Concrete service bridge for opening and closing gate of large-span prestressed flood retaining gate and construction method

A construction method and prestressing technology, applied in bridges, bridge parts, bridge applications, etc., can solve problems such as cracks in the concrete tension area, large project investment, and tensile steel bars that do not reach the design value of tensile strength, etc., to achieve reduction The effect of own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

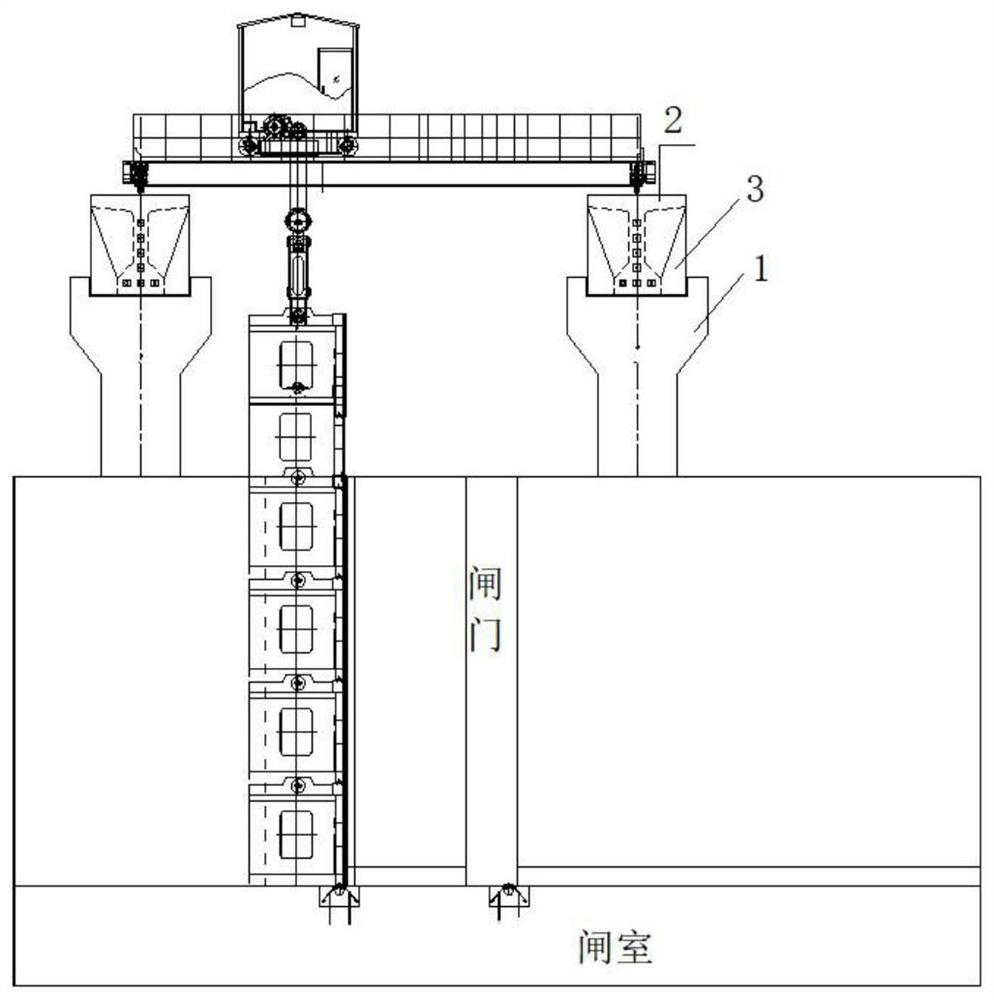

[0046] Introduce the background technology based on a certain project: In order to solve the problems of flood control, embankment connection and tributary drainage, combined with the existing conditions, flood gates and flood control traffic bridges need to be built at the intersection of tributaries and main streams. When the water level of the main stream is high during the flood season, the flood gates are closed to prevent the flood from flowing into the tributaries; when the water level of the tributaries is higher than that of the main stream, the flood gates are opened for self-flow drainage.

[0047] According to the "Code for Design of Embankment Engineering" (GB50286-2013), the embankment of the main stream is a Class 1 building. Since the flood gate is located on the important flood barrier of the embankment of the main stream, the building level of the flood gate is the same as that of the embankment, which is Class 1, secondary Buildings are level 3.

[0048]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com