Freeway bridge crack repairing method based on carbon fiber plate

A carbon fiber plate and repair method technology, applied in bridge maintenance, bridge, bridge reinforcement, etc., can solve problems such as self-heavy, increased bridge self-weight, unfavorable ultimate bearing capacity of structures, etc., to improve strength and stiffness, increase safety reserve, Effect of suppressing growth of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiment:

[0039] Taking the inspection of the bridge at the Luodai Interchange ramp of the Chengan-Yu Expressway as an example, it is found that there are many cracks in the box girder of the D ramp.

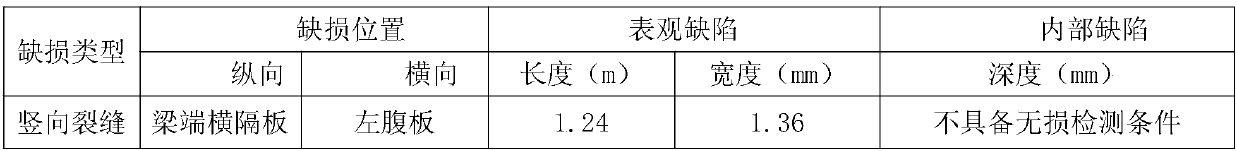

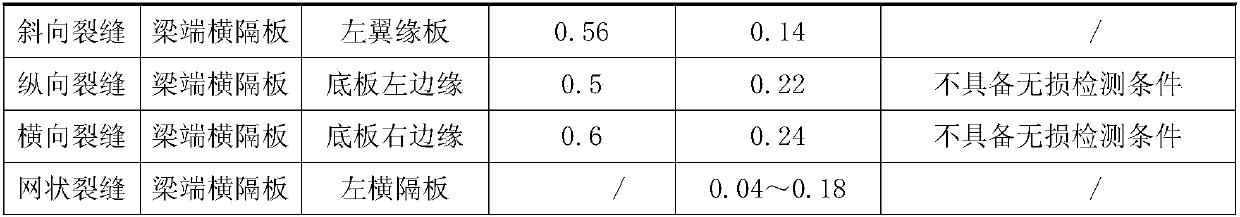

[0040] After testing, see the table below for the cracks in the first span of the first section of the D ramp.

[0041]

[0042]

[0043] Oblique cracks: oblique cracks produced by the flange plate of the box girder, generally web shear cracks, mainly appear in the range from the support to L / 4 (L is the length of the beam), and form an angle of 20° to 60° with the roof. The web junction starts to extend down to 1 / 3~1 / 2 beam height, and the direction is basically perpendicular to the main tensile stress, which directly affects the safety and durability of the structure.

[0044] Transverse cracks: Transverse cracks appear in the middle and upper part of the web, and the width is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com