Simply supported and continuous corrugated web steel box-concrete composite beam

A technology of simply supported first and then continuous, corrugated webs, applied in bridges, bridge materials, bridge construction, etc., can solve the high level of overall environmental pollution of concrete bridges, the inability to achieve continuous construction of steel-concrete composite beams, and increase bridge weight and cost and other issues, to achieve the effect of easy quality assurance, easy installation quality, and saving structural steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

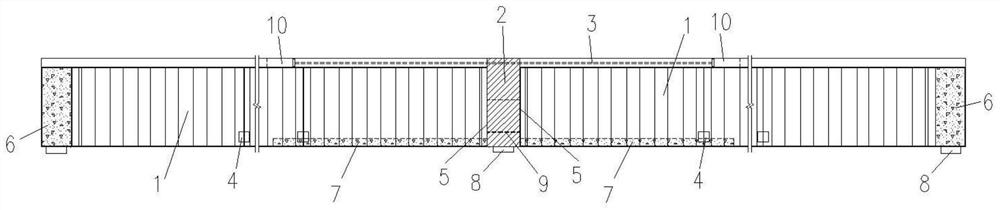

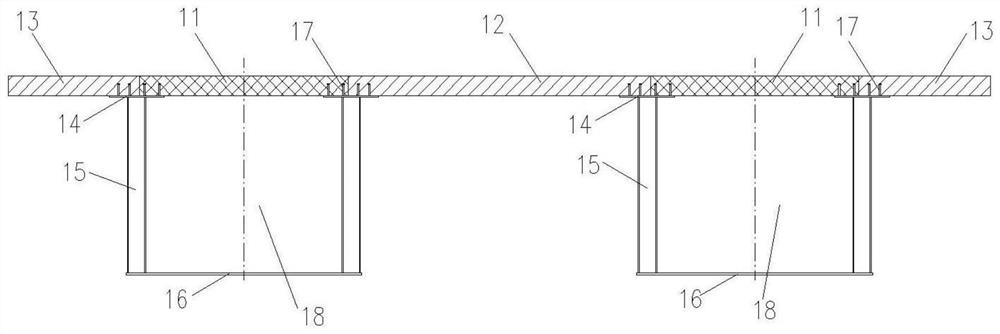

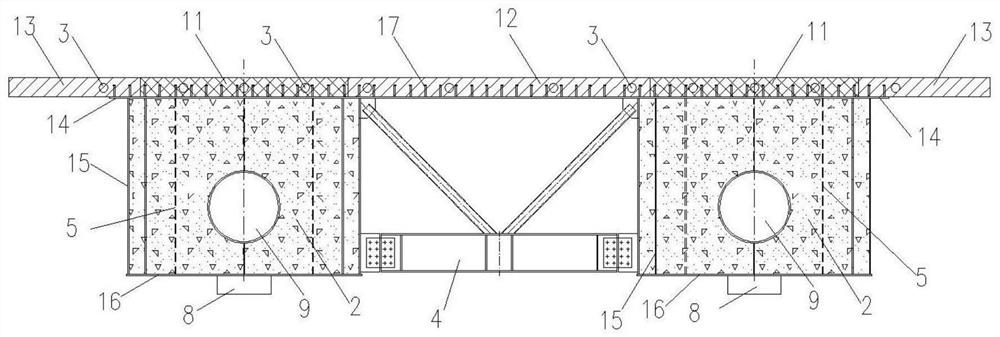

[0026] Such as Figure 1-5 As shown, the present invention provides a simple-supported and then continuous corrugated web steel box-concrete composite beam, including: processing and manufacturing single-piece prefabricated corrugated web steel box-concrete composite beam 1, multi-piece prefabricated corrugated web steel box- Concrete composite beam 1 is first erected on the bridge pier, in the direction of the bridge, the simply supported end is connected by steel box beam 6, and the rest is connected by K-shaped steel beam 4, the reinforced concrete of prefabricated corrugated web steel box-concrete composite beam 1 The roof 11 is connected by a cast-in-place reinforced concrete slab 12, and a cast-in-place reinforced concrete wing plate 13 is cast on the outside; in the longitudinal bridge direction, the continuous end is connected by a cast-in-place concrete connection section 2, and the cast-in-place concrete connection section 2 is connected to a prefabricated corrugated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com