Connection joint of double-steel-plate combined shear wall and combined floor slab connected by supporting angle steel

A technology of combined shear walls and combined floors, which is applied to floors, building components, buildings, etc., can solve the problems of small number of forms, unfavorable steel structure residences, unsuitable for double-steel combined shear walls, etc., to achieve easy construction and overall Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

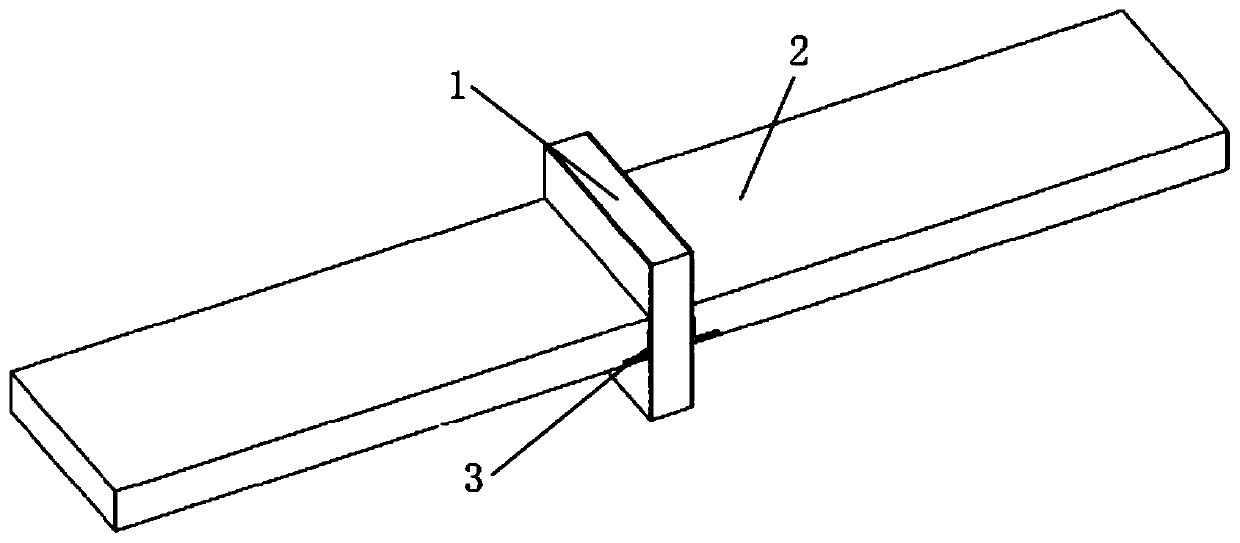

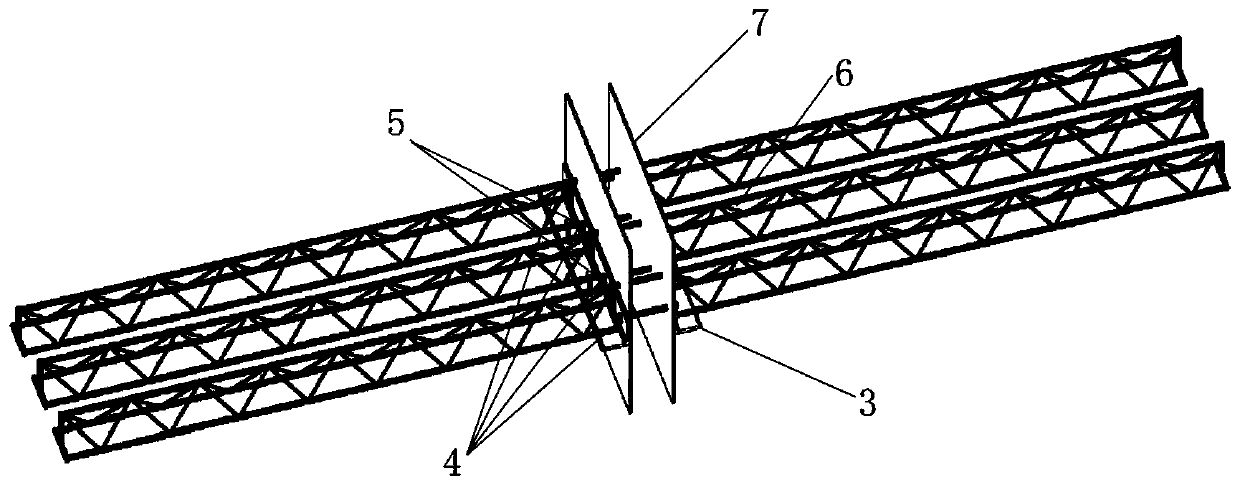

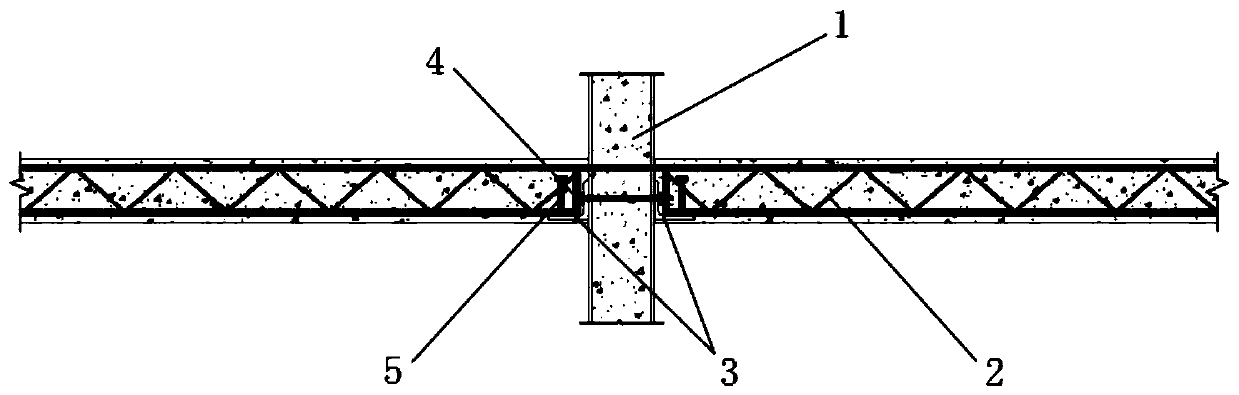

[0023] as attached Figure 1 to Figure 5 As shown, a connection node between a double-steel plate composite shear wall and a composite floor slab connected by supporting angle steel includes a double-steel composite shear wall 1 , a composite floor 2 and a supporting angle steel 3 .

[0024] The double-steel composite shear wall 1 includes two opposite steel plates 7, and the two steel plates 7 are fixed by tension bolts 4 to form a concrete pouring cavity.

[0025] The composite floor 2 includes steel bars in the floor and a steel structure main body 6, and the steel bars in the floor and the steel structure main body 6 include upper steel bars, lower steel bars and steel bar trusses, or include upper steel bars, lower steel bars, steel bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com