Side roll device of four-roll plate bending roll

A four-roller plate rolling machine and side roller technology, which is applied in the field of plate rolling machines, can solve the problems of large span of side rollers, failing to meet the requirements of rolling, and difficulty in guaranteeing the rolling accuracy of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

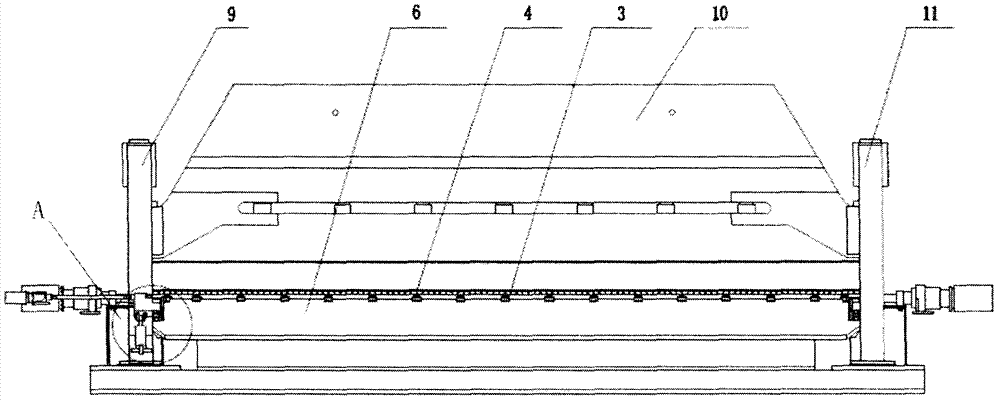

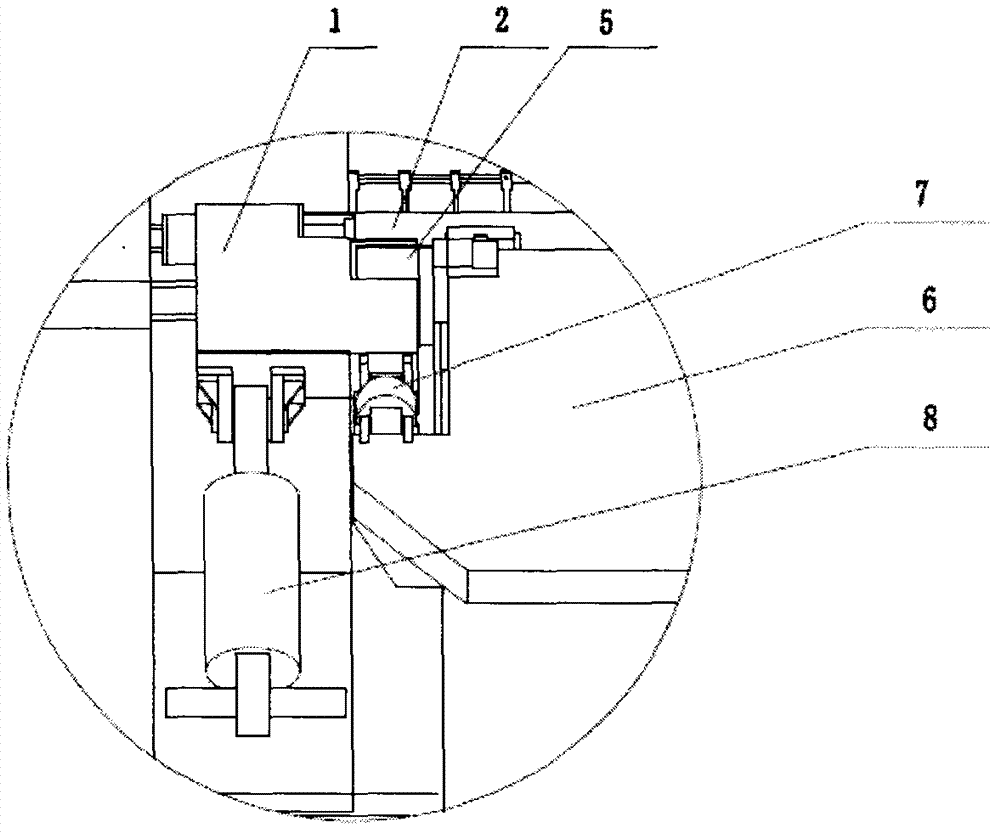

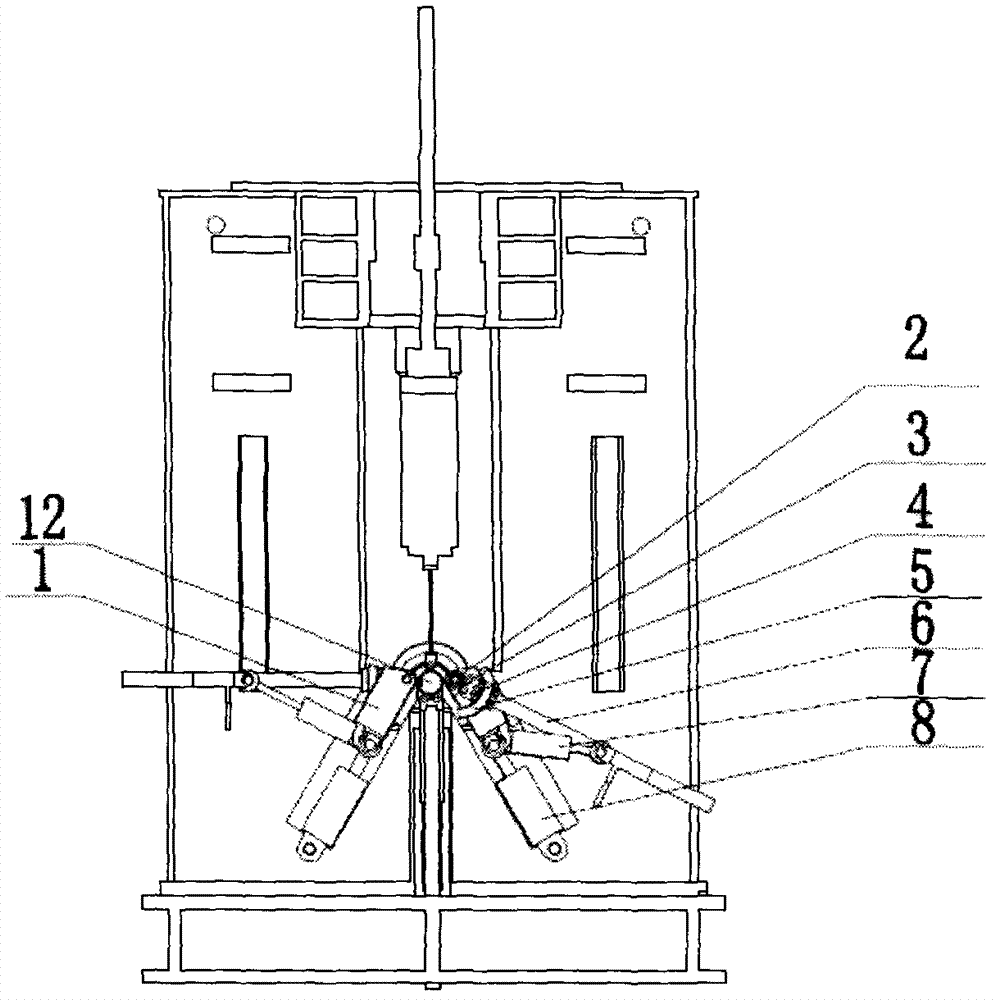

[0013] see figure 1 , figure 2 with image 3 , the upper beam 10 of the four-roll plate bending machine is located between the left frame 9 and the right frame 11, the lower roll 12 is located directly below the upper beam 10, and the side rolls 2 are located on both sides of the lower roll 12.

[0014] The side roll 2 is located on the side roll bearing seat 1, the side roll oil cylinder 8 is connected with the side roll bearing seat 1, and the side roll oil cylinder 8 is installed in the grooves of the left frame 9 and the right frame 11, and the grooves on the left and right frames are eight Glyph, the angle between the groove and the vertical force direction is 30 degrees, and the side roller bearing housing 1 can move along the groove under the action of the side roller cylinder 8, and the work of the side roller cylinder 8 can make the side roller 2 move alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com