Reinforcing method for concrete structure based on gradient releasing prestress

A concrete structure and prestressing technology, which is applied in bridge reinforcement, architecture, bridge construction, etc., can solve the problem of reducing the stress concentration at the end of FRP and the complexity of construction operations, the reinforcement structure cannot be fully utilized due to the performance of the reinforcement material, and the concrete protective layer is torn. Cracking and peeling problems, to meet the needs of aesthetics, improve the ultimate bearing capacity, reduce the effect of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

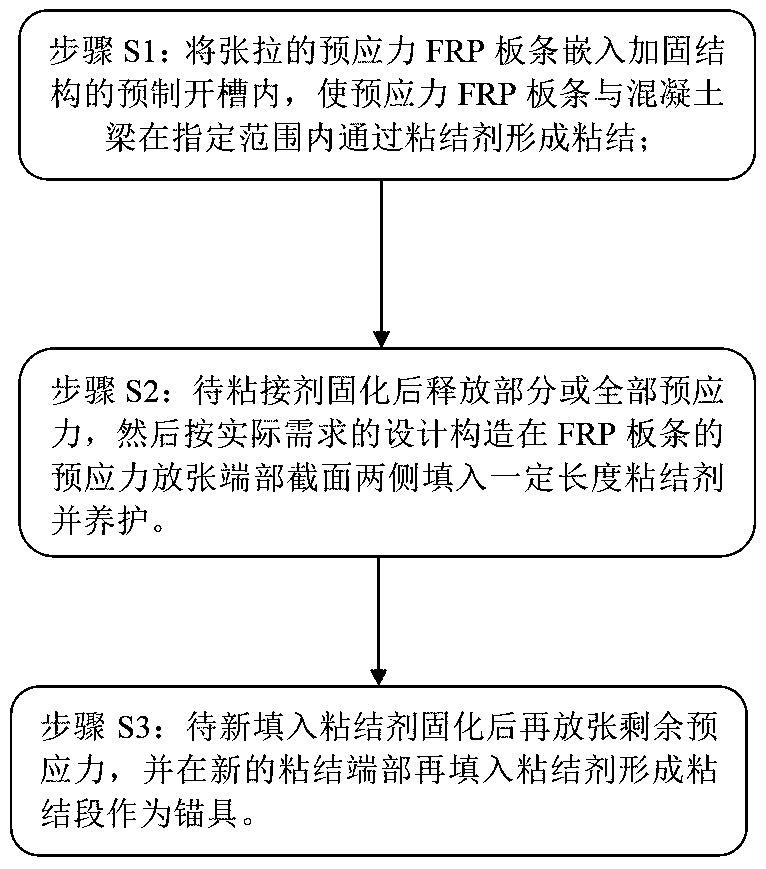

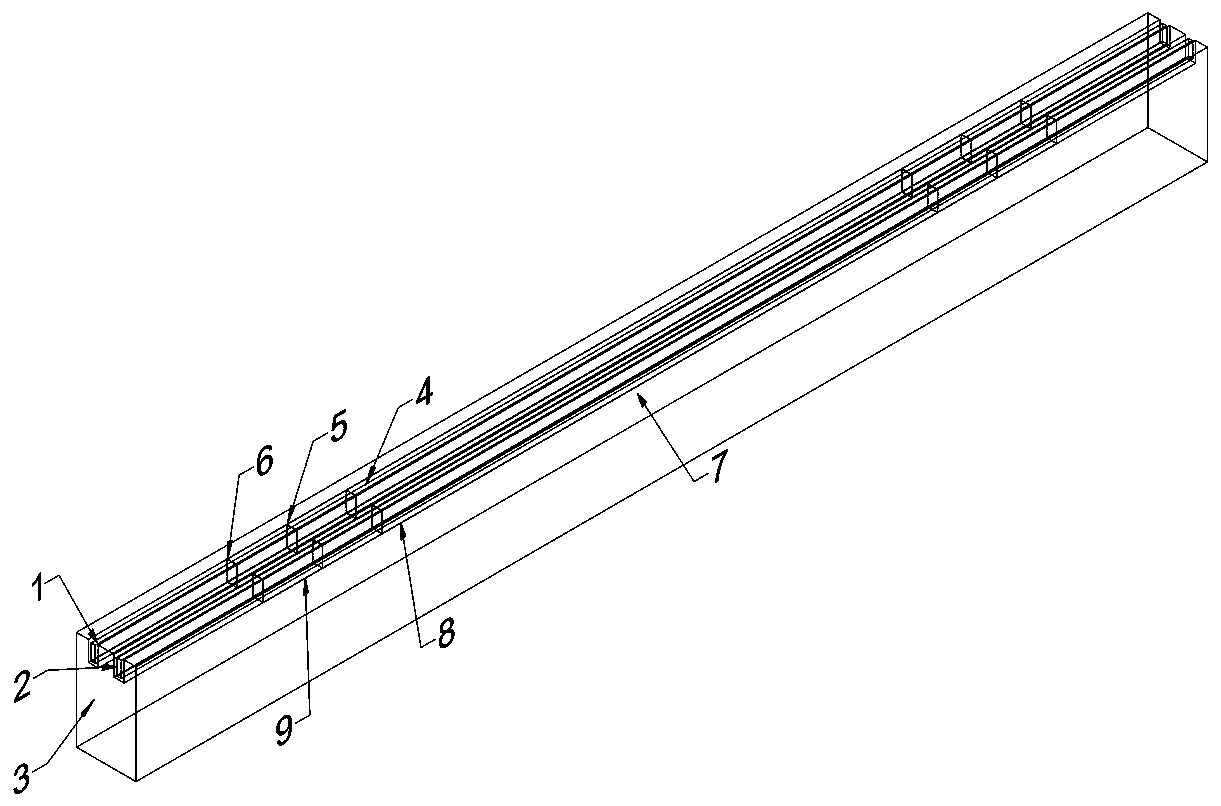

[0025] Such as figure 1 with figure 2 As shown, the method for strengthening the structure of the concrete beam 3 of the present invention is a method for strengthening the surface of the prestressed FRP concrete beam 3 based on gradient release prestress. The steps are as follows:

[0026] Step S1: Insert the tensioned prestressed FRP slats 1 into the prefabricated slots 2 of the reinforcement structure, so that the prestressed FRP slats 1 and the concrete beams 3 are bonded within a specified range through an adhesive; in step S1 The cross-sectional position of the end of the concrete beam 3 and the prestressed FRP slat 1 to form a bonding section is called the untensioned end 4. In specific applications, adhesives can be used according to actual needs, such as the epoxy resin in this embodiment, and the use of other cements shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com