Patents

Literature

62results about How to "Reduce deflection deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

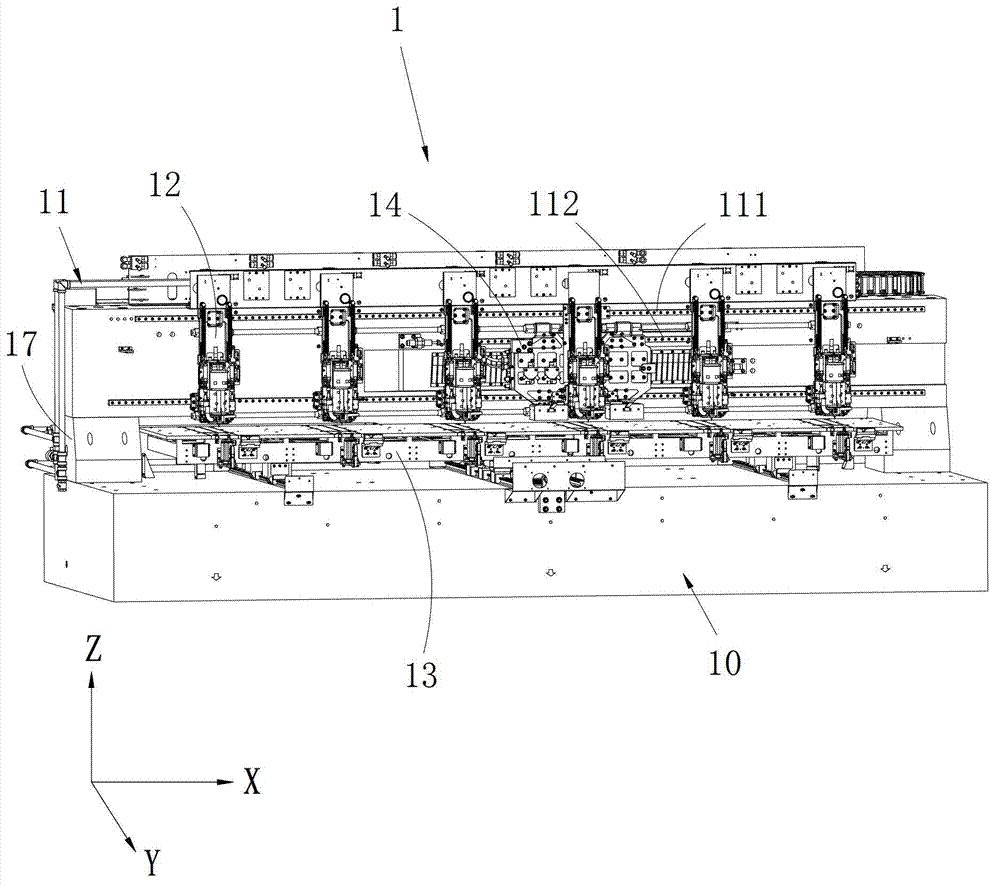

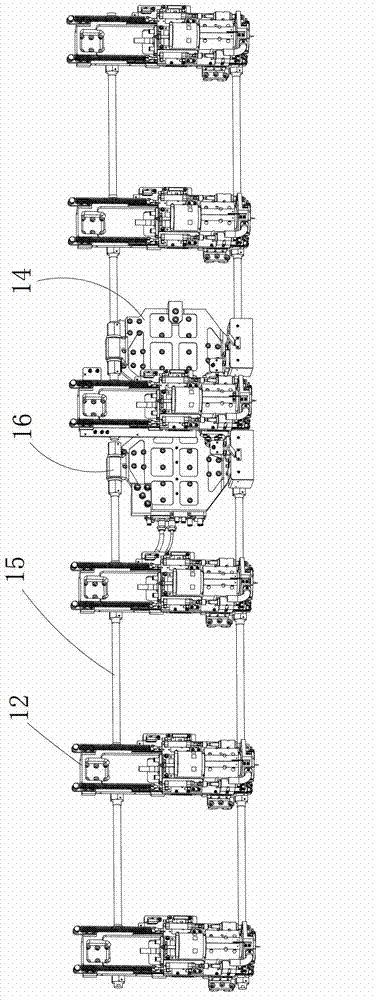

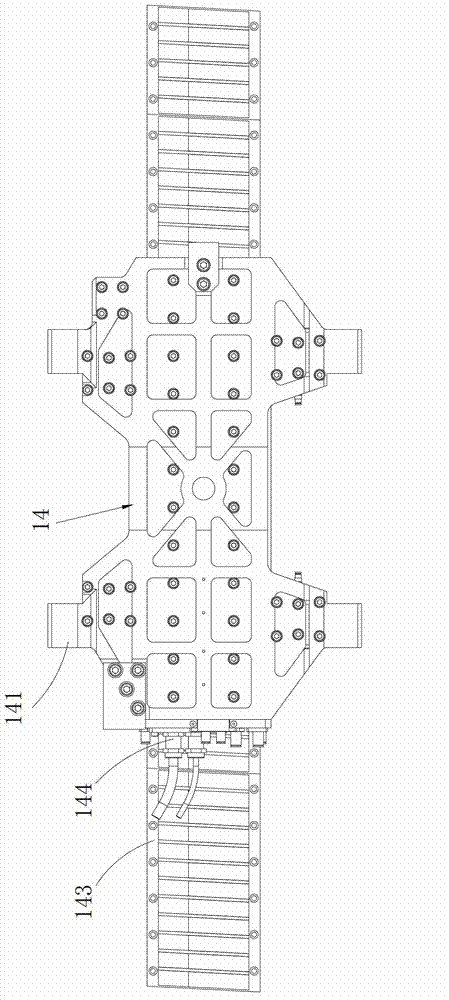

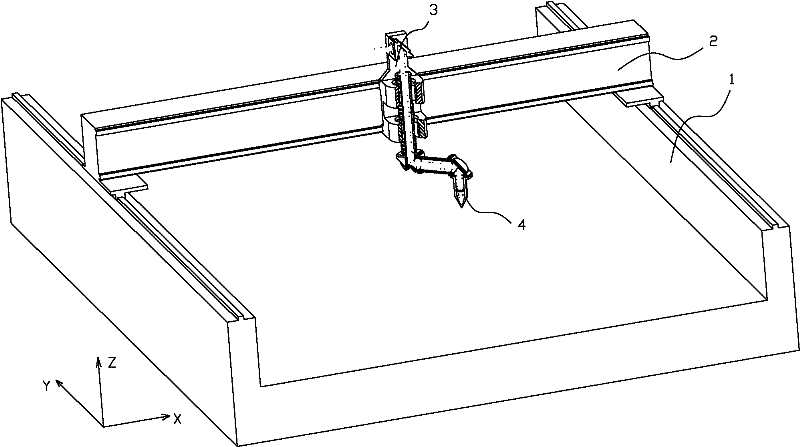

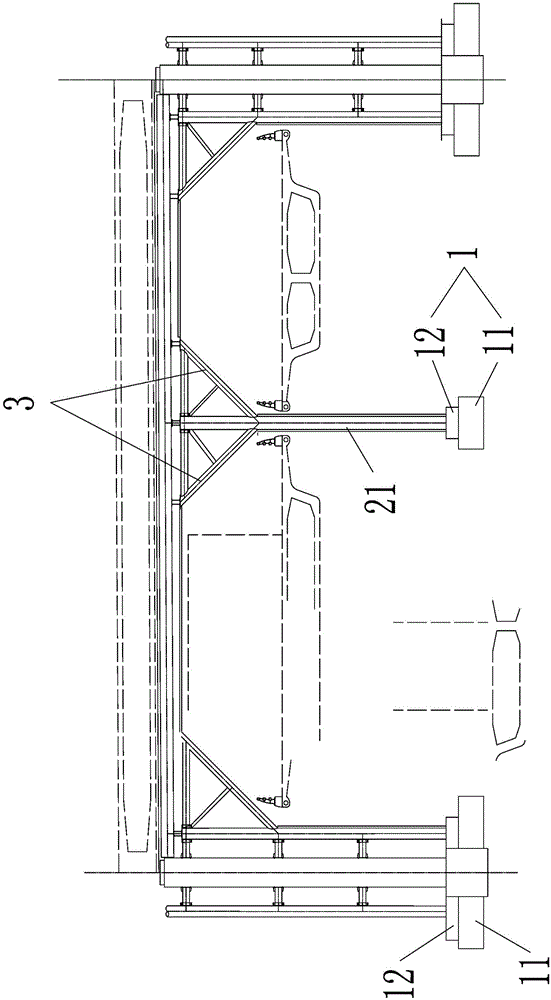

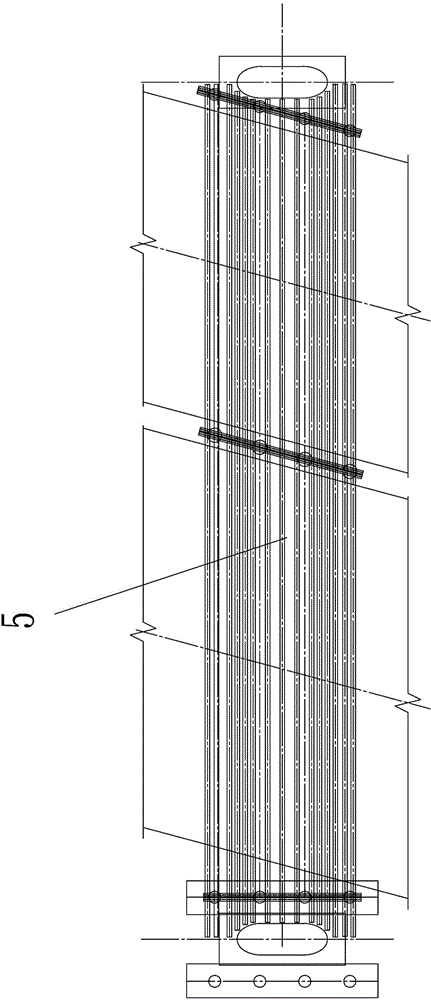

Multi-axis cascade connection direct driving PCB (printed circuit board) drilling machine

InactiveCN103921314AImprove drilling accuracyImprove stabilityMetal working apparatusHigh loadMotion system

The invention discloses a multi-axis cascade connection direct driving PCB drilling machine. The multi-axis cascade connection direct driving PCB drilling machine comprises a bed, a the bed is provided with a beam, the beam is provided with a beam motor fixing plate, an X-axis linear motor is arranged between the beam and the beam motor fixing plate, the bed is provided with a plurality of cascade connection drilling hole structures connected through cascade connection shafts, every cascade connection drilling hole structure comprises a drilling hole assembly and a Z-axis linear motor, the bed is provided with a Y-axis motion platform, and a Y-axis linear motor is arranged between the bed and the Y-axis motion platform. The multi-axis cascade connection direct driving PCB drilling machine is designed by taking factors such as manufacturing cost, operating cost and machinability into consideration, solves the problems of high load and high vibration due to high-speed driving, achieves optimum compatibility among a control system, a motion system and a mechanical system, can meet requirements of high-quality multi-level drilling hole machining, and overcomes technology defects of low accuracy and poor stability of multi-axis drilling hole machining compared to single-axis machining by improving the cascade structure so as to further improve multi-axis machining accuracy as well as maintain high machining efficiency.

Owner:HANS LASER TECH IND GRP CO LTD +1

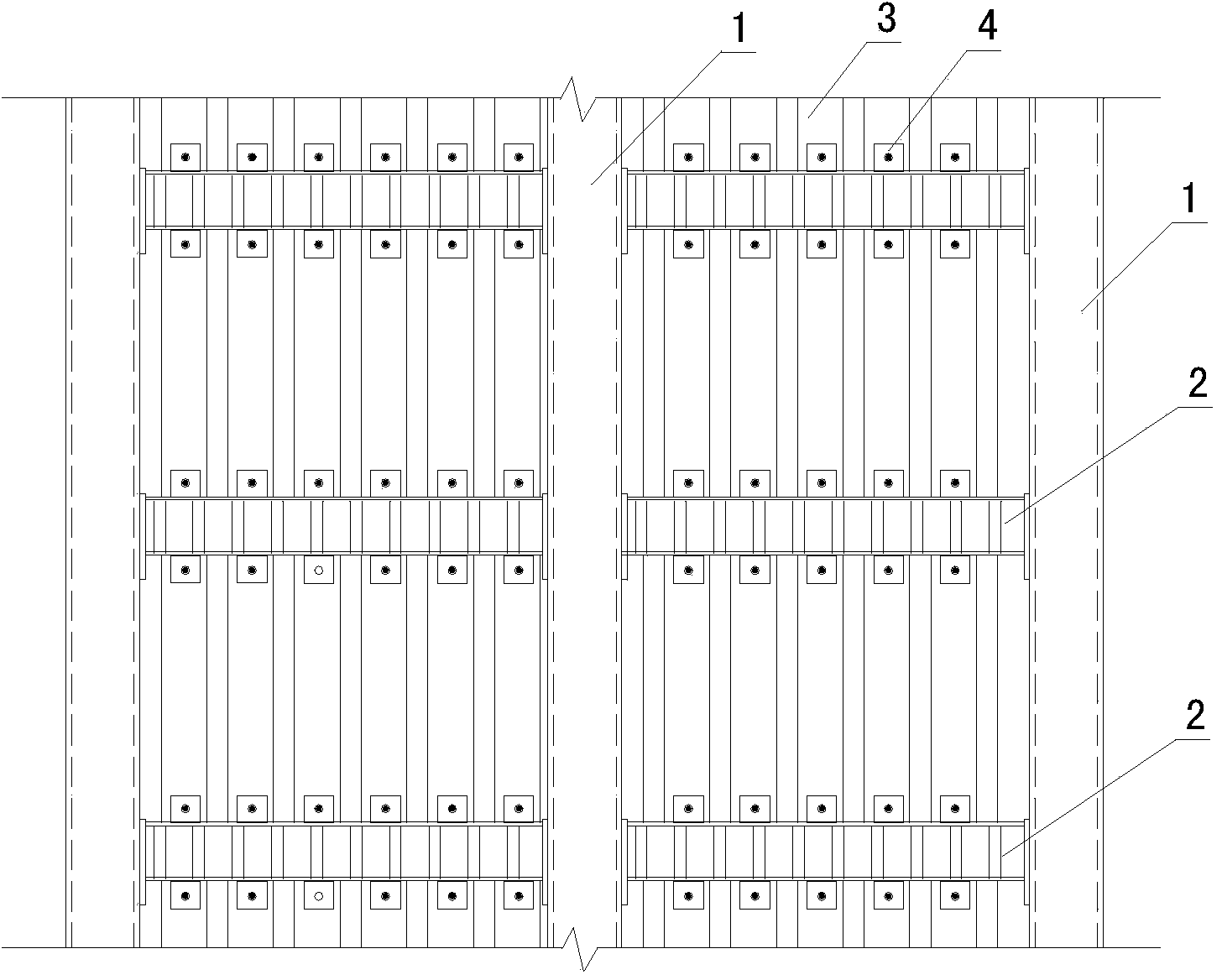

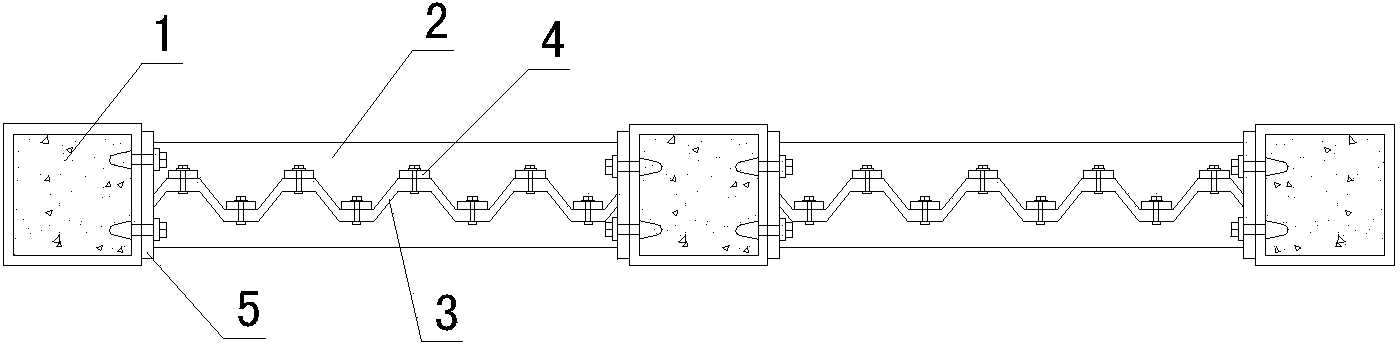

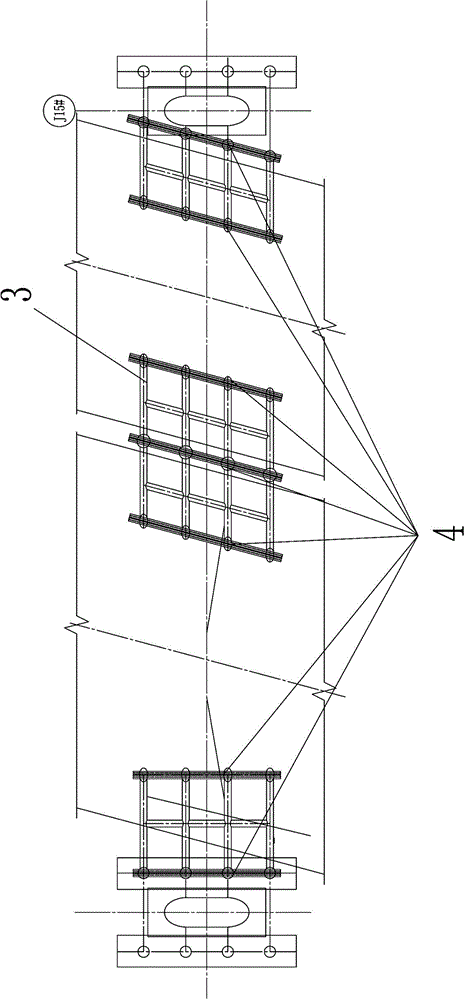

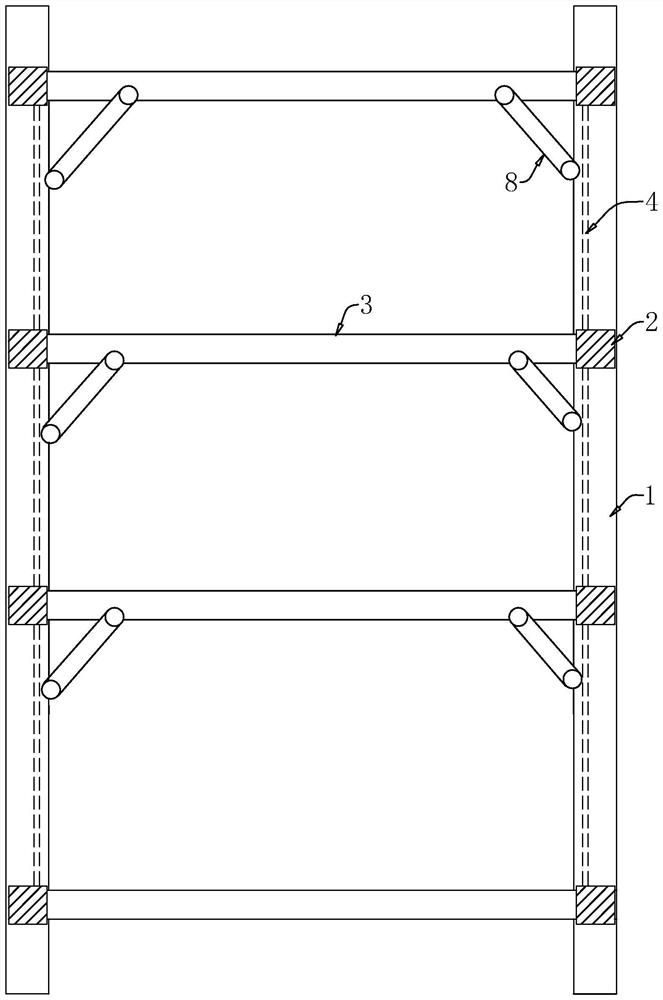

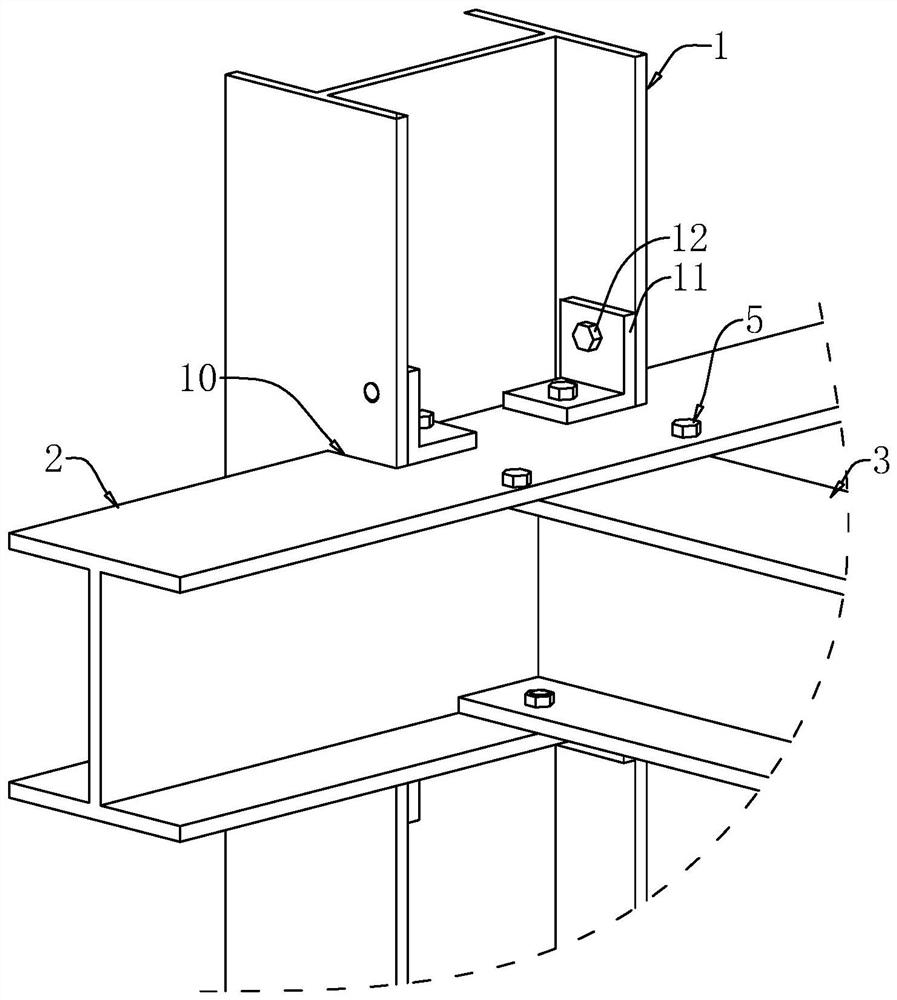

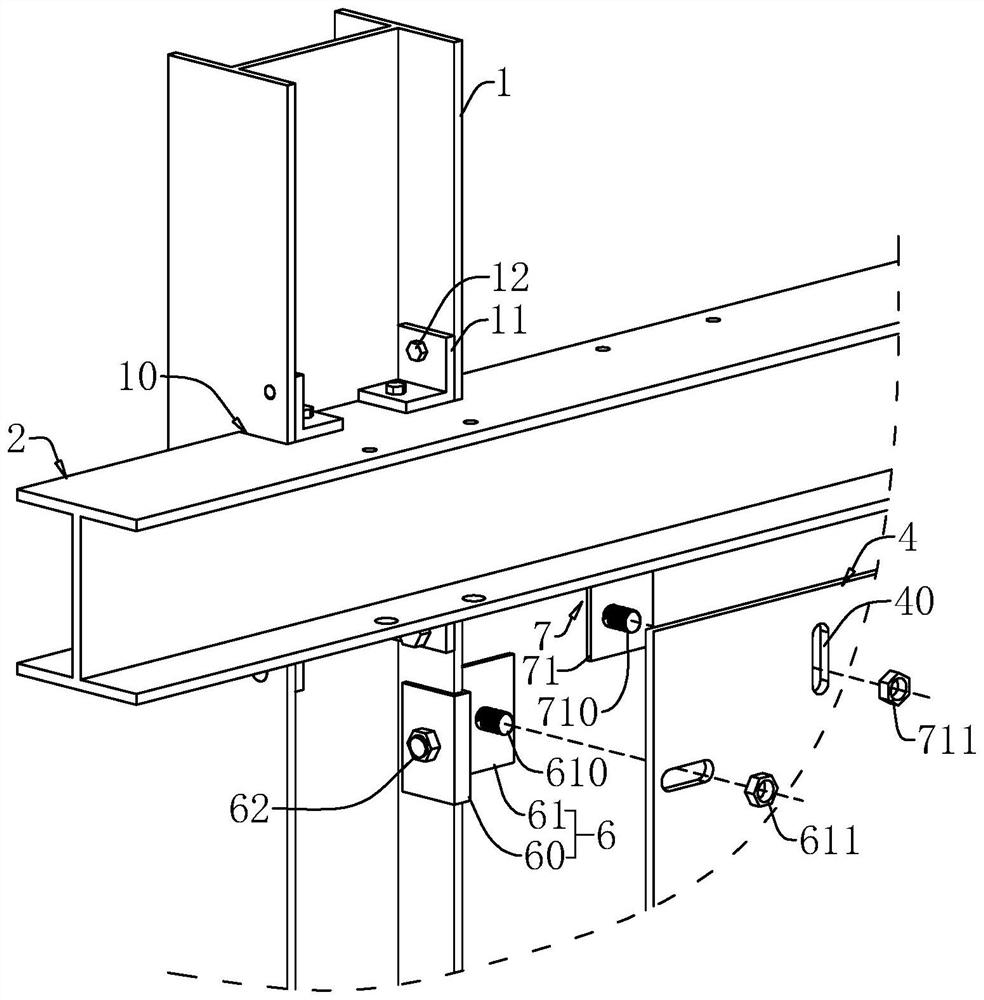

Assembling and energy consuming structural system with combined fluted frameworks and shear walls

The invention discloses an assembling and energy consuming structural system with combined fluted frameworks and shear walls. The system is characterized in that the system comprises concrete-filled steel tubular columns, fluted web plate beams and fluted steel plate shear walls; the concrete-filled steel tubular columns, the fluted web plate beams and the fluted steel plate shear walls are connected through bolts; the cross section of each fluted web plate beam is of an H shape; flange plates comprising the fluted web plate beams with the H-shaped cross sections are smooth steel plates; web plates are fluted steel plates; the fluted steel plate shear walls are made of fluted steel plates. The assembling and energy consuming structural system with the combined fluted frameworks and the shear walls is an assembly type high-rise steel-structure energy consuming building system which has the advantages that the construction progress is fast, the force transmission path is simple, and the energy consuming capacity is high.

Owner:HEFEI UNIV OF TECH

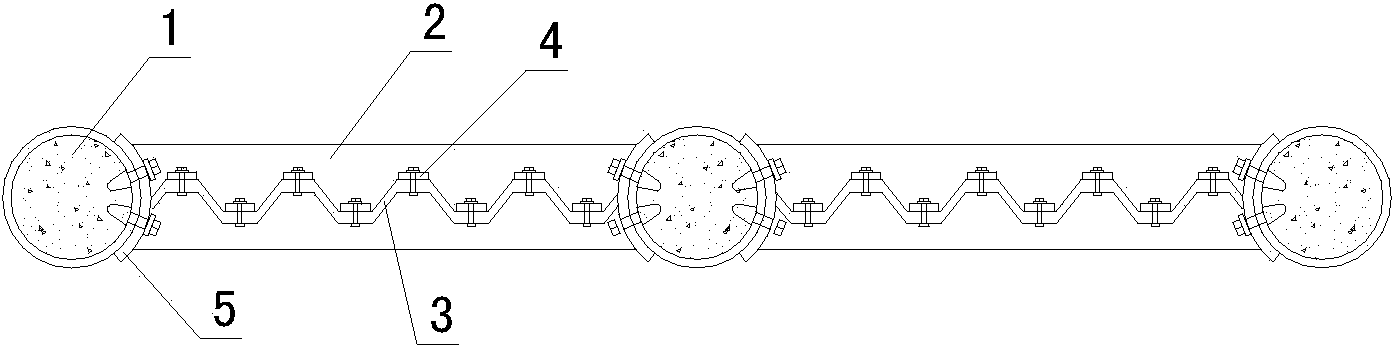

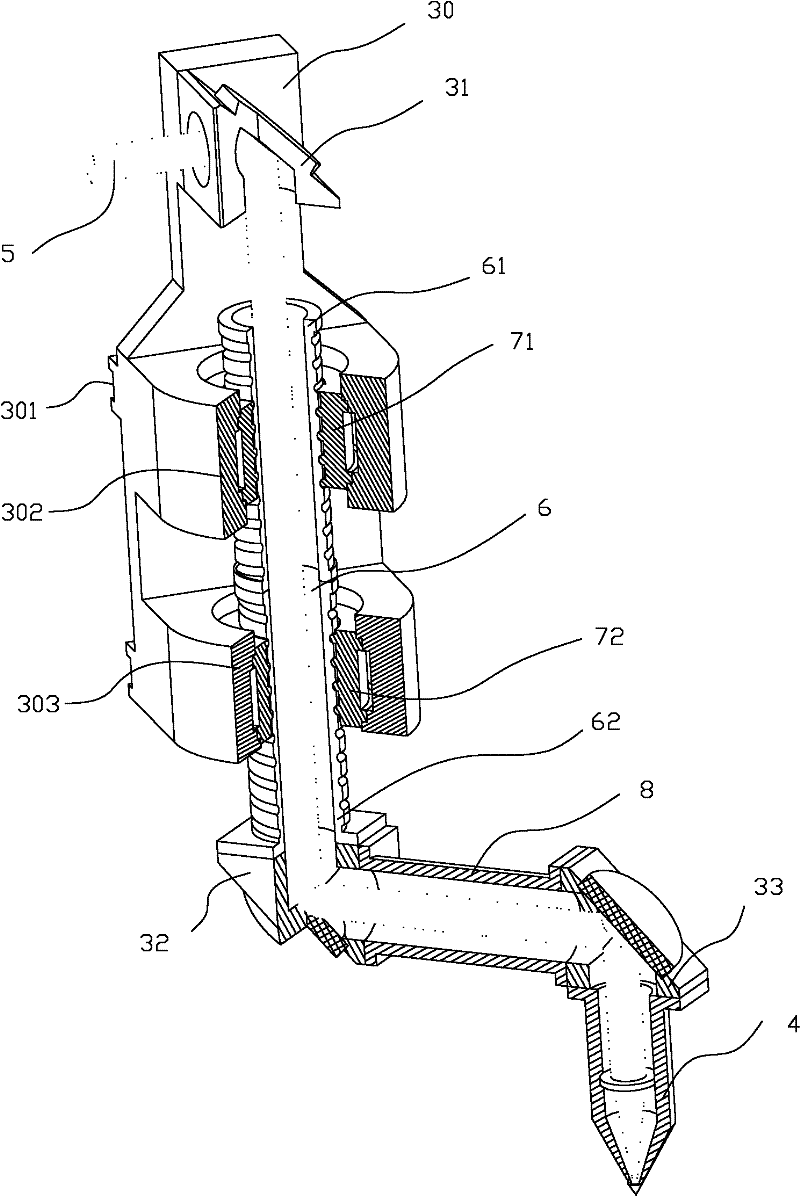

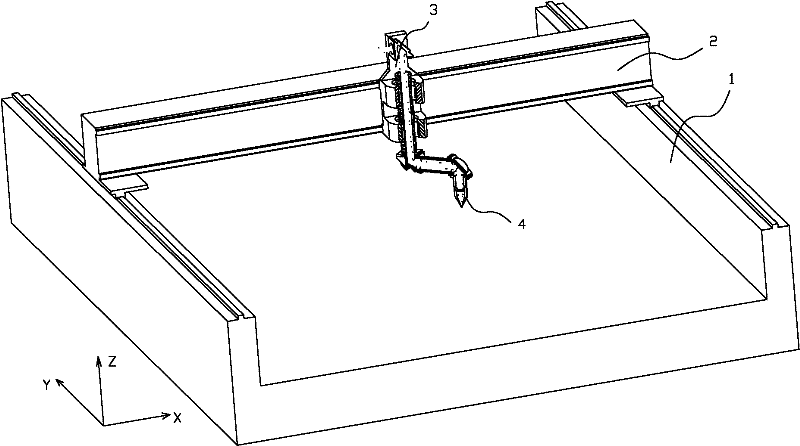

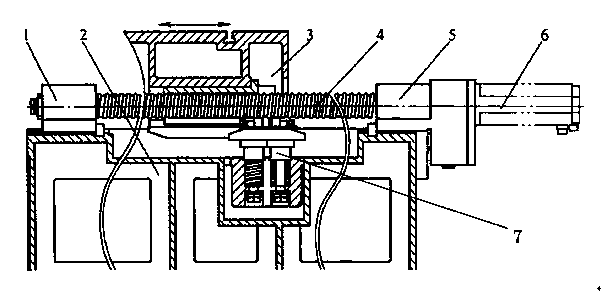

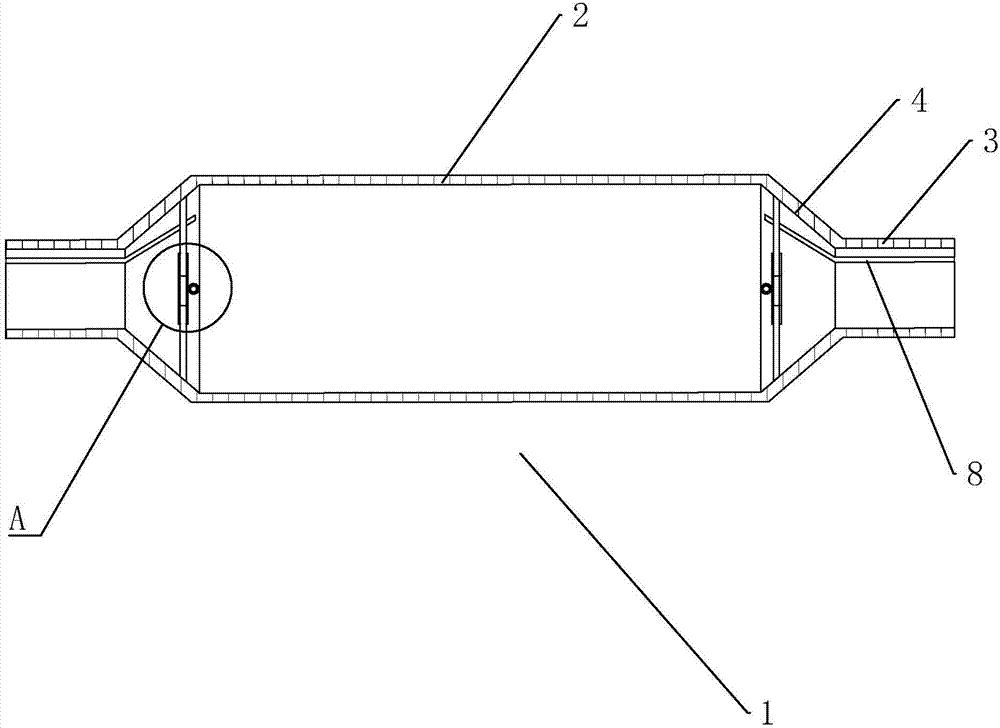

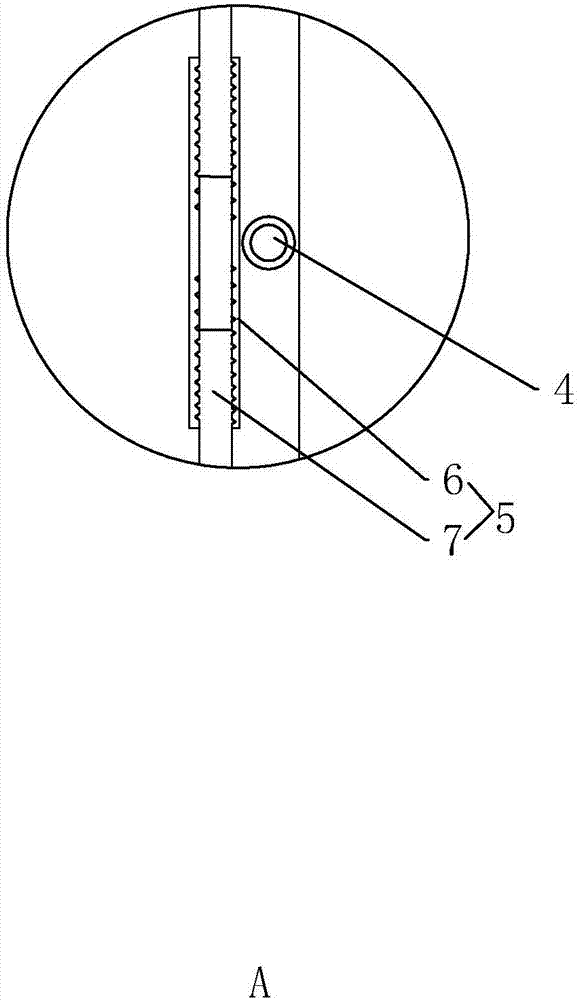

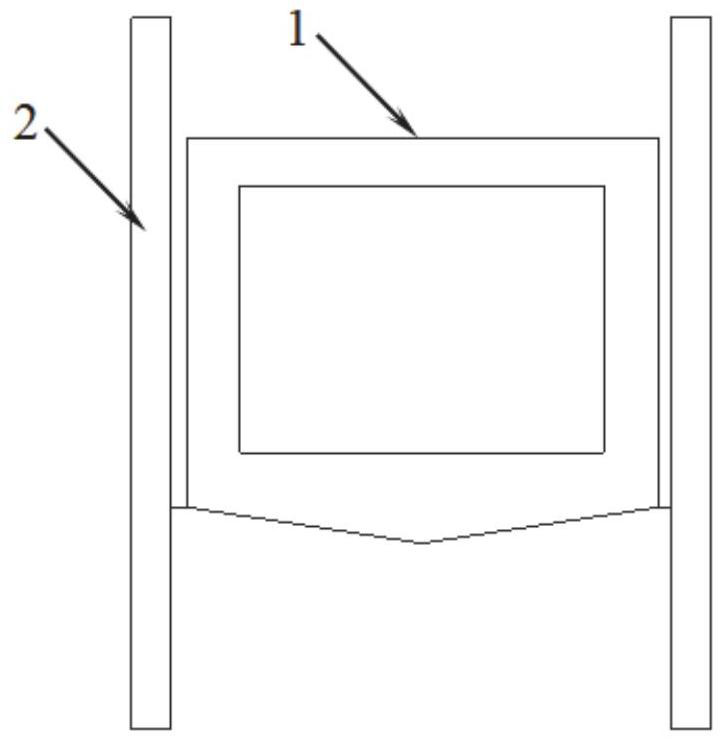

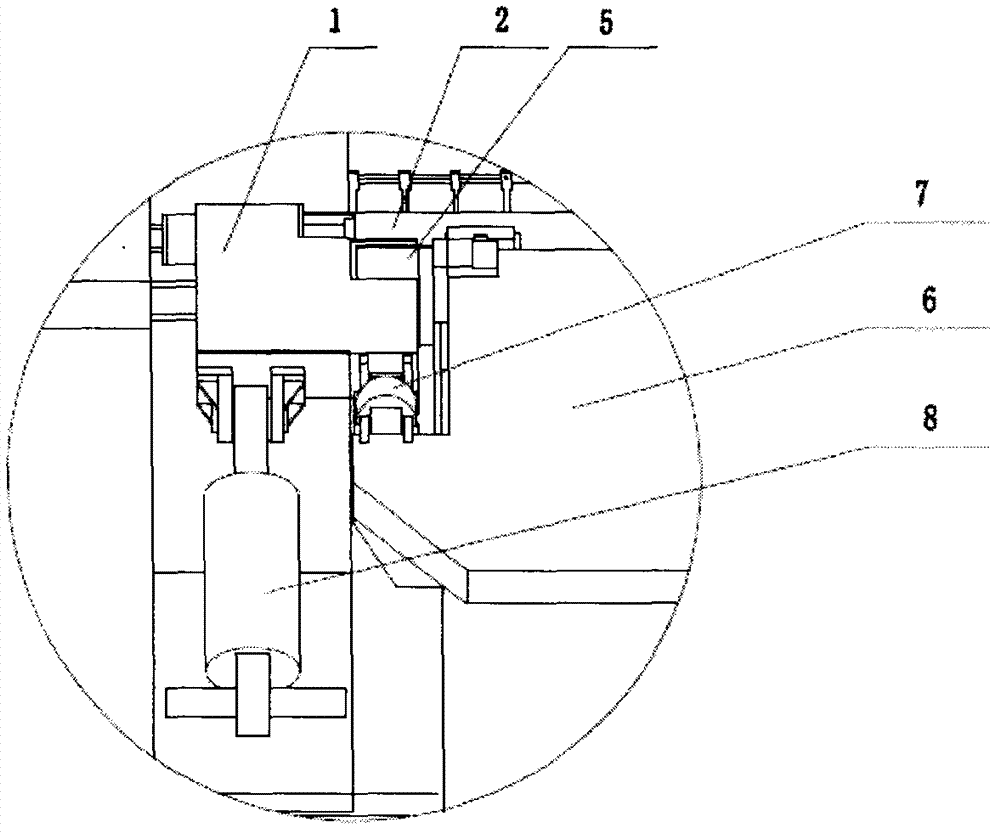

Two-dimensional laser cutting machine

InactiveCN102528287AReduce loadReduce deflection deformationLaser beam welding apparatusLight guideLaser cutting

The invention relates to a two-dimensional laser cutting machine, which is of an improvement of a driving mechanism of a cutting head of a laser cutting machine with a local high-speed cutting function within a medium and small range, and is simple in structure and convenient for follow-up control programming. The laser cutting machine comprises a machine body, a cross beam, a laser cutting head and a laser generator, wherein the machine body and the cross beam are connected through an X-direction guide track arranged on the machine body, a Y-direction guide track is arranged on the side surface of the cross beam, and the laser cutting head is movably connected on the Y-direction guide track on the side surface of the cross beam through a local motion mechanism; the local motion mechanism comprises a Y-direction motion support saddle, a two-way hollow spiral shaft, a light guide cylinder, a screw nut I, a driving motor I, a screw nut II, a driving motor II and at least two reflecting mirror groups; and the upright two-way hollow spiral shaft is arranged on the Y-direction motion support saddle, the light guide cylinder is arranged between the shaft and the laser head, and the light guide cylinder plays a role of a cross rod. Therefore, the whole machine is simple for protection and can significantly upgrade speed, precision and rigidity.

Owner:江苏扬力数控机床有限公司

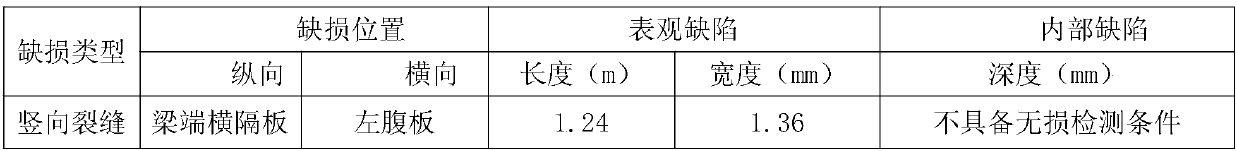

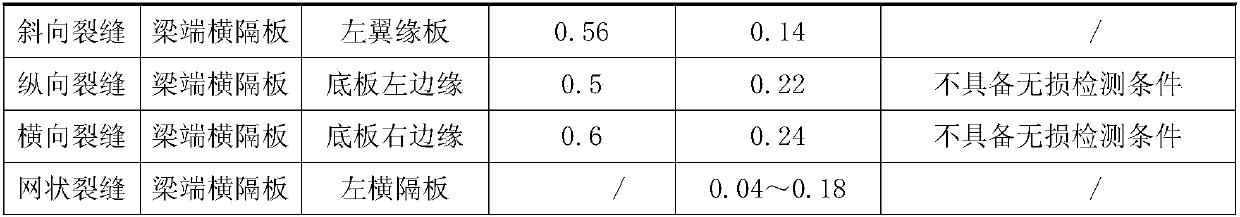

Freeway bridge crack repairing method based on carbon fiber plate

InactiveCN107740354AIncreased durabilityIncrease safety reserveBridge erection/assemblyBridge strengtheningFiberCarrying capacity

The invention discloses a freeway bridge crack repairing method based on a carbon fiber plate. The method comprises the steps of detecting and specially analyzing a crack; preparing construction materials and construction equipment and building a construction bracket platform; cleaning an opening; implanting and cleaning a bolt and fixing the bolt into the opening through vegetable glue; conducting surface treatment on a concrete member, installing an anchor, installing a fixed-end limiting frame, installing the anchor into the fixed-end limiting frame, installing a tension-end limiting frame,and installing a wedge block so that the bottom of the wedge block is arranged under concrete; fixing the carbon fiber plate to the crack through the anchor. In the method, the pre-stressed carbon fiber plate is adopted to apply external pre-stress on the bottom of a box girder for reinforcement and strengthening, the strength and the stiffness of the structure can be improved, the deflection deformation of the structure can be reduced, and the development of the crack can be restrained; besides, with the combination of a crack sealing treatment measure, the durability of a bridge and the ultimate carrying capacity of the structure can be improved, and the emergency capacity of bridge running can be improved.

Owner:SINOHYDRO BEREAU 10 CO LTD

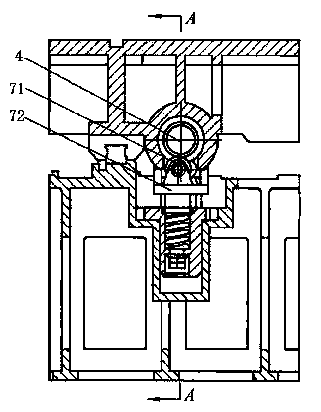

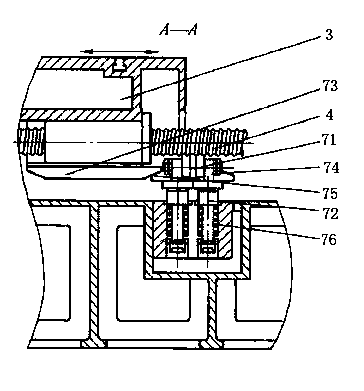

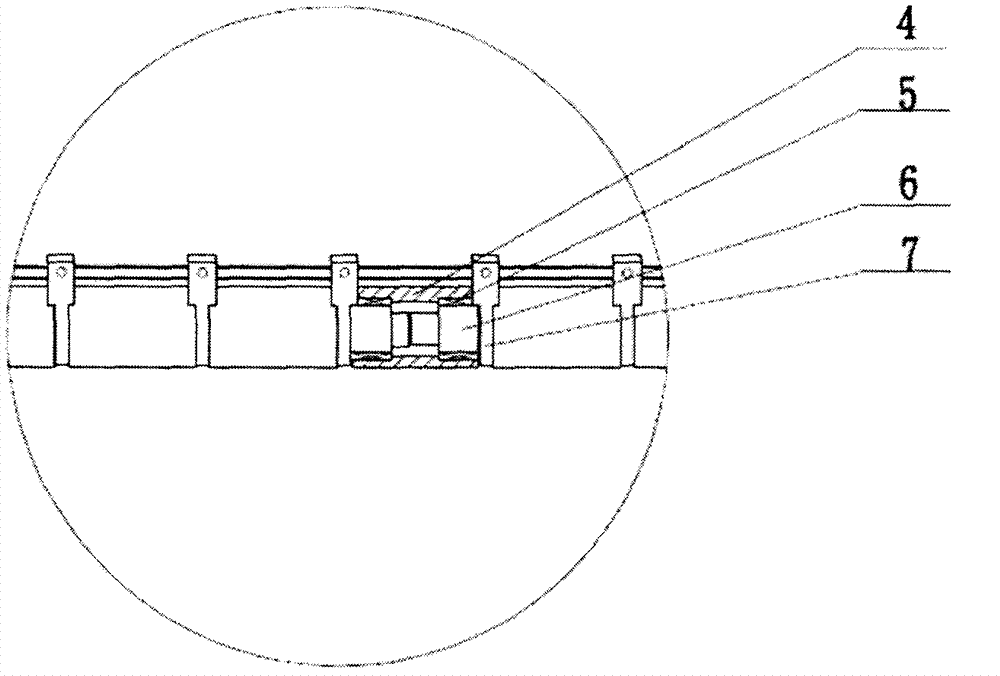

Ball screw support device

InactiveCN104325345ALess bendingReduce deflection deformationFeeding apparatusBall screwMaintainability

The invention discloses a ball screw support device. The ball screw support device comprises a support rod (72), a spring (76), an idler wheel (71), an upper inclined plate (73) and a lower inclined plate (75), wherein the spring (76) sleeves the support rod (72); the upper inclined plate (73) is arranged on an external workbench (3); the lower inclined plate (75) is arranged on the support rod (72); the idler wheel (71) is arranged on the top end of the support rod (72). According to the ball screw support device, the ball screw bending is reduced, the deflection deformation is reduced, and thus the movement precision of the workbench is guaranteed; the precision and the rigidity of a machine tool are improved. The ball screw support device is simple and reliable in structure, good in maintainability and low in cost.

Owner:南京金宇刀具制造有限公司

Combined H-shaped steel cast-in-situ box beam support adjoining to and overpassing existing lines

InactiveCN104831635APractical, simple and convenientSolve the problem of excessive deflectionBridge erection/assemblyButtressStatically indeterminate

Provided is a combined H-shaped steel cast-in-situ box beam support adjoining to and overpassing existing lines. The combined cast-in-situ beam support comprises a steel pipe column strip foundation, steel pipe buttresses, triangular diagonal braces on the two sides of steel pipe uprights, main crossbeams and main longitudinal beams. The triangular steel pipe column buttresses, the main crossbeams and the main longitudinal beams are of a combined structure, stress decomposition is conducted on H600 type steel of the main longitudinal beams through the triangular diagonal braces on the two sides of the steel pipe uprights, force is transferred to a transverse pier body and a longitudinal concrete strip foundation, deflection deformation occurring after the H600 type steel of the main longitudinal beams is stressed is greatly reduced under large span conditions, a statically indeterminate structure of the support is formed, structural stability of the support is enhanced, the construction problem that the left space, right space, upper space and lower space of a cast-in-situ box beam adjoining to and overpassing the existing lines are limited is solved, and it is guaranteed that lower deflection of H-shaped steel under large span conditions and the driving clear height of the existing lines are within specified permissible ranges.

Owner:中铁二十二局集团第三工程有限公司

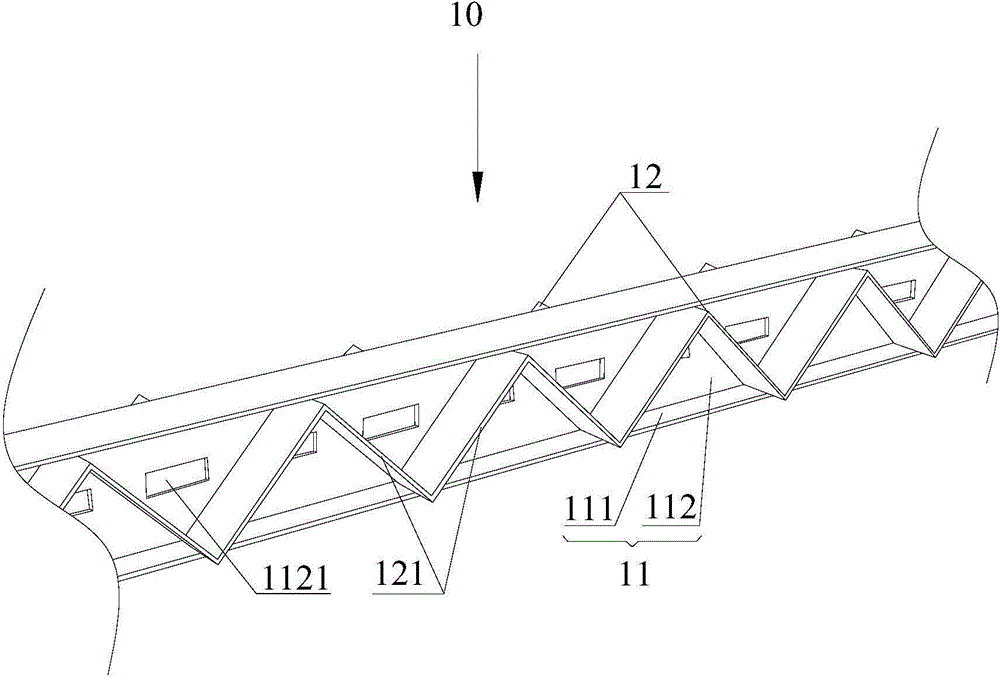

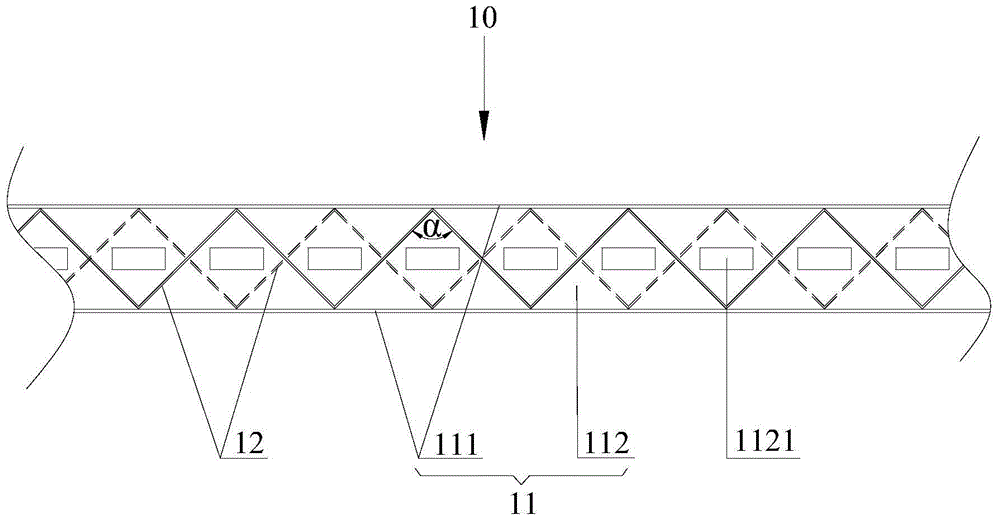

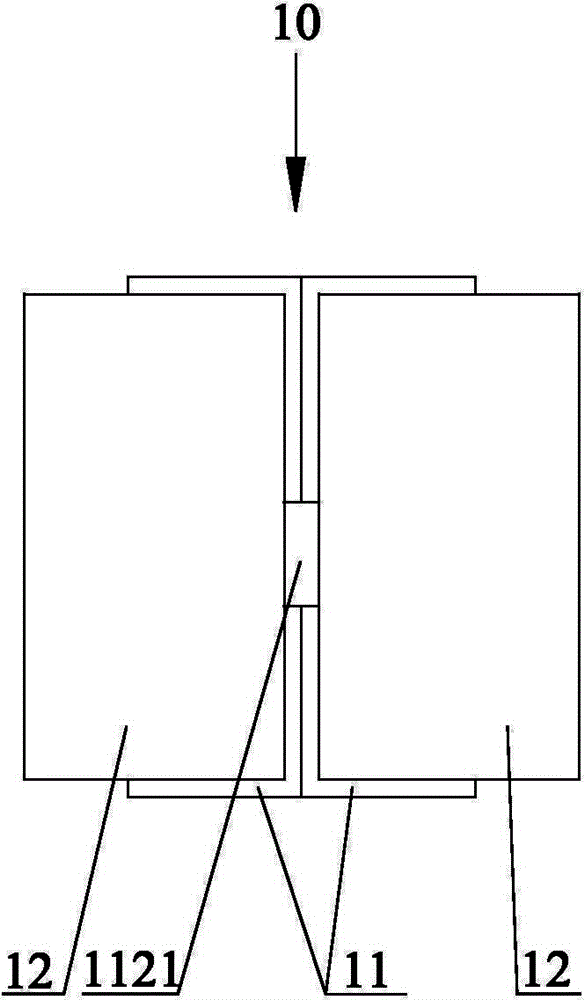

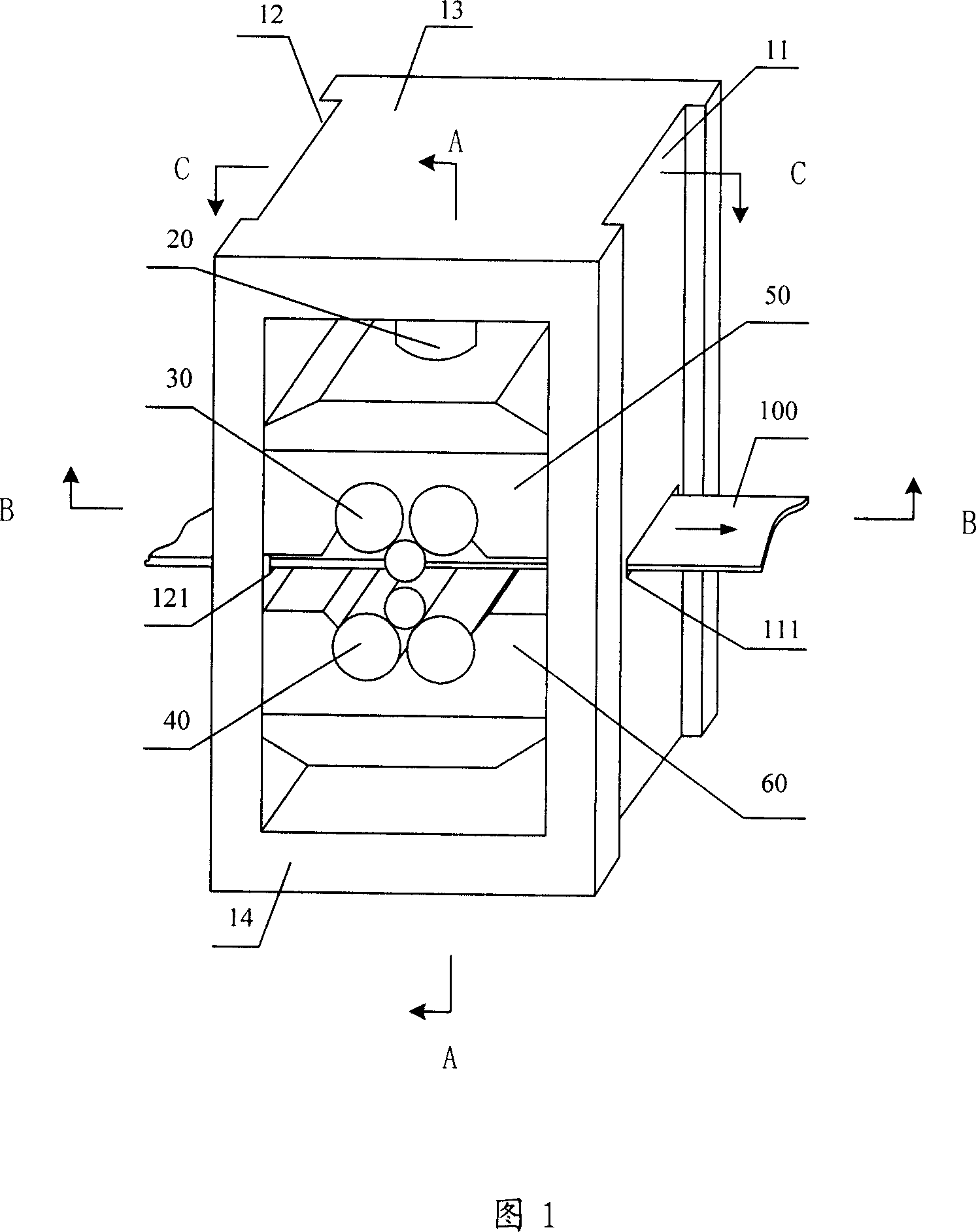

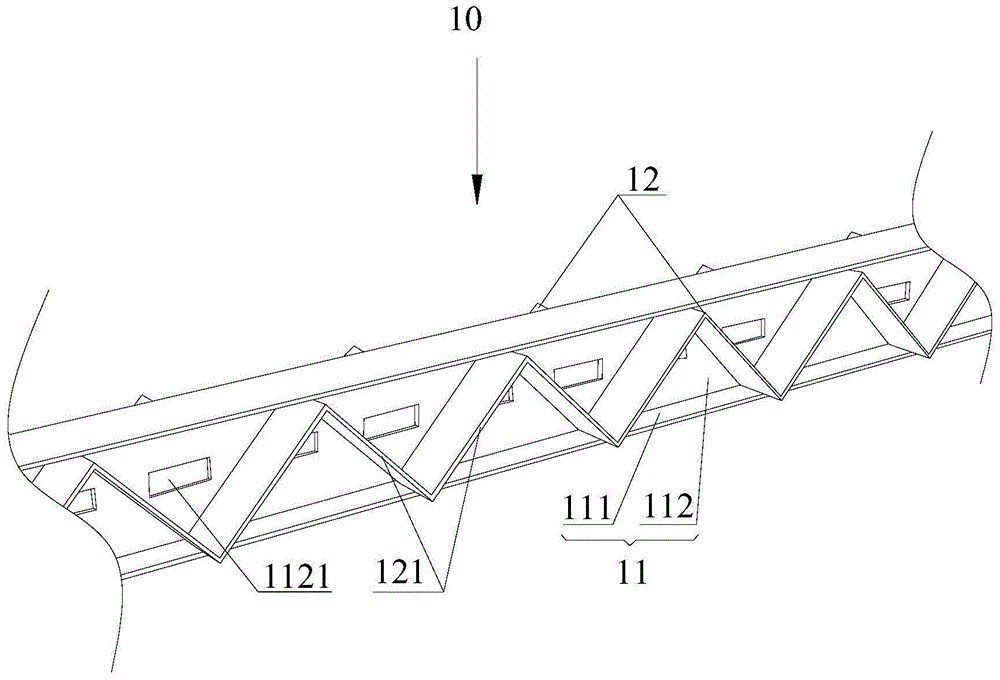

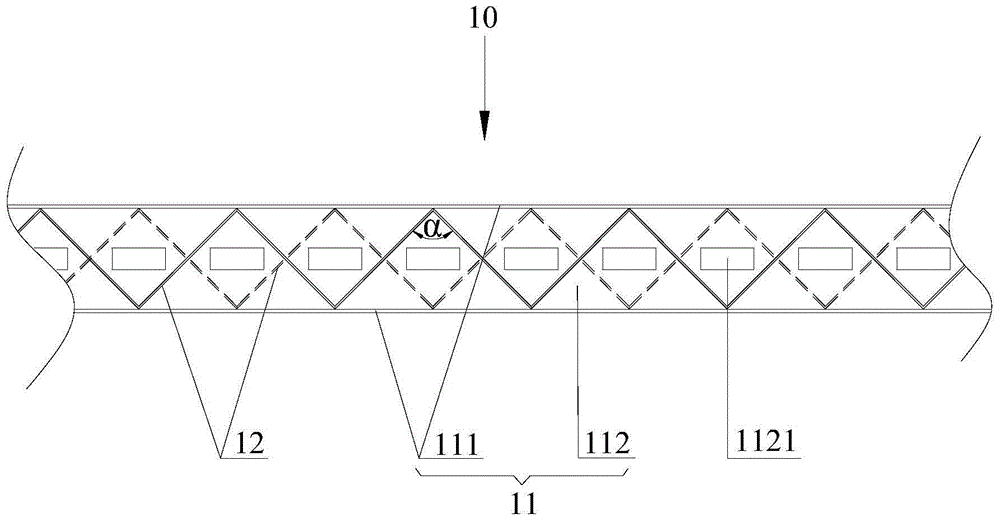

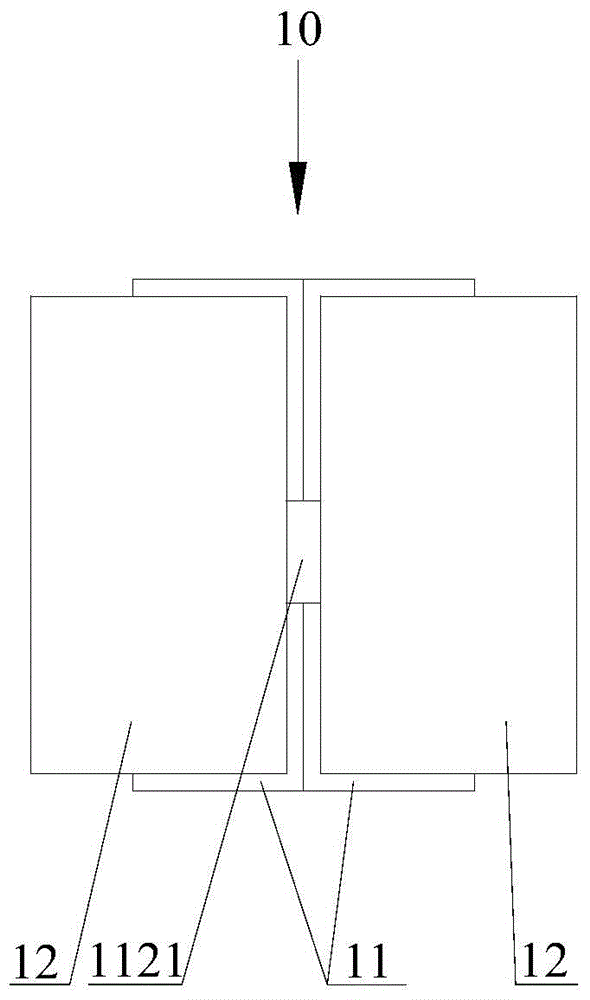

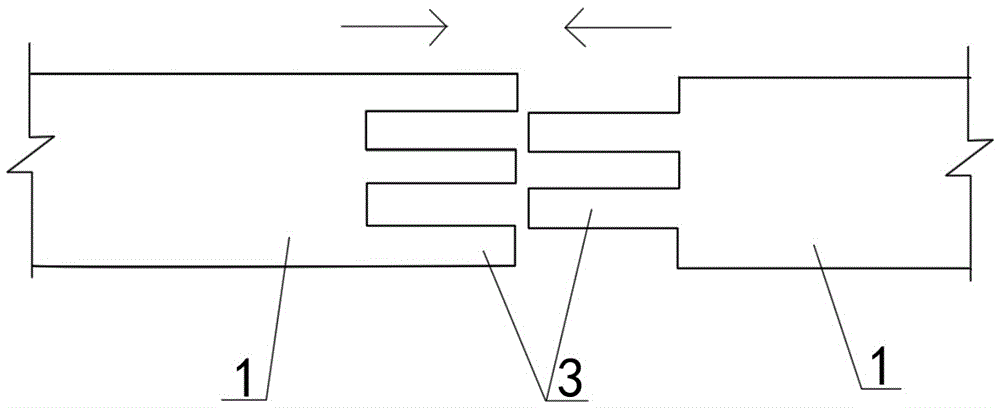

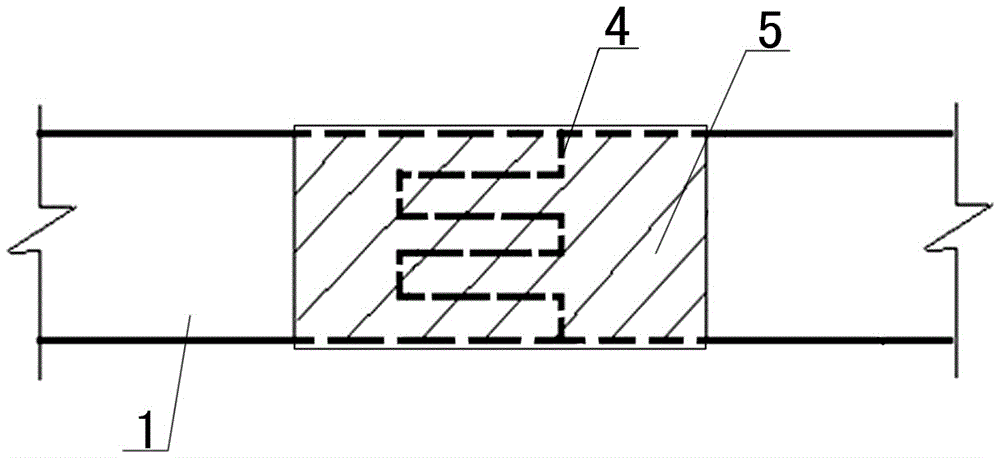

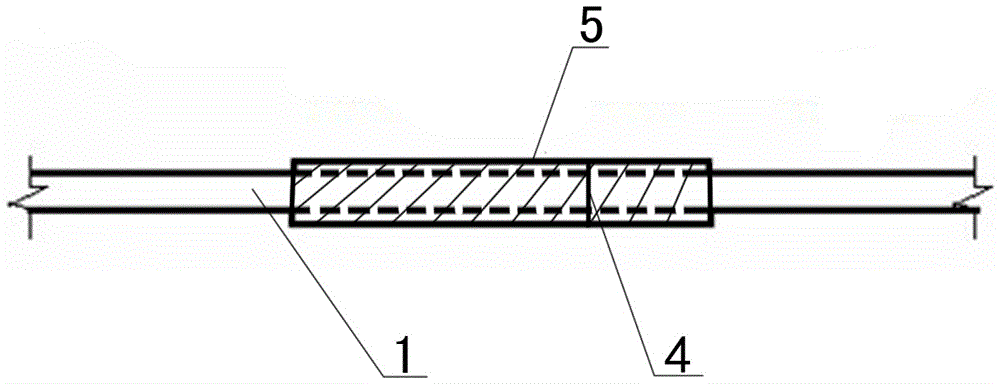

Light steel beam and structural steel frame thereof

ActiveCN104695623AReduce weightImprove structural strengthGirdersJoistsSteel frameUltimate tensile strength

The invention discloses a light steel beam and a structural steel frame thereof. The structural steel frame comprises a frame body and two shearing force bodies, wherein the frame body is provided with a bearing base body and a connecting base body perpendicular to the bearing base body, the two shearing force bodies are fixedly connected to the two side faces of the connecting base body respectively, the bearing base body, the connecting base body and the shear force bodies all extend in the length direction of the light steel beam, each shear force body is provided with multiple shear force base bodies connected in sequence with certain angles formed between the shear force base bodies, and the shear force base bodies at corresponding positions of the two shear force bodies are arranged in a crossing mode. In this way, the overall weight of the structural steel frame is effectively reduced, structural strength is improved greatly, and the development requirements for light weight and high strength of the steel beam are fully met.

Owner:孙毅

Hydraulic concrete structure composite prestress reinforcing system and construction method thereof

The invention discloses a hydraulic concrete structure composite prestress reinforcing system and a construction method thereof, and relates to the field of hydraulic concrete structure reinforcing systems. The hydraulic concrete structure composite prestress reinforcing system comprises a prestress carbon fiber board. The two ends of the prestress carbon fiber board are respectively fixed to thebottom ends of a hydraulic concrete T-shaped beam by a first anchoring mechanism and a first tensioning mechanism. The hydraulic concrete structure composite prestress reinforcing system further comprises at least two prestress steel strands. The prestress steel strands are symmetrically fixed below the partitioning plates on two lateral faces of the bottom of the hydraulic concrete T-shaped beam.One ends of the prestress steel strands are connected with a second tensioning mechanism, and the other ends of the prestress steel strands are connected with a second anchoring mechanism. The construction method comprises the following steps that paying off and positioning are conducted, base surface processing is conducted, anchoring tool mounting is conducted, prestress carbon fiber board andprestress steel strand mounting and laying are conducted, glue preparation and carbon fiber board binding element applying are conducted, prestress tensioning and locking are conducted, and surface sealing processing is conducted. The invention provides the hydraulic concrete structure composite prestress reinforcing system and the construction method thereof, strength and stiffness of the structure are effectively improved, the bearing capacity of the structure is improved, deflection deformation of the structure is reduced, and the function of reducing and sealing cracks is achieved.

Owner:BEIJING IWHR KHL +1

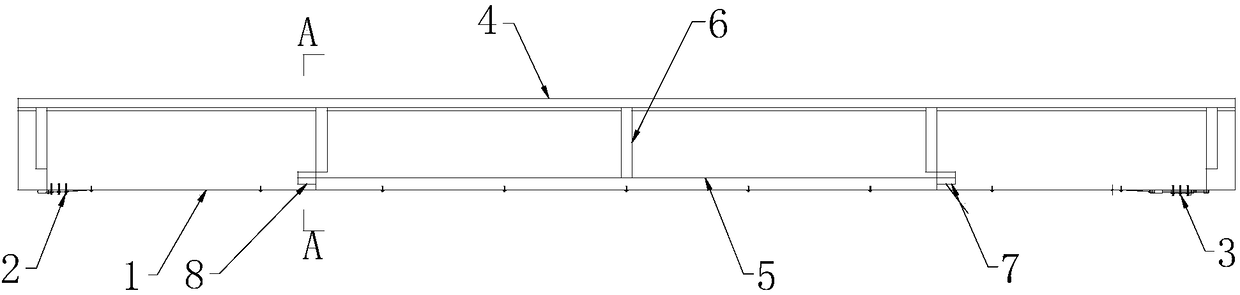

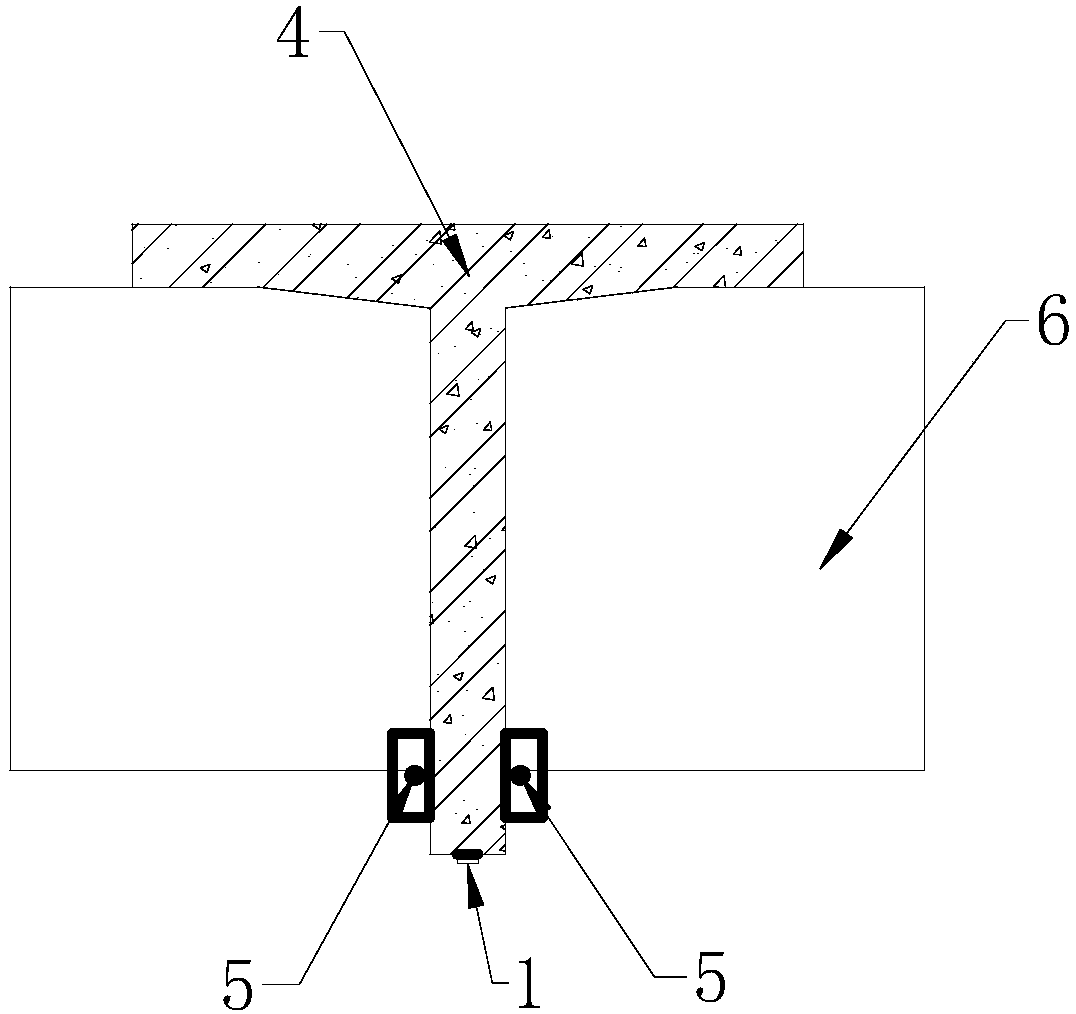

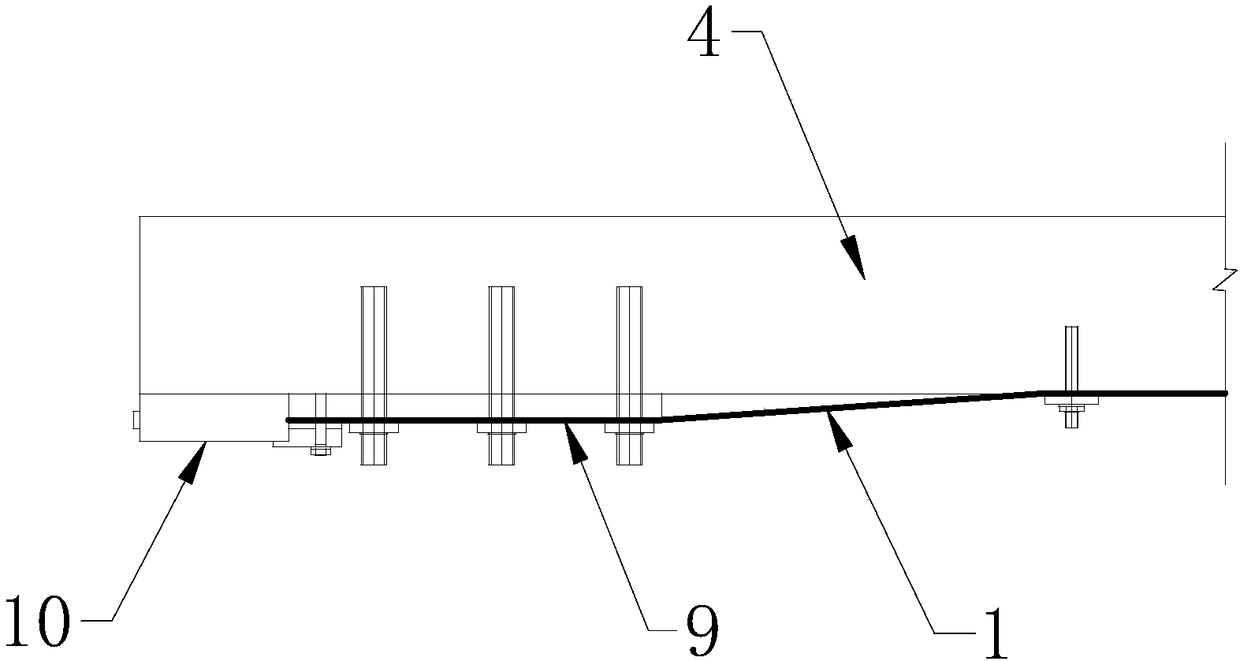

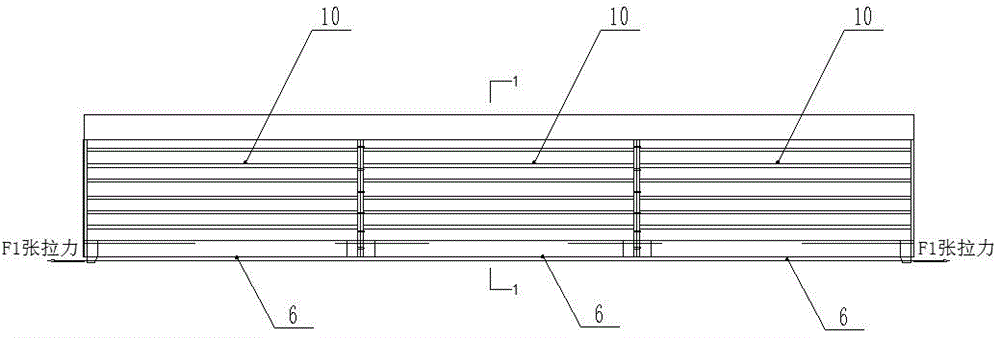

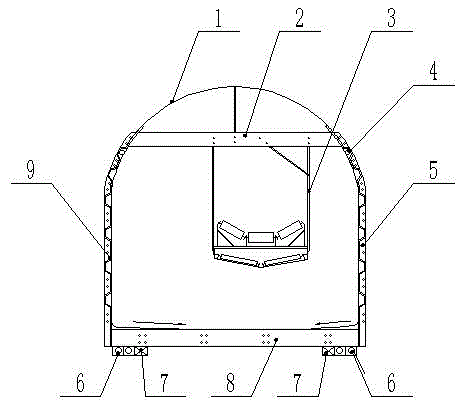

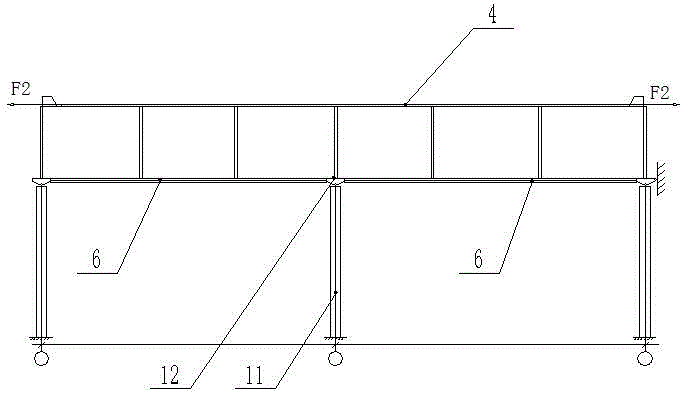

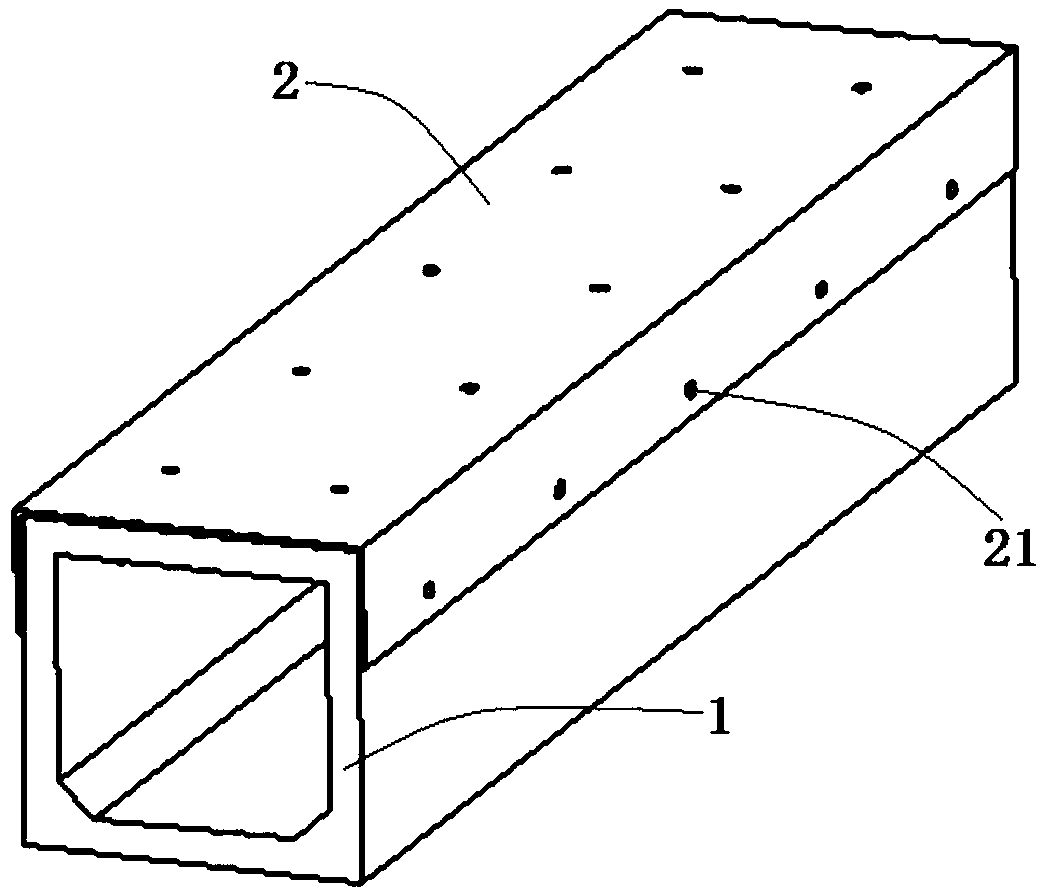

Fabrication and assembly process of integrally prestressed total-assembled box type modular trestle

ActiveCN104358215AQuality improvementReduce security risksPortable bridgeBridge erection/assemblyPre stressEngineering

The invention relates to a fabrication and assembly process of an integrally prestressed total-assembled box type modular trestle, which belongs to the technical field of belt conveyer gallery steel trestles, the solved technical problem is to provide the fabrication and assembly process of the belt conveyer gallery steel trestle, and the belt conveyer gallery steel trestle is easy to fabricate, has stable quality, and is suitable for long spans. The adopted technical solution includes: (step 1) a hoisting and assembly site has to be even and compacted; (step 2) at least two box-shaped modules are sequentially hoisted onto skids section by section, and each two neighboring sections of box-shaped modules are fixedly connected; (step 3) primary prestress tensioning is carried out under a bottom plate of a single-span trestle; (step 4) the single-span trestle is hoisted onto articulated bearings of trestle supports and temporarily fixed; (step 5) a plurality of single-span trestles are repetitively assembled and fixedly connected in pairs to form an integrated multi-span trestle; (step 6) secondary prestress tensioning is carried out for the top plate of the integrated multi-span trestle; (step 7) the secondarily prestressed integrated multi-span trestle is inspected and accepted. The fabrication and assembly process of the integrally prestressed total-assembled box type modular trestle is applied to belt conveyers.

Owner:中煤雷奥邯郸环保科技有限公司

Manufacturing method of high-gloss film plate

ActiveCN107031170AReduce surface roughnessReduce the variability between surface roughnessPhotomechanical apparatusElectroforming processesCopper platingLaser engraving

The invention discloses a manufacturing method of a high-gloss film plate. The method comprises the steps as follows: S1, manufacturing of a matrix: a plate roller is formed through machining of a seamless steel tube; S2, copper plating treatment of the matrix; S3, plate roller surface treatment after copper plating: the copper surface is ground; S4, gluing treatment: natural airing is performed after a photoresist is applied, black glue is applied, and drying is performed by the aid of an infrared drying machine; S5, laser image file manufacturing and laser engraving manufacturing of the plate roller; S6, developing of the plate roller: the black glue is removed, an exposed area of the photoresist is dissolved with an alkali, and a pattern of a non-exposed area is obtained; S7, electrotyping forming: the developed plate roller is placed in a nickel plating tank, electrotyping is performed, the photoresist after engraving and developing has the insulation performance, and meshes are formed in the development area after electrotyping; and S8, cleaning of the plate roller. Contact of the photoresist with oxygen before exposure is reduced, the condition that the photoresist cannot change drastically due to oxidation of the photoresist is avoided, the more stable flat top dot structure is obtained, and meanwhile, the smoothness difference of surfaces in different positions of the same plate roller is reduced.

Owner:TIANJIN YUNCHENG PLATE MAKING

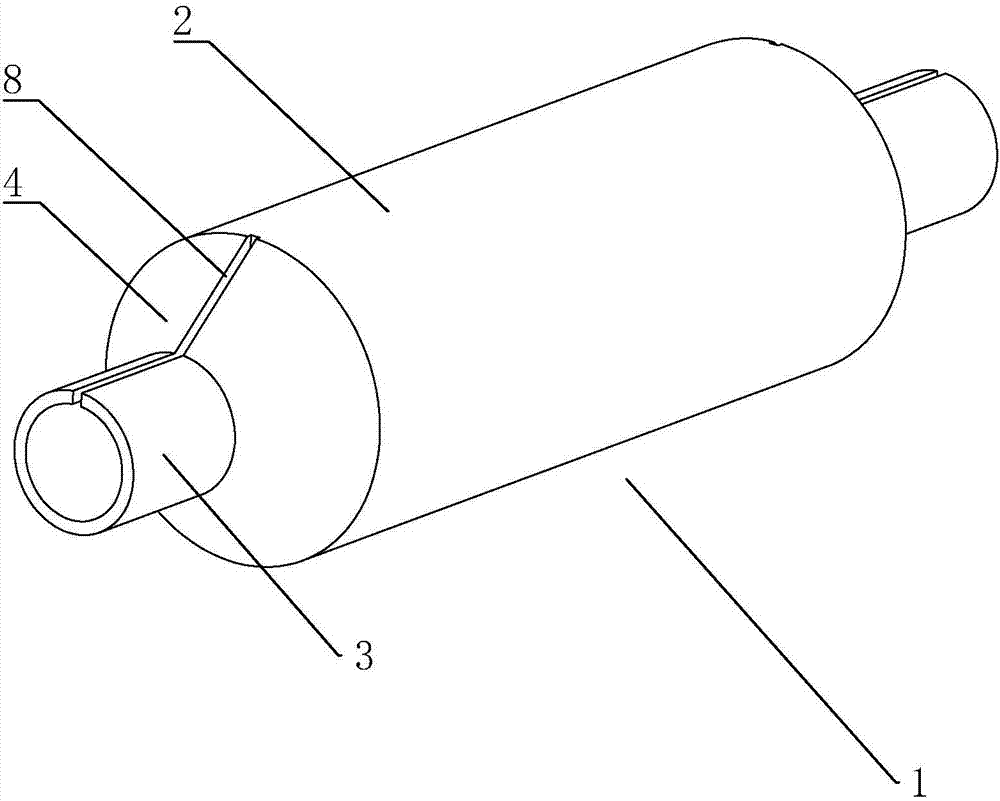

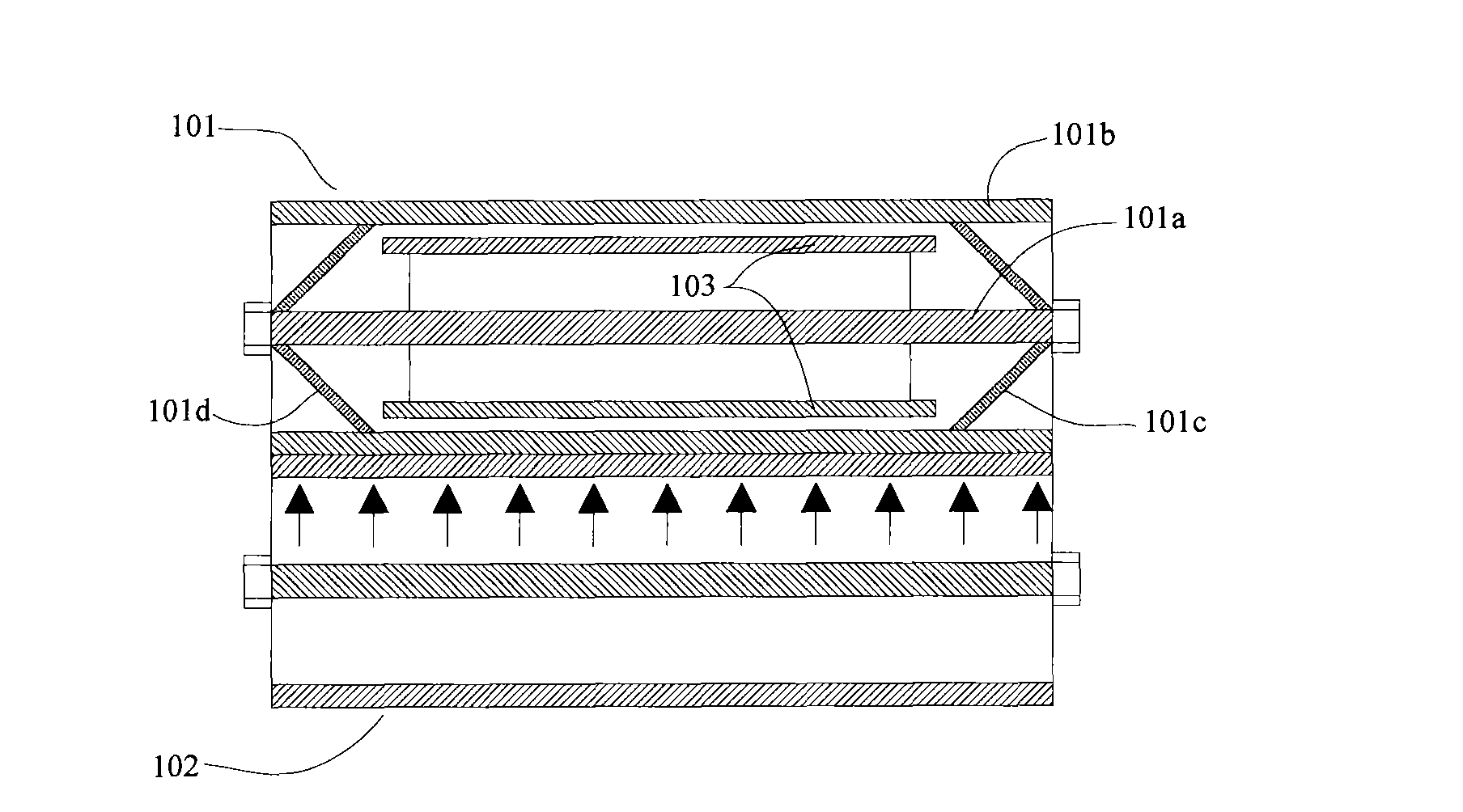

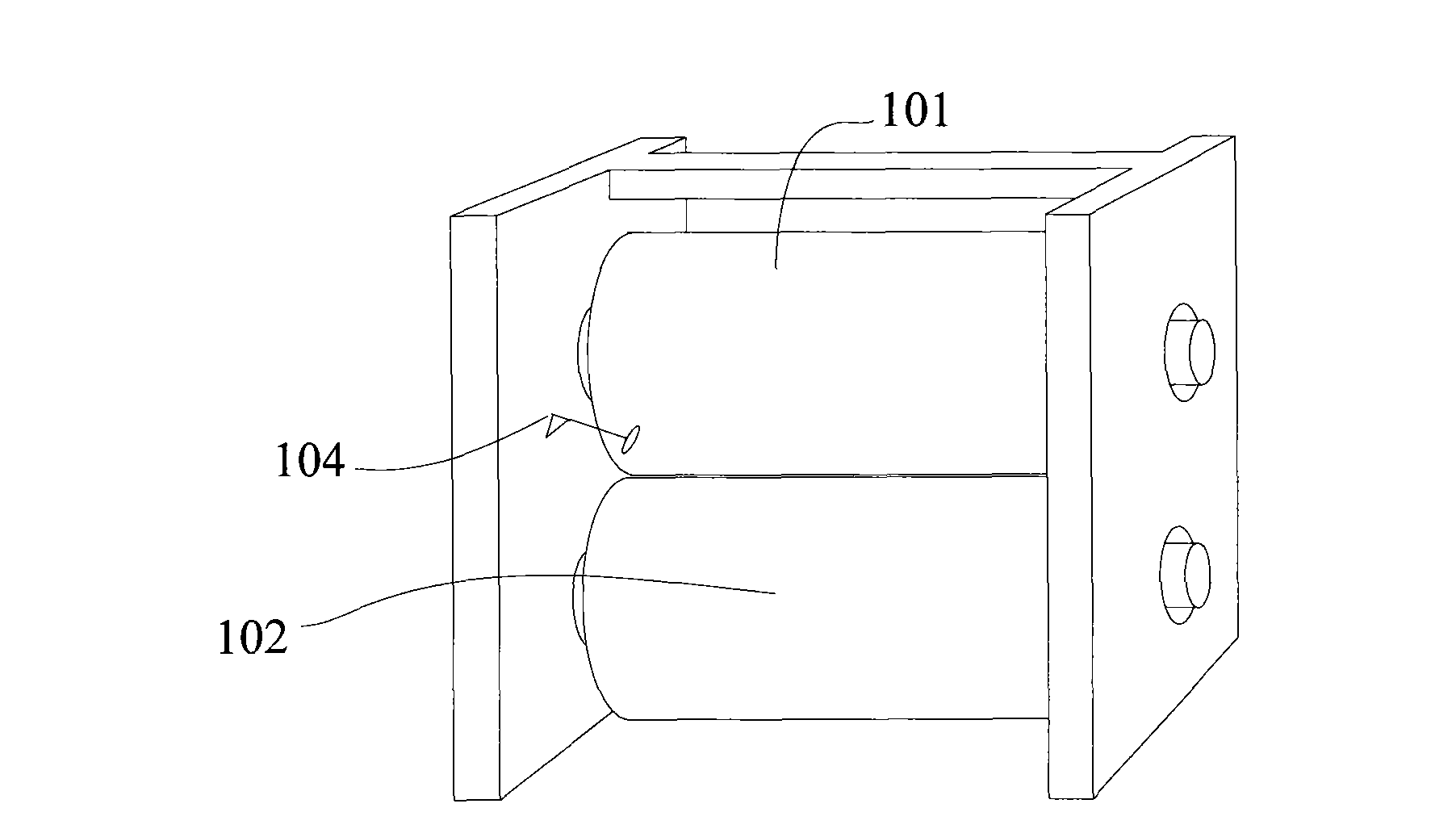

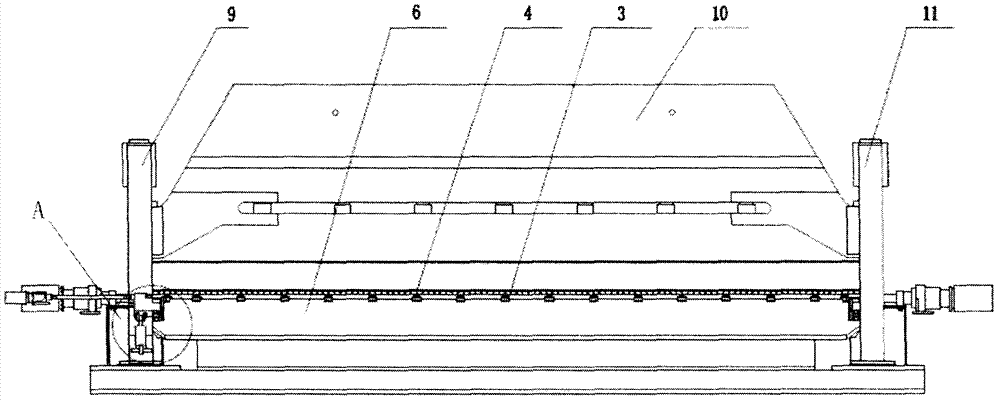

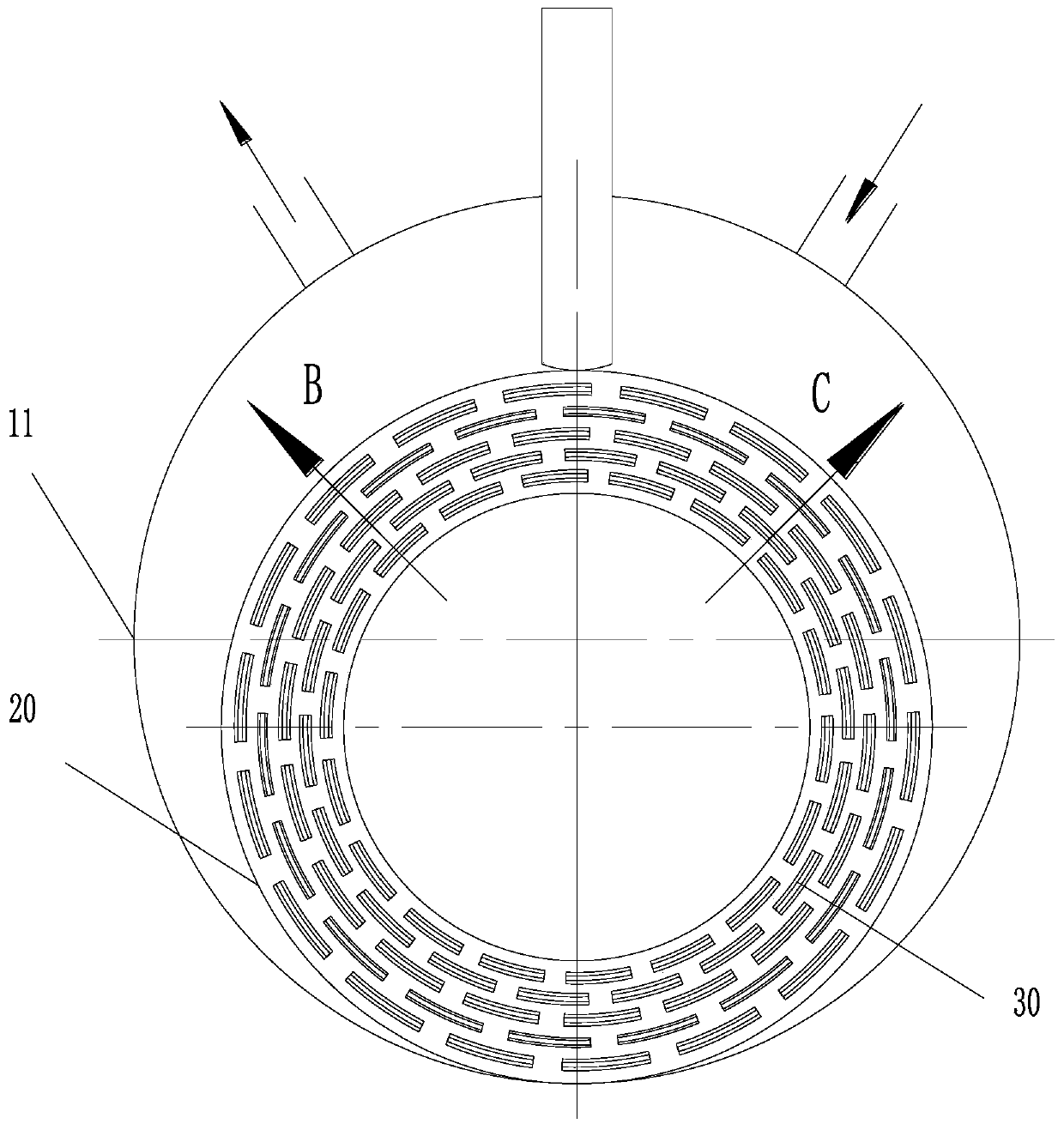

Compression roller of composite machine for preparing polyethylene fiber reinforced composite material

InactiveCN101525841AStable manufacturingUniform performanceFibre treatmentLaminationEngineeringFiber-reinforced composite

The invention discloses a compression roller of a composite machine for preparing a polyethylene fiber reinforced composite material, which comprises a shaft and a drum which is sleeved outside the shaft and keeps concentric with the shaft; two ends of the shaft and the drum are positioned and connected by a first radial plate and a second radial plate symmetrically arranged at two ends of the drum respectively to form a hollow area in the drum; a heating device is arranged in the hollow area; and the first radial plate and the second radial plate are oblique towards the middle of the drum to connect the inside of the drum. The compression roller effectively reduces the flexural deformation of the compression roller, can effectively and evenly heat the surface of the hollow drum through arrangement of an optical heating pipe device in the hollow compression roller, and is suitable for continuously preparing polyethylene fiber reinforced laminated cloth with even performance.

Owner:杨珍芬

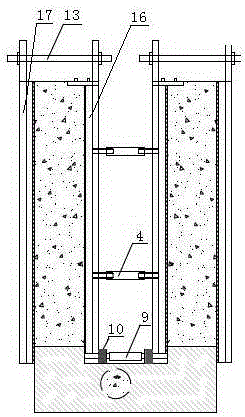

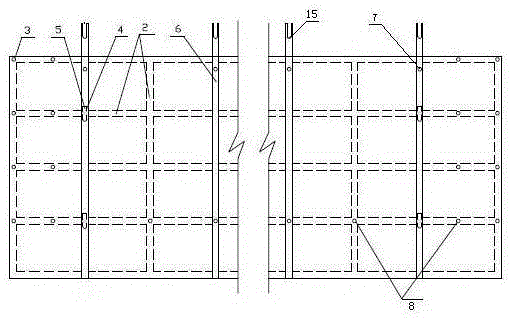

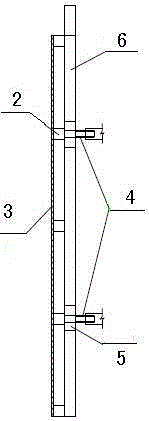

Wall continuous pouring nonmetal horizontal slip form system for deep and narrow drainage ditch

ActiveCN105178256AIncreased shear strengthReduce deflection deformationSewerage structuresArtificial water canalsRear quarterEngineering

A wall continuous pouring nonmetal horizontal slip form system for a deep and narrow drainage ditch comprises a unit slip form. A unit slip form body is composed of inside plates and outside plates. The inside plates are manufactured and located through adjusting type fixed supporting rods, and bottom rolling wheel shaft sleeves and bottom rolling wheels are arranged at the bottoms of the inside plates. The tops of the inside plates and the tops of the outside plates are fixed through top opposite-pull lead screws, and the surfaces of the tops of the inside plates and the surfaces of the tops of the outside plates are closed by cover plate pressing plates. The system has the beneficial effects that a novel form board is high in bending resisting and shear resisting strength and small in flexibility deformation, and the mechanical property is great superior to that of a common wood form board; plant prefabrication machining standardization and serialization are achieved, machining losses are small, and the cyclic use frequency is large; and mounting and dismounting are convenient, the workloads of form erecting and dismounting are greatly reduced, and the form board use efficiency is improved.

Owner:江苏海宏智能科技有限公司

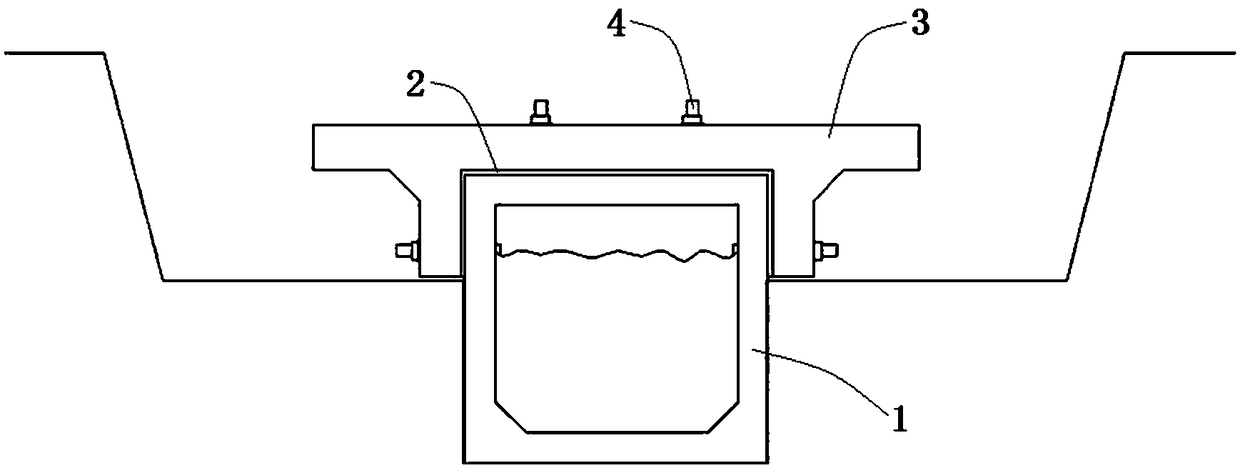

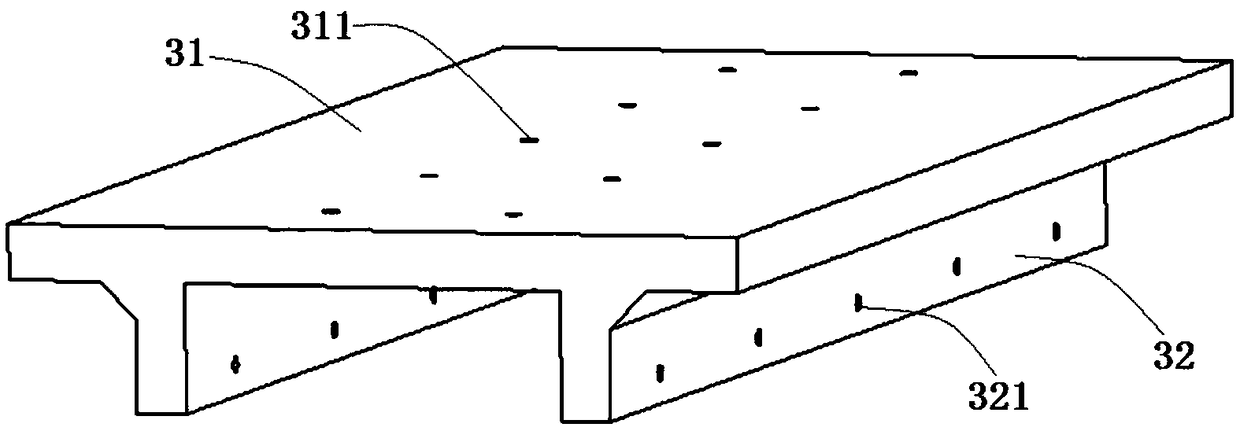

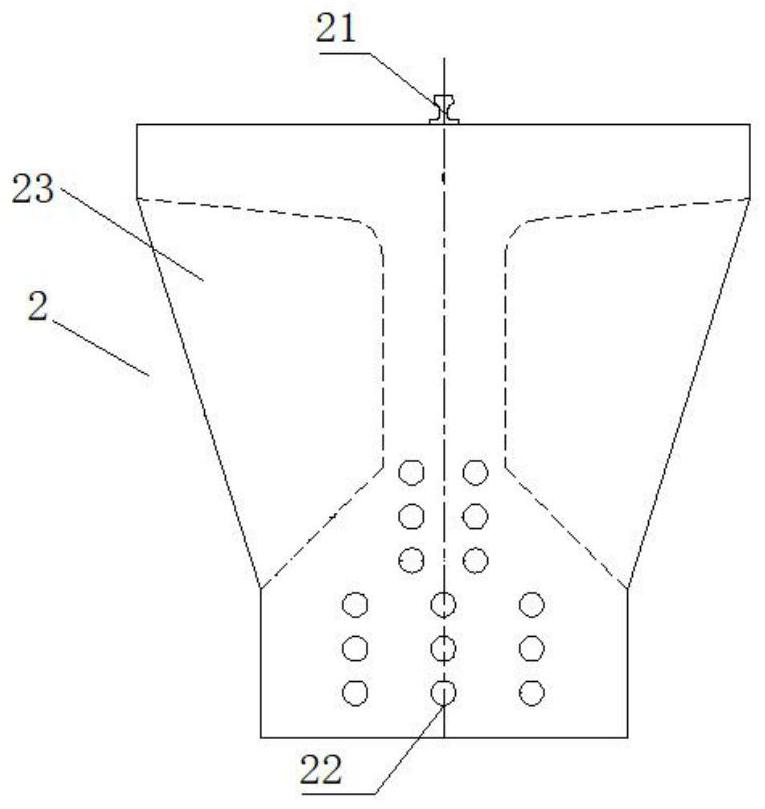

Prefabricated assembly device for rapidly increasing culvert bearing capacity and method for strengthening culvert

ActiveCN109137764AImprove bearing capacityReduce construction difficultyGround-workArchitectural engineeringCulvert

The invention discloses a prefabricated assembly device for rapidly increasing culvert bearing capacity, comprising a top plate and flanges on both sides of the top plate, the top plate is used for mounting on the top of the culvert, the flanges are used for mounting on both sides of the culvert, and the dimensions of the top plate and the flanges are prefabricated according to the dimensions of the culvert. The invention also discloses a method for strengthening a culvert by adopting the prefabricated assembly device. The invention excavates part of the culvert to cover soil, not all of it; the reinforcement position is outside the culvert, not inside; the construction difficulty is low, the construction efficiency is high, does not need to enter the narrow culvert, greatly enhances the culvert's bearing capacity; the construction process of the invention is all on the outside of the culvert, and the bad construction environment of the culvert sewer pipe is avoided. The prefabricatedassembly device of the invention is integrated with the culvert after being strengthened, and does not need to be dismantled; the invention can greatly reduce the deflection deformation of the top ofthe culvert.

Owner:EAST CHINA JIAOTONG UNIVERSITY

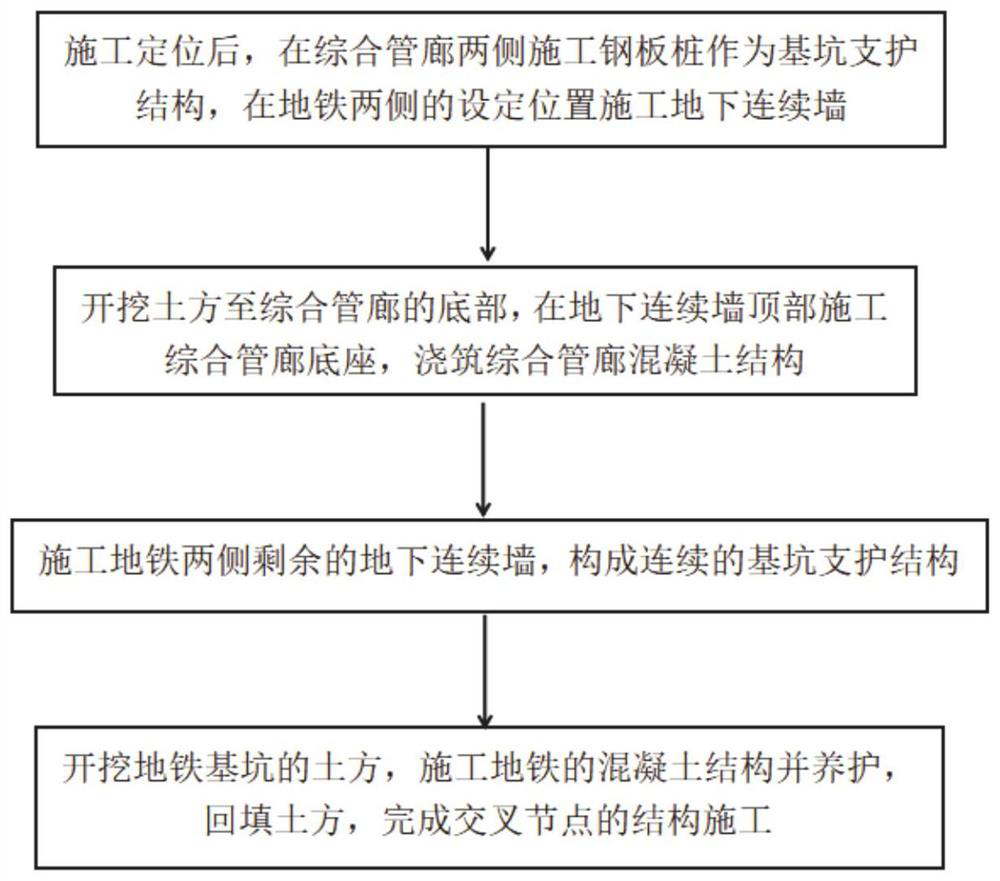

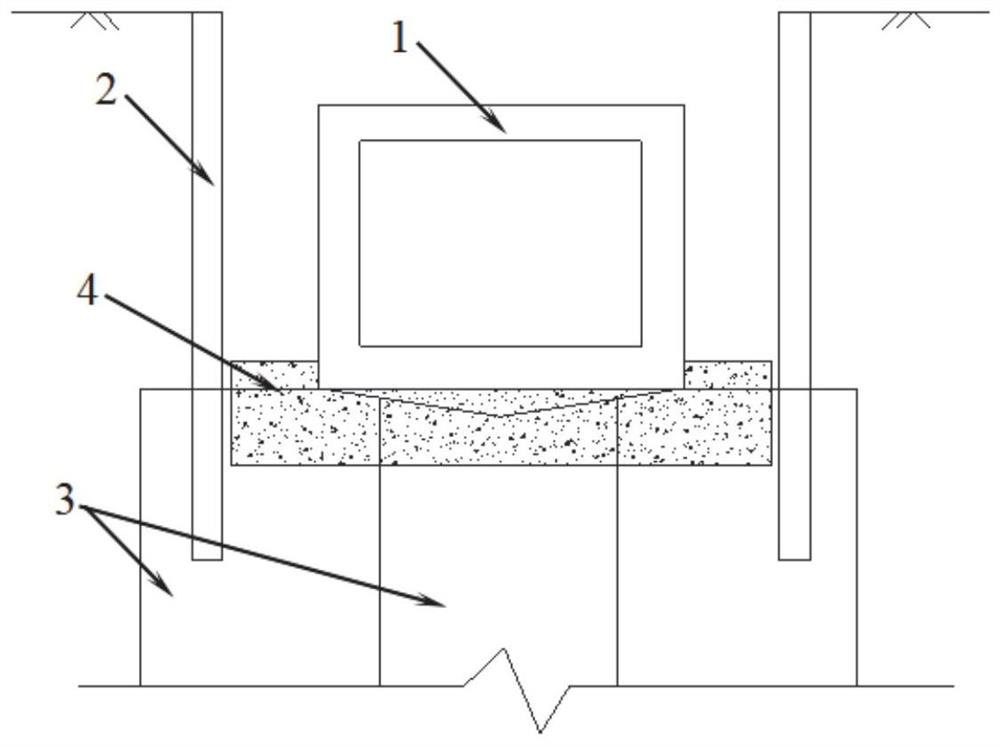

Structure construction method for crossing subway cross-joint on pipe gallery

ActiveCN112982481ALow costReduce deflection deformationArtificial islandsClimate change adaptationSteel platesGeotechnical engineering

The invention discloses a structure construction method for crossing a subway crossing-joint on a pipe gallery. The structure construction method comprises the following steps that after construction positioning is carried out, steel sheet piles are constructed on two sides of a comprehensive pipe gallery as foundation pit supporting structures, and underground diaphragm walls are constructed at set positions on two sides of a subway; earthwork is excavated to the bottom of the comprehensive pipe gallery, a comprehensive pipe gallery base is constructed at the tops of the underground continuous walls, and a comprehensive pipe gallery concrete structure is poured; the remaining underground diaphragm walls on the two sides of the subway are constructed, and a continuous foundation pit supporting structure is formed; and earthwork of the subway foundation pit is excavated, a concrete structure of the subway is constructed and maintained, the earthwork is backfilled, and structural construction of the cross-joint is completed.

Owner:济南国际机场建设有限公司 +1

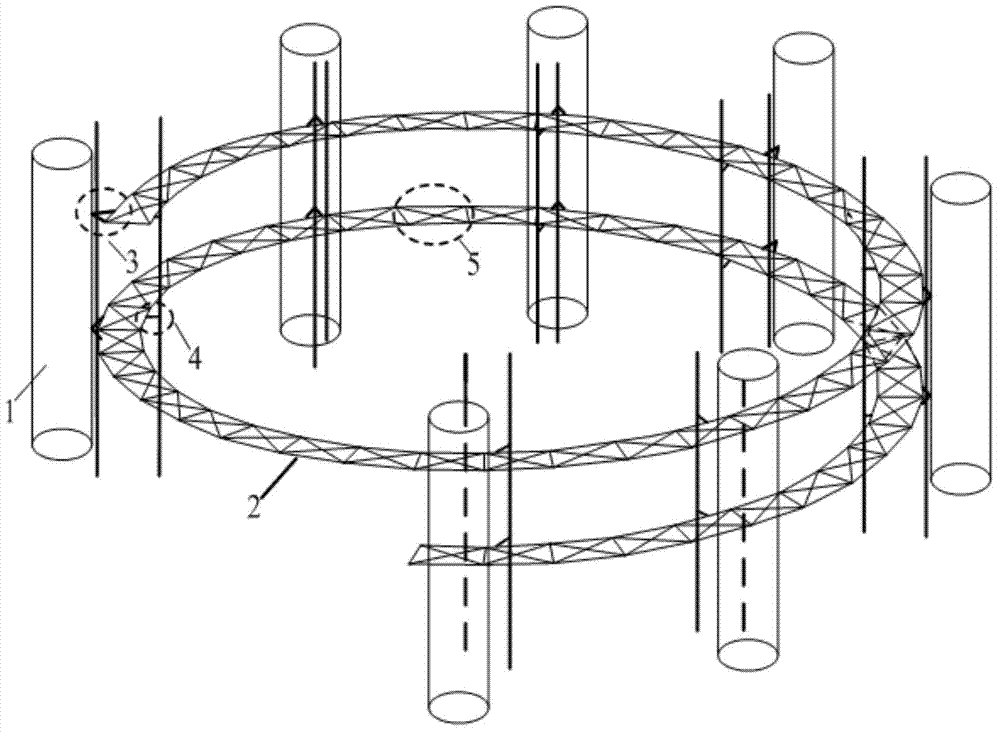

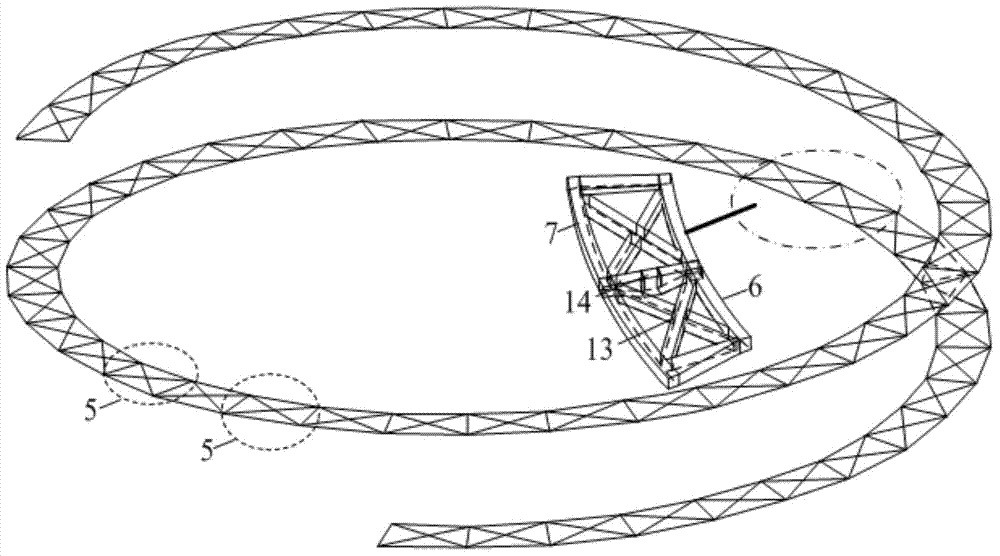

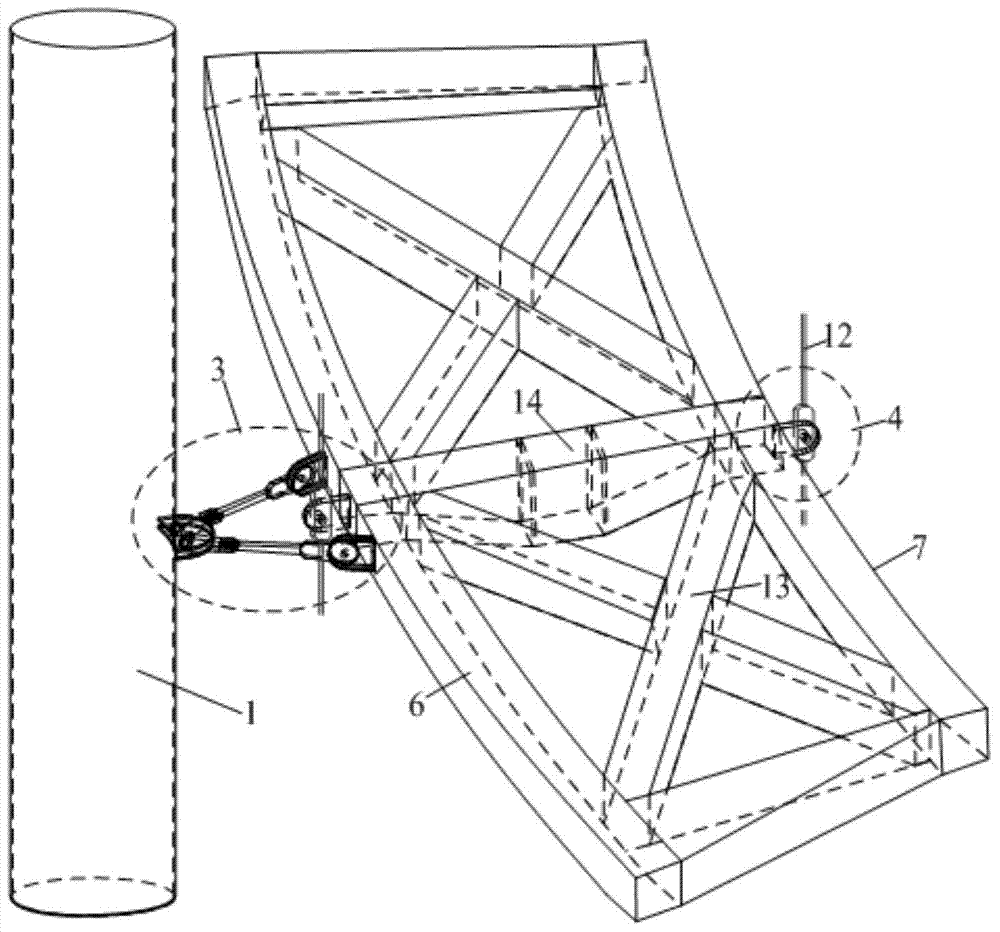

Column and curved beam horizontal and flexible connection space structure system

The invention provides a column and curved beam horizontal and flexible connection space structure system. Columns and curved beams are horizontally and flexibly connected through horizontal and flexible connecting devices, each horizontal and flexible connecting device comprises a column connector, a curved beam connector a and a steel pull rod for connecting the column connector with the curved beam connector. A vertical suspending connecting device is further connected onto each curved beam and comprises a curved beam connector b and a movable steel suspending rod. The column and curved beam horizontal and flexible connection space structure system is a grid structure and suspended-cable structure combined space structure system. In a space truss structure system, the strength and ductility of a grid curved beam structure are improved, bending resistance bearing capacity of the curved beams is remarkably improved, and deflection deformation of the curved beams is reduced. In a suspended-cable structure, suspended steel structure curved beams are connected through flexible suspending rods. The column and curved beam horizontal and flexible connection space structure system has the flexible connection characteristic, accordingly is simple in overall appearance, even in stress, good in anti-seismic energy dissipation performance and easy to repair and maintain and meets the comfort degree requirement of a suspended steel structure.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD +1

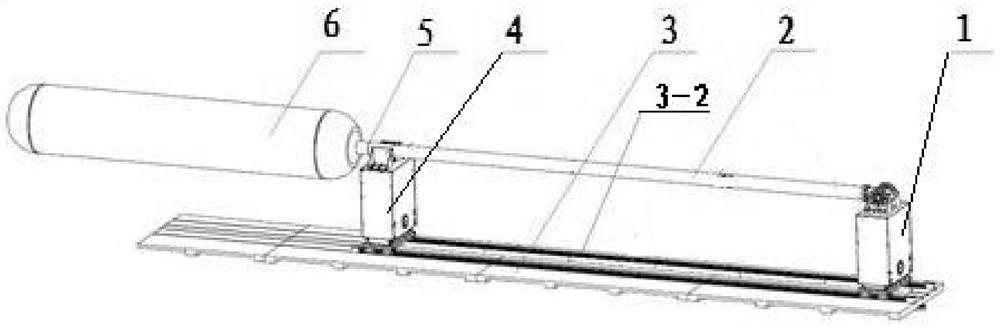

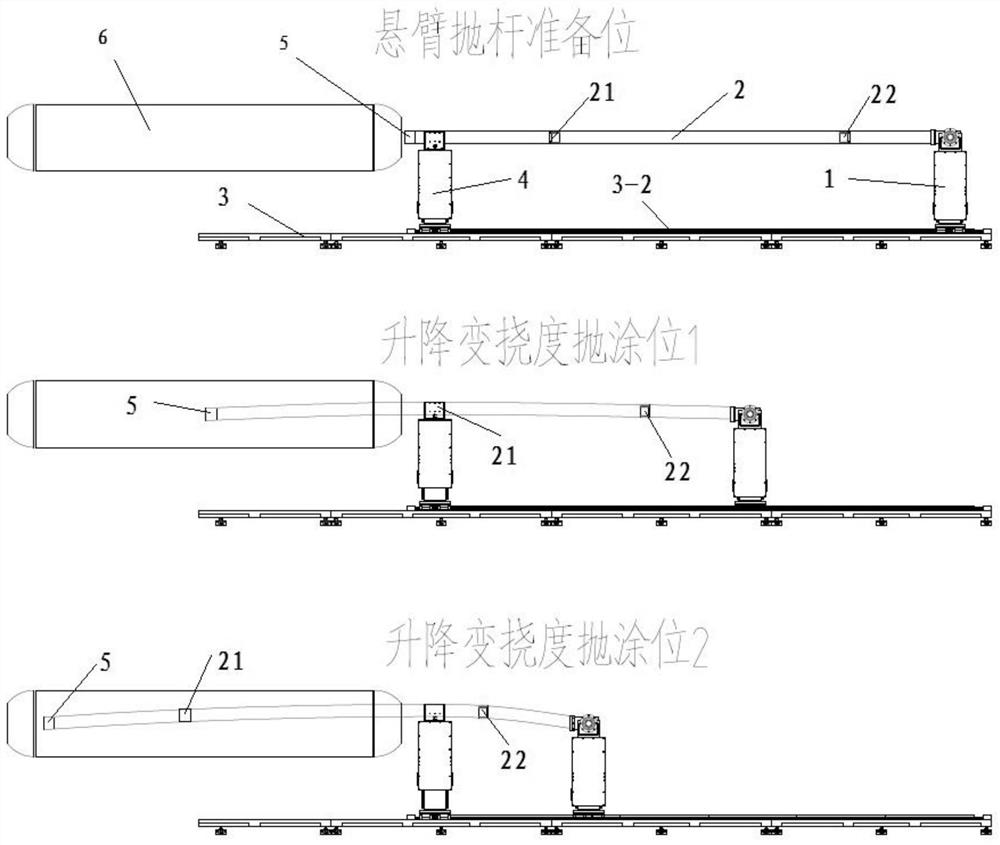

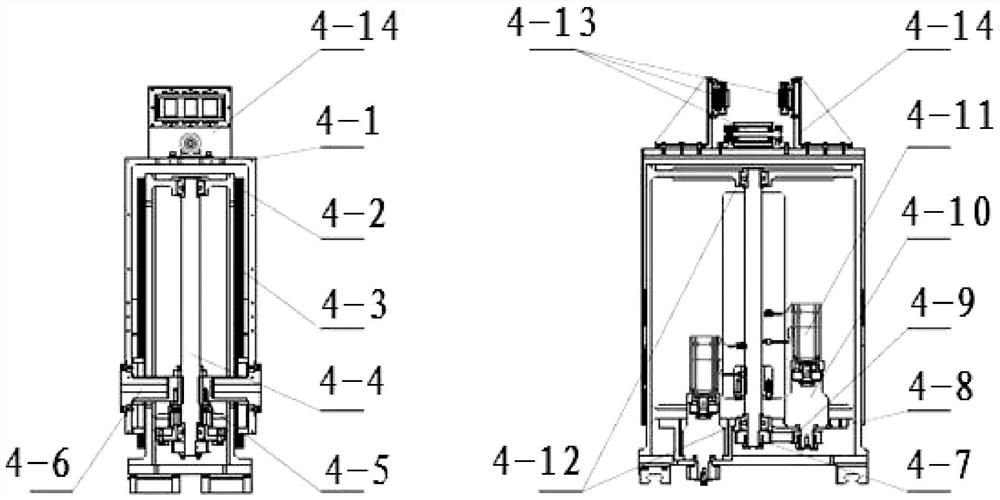

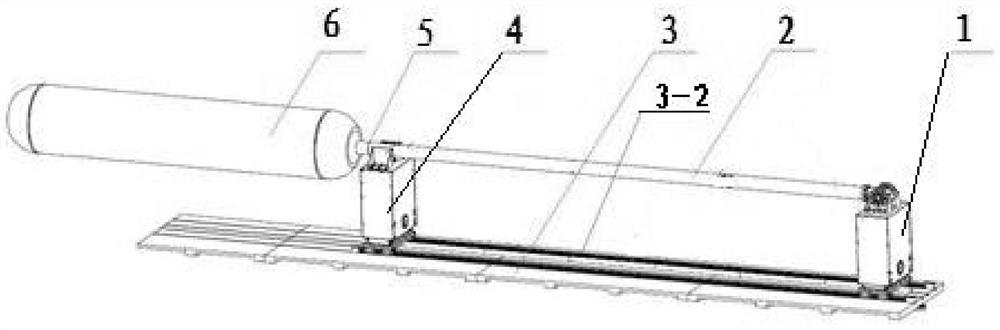

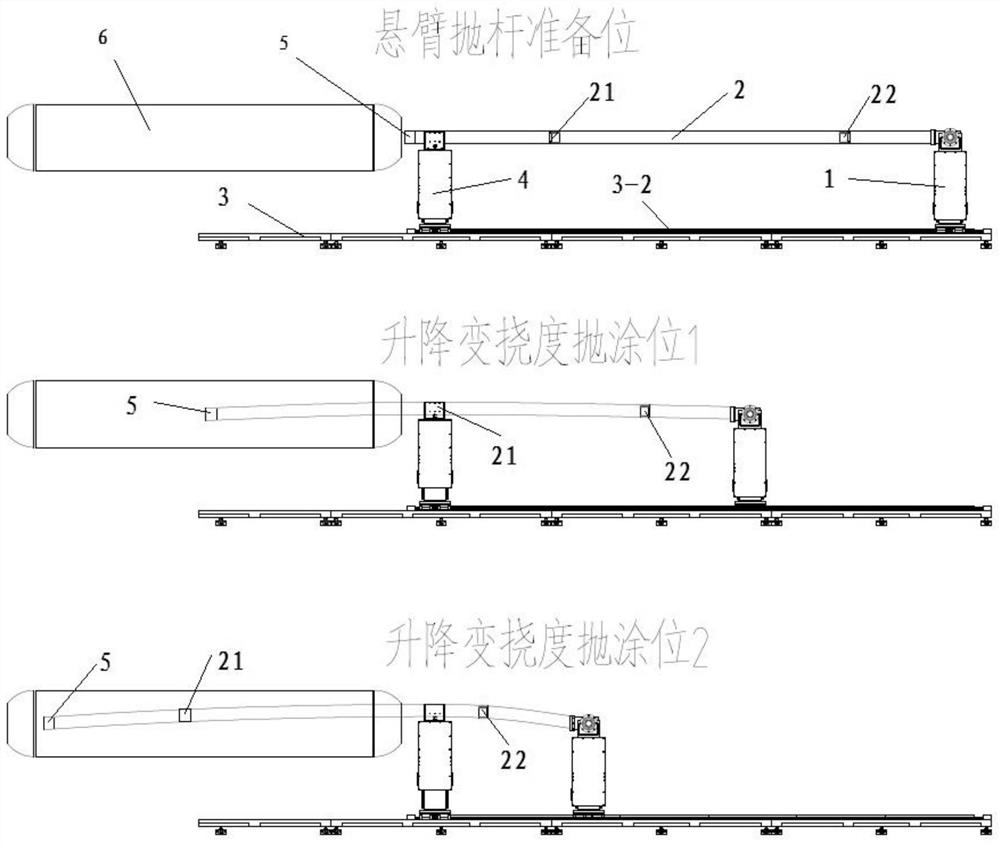

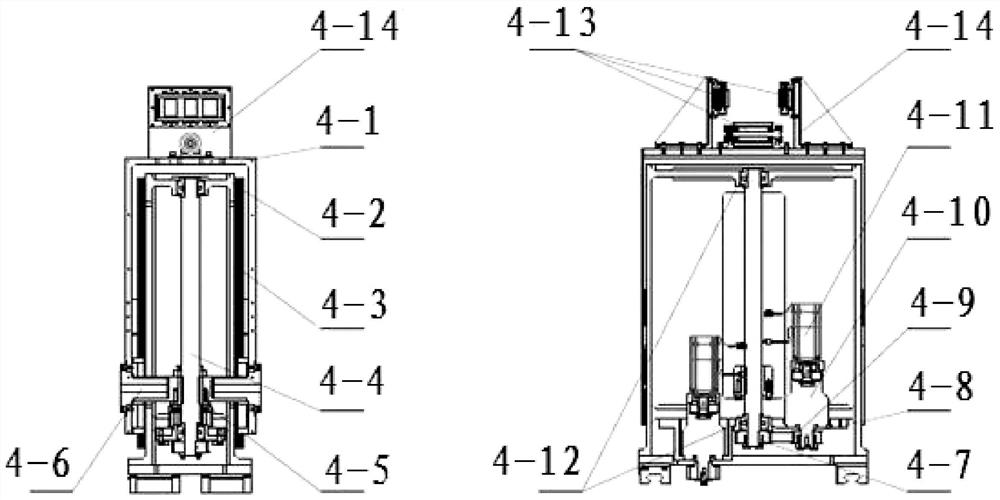

Large-span liftable variable-deflection cantilever throwing rod device

The invention relates to a large-span liftable variable-deflection cantilever throwing rod device, and belongs to the technical field of rocket engine charging manufacturing robots. The device comprises a mobile end lifting group module, a cantilever rod, a platform base, a fixed end lifting group module, a tail end throwing and coating device and a shell, wherein a guide rail is arranged on the upper surface of the platform base; the movable end lifting group module and the fixed end lifting group module are both arranged on the guide rail and are in sliding fit with the guide rail; the cantilever rod is axially arranged above the guide rail in parallel; the axial head end of the cantilever rod is rotationally connected with the top of the movable end lifting group module; the axial tail end of the cantilever rod is in lap joint with the top of the fixed end lifting group module; the tail end throwing and coating device is sleeved at the axial tail end of the cantilever rod; the shell is of a hollow columnar structure; and the shell is coaxially arranged at the axial tail end of the cantilever rod. The coating device has the capacity of considering the coating quality and efficiency, and can flexibly extend and retract in small spaces of engine shells with different lengths and different diameters, so that the problems in the prior art are solved.

Owner:HARBIN INST OF TECH

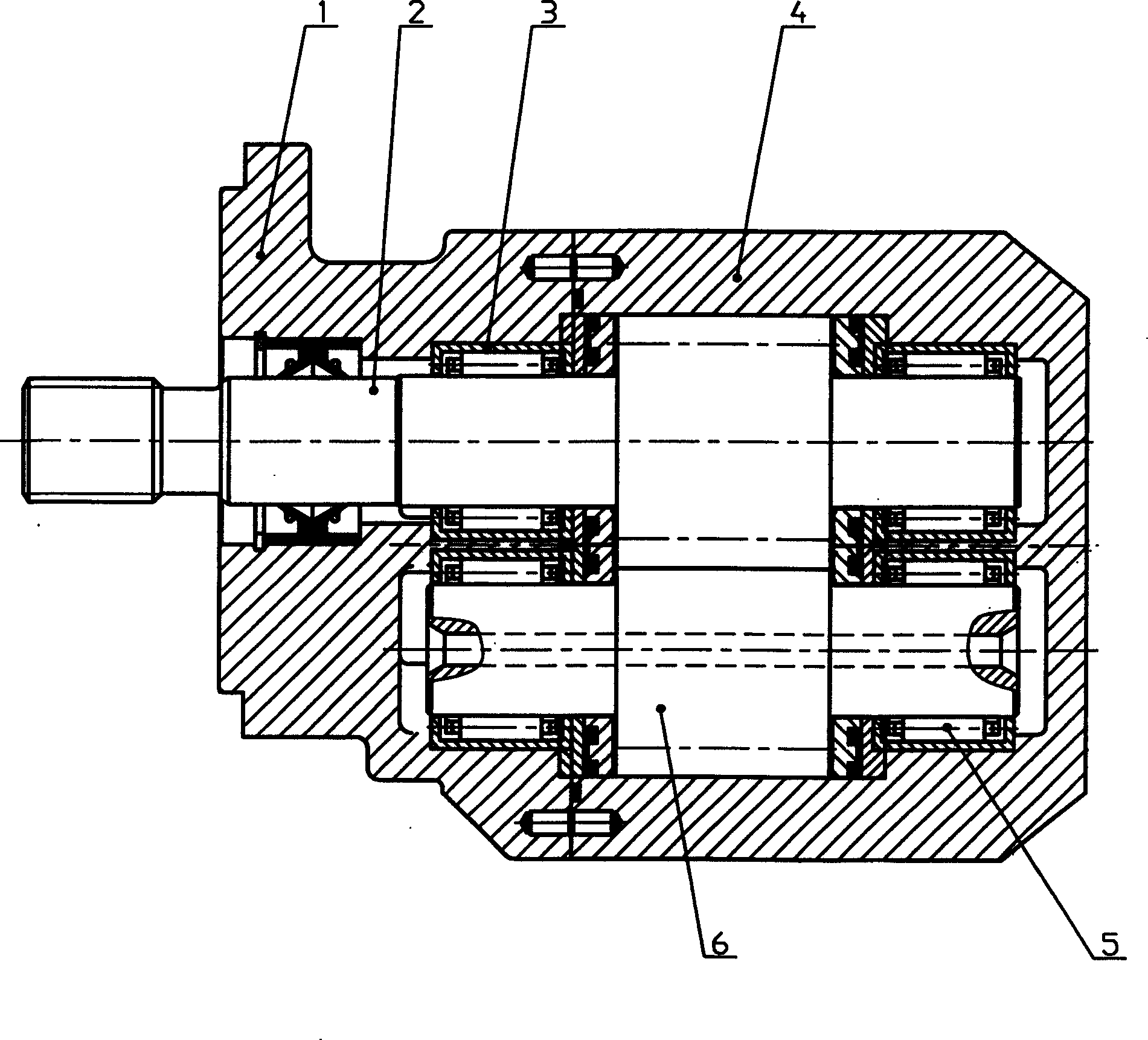

Hydraulic gear pump

InactiveCN1598314AReduce wearHeavy loadRotary piston pumpsRotary piston liquid enginesGear pumpGear wheel

The invention relates to a hydraulic pressure gear pump. It is used to improve the working press and length of life of the hydraulic pressure but need not to change the structure of the original pump body. It includes drive gear which is fasten by two drive gear axle bearing and driven gear which is fasten by two driven gear axle bearing, the particular lie on the external diameter of the driven gear must be greater than the drive gear's. The advantages are simple processing, high operation pressure and long service life.

Owner:徐福刚

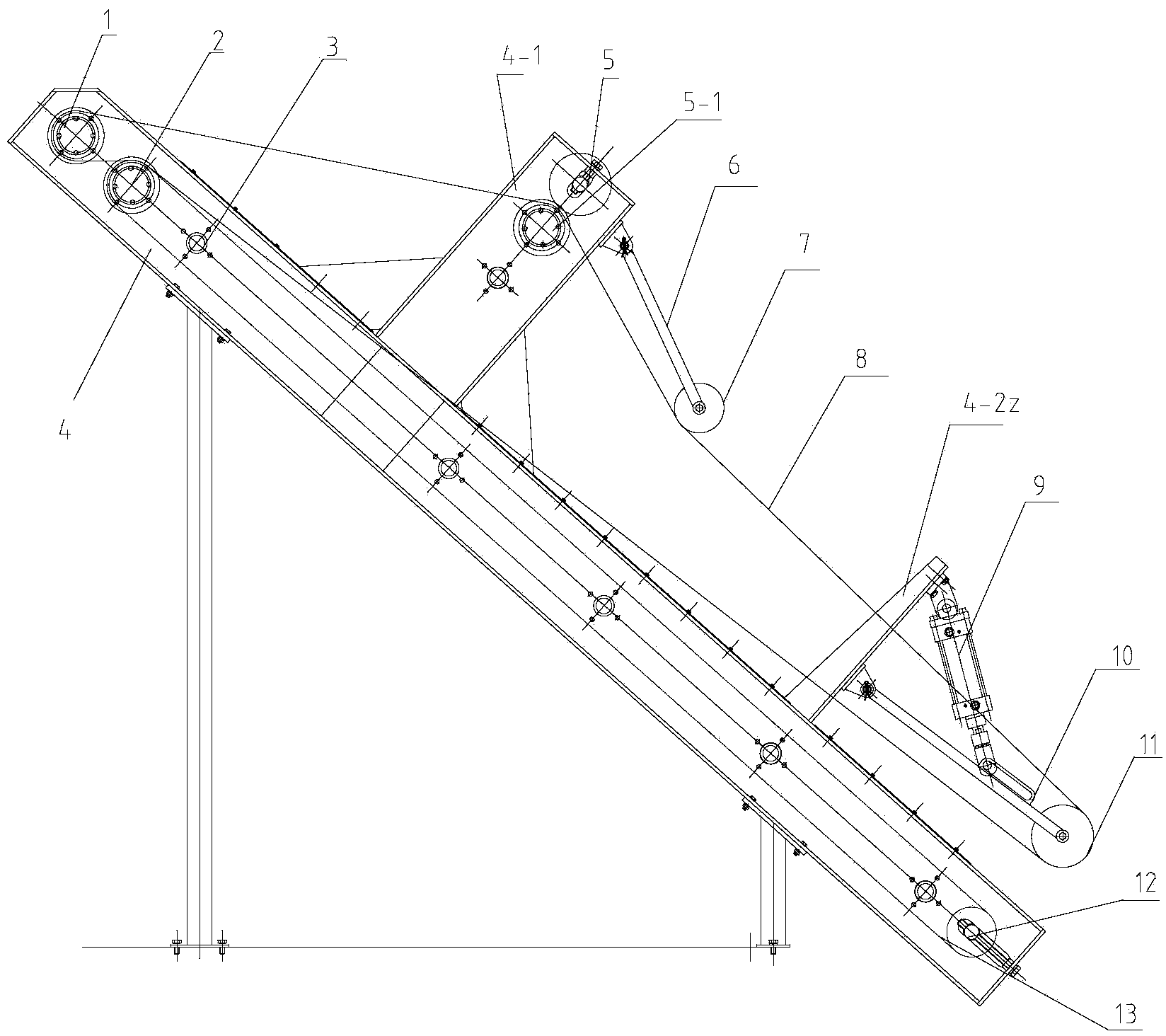

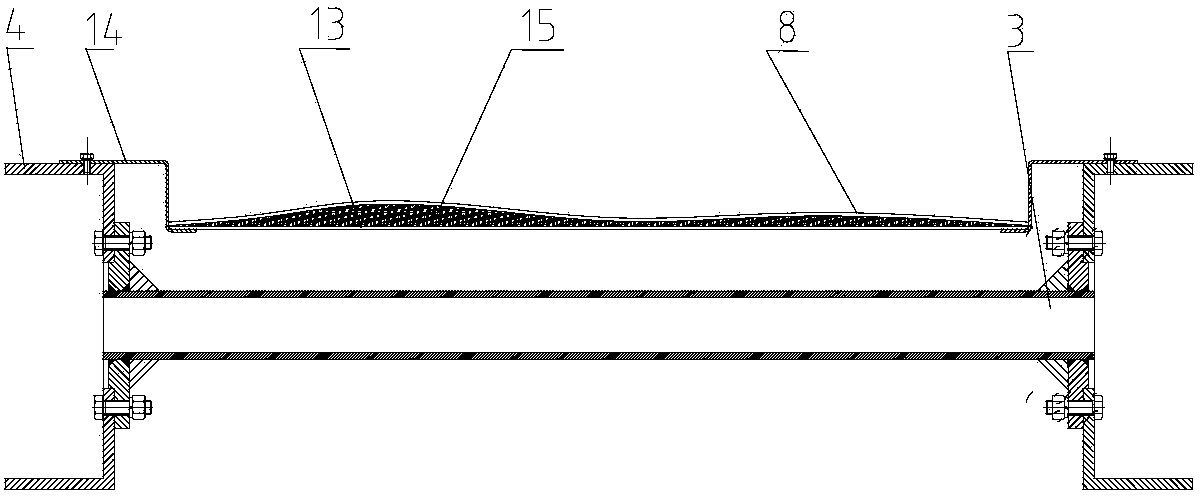

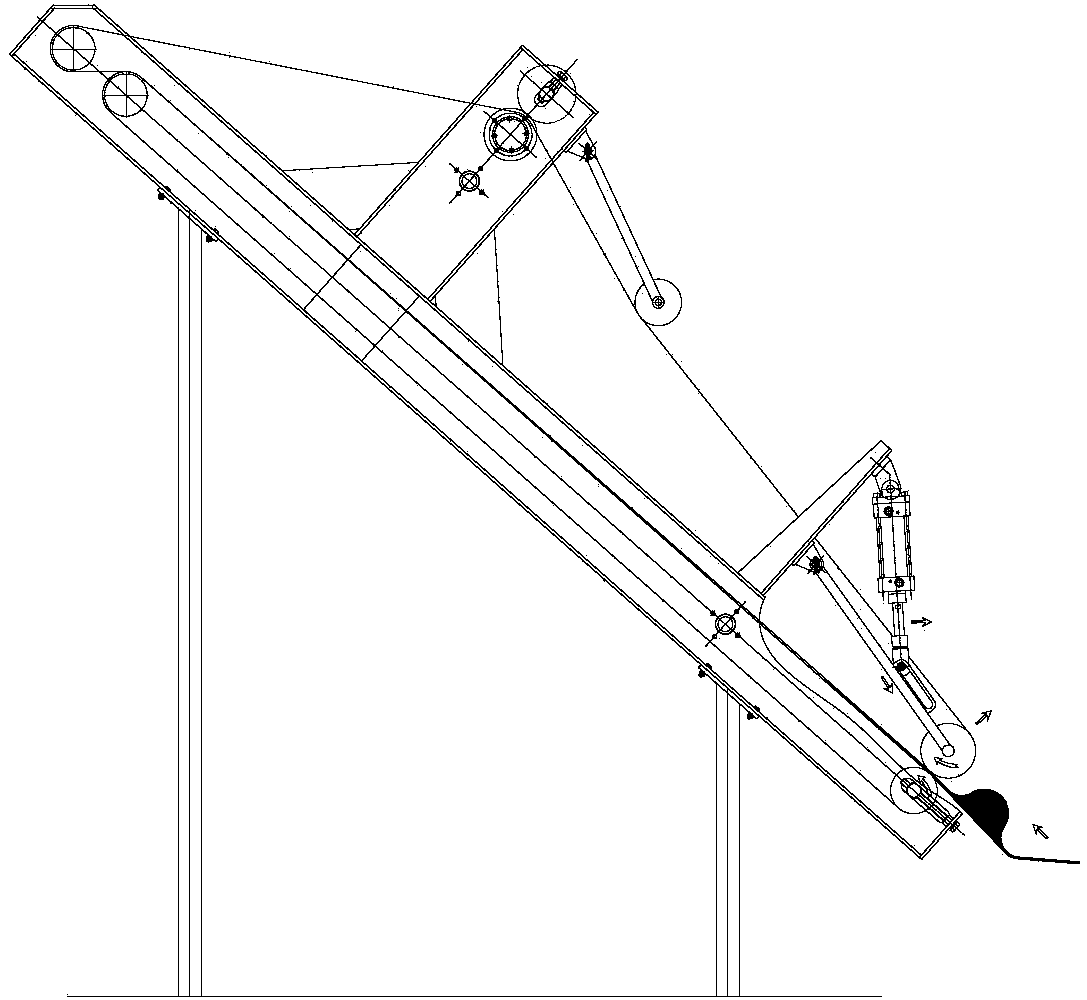

Dual-belt synchronous clamping conveying device

The invention relates to a dual-belt synchronous clamping conveying device, and belongs to the technical field of material conveying. The device comprises an oblique frame for supporting a driving roller and a pull-down tension roller, wherein a lower layer conveying belt is wound on the driving roller and the pull-down tension roller; an upper framework and a lower framework extend out of the frame; a driven roller is further supported on the driving roller of the frame; a synchronous driving roller is supported on the upper framework; a swinging rod of which the lower end is provided with a floating roller is hinged to the upper framework; a slide rail swinging rod of which the lower end is provided with a gravity roller is hinged to the lower part of the lower framework; the upper end of a bilateral cylinder is hinged to the upper end of the lower framework; the lower end of the bilateral cylinder and the slide rail extending along the length direction of the slide rail swinging rod construct a moving pair; an upper layer conveying belt is wound on the driven roller, the synchronous driving roller and the gravity roller; the floating roller is arranged on the upper layer conveying belt. According to the dual-belt synchronous clamping conveying device, stable and continuous conveying can be realized under the condition of large inclination angle, and a material inlet can float along with a shape to adapt to the height change; moreover, an automatic tensioning mechanism is flexible and reliable, materials are prevented from falling off, and automation and centralized control are realized easily.

Owner:AEROSUN CORP

Construction method of hollow floor slab

The invention discloses a construction method of a hollow floor slab. The construction method of the hollow floor slab comprises the following steps of 1, construction preparation; 2, formwork installation; 3, surveying and laying-out; 4, steel bar binding; 5, water and electricity line pre-embedment; 6, information of a gypsum filling box; 7, installation of plate steel bars; and 8, concrete pouring and vibrating. According to the construction method, a gypsum filling box dense rib floor structure system is adopted, the long-span structure space clear height can be increased, and the buildingspace is open and light in weight. Meanwhile, the hollow floor slab has the remarkable advantages that identical bidirectional stress force and transfer force, small deflection deformation, good shear and torsion properties, good crack resistance and earthquake resistance and the like, the overall performance of a floor system is improved, the thickness of the floor system is effectively reduced,and the dead weight of the structure is reduced.

Owner:重庆比瑞实建材有限公司

Four-roll plate bending machine

The invention relates to a four-roll plate bending machine comprising an upper crossbeam, an upper-roll bearing seat plate and upper rolls. The upper beam is fixed on a left and right frame of the plate bending machine, the upper-roll bearing seat plate is fixed under the upper crossbeam, and the upper rolls are fixed under the upper-roll bearing seat plate. Each upper roll is composed of an upper-roll shaft and upper-roll units, and the upper-roll units are sequentially connected and sleeved on the upper-roll shaft. Each upper-roll unit comprises an upper-roll bearing seat, an upper-roll bearing and small upper rolls, the upper-roll bearing and the small upper rolls are arranged in the upper-roll bearing seat. Each upper-roll bearing is sleeved on the upper-roll shaft, and two sides of each upper-roll bearing are respectively provided with the small upper rolls. The upper rolls are designed to be composed of the upper-roll units short in length, so that large deflection caused by large span when the upper rolls are longer in length is avoided, and deformation due to deflection is reduced. Besides, the upper rolls different in length can be designed according to number of the upper-roll units, and accordingly, the four-roll plate bending machine is flexible in structure.

Owner:张瑞瑞

Side roll device of four-roll plate bending roll

InactiveCN103357698AReduce deflection deformationGuaranteed rolling accuracyEngineeringMechanical engineering

Owner:张瑞瑞

Deflection-degree-decreasing rolling mill

InactiveCN101015837AReduce deflectionReduce distortionMetal rolling stand detailsCounter-pressure devicesTowerRolling mill

The invention relates to a roller for reducing flexural degree, comprising a frame which contains an upper roller base and a lower roller base via multipoint support beams respectively connected with an upper roller system and a lower roller system in tower structure. The frame is formed by a panel, a back plate, a top plate and a bottom plate, wherein the back plate and the panel are disposed with a material inlet and an outlet, the top plate and the upper roller base are symmetry arranged with two presses which is pressed on the upper roller base via a safe concave along the axle of the upper roller system, the minimum distance between two nearest function points of two presses on the upper roller base is smaller than the distance between two furthest function points of upper roller system on the upper roller base. The invention can reduce flexural degree and reduce deformation.

Owner:郑红专 +1

A light steel beam and its structural steel skeleton

ActiveCN104695623BReduce weightImprove structural strengthGirdersJoistsSteel frameUltimate tensile strength

The invention discloses a light steel beam and a structural steel frame thereof. The structural steel frame comprises a frame body and two shearing force bodies, wherein the frame body is provided with a bearing base body and a connecting base body perpendicular to the bearing base body, the two shearing force bodies are fixedly connected to the two side faces of the connecting base body respectively, the bearing base body, the connecting base body and the shear force bodies all extend in the length direction of the light steel beam, each shear force body is provided with multiple shear force base bodies connected in sequence with certain angles formed between the shear force base bodies, and the shear force base bodies at corresponding positions of the two shear force bodies are arranged in a crossing mode. In this way, the overall weight of the structural steel frame is effectively reduced, structural strength is improved greatly, and the development requirements for light weight and high strength of the steel beam are fully met.

Owner:孙毅

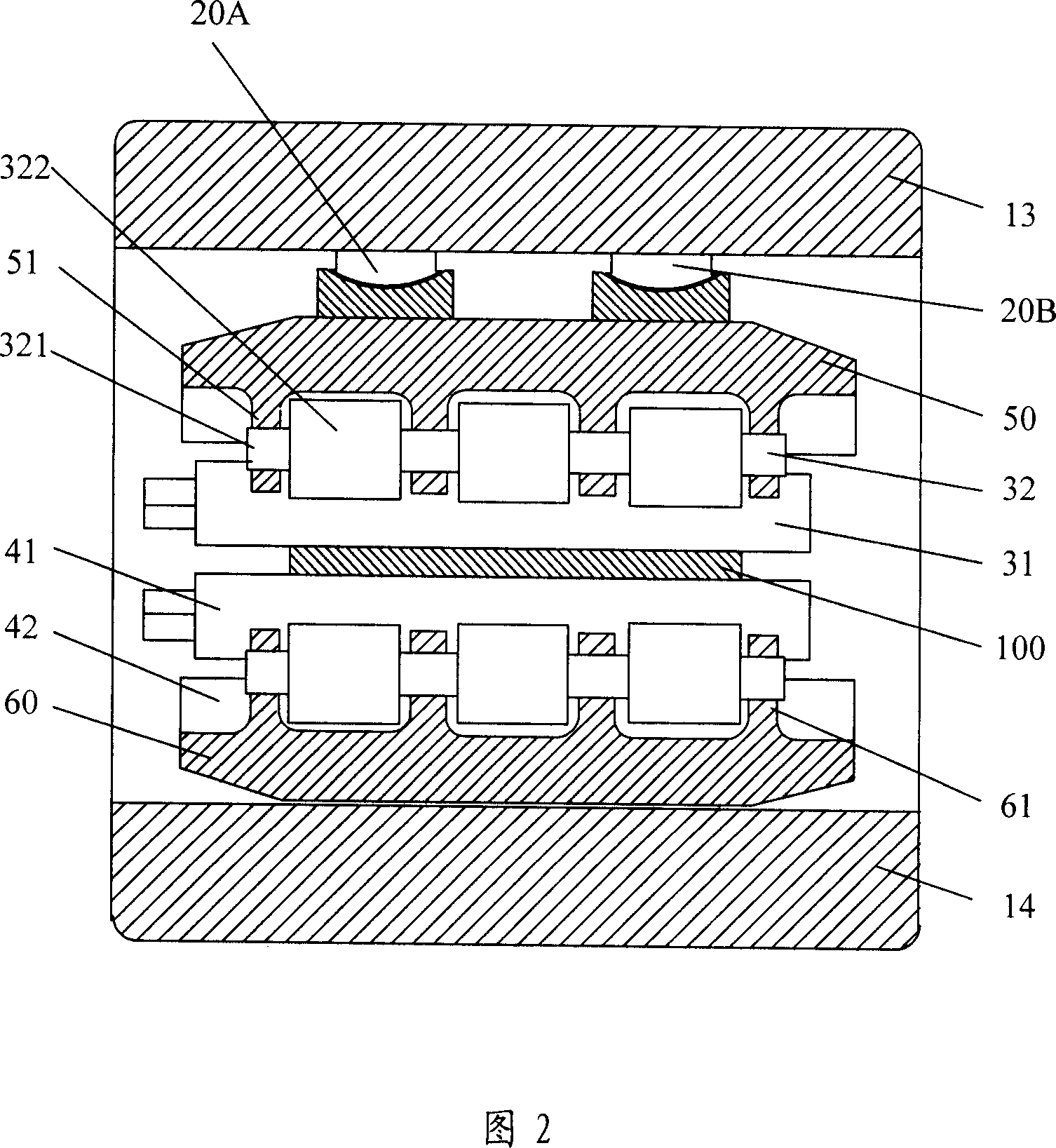

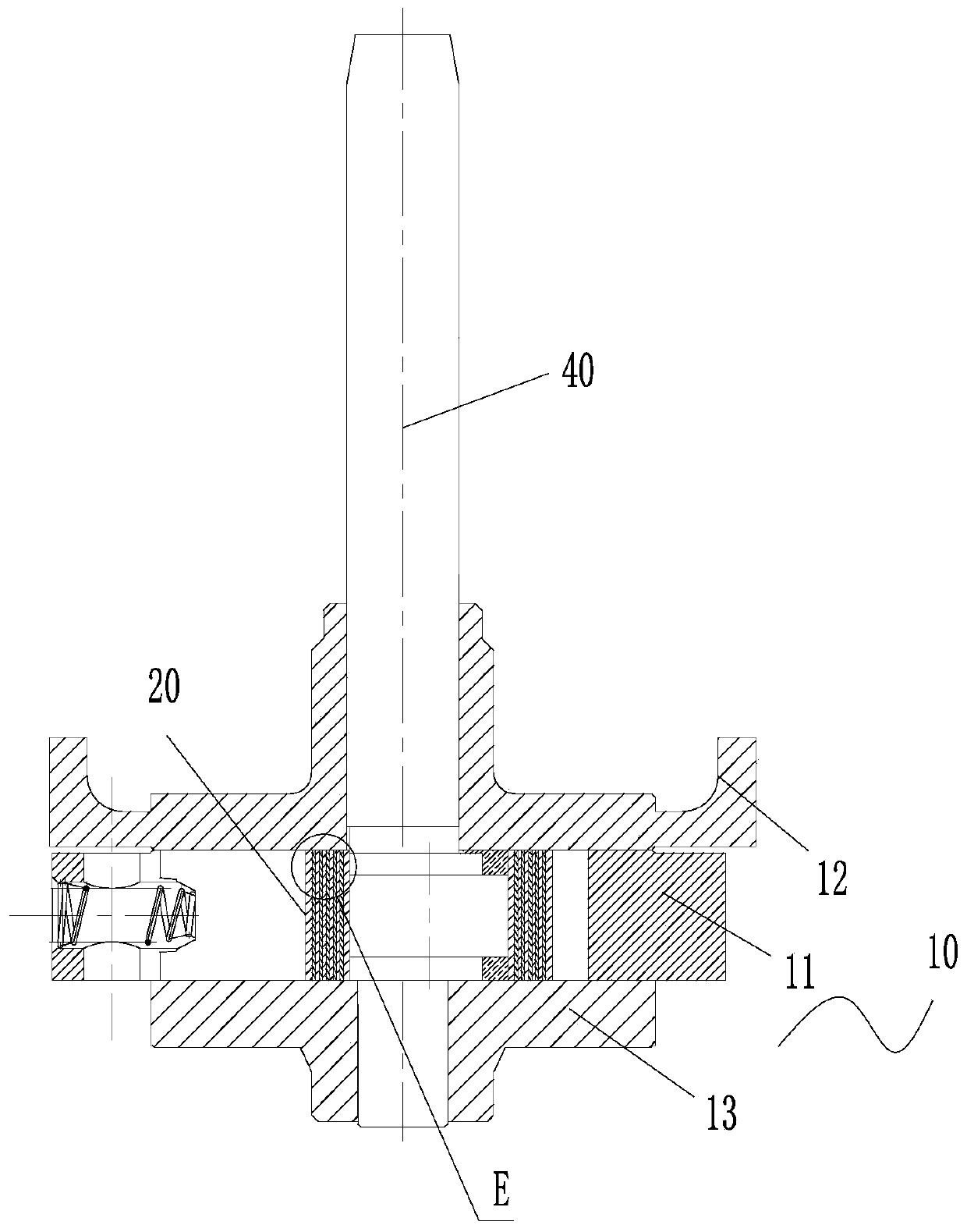

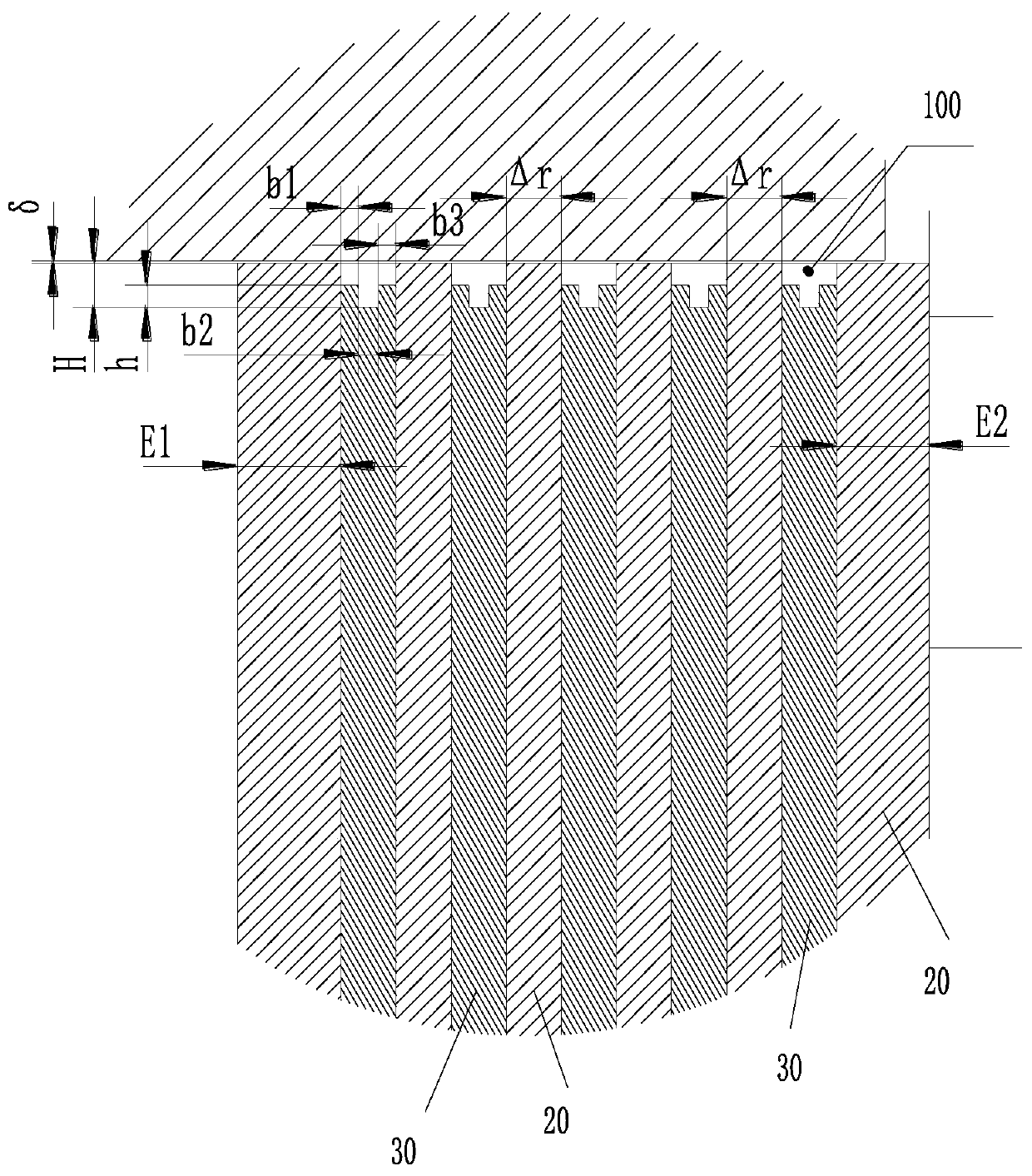

Pump body assembly of rotor compressor, rotor compressor and air conditioner

PendingCN110985382AReduce deflection deformationSolve the problem of easy to produce deflection deformationRotary piston pumpsRotary piston liquid enginesPhysicsPiston

The invention provides a pump body assembly of a rotor compressor, the rotor compressor and an air conditioner. The pump body assembly of the rotor compressor comprises an air cylinder structure; a piston, which is arranged in the air cylinder structure, a mounting space is formed in the piston, and an opening of the mounting space is formed in the first end face of the piston; a balance block, which is arranged in the mounting space; and a crankshaft, which is connected with the first end face of the piston. According to the technical scheme, the problem that a crankshaft is prone to deflection deformation due to eccentric arrangement of the mass center of the pump body assembly in the prior art is effectively solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

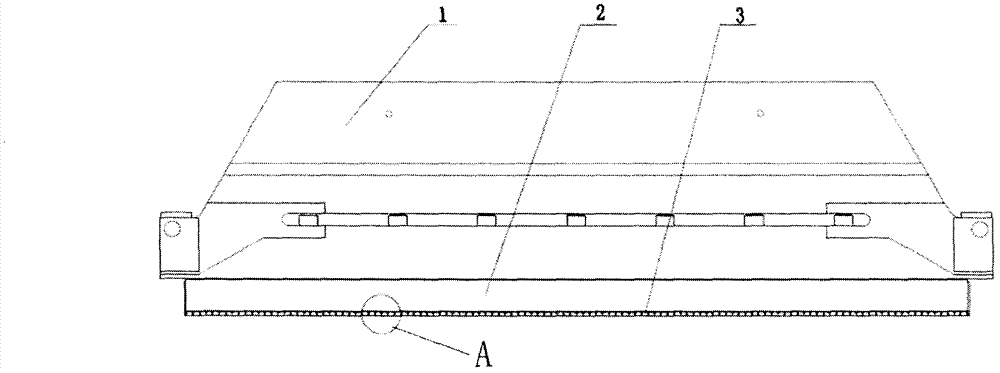

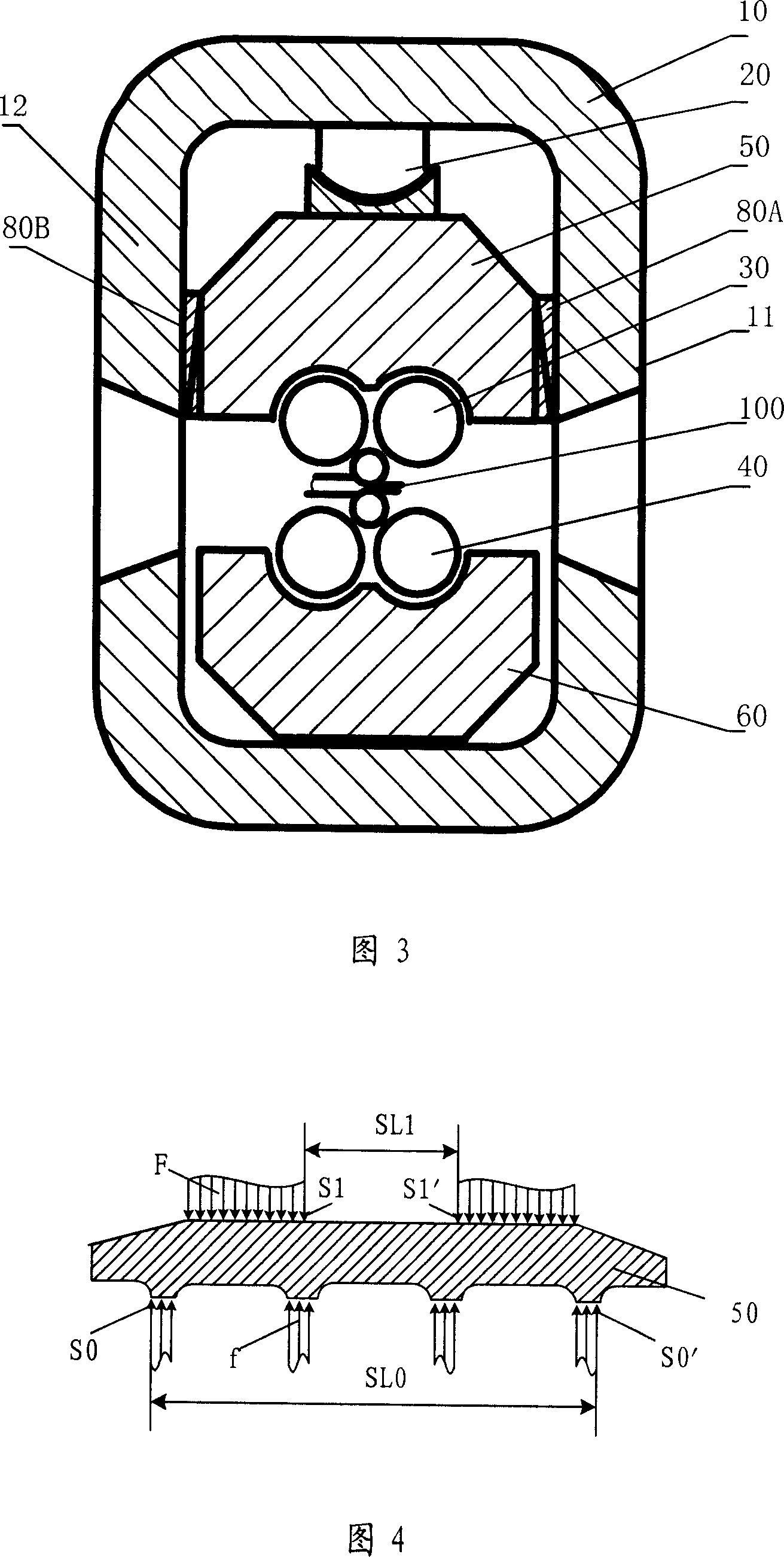

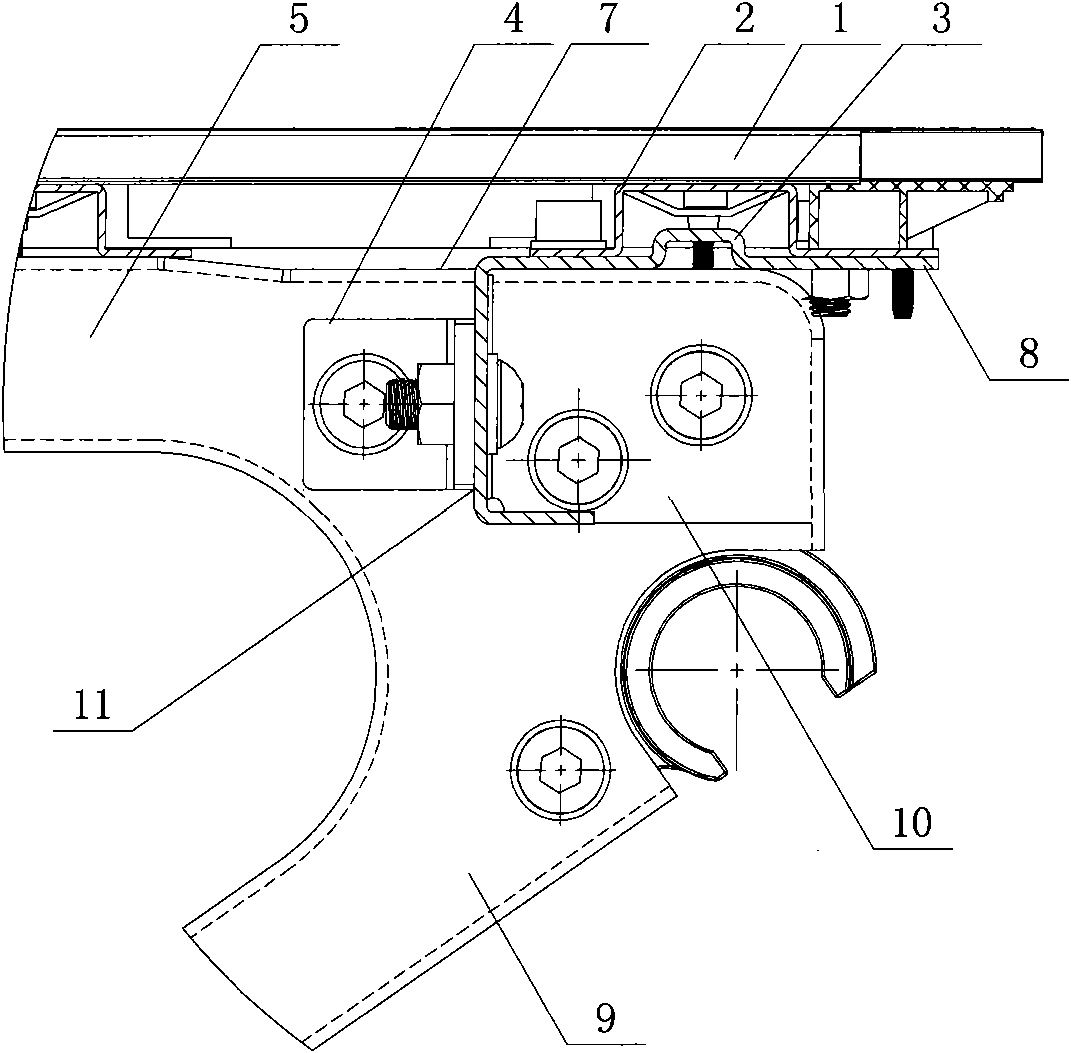

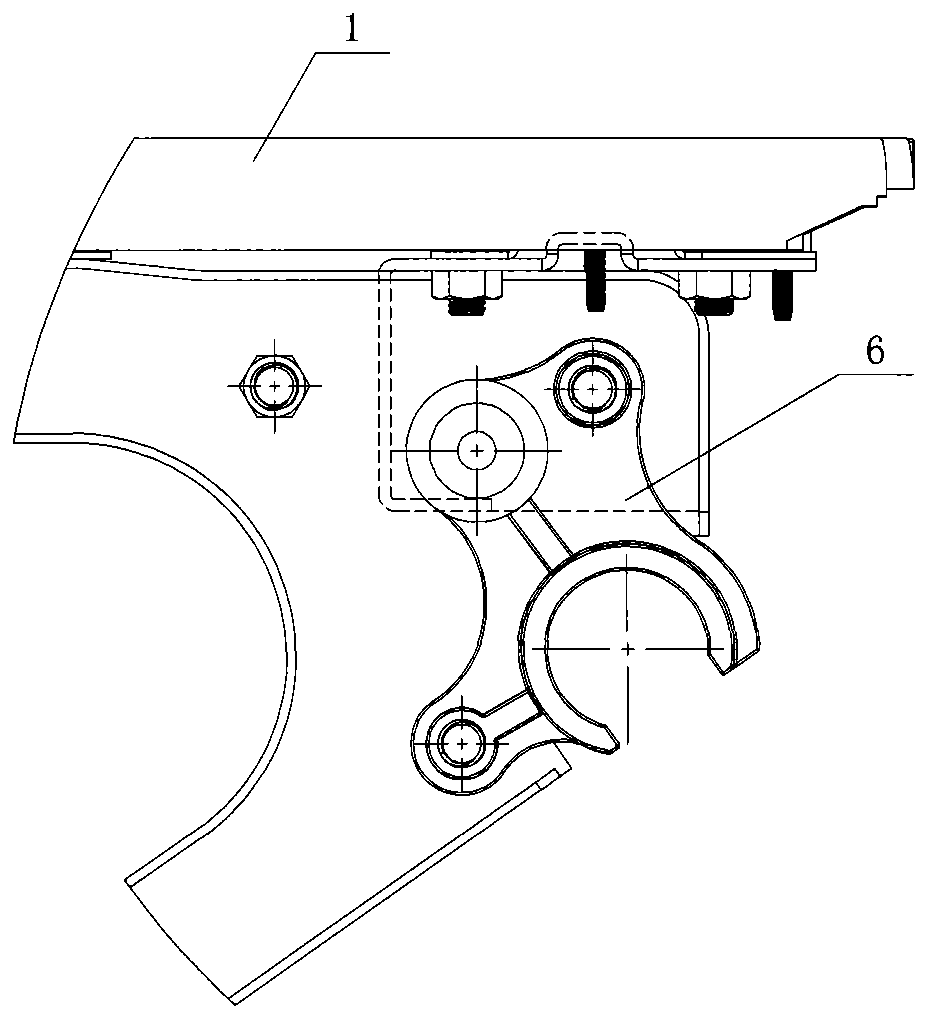

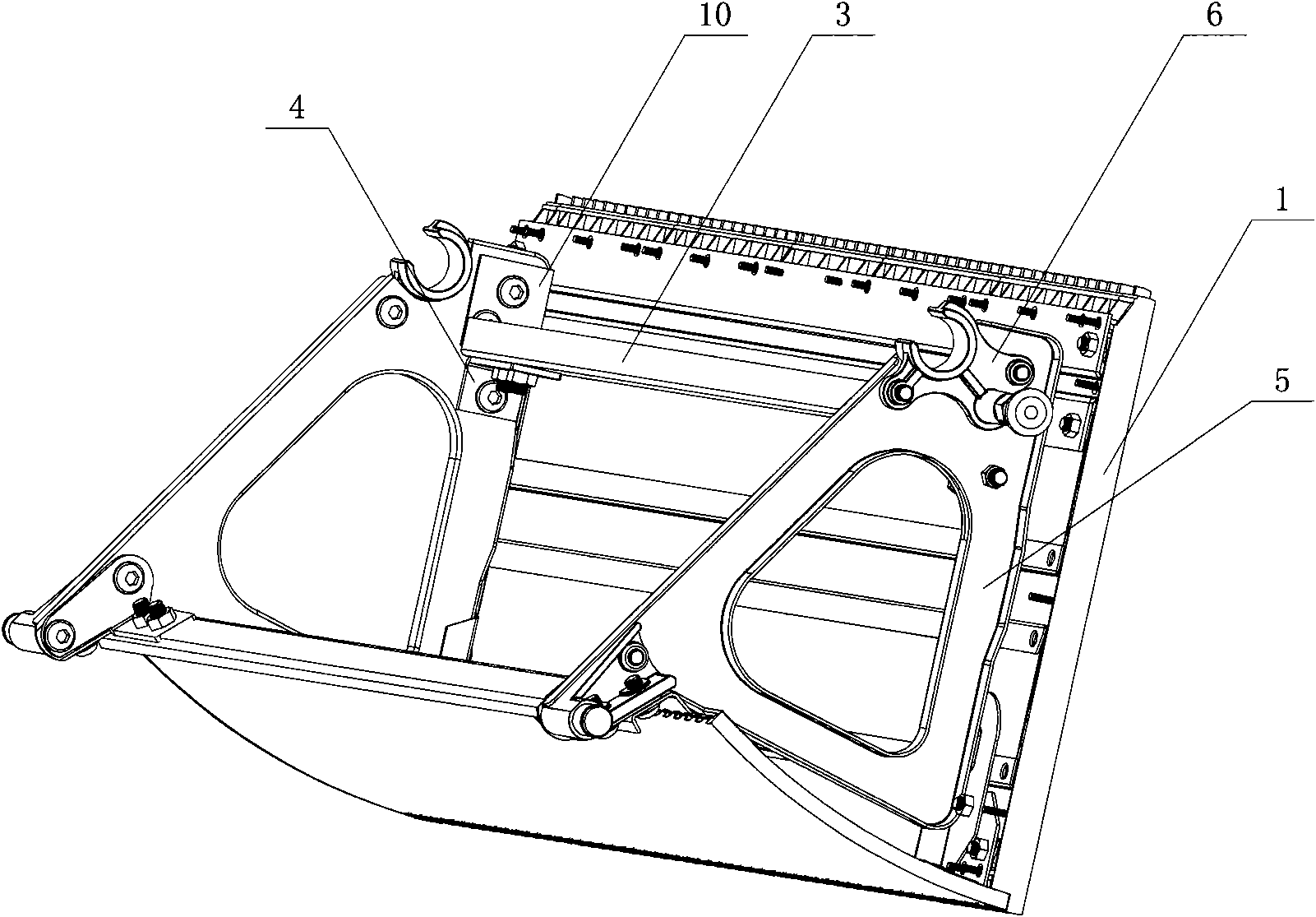

Front end assembly structure of stainless steel staircase step

InactiveCN101570299AEffective control of precisionAnti-deformation purpose is clearEscalatorsStructural engineeringAssembly structure

The invention relates to a front end assembly structure of a stainless steel staircase step, in particular to a front end assembly structure of a split assembled step, and belongs to the field of escalator manufacture. By using a horizontal positioning surface as a standard, a front end cross beam for realizing height horizontal positioning is placed above triangular brackets and the horizontal positioning surface which are arranged in parallel; the triangular brackets and the horizontal positioning surface are contacted and connected with and position a first vertical positioning surface and a second vertical positioning surface to realize the vertical positioning and specific size span positioning of two triangular brackets. The invention solves the technical problem and provides the technical task that the structure overcomes the technical defects in the front end assembly structure of the prior stainless steel staircase step, and provides an implementation proposal for the front end assembly structure of the step with good integrity, deformation resistance, definite assembly standard aim, large overload capacity, convenient assembly and easy quality control.

Owner:SUZHOU BENYI MECHANICAL & ELECTRICAL EQUIP

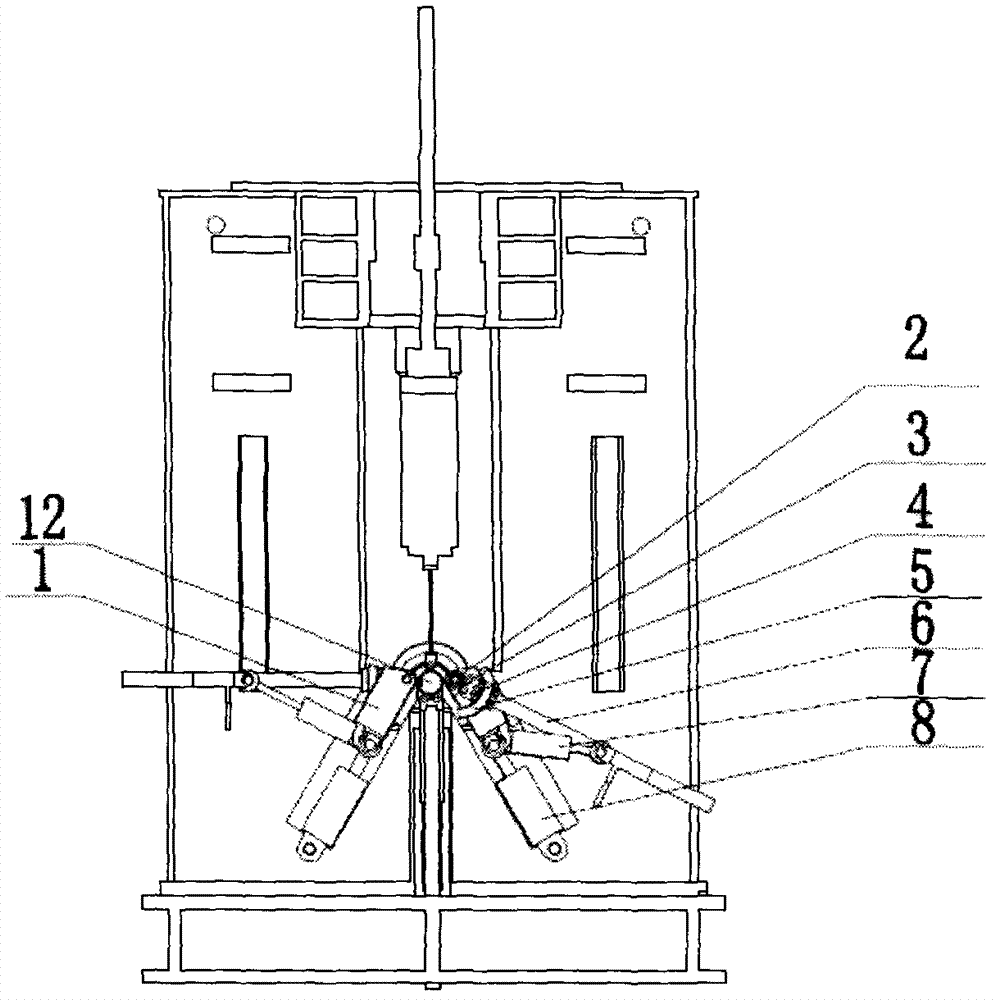

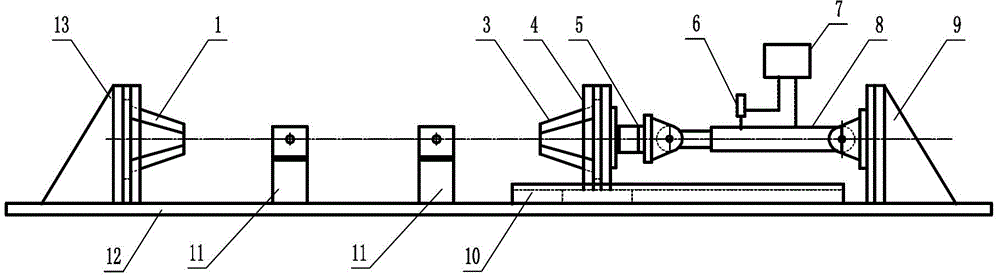

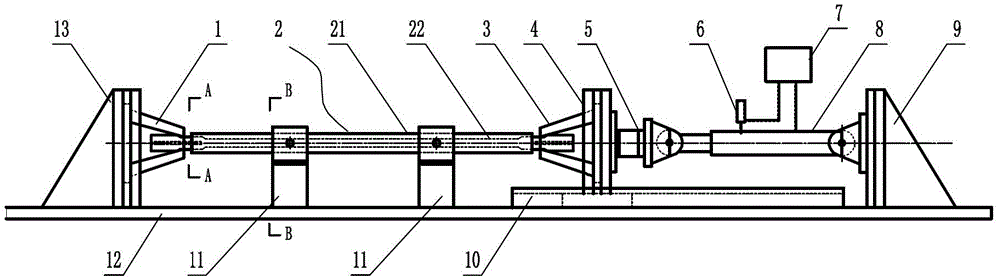

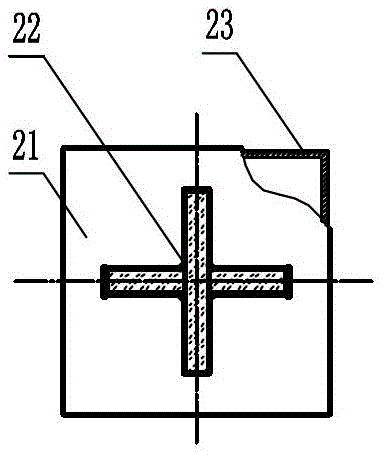

Buckling-restrained brace manufacturing device and method for manufacturing buckling-restrained brace by device

ActiveCN103243833BCompact structureDesign scienceBuilding material handlingMetal working apparatusPull forceIndustrial engineering

A buckling-restrained brace manufacturing device comprises a clamping mechanism, an adjusting and leveling mechanism, a tension mechanism, a control mechanism and a pressure sensor, wherein the clamping mechanism is used for clamping a steel core, the tension mechanism is used for applying axial tension to the steel core to realize secondary leveling, the control mechanism is used for controlling stretching action and tension strength of the tension mechanism by extracting information of the pressure sensor, and the adjusting and leveling mechanism is used for adjusting a restraint sleeve to be centered. A manufacturing method includes the steps: clamping the steel core penetrating into the restraint sleeve; applying axial tension to the steel core to realize secondary leveling; adjusting the steel core to be positioned at the center of the restraint sleeve; sealing end openings of the restraint sleeve; filling fillers into the restraint sleeve; and unloading, loosening a fixture and taking down a finished product. The buckling-restrained brace manufacturing device is simple in structure, scientific in design, convenient to mount, economical and practical. The manufacturing method is simple to operate, accurate in control, fine in secondary leveling effect and low in manufacturing cost, the steel core is high in planeness precision, and superior overall performance of a buckling-restrained brace is ensured.

Owner:柳州东方工程橡胶制品有限公司

A large-span liftable variable deflection cantilever throwing device

ActiveCN112676076BReduce deflection deformationReduce weightSpraying apparatusCantileverMechanical engineering

The invention relates to a large-span liftable variable-deflection cantilever throwing rod device, which belongs to the technical field of rocket engine charging manufacturing robots; including a mobile end lifting group module, a cantilever rod, a platform base, a fixed end lifting group module, and an end throwing coating device and the shell; the upper surface of the platform base is provided with a guide rail; the mobile end lifting group module and the fixed end lifting group module are both arranged on the guide rail to realize sliding cooperation with the guide rail; the cantilever rod is arranged axially parallel above the guide rail; and the cantilever The axial head end of the rod is rotatably connected to the top of the lifting group module at the moving end; the axial tail end of the cantilever rod is overlapped with the top of the lifting group module at the fixed end; the end coating device is set on the axial tail end of the cantilever rod; the shell It is a hollow columnar structure; the shell is coaxially arranged at the axial tail end of the cantilever rod; while the present invention has both coating quality and efficiency capabilities, it can flexibly expand and contract in a small space with different lengths and different diameters of the engine shell , so as to solve the problems existing in the prior art.

Owner:HARBIN INST OF TECH

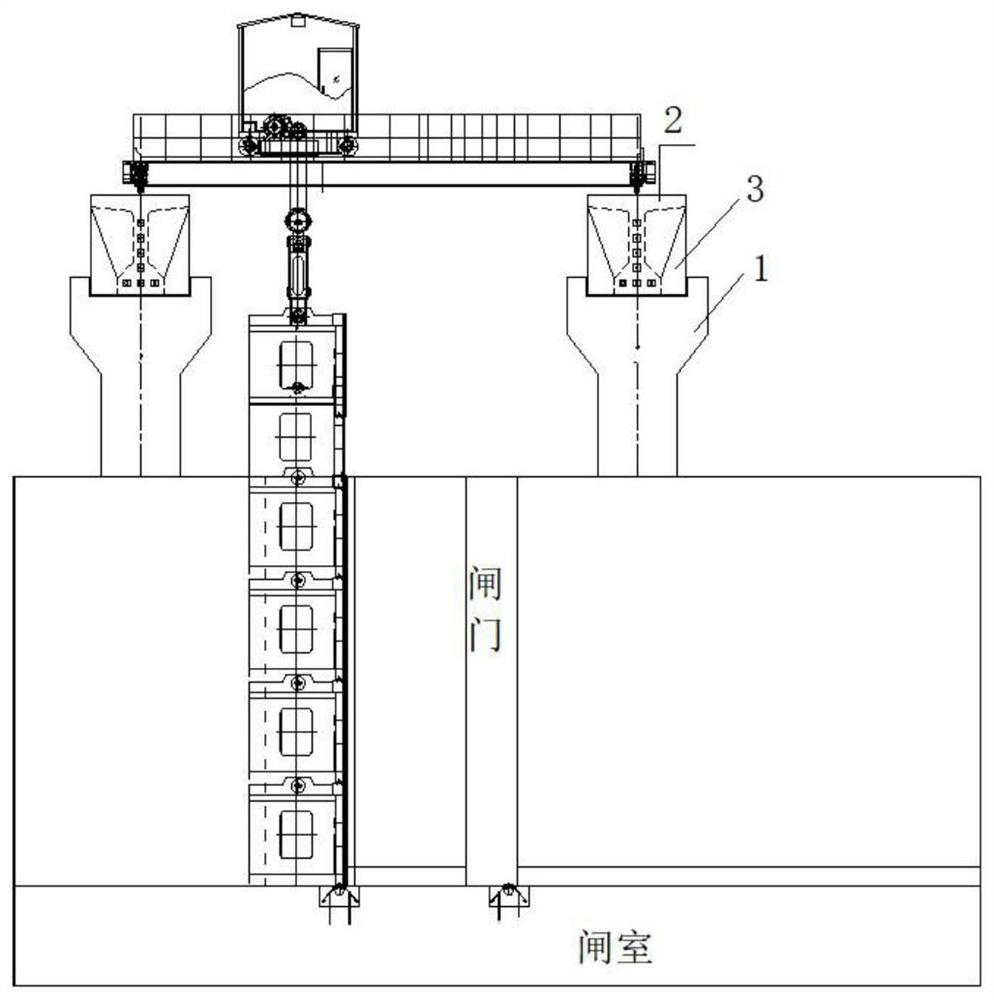

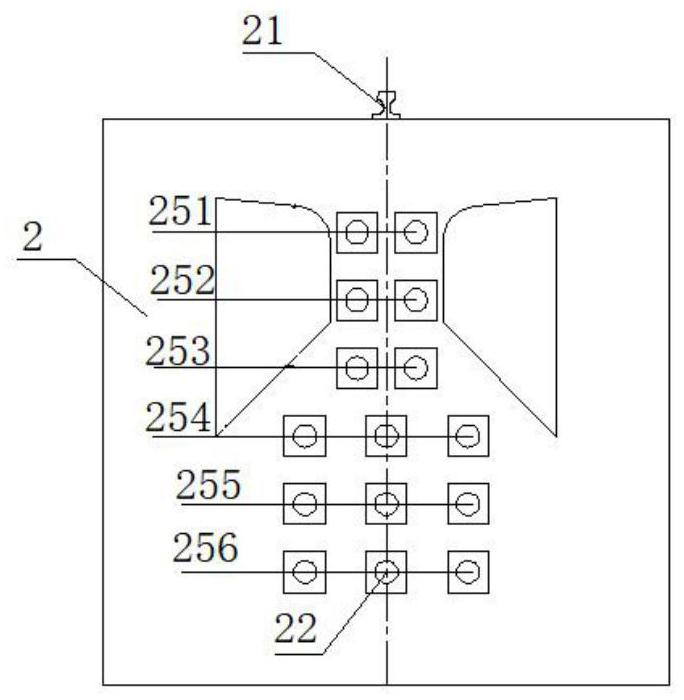

Concrete service bridge for opening and closing gate of large-span prestressed flood retaining gate and construction method

PendingCN114481804AReduce deflection deformationReduce or avoid crackingBarrages/weirsBridge applicationsPre stressArchitectural engineering

The invention discloses a concrete service bridge for opening and closing a gate of a large-span prestressed flood retaining gate, and relates to the technical field of water conservancy and hydropower engineering. The structure comprises pier columns, a prestress service bridge and a bridge crane, a bridge crane rail is pre-buried in the prestress service bridge, a pre-tensioning steel strand is arranged in the prestress service bridge, the prestress service bridge adopts a T-shaped section, and rib plates are arranged on the two sides of the prestress service bridge at intervals. According to the method, the high tensile property of the pre-tensioning steel strands in the tensile area is fully utilized, the deflection deformation of the service bridge can be reduced by about 6 mm according to the scheme comparison and selection calculation result, the reduction proportion is about 15%, and therefore the concrete cracking degree of the tensile area is reduced or avoided. The invention further relates to a construction method of the concrete service bridge for opening and closing the gate of the large-span prestressed flood retaining gate.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

A kind of preparation method of prestressed basalt fiber board composite wooden beam

ActiveCN104120832BImprove carrying capacityIncreased bending stiffnessGirdersJoistsPre deformationPre stress

The invention discloses a pre-stress basalt fiber board composite wood beam which comprises wood boards and basalt fiber boards, wherein the wood boards in the same layer of the composite beam are spliced into a whole in the length directions of the wood boards; a splicing part between two upper and lower adjacent layers of wood boards in the thickness directions of the wood boards are staggered; basalt fiber cloth wraps the outer part of each splicing part and spliced outside the splicing part; the basalt fiber boards are arranged in a though manner along the length of the composite beam and bonded with two sides of the wood board on the outmost side of the composite beam; the basalt fiber boards comprise first basalt fiber boards arranged on the inner sides of the wood boards and second basalt fiber boards arranged on the outer sides of the wood boards; the second basalt fiber boards are reinforced boards; pre-tress is applied to the second basalt fiber boards. A preparation method of the pre-stress basalt fiber board composite wood beam comprises the following steps: manufacturing the composite wood beam, generating pre-deformation, rebounding for generating pre-tension, reversing by 180 degrees and forming a pre-tress composite wood beam component. According to the pre-stress basalt fiber board composite wood beam, the technical problems of high consumption of overall wood, relatively high cost, relatively low utilization rate of short wood materials with ordinary lengths and ordinary diameters, great possibility of causing of great material waste and unreasonable use of the wood in the conventional wood structure construction can be solved.

Owner:中科华研(重庆)玄武岩纤维新材料研究院有限公司

Steel sheet pile supporting structure and supporting method

PendingCN114439013AImprove support strengthReduce deflection deformationExcavationsBulkheads/pilesSteel platesStructure support

The invention relates to a steel sheet pile supporting structure and method, and relates to the field of building construction.The steel sheet pile supporting structure comprises two rows of stand columns which are oppositely arranged, a plurality of cross beams are fixedly connected to each row of stand columns, and the length direction of the cross beams is parallel to the arrangement direction of each row of stand columns; the cross beams are arranged in the height direction of the stand columns, a plurality of supporting beams arranged in the length direction of the cross beams are arranged on the cross beams, and the two ends of each supporting beam are fixedly connected with the cross beams at the same height position on the two rows of stand columns respectively; a baffle used for blocking the space between the stand column and the cross beam is arranged between the stand column and the cross beam. The method has the advantages that the supporting structure strength is improved, the safety of structural supporting construction in the deep foundation pit is improved, and the construction progress is guaranteed.

Owner:北京易成市政工程有限责任公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com