Patents

Literature

51results about How to "Improve ultimate carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

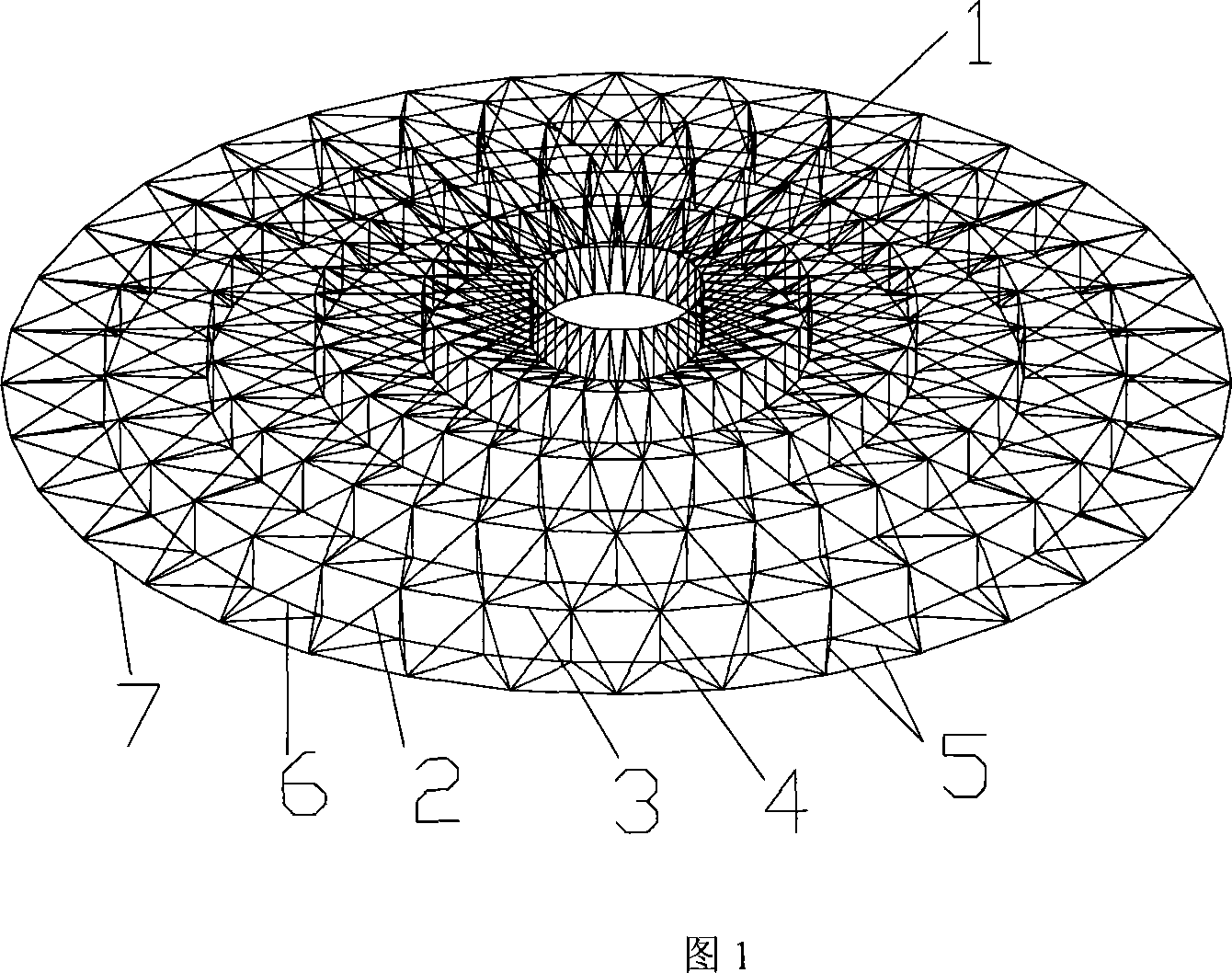

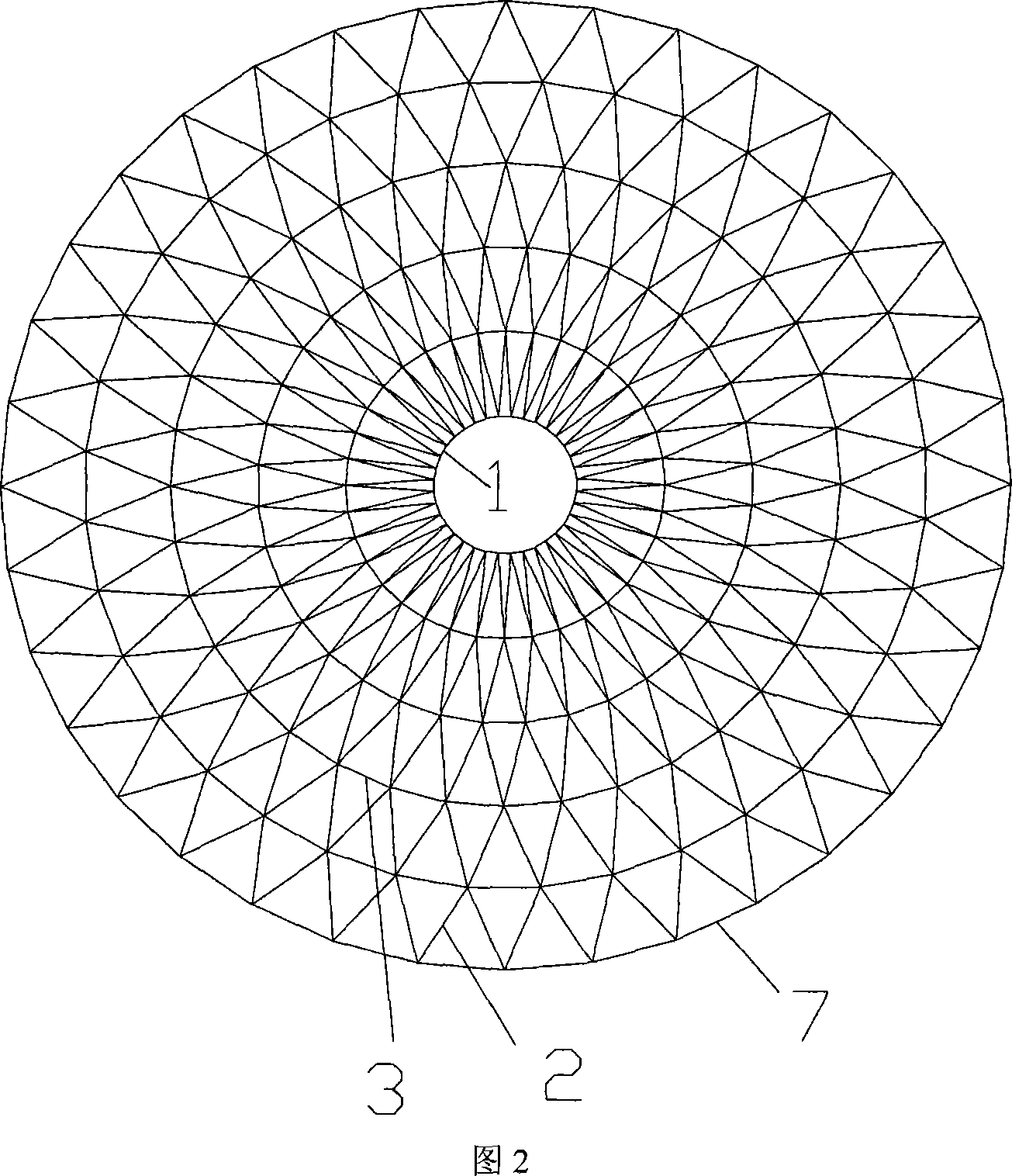

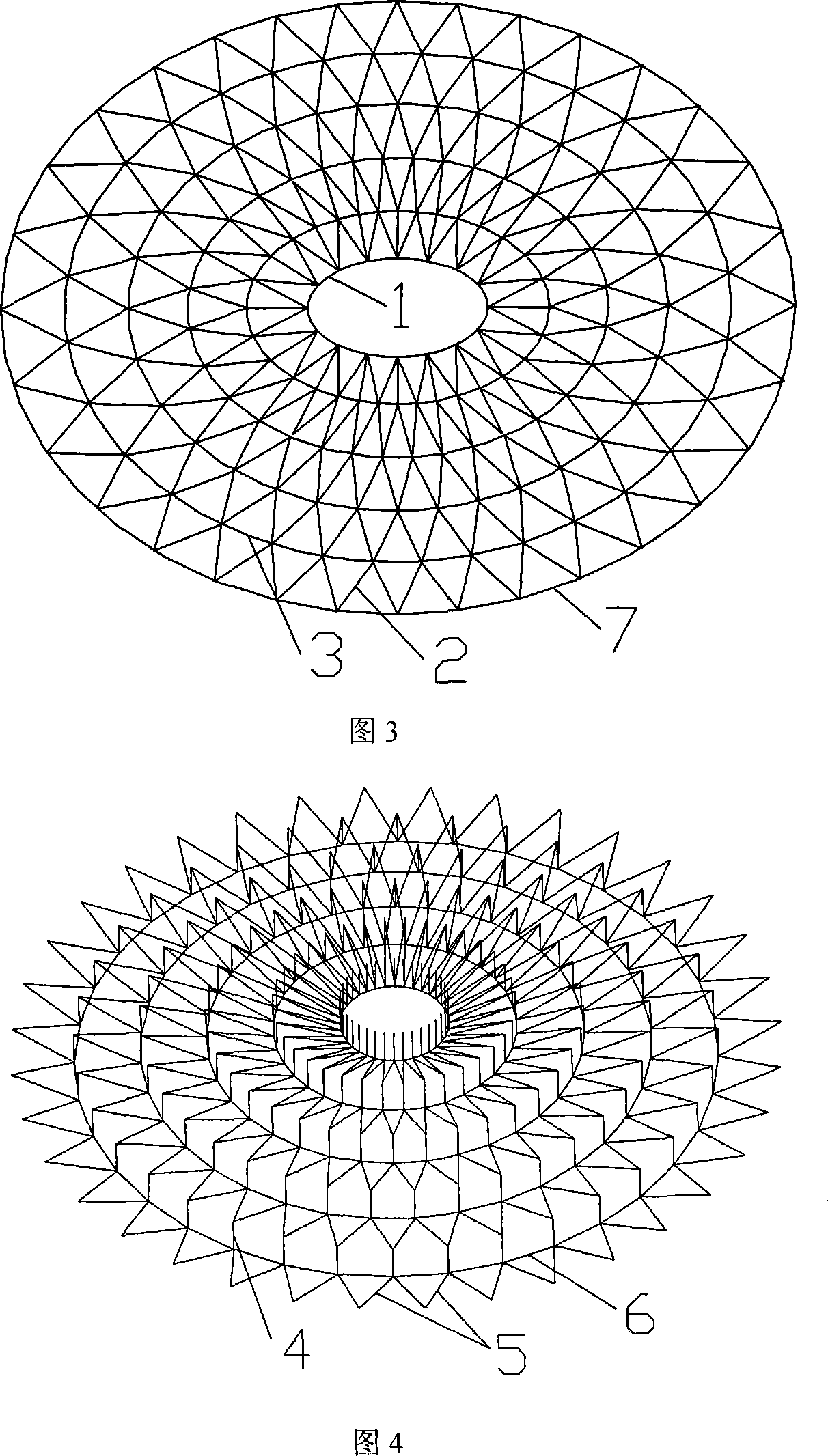

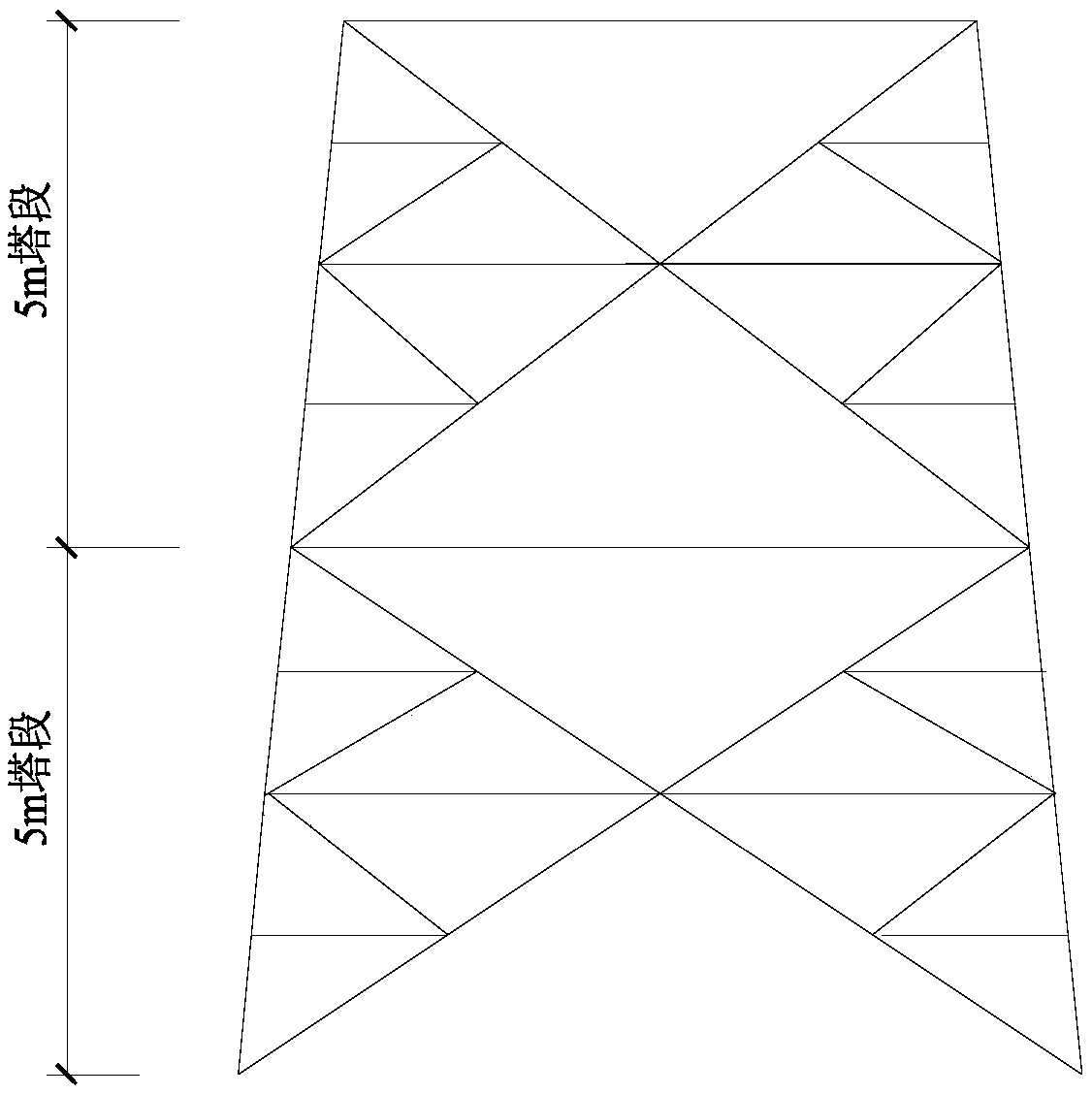

Suspended-dome multi-time prestressed construction method

InactiveCN101158195APower transmission is simpleReduce pressure peaksBuilding roofsInstabilityPre stress

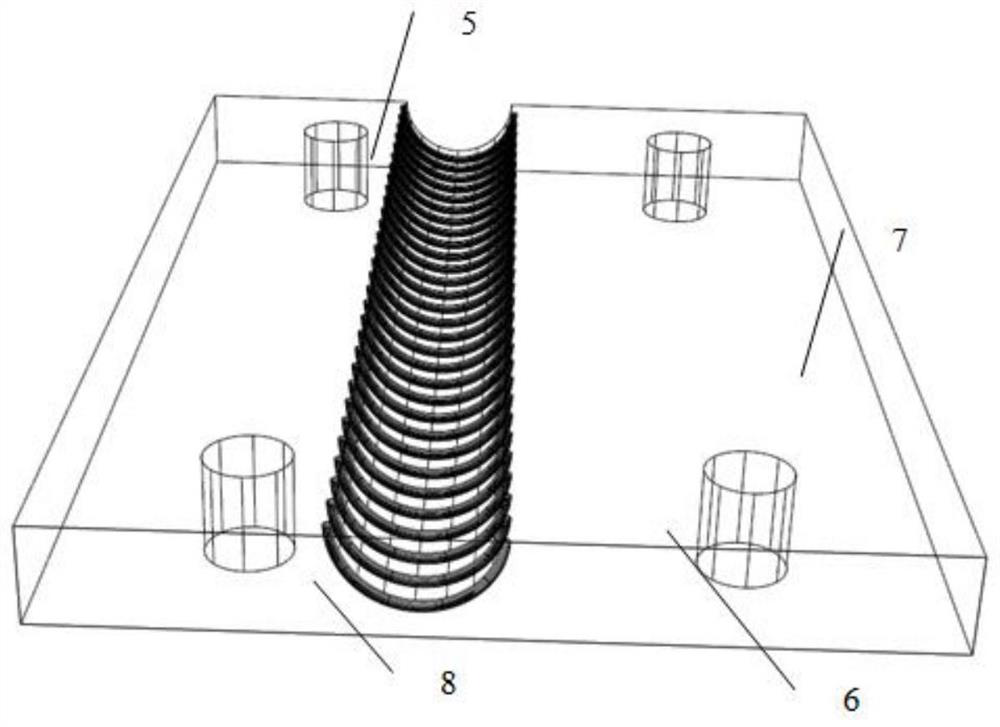

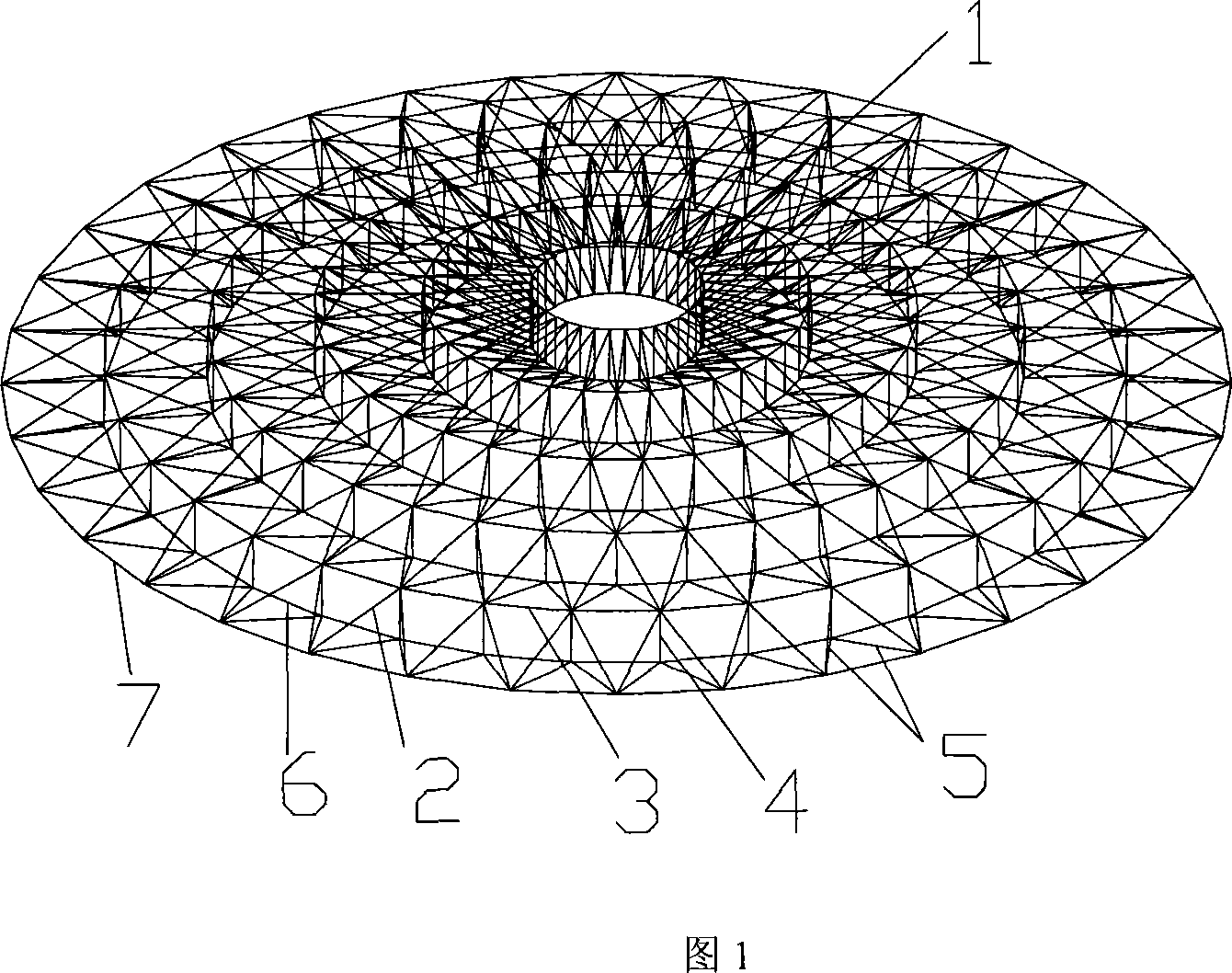

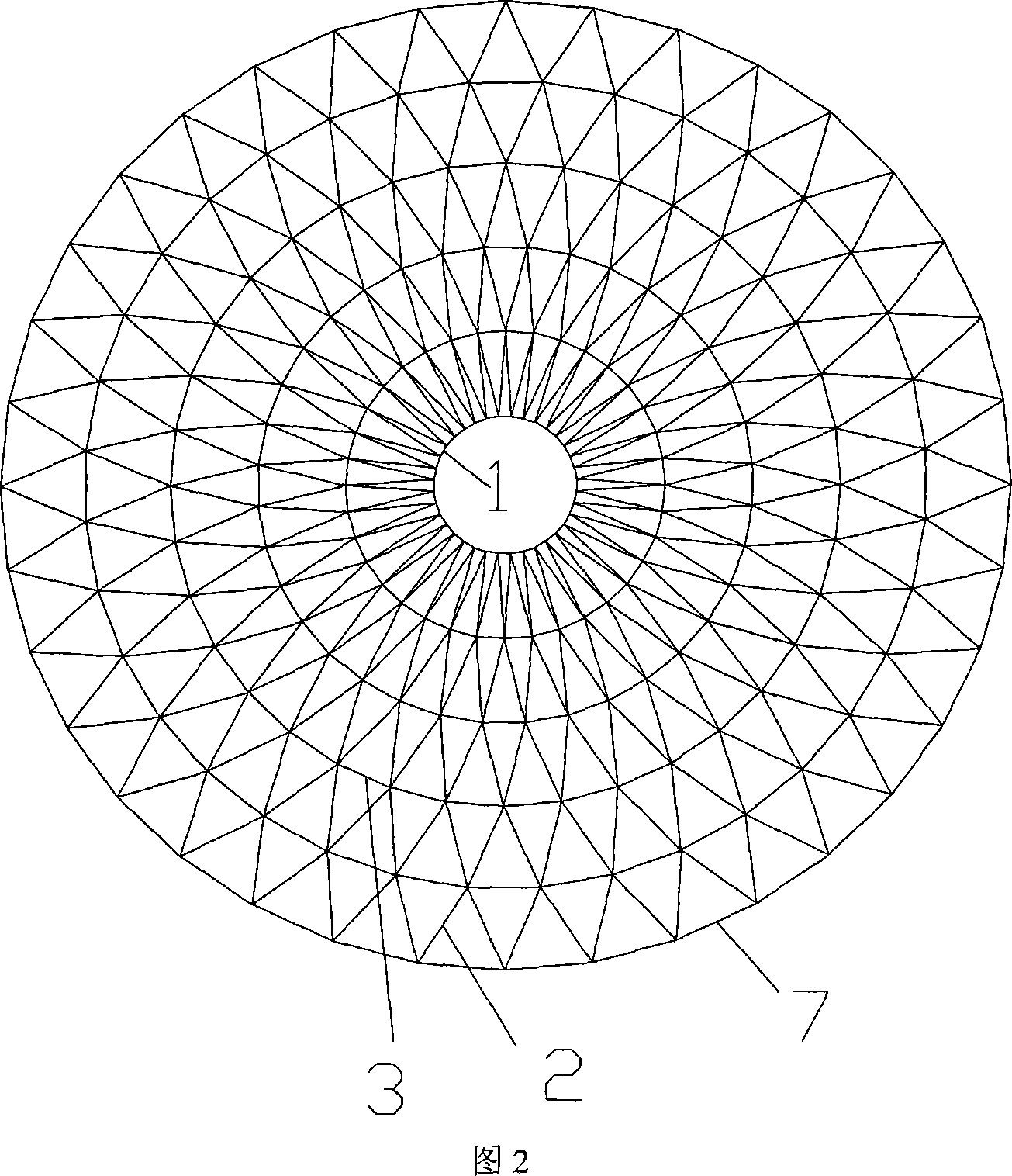

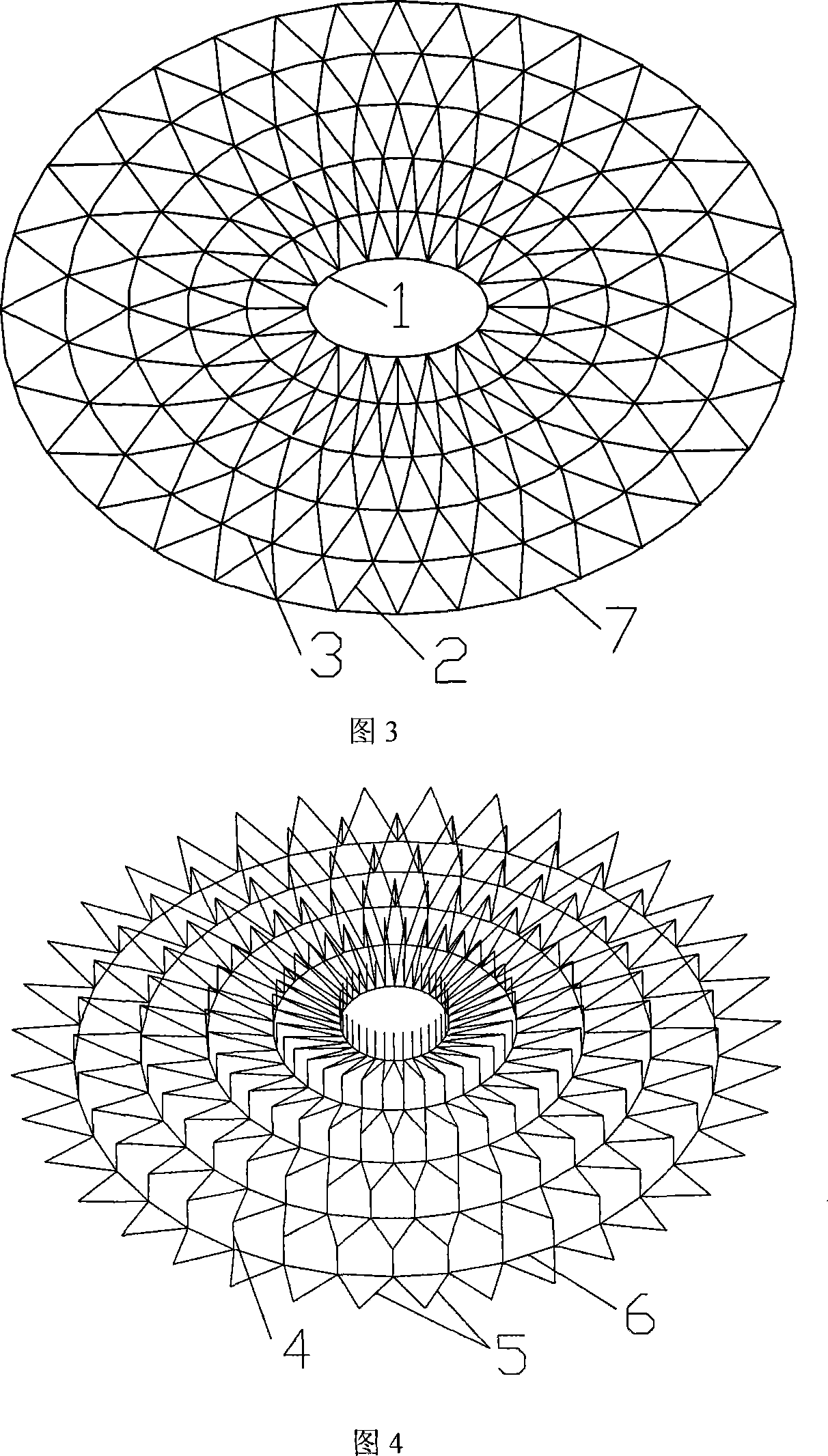

The invention discloses a suspend dome structure multi-prestressed construction method used in construction field. The construction method is that: firstly, a central pressure ring, an upper radial bar and edge elements are arranged on an upper layer; secondly, a lower radial rope, a lower ring rope and a strut are arranged on a lower layer; thirdly, prestress is applied in the structure by stretching the lower ring rope or stretching the lower radial rope or adjusting the length of the strut; fourthly, a ring bar is arranged; fifthly, an external load is applied on the structure. Compared with the structure formed by a traditional method, the suspend dome structure formed by the invention reduces peak pressure of elements with concise force, even changes a part of elements from a pressure bar to a tension bar, avoids instability of elements, at the same time enhances the entire stability of the whole structure and enlarges the ultimate bearing capacity. Furthermore, the invention leads a more even distribution of internal force of the upper layer network shell bar elements, is helpful to the unity of the elements and convenient for design and construction, at the same time, the invention reduces the applied prestress value and reduces construction difficulty.

Owner:BEIJING UNIV OF TECH

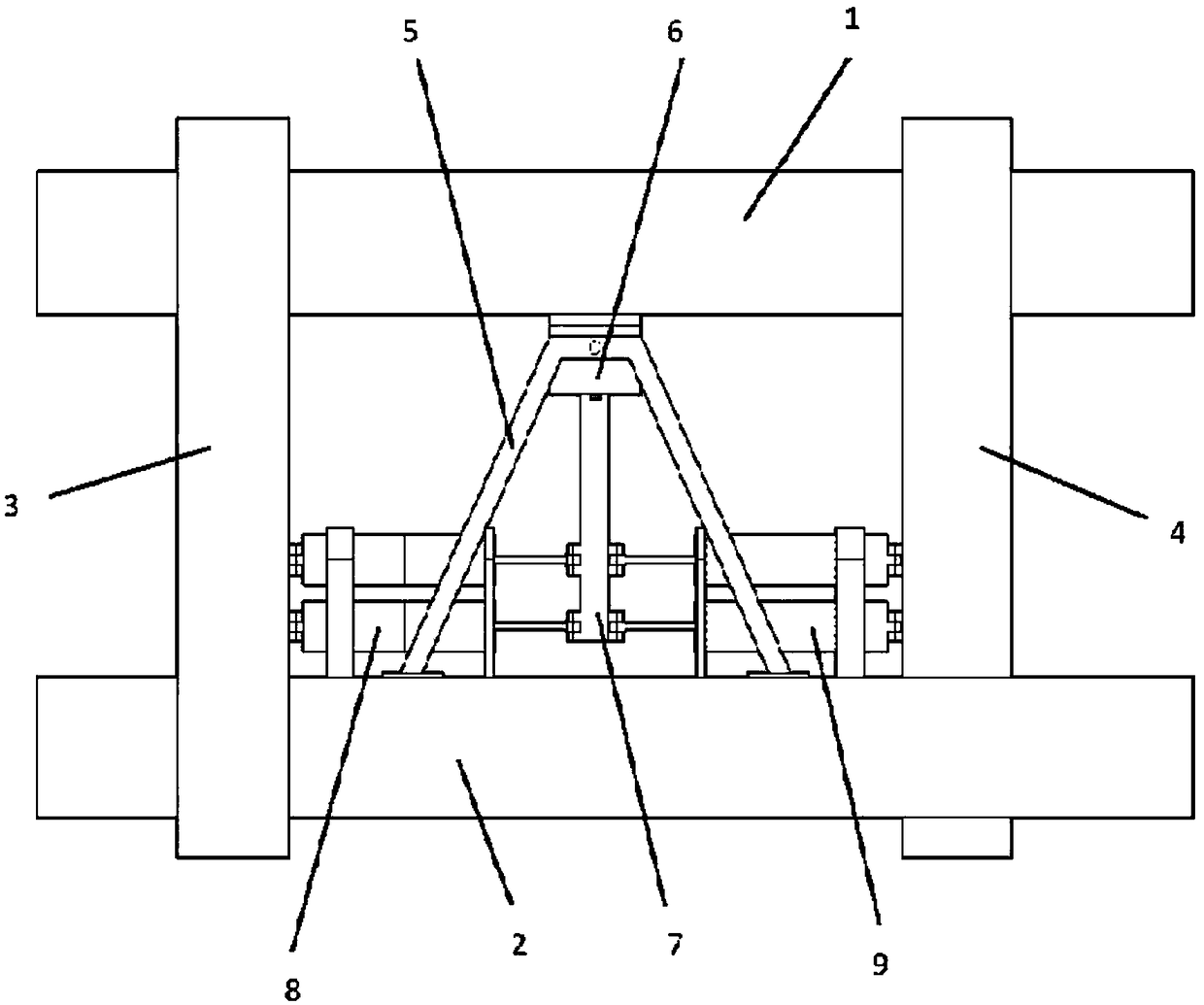

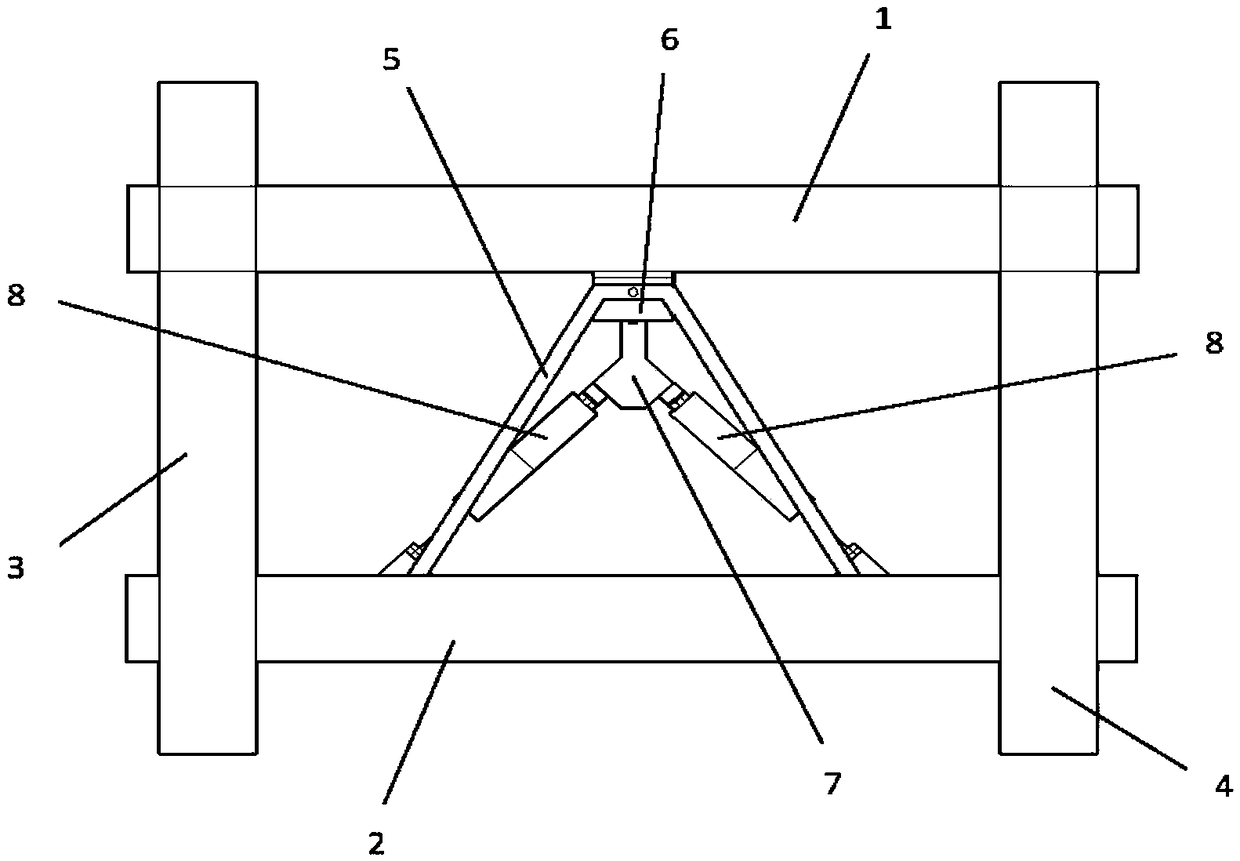

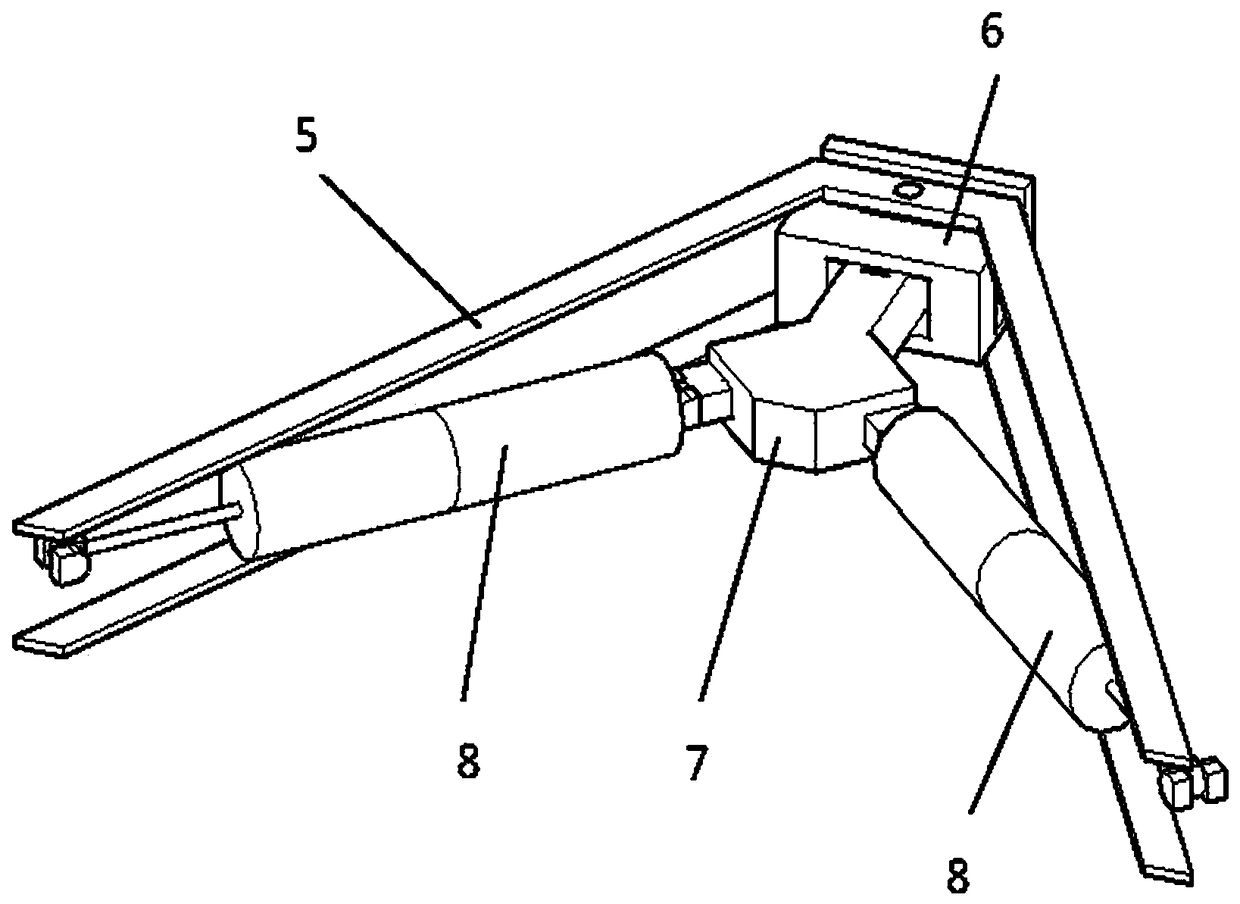

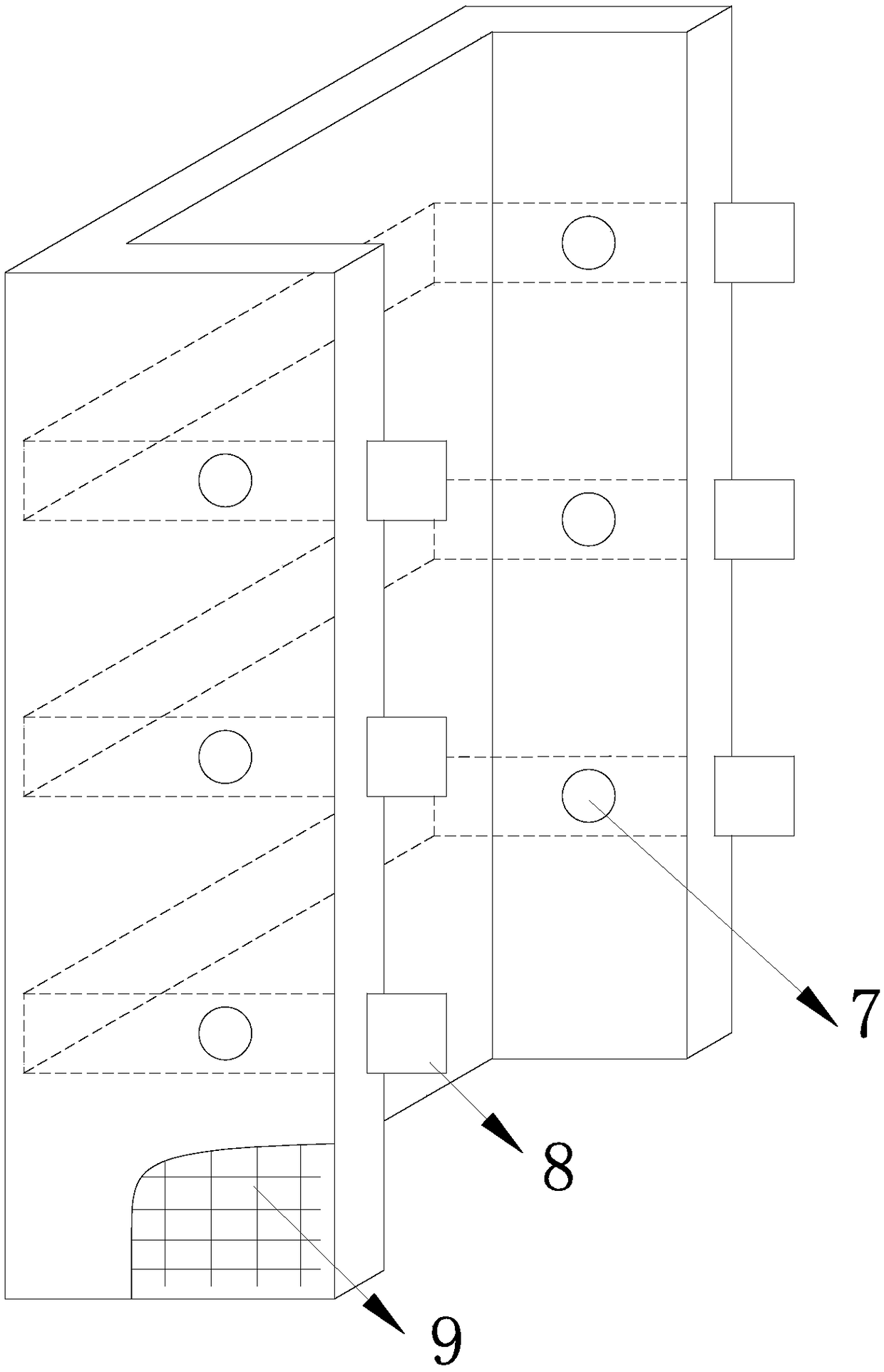

Damping mechanism of upper and lower beam connection

PendingCN109208992AThe effect of good damping energy dissipationImprove ultimate carrying capacityProtective buildings/sheltersShock proofingEngineeringShock absorber

The invention relates to a damping mechanism of upper and lower beam connection. The mechanism comprise a supporting block fixed to the upper beam, a support fixed to the lower beam, a swing bar, first and second connecting shafts, a slide block and left and right viscous dampers; one end of the left viscous damper is mounted together with a left column in a rotational way, the other end of the viscous damper is mounted together with the swing bar in the rotational way, one end of the right viscous damper is mounted together with a right column in the rotational way, the other end of the rightviscous damper is mounted together with the swing bar in the rotational way, and the left and right viscous dampers are positioned in the two sides of the swing bar respectively; and the swing bar isrotationally mounted on the support via the first connecting shaft, the swing bar is provided with a chute, the slide block is arranged in the chute of the swing bar in a sliding manner, and the second connecting shaft is mounted together with the supporting block in the rotational way. The damping mechanism has a good anti-vibration effect and belongs to the field of anti-vibration technologiesof houses.

Owner:GUANGZHOU UNIVERSITY

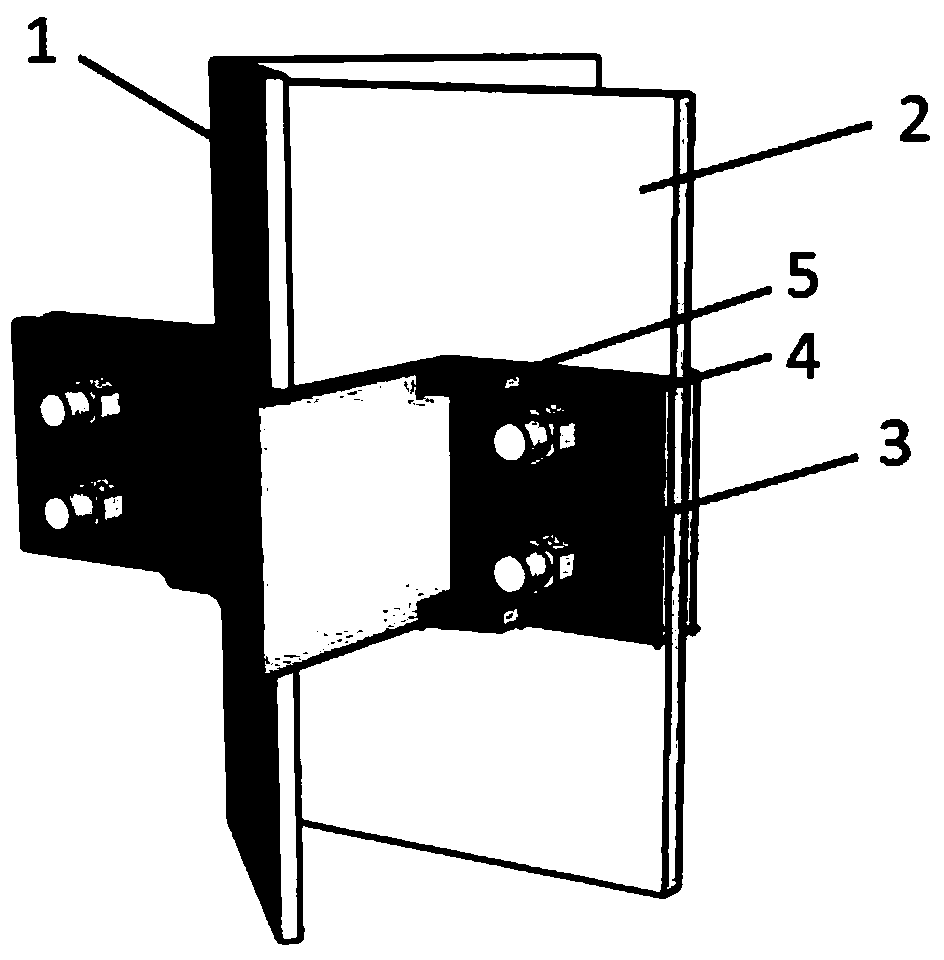

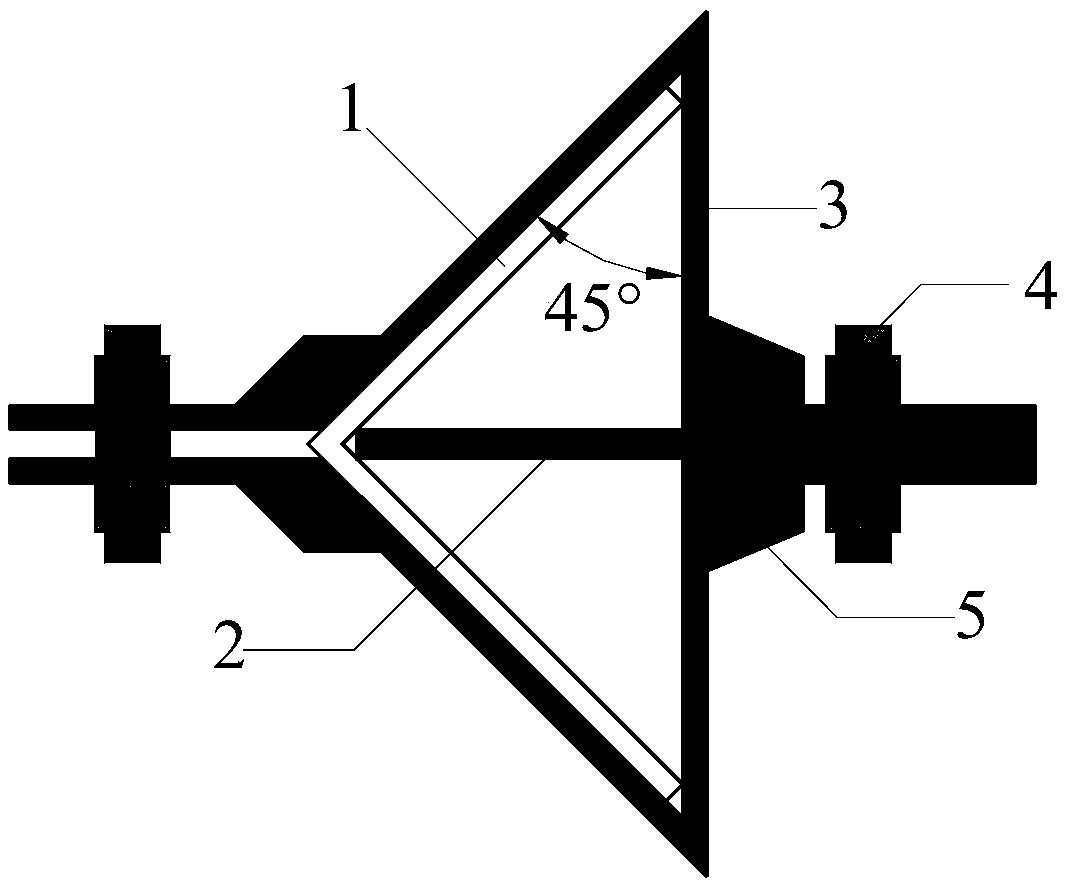

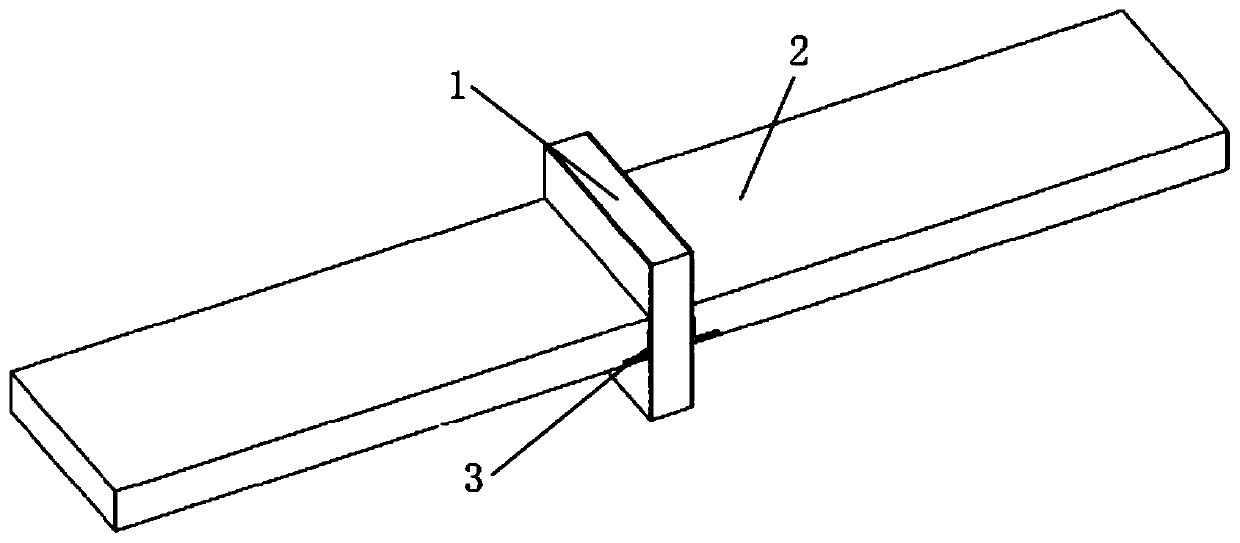

Steel structure beam-column slotted hole rotating type high-strength bolt connection ductility joint

InactiveCN101624845AImprove ultimate carrying capacityLarge deformation spaceBuilding constructionsEngineeringDistortion

The invention relates to a steel structure beam column, in particular to a high-strength bolt connection joint for the steel structure beam column. The invention provides a slotted hole rotating type high-strength bolt connection ductility joint for the steel structure beam column, which comprises a column, a top flange plate of a beam, a bottom flange plate of the beam, a web of the beam, a top flange splicing plate of the beam, a bottom flange splicing plate of the beam, a web splicing plate and a plurality of web friction type high-strength bolts, wherein the top flange plate and the bottom flange plate are connected through the high-strength bolt in a butted mode. The bolt hole of the high-strength bolt is a slotted hole along the shearing direction of the bolt hole, and the high-strength bolt is positioned in the middle in the length direction of the slotted hole. The high-strength bolt connection ductility joint can provide larger distortion space, improve the energy consumption and the internal force redistribution capability of the structure, and cannot cause brittle failure during the earthquake; therefore, the shock-proof performance of the structure is enhanced.

Owner:SHANGHAI BAOYE GRP CORP +1

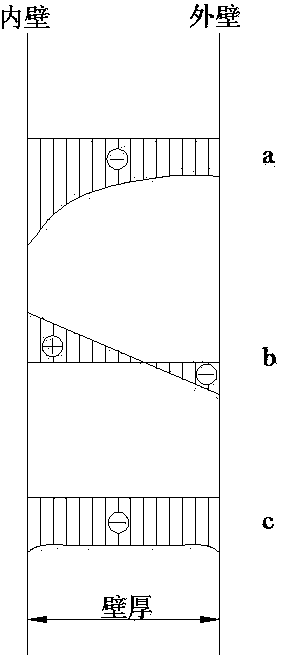

Warship board multilayer anti-detonation protection structure

ActiveCN103991518AIncreased damage areaReduce distortionVessel cleaningHullsDetonationUltimate tensile strength

The invention discloses a warship board multilayer anti-detonation protection structure. The warship board multilayer anti-detonation protection structure comprises a double-layer shell, a void compartment, a first liquid compartment and a second liquid compartment, wherein the double-layer shell, the void compartment, the first liquid compartment and the second liquid compartment are sequentially ranked from the outer side of a warship body to the inner side of the warship body, the water filling height h of the first liquid compartment and the water filling height h of the second liquid compartment are 70%-80% of a compartment height H, the void compartment is separated from the first liquid compartment through a first compartment separation plate, the first liquid compartment is separated from the second liquid compartment through a second compartment separation plate, the second liquid compartment is separated from an inner compartment of a warship through a third compartment separation plate, and the side, towards a compartment body, of the second liquid compartment is fixedly connected with a plurality of longitudinal box girders which are vertically ranked at intervals. The warship board multilayer anti-detonation protection structure with the structural style has the advantages of being light in weight, good in anti-detonation performance, high in residual intensity and the like, when a warship board is impacted by detonation, most detonation impact energy can be absorbed, the compartments of the warship are prevented from being damaged, and personal losses are avoided.

Owner:JIANGSU UNIV OF SCI & TECH

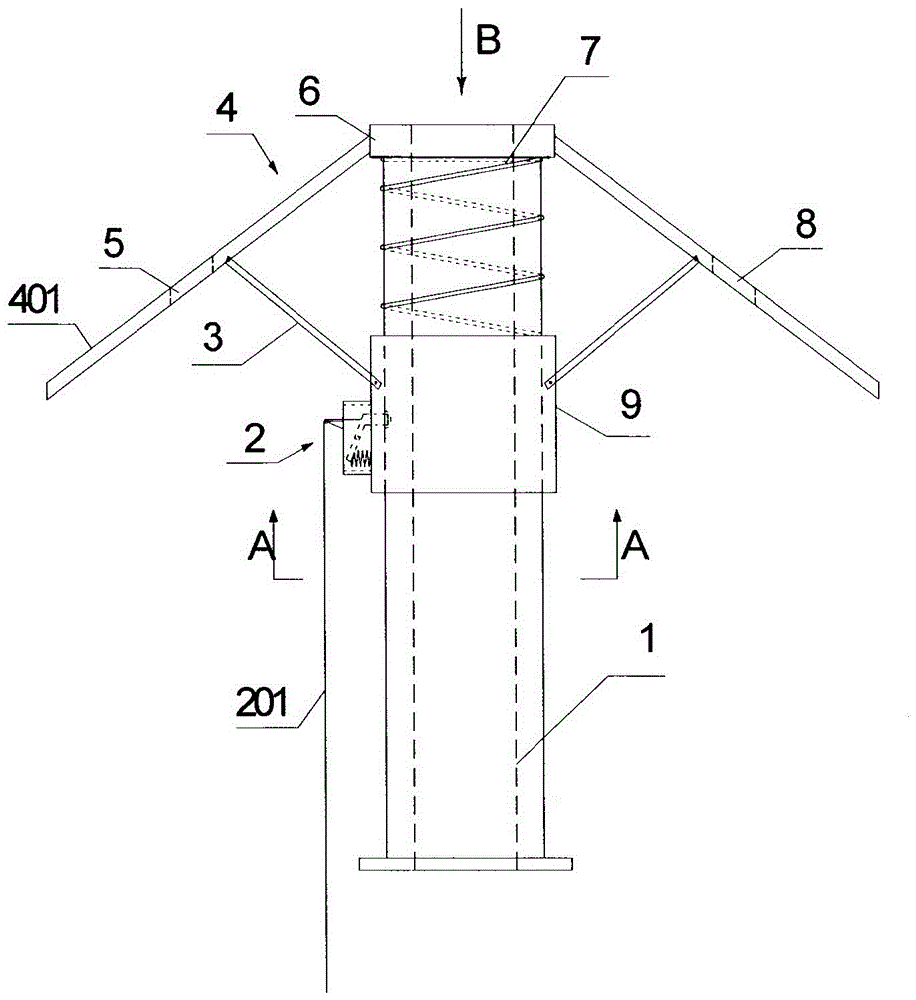

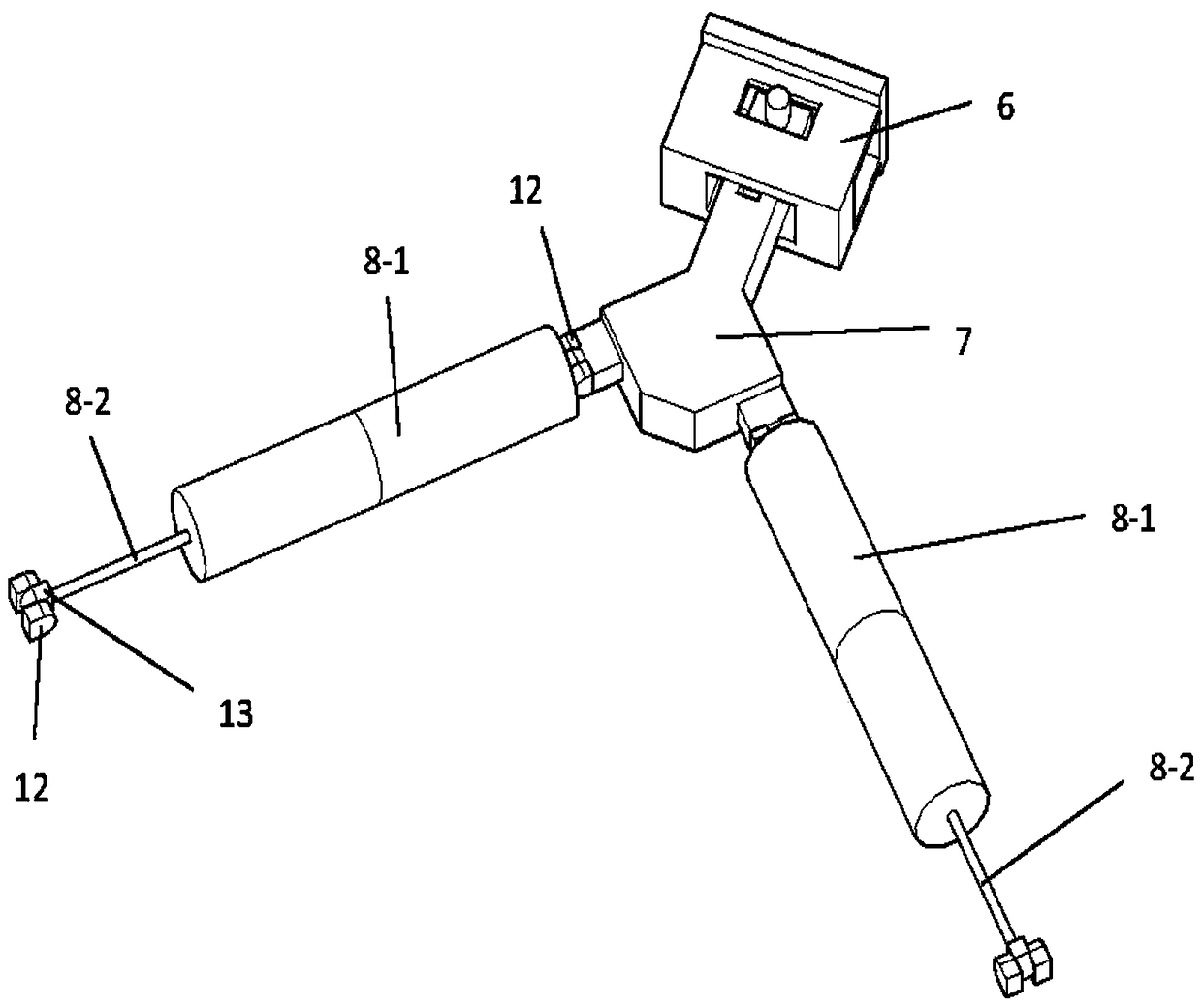

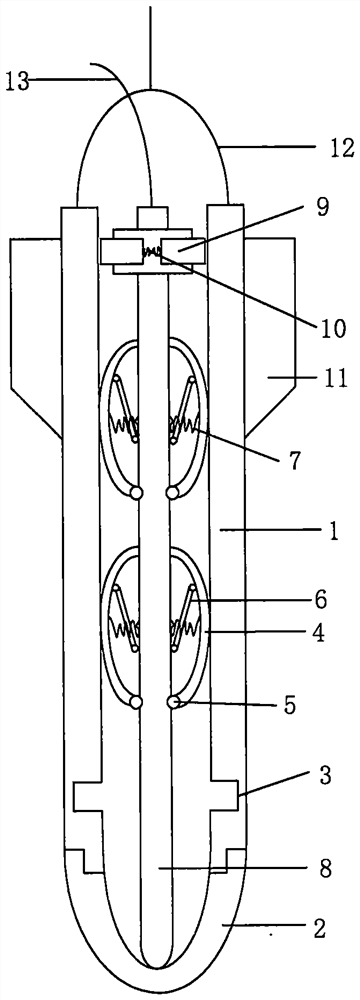

Recoverable side slope anchor rod grout stop device

ActiveCN106436705AOptimize the force structureImprove ultimate carrying capacityBulkheads/pilesAnchoring boltsStops deviceEngineering

A recoverable side slope anchor rod grout stop device is provided with a casing pipe, a sliding sleeve, a check ring, a compression spring, a switch mechanism, a grout stop face and a plurality of frameworks. The grout stop face is formed by annularly distributing and combining a plurality of sector-ring-shaped steel sheets. Every two adjacent sector-ring-shaped steel sheets are hinged to each other, and each sector-ring-shaped steel sheet is connected with the check ring. The frameworks and the sector-ring-shaped steel sheets are in one-to-one correspondence. One end of each framework is hinged to the sliding sleeve, and the other end of each framework is hinged to the sector-ring-shaped steel sheet corresponding to the framework. A grout inlet hole connected with a grouting pipe and an exhaust hole connected with an exhaust pipe are formed in the grout stop face, and the casing pipe is provided with a groove which cooperates with a switch to enable the sliding sleeve to be located on the casing pipe to open the grout stop face. During anchor rod grouting, an anchoring segment can be blocked, a bonding material is prevented from flowing towards the free end, the stress structure of an anchor rod is optimized, grouting materials are saved, and the anchoring effect is increased; and after the grouting task is completed, the grout stop device can be recovered by closing the sector-ring-shaped steel sheets through the switch mechanism.

Owner:河北建科唐秦建筑科技有限公司

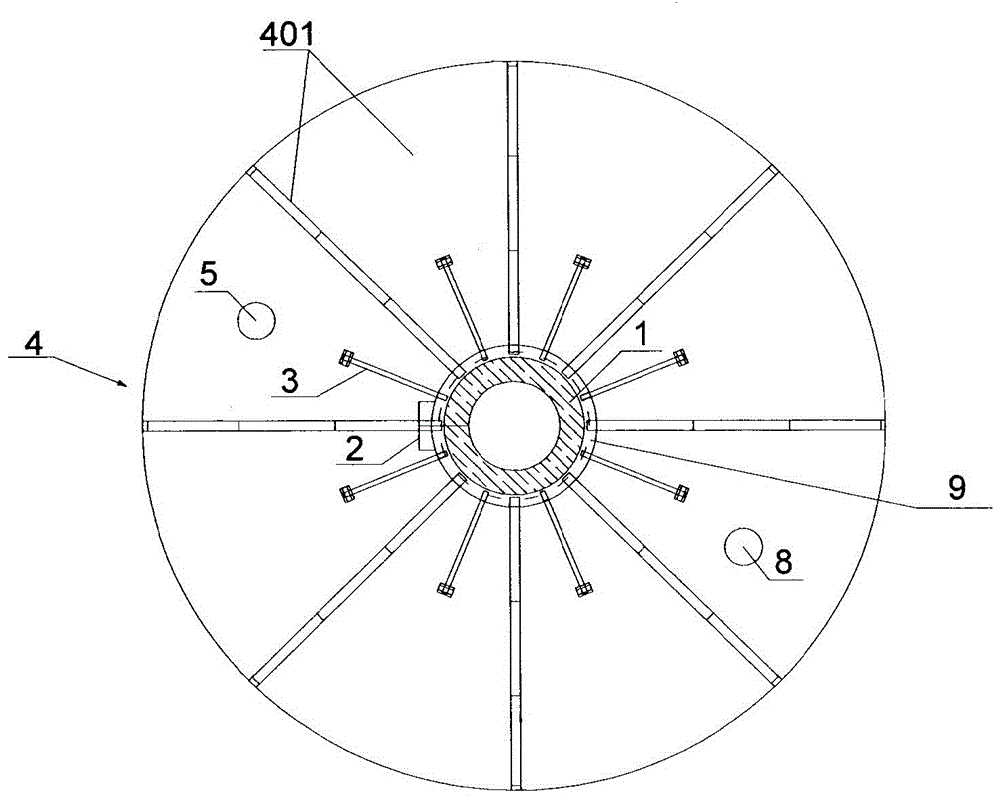

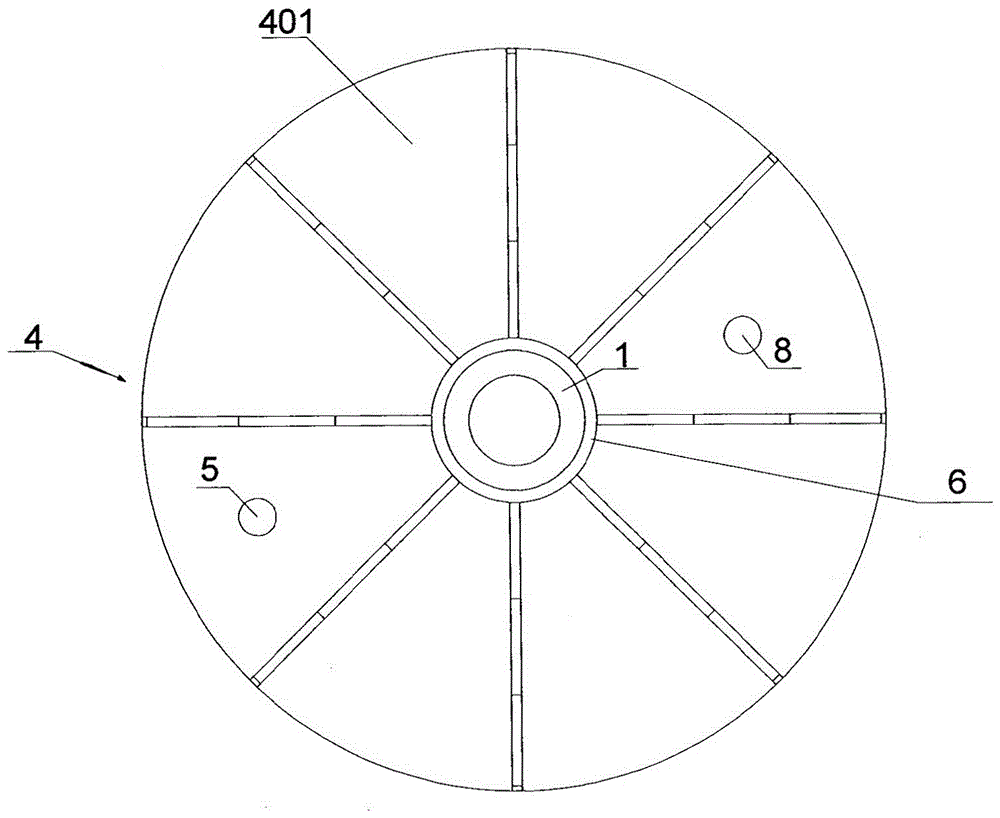

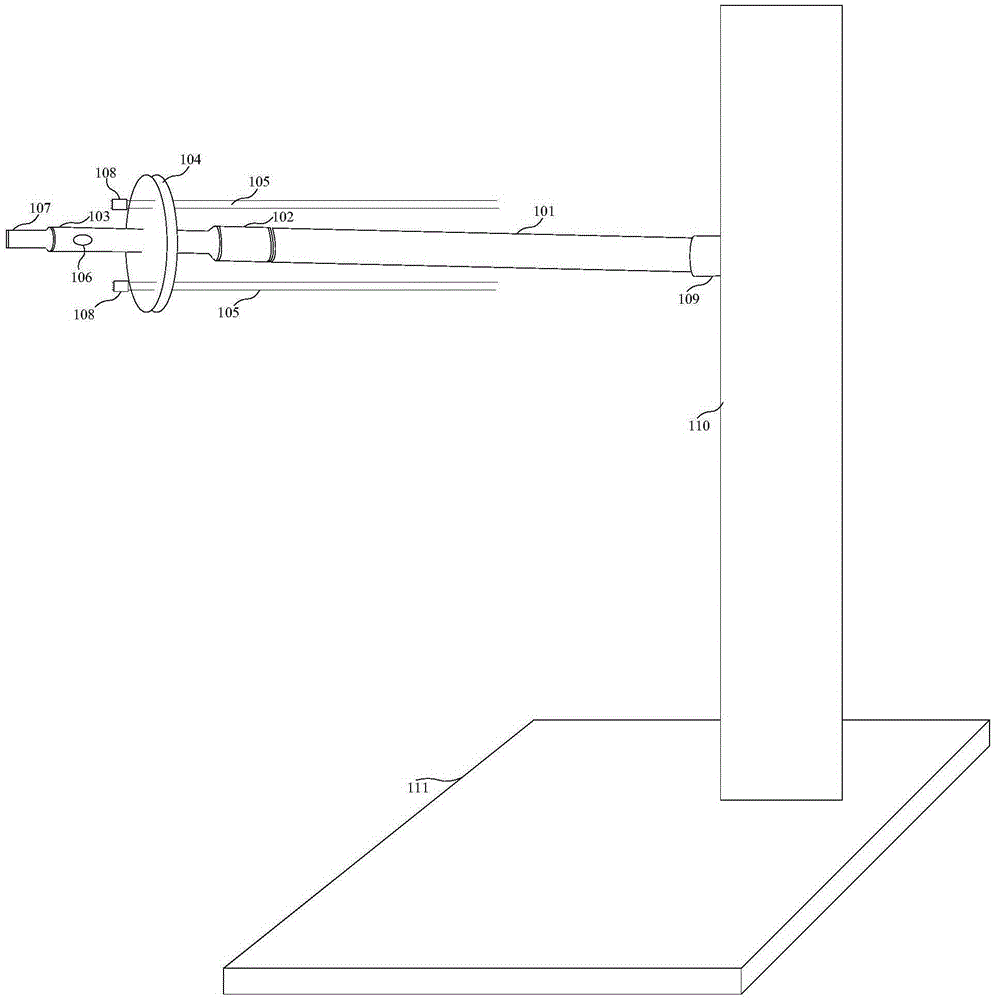

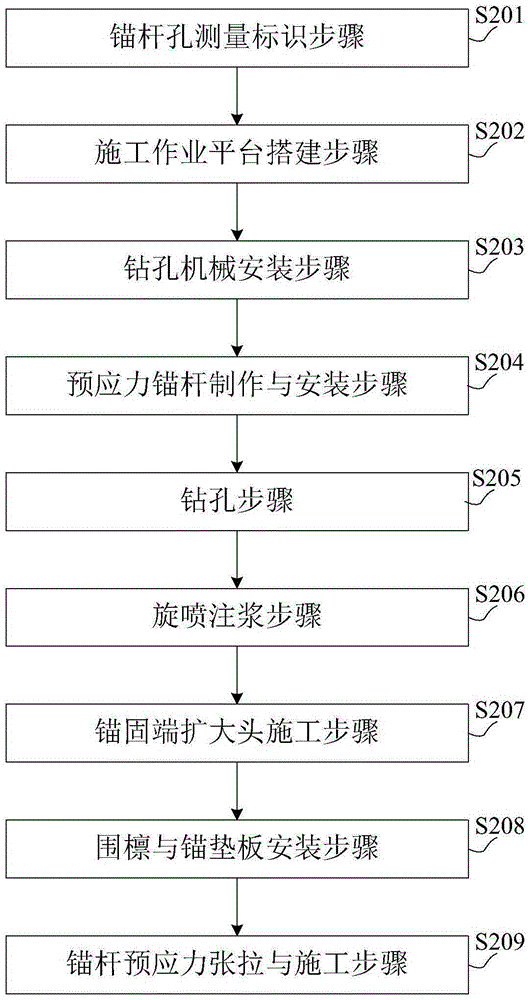

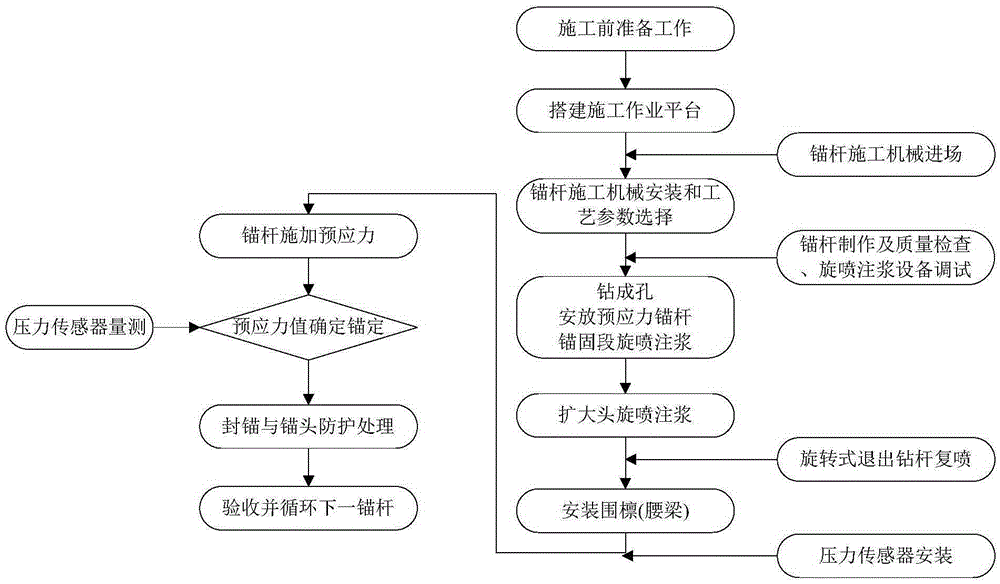

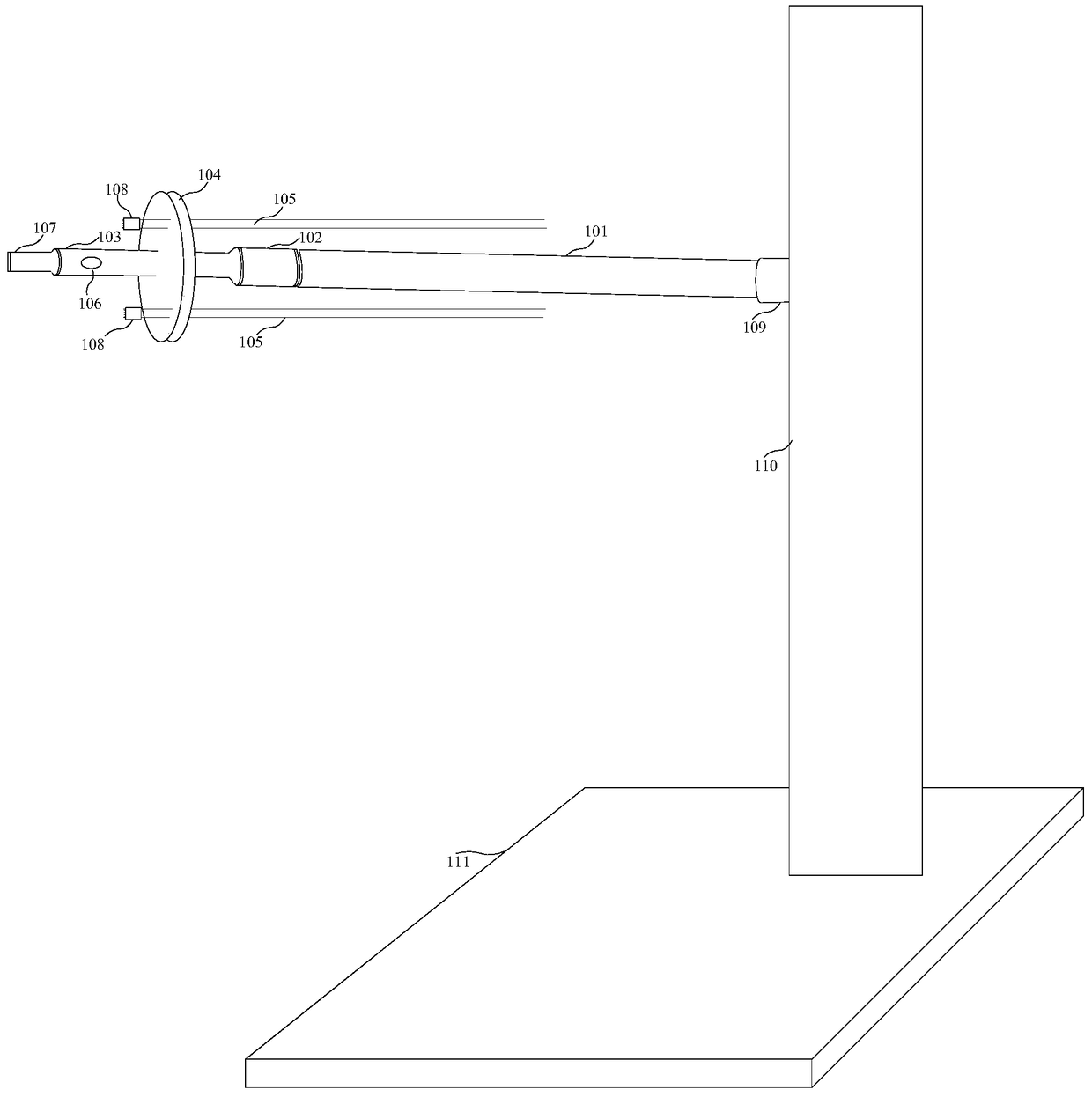

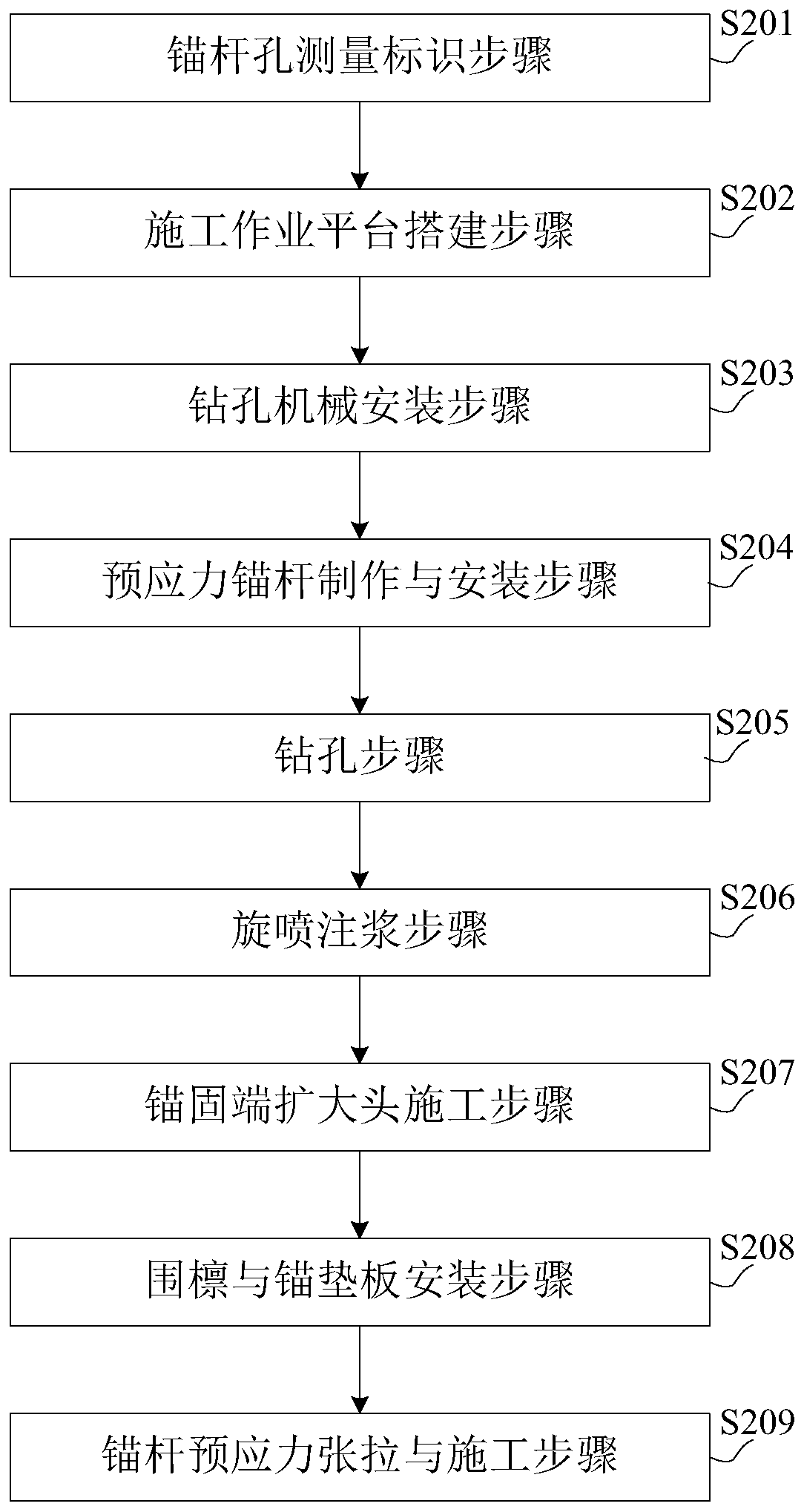

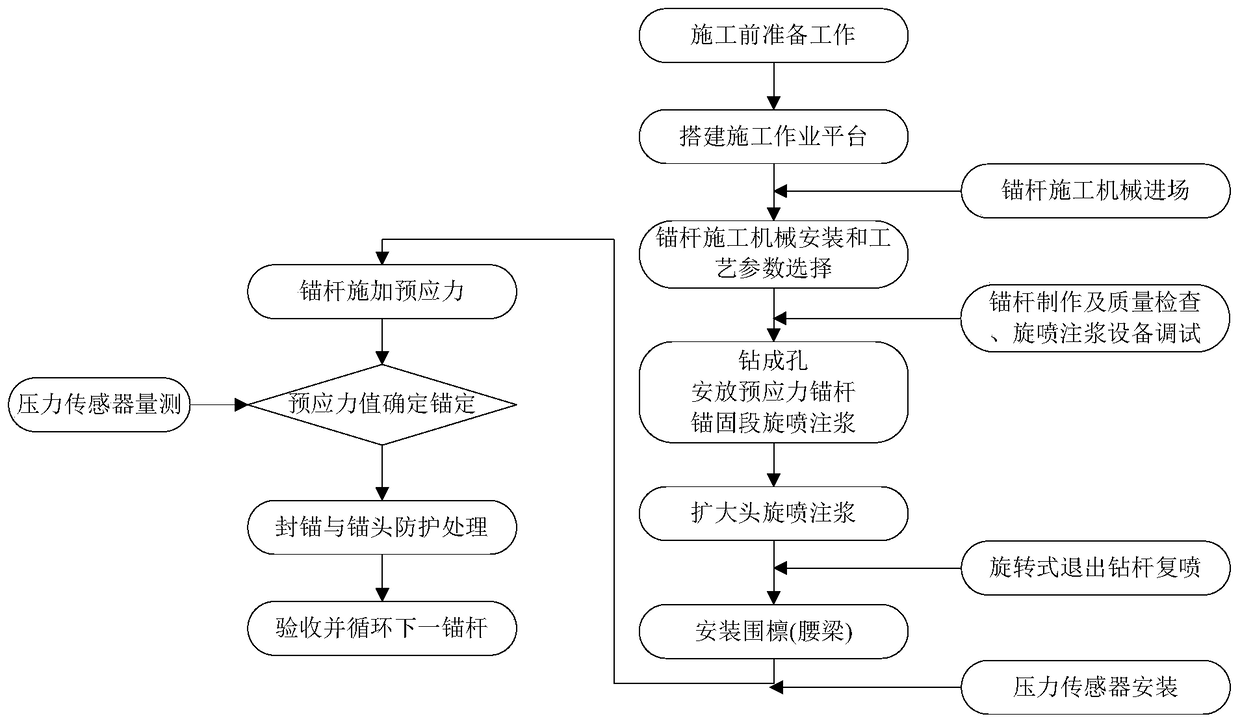

One-time high pressure jet grouting type expansion head prestress soil anchor rod construction method

ActiveCN106498943AImprove ultimate pull-out capacityLow costBulkheads/pilesHigh pressureDrilling machines

The invention provides a one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method. The one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method comprises the step of measuring and marking of an anchor rod hole, the step of construction of a construction work platform, the step of installation of a drilling machine, the step of manufacturing and installing of a prestress anchor rod, the step of hole drilling, the step of rotary jet grouting, the step of construction of an expansion head at the anchor end, the step of installation of a purlin and an anchor bearing plate, and the step of prestress tension and construction of the anchor rod. Compared with conventional grouting prestress anchor rod construction methods, through the application practices in multiple ultra-large irregular deep foundation pit engineering, the one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method has the extremely good anchoring force and anti-pulling bearing force. By adoption of the one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method, the extreme anti-pulling bearing force of the anchor rod can be greatly improved, and the manufacturing cost of the anchor rod for unit bearing force is reduced.

Owner:宏润建设集团上海有限公司

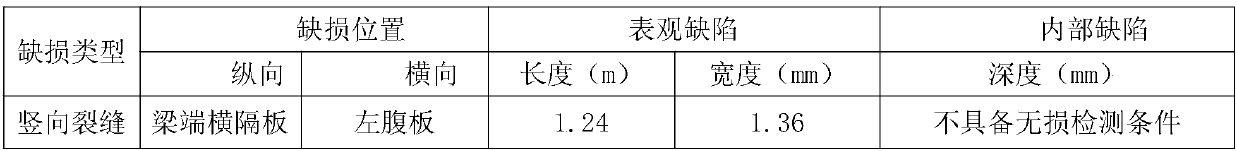

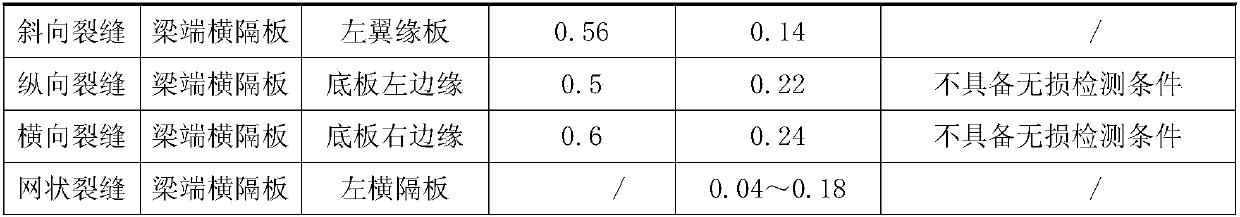

Freeway bridge crack repairing method based on carbon fiber plate

InactiveCN107740354AIncreased durabilityIncrease safety reserveBridge erection/assemblyBridge strengtheningFiberCarrying capacity

The invention discloses a freeway bridge crack repairing method based on a carbon fiber plate. The method comprises the steps of detecting and specially analyzing a crack; preparing construction materials and construction equipment and building a construction bracket platform; cleaning an opening; implanting and cleaning a bolt and fixing the bolt into the opening through vegetable glue; conducting surface treatment on a concrete member, installing an anchor, installing a fixed-end limiting frame, installing the anchor into the fixed-end limiting frame, installing a tension-end limiting frame,and installing a wedge block so that the bottom of the wedge block is arranged under concrete; fixing the carbon fiber plate to the crack through the anchor. In the method, the pre-stressed carbon fiber plate is adopted to apply external pre-stress on the bottom of a box girder for reinforcement and strengthening, the strength and the stiffness of the structure can be improved, the deflection deformation of the structure can be reduced, and the development of the crack can be restrained; besides, with the combination of a crack sealing treatment measure, the durability of a bridge and the ultimate carrying capacity of the structure can be improved, and the emergency capacity of bridge running can be improved.

Owner:SINOHYDRO BEREAU 10 CO LTD

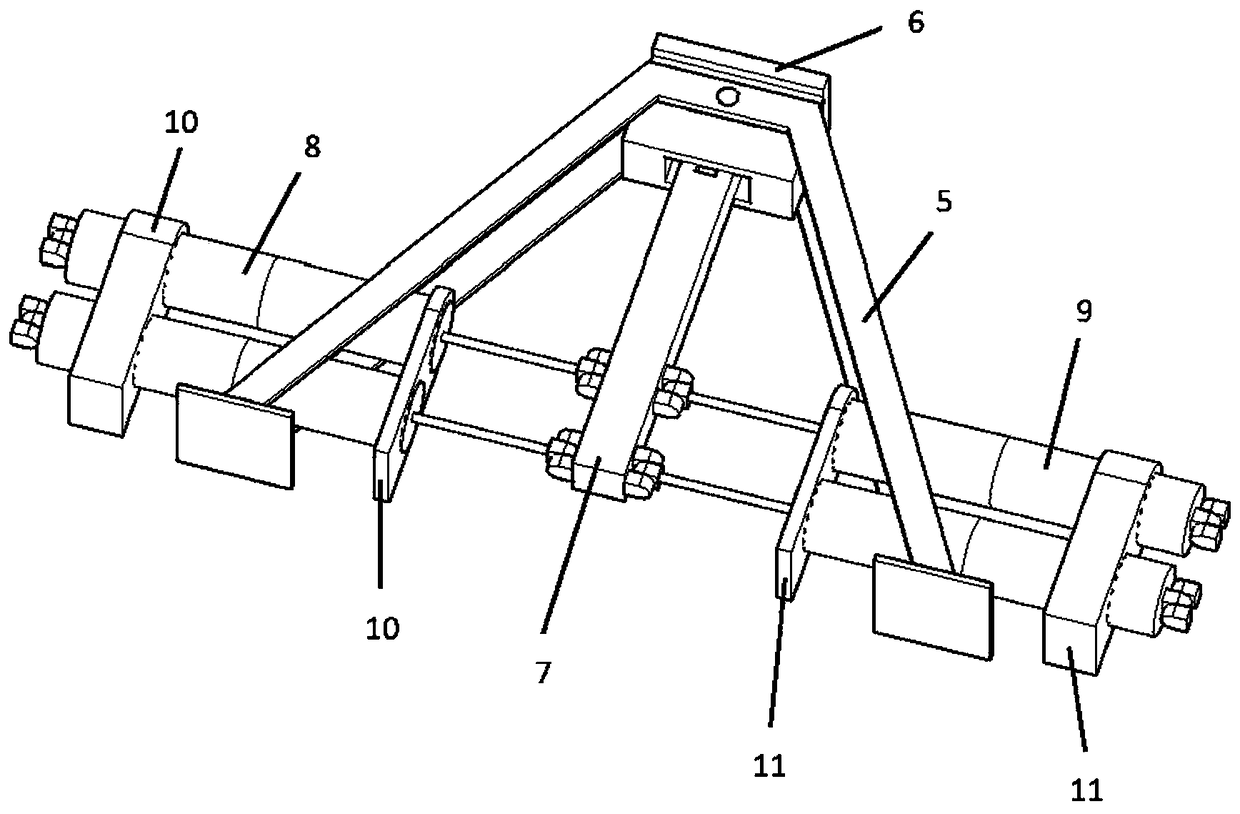

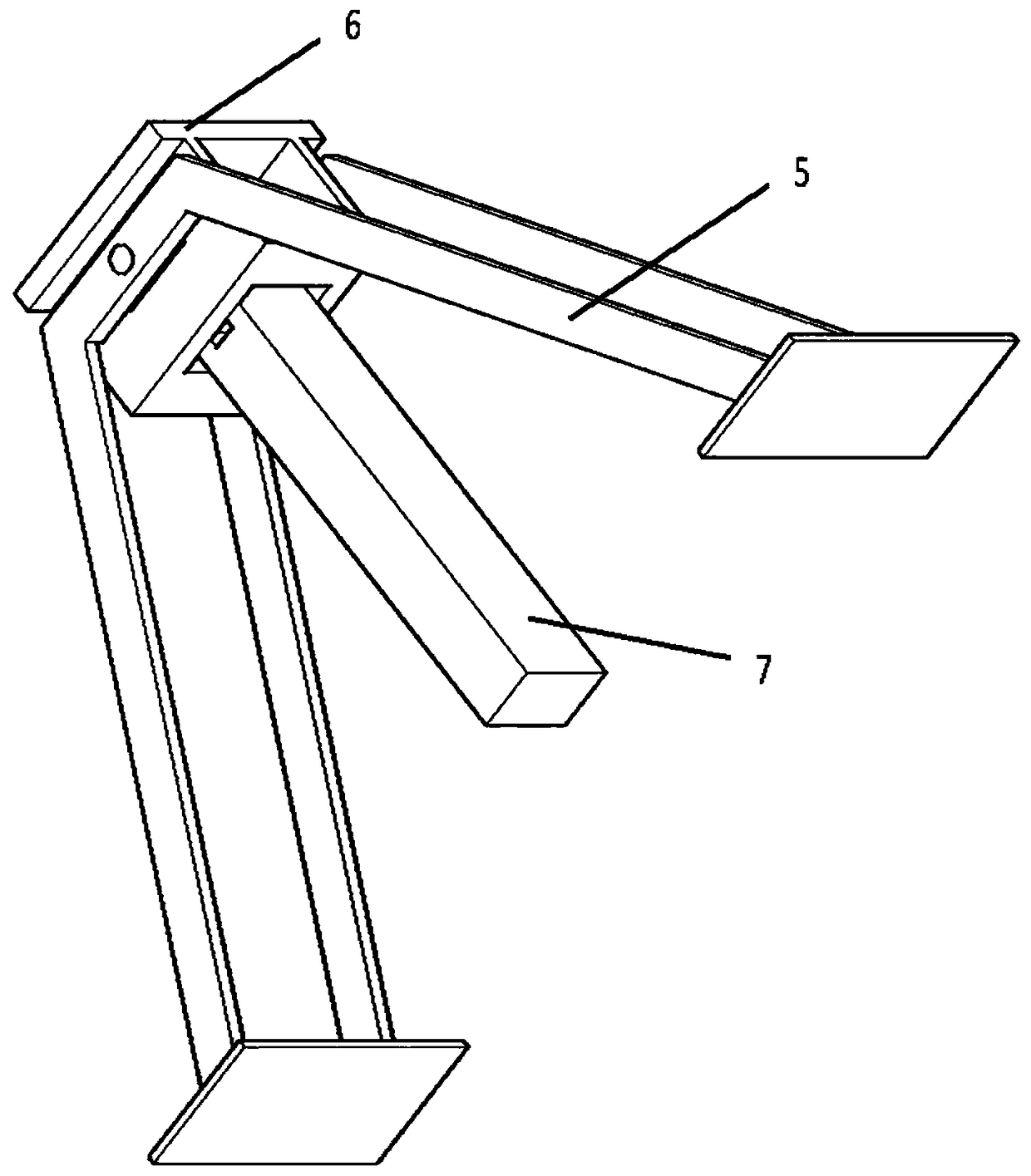

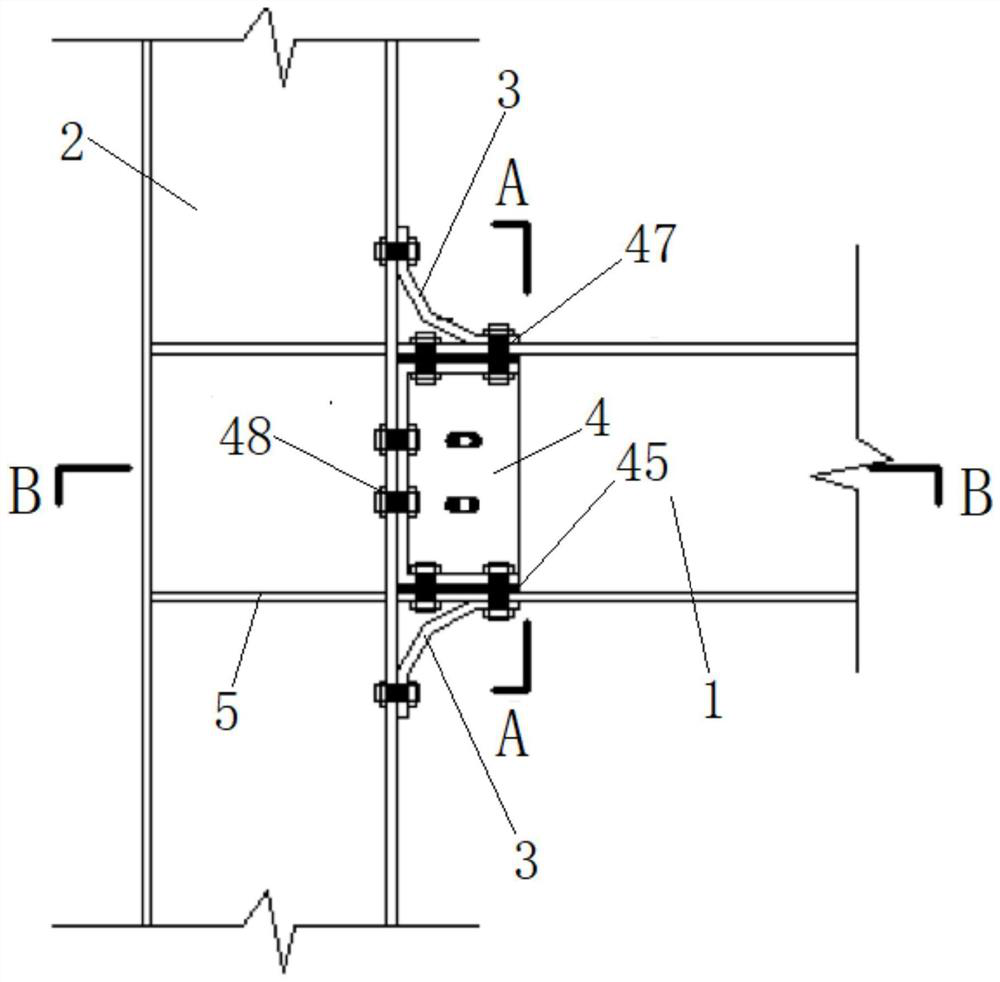

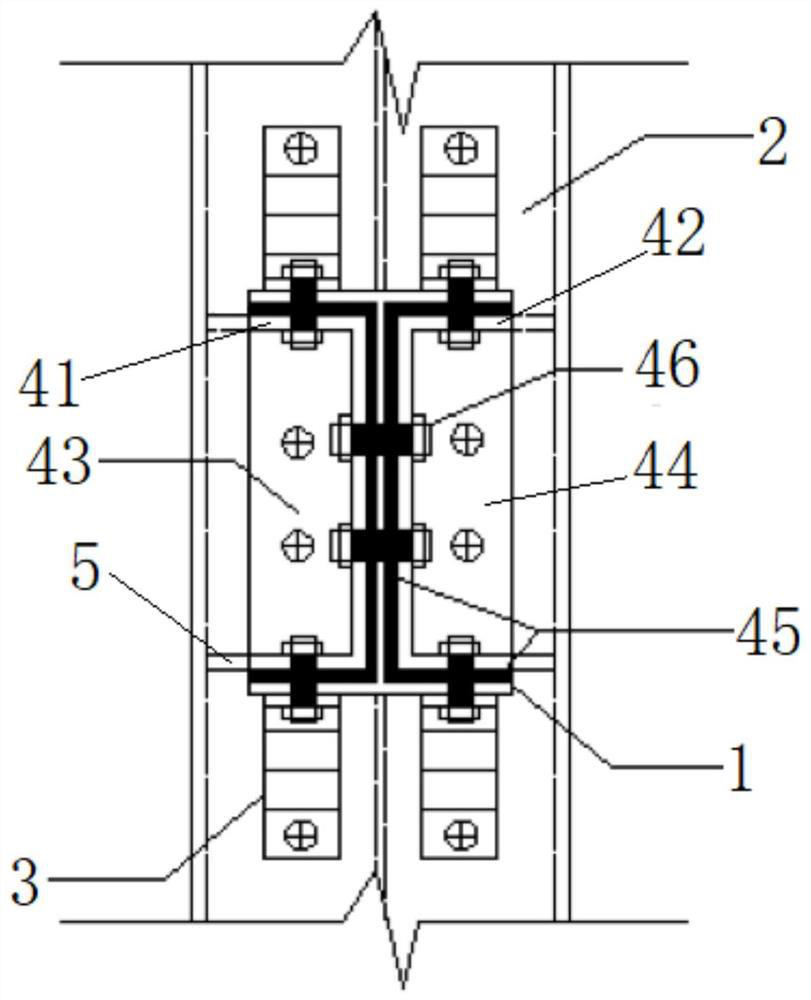

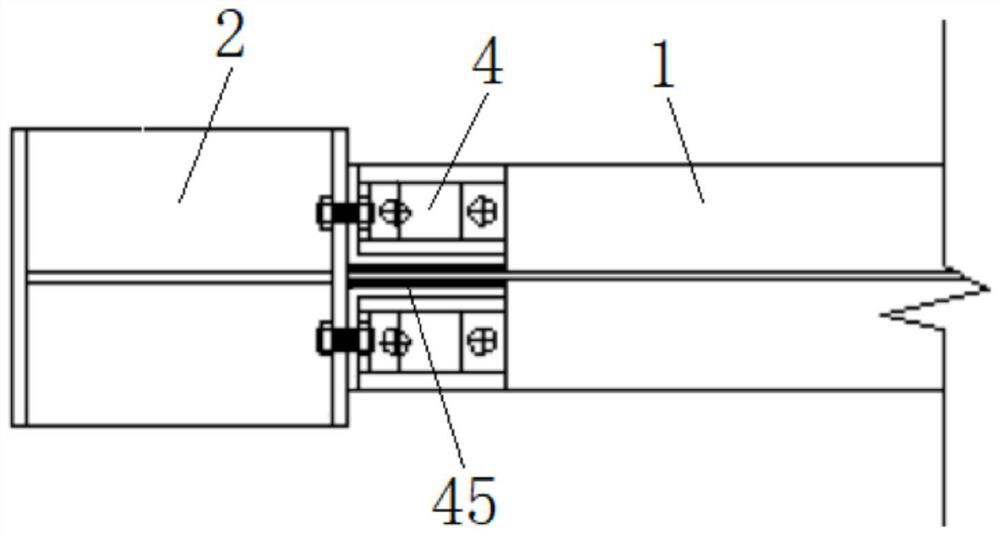

Non-destructive reinforcement device for angle steels of communication iron tower, and construction method thereof

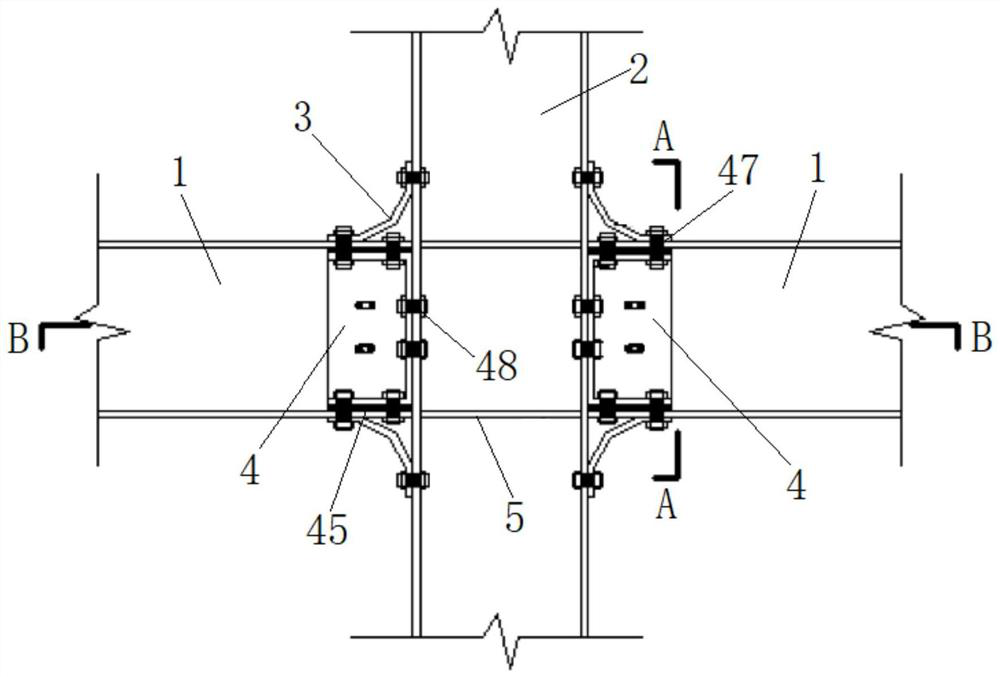

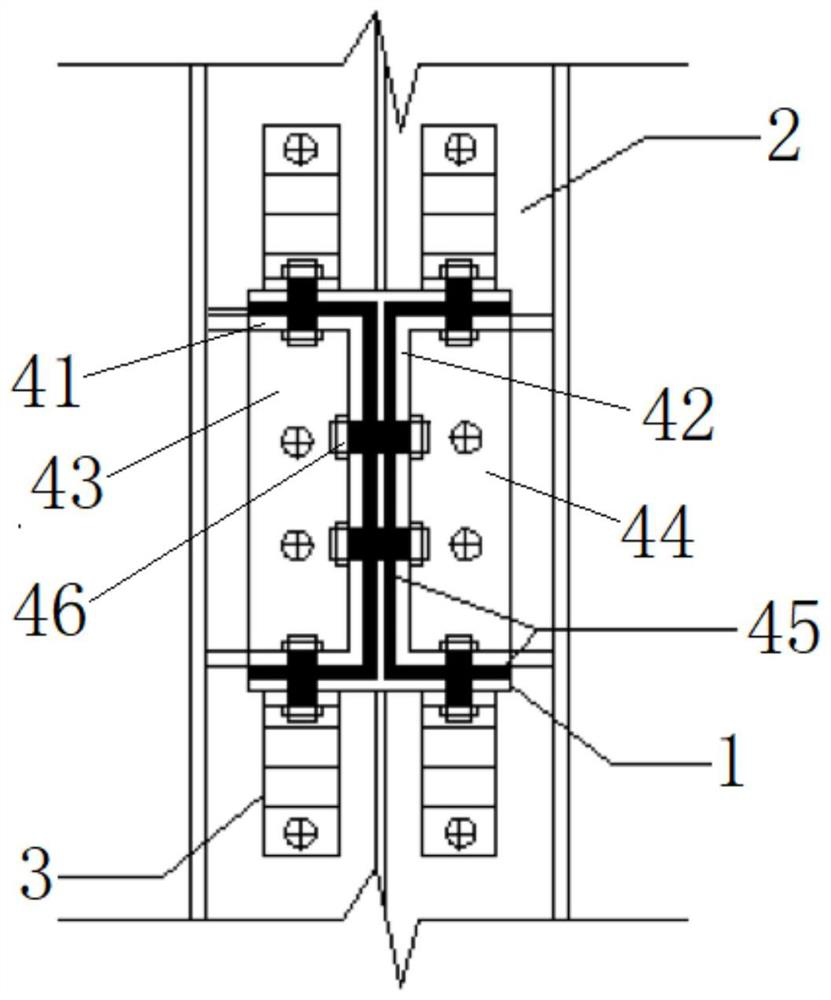

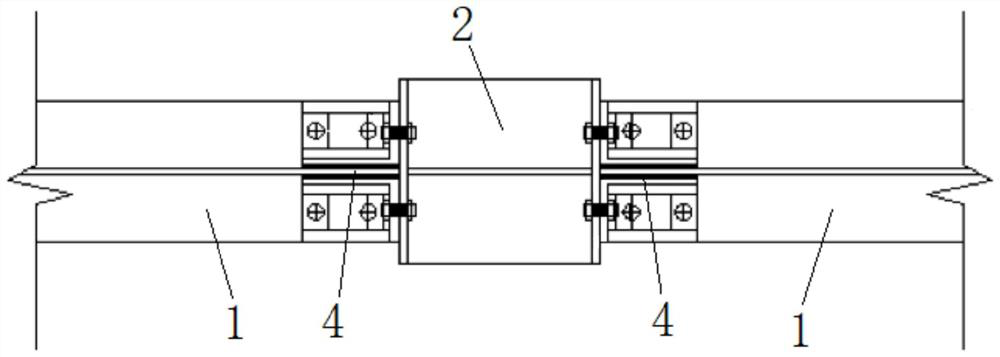

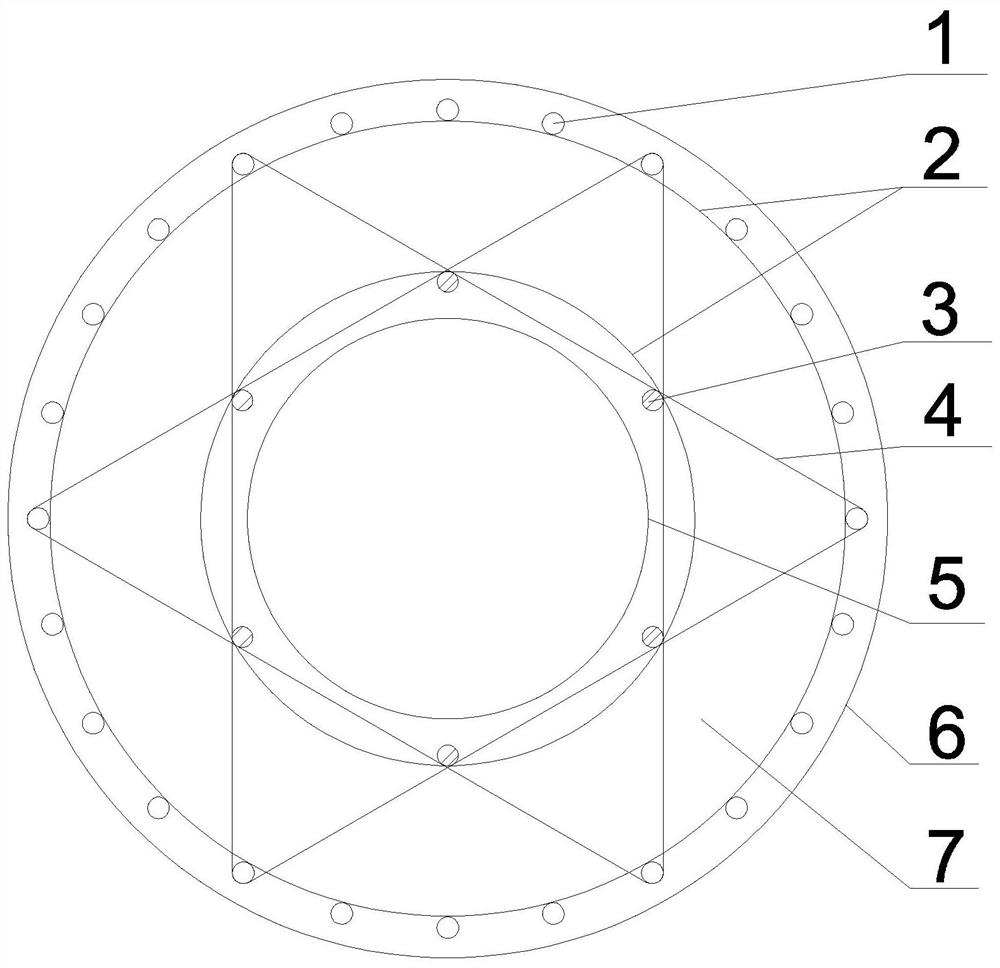

InactiveCN109577733AImprove ultimate carrying capacitySimple structureBuilding repairsTowersStructure of the EarthFlat panel

The invention provides a non-destructive reinforcement device for angle steels of a communication iron tower, and a construction method thereof. The communication iron tower comprises a plurality of tower segments, each tower segment comprises a plurality of reinforcement units, and each reinforcement unit comprises an angle steel, a plate member and a plurality of hoop members; the plate membersare arranged along the inner length direction of the angle steels; the hoop members are symmetrically arranged on the outer sides of the angle steels, clamp the plate members, and are mutually connected through bolts. According to the requirements on suspension devices of communication iron towers, gusset plates and the hoop members are connected through bolts, and to-be-suspended devices are connected to the gusset plates through bolts; or one ends of double angles are screwed to the gusset plates, arc-shaped plates are fixed at the other ends of the double angles, and arc-shaped members arescrewed to the arc-shaped plates. The non-destructive reinforcement device and the construction method thereof have the advantages that the plate members and the hoop members are fixedly connected through high-strength bolts without damaging the angle steels of the communication iron tower, and accordingly, the ultimate bearing capacity of the angle steels is improved; the non-destructive reinforcement device is simple in structure, high in stability, low in cost and easy to operate.

Owner:TONGJI UNIV

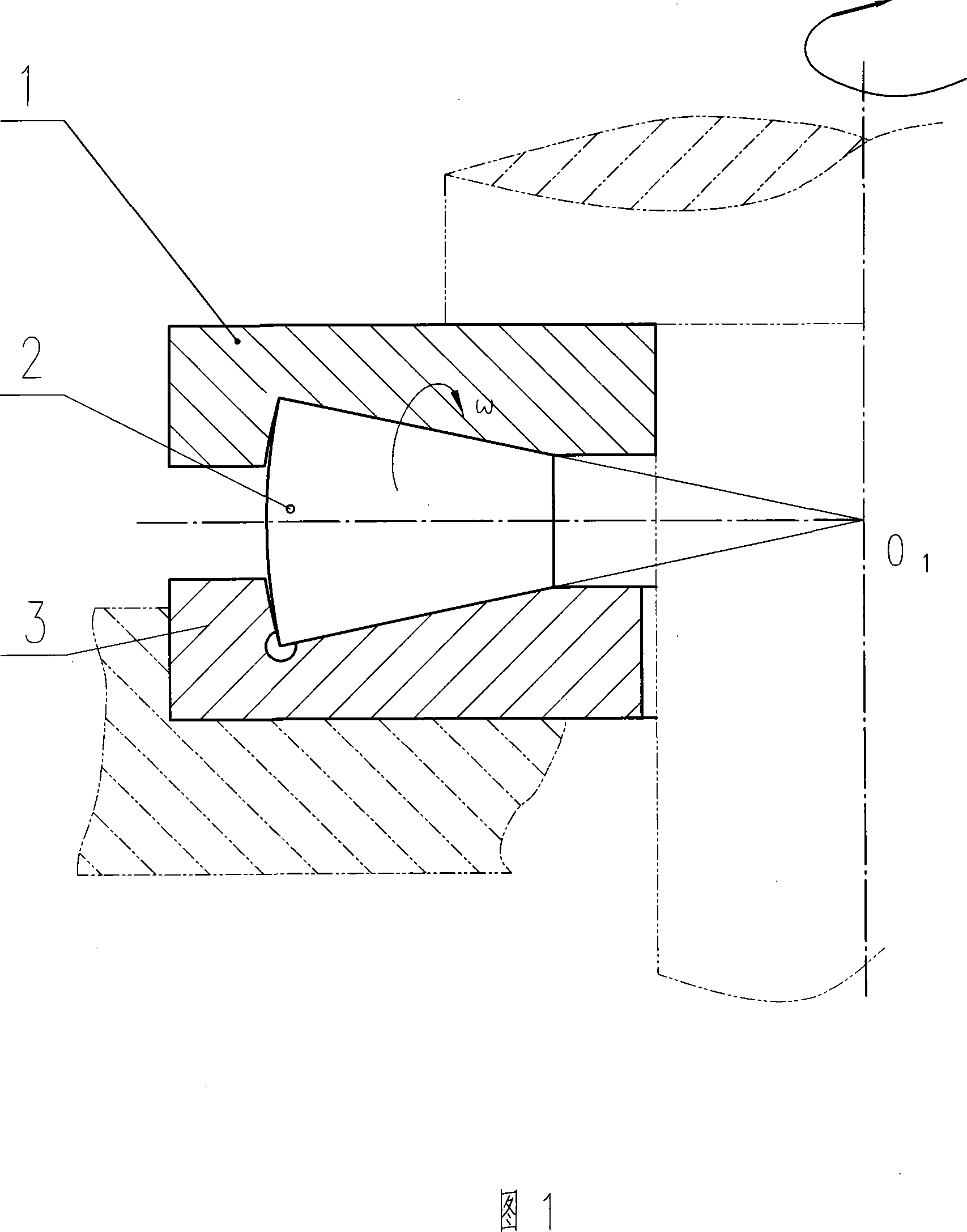

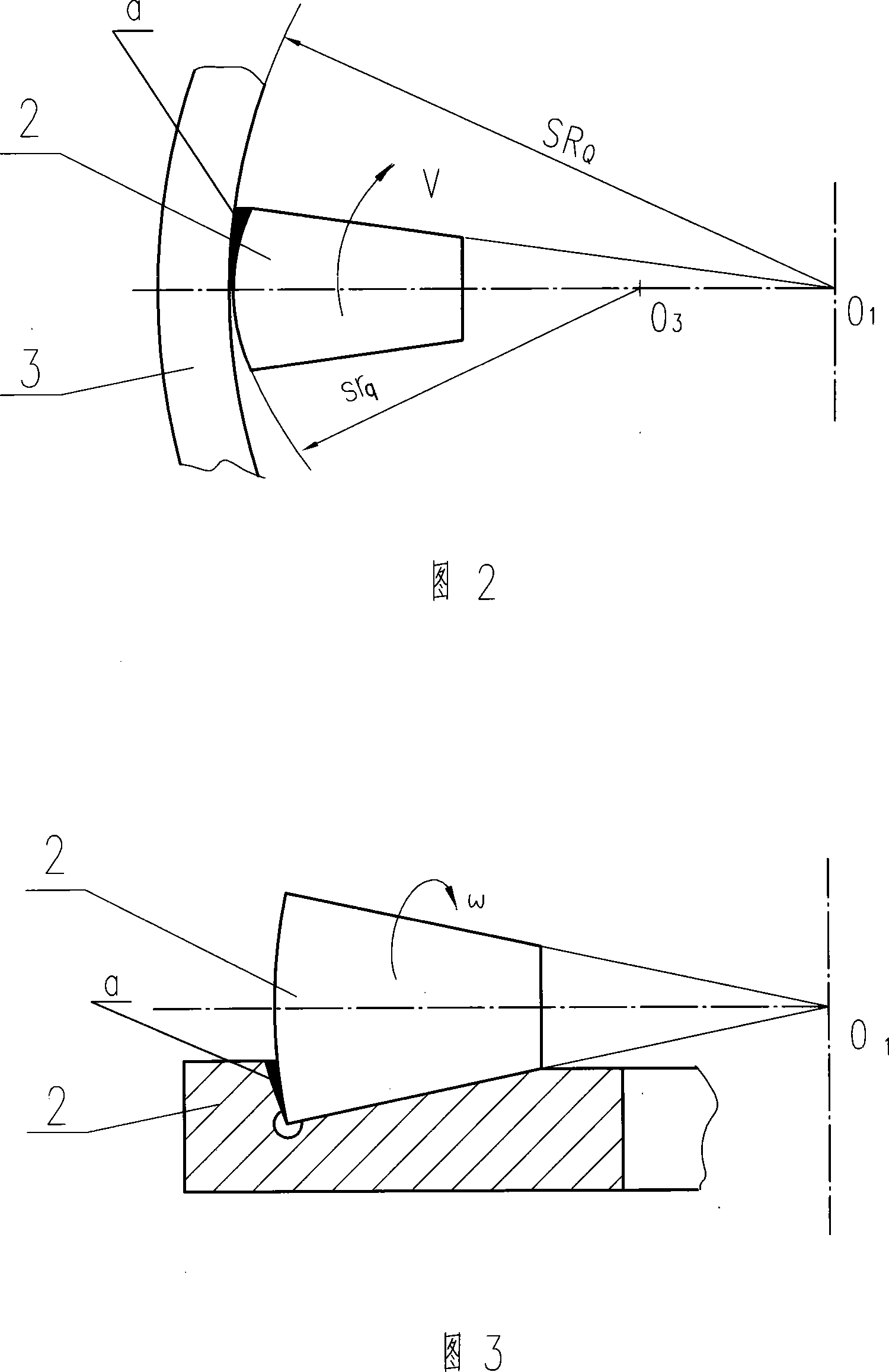

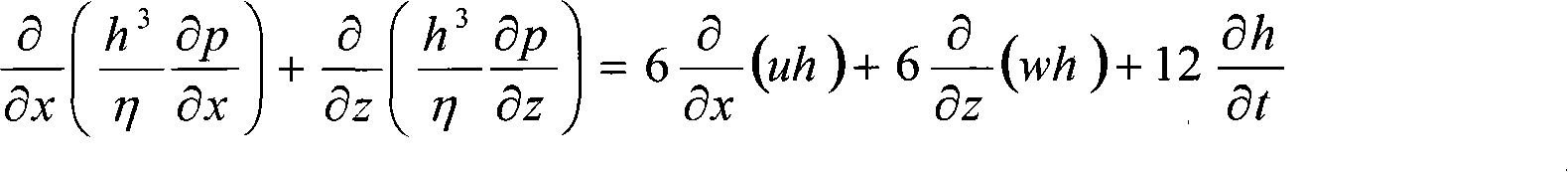

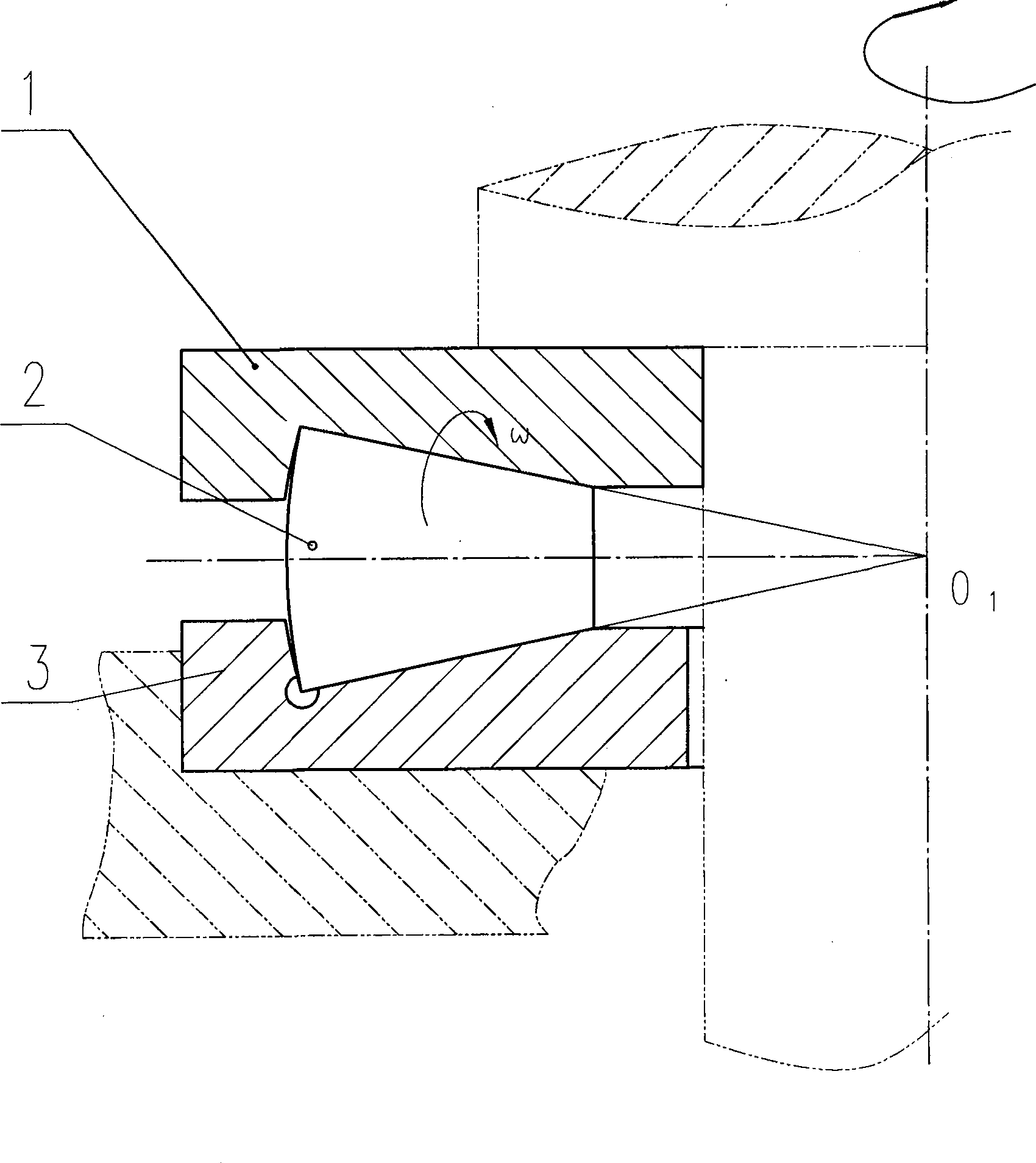

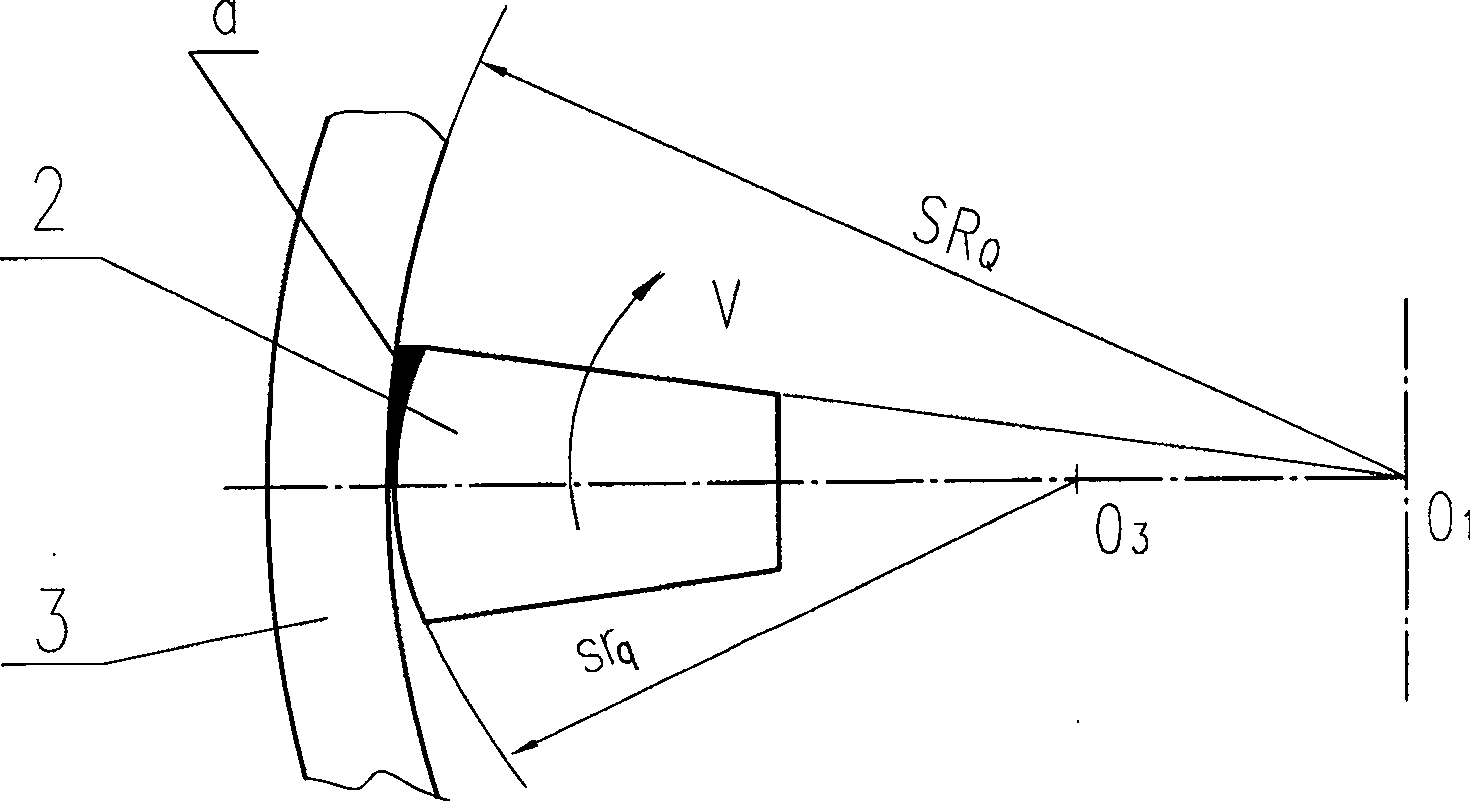

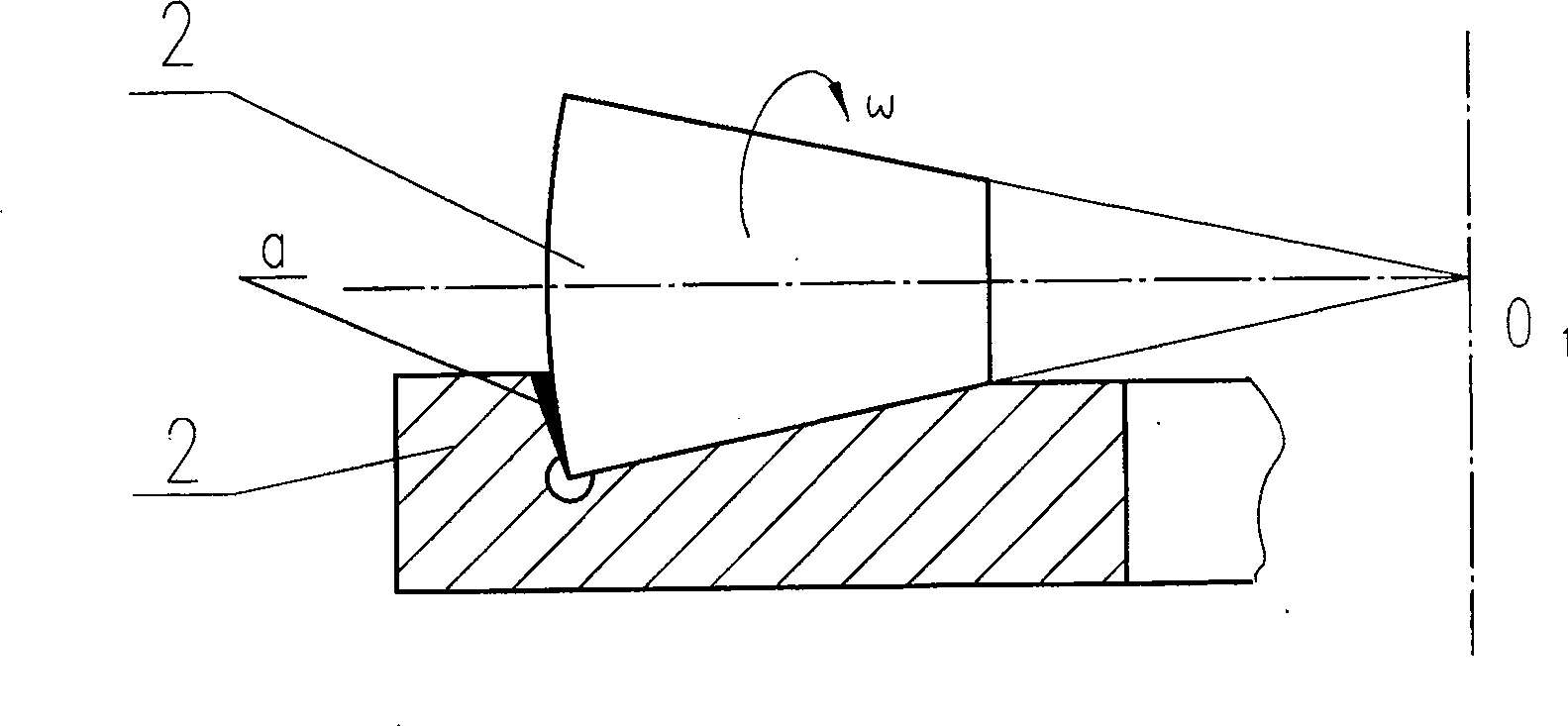

Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

InactiveCN101092992AImprove performanceRich design methodBearing componentsRolling-element bearingThrust bearing

This invention discloses a film lubrication method for thrust bearing roller cone races and ribs, which forms a wedge clearance between the large end surface of a roller and inside wall of a ring rib and fills it with lubrication oil, when the shape, size of the clearance and axial load, glide speed and viscosity of the oil are matched to each other, a dynamic pressure film is formed between the two surfaces, in which the wedge clearance is formed by cone roller spherical large end surface and the ring rib spherical ring, so it's easy to form a dynamic pressure film by selecting race SRQ of the inner surface of the race and axis ring and srq of the cone large end surface reasonably.

Owner:郭溪泉

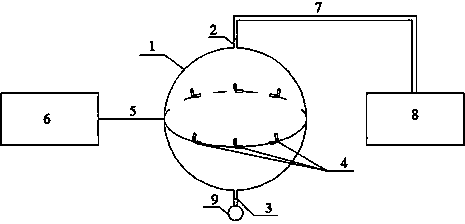

Technological method for enhancing bearing capacity of pressure-resistant structure

The invention relates to the technical field of maritime work and oil production equipment, in particular to a technological method for enhancing bearing capacity of a pressure-resistant structure. The technical scheme comprises the steps as follows: a spherical shell is prepared; drill holes are connected, and a strain gauge is glued, so that the spherical shell is connected with a booster pump and a data collection system; pressurization is performed step by step, pressure maintaining is performed; the strain change rate of each observing point is smaller than 0.01s<-1> after each observing point is in a full-plastic state, and the spherical shell automatically performs sphere hastening; pressurization is continuously performed step by step until strain of each point reaches above 0.02, then the pressurization is stopped, and the pressure maintaining is performed; and orientational and uniformly-distributed residual stress is formed after the unloading treatment is performed step by step. According to the technological method for enhancing the bearing capacity of the pressure-resistant structure, the bearing capacity is further improved, the influence of various initial defects is reduced, and then the technological difficulty is reduced; and the bearing limit is improved through stress treatment, so that the bearing capacity can be improved on the premise that the structure weight is not increased, the buoyancy reservation of a marine structure can be greatly increased, and the method has the outstanding significance to a deep submersible vehicle.

Owner:QINGDAO SCAN EQUIP TECH CO LTD

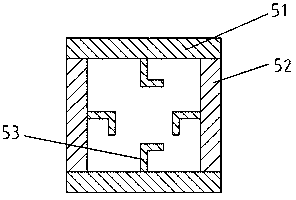

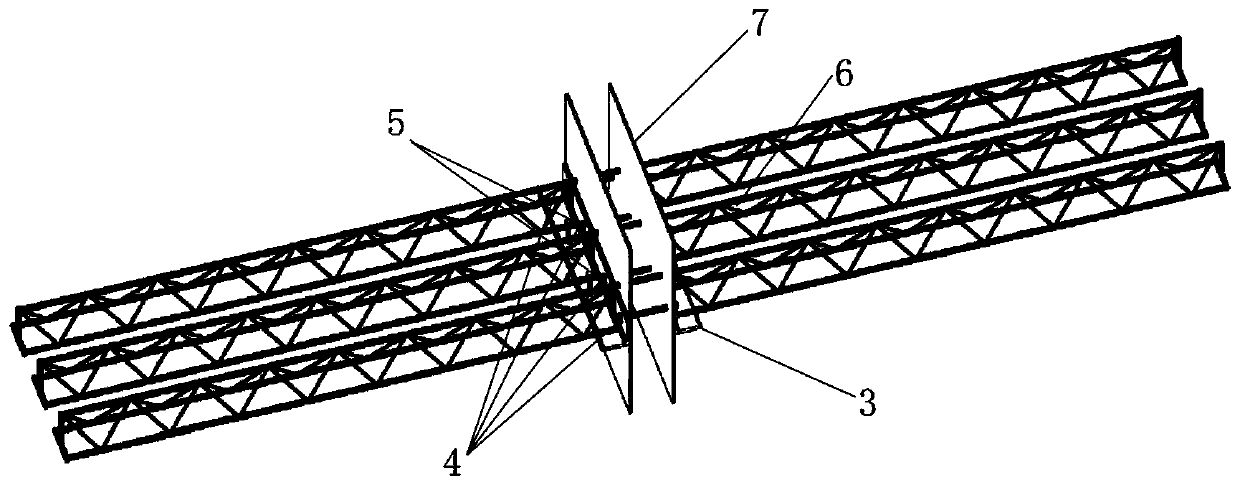

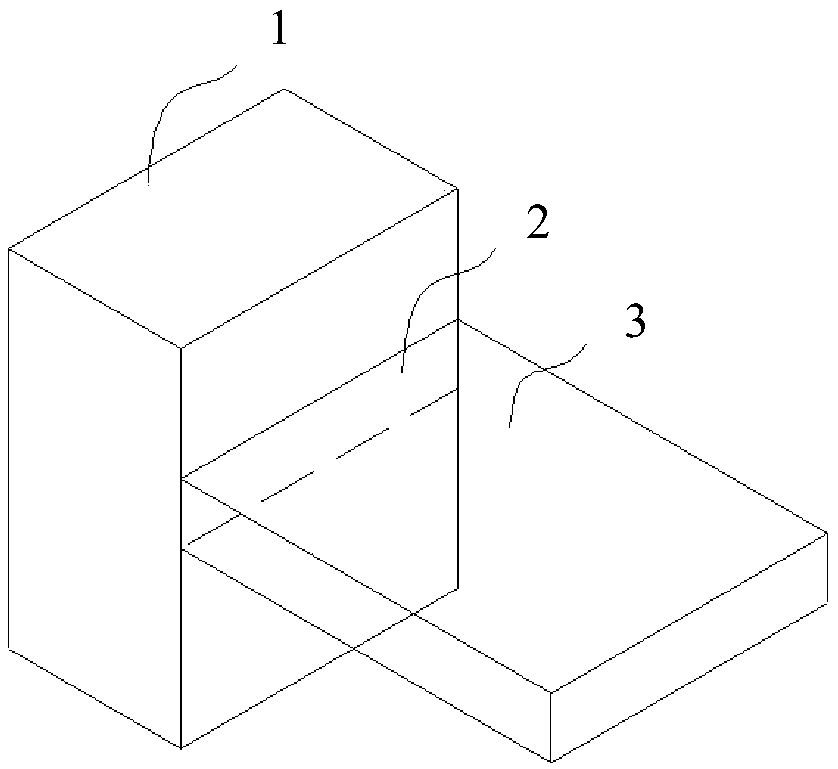

Connection joint of double-steel-plate combined shear wall and combined floor slab connected by supporting angle steel

The invention discloses a connection joint of a double-steel-plate combined shear wall and a combined floor slab connected by supporting angle steel. The connection joint comprises a double-steel-plate combined shear wall, a combined floor slab and supporting angle steel arranged on both sides of the double-steel-plate combined shear wall, wherein one flange of the supporting angle steel is fixedly connected to the double-steel-plate combined shear wall and extends into the combined floor slab to be a fixing flange, and the other flange of the supporting angle steel is cantilevered and positioned at the bottom of the combined floor slab to be a cantilevered flange; upper reinforcing bars of the combined floor slab is continuous at the double-steel-plate combined shear wall and penetrate through the two steel plates; and lower steel bars or a bottom thin steel plate or a profiled steel plate of the combined floor slab is interrupted at the double-steel-plate combined shear wall and is respectively fixedly connected to the inner surfaces of the cantilevered flange of the supporting angle steel positioned on two sides of the wall. The combined floor slab is connected by the supportingangle steel, so that the performance of the double-steel-plate combined shear wall is complete, and joint domains are stressed together; and the structure is simple, the force transmission path is clear, and the assembly trend is met.

Owner:TIANJIN UNIV

Self-resetting steel frame beam-side column joint and construction method thereof

PendingCN112177174ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingClassical mechanicsShape-memory alloy

The invention provides a self-resetting steel frame beam-side column joint and a construction method thereof. The self-resetting steel frame beam-side column joint comprises a steel beam, wherein thesteel beam is horizontally arranged on one side of a steel column; a shape memory alloy plate is arranged between a flange of the steel beam and a flange of the steel column, and the shape memory alloy plate is arranged on the outer side of the flange of the steel beam; one end of the shape memory alloy plate is connected with the flange of the steel beam, and the other end of the shape memory alloy plate is connected with the flange of the steel column; and friction energy dissipaters are symmetrically arranged on the two sides of a web of the steel beam, one end of each friction energy dissipater is connected with the steel beam, and the other end of each friction energy dissipater is connected with the flange of the steel column. According to the self-resetting steel frame beam-side column joint and the construction method thereof, the shape memory alloy plate is arranged, and the self-resetting function of the joint is achieved by utilizing the plastic deformation of the shape memory alloy plate; and friction energy dissipation can be achieved between the friction energy dissipaters and the flange and the web of the steel beam, and the friction energy dissipaters and the shapememory alloy plate generate a synergistic effect to jointly absorb seismic energy at the joint, so that the structural ductility and energy dissipation capacity of the steel frame beam-side column joint are effectively improved, and the post-earthquake repair cost of the structure is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

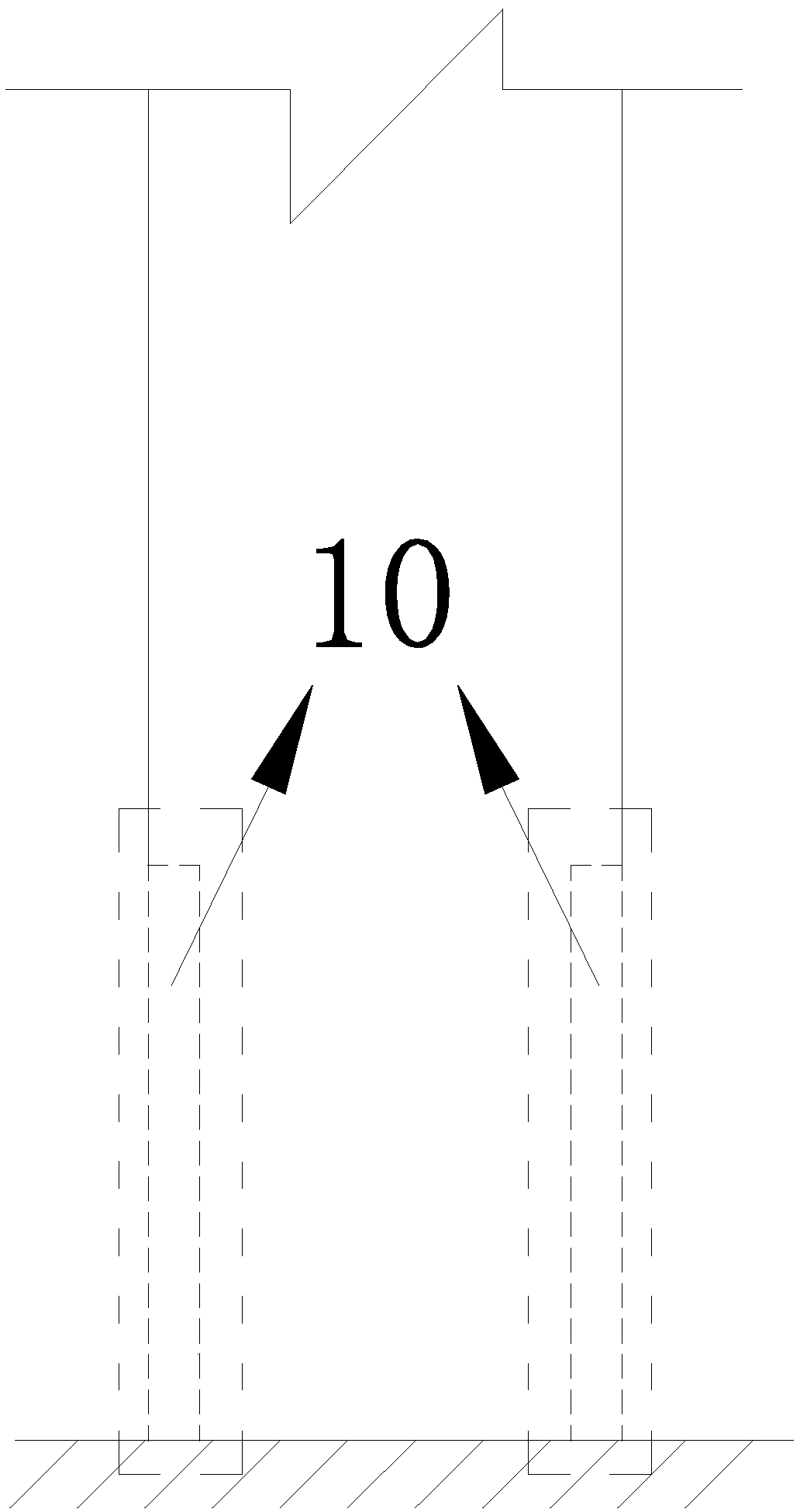

Energy dissipating mechanism for wall

PendingCN109138202AThe effect of good damping energy dissipationImprove ultimate carrying capacityProtective buildings/sheltersShock proofingShock resistanceMechanical engineering

The invention relates to an energy dissipating mechanism for a wall, and belongs to the technical field of building shock resistance. The energy dissipating mechanism comprises a bearing block fixed to an upper beam, a bracket fixed to a lower beam, a swinging bar, a first connecting shaft, a second connecting shaft, a sliding block, and two viscous dampers distributed in an eight-shaped mode. Theupper ends of the two viscous dampers are all rotatably installed together with the swinging bar, the lower ends of the two viscous dampers are all rotatably installed together with the lower beam, and the two viscous dampers are arranged on the two sides of the swinging bar correspondingly. The swinging bar is rotatably installed on the bracket through the first connecting shaft, a sliding groove is formed in the swinging bar, the sliding block is slidably arranged in the sliding groove of the swing bar, the first connecting shaft vertically penetrates through the swinging bar, the second connecting shaft vertically penetrates through the sliding block, and the second connecting shaft is rotatably installed together with the bearing block. The energy dissipating mechanism has a good shock resistant effect.

Owner:GUANGZHOU UNIVERSITY

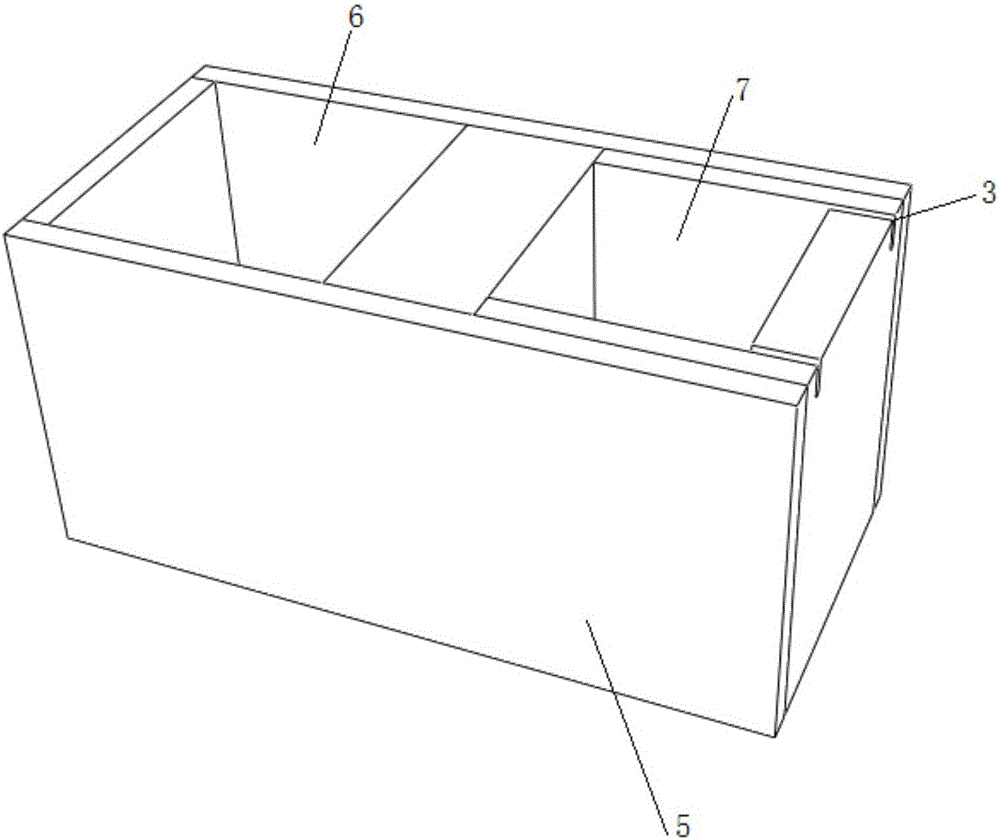

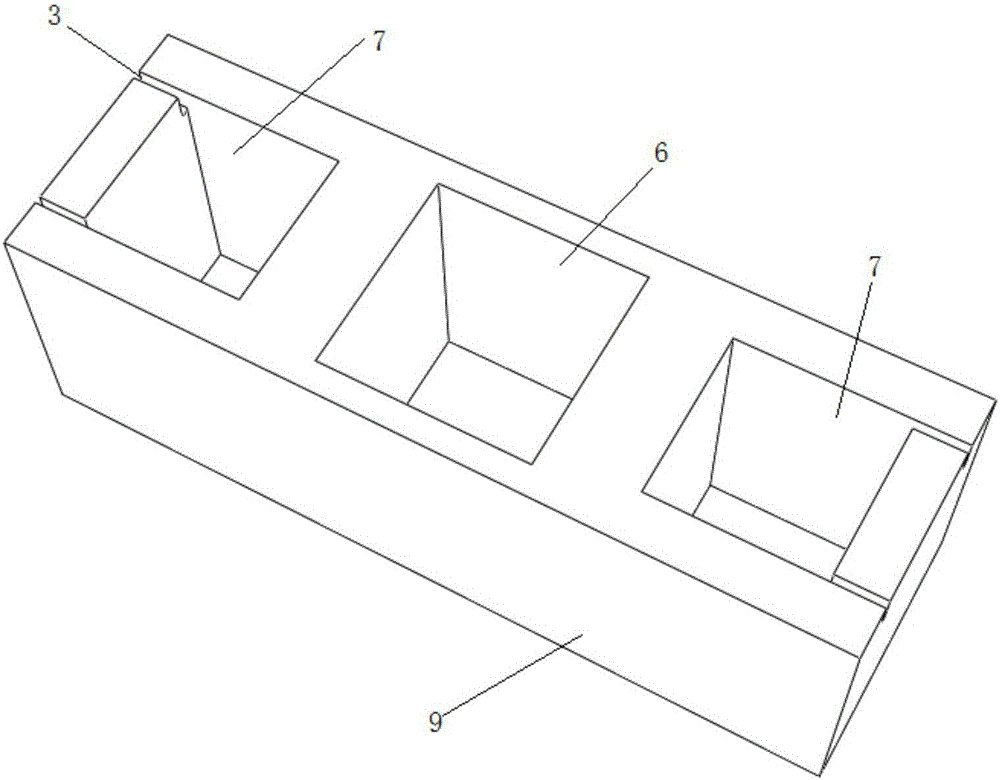

Combined building block and construction method for forming wall body with combined building block

InactiveCN106049742ALow costSimple constructionWallsBuilding material handlingStructural propertyFortification

The invention discloses a combined building block and a construction method for forming a wall body with the combined building block. The reinforced block masonry disclosed by the invention is of a structure which is high in earthquake fortification level, small in construction difficulty, good in overall property, excellent in structural property and low in manufacturing cost, is capable of relatively well solving the problems of buildings in villages and towns, has good characteristics of an assembled structure, and has relatively good application and popularization prospects.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Self-resetting steel frame beam-middle column joint and construction method thereof

PendingCN112144672ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingShape-memory alloyEngineering

The invention provides a self-resetting steel frame beam-middle column joint and a construction method thereof. The self-resetting steel frame beam-middle column joint comprises two steel beams; the two steel beams are horizontally arranged on two sides of a middle column; a shape memory alloy bent steel plate is arranged between the flange of each of the steel beams and the flange of the middle column; the shape memory alloy bent steel plates are arranged on the outer sides of the flanges of the steel beams; one ends of the shape memory alloy bent steel plates are connected with the flanges of the steel beam, and the other ends are connected with the flange of the middle column; friction energy dissipaters are symmetrically arranged on two sides of webs of the steel beams; and one ends ofthe friction energy dissipaters are connected with the steel beams, and the other ends are connected with the flange of the middle column. The self-resetting function of the joint is achieved throughplastic deformation of the shape memory alloy bent steel plates; and friction energy dissipation can be achieved between the friction energy dissipaters and the flanges and webs of the steel beams, the friction energy dissipaters and the shape memory alloy bent steel plates generate a synergistic effect to jointly absorb earthquake energy at the joint, the structural ductility and energy dissipation capacity of the steel frame beam-middle column joint are effectively improved, and the post-earthquake repair cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

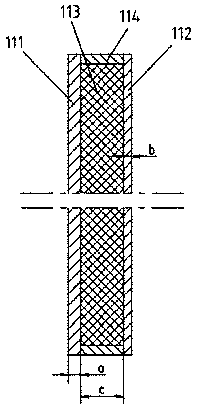

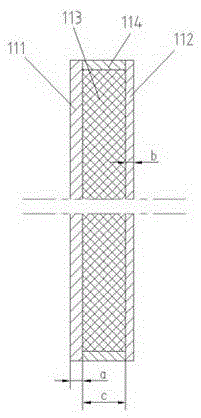

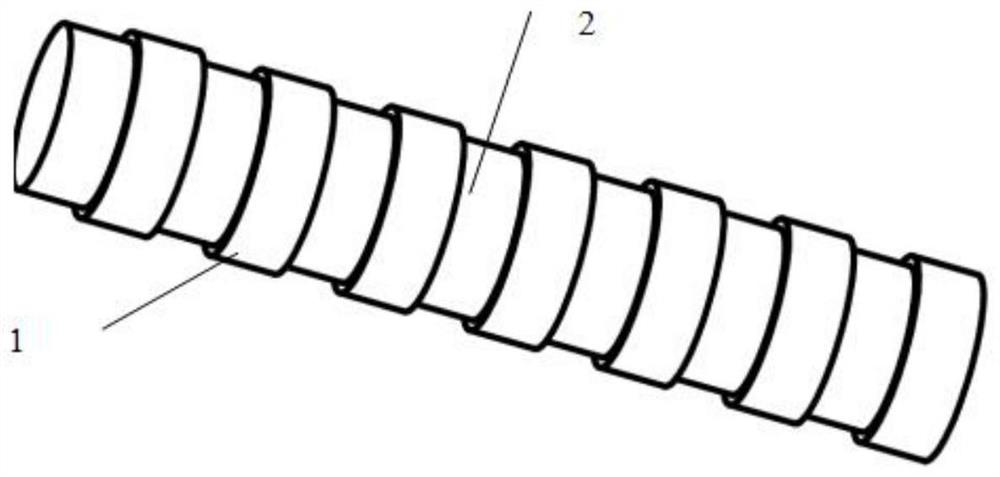

Large-diameter PHC tubular pile with double-layer reinforcement cage and preparation method thereof

PendingCN113026726ASlow yieldImprove ultimate carrying capacityShaping reinforcementsBulkheads/pilesEarthquake resistancePre stress

The invention discloses a large-diameter PHC tubular pile of a double-layer reinforcement cage and a preparation method thereof, and relates to the technical field of PHC tubular piles. According to the large-diameter PHC tubular pile, the PHC tubular pile is optimized in the mode that ordinary steel bars and prestressed steel bars are combined and configured, a plurality of ordinary steel bars are arranged in a high-strength concrete pile body and are close to the outer side wall, a plurality of prestressed steel bars are arranged in the high-strength concrete pile body and are close to the inner side wall, the steel bars which are enclosed into a triangle are welded to the prestressed steel bars in the corresponding positions, and the angular points of the triangular steel bars are bound and connected with the ordinary steel bars in the corresponding positions. In the mode, on one hand, the maximum bending resistance and shearing resistance of the pile body are increased, and on the other hand, the pile body has certain energy dissipation capacity, namely certain ductility performance, so that under the action of horizontal cyclic loads, the pile body can have enough deformation to consume more energy, and brittle failure is avoided. The large-diameter PHC tubular pile has the characteristics of convenience in manufacturing, economy, reliability and high practicability, and the anti-seismic performance of the high-strength prestressed tubular pile is improved.

Owner:HARBIN INST OF TECH

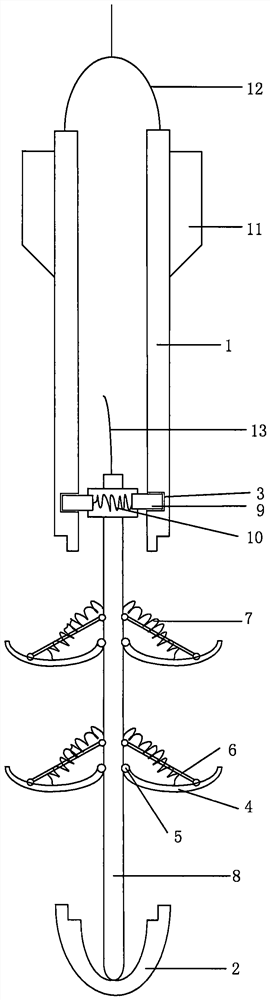

Device and method for reversely pulling and shelling lengthening type torpedo anchor

ActiveCN114435538AIncrease the lengthImprove pullout resistanceClimate change adaptationAnchorsMaterial consumptionStructural engineering

The invention provides a device and a method for reversely pulling a shelling lengthening type torpedo anchor. The device comprises an anchor body, an anchor head, a clamping groove, an arc-shaped unfolding cutter, a hinge point, a pull rod, a high-pressure spring I, a middle lever, a clamping head, a high-pressure spring II, a tail wing, a working anchor chain and a temporary lifting chain. The anchor body and the middle bar are separated through reverse pulling shelling, the length of the torpedo anchor is increased to the maximum extent, the contact area between the torpedo anchor and soil is increased, and the pulling resistance of the torpedo anchor is improved. Multiple sets of arc-shaped unfolding knives can be arranged according to the length of an anchor body, inner arcs of all the arc-shaped unfolding knives face upwards after the arc-shaped unfolding knives are unfolded, the arc-shaped unfolding knives are pulled by a pull rod, the structure stability is high, the arc-shaped unfolding knives and the anchor head form an arc-shaped anti-pulling structure, the situation that unfolding fails due to insufficient unfolding is prevented, and the bearing capacity of the torpedo anchor is fully exerted; the anti-pulling capacity of the torpedo anchor is maximized, the requirements for the self weight and the size of the torpedo anchor are low, lightweight manufacturing of the torpedo anchor can be achieved, the material consumption is reduced, and the manufacturing cost, the transportation cost and the installation cost are saved.

Owner:NANJING FORESTRY UNIV

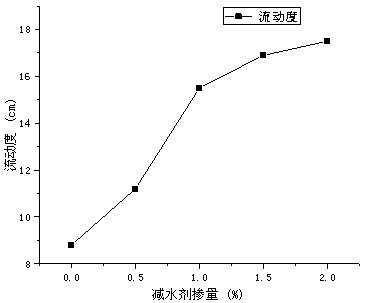

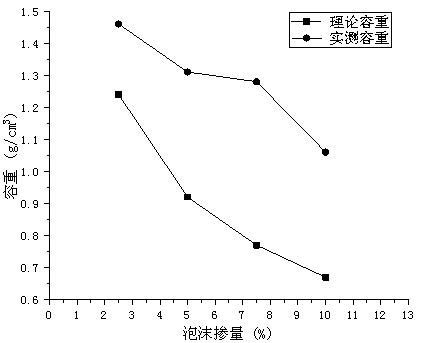

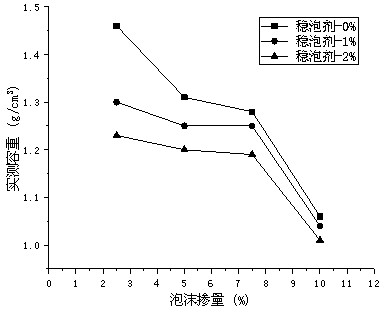

Light cement soil for deep foundation treatment and preparation method thereof

The invention discloses light cement soil for deep foundation treatment and a preparation method thereof. Foam and cement slurry are mixed in a stirring manner by using a surfactant foaming agent forfoaming treatment to introduce the foam, so that the volume weight of the cement soil is reduced. Meanwhile, due to the increase of the pores, the compactness and strength of the cement soil are reduced; by adding silicon powder and metakaolin, the cementing performance of the cement curing agent is improved, so that the strength of the light cement soil is improved; the fluidity of the light cement soil is improved by adding polycarboxylic acid; the stability of foam is improved by adding the foam stabilizer, so that the product is prevented from defoaming under pressure when being applied todeep foundation treatment, the cement soil meets the requirements of strength, volume weight and fluidity in practical engineering, and the research and development of a light cement soil material are realized.

Owner:SOUTHEAST UNIV

Construction Method of Prestressed Soil Anchor Rod with One-time High Pressure Rotary Spraying Type Expansion Head

The invention provides a one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method. The one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method comprises the step of measuring and marking of an anchor rod hole, the step of construction of a construction work platform, the step of installation of a drilling machine, the step of manufacturing and installing of a prestress anchor rod, the step of hole drilling, the step of rotary jet grouting, the step of construction of an expansion head at the anchor end, the step of installation of a purlin and an anchor bearing plate, and the step of prestress tension and construction of the anchor rod. Compared with conventional grouting prestress anchor rod construction methods, through the application practices in multiple ultra-large irregular deep foundation pit engineering, the one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method has the extremely good anchoring force and anti-pulling bearing force. By adoption of the one-time high pressure jet grouting type expansion head prestress soil anchor rod construction method, the extreme anti-pulling bearing force of the anchor rod can be greatly improved, and the manufacturing cost of the anchor rod for unit bearing force is reduced.

Owner:宏润建设集团上海有限公司

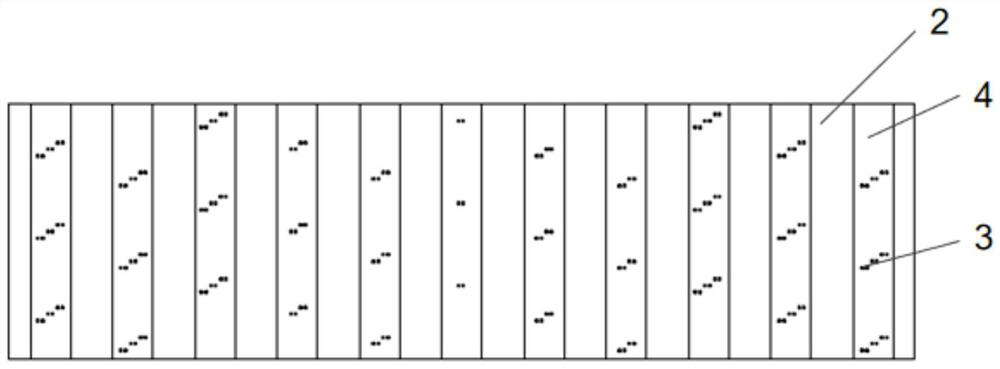

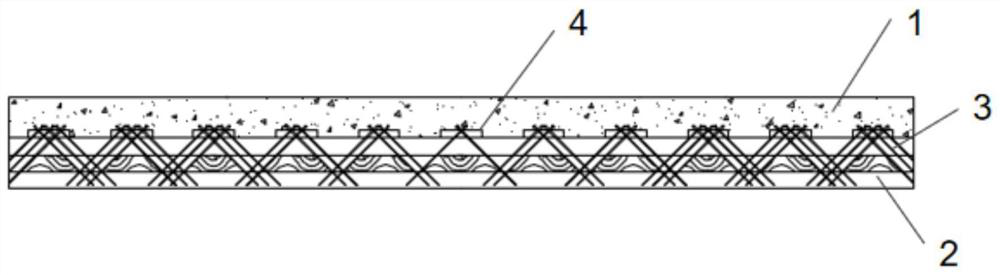

Orthogonal laminated wood-concrete composite floor and reinforcing method

InactiveCN113187139AImprove ultimate carrying capacityImproved interlaminar shear performanceFloorsBuilding repairsFloor slabInterlaminar shear

The invention discloses an orthogonal laminated wood-concrete composite floor. The orthogonal laminated wood-concrete composite floor comprises a concrete plate, a CLT plate, a plurality of pneumatic strip nails and a plurality of wood cushion blocks; the plurality of wood cushion blocks are arranged on the first surface of the CLT plate, the plurality of pneumatic strip nails penetrate through the wood cushion blocks from the upper surfaces of the wood cushion blocks and are inserted into the CLT plate, and an included angle exists between the insertion direction of the pneumatic strip nails and the vertical direction; and the concrete plate is poured on the first surface of the CLT plate, the wood cushion blocks and the pneumatic strip nails. The pneumatic strip nails are driven into the wood cushion blocks and the CLT plate so that the interlayer shearing capacity of concrete and the CLT plate can be remarkably improved, the interlayer shearing capacity of all layers of the CLT plate and the rolling shearing capacity of the CLT plate are improved, the application range of the orthogonal laminated wood-concrete composite floor is convenient to popularize and expand, and the development of a multi-story and high-rise wood structure is promoted; and meanwhile, according to the orthogonal laminated wood-concrete composite floor, the ultimate bearing capacity, the structural rigidity and the stability of the CLT-concrete composite floor can be effectively improved, and the ultimate bearing capacity of the CLT-concrete composite floor can be improved by about 60%.

Owner:SHANGHAI INST OF TECH

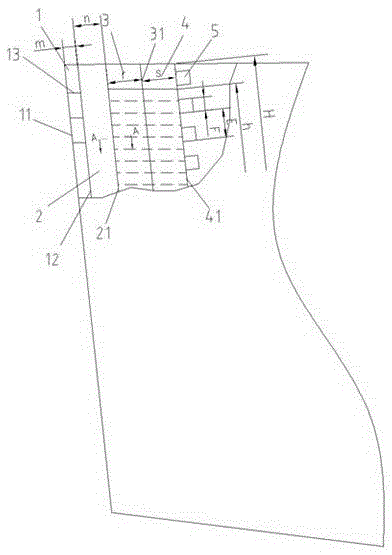

Design and construction method for improving the force transmission of interface between old and new concrete

PendingCN109518985AImprove ultimate carrying capacityIncrease mechanical bite forceBuilding repairsEngineeringRebar

The invention discloses a design and construction method for improving the force transmission of an interface between old and new concrete. The design and construction method comprises the following steps of (1) cutting a groove in a new and old concrete bonding surface of an existing concrete member; (2) chiseling the groove; (3) bundling steel bars of a new concrete member and constructing a pouring formwork, wherein the pouring formwork surrounds a groove opening of the groove; (4) smashing the new concrete member into the pouring formwork; (5) after the concrete reaches the strength, the pouring formwork is removed, that is, the new concrete member is added to the existing concrete member. According to the method, the groove is cut in the new and old concrete bonding surface of the existing concrete member and smashing the new concrete member, due to the fact that the groove is partially stressed to provide most mechanical engagement force required by the new and old concrete bonding surface, mechanical interface forces such as the mechanical engagement forces and Van der Waals' forces of the new and old concrete bonding surface can be greatly increased, control of constructionquality is facilitated, and the ultimate bearing capacity of the new and old concrete bonding surface is improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Multi-layer anti-blast protection structure on ship side

ActiveCN103991518BIncreased damage areaReduce distortionVessel cleaningHullsResidual strengthDetonation

Owner:JIANGSU UNIV OF SCI & TECH

Connection mechanism between joint and cross beam

PendingCN109113197AEasy constructionImprove plasticityProtective buildings/sheltersShock proofingEarthquake resistanceEngineering

The invention relates to a connection mechanism between a joint and a cross beam. The connection mechanism between the joint and the cross beam comprises a first connection part and a second connection part, wherein the first connection part and the second connection part are rotatably installed together. The first connection part comprises a front plate, a rear plate, a first fixed block, a firstannular plate integrally formed with the front plate and a second annular plate integrally formed with the rear plate, wherein the front plate is connected with the rear plate through the first fixedblock. The second connecting part comprises a second fixed block, a middle plate fixed to the second fixed block, a third annular plate and a fourth annular plate, wherein the third annular plate andthe fourth annular plate are integrally formed with the middle plate. The third annular plate is located in front of the fourth annular plate, the rear end face of the front plate is in contact withthe front end face of the third annular plate, the rear end face of the fourth annular plate is in contact with the front end face of the rear plate, the front plate, the rear plate and the middle plate are connected together through a rotating shaft, the first fixed block is fixed to the joint, and the second fixed block is fixed to the cross beam. The connecting mechanism has good damping and energy dissipation effects, and belongs to the technical field of earthquake resistance of houses.

Owner:GUANGZHOU UNIVERSITY

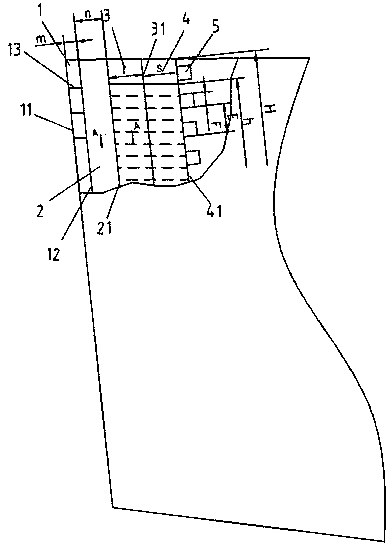

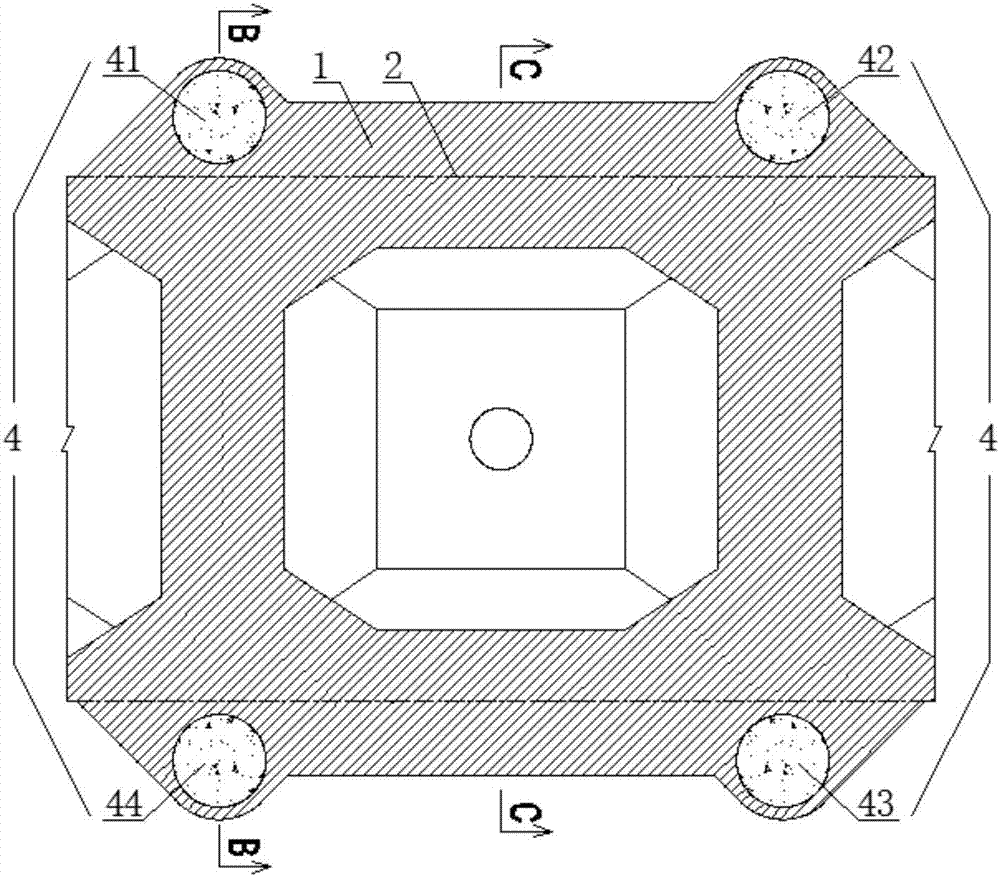

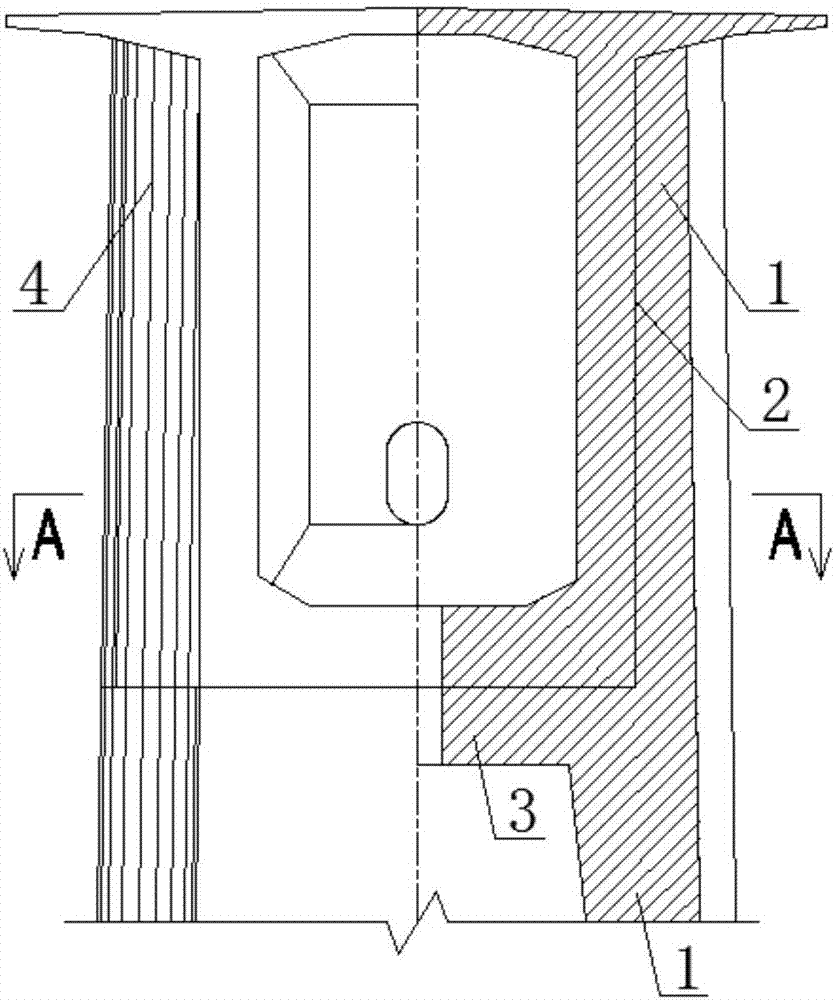

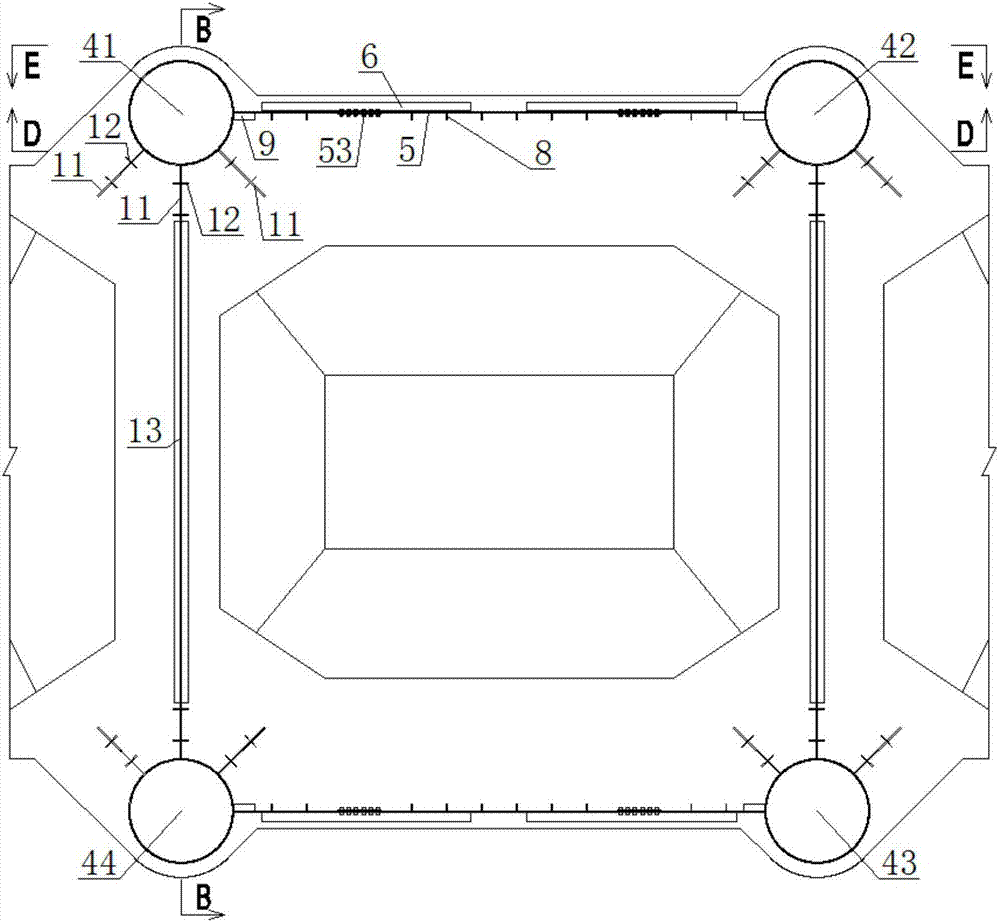

Overall pier and beam built-in connecting structure and construction method thereof

ActiveCN107254835AImprove integrityIncrease stiffnessClimate change adaptationBridge structural detailsPre stressEngineering

The invention relates to an overall pier and beam built-in connecting structure and a construction method thereof. The connecting structure comprises a main beam and concrete-filled steel tube combined pier. The built-in section of the pier and a main beam are integrally formed in an integral pouring mode, the main beam is arranged between main steel tubes of four corner points of the pier, steel frameworks are connected between the adjacent main steel tubes, and prestress steel strands are arranged between the main steel tubes and on the box walls of the steel frameworks and the main beam. Aiming at the problems that the ultimate bearing capacity of a pier and beam connecting position is lower than other positions of the structure, and the pier beam connecting position is firstly damaged under the earthquake load effect, through structure overall rigidity demonstration and system rigidity matching demonstration, the transverse size of the top face of the pier is increased, a beam body of the main beam is embedded between the main steel tubes of the pier in an overall width mode, the steel frameworks are arranged to be connected with the main steel tubes of the pier, the longitudinal and transverse prestress steel strands are tensioned, finally rebar pouring concrete is arranged, the connecting intensity of the pier and the main beam is improved, the ultimate bearing capacity of the pier and beam fixed connecting position is effectively improved, and then the pier and beam connecting position is not a weak link of a structural system any more.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE OF COMM

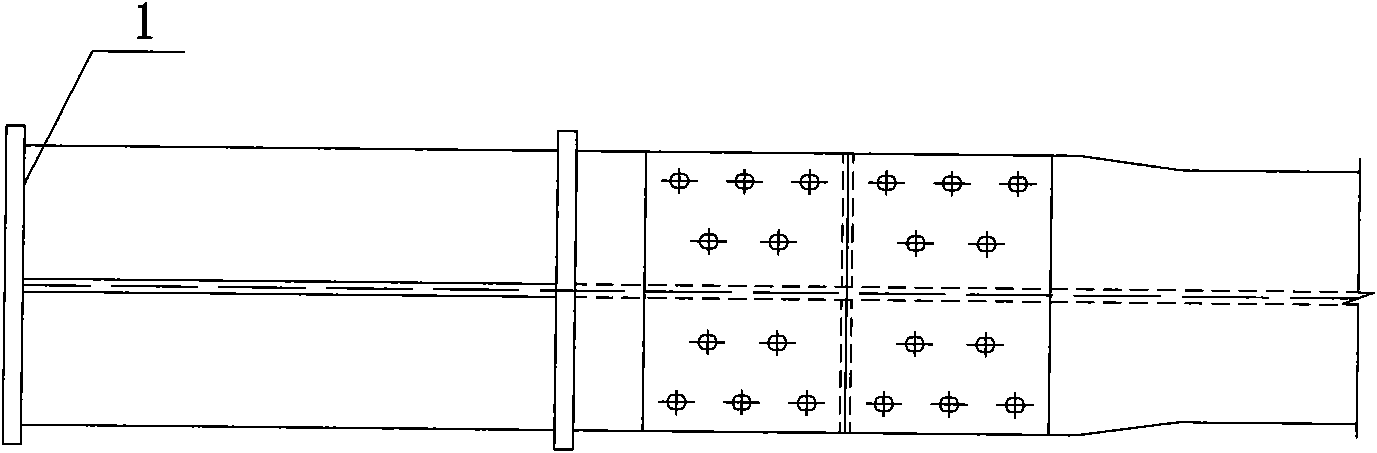

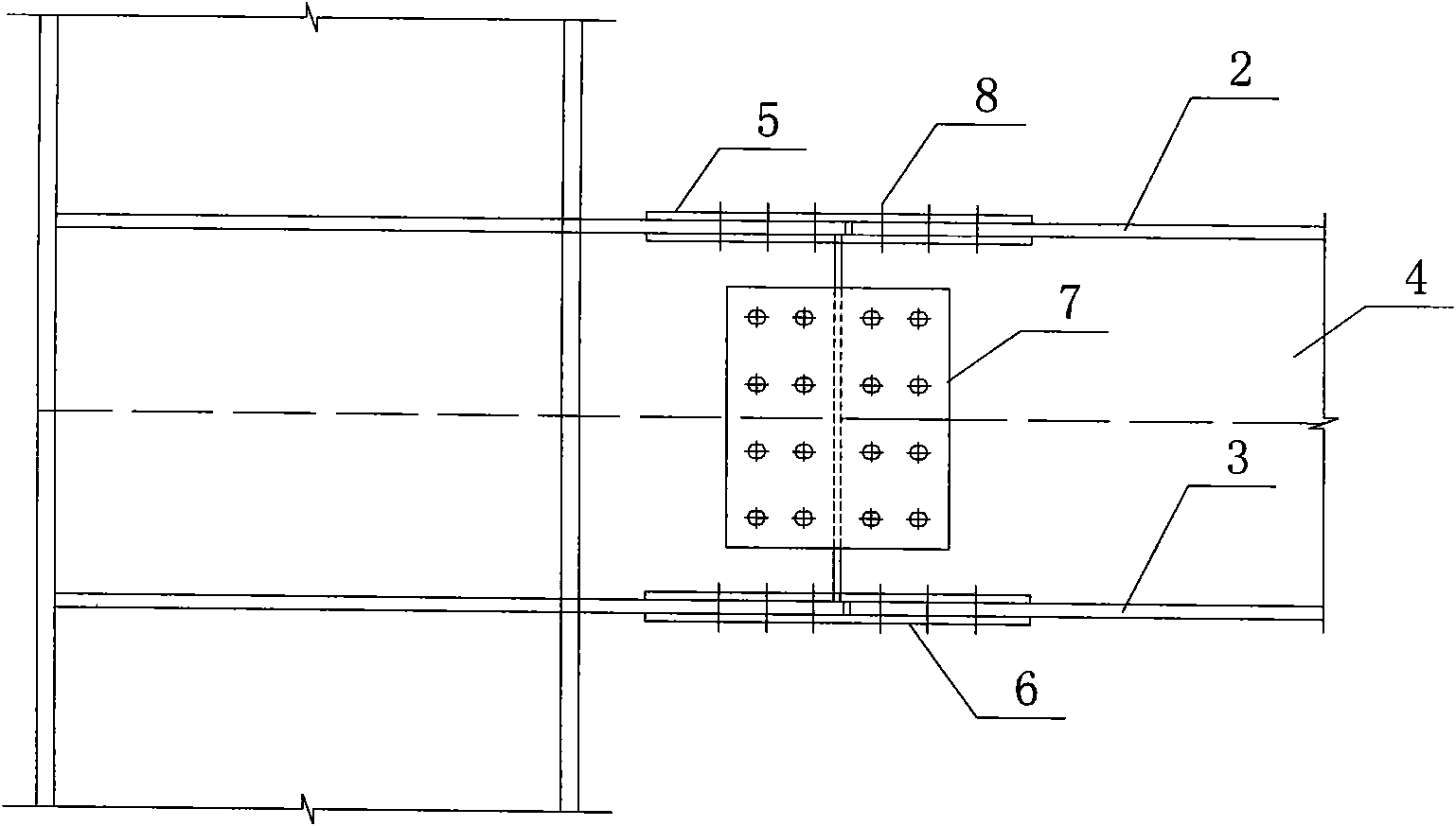

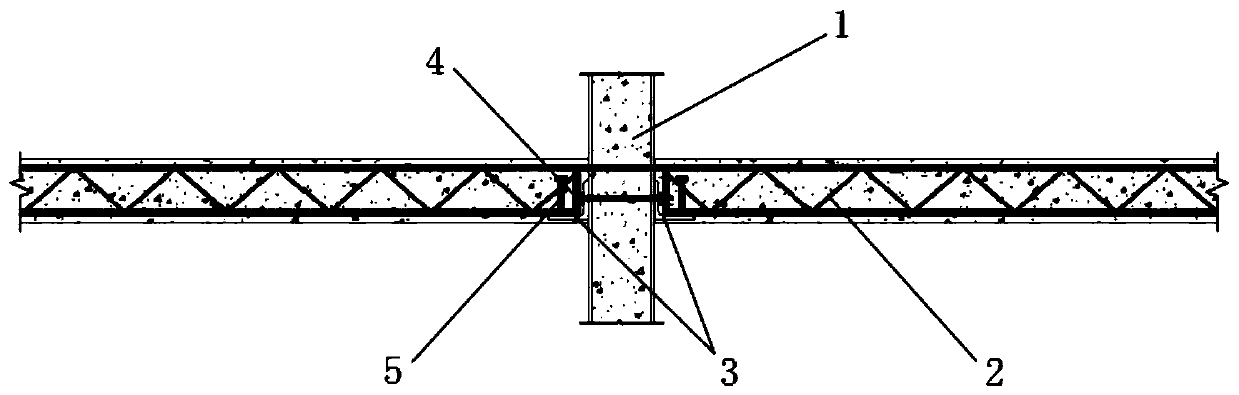

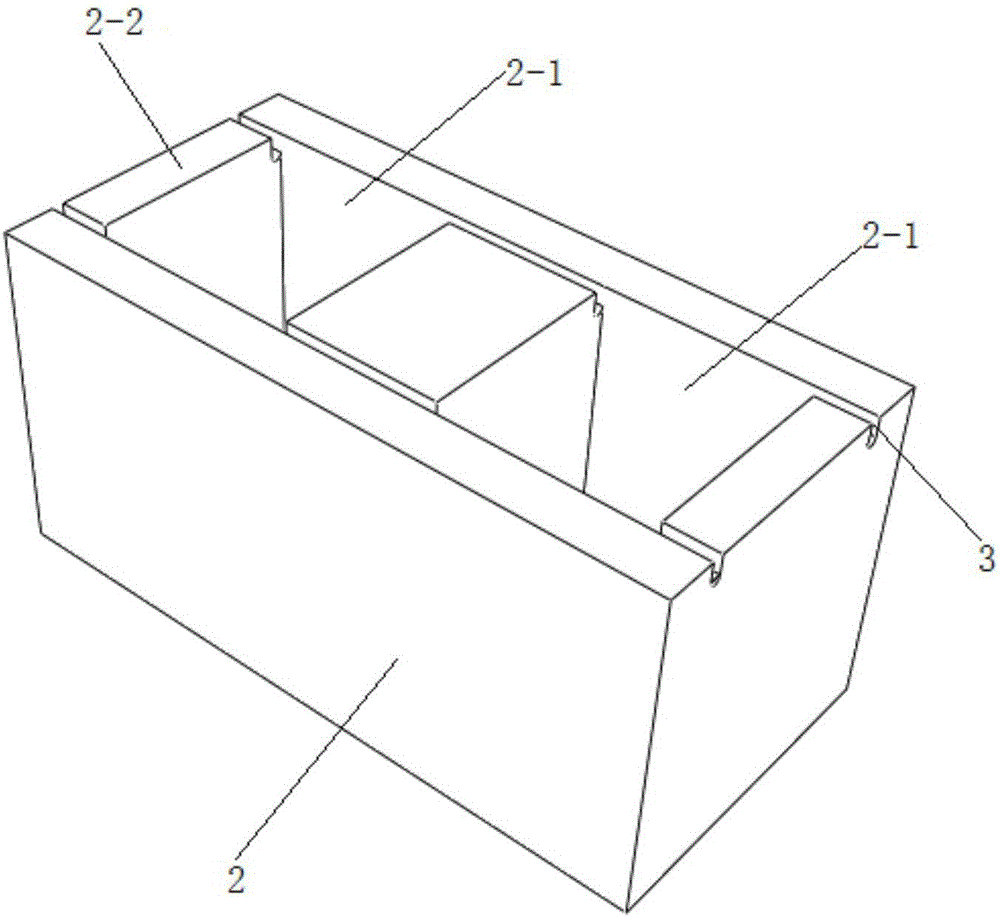

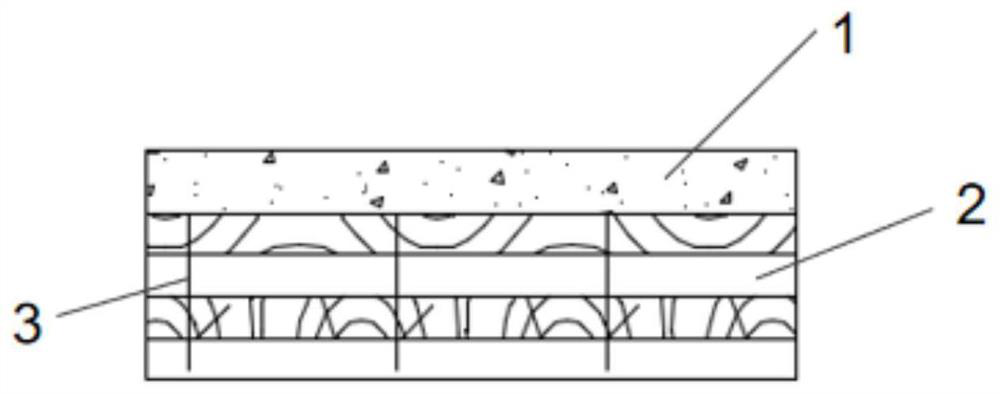

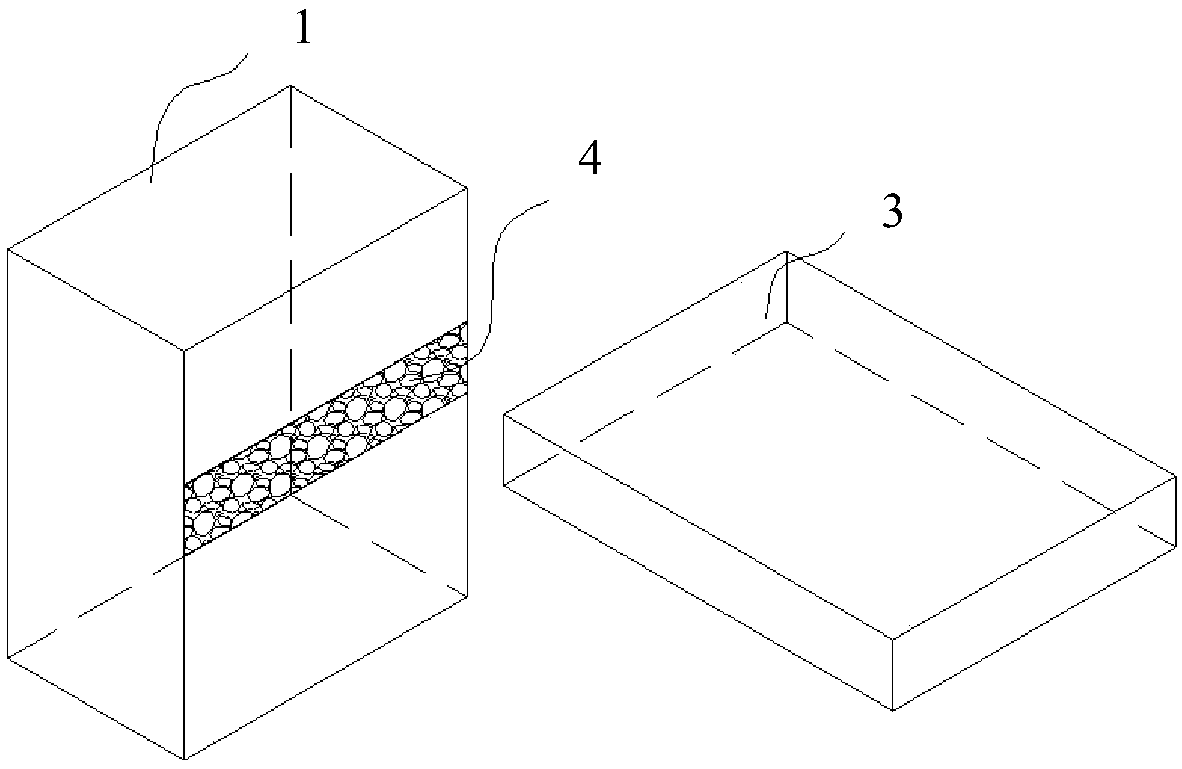

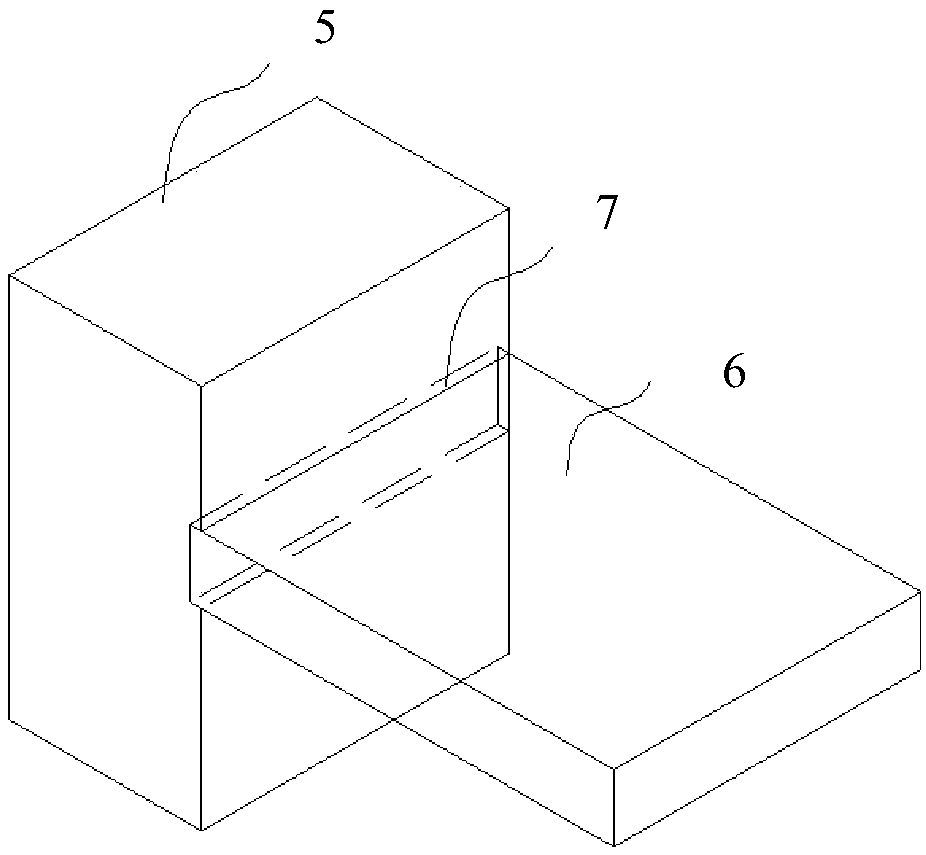

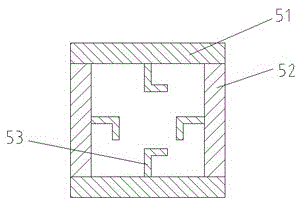

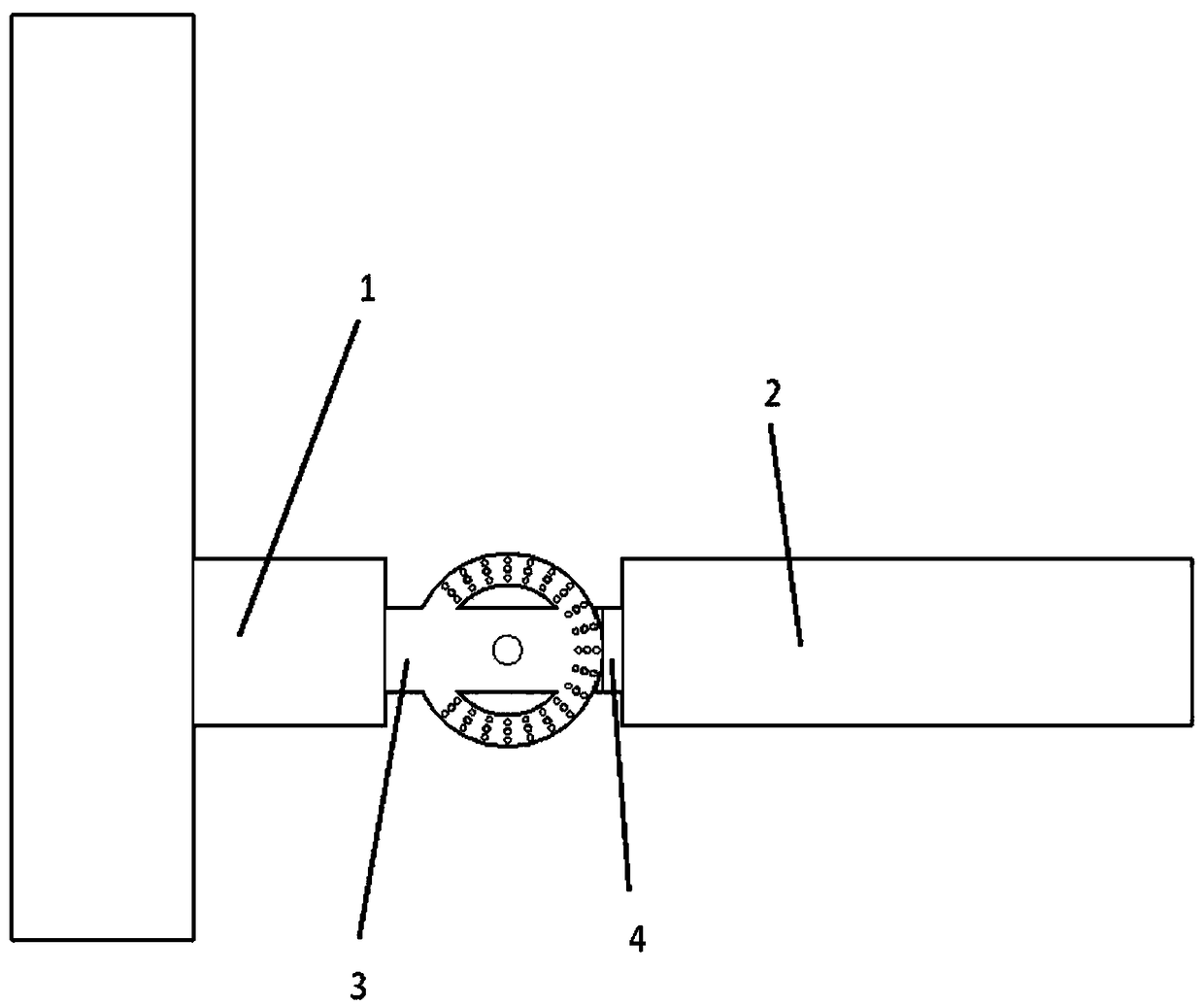

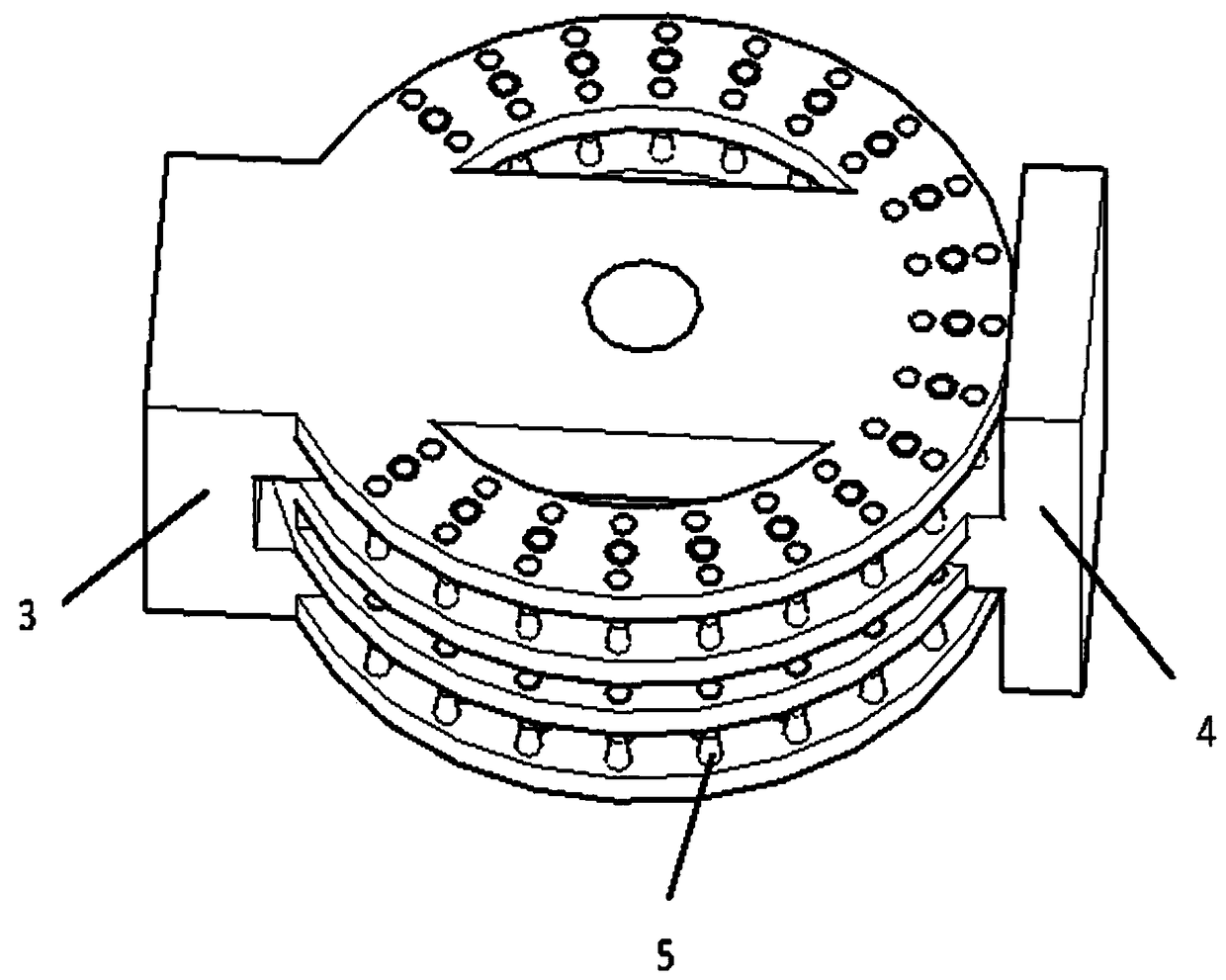

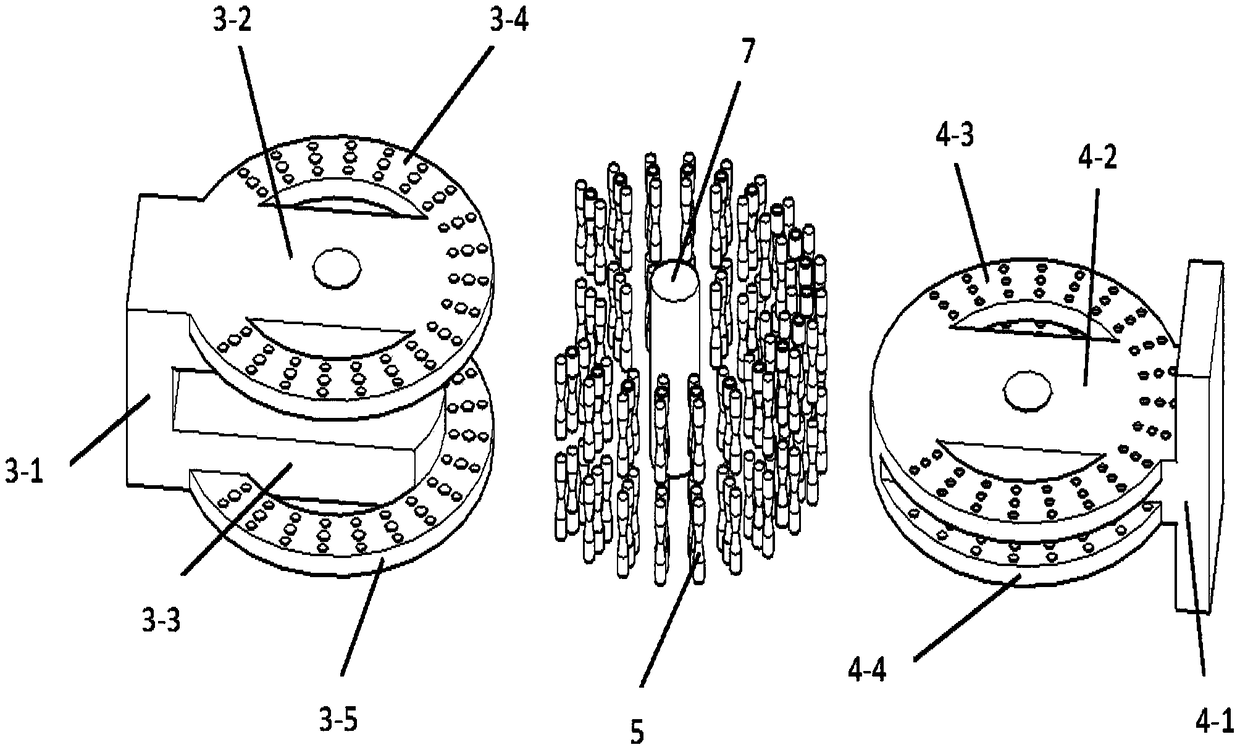

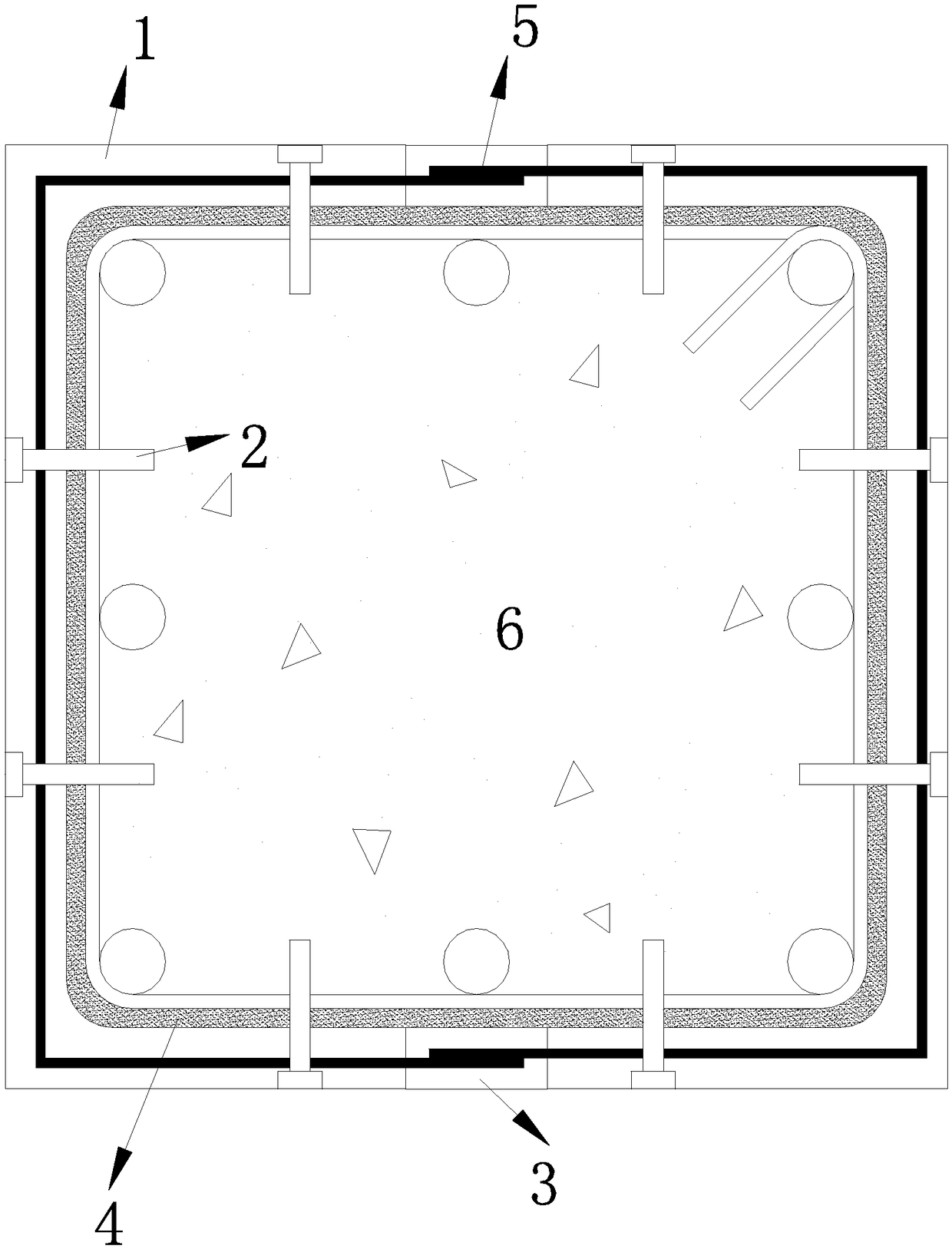

Method and device for reinforcing damaged RC column rapidly via prefabricated part

PendingCN109208935AImprove ultimate carrying capacityImprove crack resistanceBuilding repairsSteel platesSelf-consolidating concrete

The invention discloses a method and device for reinforcing a damaged RC column rapidly via a prefabricated parts. The prefabricated parts (1), an anchor bolt (2), a post-cast strip (3) and a contraction-free high-strength seam pouring material (4) are included, and each prefabricated part is composed of a pre-buried groove type steel plate hoop, a pre-buried wire mesh sheet and self-compact concrete. According to the reinforcing method, concrete is removed from a damaged protective layer, the prefabricated parts are installed on the reinforced column via the anchor bolt, the right and left prefabricated parts are overlapped with each other and connected to the post-cast strip after welding, joint seams are reinforced, and the reinforced column is more integral. The contraction-free high-strength seam pouring material is used to bind the prefabricated part with a core concrete area of the column, and the column whose performance is improved after reinforcement is obtained. All prefabricated parts can be produced in a factory and assembled and connected onsite, wet work onsite is reduced substantially, the reinforcing efficiency is improved, and the damaged column can be reinforcedrapidly after shocking.

Owner:HUNAN UNIV

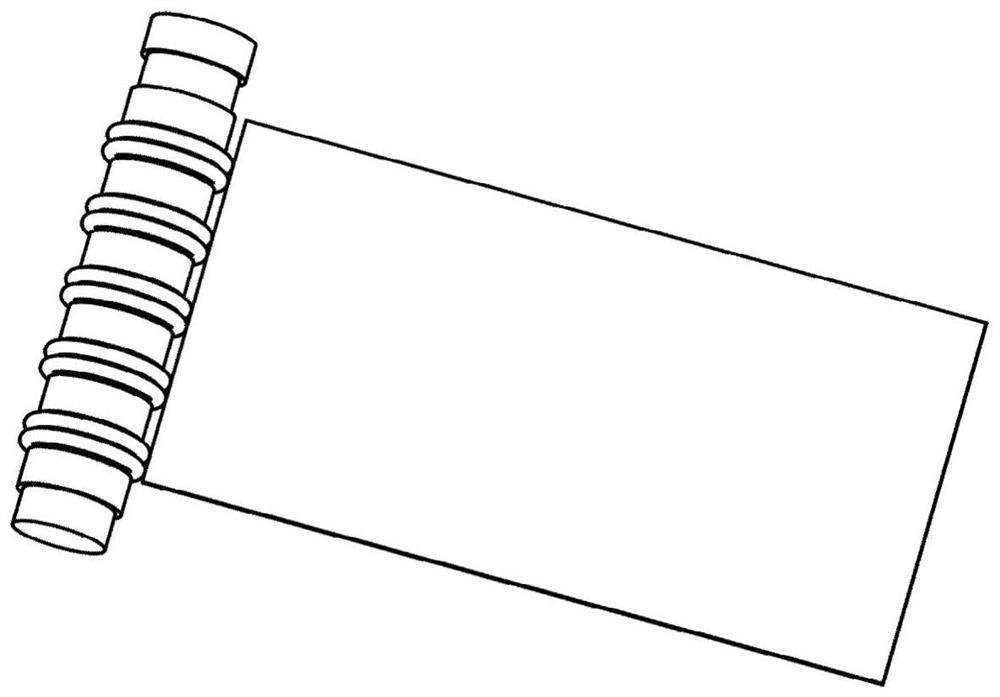

An anchoring device for a wound composite carbon fiber plate

ActiveCN109944173BEffectively exert high-strength performanceImprove bondingBridge erection/assemblyBridge strengtheningFiberCarbon fibers

The invention discloses a winding composite carbon fiber plate anchoring device. The device consists of an inner part and an outer part structures; the inner part is a carbon fiber plate winding ribbed steel column, and the outer part is an upper-lower two-piece clamping groove type steel plate; threads are arranged in a clamping groove of the outer steel plate at certain intervals; and coating colloid is engaged with the ribbed steel column. The manufacturing process for the carbon fiber plate winding ribbed steel column comprises the following steps of: winding a carbon fiber plate prepreg on a ribbed steel column, electrifying and heating the steel column until the prepreg is solidified for heating, specifically, the temperature for heating the steel column is controlled preferably to be between 165 DEG C and 175 DEG C, and the heating time of the steel column is controlled preferably to be 120 to 150 seconds; after the carbon fiber prepreg winding ribbed steel column is manufactured, the carbon fiber prepreg winding ribbed steel column is placed into the outer steel plate; the groove with a certain diameter is arranged in the outer steel plate; the outer steel plate is a two-piece structure and is provided with bolt holes with two different aperture sizes; bolts with small aperture size can be used for locking the upper and lower two-piece structures of the outer steel plate; and the anchoring device is fixed at a position to be reinforced of a concrete structure through bolts with large aperture size.

Owner:山西省交通科技研发有限公司

Suspended-dome multi-time prestressed construction method

InactiveCN101158195BPower transmission is simpleReduce pressure peaksBuilding roofsPre stressInstability

The invention discloses a suspend dome structure multi-prestressed construction method used in construction field. The construction method is that: firstly, a central pressure ring, an upper radial bar and edge elements are arranged on an upper layer; secondly, a lower radial rope, a lower ring rope and a strut are arranged on a lower layer; thirdly, prestress is applied in the structure by stretching the lower ring rope or stretching the lower radial rope or adjusting the length of the strut; fourthly, a ring bar is arranged; fifthly, an external load is applied on the structure. Compared with the structure formed by a traditional method, the suspend dome structure formed by the invention reduces peak pressure of elements with concise force, even changes a part of elements from a pressure bar to a tension bar, avoids instability of elements, at the same time enhances the entire stability of the whole structure and enlarges the ultimate bearing capacity. Furthermore, the invention leads a more even distribution of internal force of the upper layer network shell bar elements, is helpful to the unity of the elements and convenient for design and construction, at the same time, the invention reduces the applied prestress value and reduces construction difficulty.

Owner:BEIJING UNIV OF TECH

Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

InactiveCN100523532CImprove performanceRich design methodBearing componentsFluid film lubricationThrust bearing

Owner:郭溪泉

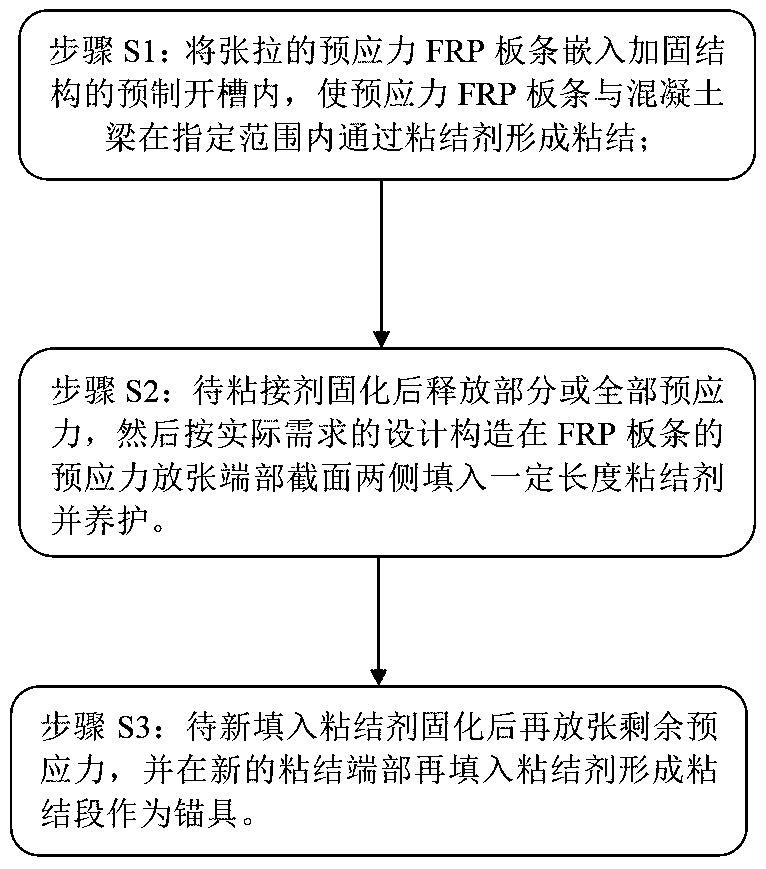

Reinforcing method for concrete structure based on gradient releasing prestress

ActiveCN110629685AReduce engineering costsAvoid tearing and peeling situationsBridge erection/assemblyBridge strengtheningPre stressConcrete beams

The invention discloses a reinforcing method for a concrete structure based on gradient releasing prestress. The reinforcing method comprises the following steps: S1, embedding a tensioned prestress fiber reinforced composite material (FRP) batten into a prefabricated slot of a reinforced concrete structure, wherein the prestress FRP batten and a concrete beam are bonded by means of a bonder within an appointed range; S2, releasing part of or all prestress after the bonder is cured and then filling two sides of a section of a prestress releasing end part of the FRP batten with the bonder of acertain length for curing according to a design structure of an actual need; and S3, releasing residual prestress after the newly filled bonder is cured, and filling the newly bonding end part with the bonder to form a bonding section as an anchorage device. The reinforcing method has the advantages of being simple in structure, convenient to construct, good in effect and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

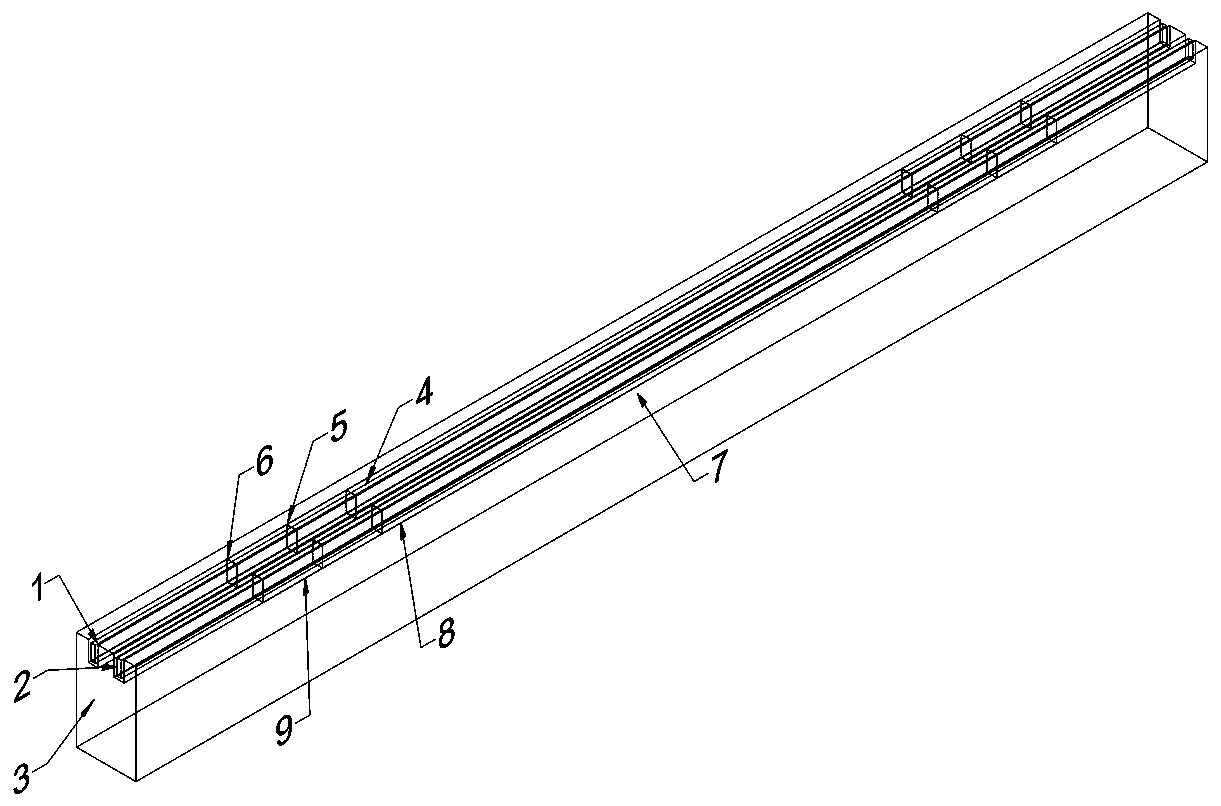

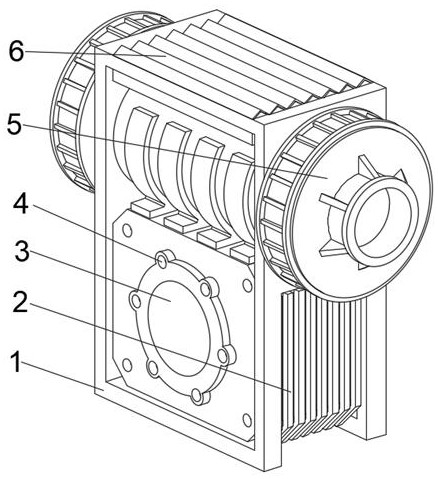

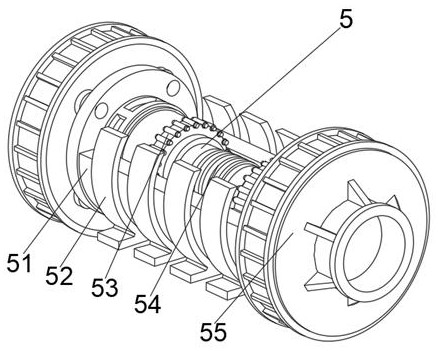

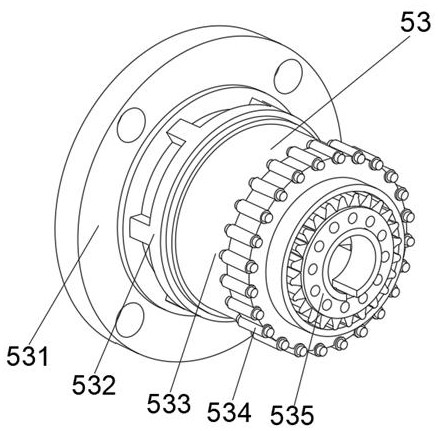

An industrial robot deceleration device

ActiveCN113696170BEasy to blockService life effectProgramme-controlled manipulatorConfined spaceEngineering

The invention discloses an industrial robot deceleration device, which comprises a main body, a cover plate is fixedly connected to the middle position of the front bottom of the main body, communicating holes are opened on both sides of the front of the cover plate, and the bottoms of the outer walls of the two sides of the main body A support plate is fixedly connected, and a deceleration device is provided at the middle of the top of the inner wall on both sides of the main body. The two sides of the deceleration device pass through the main body and extend to the outside of the main body. Involved in the field of robotics. The industrial robot deceleration device, when decelerating and stopping the device, the uneven surface of the dust plate can collect a certain amount of dust, which effectively improves the transmission stiffness of the deceleration force in a limited space, making it further increase. The ultimate bearing capacity of the device is increased, and the precision of the internal deceleration control of the device is increased, which is convenient for reducing the noise when the device rotates and decelerates, and is conducive to avoiding errors caused by the overall installation in the later stage.

Owner:思岚机器人(南通)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com