Continuous rigid frame bridge based on steel truss-concrete slab composite beam

A technology of concrete slabs and steel trusses, applied in truss bridges, bridges, bridge parts, etc., can solve the problems of low bearing capacity, single structural form, and difficult construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

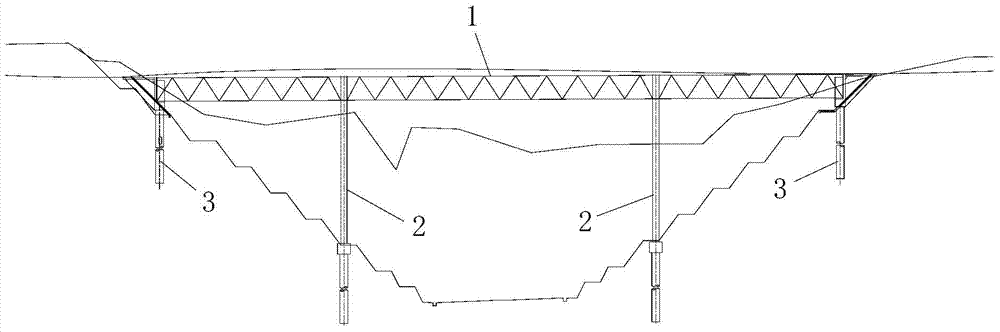

[0088] Such as figure 1 The shown continuous rigid frame bridge based on steel truss-concrete slab composite beams comprises a bridge substructure and a steel truss-concrete slab composite beam 1 supported on the bridge substructure, and the bridge substructure includes The bridge pier 2 and abutment 3 supported by the steel truss-concrete slab composite girder 1, both of which are concrete structures.

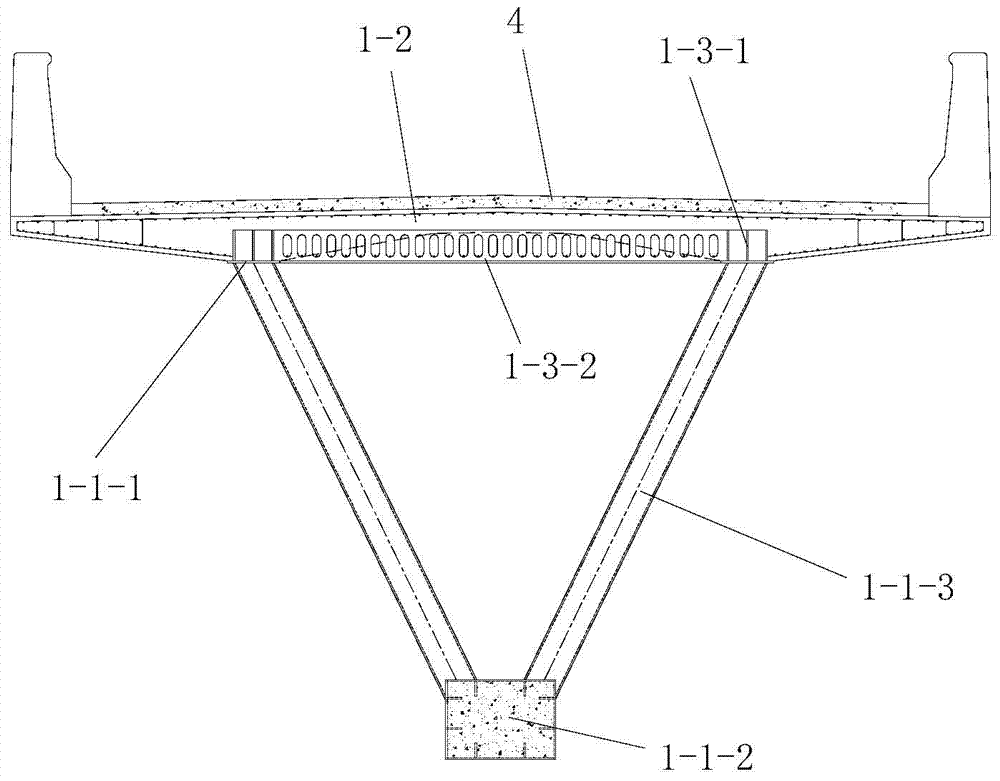

[0089] Such as Picture 1-1 , Figure 1-2 As shown, the steel truss-concrete slab composite girder 1 includes a steel truss arranged in the longitudinal bridge direction and a concrete bridge deck 1-2 arranged directly above the steel truss, and the concrete bridge deck 1-2 is in the form of a longitudinal bridge to layout. The steel truss includes one or more steel truss units 1-1 arranged in the direction of the longitudinal bridge, and a plurality of steel truss units 1-1 are arranged on the same horizontal plane from left to right in the direction of the transverse brid...

Embodiment 2

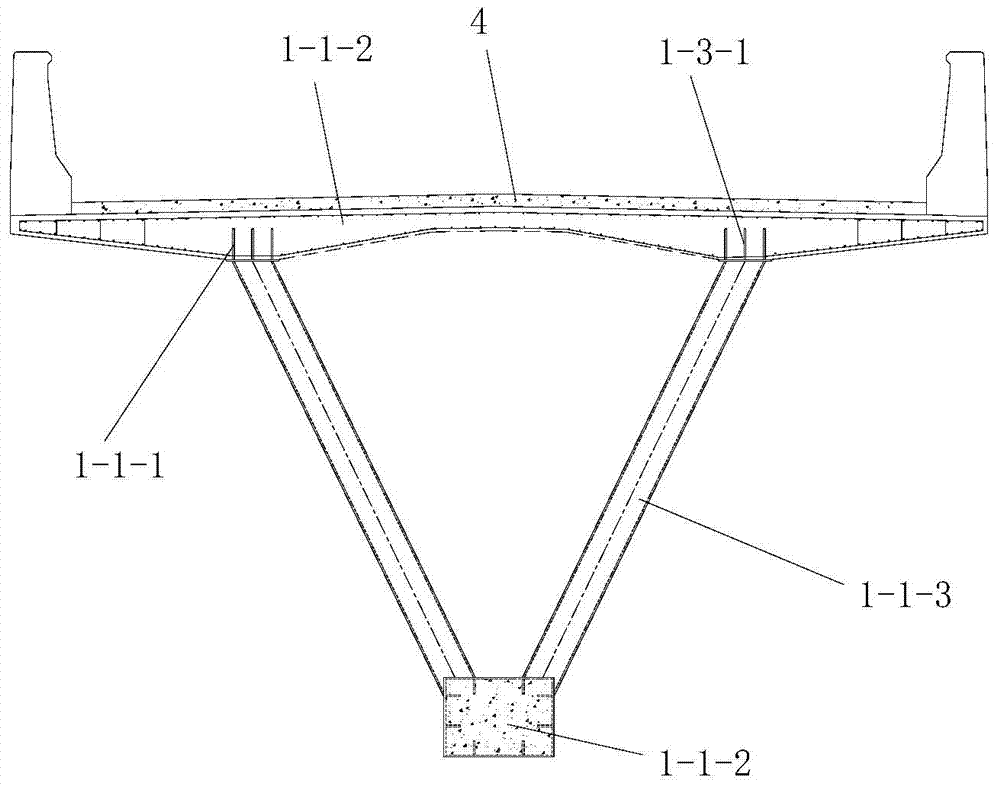

[0166] In this example, if Figure 4 As shown, the difference from Embodiment 1 is that the number of steel truss units 1 included in the steel truss is multiple, and the left and right adjacent steel truss units 1-1 in the lattice type upper chord structure share the same The upper chords 1-1-1 of the common type upper chords are common type upper chords, and the upper chords 1-1-1 in the lattice type upper chord structure are all common type upper chords except the shared type upper chords; The distance between two adjacent vertical perforated steel plates 1-3-1 in the upper chord is greater than the distance between the two adjacent vertical perforated steel plates 1-3-1 in the ordinary upper chord spacing between.

[0167] In this embodiment, the left and right adjacent lower chords 1-1-2 of the two steel truss units 1-1 are two left and right adjacent lower chords 1-1-2 arranged on the same plane, and the lower chord transverse connection system 1-1-5 is arranged on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com