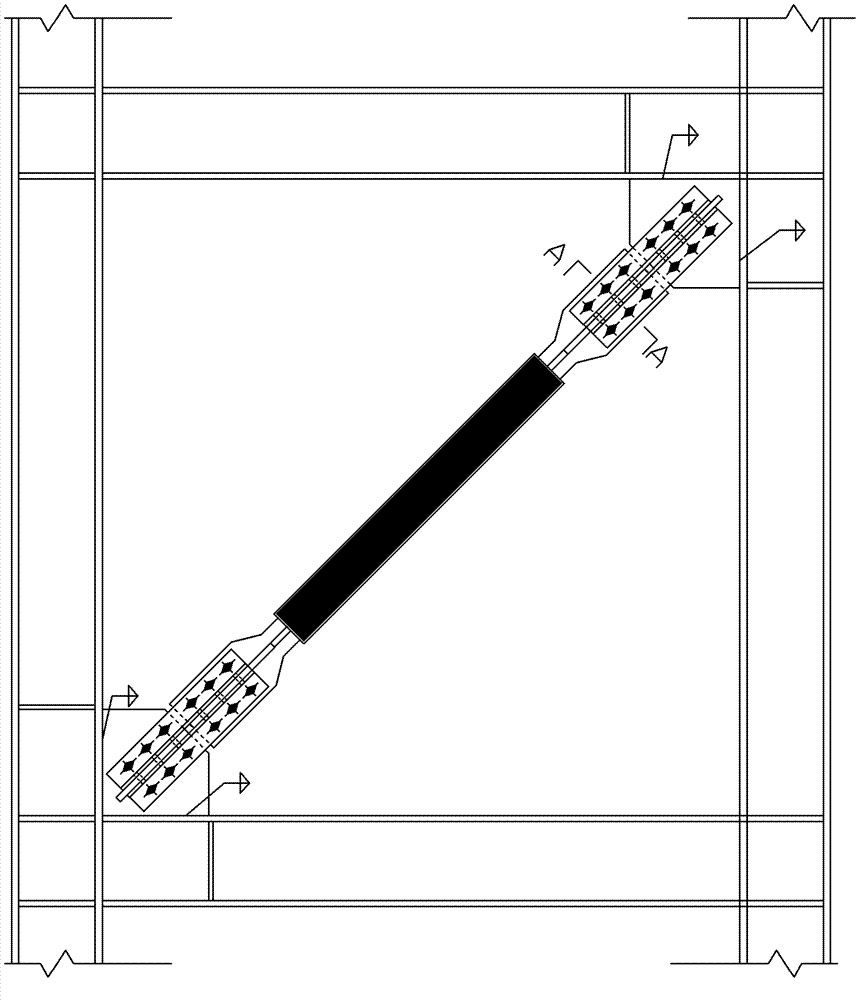

Duplex I-shaped energy dissipation device and supporting structure thereof

PendingCN108547384AAvoid weld tear damageEnhanced out-of-plane stabilityProtective buildings/sheltersShock proofingWeld seamEngineering

The invention discloses a duplex I-shaped energy dissipation device. The duplex I-shaped energy dissipation device comprises two energy dissipation plates oppositely arranged in a spaced mode, reinforcing plates obliquely arranged in each energy dissipation plate and an arc-shaped sealing plate fixedly connected with the two energy dissipation plates. Each energy dissipation plate is a U-shaped plate integrally formed by an upper wing plate, a lower wing plate and a web plate. A plurality of oblique elliptical holes are formed in the web plates. Arc-shaped end faces consistent with the radianof the arc-shaped sealing plate are formed in the end faces of the two sides of each web plate. The arc-shaped end faces and the arc surface of the arc-shaped sealing plate are fixed together. The upper wing plates and the upper end face of the arc-shaped sealing plate are fixed together, and the lower wing plates and the lower end face of the arc-shaped sealing plate are fixed together. In the duplex I-shaped energy dissipation device, the upper wing plate, the lower wing plate and the web plate of each energy dissipation plate are of an integrally-formed structure, the situation that the phenomenon that weld seams cracks and damage occur at the end corner points of the welding connecting positions of the web plates and the wing plates, and consequently, the capacity that the energy dissipation device cooperates with a building structure to dissipate seismic energy is lost in advance by the energy dissipation device is avoided, and it is ensured that under the action of an earthquake,the effect of dissipating the energy of the energy dissipation device can be fully achieved.

Owner:SOUTHEAST UNIV +2

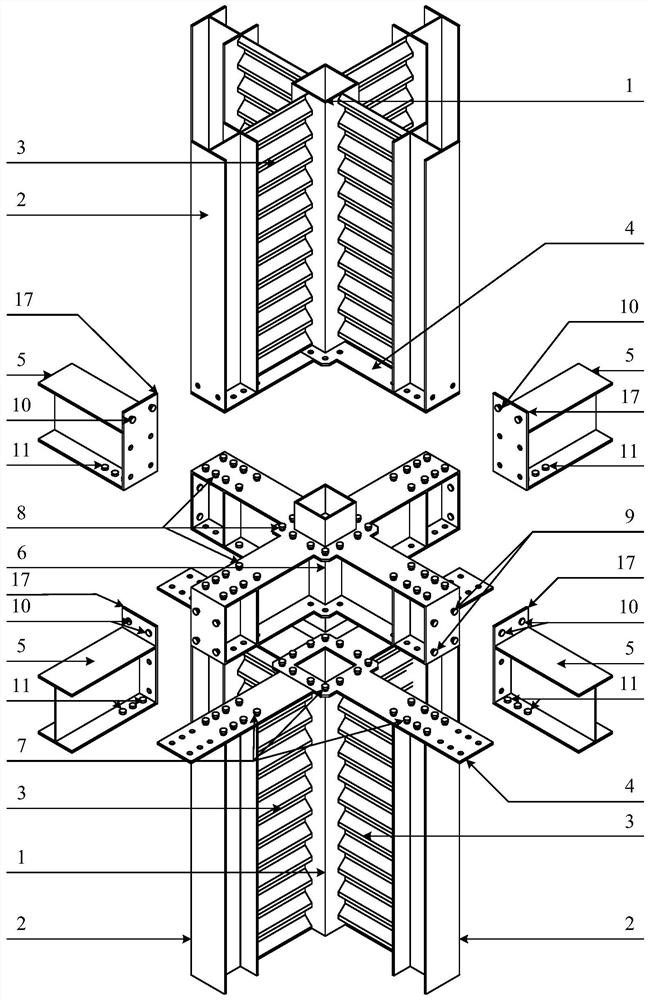

Assembly type steel structure special-shaped column frame structure system

PendingCN112302167AIncrease lateral stiffnessImprove seismic performanceStrutsPillarsEarthquake resistanceShaped beam

The invention discloses an assembly type steel structure special-shaped column frame structure system, and belongs to the technical field of structural engineering. The assembly type steel structure special-shaped column frame structure system involves a structure system, a roof panel system and an enclosure structure. The roof panel system is laid on steel beams of the structural system, the space between beam column vertical face frames of the structural system is filled with the enclosure system, the structural system adopts an assembly type steel structure special-shaped column frame system, and the corrugated plate anti-side special-shaped column comprises a square steel pipe column, a section steel column and a corrugated plate; and a connecting joint of the system is composed of a corrugated plate anti-side special-shaped column, an H-shaped beam with an end plate, a beam column-column connecting part with a protruding column and high-strength bolts. According to the assembly type steel structure special-shaped column frame structure system, the structure is flexible in arrangement and high in assembly efficiency, the protruding column and protruding beam problem can be reasonably solved, the bearing capacity and the anti-seismic property are higher compared with a traditional steel structure, and the application range is wider.

Owner:BEIJING UNIV OF TECH

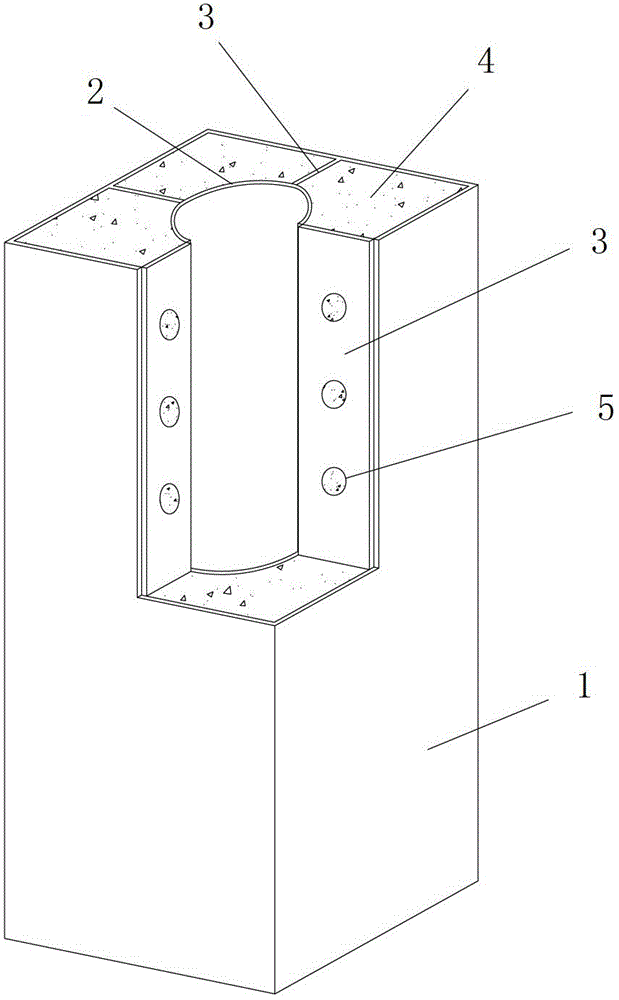

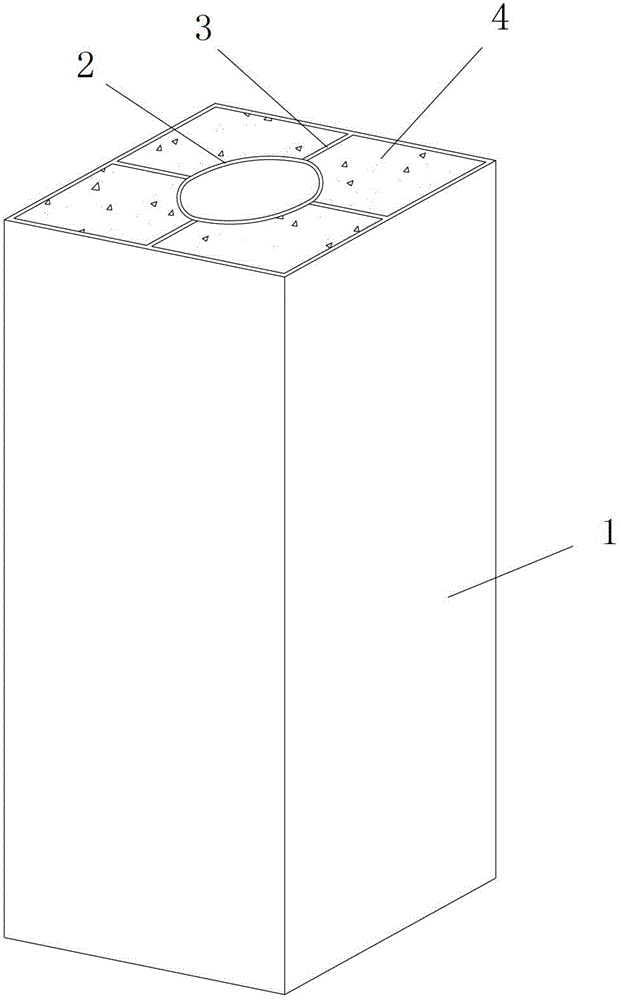

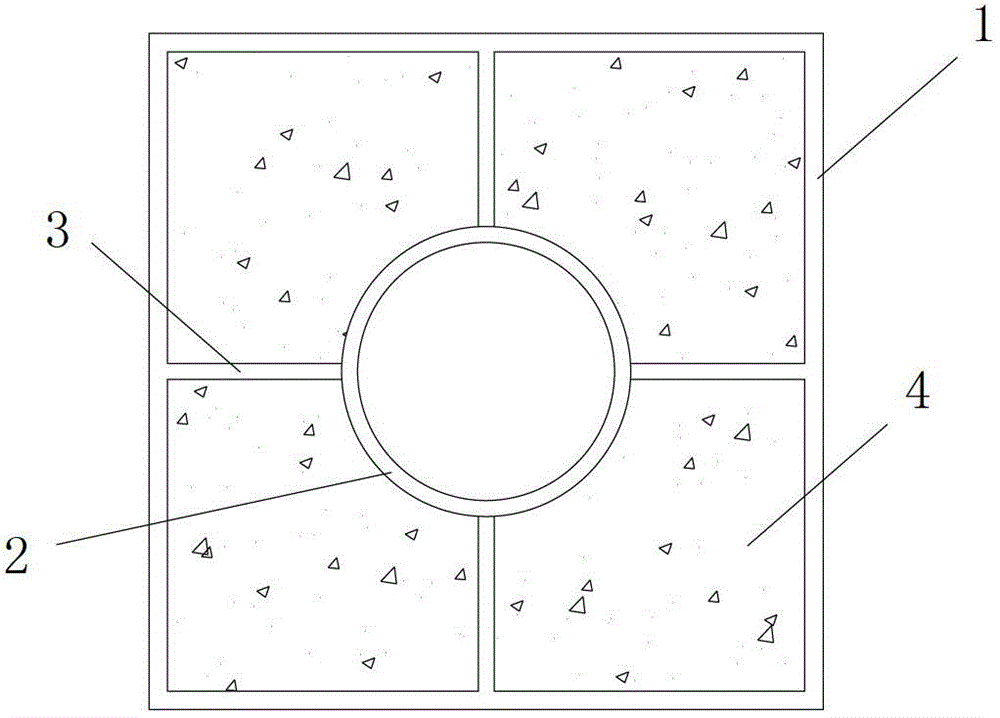

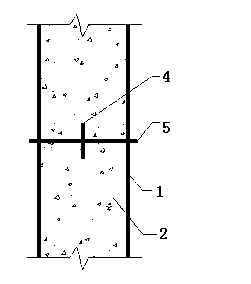

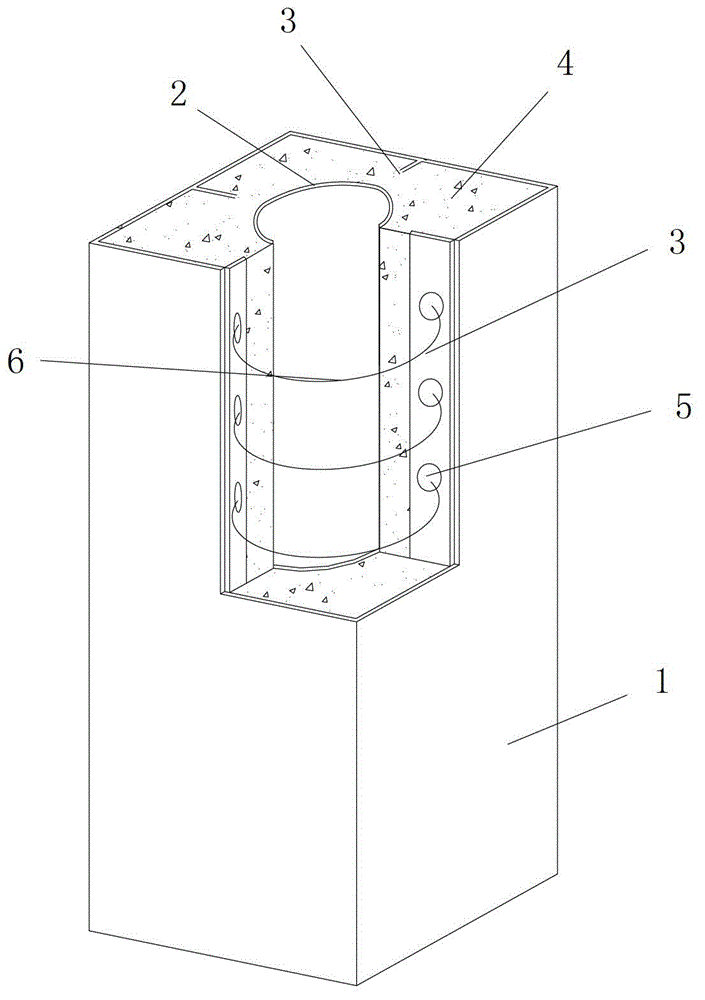

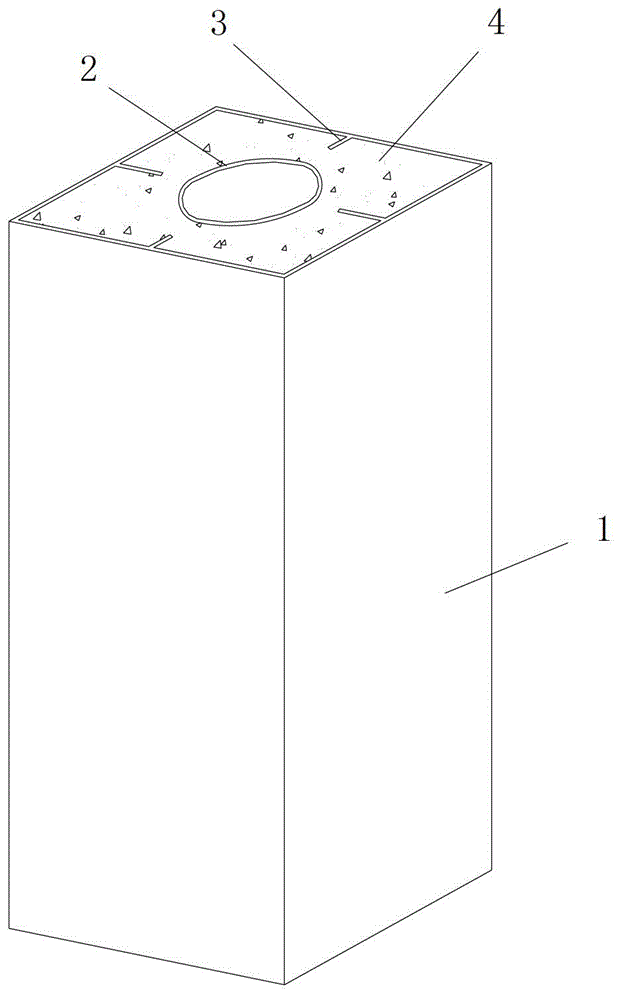

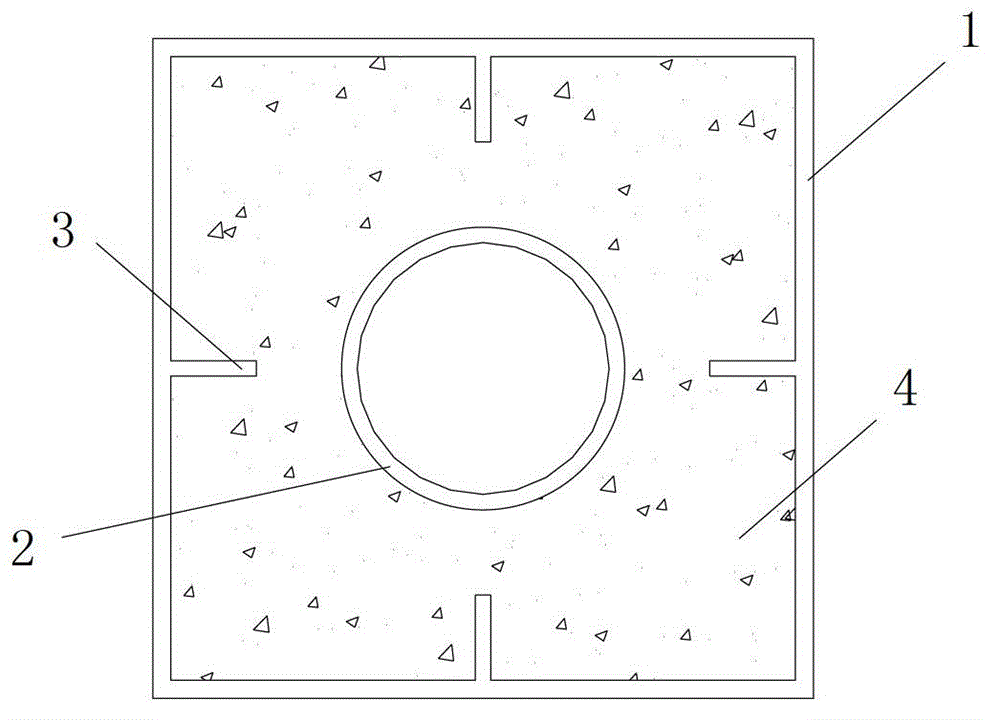

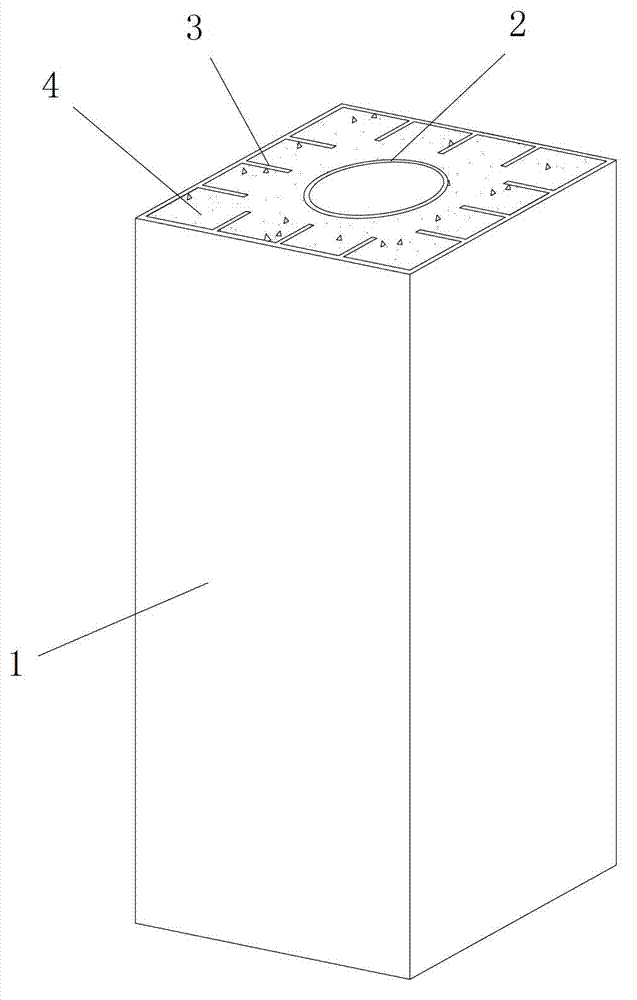

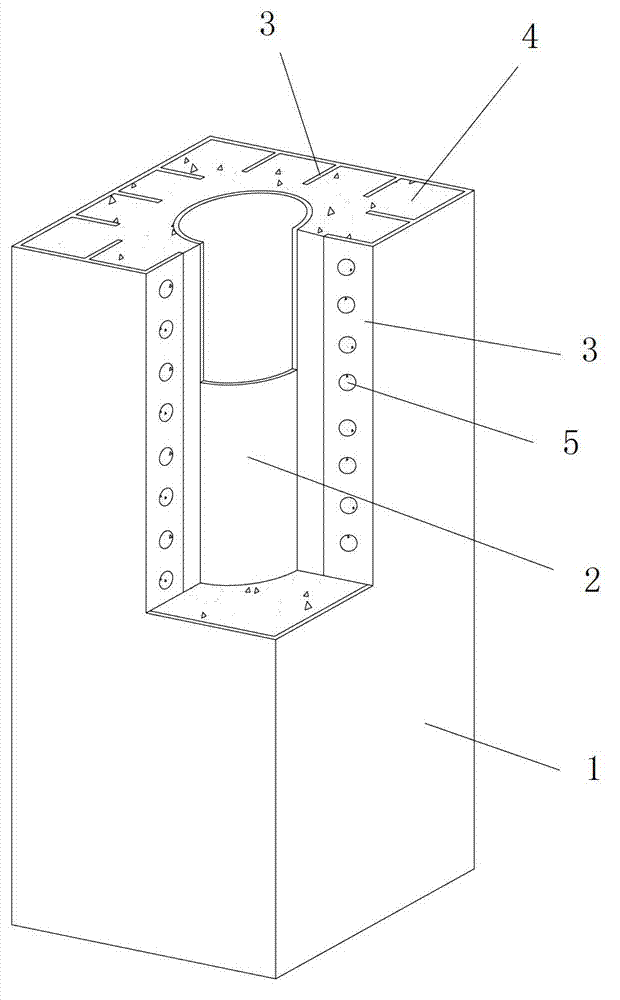

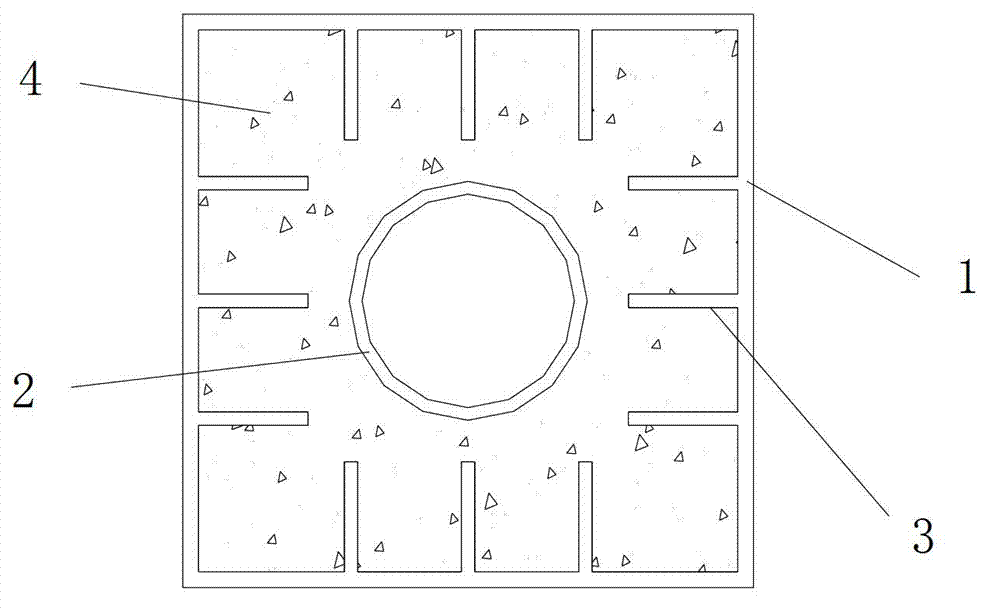

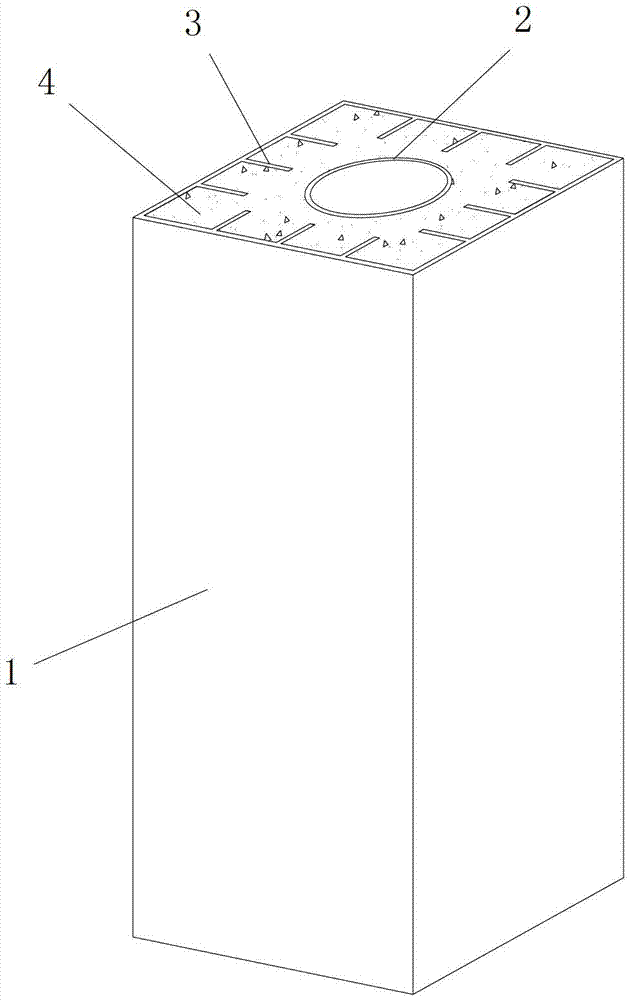

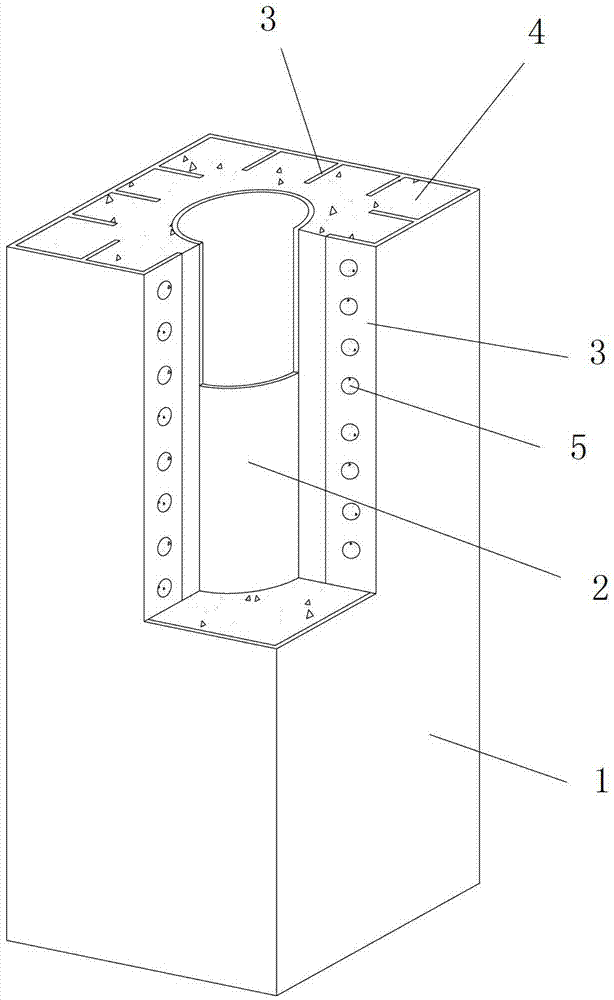

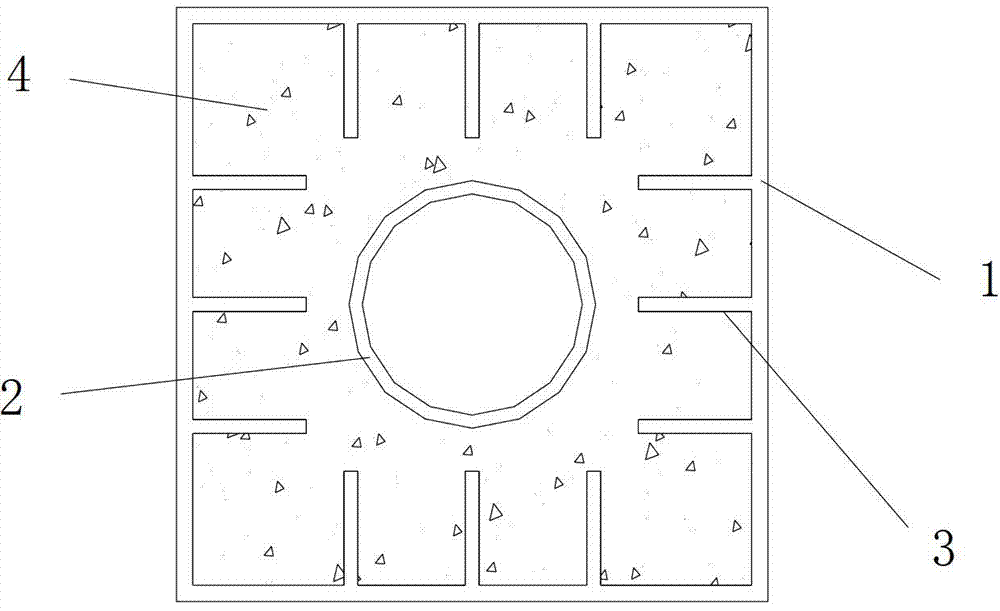

A double stiffened SCS square steel tube concrete structure based on stirrups and stiffening ribs

InactiveCN103061449ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The present invention discloses a double stiffened SCS square steel tube concrete structure based on stirrups and stiffening ribs, including a square steel pipe, a round steel pipe sleeved inside the square steel pipe, a plurality of PBL stiffening ribs laid between the square and round steel tube, a plurality of stirrups laid in the plurality of PBL stiffening ribs from top to bottom, and a concrete structure pouring formed by concrete filled in the cavity between the square steel tube and the round steel pipe, and the square steel pipe and the round steel pipe laid around the same axis. The layout directions of the plurality of PBL stiffening ribs are all the same with the central axis direction of the round steel pipe; the longitudinal lengths of the square steel pipe, the round steel pipe and the plurality of PBL stiffening ribs are the same; the plurality of PBL stiffening ribs are laid along the circumferential direction; and the plurality of stirrups are laid in parallel. The concrete structure of the invention has simple structure, reasonable design, easy construction and low construction cost, excellent mechanical properties and good use effect, and can solve many problems existing in current square steel concrete structures.

Owner:XIAN HIGHWAY INST +1

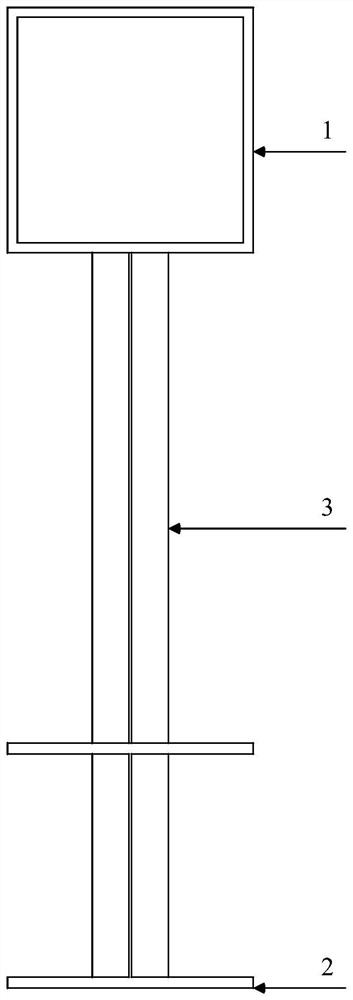

Self-resetting shear wall capable of optimizing stress distribution

ActiveCN110005090AUniform distribution of stress levelsFully utilized materialsWallsProtective buildings/sheltersRebarStress level

The invention belongs to the technical field of building structures, and relates to a self-resetting shear wall capable of optimizing stress distribution. The self-resetting shear wall comprises a reinforced concrete wall panel, a first force transmitting device, a second force transmitting device, a first flexible backing plate and a second flexible backing plate. The first force transmitting device and the second force transmitting device are separately arranged on two sides of the reinforced concrete wall panel. The lower end of the first force transmitting device penetrates through the first flexible backing plate, the lower end of the second force transmitting device penetrates through the second flexible backing plate, and the lower end of the first force transmitting device and thelower end of the second force transmitting device are both embedded in a reinforced concrete foundation beam. When a wall body of the shear wall is deformed, concrete of the foot of the wall is not prone to being plastically fractured; the overall stress level is evenly distributed, and materials are fully utilized; no obvious damage accumulation exists in reciprocating deformation, and no residual displacement occurs; the yield displacement is shifted backward; a plastic energy dissipation region is wide, and high ductility is achieved; a lateral deformation elastic stroke is large; the resetting ability is achieved; the out-of-plane stability is higher; and no additional internal force is applied to a wallboard.

Owner:BEIJING JIAOTONG UNIV

Fabricated beam-column connecting joint based on corrugated plate anti-side special-shaped column

PendingCN112160420ASufficient lateral stiffnessReduce layer driftStrutsPillarsEarthquake resistanceShaped beam

The invention discloses a fabricated beam-column connecting joint based on a corrugated plate anti-side special-shaped column, and belongs to the technical field of structural engineering. The beam-column connecting joint is composed of the corrugated plate anti-side special-shaped column, an I-shaped beam with an end plate, and a beam-column column connecting part with a protruding column. The manufacturing and the welding of steel elements are completed in a factory, so that the welding and the element quality are easy to control; and only steel components need to be hoisted and connected through high-strength bolts on a construction site, so that the construction efficiency is high. According to the fabricated beam-column connecting joint based on the corrugated plate anti-side special-shaped column, the connecting joint has the advantages of mechanical property and practical property at the same time: in the aspect of the mechanical property, the bearing capacity and the lateral stiffness of the special-shaped column are fully utilized, and the connecting joint has good anti-seismic property; and in the aspect of the practical property, a rapid assembly concept is emphaticallyachieved, and the protruding column problem in a house is solved.

Owner:BEIJING UNIV OF TECH

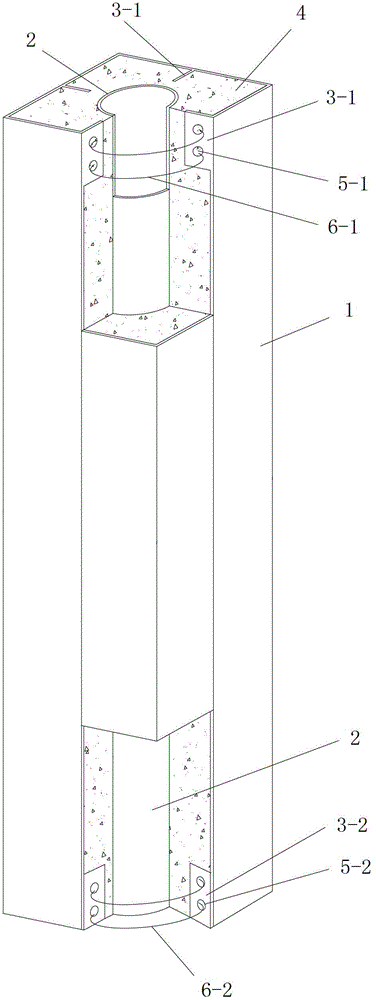

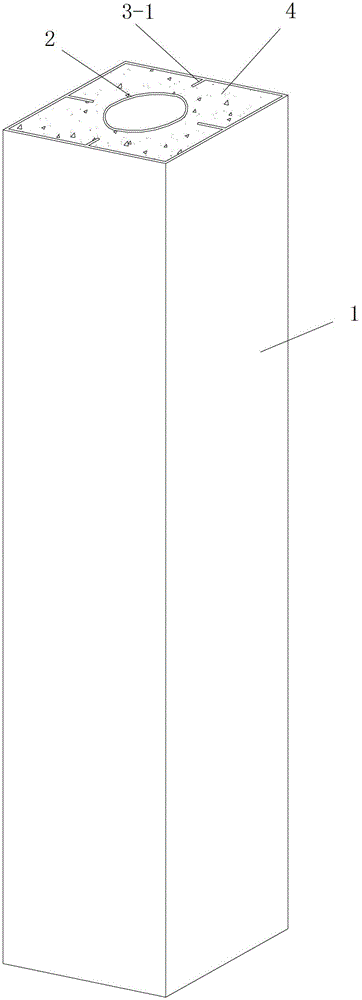

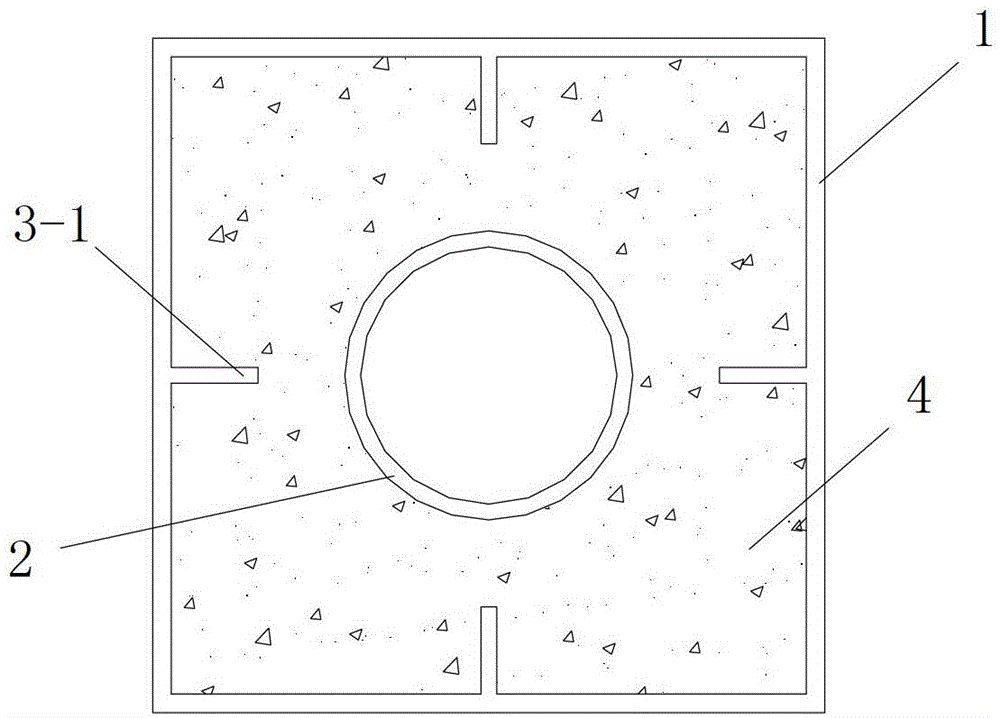

SCS square concrete-filled steel tube pier column

InactiveCN103031927ASimple structureReasonable designStrutsBridge structural detailsMechanical propertySteel tube

The invention discloses an SCS (square concrete-filled steel) tube pier column which comprises a square steel tube, a circular steel tube, four stiffening rib plate groups and a concrete structure, wherein the circular steel tube is mounted in the square steel tube in a sleeving manner; the four stiffening rib plate groups are arranged on four inner side walls of the square steel tube respectively; the concrete structure is formed by pouring concrete filled in a cavity between the square steel tube and the circular steel tube; each stiffening rib plate group comprises a plurality of longitudinal stiffening ribs that are arranged in parallel; the longitudinal stiffening ribs are perpendicular to the inner side walls of the square steel tube where the longitudinal stiffening ribs are located respectively; all the longitudinal stiffening ribs in the four stiffening rib plate groups have identical structures and sizes; the square steel tube and the circular steel tube are arranged coaxially; and the transverse width of each longitudinal stiffening rib is less than a distance between the square steel tube and the circular steel tube where the longitudinal stiffening rib is arranged. The pier column is simple in structure, reasonable in design, convenient to construct, lower in construction cost, good in mechanical property and good in use effect, and can effectively solve the problems existing in the existing square concrete-filled steel tube structure.

Owner:CHANGAN UNIV

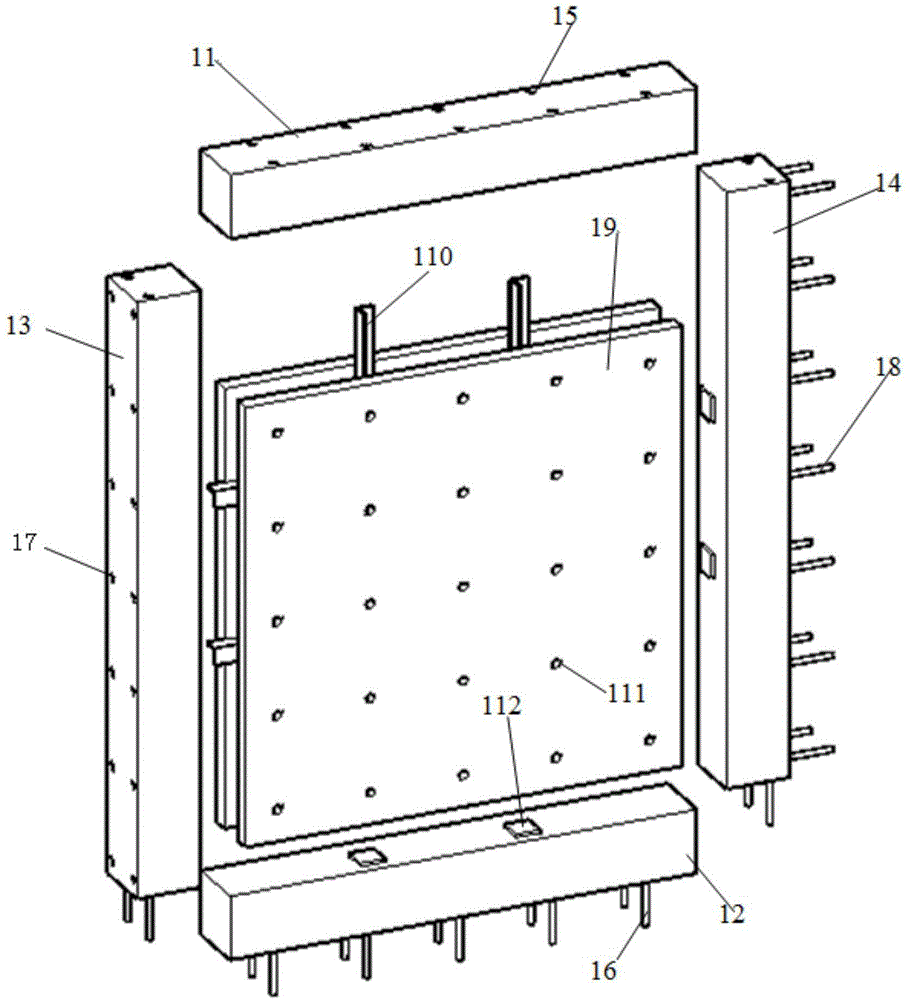

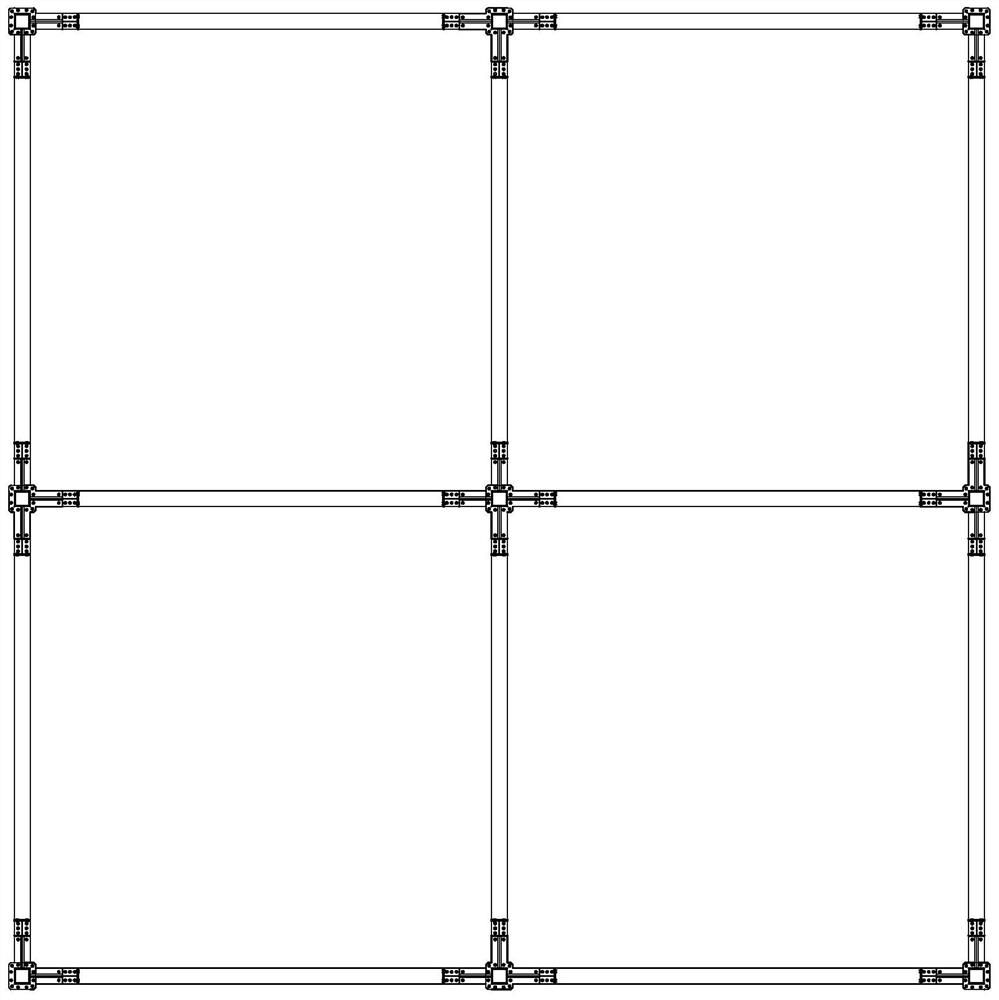

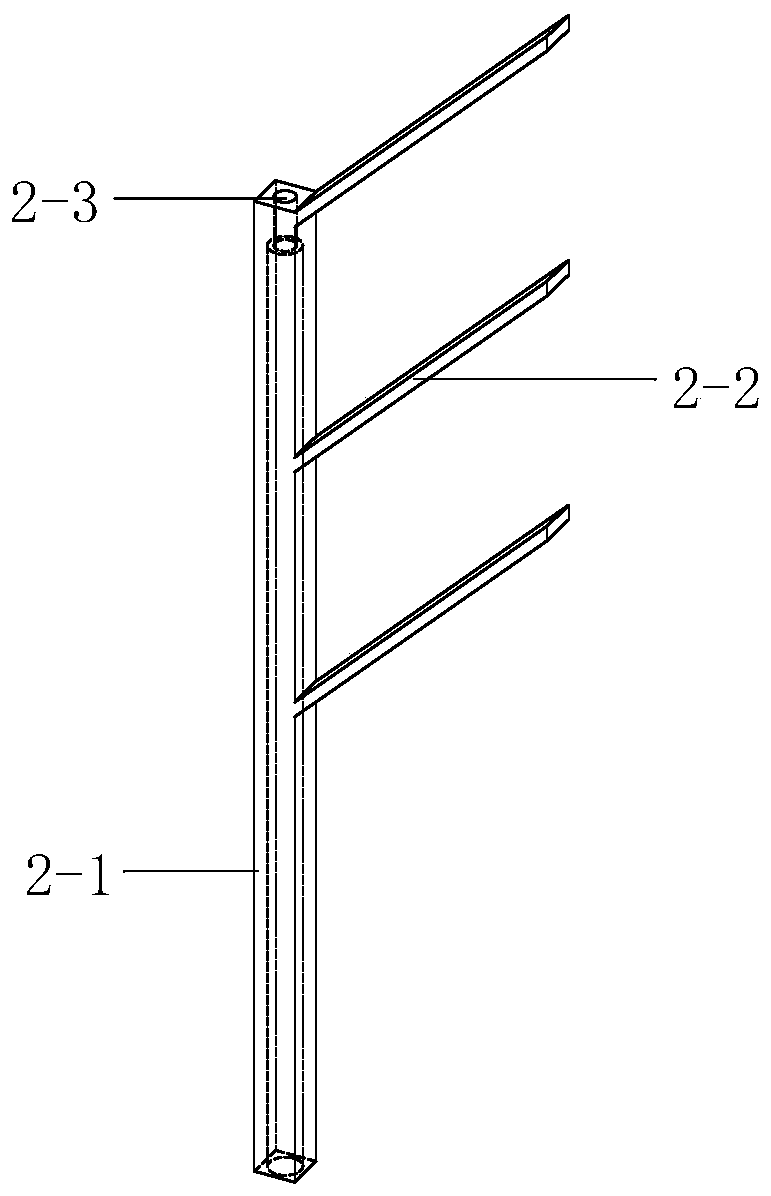

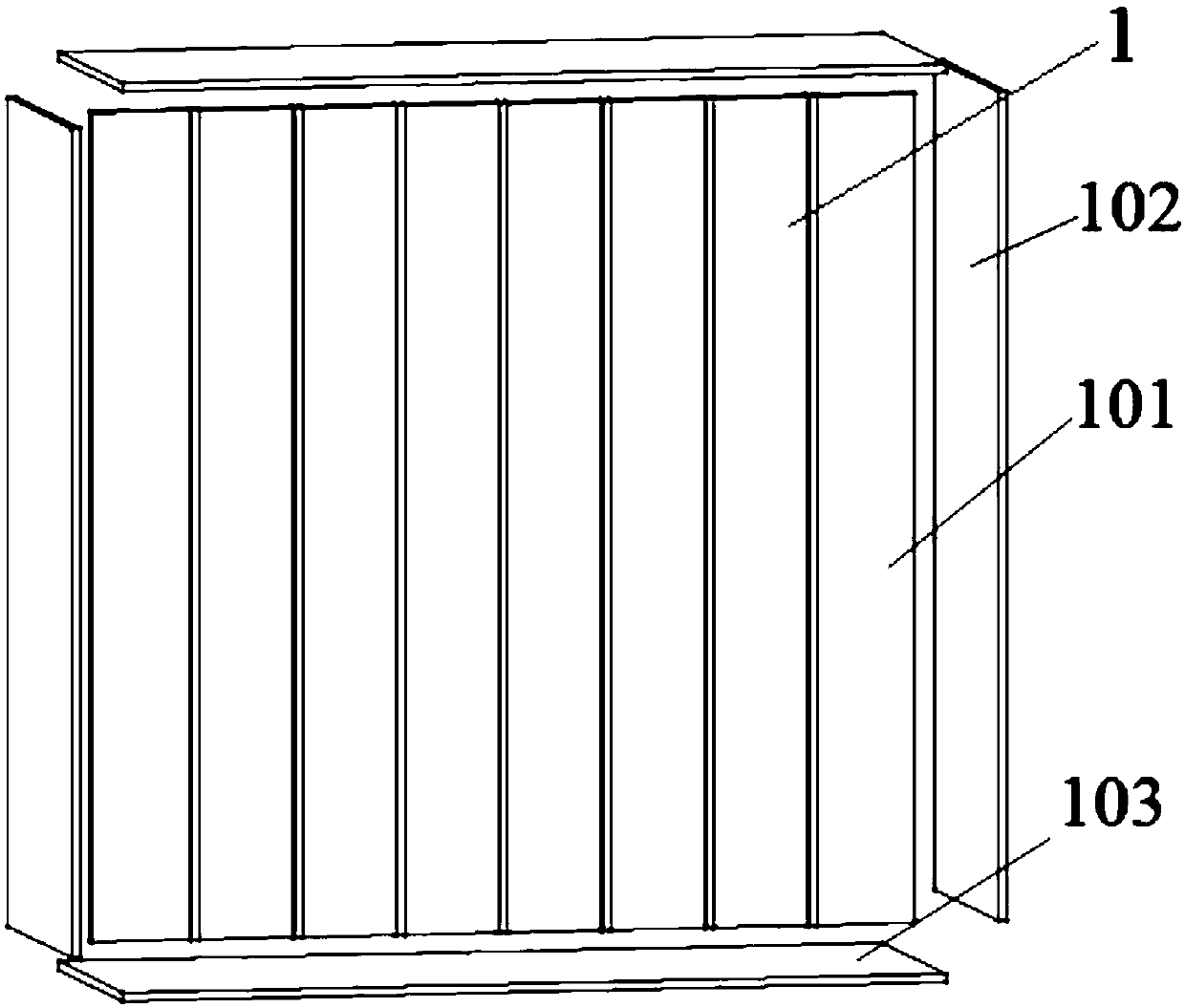

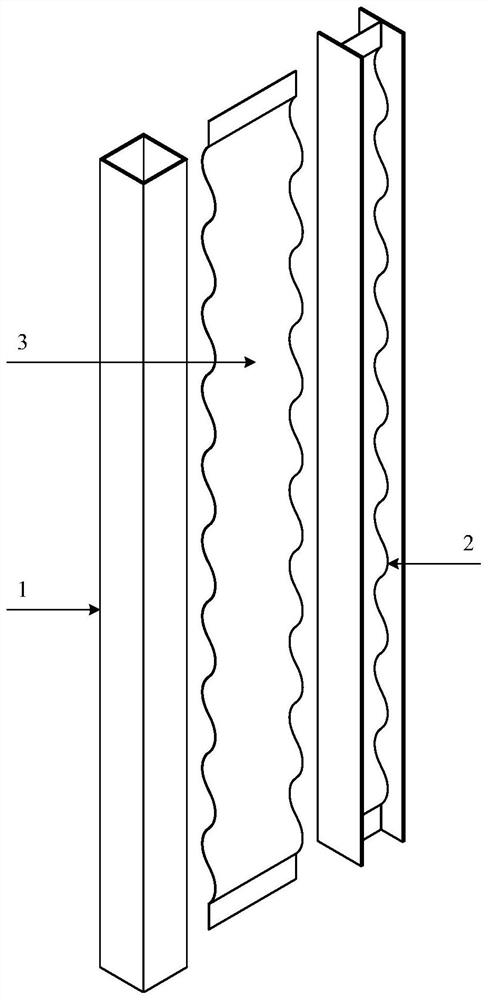

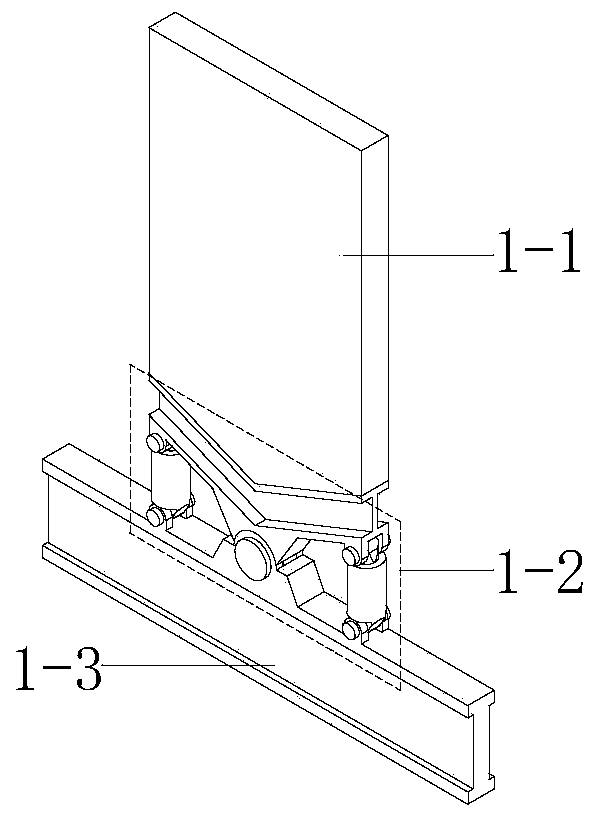

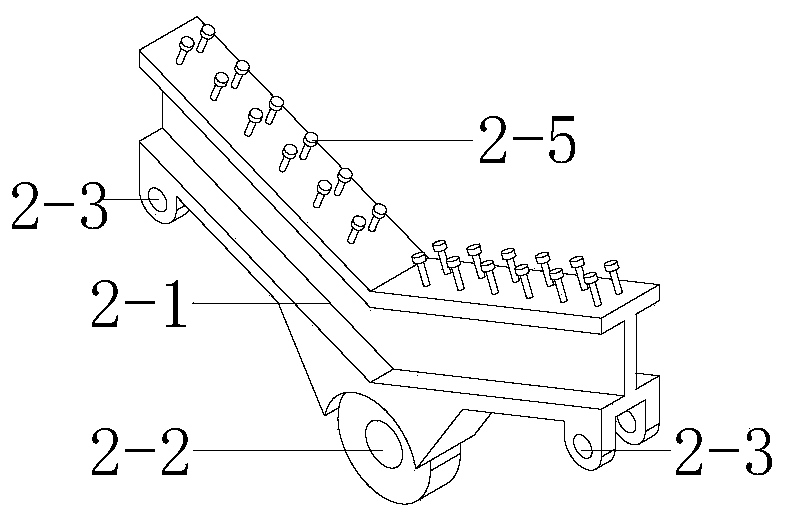

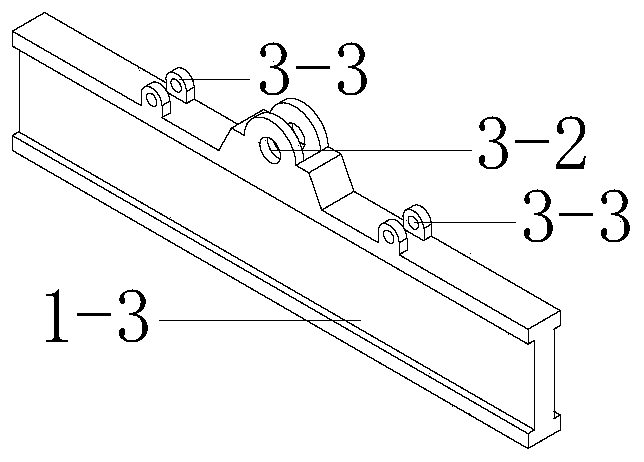

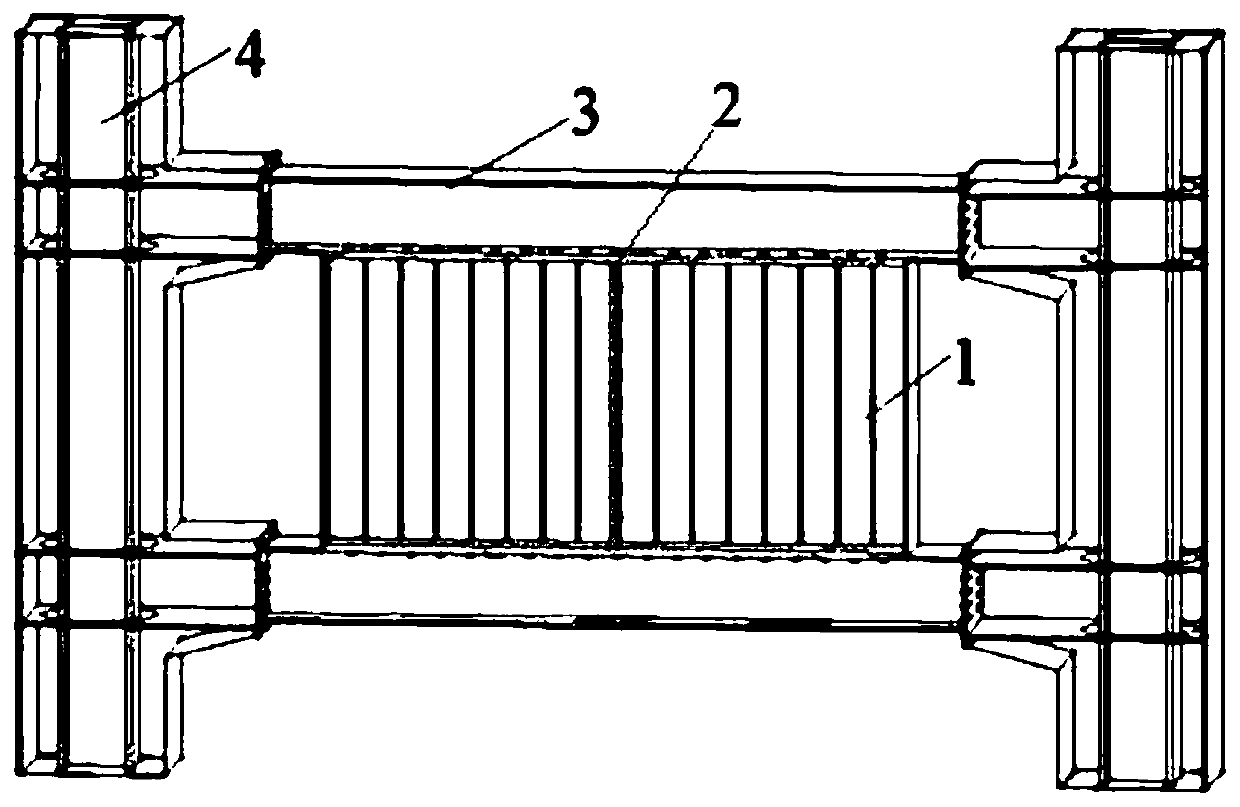

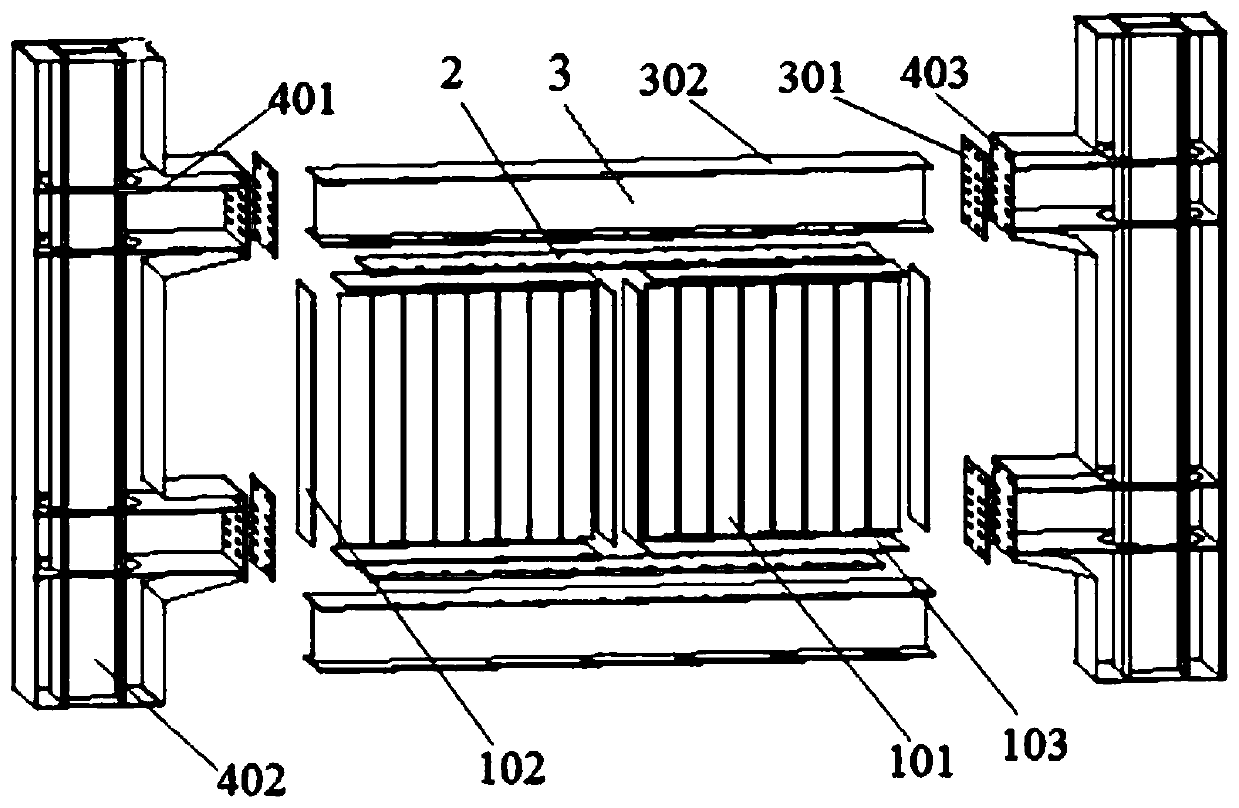

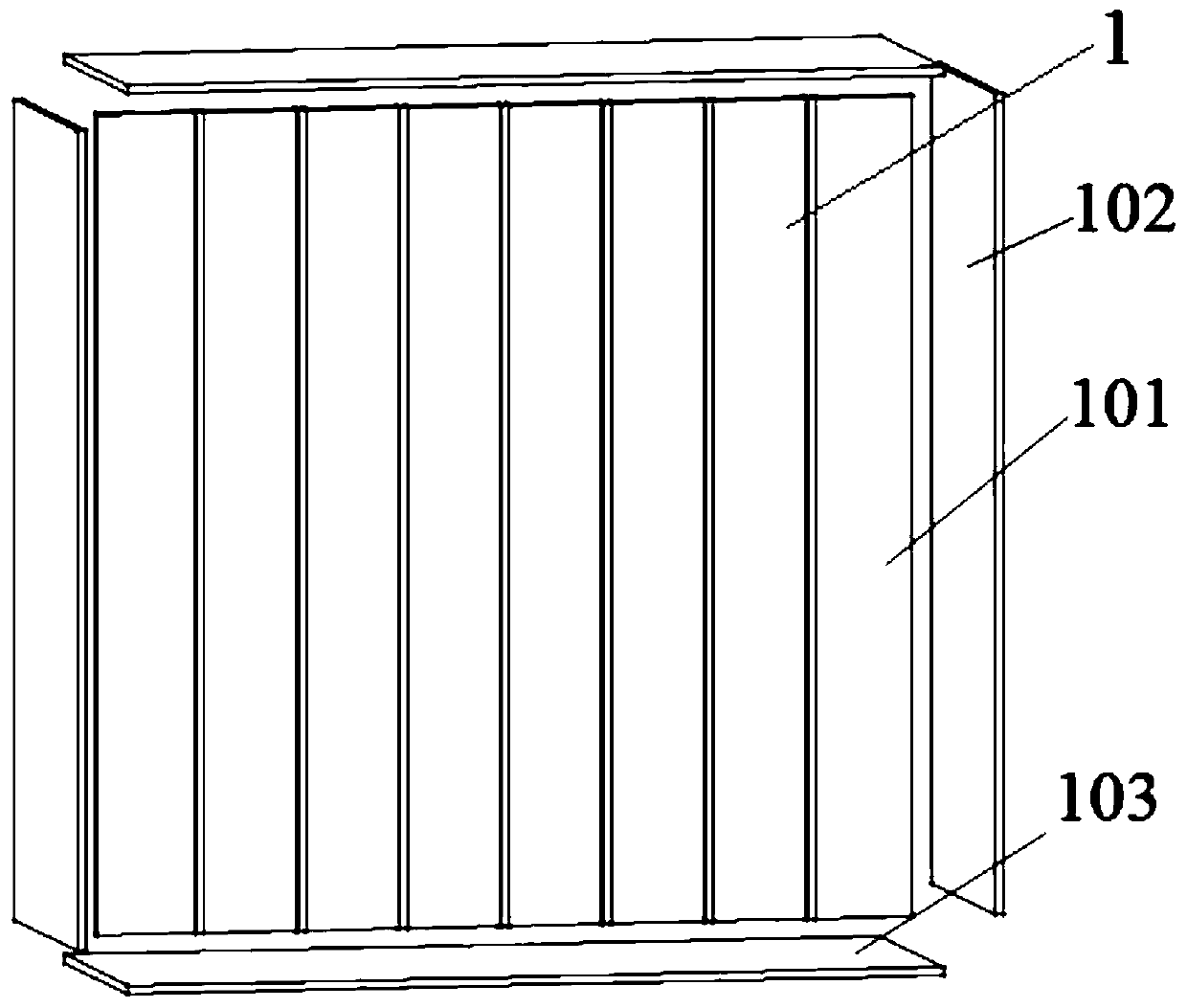

Assembly-type ribbed steel plate-shear wall

ActiveCN107780564AIncreased buckling loadEnhanced out-of-plane stabilityWallsMaterials scienceSteel plate shear wall

The invention discloses an assembly-type ribbed steel plate-shear wall. The problems of poor anti-seismic property and repairing difficulty are solved. The assembly-type ribbed steel plate-shear wallcomprises assembly-type ribbed steel plates, connection plates, frame steel beams and frame columns. The assembly-type ribbed steel plates are connected through bolts, and the assembly-type ribbed steel plates are connected with the frame steel beams through the connection plates and bolts; the frame columns are connected with the frame steel beams but not connected with the assembly-type ribbed steel plates. The prefabrication assembly degrees of all components of the assembly-type ribbed steel plate-shear wall are greatly improved, the anti-seismic property is improved, and meanwhile the assembly-type ribbed steel plate-shear wall is easy to mount, transport and repair and suitable for being widely applied to buildings with walls such as shock-proof walls.

Owner:XIAN UNIV OF TECH

Sequence control system (SCS) concrete filled steel tube bridge pier with shear nails added at bottom

InactiveCN102995554ASimple structureReasonable designBridge structural detailsSequence controlMechanical property

The invention discloses an SCS concrete filled steel tube bridge pier with shear nails added at bottom. The SCS concrete filled steel tube bridge pier comprises an outer steel tube, an inner steel tube, a top end shear resistant structure, a bottom end shear resistant structure and a concrete structure. The inner steel tube is sleeved inside the outer steel tube, the top end shear resistant structure is distributed between the top end of the outer steel tube and the top end of the inner steel tube, the bottom end shear resistant structure is distributed between the bottom end of the outer steel tube and the bottom end of the inner steel tube, the concrete structure is molded by pouring concrete filled in a cavity between the outer steel tube and the inner tube after the top end shear resistant structure and the bottom end shear resistant structure are distributed, the inner steel tube is a round steel tube, the outer steel tube and the inner steel tube are coaxially distributed, the outer steel tube is an outer steel tube one or two, the shape of the cross section of the outer steel tube one is a circle, and the shape of the cross section of the outer steel tube two is a rectangle or regular polygon. According to the SCS concrete filled steel tube bridge pier with stiffening ribs added at the bottom, the structure is simple, the design is reasonable, the construction is convenient, the construction cost is low, the mechanical property and the usage effect are good, and problems in concrete filled steel tube bridge piers are solved.

Owner:CHANGAN UNIV

L-shaped special-shaped column and beam fabricated connecting joint

InactiveCN112302169AReduce side shiftImprove lateral stiffnessStrutsPillarsAbnormal shapedLateral stiffness

The invention discloses an L-shaped special-shaped column and beam fabricated connecting joint, and belongs to the technical field of structural engineering. The L-shaped special-shaped column and beam fabricated connecting joint is composed of a special-shaped column, I-shaped beams, channel steel connecting pieces and high-strength bolt groups. Manufacturing and welding parts of steel componentsare completed in a factory, the welding quality is easy to control, only each prefabricated component needs to be hoisted, and is connected through a high-strength bolt on a construction site, and the construction efficiency is high; and the connecting joint has the advantages of mechanical property and practical property at the same time, and specifically, in the aspect of the mechanical property, the connecting joint makes full use of the bearing capacity and the lateral stiffness of the special-shaped column, and has the good anti-seismic property; and in the aspect of the practical property, the connecting joint emphatically achieves the rapid assembly concept, and solves the "protruding column" problem in a house.

Owner:BEIJING UNIV OF TECH

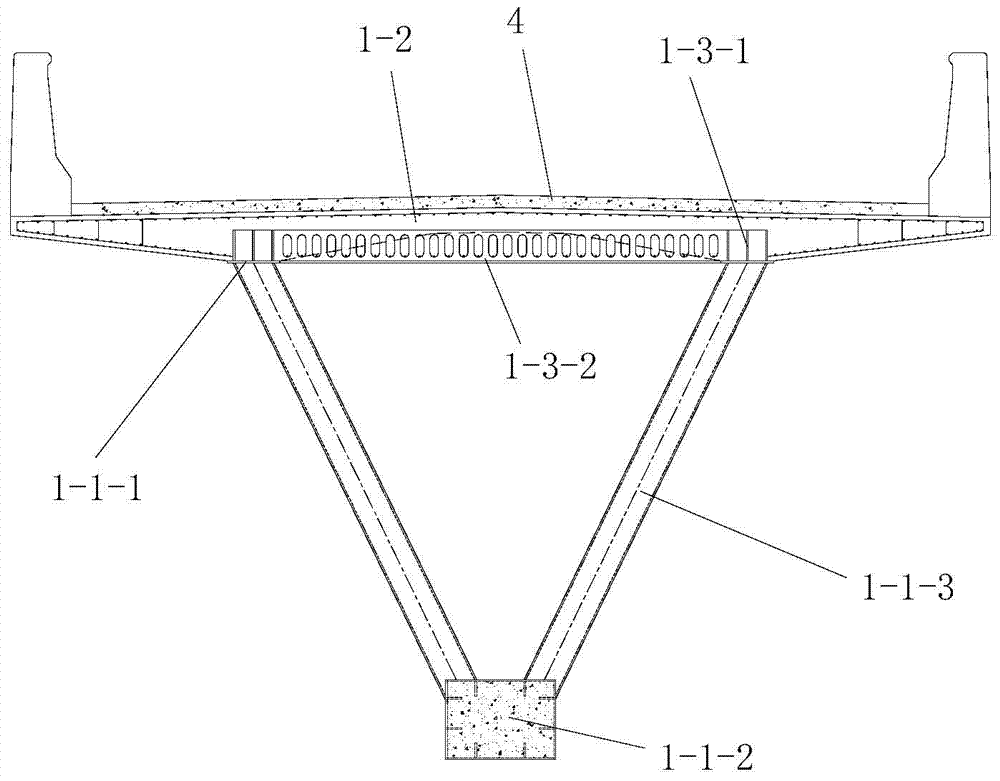

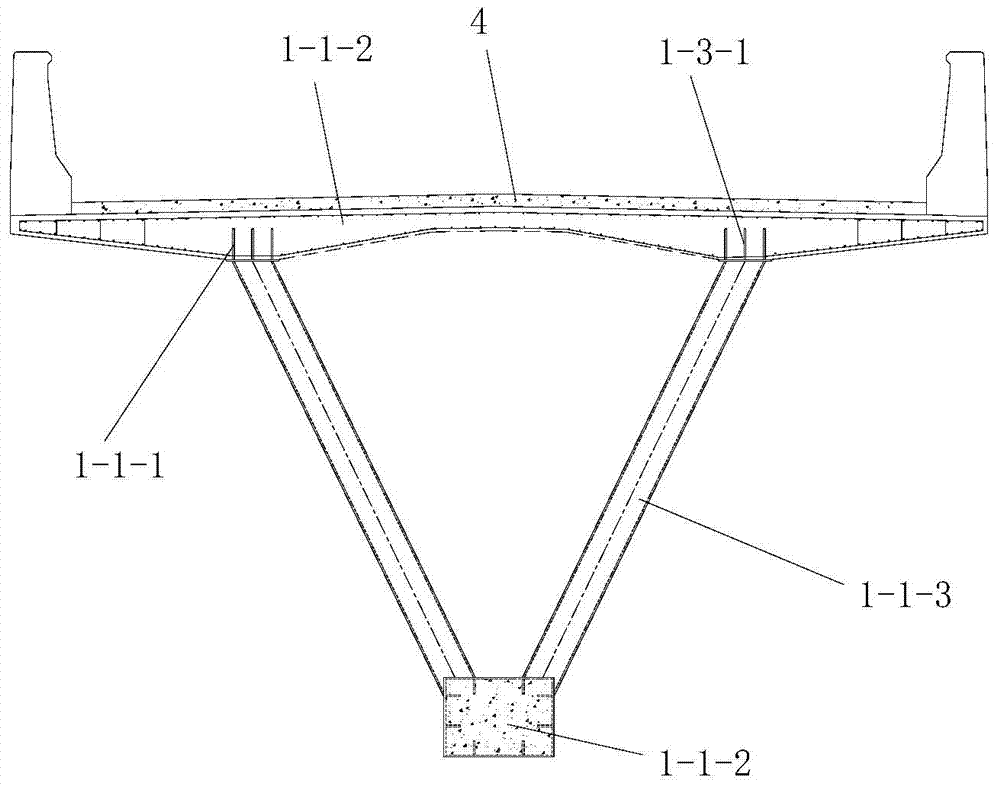

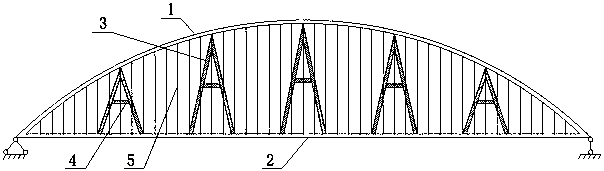

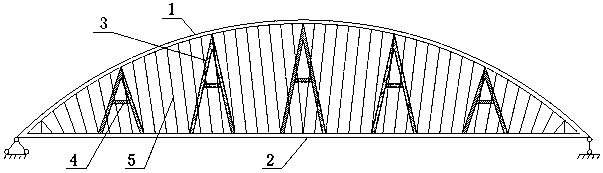

Beam-arch consolidated triangular arch bridge

PendingCN108930222AImprove line stiffnessIncrease stiffnessArch-type bridgeBridge materialsEngineeringStructural engineering

The invention discloses a beam-arch consolidated triangular arch bridge. The beam-arch consolidated triangular arch bridge mainly comprises an arch rib (1), a main beam (2), flexible lifting rods (5)and arch rib transverse braces (6); the flexible lifting rods (5) are placed between the arch rib (1) and the main beam (2), wherein a rigid diagonal rod assembly is also arranged between the arch rib(1) and the main beam (2); the rigid diagonal rod assembly mainly consists of two rigid diagonal rods (3) in an inverted V shape; that is to say that the two rigid diagonal rods (3) and the main beam(2) form a triangular structure; and a diagonal rod cross-link (4) is also arranged between the two rigid diagonal rods. According to the beam-arch consolidated triangular arch bridge, the arch rib and the main beam are restricted by using a triangle; and meanwhile, the linear stiffness of the main beam is enhanced; and therefore, the integral rigidity of the structure is greatly enhanced; and the problem that a see-saw effect of the arch bridge is obvious under the action of half-span load can be greatly solved.

Owner:GUANGXI UNIV

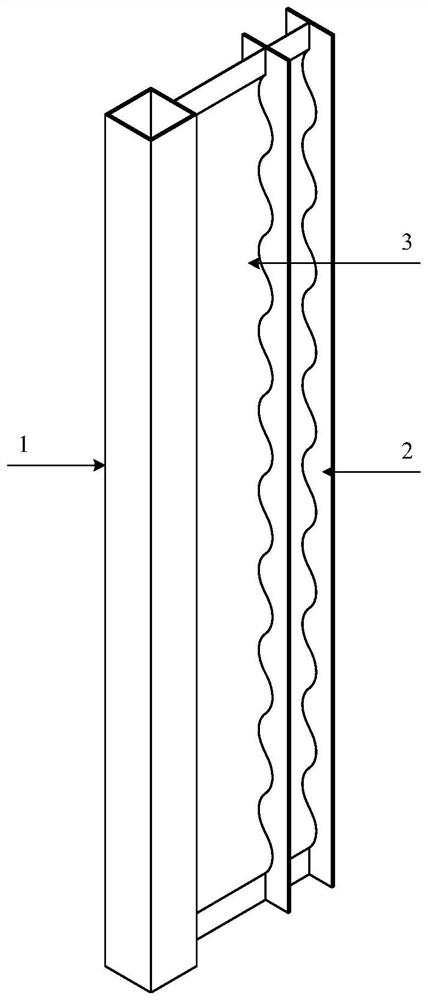

Steel pipe-profile steel special-shaped column with double corrugated plates and side-resistant double-column bearing function

The invention discloses a steel pipe-profile steel special-shaped column with double corrugated plates and a side-resistant double-column bearing function, and belongs to the technical field of structural engineering. The column comprises a square steel pipe column, a profile steel column, and corrugated plates. The welding part of the special-shaped column is completed in a factory, so that the welding quality is easy to control; and only the prefabricated special-shaped column needs to be hoisted and connected with other elements on a construction site. The corrugated plates can provide enough out-of-plane rigidity with low thickness in the manufacturing, transportation and construction processes of the special-shaped column, so that the steel consumption of components is effectively reduced, and the economy is improved. According to the steel pipe-profile steel special-shaped column with the double corrugated plates and the side-resistant double-column bearing function, the special-shaped column has the advantages of mechanical property and practical property at the same time: in the aspect of the mechanical property, the height of the anti-side section of the special-shaped column is increased by adopting a double-corrugated-plate structure, so that the anti-side capacity of the special-shaped column is improved; and in the aspect of the practical property, the problem of protruding columns in a house can be effectively solved.

Owner:BEIJING UNIV OF TECH

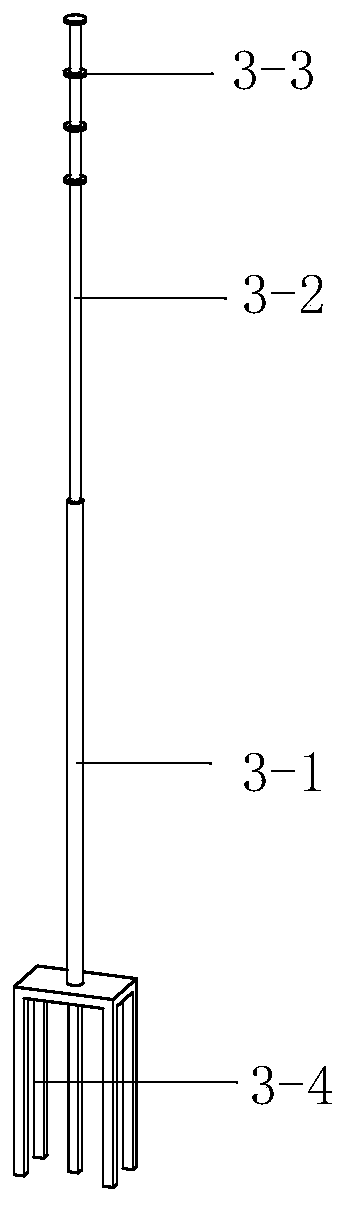

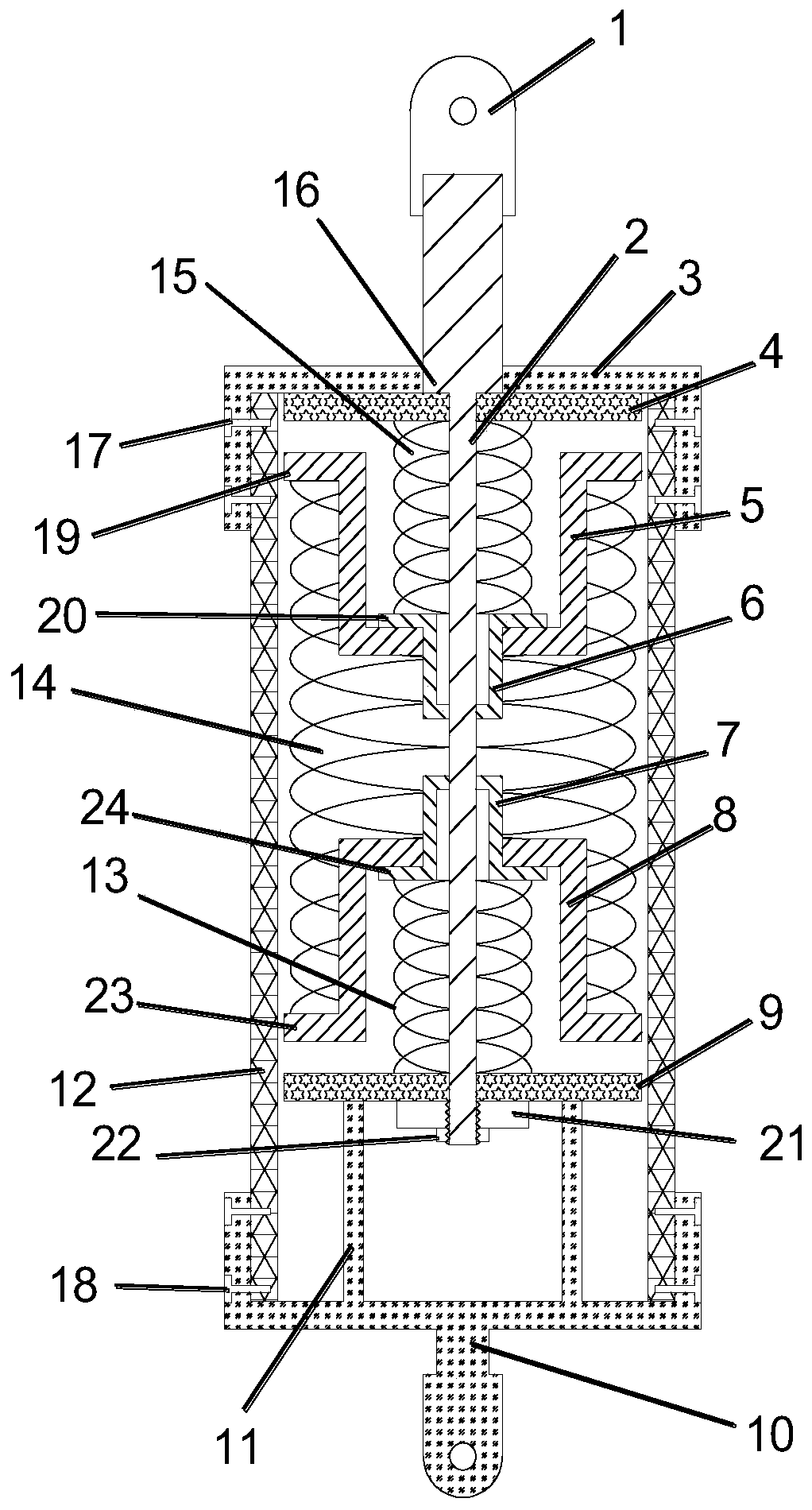

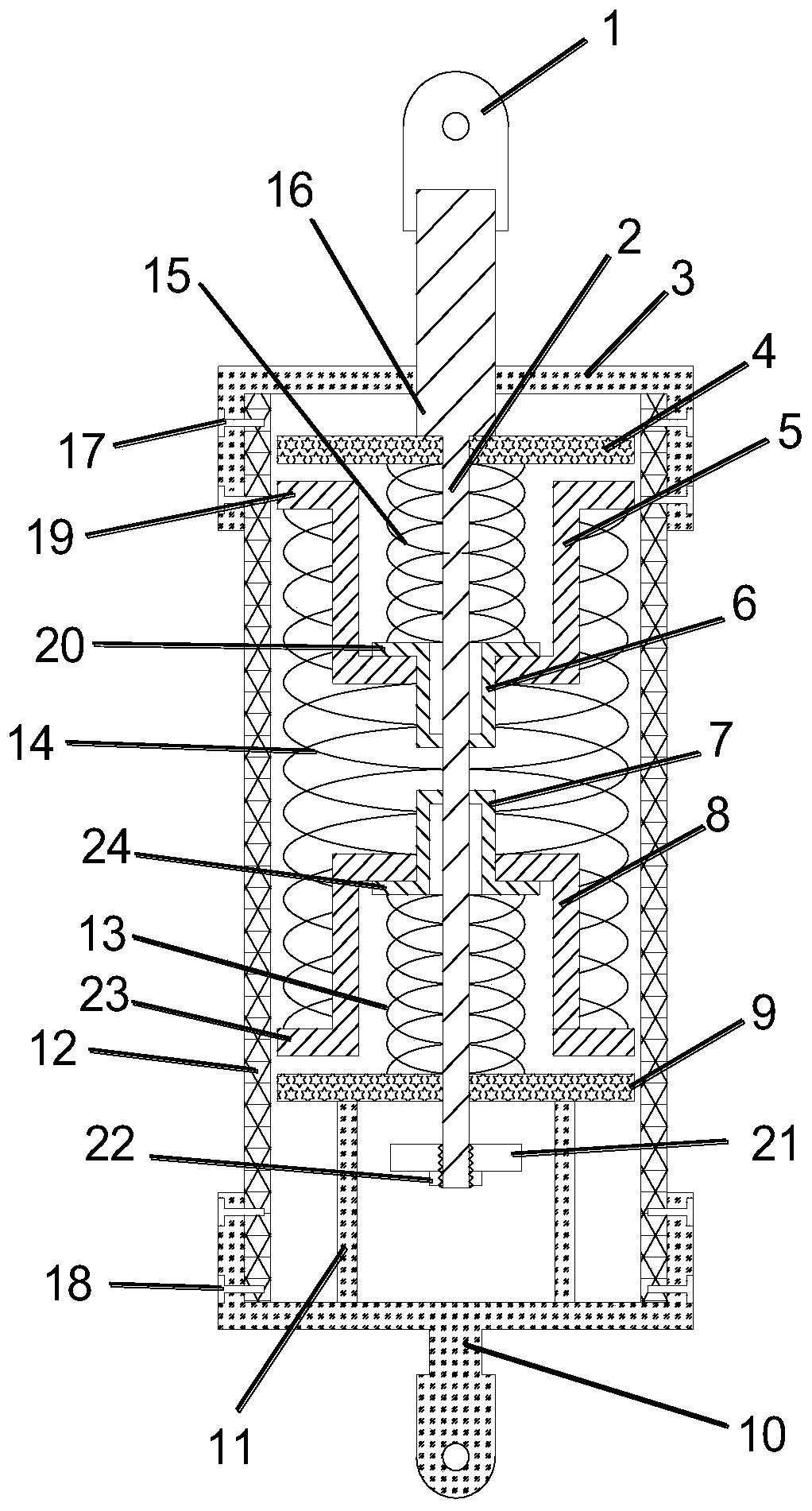

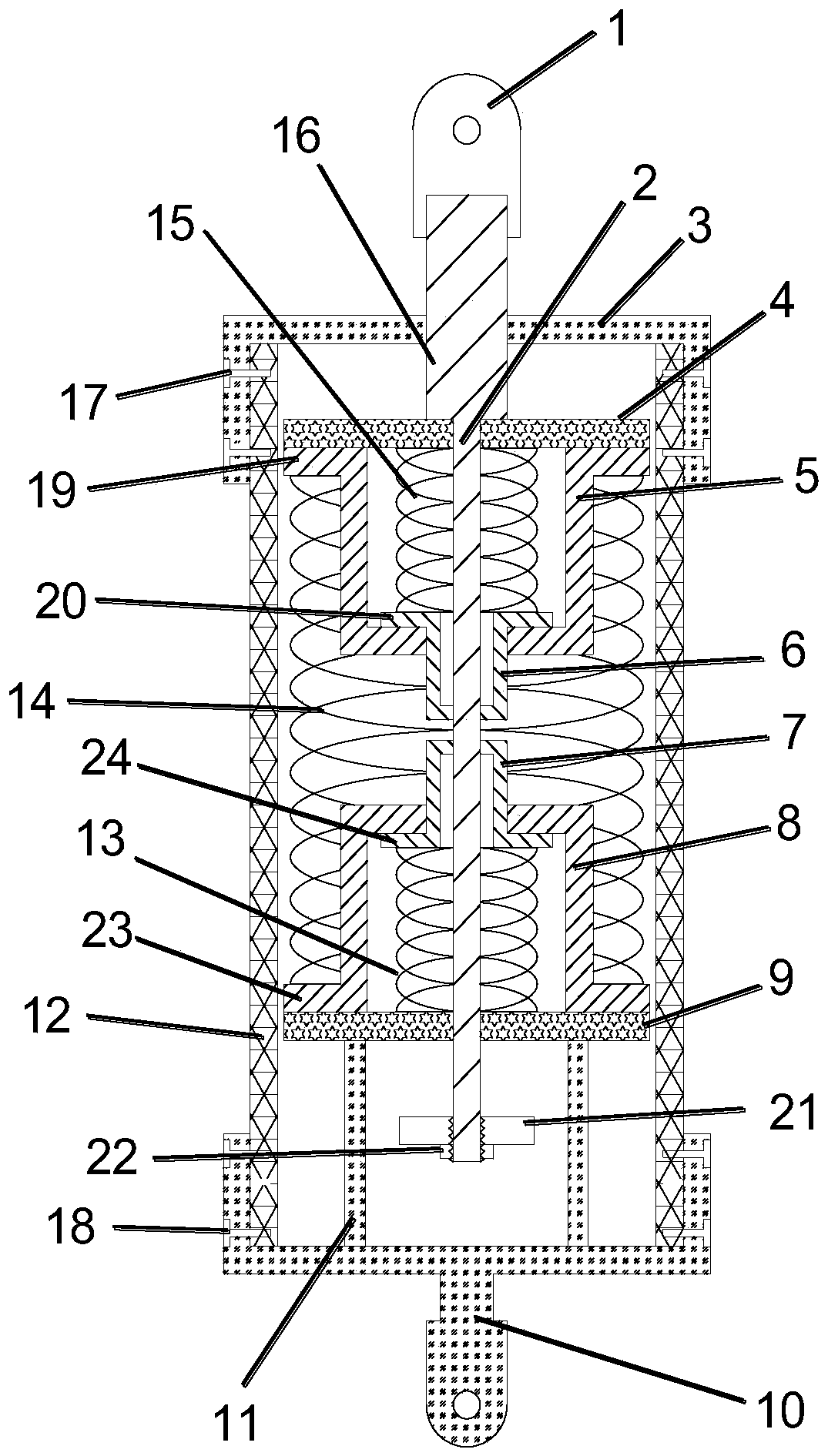

Self-resetting device with capacity of multi-stage rigidity self-adjustment

PendingCN111379344AStable and reliable self-resetting forceMechanical properties are automatically adjustedProtective buildings/sheltersShock proofingStructural engineeringMechanical engineering

The invention relates to a self-resetting device with capacity of multi-stage rigidity self-adjustment. A guide rod penetrates through an upper movable plate, an upper outer concave barrel, an upper inner concave barrel, a lower inner convex barrel, a lower outer convex barrel and a lower movable plate in an outer cylinder from top to bottom; the guide rod is provided with surfaces which are propped against the upper surface of the upper movable plate and the lower surface of the lower movable plate respectively; the lower end of the outer cylinder is fixed with a lower connecting part, the lower connecting part is provided with a reinforcing rib barrel extending upwards, and the upper end of the reinforcing rib barrel limits downward movement of the lower movable plate; an upper inner spring is arranged outside the guide rod in a sleeving manner and is mounted between an outer extended flange I and the upper movable plate; a lower inner spring is arranged outside the guide rod in a sleeving manner and mounted between the lower movable plate and an outer extended flange IV; and an outer spring is arranged outside the guide rod in a sleeving manner and mounted between the upper outer concave barrel and the lower outer convex barrel. The self-resetting device can automatically adjust own properties according to the current external excitation action on the structure and the characteristics of structural dynamic response, and the engineering problem of single applicable scene of the existing self-resetting device is solved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

Suspended-dome multi-time prestressed construction method

InactiveCN101158195BPower transmission is simpleReduce pressure peaksBuilding roofsPre stressInstability

The invention discloses a suspend dome structure multi-prestressed construction method used in construction field. The construction method is that: firstly, a central pressure ring, an upper radial bar and edge elements are arranged on an upper layer; secondly, a lower radial rope, a lower ring rope and a strut are arranged on a lower layer; thirdly, prestress is applied in the structure by stretching the lower ring rope or stretching the lower radial rope or adjusting the length of the strut; fourthly, a ring bar is arranged; fifthly, an external load is applied on the structure. Compared with the structure formed by a traditional method, the suspend dome structure formed by the invention reduces peak pressure of elements with concise force, even changes a part of elements from a pressure bar to a tension bar, avoids instability of elements, at the same time enhances the entire stability of the whole structure and enlarges the ultimate bearing capacity. Furthermore, the invention leads a more even distribution of internal force of the upper layer network shell bar elements, is helpful to the unity of the elements and convenient for design and construction, at the same time, the invention reduces the applied prestress value and reduces construction difficulty.

Owner:BEIJING UNIV OF TECH

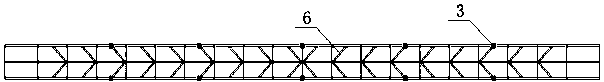

Simply supported and continuous corrugated web steel box-concrete composite beam

PendingCN113279316AEasy to processEnhanced out-of-plane stabilityBridge structural detailsBridge erection/assemblyArchitectural engineeringContinuous beam

The invention relates to the field of bridges, and in particular relates to a simply supported and continuous corrugated web steel box-concrete composite beam. The simply supported and continuous corrugated web steel box-concrete composite beam comprises a plurality of prefabricated corrugated web steel box-concrete composite beams, the prefabricated corrugated web steel box-concrete composite beams are connected through steel box type cross beams and K-shaped steel cross beams in the transverse bridge direction, composite beam reinforced concrete top plates are connected through cast-in-place reinforced concrete plates, cast-in-place reinforced concrete side wing plates are poured on the outer sides of the composite beam reinforced concrete top plates, the continuous ends of the multiple prefabricated corrugated web steel box-concrete composite beams in the longitudinal bridge direction are connected through cast-in-place concrete connecting sections, the cast-in-place concrete connecting sections are connected with open corrugated web steel boxes through studs, supports are arranged below the cast-in-place concrete connecting sections, and the simply supported and continuous corrugated web steel box-concrete composite beam is formed. The advantages of corrugated steel webs and the excellent stress characteristic of continuous beams are fully utilized, the self weight is light, machining and manufacturing are easy, the construction quality is guaranteed, the bridge construction speed is high, and very wide practicability is achieved.

Owner:甘肃省交通规划勘察设计院股份有限公司

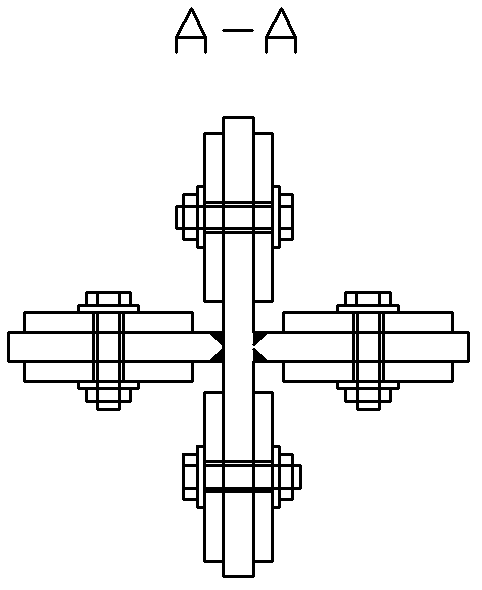

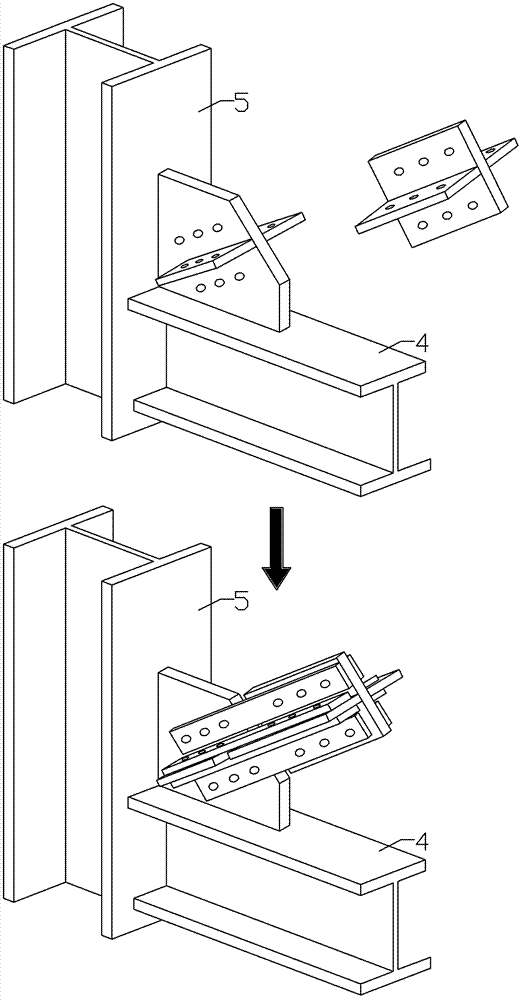

End part local elongation type anti-buckling support-beam-column connecting node

InactiveCN102296704BWith detachableNode link length is shortBuilding constructionsArchitectural engineeringSteel columns

The invention discloses an end part local elongation type anti-buckling support-beam-column connecting node and relates to an anti-buckling support-beam-column connecting node which is used for solving the problems in the aspects of anti-seismic performance of support and building structures, stability outside the plane of the node, seismic rehabilitation, construction, installation and the like caused by support-node plate bolted connection and node plate-beam column welded connection. An intermediate node plate of a framework node plate is plugged in an open slot on the end part local elongation type node, an intermediate core plate and a local elongation stiffening rib or a local elongation core plate are welded together with the intermediate node plate, the framework node plate is placed on the upper surface of the top flange of an I-shaped steel beam, vertical end plates of the framework node plate lean against each other and prop against the side flange of an H-shaped steel column, and the framework node plate is fixedly connected with the H-shaped steel column and the I-shaped steel beam respectively through a plurality of first and second high-strength bolts. The end part local elongation type anti-buckling support-beam-column connecting node is used for civil construction structures, especially in multi-storey and high-rise anti-seismic, energy-consuming and shock-absorption building structures.

Owner:HARBIN INST OF TECH

SCS square concrete-filled steel tube pier column

InactiveCN103031927BSimple structureReasonable designStrutsBridge structural detailsMechanical propertySteel tube

The invention discloses an SCS (square concrete-filled steel) tube pier column which comprises a square steel tube, a circular steel tube, four stiffening rib plate groups and a concrete structure, wherein the circular steel tube is mounted in the square steel tube in a sleeving manner; the four stiffening rib plate groups are arranged on four inner side walls of the square steel tube respectively; the concrete structure is formed by pouring concrete filled in a cavity between the square steel tube and the circular steel tube; each stiffening rib plate group comprises a plurality of longitudinal stiffening ribs that are arranged in parallel; the longitudinal stiffening ribs are perpendicular to the inner side walls of the square steel tube where the longitudinal stiffening ribs are located respectively; all the longitudinal stiffening ribs in the four stiffening rib plate groups have identical structures and sizes; the square steel tube and the circular steel tube are arranged coaxially; and the transverse width of each longitudinal stiffening rib is less than a distance between the square steel tube and the circular steel tube where the longitudinal stiffening rib is arranged. The pier column is simple in structure, reasonable in design, convenient to construct, lower in construction cost, good in mechanical property and good in use effect, and can effectively solve the problems existing in the existing square concrete-filled steel tube structure.

Owner:CHANGAN UNIV

A low-damage self-resetting shear wall hinged at the bottom

ActiveCN110005091BNo plastic damageSection internal force does not surgeWallsProtective buildings/sheltersReinforced concreteRebar

The invention relates to a bottom-hinged-supporting low-damage self-reset shear wall. The bottom-hinged-supporting low-damage self-resetting shear wall comprises a reinforced concrete wall plate, a self-reset wall bottom and a foundation beam; the reinforced concrete wall plate is connected with the upper end of the self-reset wall bottom, the foundation beam is connected with the lower end of theself-reset wall bottom, a connecting plate is arranged in the middle of the upper surface of the foundation beam and provided with a connecting beam hinged joint, and self-reset short support hingedjoints II are arranged on the two sides of the connecting beam hinged joint correspondingly; the self-reset wall bottom comprises a connecting beam and a self-reset short support; an anti-shear key isarranged on the upper surface of the connecting beam, a foundation beam hinged joint is arranged in the middle of the lower surface of the connecting beam, and self-reset short support hinged jointsI are arranged on the positions, corresponding to the two self-reset short support hinged joints II, of the two ends of the lower surface of the connecting beam; and the self-reset short support comprises an inner pipe, an outer pipe, a disc spring and baffles, the disc spring is arranged in the outer pipe, the baffles are arranged at the two ends of the disc spring, the inner pipe penetrates through an inner hole of the disc spring and the baffles at the two ends and are capped at the two ends of the inner pipe through a stop block, and self-reset short support hinged joints III are arrangedat the two ends of the self-reset short support.

Owner:BEIJING JIAOTONG UNIV

A prefabricated ribbed steel plate-shear wall

ActiveCN107780564BIncreased buckling loadEnhanced out-of-plane stabilityWallsSteel plate shear wallPrefabrication

The invention discloses an assembly-type ribbed steel plate-shear wall. The problems of poor anti-seismic property and repairing difficulty are solved. The assembly-type ribbed steel plate-shear wallcomprises assembly-type ribbed steel plates, connection plates, frame steel beams and frame columns. The assembly-type ribbed steel plates are connected through bolts, and the assembly-type ribbed steel plates are connected with the frame steel beams through the connection plates and bolts; the frame columns are connected with the frame steel beams but not connected with the assembly-type ribbed steel plates. The prefabrication assembly degrees of all components of the assembly-type ribbed steel plate-shear wall are greatly improved, the anti-seismic property is improved, and meanwhile the assembly-type ribbed steel plate-shear wall is easy to mount, transport and repair and suitable for being widely applied to buildings with walls such as shock-proof walls.

Owner:XIAN UNIV OF TECH

Integral Pouring Technology of Reinforced Concrete Wastewater Pool in Pre-drilling Project

ActiveCN103015719BShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

SCS concrete filled steel tube pier reinforced by stirrup and stiffening rib at end

InactiveCN103015311BSimple structureReasonable designBridge structural detailsBridge materialsSteel tubeMaterials science

The invention discloses an SCS concrete filled steel tube pier reinforced by a stirrup and a stiffening rib at an end, which comprises an outer steel tube, an inner steel tube sleeved in the outer sleeve tube, a top reinforcing structure, a bottom reinforcing structure and a concrete structured poured and formed by concrete in a cavity between the outer and inner steel tubes. The inner steel tube is circular. The inner and outer steel tubes are coaxially arranged. The top reinforcing structure comprises a plurality of PBL stiffening ribs I and a stirrup I arranged from top to bottom. The bottom reinforcing structure comprises a plurality of PBL stiffening ribs II and a stirrup II arranged from top to bottom. The transverse width of each PBL stiffening rib I and each PBL stiffening rib II is smaller than the distance between the outer and inner steel tubes arranged at the position. The SCS concrete filled steel tube pier reinforced by the stirrup and the stiffening rib at the end is simple in structure, reasonable in design, convenient to construct, lower in construction cost, excellent in mechanical performance and good in using effect, and various problems of current concrete filled steel tube piers can be effectively solved.

Owner:CHANGAN UNIV

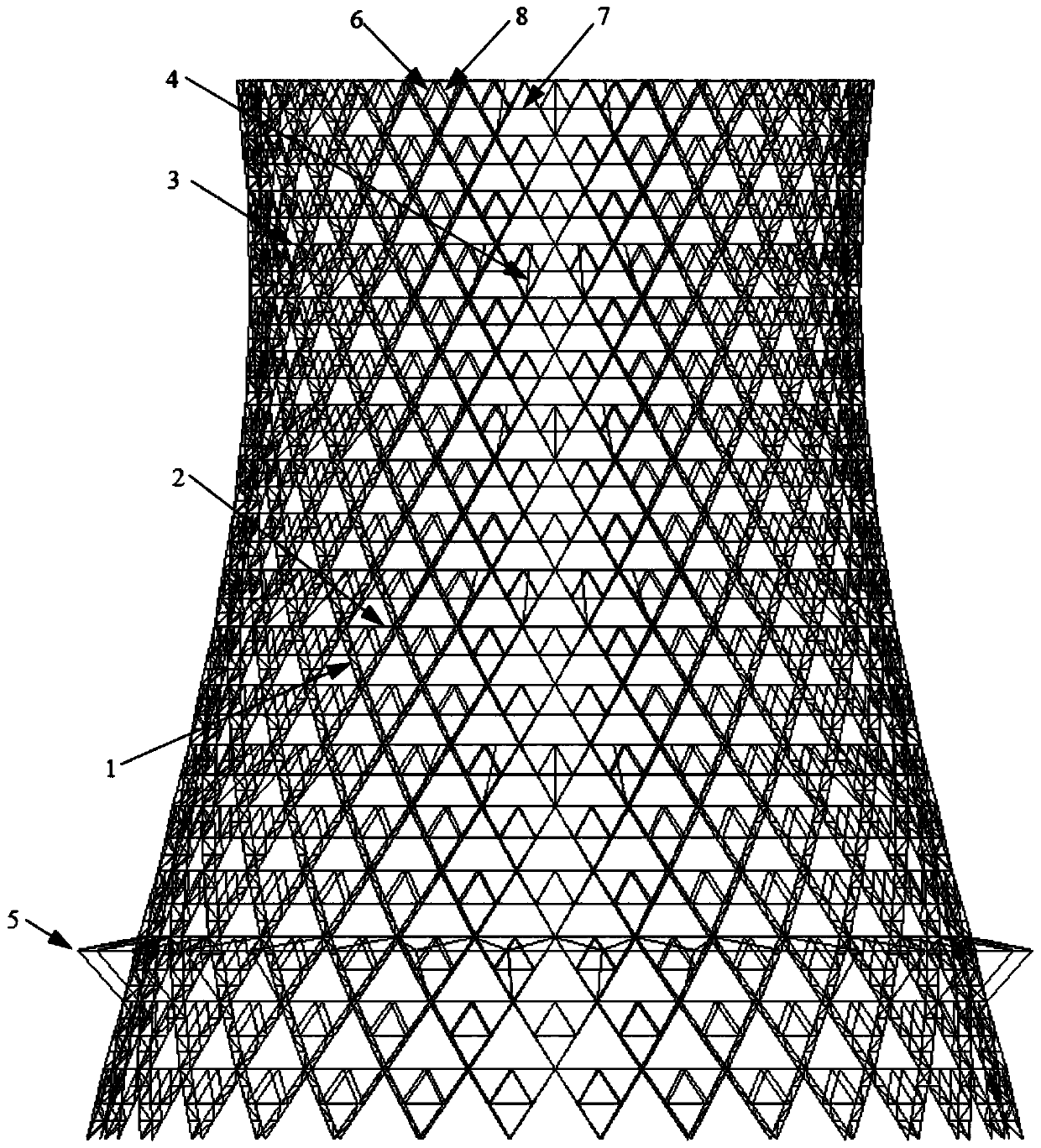

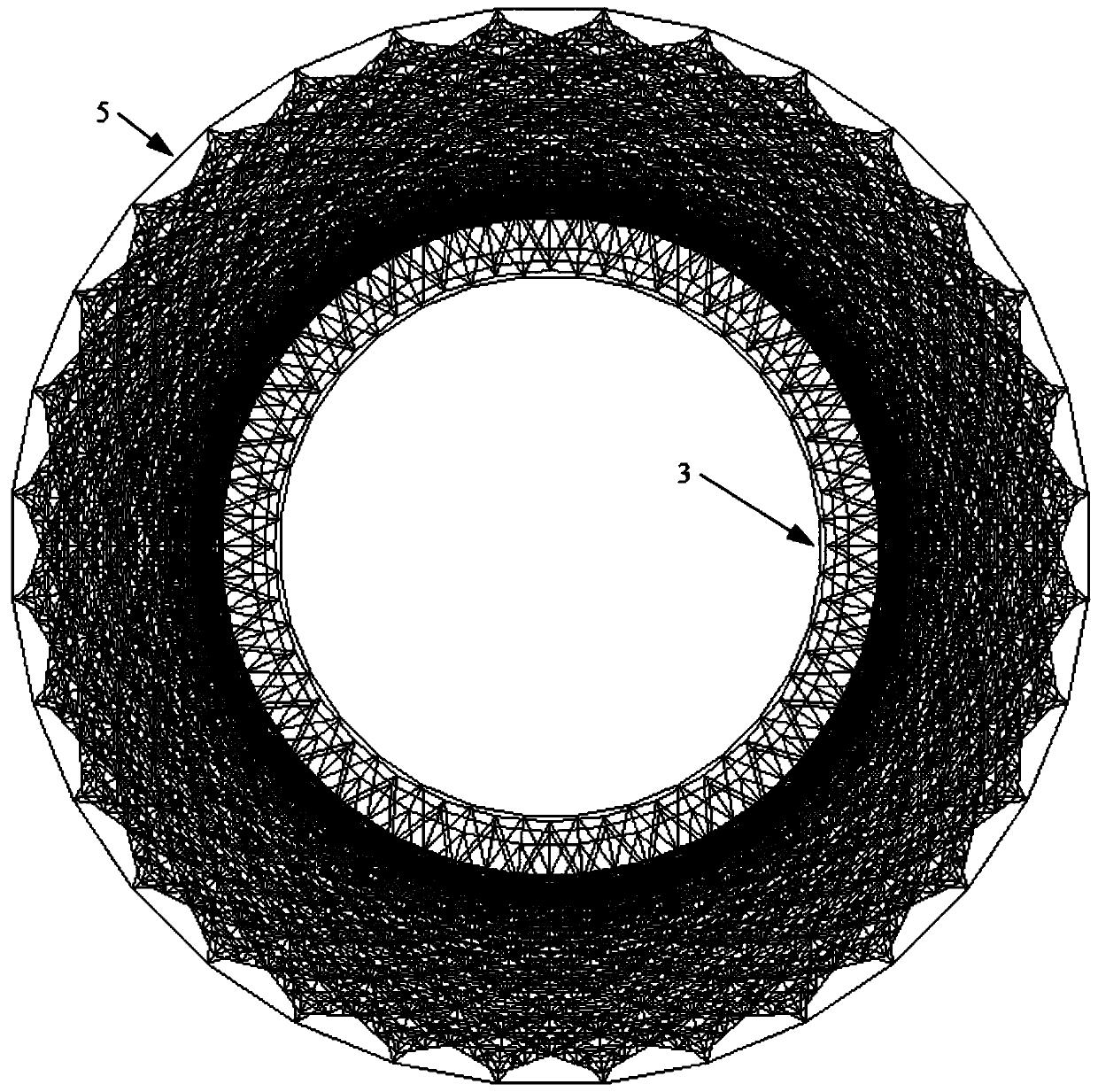

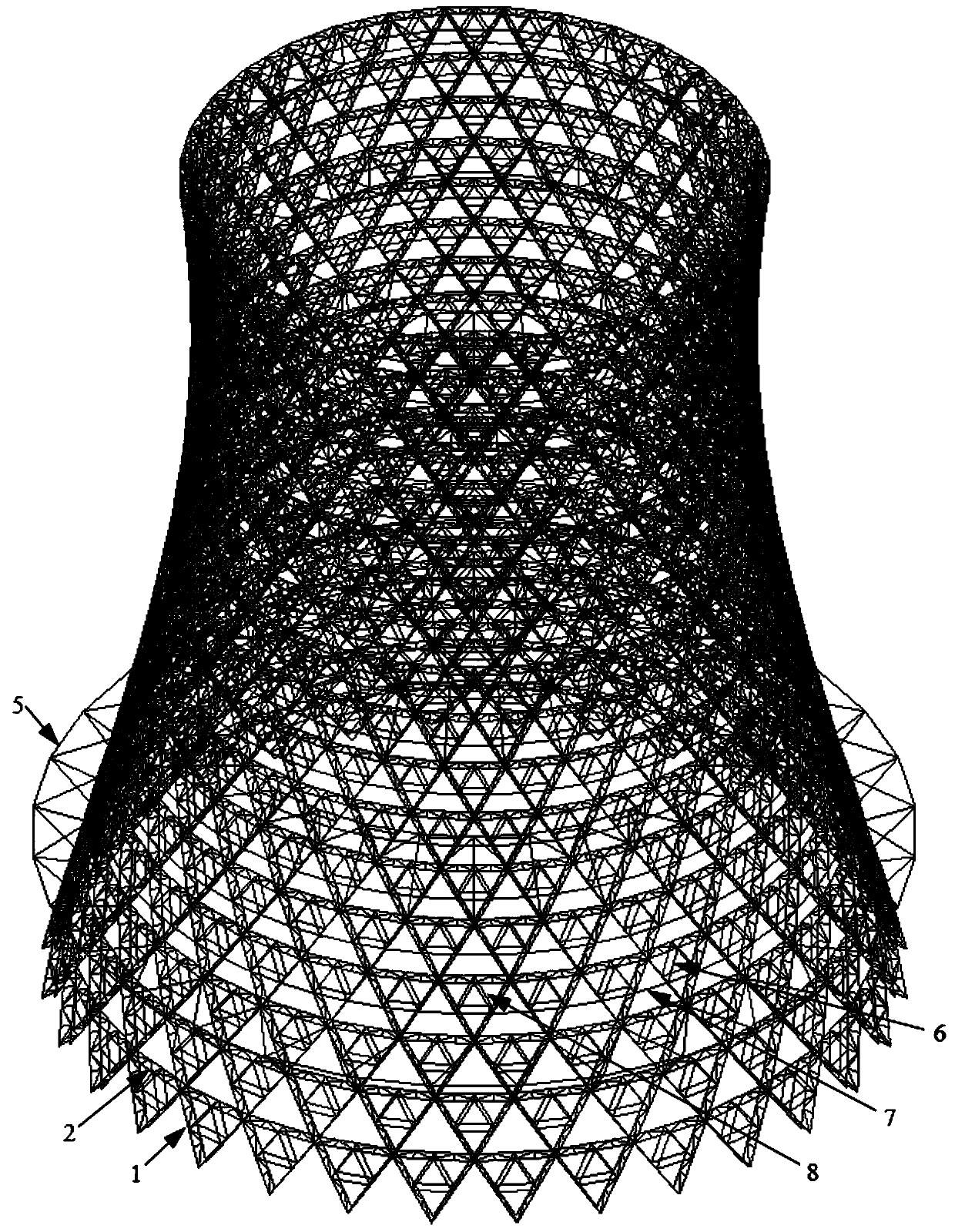

Steel structure cooling tower with a cross plane truss system

PendingCN110130686AImprove mechanical performanceLight weightBuilding constructionsCooling plantsCooling towerReinforced concrete

The invention discloses a steel structure cooling tower with a cross plane truss system. A tower body of the cooling tower is formed by connecting plane trusses in a combined mode, and the plane trusses include inclined trusses in two directions and horizontal trusses; the horizontal trusses and the inclined trusses in the two directions form a series of isosceles triangular grids, and out-of- plane supports of the plane trusses are arranged in the isosceles triangular grids; reinforcing ring trusses are arranged on the inner side of the tower body at certain height intervals; and widening platform trusses are arranged on the outer side of the lower part of the tower body. Compared with a traditional cooling tower with a steel bar and reinforced concrete structure, the cooling tower with the cross plane truss system and the steel structure has advantages that the force performance is good, the self-weight is low, construction is convenient, the construction period is short, and the construction cost is low; in addition, the cooling tower with the cross plane truss system and the steel structure makes full use of the in-of-plane rigidity of the plane trusses, thus the tower body ofthe cooling tower has good out-of-plane stability; by arranging supports in the out-of-plane direction of the plane trusses, the stability in out-of-plane of trusses can be improved, and the computinglength of out-of-planes of truss chord members is decreased; and through reasonable structure arrangement, the mechanical property of structure parts is fully exerted.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com