Buckling-restrained brace manufacturing device and method for manufacturing buckling-restrained brace by device

An anti-buckling bracing and manufacturing device technology, which is applied to manufacturing tools, earthquake resistance, building structures, etc., can solve the problems of difficult to achieve accurate positioning and limit, increased plane deflection recovery, and low leveling accuracy. Compact structure, reduced deflection and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

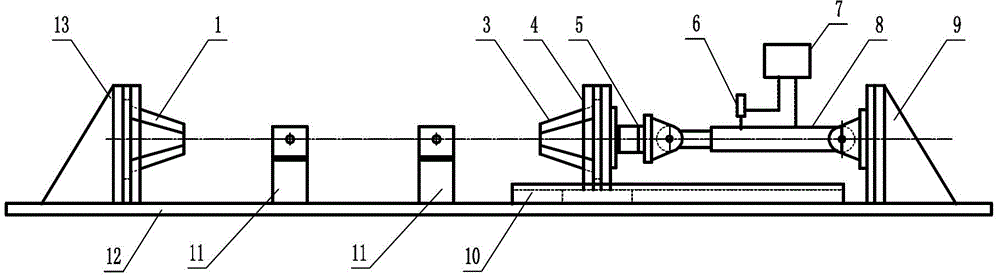

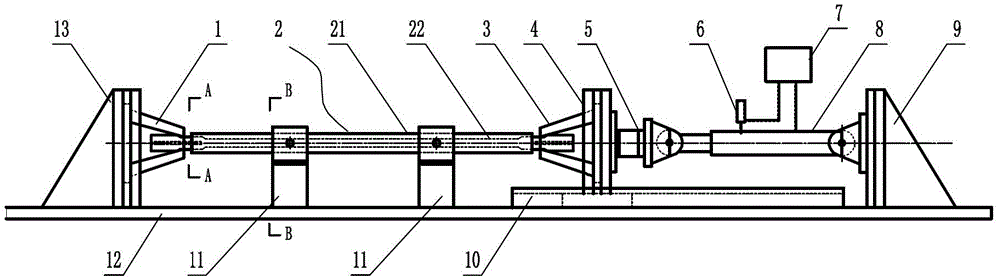

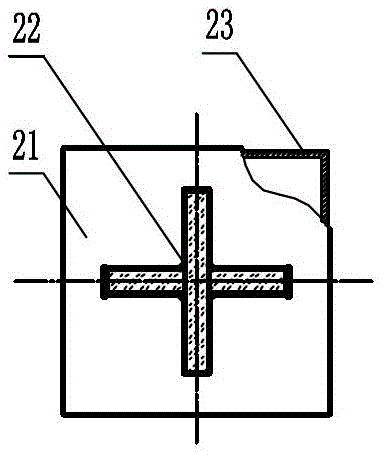

[0031] A kind of anti-buckling brace manufacturing device, described device comprises the clamping mechanism that is installed on the workbench 12, adjusts pad leveling mechanism, tension mechanism 8, control mechanism 7 and and The pressure sensor 6 used in conjunction with the tension mechanism, the clamping mechanism includes a front reaction force seat 13 and a receiving seat 4, the front reaction force seat is fixedly installed on one end of the worktable 12, and the receiving seat 4 is slidably connected in the workbench through the slide rail 10 The opposite side of the front reaction force seat and the receiving seat is equipped with clamps 1 and 3 for clamping the steel core, the clamp 1 is installed on the right side of the front reaction force seat, and the clamp 3 is installed on the left side of the receiving seat, The back side (right side) of the receiving seat is connected to the tension mechanism through the connector 5; one end of the tension mechanism 8 is c...

Embodiment 2

[0037] A method of manufacturing buckling-resistant braces using a buckling-resistant brace manufacturing device, comprising the steps of:

[0038] 1) Put the steel core 22 that has been leveled and straightened by applying a force perpendicular to the length direction of the steel core into the restraint sleeve 21, and clamp its two ends on the front reaction force seat 13 and the receiving seat 4 on fixtures 1 and 3;

[0039] 2) Start the power system of the tension mechanism to apply axial tension to the steel core for secondary leveling, and control the start and stop of the power system of the tension mechanism through the control mechanism 7 under the monitoring of the pressure sensor to keep the applied axial tension at Within the yield bearing capacity of the steel core;

[0040] 3) Start and adjust the leveling mechanism 11 to first adjust the horizontal height of the restraint sleeve 21 so that the position of the steel core 22 in the restraint sleeve is horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com