Patents

Literature

33results about How to "Effective control of precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

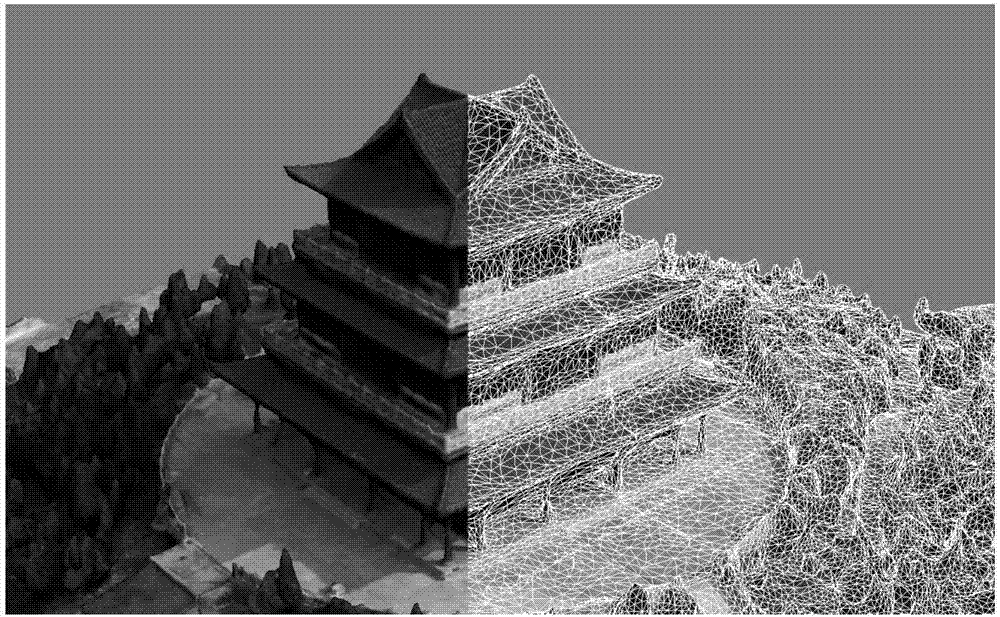

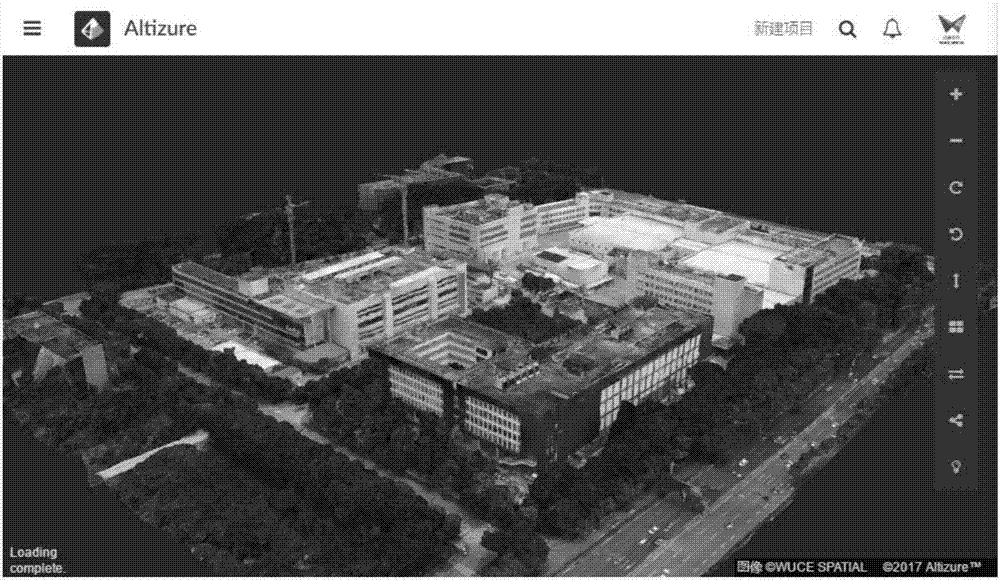

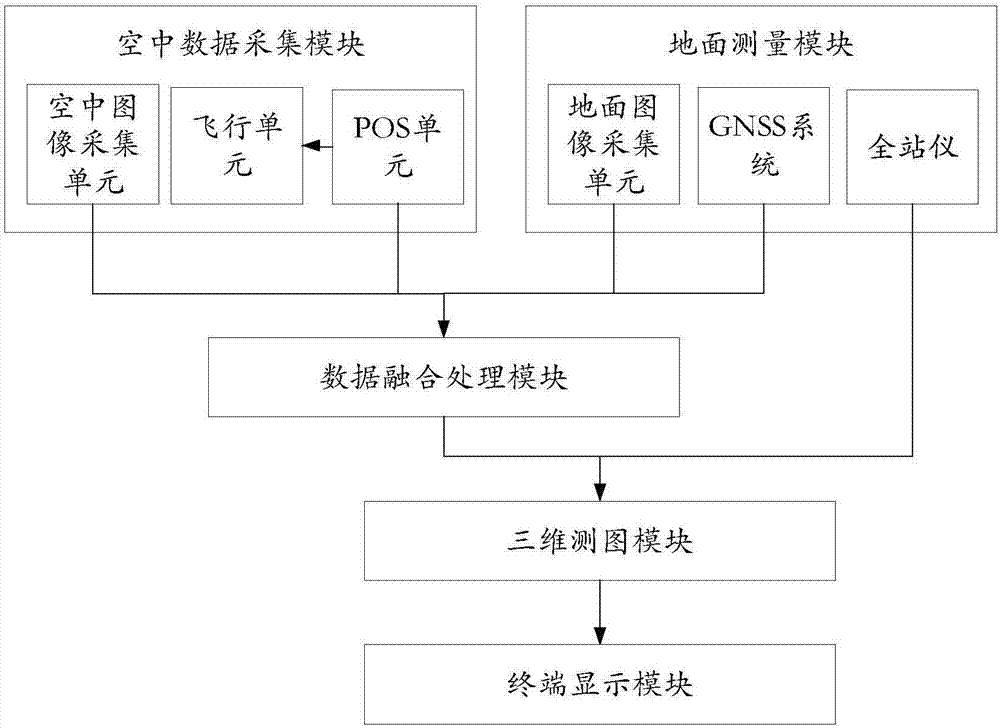

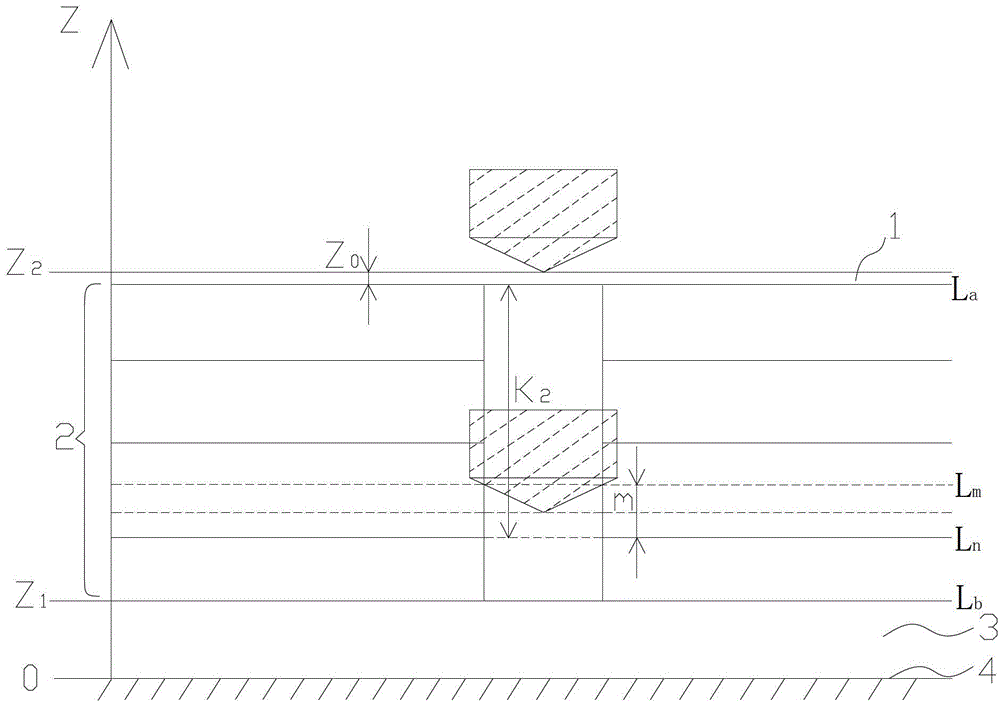

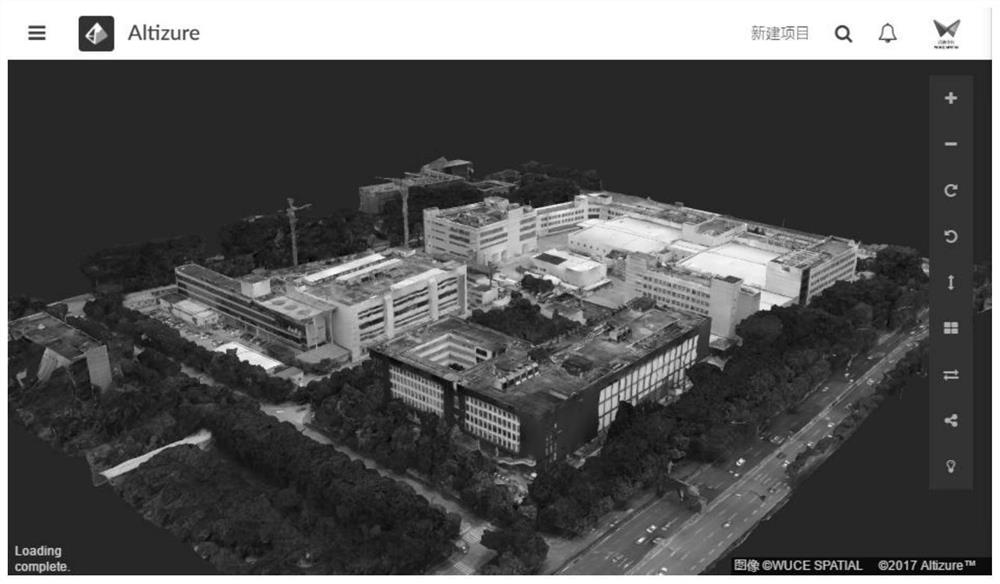

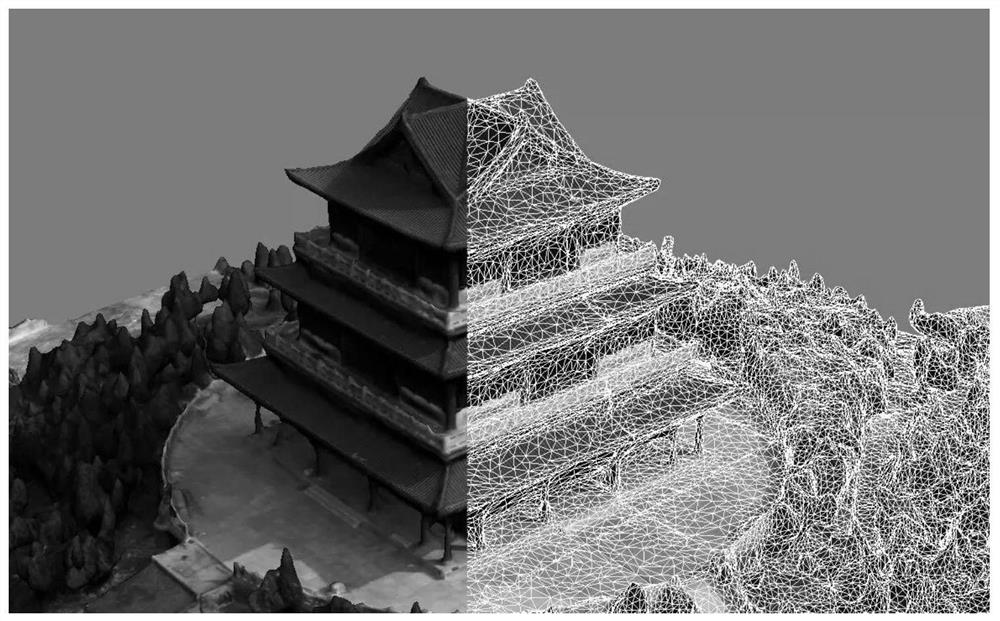

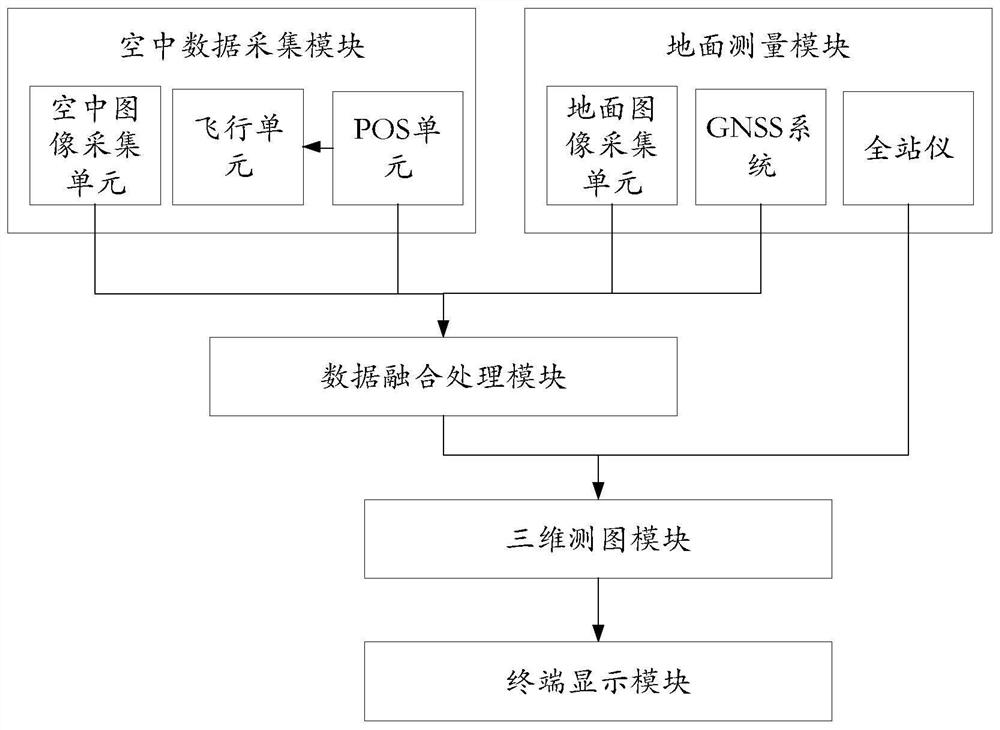

Digital mapping method and system based on live-action 3D model

ActiveCN107356230AEffective control of precisionPortable and flexible digital mappingImage enhancementImage analysisLive actionData acquisition

The invention relates to the field of photogrammetry and surveying and mapping, particularly to a digital mapping method and system based on a live-action 3D model. Digital mapping is carried out by unmanned aerial vehicle oblique photography 3D modeling and cooperation with a ground survey robot, digital mapping of the data acquisition result is more portable and flexible, at the same time high resolution live-action 3D model data can be acquired, and the sense of reality is strong. A control point coordinate acquired by the ground survey robot can effectively control the overall accuracy of the model, an acquired feature point coordinate can effectively compensate for the defect of low coordinate precision because of the influence of a barrier object on unmanned aerial vehicle aerial photography modeling. The method and system provided by the invention have greatly improved work efficiency, also can acquire vivid 3D topographic and geomorphic data at the same time, and meet the demand for diversified data results.

Owner:深圳市武测空间信息有限公司

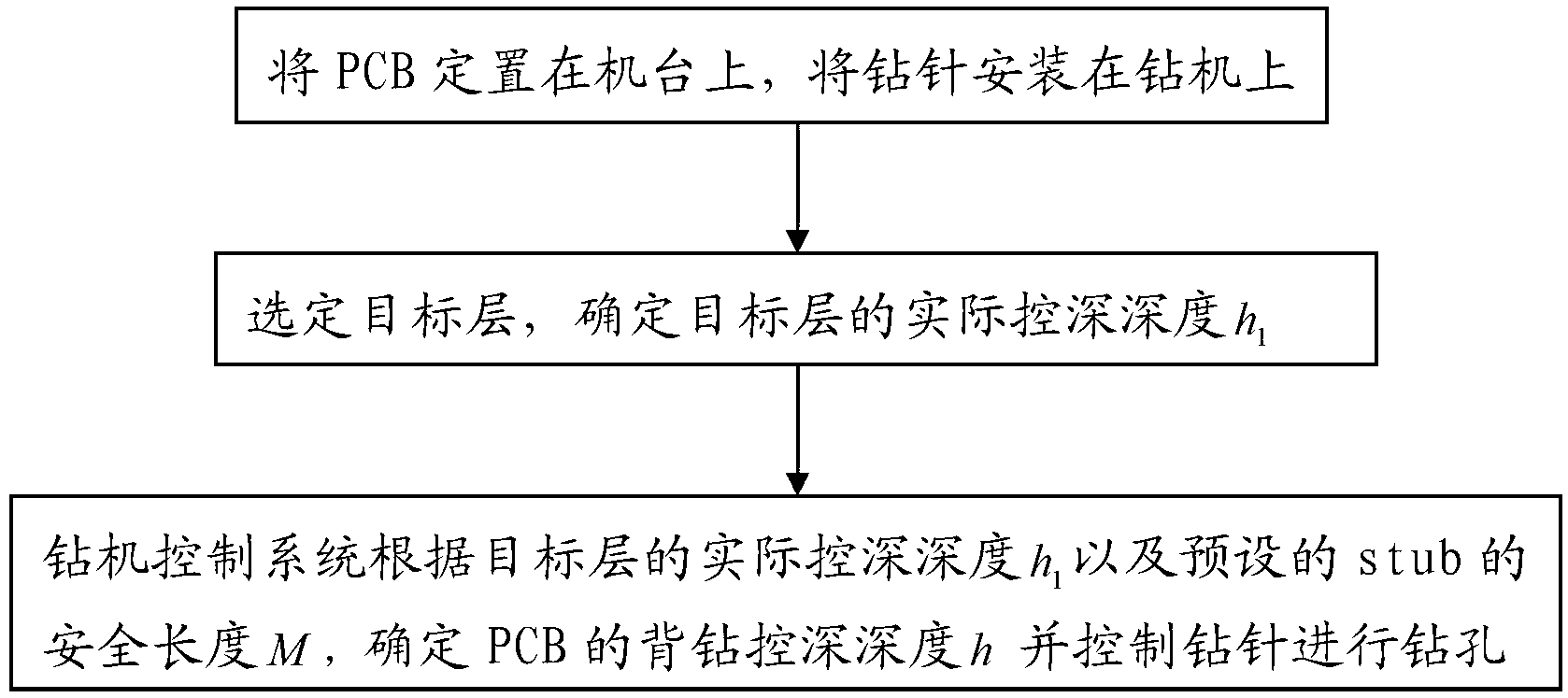

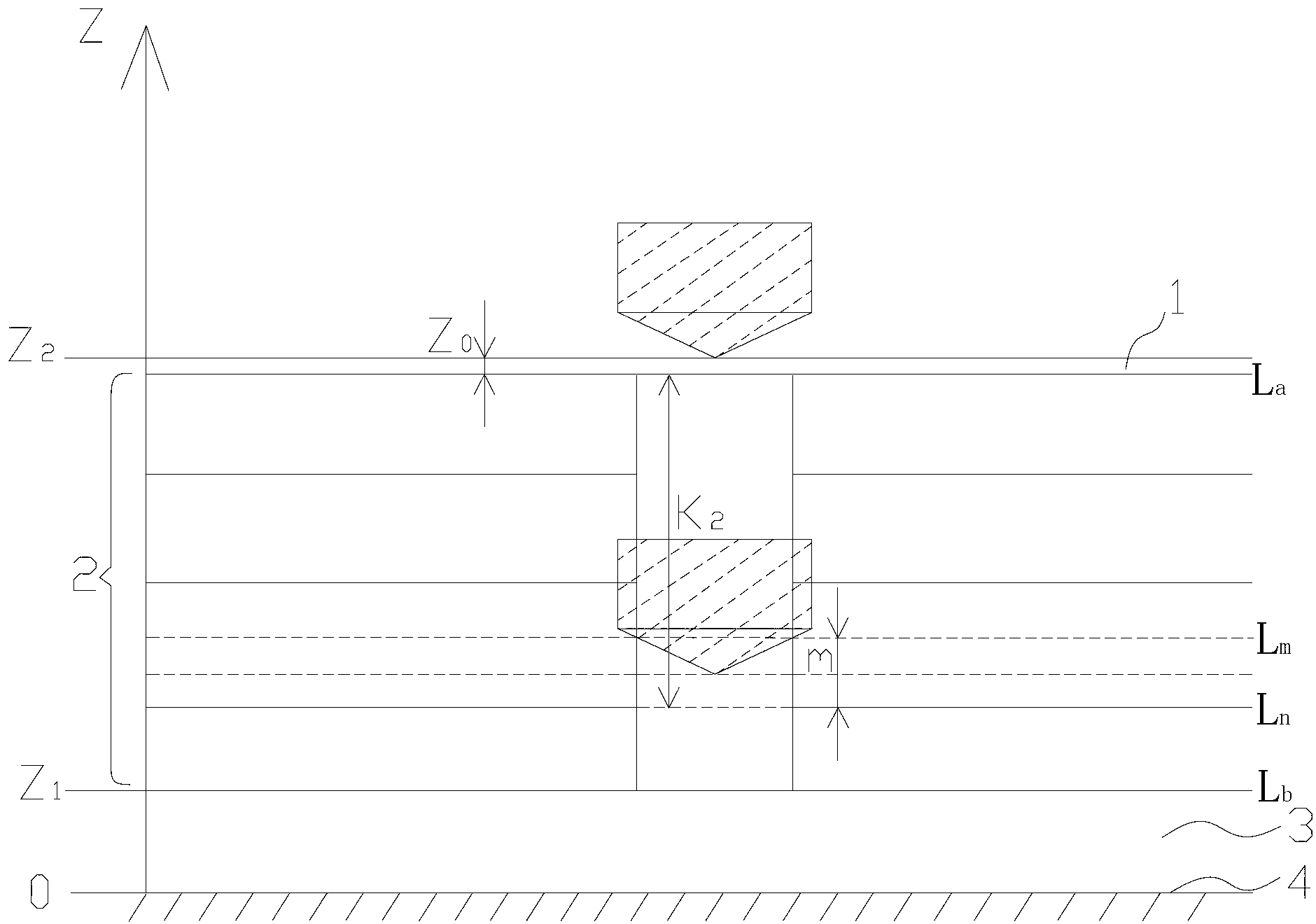

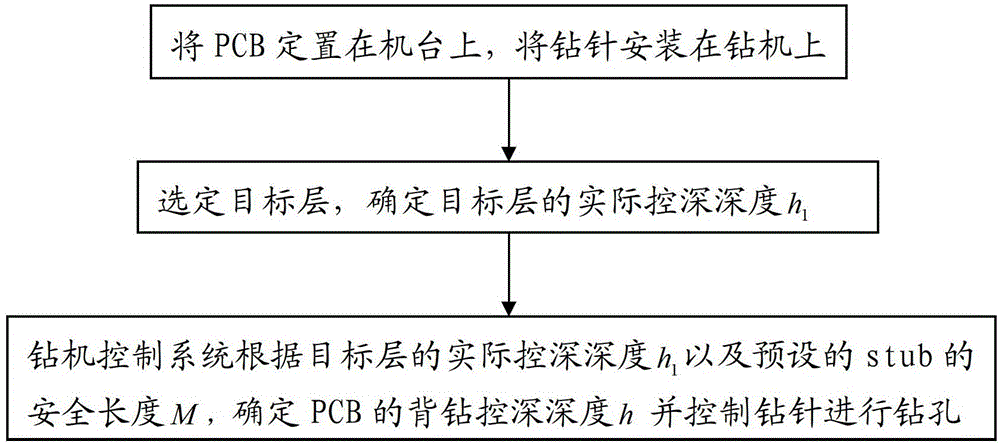

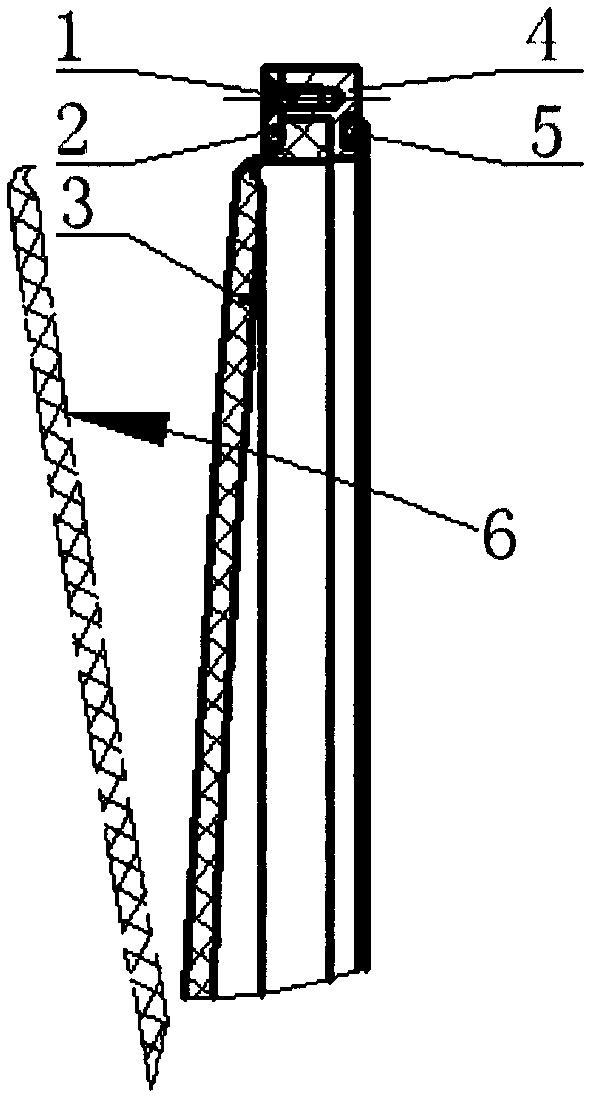

PCB (printed circuit board) back drilling method

The invention relates to a PCB (printed circuit board) back drilling method. The PCB back drilling method comprises the following steps: fixing a PCB on a machine table, and mounting a drill bit on a drilling machine; selecting a target layer, and determining an actual control depth h1 of the target layer; and determining a back drilling control depth h of the PCB according to the actual control depth h1 of the target layer and a preset safety length M of a stub and controlling the drill bit to drill a hole drilling machine control system. According to the PCB back drilling method, influence of thickness uniformity of the board, cone height of a drill tip and copper / tin-plating process variation on the accuracy of the control depth can be reduced; and through introduction of the safety length M of the stub, the precision of the PCB back drilling control depth h can be effectively controlled, thus achieving precision control of the stub and eliminating adverse effects of the stub on a signal.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH

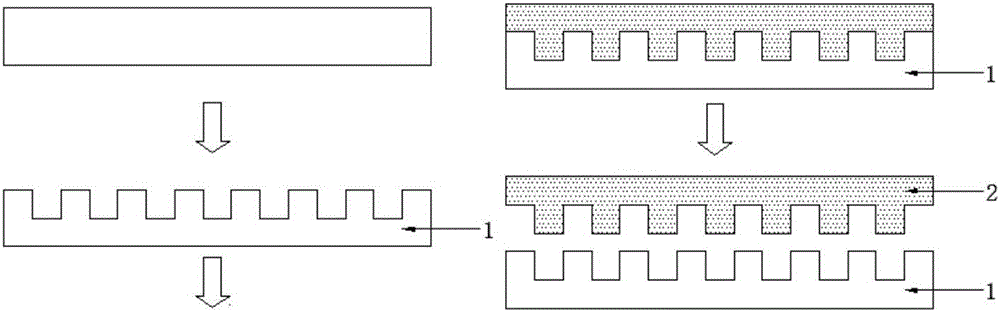

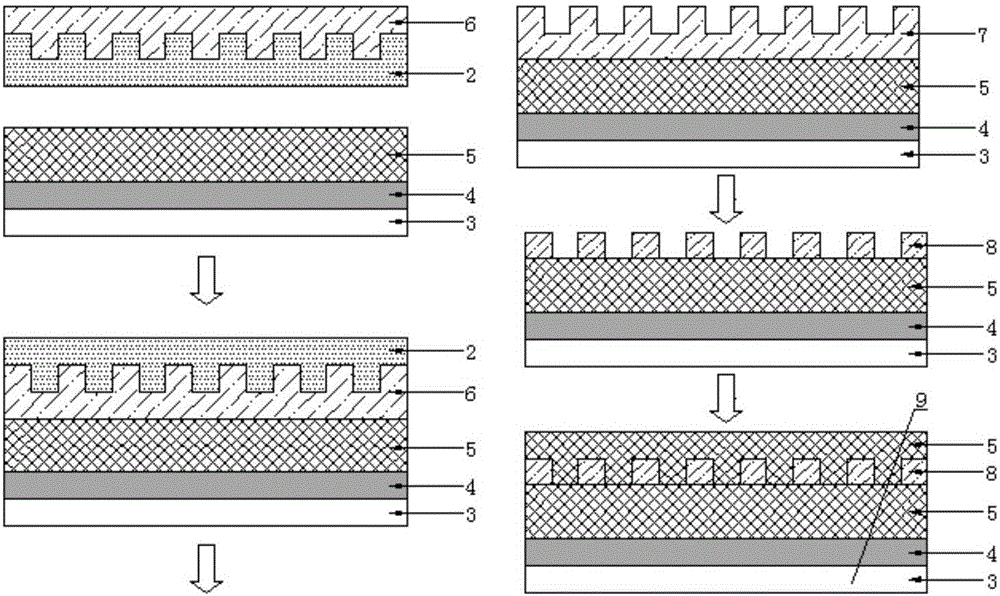

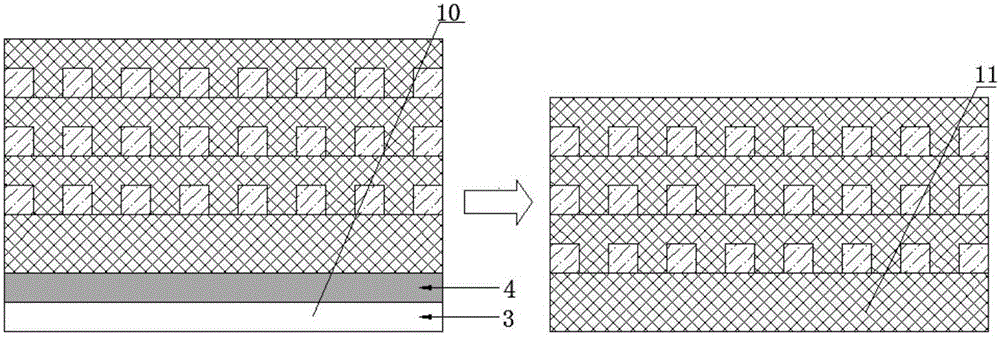

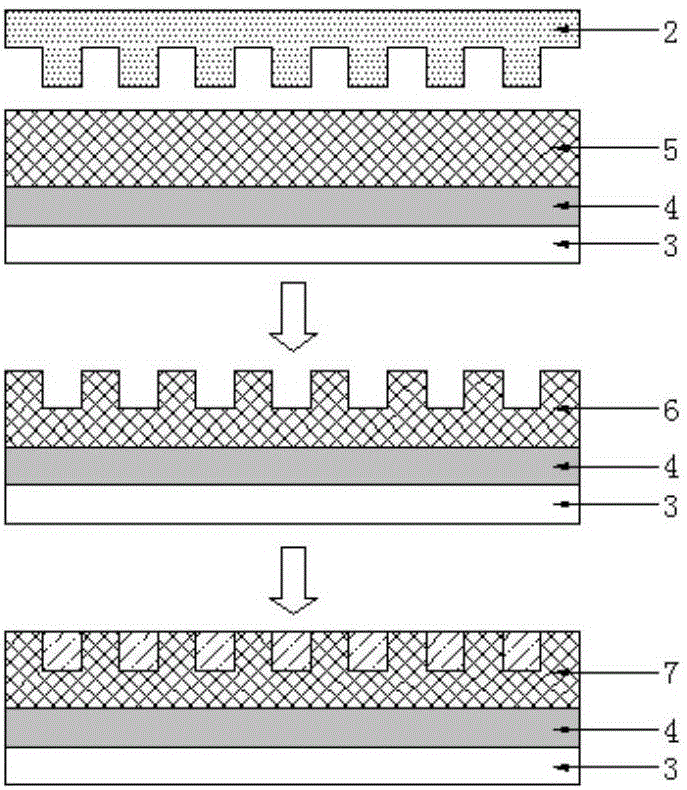

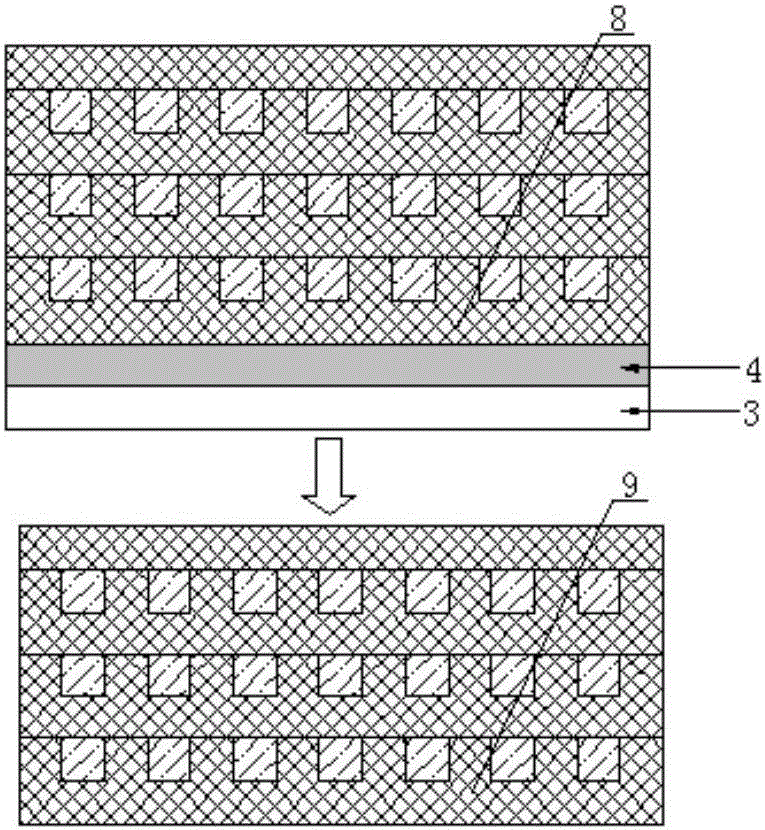

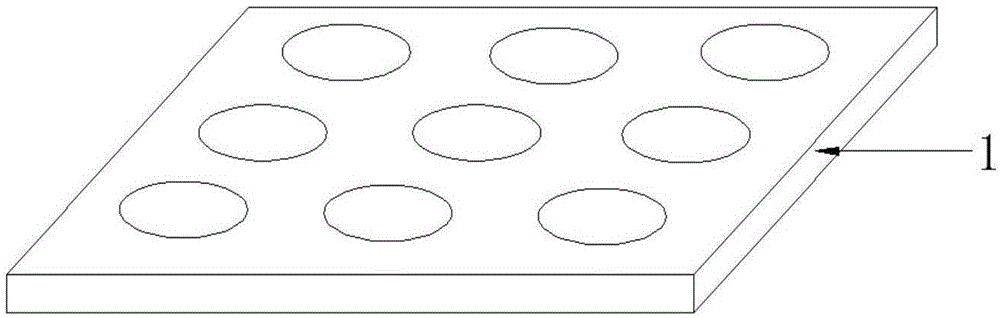

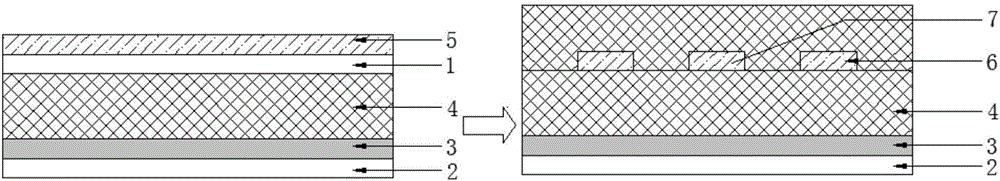

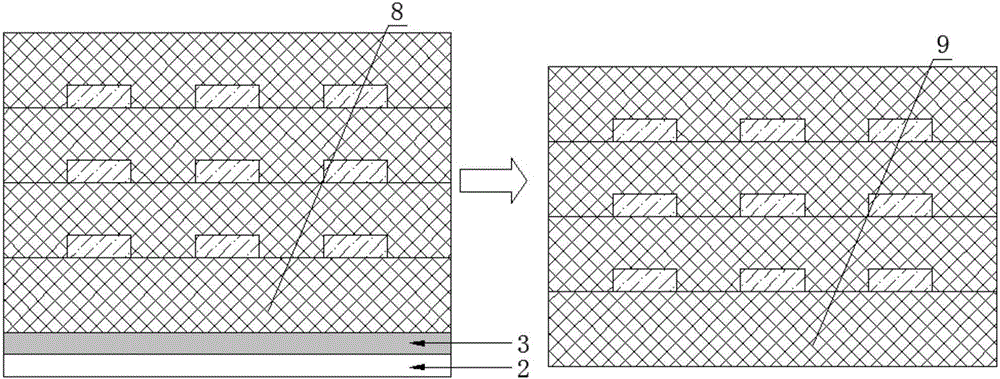

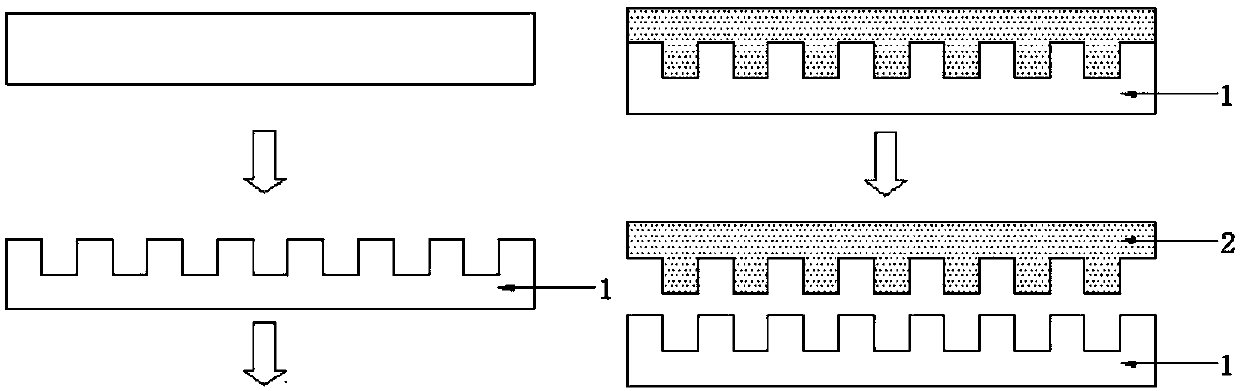

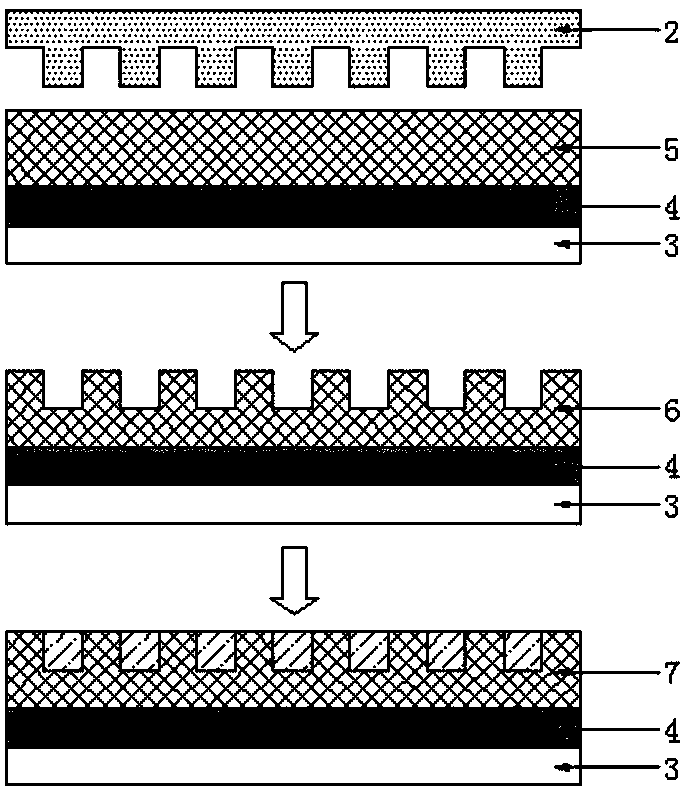

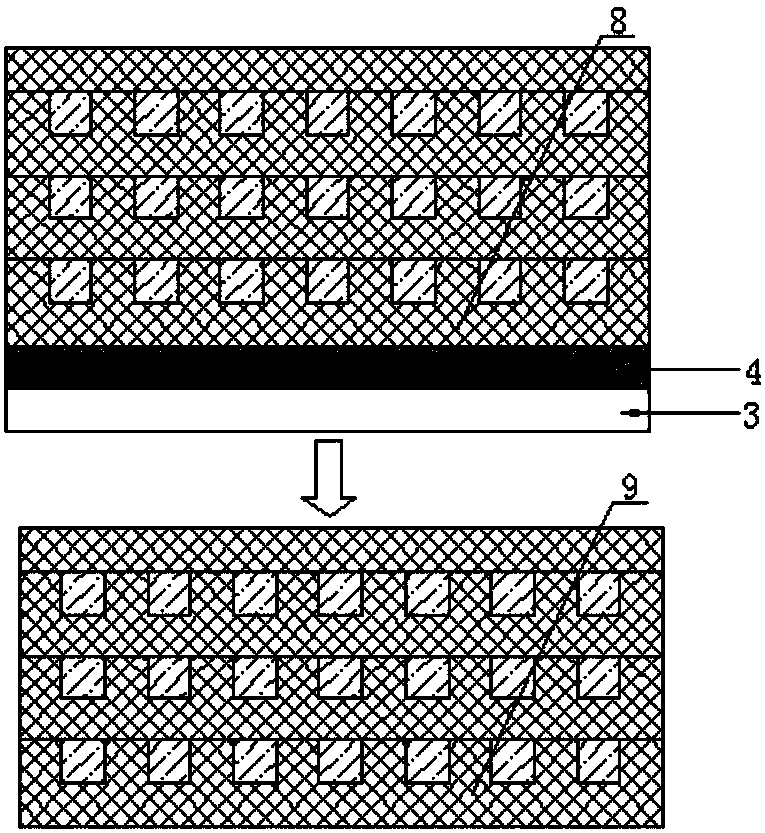

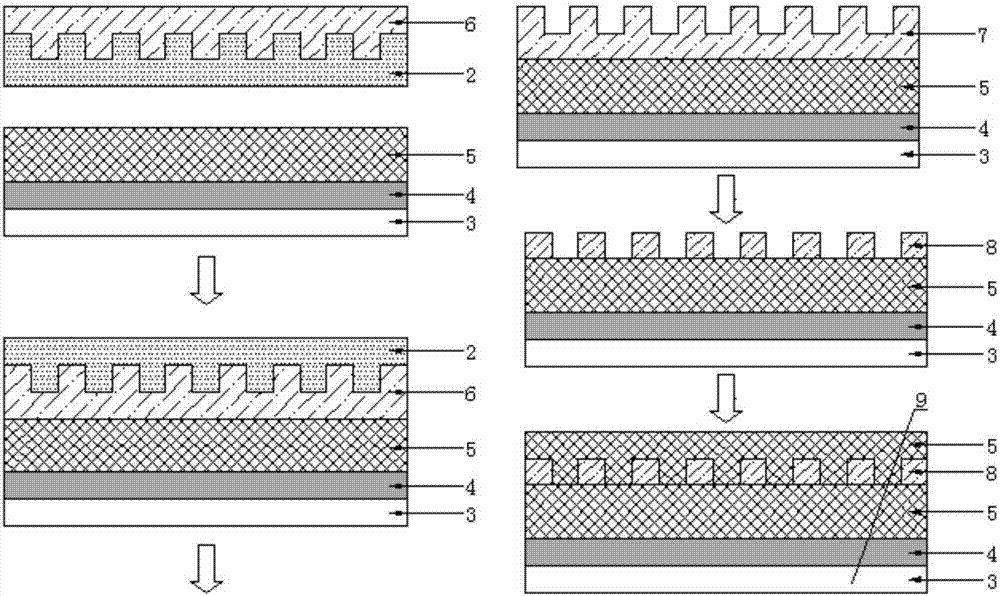

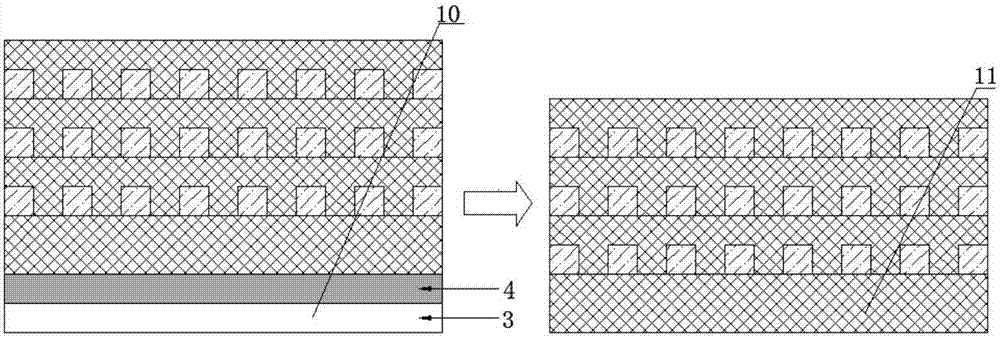

Method for manufacturing force responsive photonic crystal materials based on inverse compressing nano-forming technology

ActiveCN106226846ASimple processShort preparation cycleOptical elementsPhotonic crystal structureElectron-beam lithography

The invention discloses a method for manufacturing force responsive photonic crystal materials based on inverse compressing nano-forming technology. Electron beam lithography technology and reactive ion etch technology are employed. A nanometer magnitude pattern is etched on a rigid template to serve as a mother template according to preset photonic crystal structure parameters. An elastic polymer soft template with an inverse nanometer magnitude pattern can be made and serves as a secondary template. With highly elastic gel as filling material and visco-elastic polymer as moulding material, the pattern on the mother template is copied on to the visco-elastic polymer in a high fidelity way through inverse compressing, so as to produce nanometer magnitude and structure-controllable force responsive photonic crystal. Compared with the prior art, the method has the advantages of simple process, short flow, easily controlled technological parameters, repeatedly usable templates, high product precision level, stable and reliable product quality and low cost.

Owner:SHANDONG UNIV OF SCI & TECH

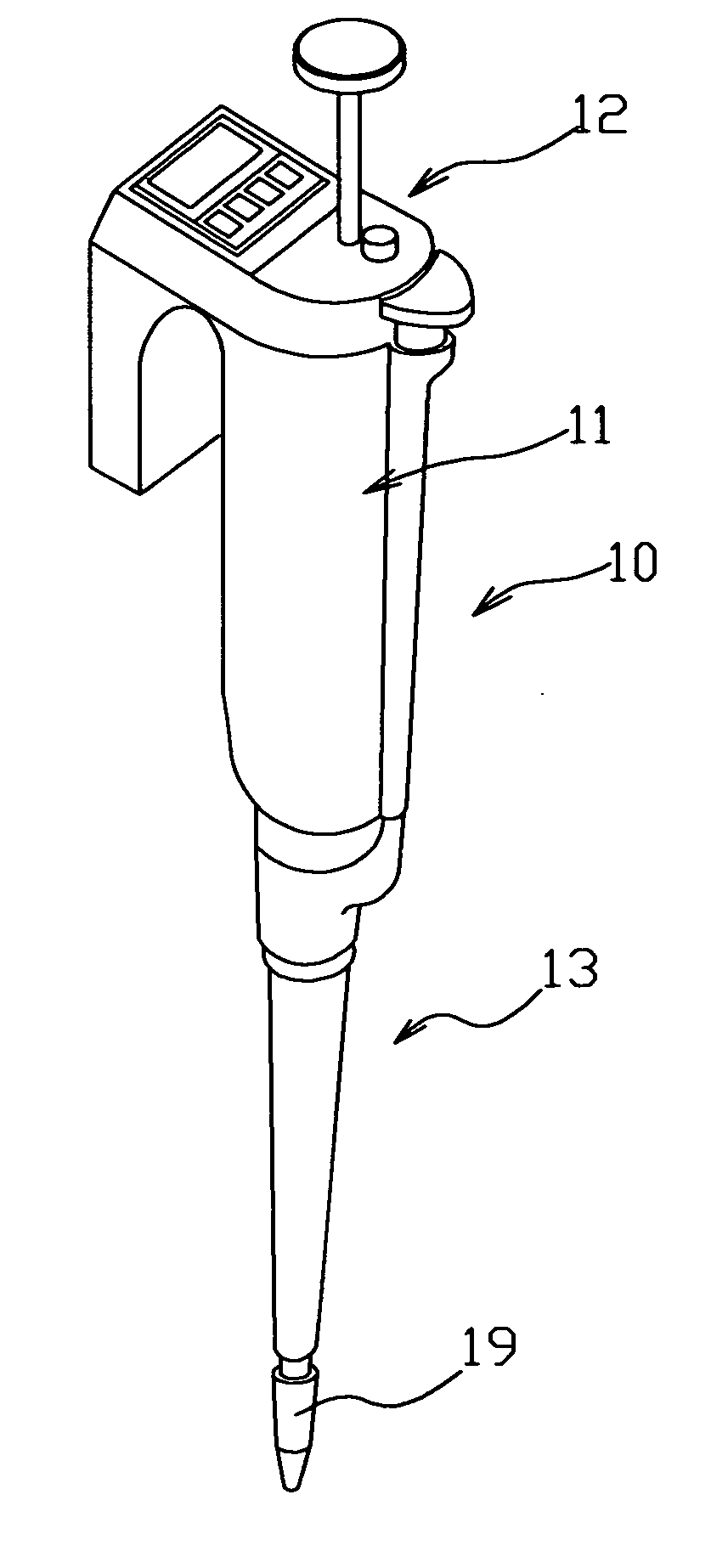

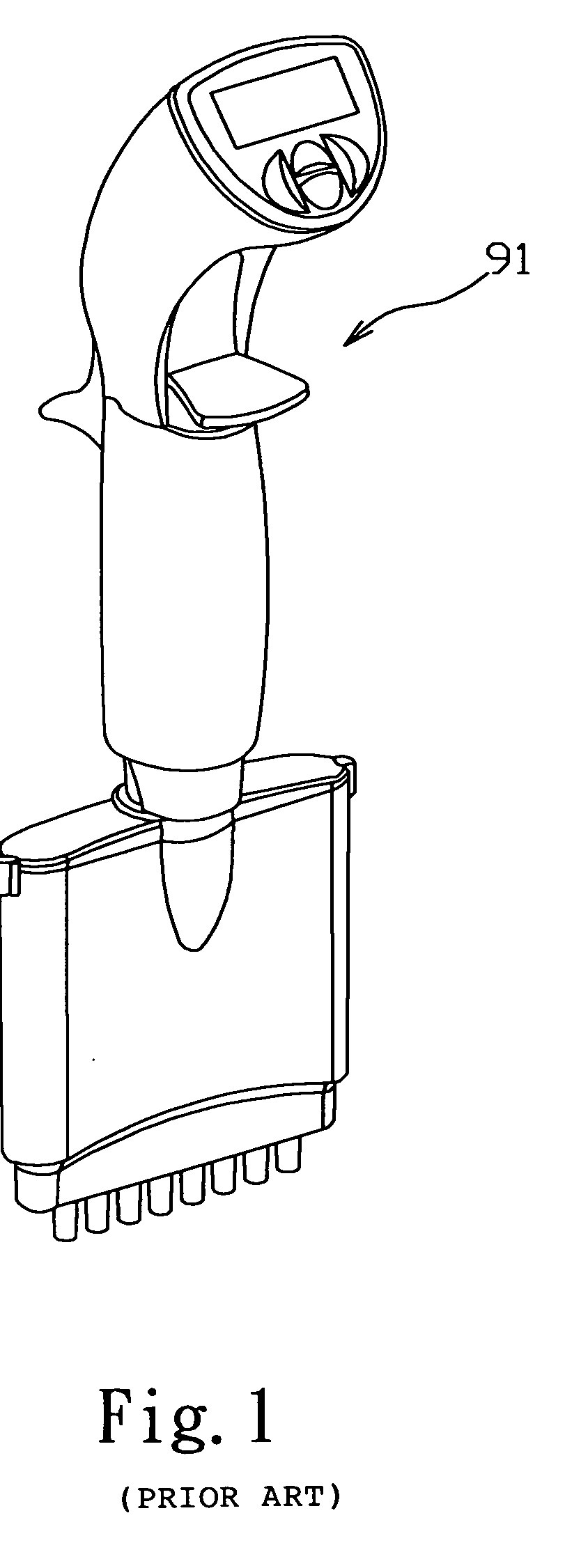

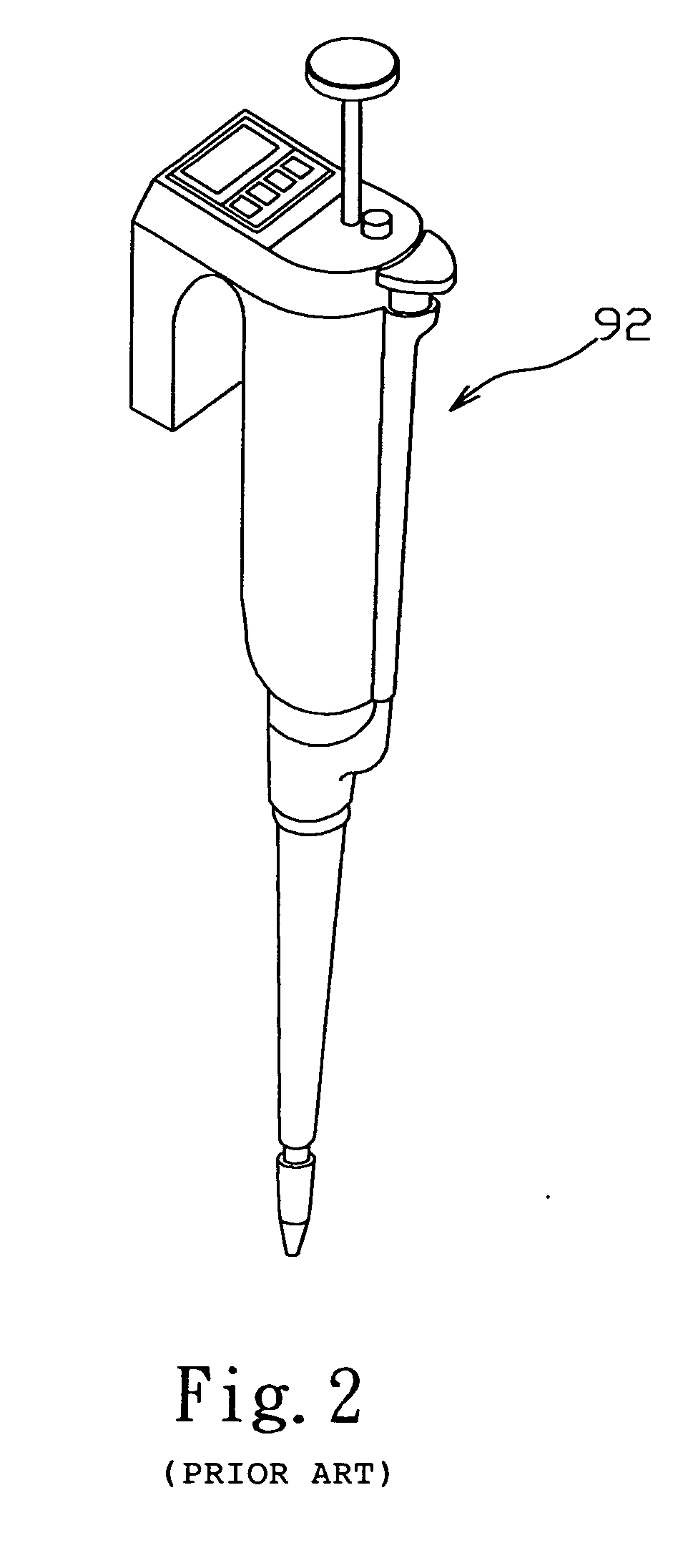

Micro pipette sensing device

InactiveUS20070059215A1High precisionImprove precisionAnalysis using chemical indicatorsVolume/mass flow measurementFlow transducerMICRO PIPETTE

A micro pipette sensing device includes a micro pipette and a sensing device. The micro pipette includes a main portion, an operation portion and at least one tube portion. The tube portion defines an operation space therein. The sensing device is located at a proper position in the operation space of the tube portion. The sensing device includes a MEMS flow sensor for sensing a gas movement in the operation space, thereby effectively improving the precision of solution to be taken and therefore improving the precision of the overall measurement and analysis results.

Owner:PACIFIC IMAGE ELECTRONICS

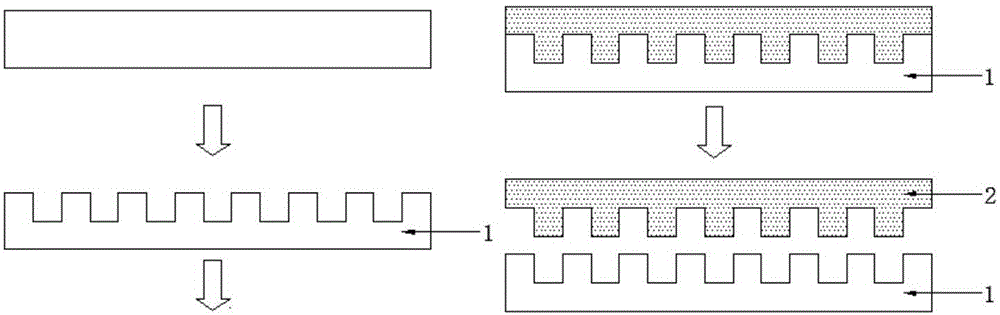

Method for preparing force response photonic crystal material on basis of nano molding technique

ActiveCN106291776ASimple processShort preparation cycleOptical elementsNanometrePhotonic crystal structure

The invention discloses a method for preparing a force response photonic crystal material on the basis of a nano molding technique. The method comprises the following steps: etching a main template according to pre-designed photonic crystal structure parameters, preparing an elastic polymer soft template with inverse nano-grade patterns, and by taking the soft template as a secondary template, 'copying' the patterns on the main template into a high -elasticity gel matrix layer in a 'high-fidelity 'manner in a mode of three-step pattern transfer so as to fix the position of crystal lattice of photonic crystal; filling the crystal lattice with a viscous polymer so as to obtain a single-layer high-elasticity gel-viscous polymer composite layer with a photonic crystal structure, and implementing a layer-by -layer embossing method,thereby obtaining the force response photonic crystal material. Compared with the prior art,the method disclosed by the invention has the characteristics that the process is simple, the procedure time is short, process parameters are easy to control, the templates can be repeatedly used, and a product is high in precision grade, stable and reliable in quality and relatively low in cost, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of force responsiveness nanometer magnitude photonic crystal materials

ActiveCN106226847ASimple processShort preparation cycleOptical elementsPhotonic crystal structureCurrent technology

The present invention discloses a preparation method of force responsiveness nanometer magnitude photonic crystal materials. Through adoption of the electron beam lithography technology and the reactive ion etch technology, a rigid template with a nanometer magnitude pattern is etched and taken as a filling template according to photonic crystal structure parameters designed in advance, high-elastic gel with good mechanical property is taken as matrix materials, and a visco-elastic polymer is taken as filling materials; and through the mode of the filling template, the photonic crystal pattern designed in advance in the high fidelity mode is transferred into the visco-elastic polymer, and the nanometer magnitude and structure controllable photonic crystal materials with force responsiveness are prepared through spin coating, stacking and the like. Compared to the current technology, the preparation method of force responsiveness nanometer magnitude photonic crystal materials is simple in technology and short in flow, technology parameters are easy to control, the template can be reused, the precision of products is high in level, the quality is stable and reliable, and the cost is low, etc.

Owner:SHANDONG UNIV OF SCI & TECH

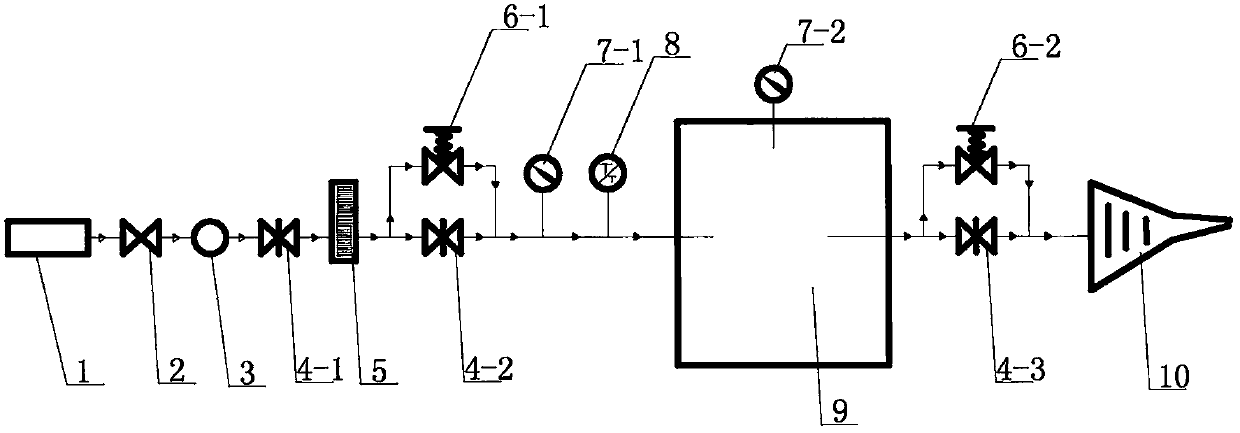

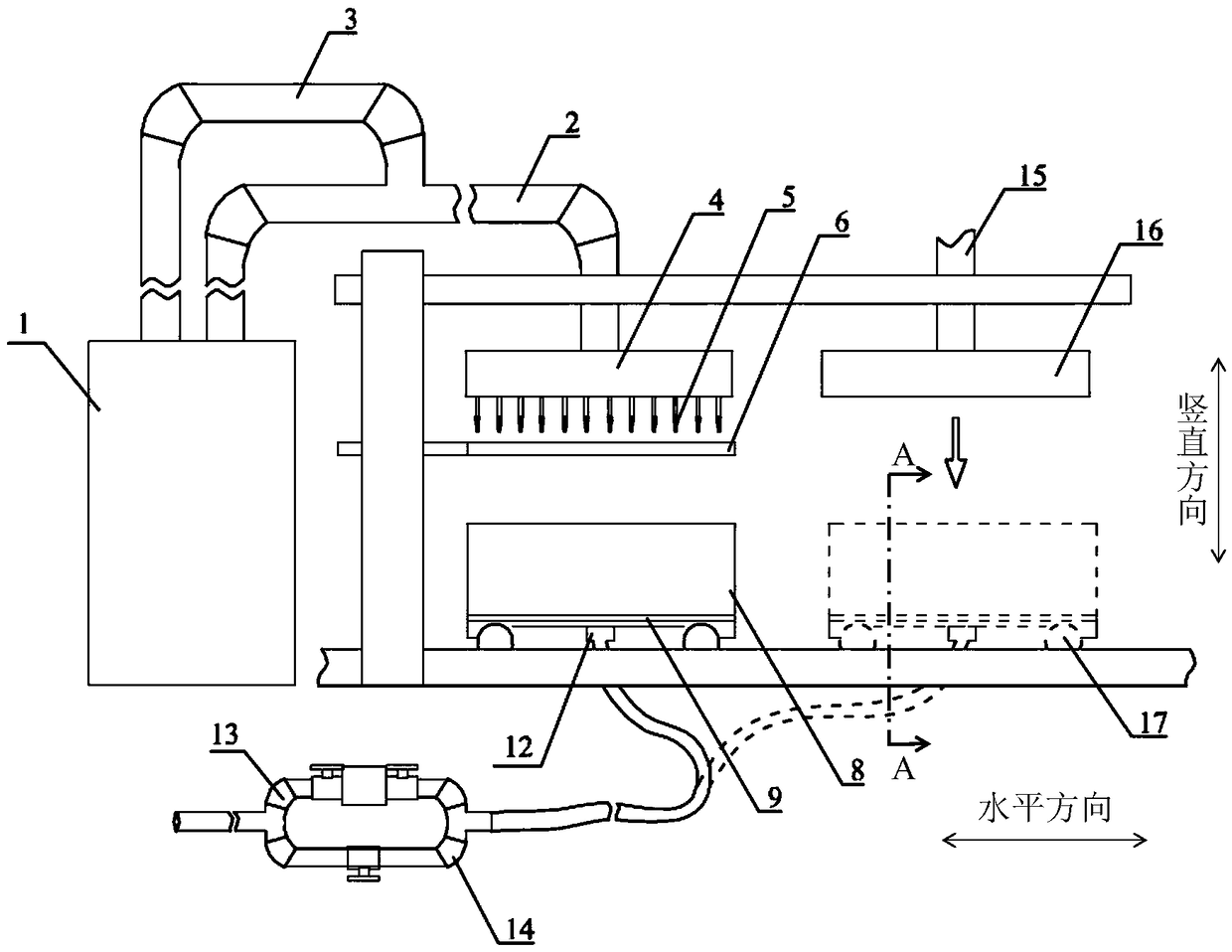

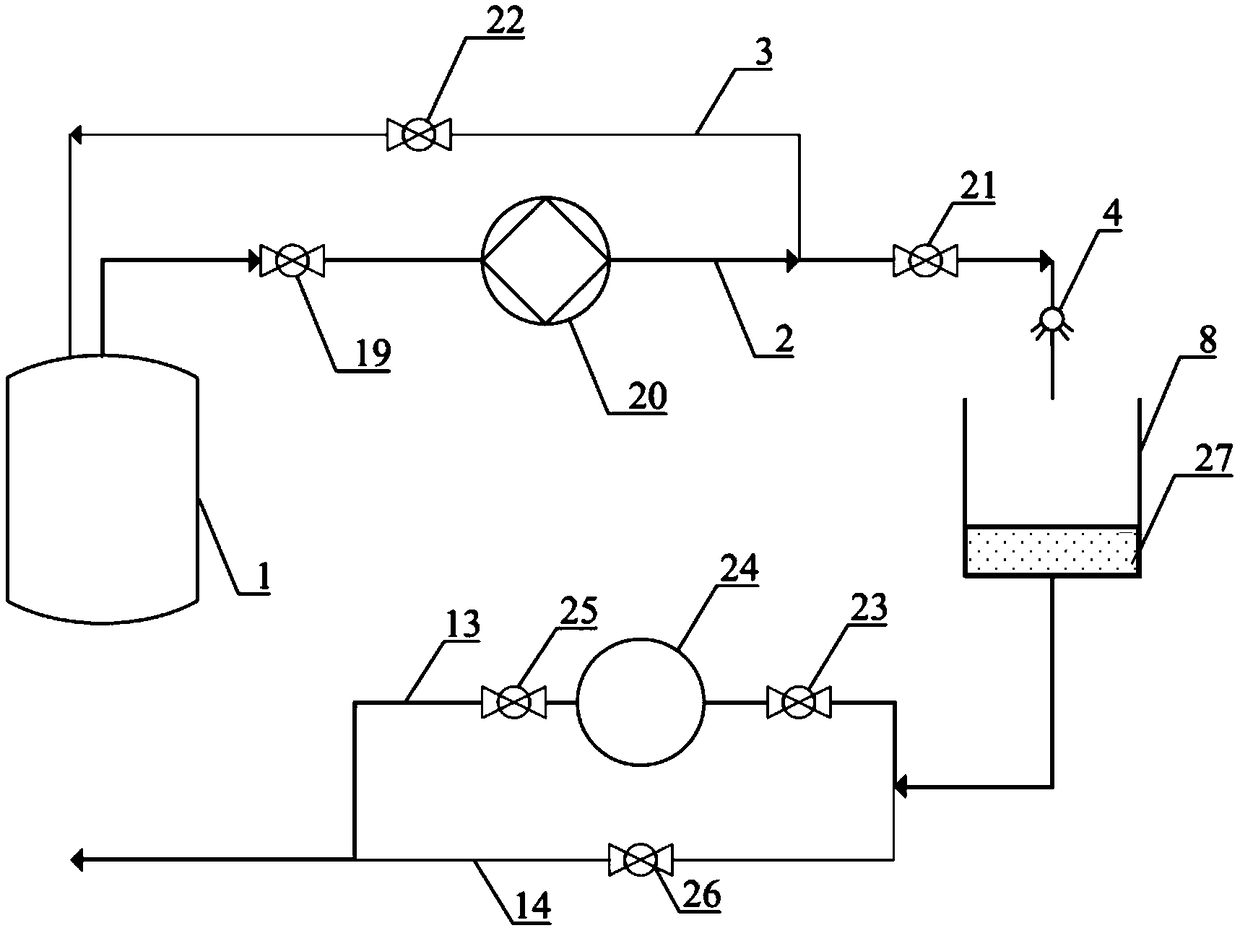

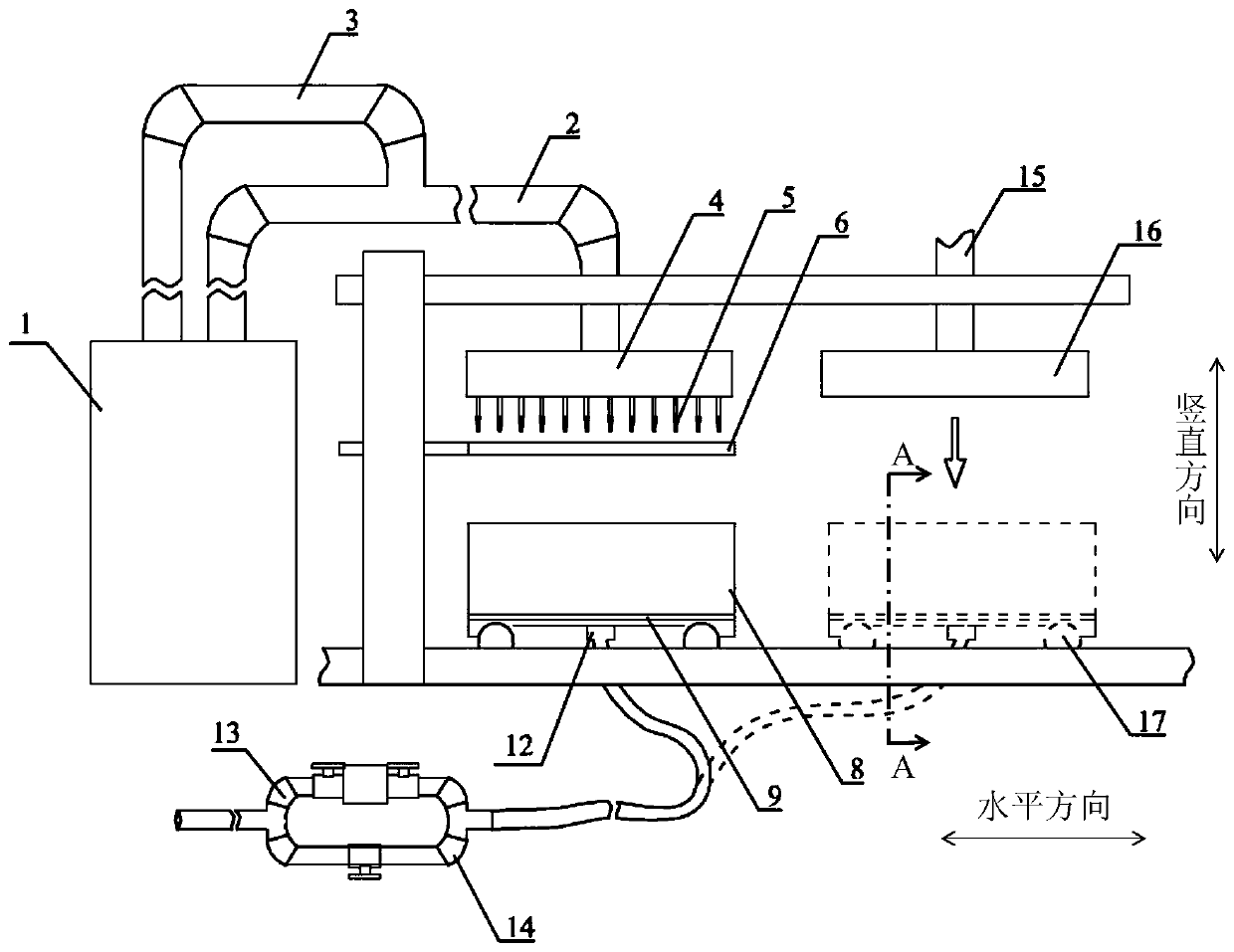

Fuel oil nozzle cyclone air flow test bench and test method thereof

PendingCN107560837AEffective control of precisionControl precisionMachine part testingEngine testingFuel oilEngineering

The invention belongs to the technical test field of an aerospace engine fuel oil injection system and especially relates to a fuel oil nozzle cyclone air flow test bench. The test bench comprises anexternal air source mechanism, a working chamber and an exhaust chamber, which are communicated in sequence through air pipes. The air pipe between the external air source mechanism and the working chamber is provided with a stop valve, an oil and gas separator, a regulating valve, a float flowmeter, a first-stage pressure fine-tuning assembly and a first pressure meter. The air pipe between the working chamber and the exhaust chamber is provided with a second-stage pressure fine-tuning assembly. The working chamber is provided with a second pressure meter. The first-stage pressure fine-tuningassembly comprises a first-stage regulating valve and a first-stage high-precision fine-tuning regulating valve, which are arranged in parallel. The second-stage pressure fine-tuning assembly comprises a second-stage regulating valve and a second-stage high-precision fine-tuning regulating valve, which are arranged in parallel. The invention also relates to a method for carrying out test throughthe test bench above.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

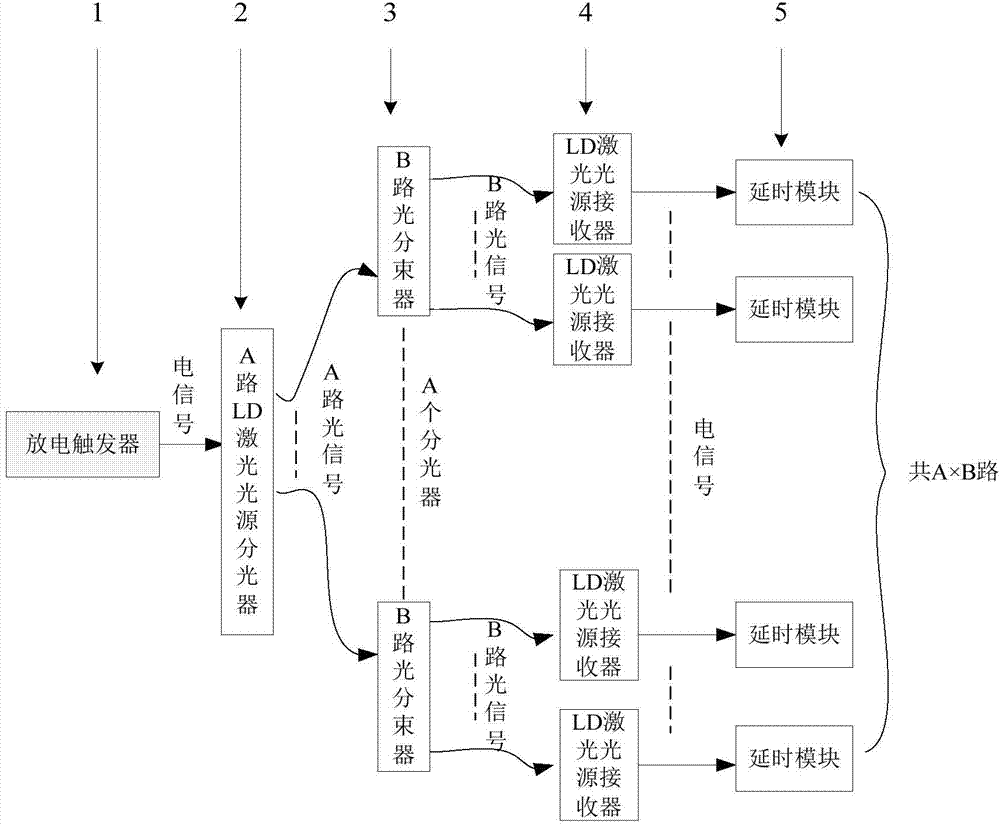

Multichannel timing sequence trigger

InactiveCN104270128AEnables programmable outputAchieve differentiationElectronic switchingTime delaysLight beam

A multichannel timing sequence trigger comprises a discharging trigger (1), an A-channel LD laser light source optical splitter (2), B-channel light beam splitting devices (3), LD laser light source receivers (4) and time delay modules (5). The input end of the discharging trigger (1) is connected with a 5V direct-current power supply. The output end of the discharging trigger (1) is connected with the A-channel LD laser light source optical splitter (2). The A-channel LD laser light source optical splitter (2) divides the input electrical signals into A-channel optical signals. The A-channel optical signals are connected with the A B-channel light beam splitting devices (3) through A-channel optical fibers. The A B-channel light beam splitting devices altogether output A*B channels of optical signals. The A*B channels of optical signals are connected with A*B LD laser light source receivers (4) through optical fibers. The output of the A*B LD laser light source receivers (4) is connected with the A*B time delay modules (5). The output of the A*B time delay modules (5) are the A*B channels of time delay trigger signals with different time delays.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

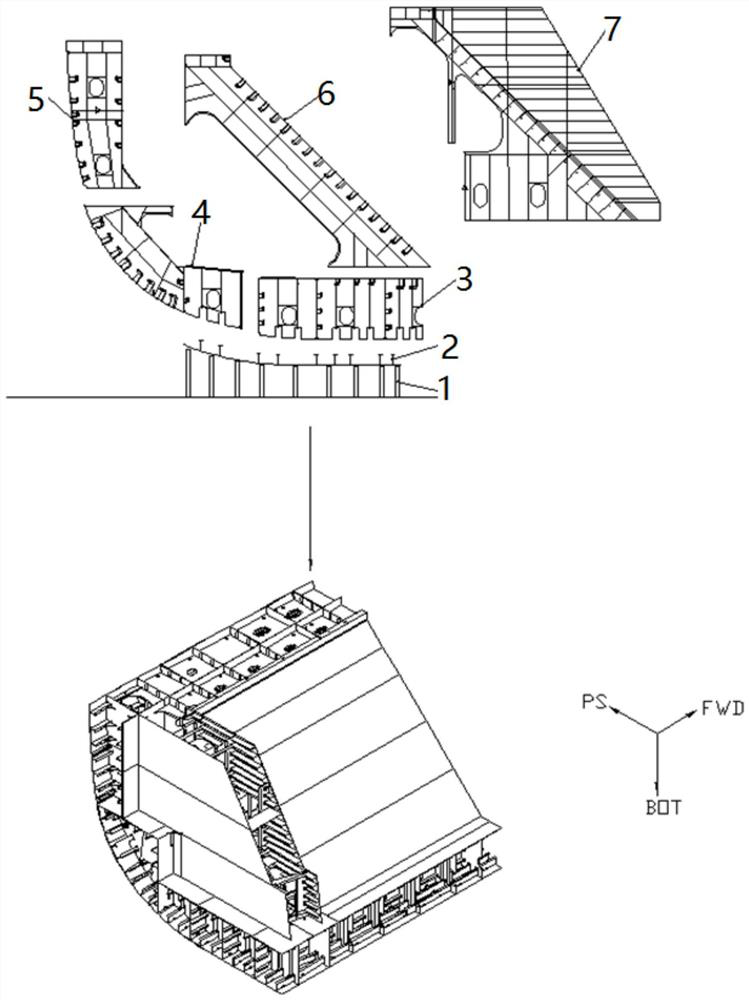

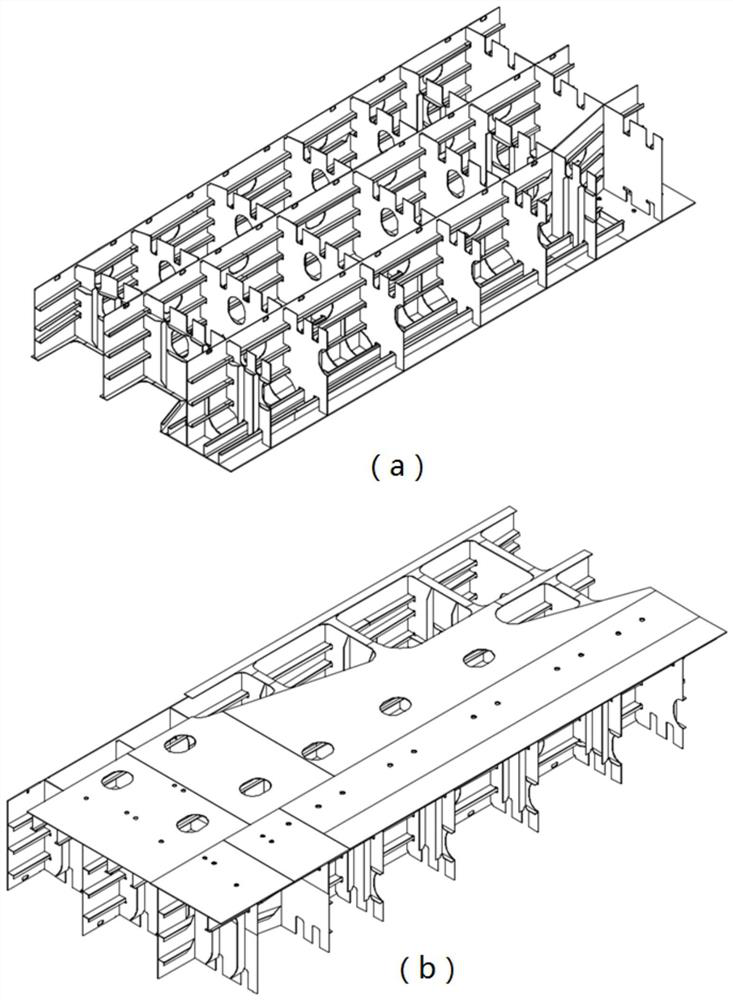

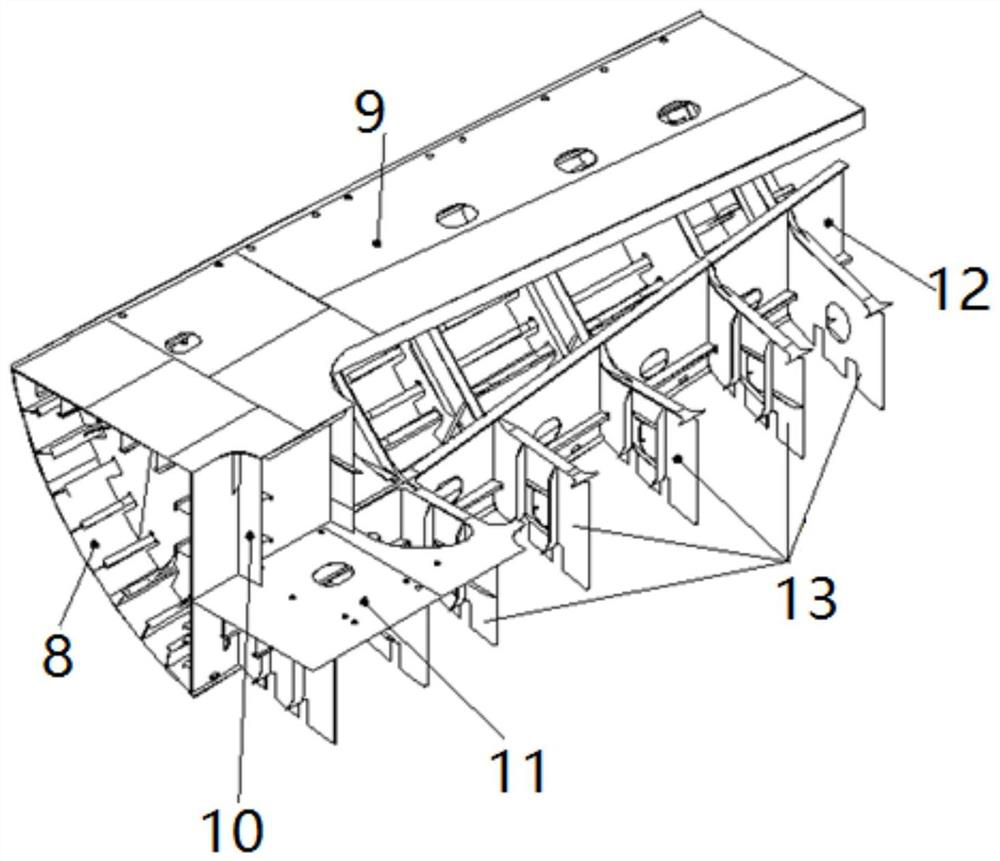

Method for constructing bilge section of fuel tank of dual-fuel container ship

InactiveCN112550611AAvoid turning over in sectionsAvoid working at heightsWaterborne vesselsBilgeFuel tank

The invention discloses a method for constructing a bilge section of a fuel tank of a dual-fuel container ship, which comprises the following steps: dividing a fuel tank bilge section into an inner bottom plate middle group, a platform middle group, a broadside middle group, an inclined side plate middle group and a bulkhead middle group according to a dual-fuel container ship fuel tank bilge section structure model; and taking the outer bottom plate as a base plane in the large group, and sequentially mounting the inner bottom plate middle group, the platform middle group, the broadside middle group, the inclined side plate middle group and the bulkhead middle group to form a complete subsection. Through sectional normal construction, sectional turnover is avoided, and sectional hoistingreverse side reinforcement is prevented from being increased.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

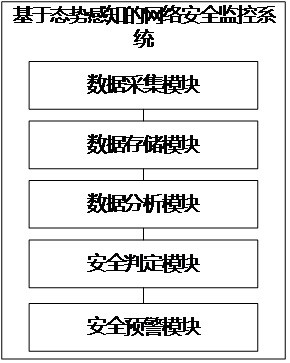

Network security monitoring system based on situation awareness

ActiveCN114154172AImprove analytical precisionImprove securityHardware monitoringPlatform integrity maintainanceMonitoring systemNetwork data

The invention relates to a network security monitoring system based on situation awareness, in particular to the technical field of system security data processing, and the system comprises a data collection module which is used for collecting system security data in real time, and the system security data comprises node data, network data and application data; the data storage module is used for storing system security data acquired in real time and is connected with the data acquisition module; the data analysis module is used for performing data analysis on the system security data and generating a data analysis result, and is connected with the data storage module; the security judgment module is used for carrying out security judgment on the system according to the data analysis result and is connected with the data analysis module; and the safety early warning module is used for performing different degrees of safety early warning according to the safety judgment result and is connected with the safety judgment module. According to the invention, the security monitoring efficiency of the system data is effectively improved.

Owner:北京国信网联科技有限公司

A kind of pcb back drilling method

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH

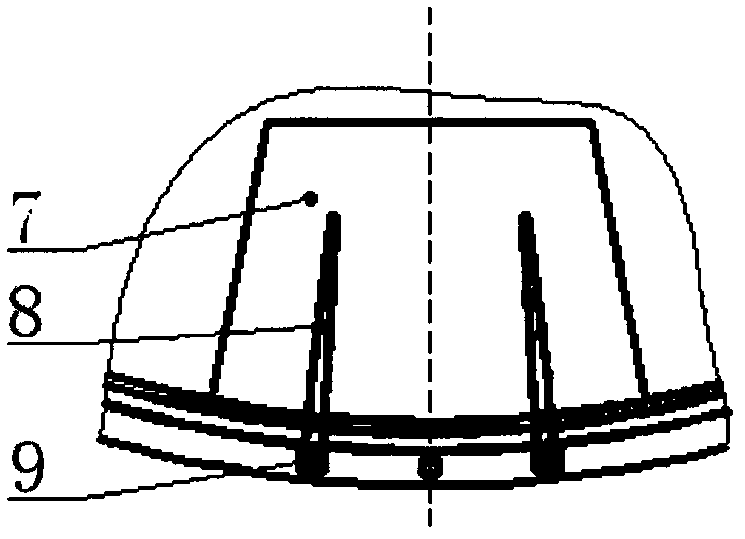

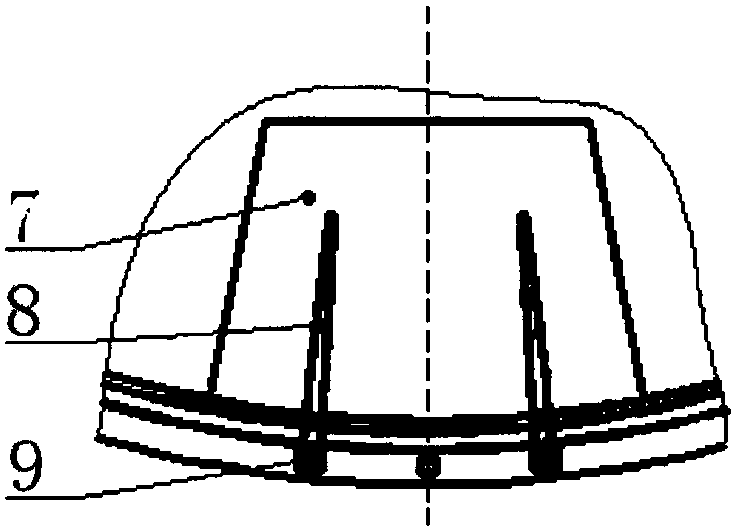

Composite easily-cracking front cover opened in one side and making method of composite easily-cracking front cover

The invention relates to a missile launcher technology. In order to solve the problems of easy embrittlement during long-term storage of an easily-cracking front cover and potential safety hazards due to a large quantity of fragments after the cover is broken after launched, the invention provides a composite easily-cracking front cover opened in one side and a making method of the composite easily-cracking front cover. Compared with the prior art, the composite easily-cracking front cover has the advantages and the beneficial effects of light weight, high strength and good compaction due to the adoption of a composite, and can ensure that the front cover structure is more reasonable in performance and is greatly improved in sealing property; and made by adopting a mold, the composite easily-cracking front cover has the advantages of capability of effectively controlling precision and ensuring that cover breaking pressures are consistent, rapidness, high efficiency and stable quality; and an opened cover body can not be separated from the launcher so as to eliminate potential safety hazard caused by scattering broken fragments after the cover is opened. The composite easily-cracking front cover is formed through medium-temperature curing, can be reliably used under the condition of high-temperature and low-temperature environments, and is difficult in embrittling and cracking.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

A preparation method of force-responsive photonic crystal material based on nano-molding technology

ActiveCN106291776BSimple processShort preparation cycleOptical elementsPhotonic crystal structureCrystal structure

The invention discloses a method for preparing a force-responsive photonic crystal material based on nano-molding technology, which etches a master template according to pre-designed photonic crystal structure parameters to prepare elastic polymers with inverse nanoscale patterns Soft template, using the soft template as a secondary template, "copy" the pattern on the master template to the high-elastic gel matrix layer with "high fidelity" through a three-step pattern transfer method to fix the lattice of the photonic crystal position; then, the viscoelastic polymer is filled in the lattice to obtain a single-layer highly elastic gel-viscoelastic polymer composite layer with a photonic crystal structure, and then a force-responsive photon crystal material. Compared with the prior art, the preparation method of the present invention has the characteristics of simple process, short process, easy control of process parameters, reusable template, high product precision level, stable and reliable quality, and low cost.

Owner:SHANDONG UNIV OF SCI & TECH

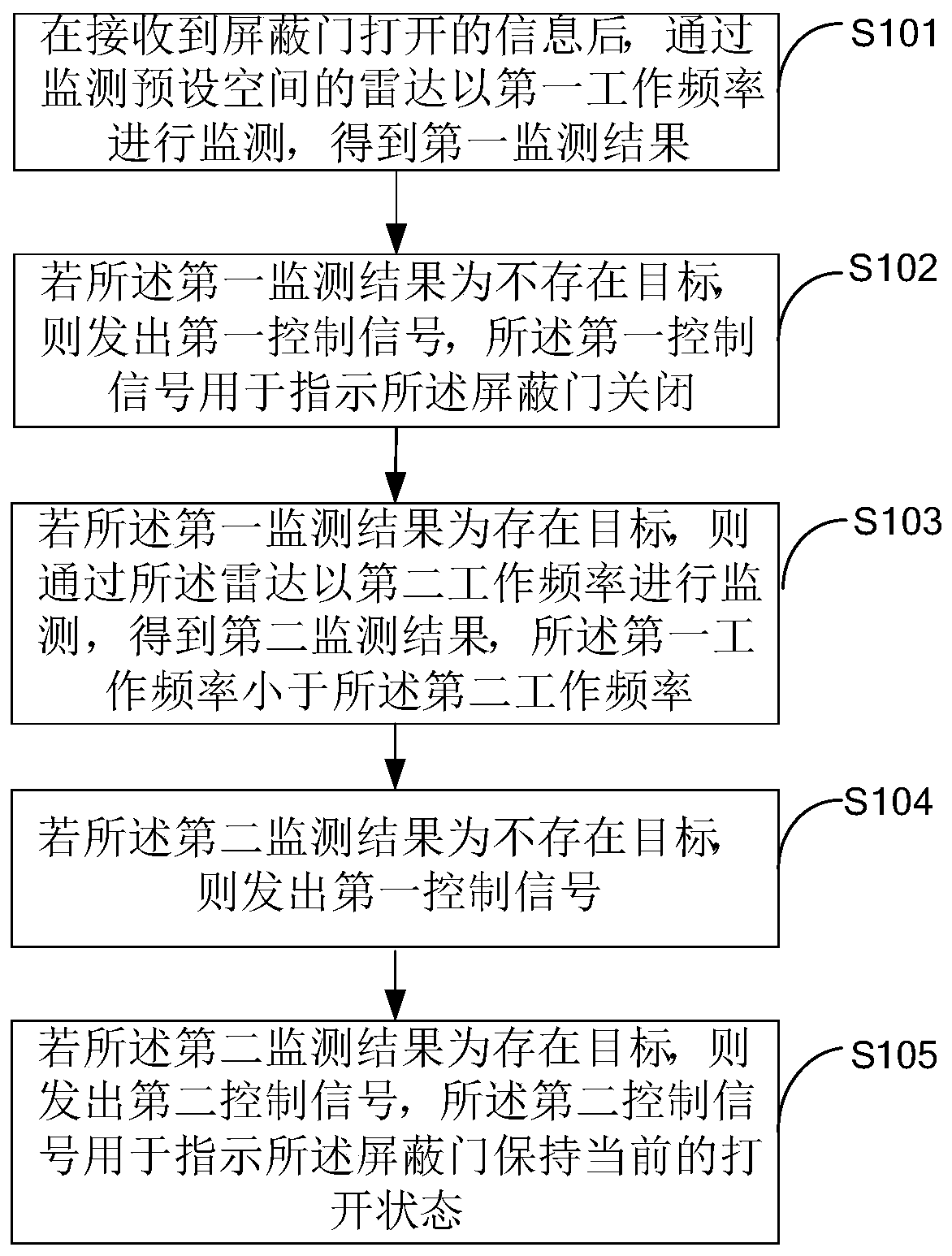

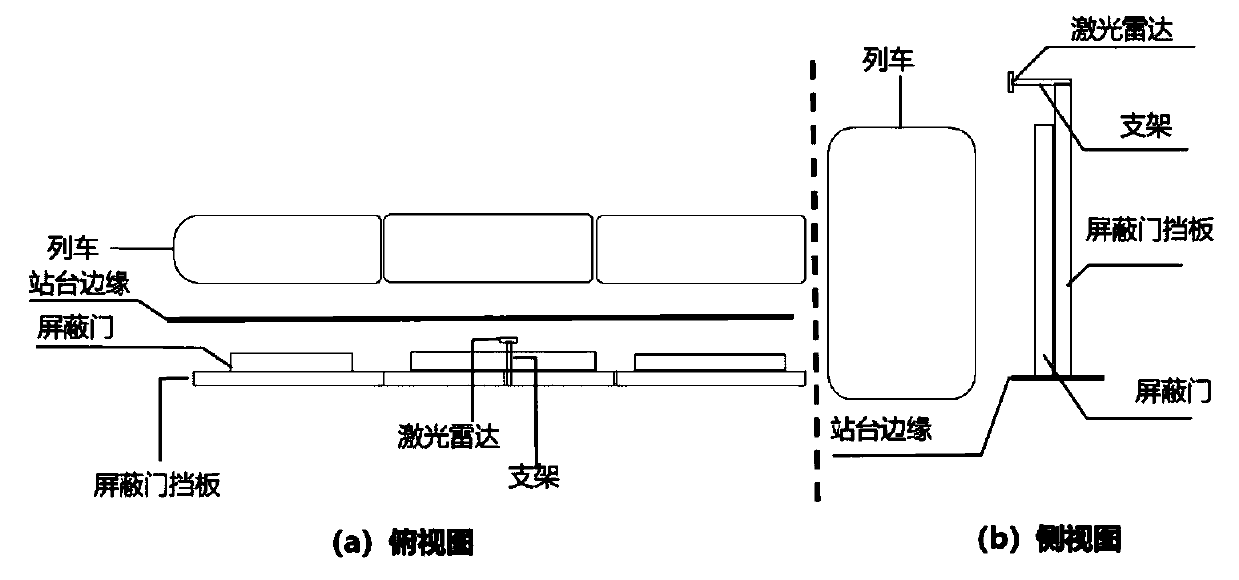

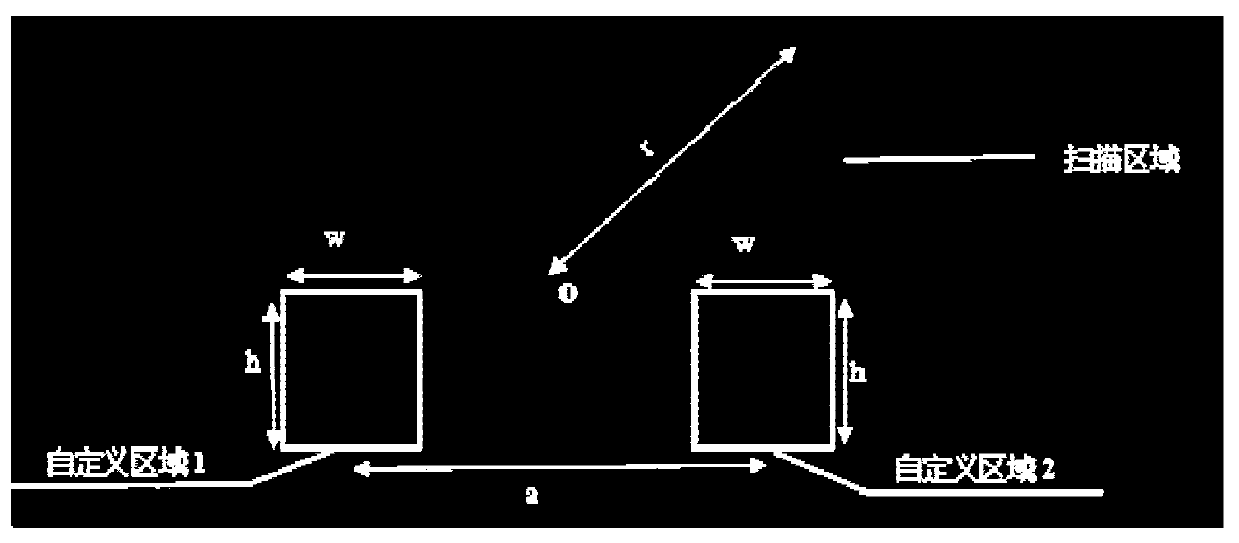

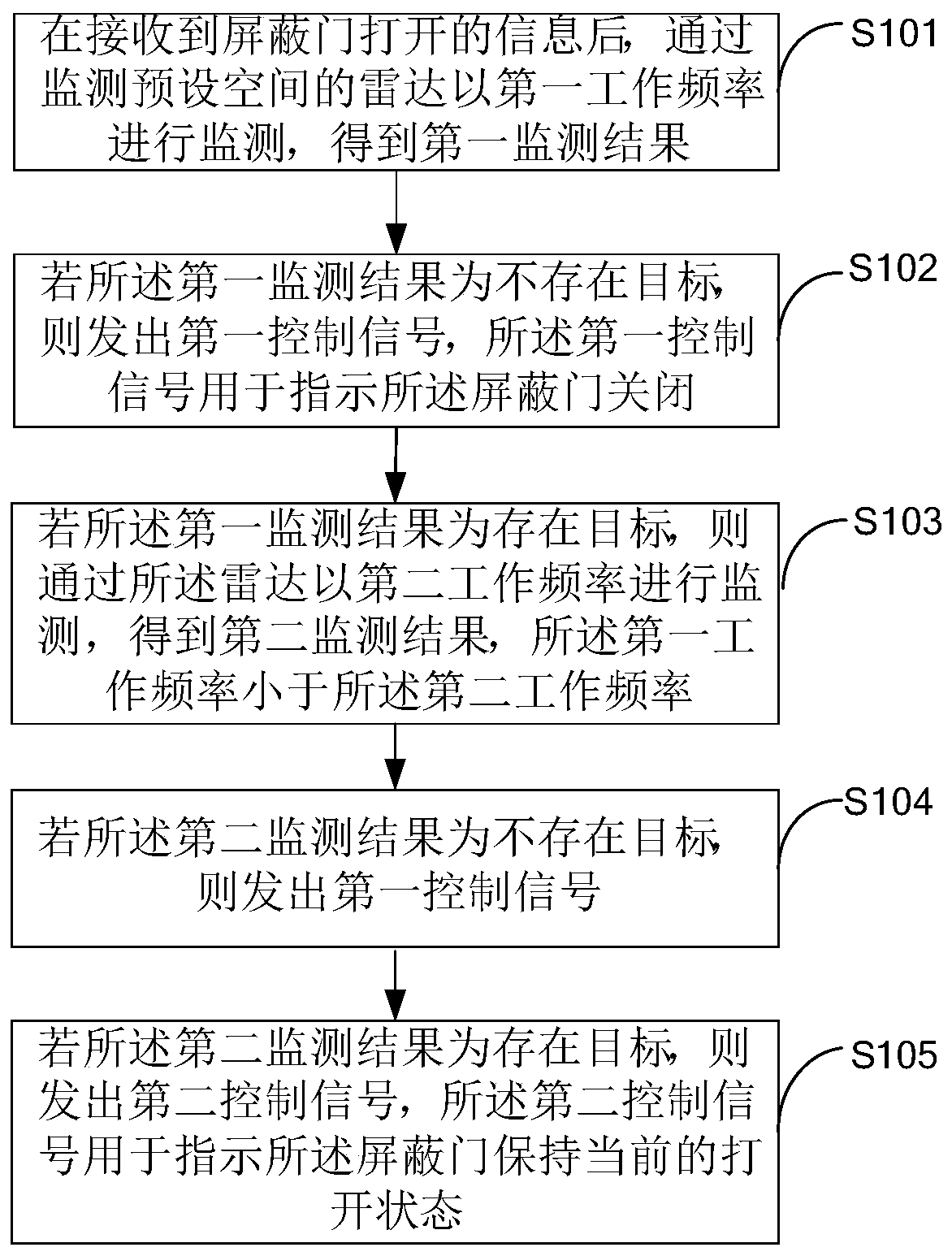

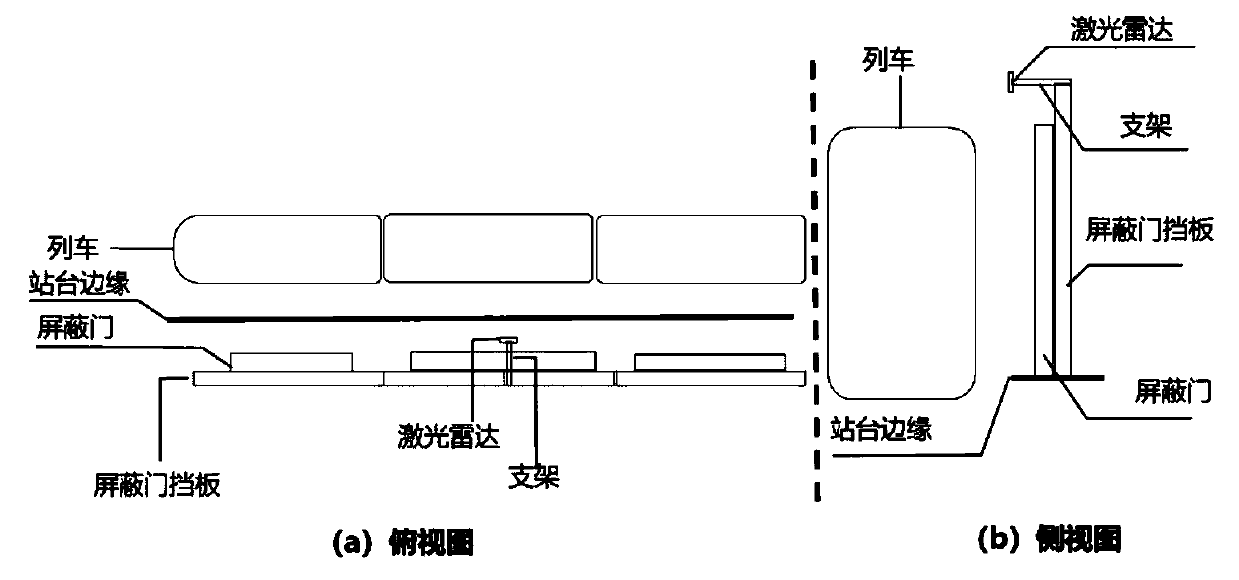

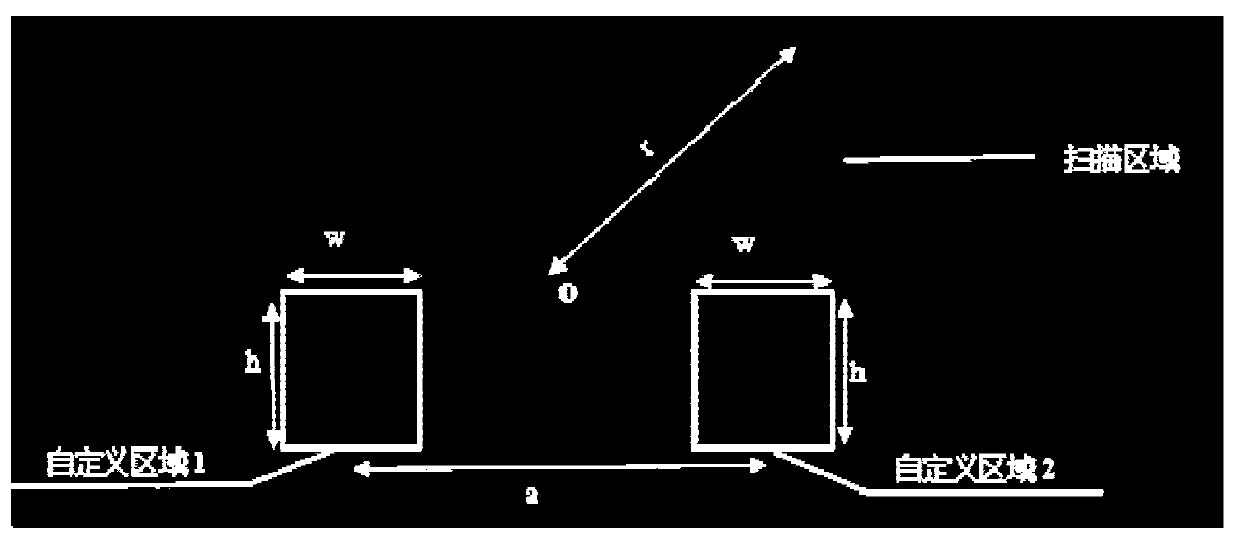

Control method and control device of shielding door and radar

ActiveCN110217244AEffective control of precisionExtended service lifePower-operated mechanismRailway signalling and safetyVIT signalsEngineering

The invention is suitable for the technical field of control and provides a control method and a control device of a shielding door and a radar. The control method of the shielding door comprises thesteps of using the radar for monitoring a preset space to monitor at a first working frequency to obtain a first monitoring result after receiving a shielding door opening information; if the first monitoring result is that a target does not exist, transmitting a first control signal, wherein the first control signal is used for indicating the shielding door to be closed; if the first monitoring result is that the target exists, using the radar to monitor at a second working frequency to obtain a second monitoring result, wherein the first working frequency is less than the second working frequency; and if the second monitoring result is that the target exists, transmitting a second control signal, wherein the second control signal is used for indicating the shielding door to keep a current open state. Through the method, the shielding door control accuracy can be effectively improved, the service life of the radar can be prolonged, and the reliability and adaptability of the radar canbe enhanced.

Owner:WHST CO LTD

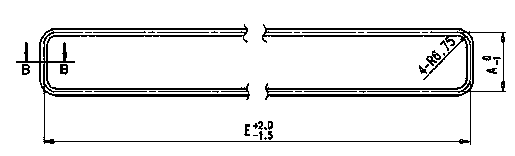

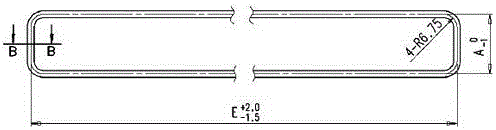

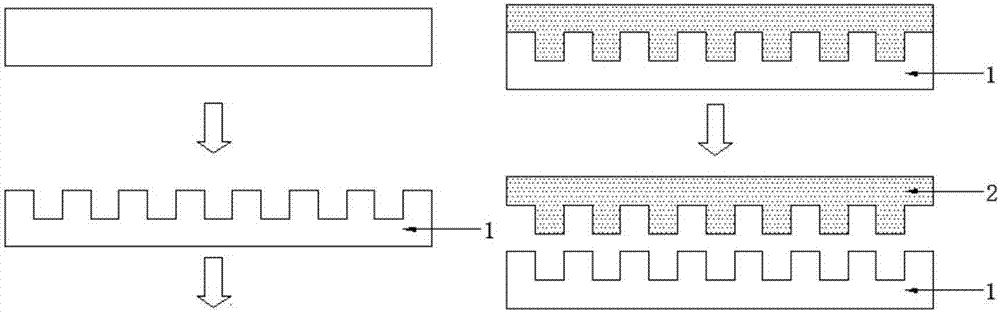

Rectangular sealing part manufacturing method

ActiveCN104006160AImprove efficiencyEffective control of precisionEngine sealsManufacturing efficiencyManufacturing engineering

The invention provides a rectangular sealing part manufacturing method. The method includes the first step of drawing a drawing of a rectangular sealing part according to the required shape and dimensions of the part, the second step of designing a rectangular sealing ring mould according to the drawing, wherein the designed height of the mould is not allowed to be larger than the width of a nylon column of a slitter machine, the third step of conducting vulcanization to form the rectangular sealing parts according with the drawing, then overlaying the rectangular sealing parts to reach a certain thickness and placing the overlaid rectangular sealing parts into the rectangular sealing ring mould for integral vulcanization to obtain a rectangular sealing ring, and the fourth step of propelling the rectangular sealing ring through gas to enable the rectangular sealing ring to be arranged on the nylon column of the slitter machine in a sleeved mode, and slitting rectangular sealing ring through the slitter machine to obtain the rectangular sealing parts. The rectangular sealing part manufacturing method has the advantages that the manufacturing efficiency of the rectangular sealing parts is high, and the accuracy of the rectangular sealing parts can be effectively controlled.

Owner:SHANGHAI RONGNAN TECH CO LTD +2

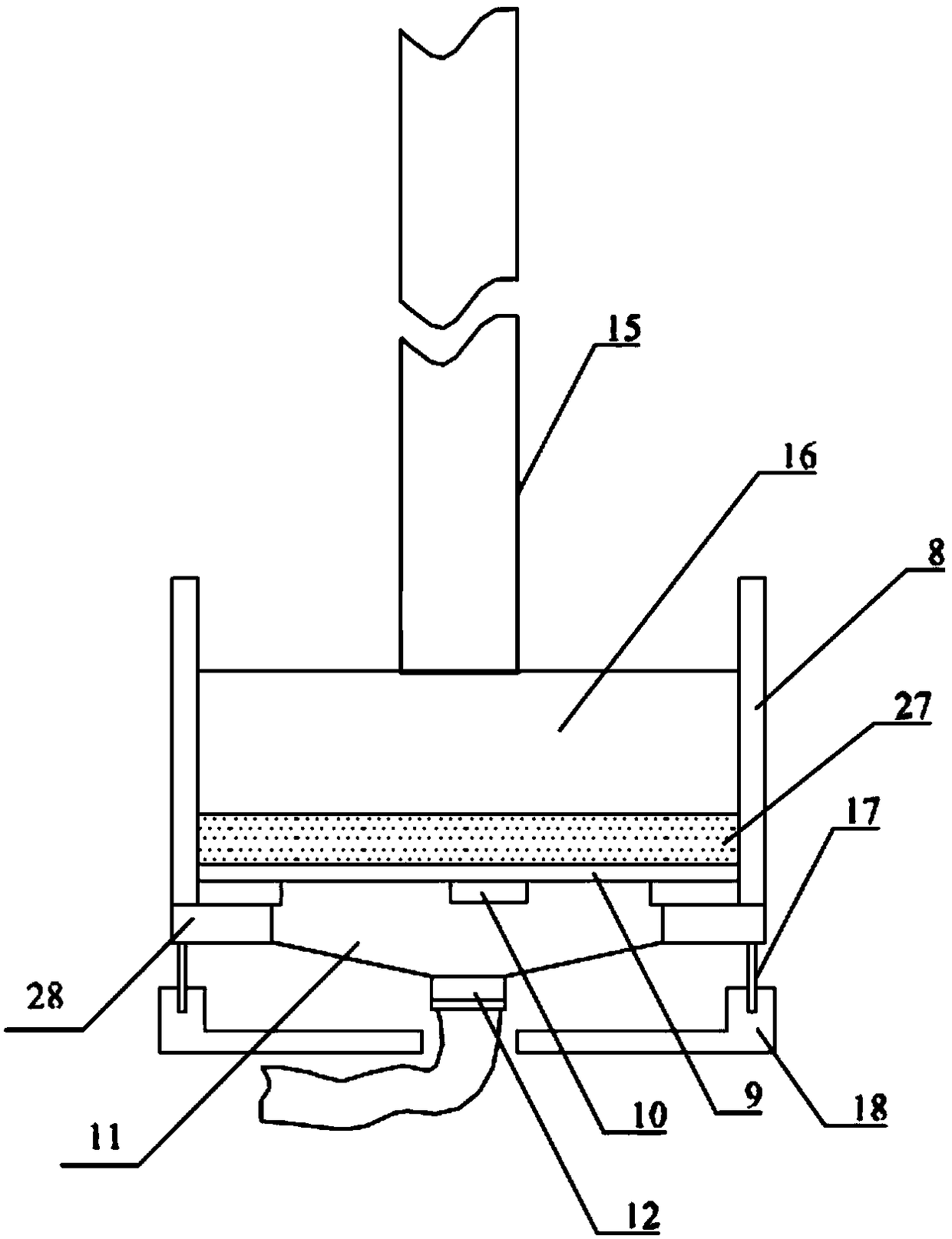

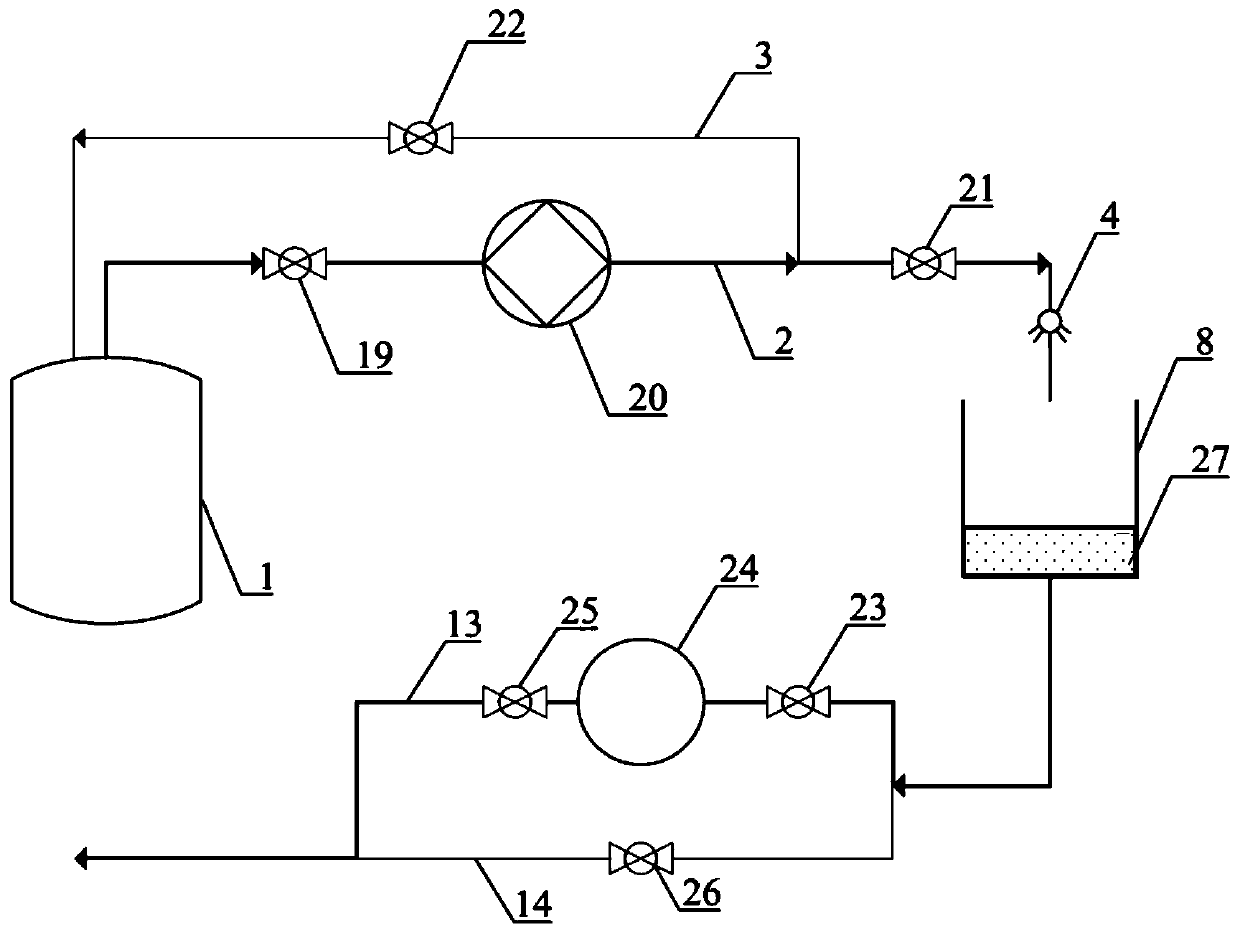

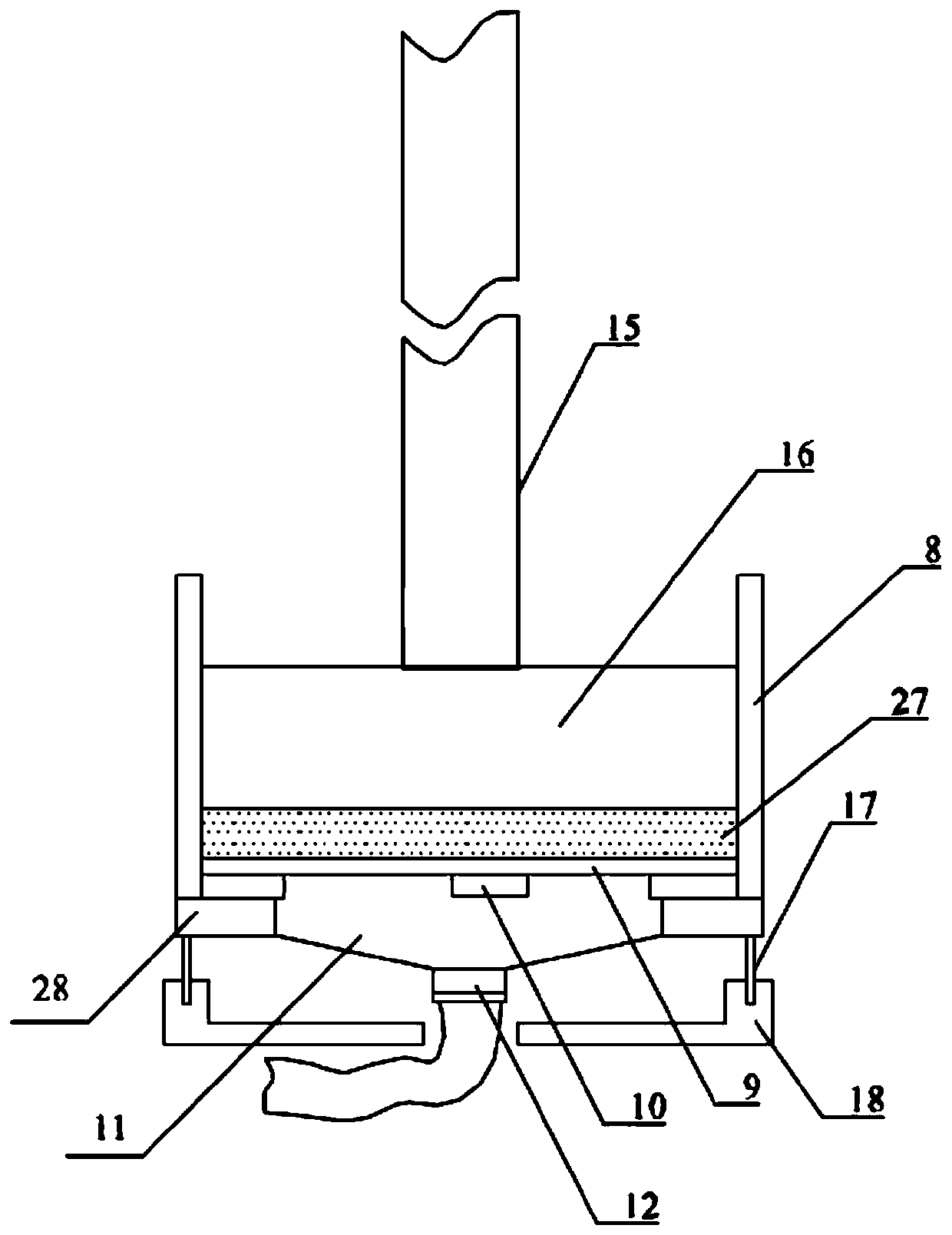

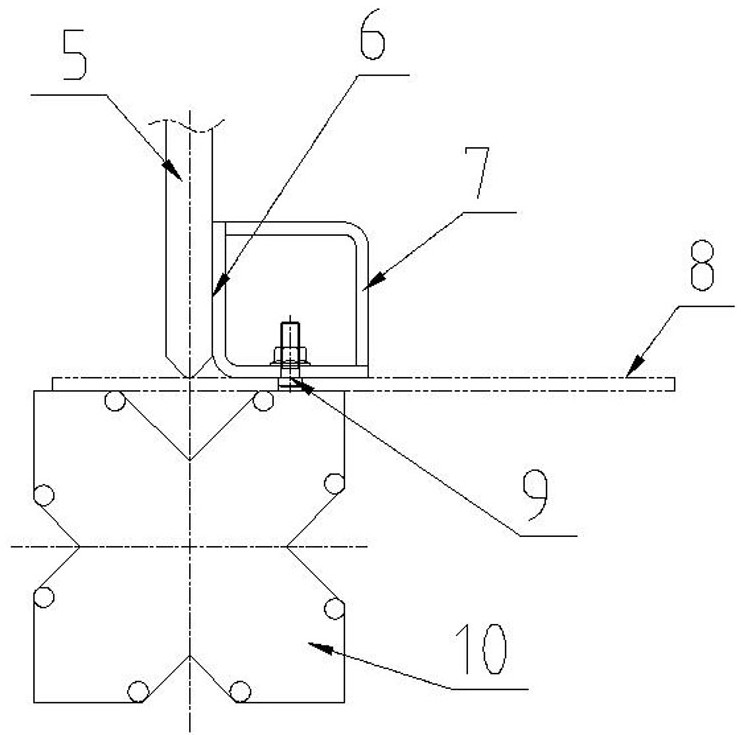

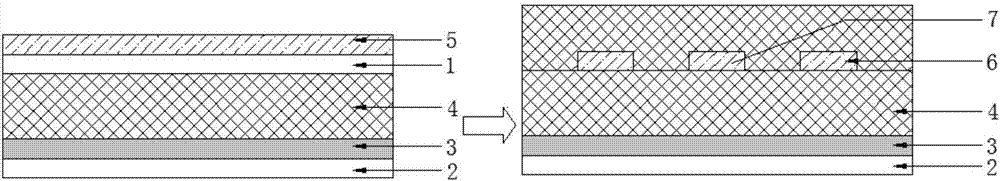

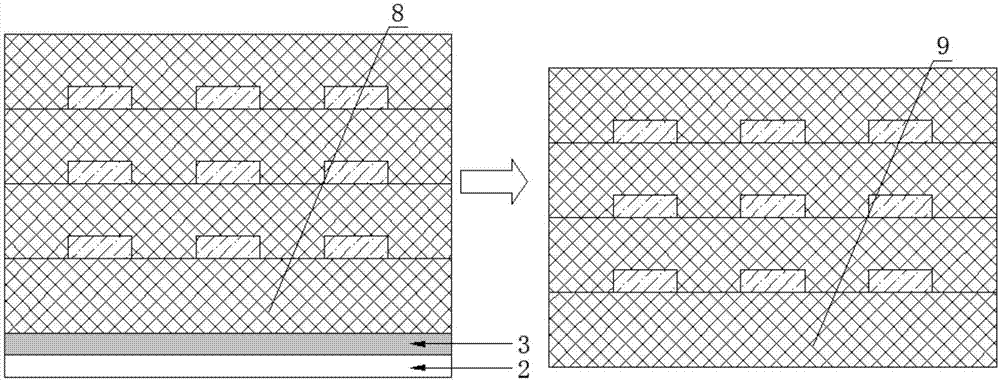

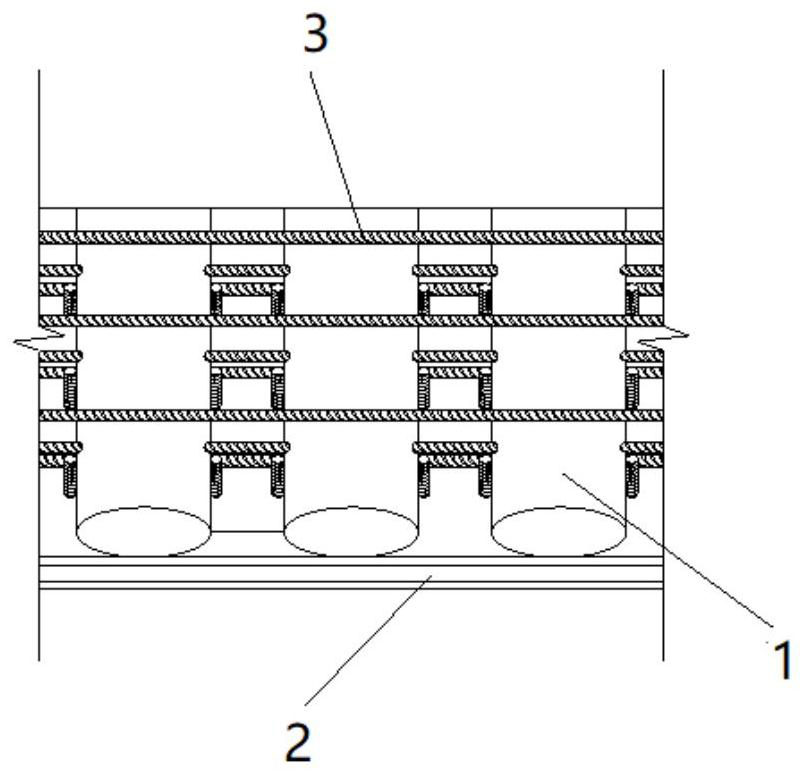

Device for additive manufacturing of rigid thermal insulation tile bodies

ActiveCN108608721AEffective control of precisionUniform densityAdditive manufacturing apparatusThermal insulationSpray nozzle

The invention relates to a device for additive manufacturing of rigid thermal insulation tile bodies. The device comprises a filter container capable of being operated to move in the horizontal direction, a liquid discharging pipe communicated with a liquid outlet of the liquid collecting part, a feeding system for feeding materials into the filter container as well as a pressurizing device located on one side of the spray head and used for pressurizing materials in the filter container, wherein the filter container comprises a bottom plate comprising openings in the peripheral walls and the middle, a bottom net at the lower part of an inner cavity defined by the peripheral walls, reinforcing ribs for supporting the bottom net and a liquid collecting part below the reinforcing ribs; the feeding system comprises a storage chamber, a feeding pipe, a spray head communicated with an outlet end of the feeding pipe and a perforated plate arranged below the spray head and having a hole array,holes in the hole array are through holes, and the through holes correspond to nozzles of the spray head and are used for supporting and fixing the nozzles; the pressurizing device comprises a pressure head, a pressure arm fixedly connected with the pressure head and a driving device for driving the pressure arm to vertically stretch and retract. The device can manufacture the rigid thermal insulation tile bodies with uniform density and accurate thickness and has the advantages of simple structure, low manufacturing cost and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

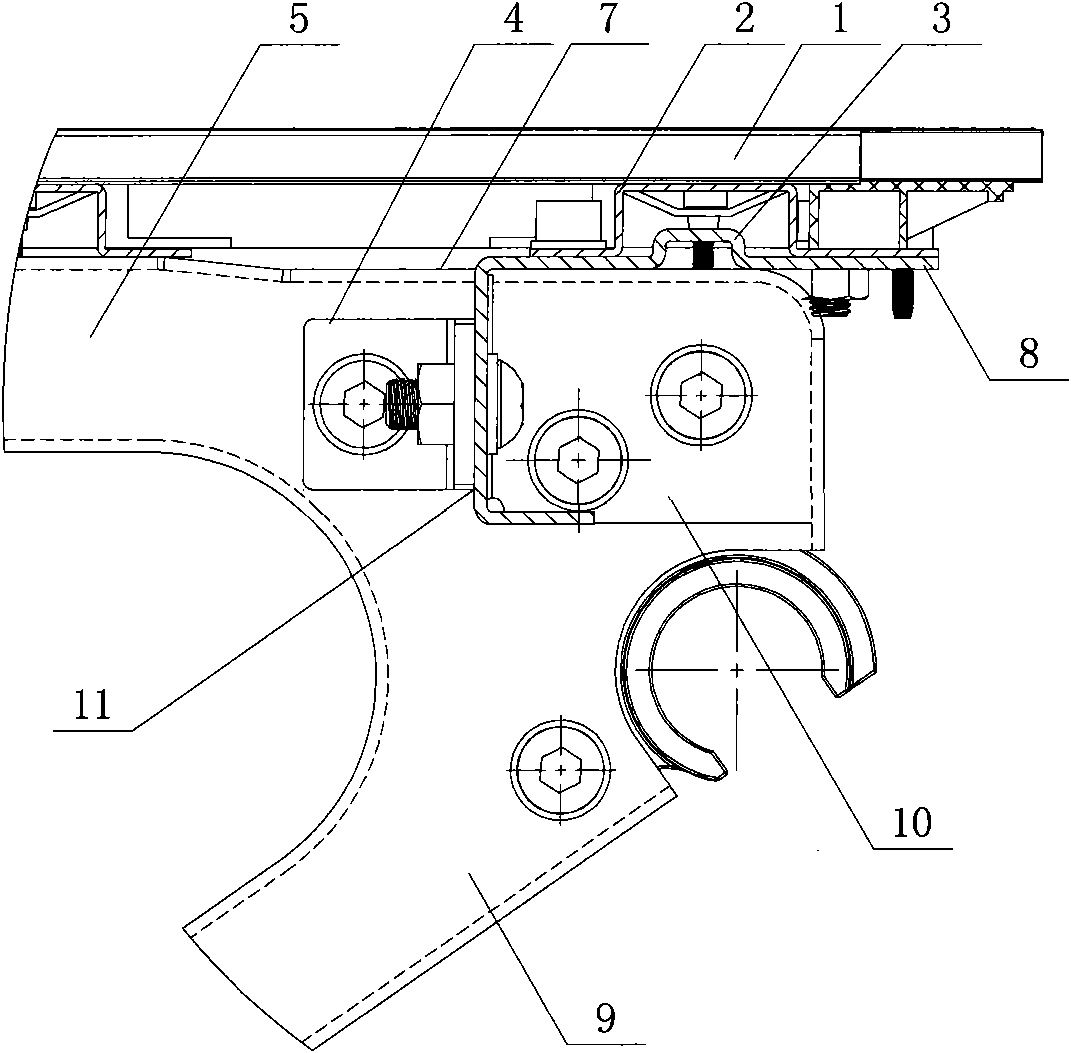

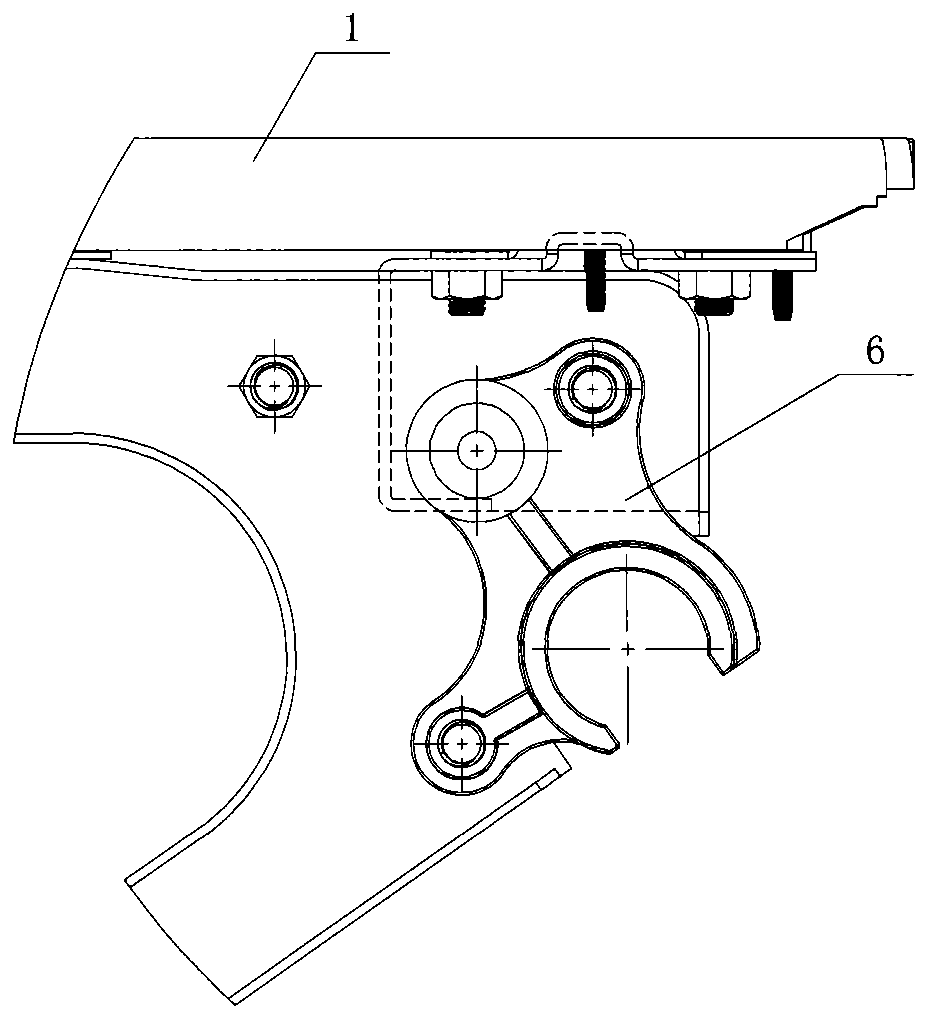

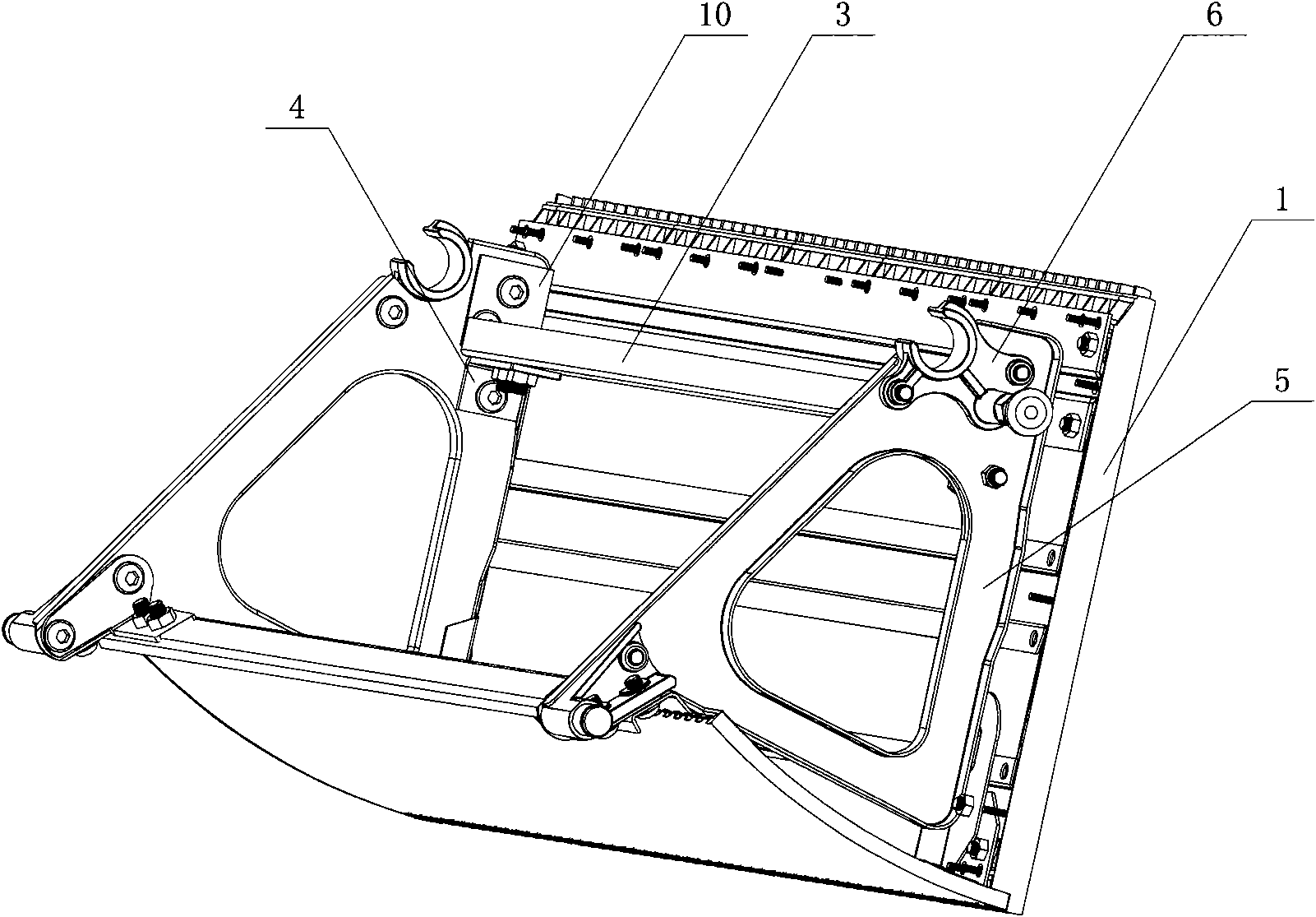

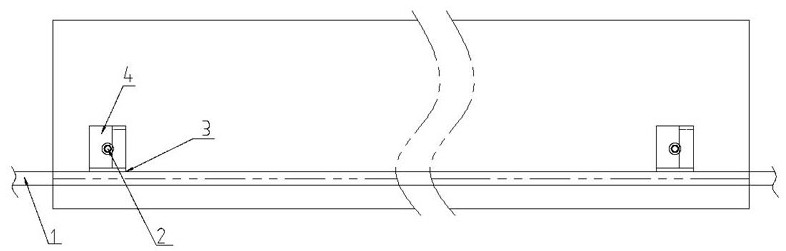

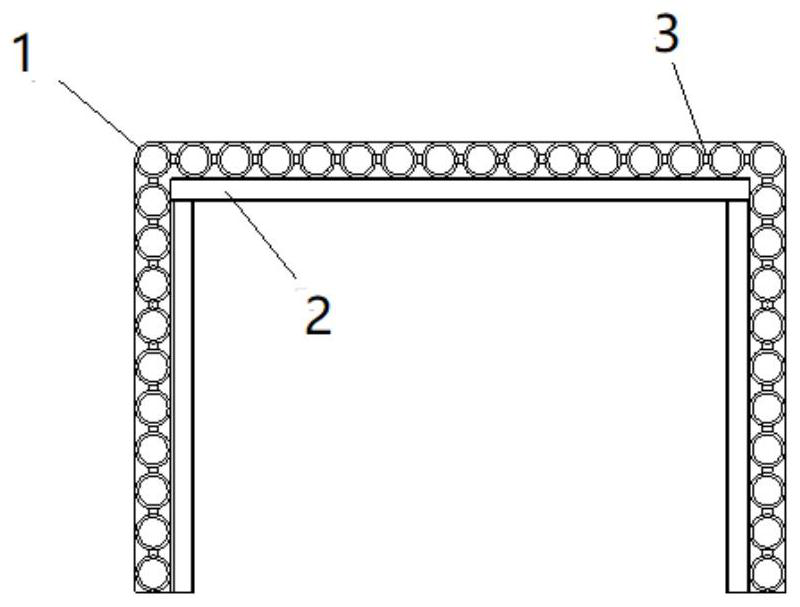

Front end assembly structure of stainless steel staircase step

InactiveCN101570299AEffective control of precisionAnti-deformation purpose is clearEscalatorsStructural engineeringAssembly structure

The invention relates to a front end assembly structure of a stainless steel staircase step, in particular to a front end assembly structure of a split assembled step, and belongs to the field of escalator manufacture. By using a horizontal positioning surface as a standard, a front end cross beam for realizing height horizontal positioning is placed above triangular brackets and the horizontal positioning surface which are arranged in parallel; the triangular brackets and the horizontal positioning surface are contacted and connected with and position a first vertical positioning surface and a second vertical positioning surface to realize the vertical positioning and specific size span positioning of two triangular brackets. The invention solves the technical problem and provides the technical task that the structure overcomes the technical defects in the front end assembly structure of the prior stainless steel staircase step, and provides an implementation proposal for the front end assembly structure of the step with good integrity, deformation resistance, definite assembly standard aim, large overload capacity, convenient assembly and easy quality control.

Owner:SUZHOU BENYI MECHANICAL & ELECTRICAL EQUIP

A digital mapping method and system based on a real-world three-dimensional model

ActiveCN107356230BEffective control of precisionPortable and flexible digital mappingImage enhancementImage analysisData acquisitionEngineering

The invention relates to the field of photogrammetry and surveying and mapping, particularly to a digital mapping method and system based on a live-action 3D model. Digital mapping is carried out by unmanned aerial vehicle oblique photography 3D modeling and cooperation with a ground survey robot, digital mapping of the data acquisition result is more portable and flexible, at the same time high resolution live-action 3D model data can be acquired, and the sense of reality is strong. A control point coordinate acquired by the ground survey robot can effectively control the overall accuracy of the model, an acquired feature point coordinate can effectively compensate for the defect of low coordinate precision because of the influence of a barrier object on unmanned aerial vehicle aerial photography modeling. The method and system provided by the invention have greatly improved work efficiency, also can acquire vivid 3D topographic and geomorphic data at the same time, and meet the demand for diversified data results.

Owner:深圳市武测空间信息有限公司

A method of manufacturing a rectangular seal

ActiveCN104006160BImprove efficiencyEffective control of precisionEngine sealsVulcanizationIndustrial engineering

A method for processing and manufacturing a rectangular seal. First draw a drawing of the rectangular seal according to the shape and size required by the product, and then design a rectangular sealing ring mold according to the drawing. The height of the mold design must not be greater than the width of the nylon column of the slitting equipment. Produce a rectangular seal that meets the drawings, then superimpose the thickness of the rectangular seal to a certain height and put it into the rectangular seal ring mold, heat vulcanize the whole to obtain a rectangular seal, and finally use the gas to push the rectangular seal into the nylon that is set on the slitting equipment On the column, the rectangular sealing ring is cut by a slitting device to obtain a rectangular sealing member; the advantage of the present invention is that the manufacturing efficiency of the rectangular sealing member is high, and the precision can be effectively controlled.

Owner:SHANGHAI RONGNAN TECH CO LTD +2

Screen door control method, control device and radar

ActiveCN110217244BEffective control of precisionExtended service lifePower-operated mechanismRailway signalling and safetyControl signalRadar

The invention is suitable for the technical field of control and provides a control method and a control device of a shielding door and a radar. The control method of the shielding door comprises thesteps of using the radar for monitoring a preset space to monitor at a first working frequency to obtain a first monitoring result after receiving a shielding door opening information; if the first monitoring result is that a target does not exist, transmitting a first control signal, wherein the first control signal is used for indicating the shielding door to be closed; if the first monitoring result is that the target exists, using the radar to monitor at a second working frequency to obtain a second monitoring result, wherein the first working frequency is less than the second working frequency; and if the second monitoring result is that the target exists, transmitting a second control signal, wherein the second control signal is used for indicating the shielding door to keep a current open state. Through the method, the shielding door control accuracy can be effectively improved, the service life of the radar can be prolonged, and the reliability and adaptability of the radar canbe enhanced.

Owner:WHST CO LTD

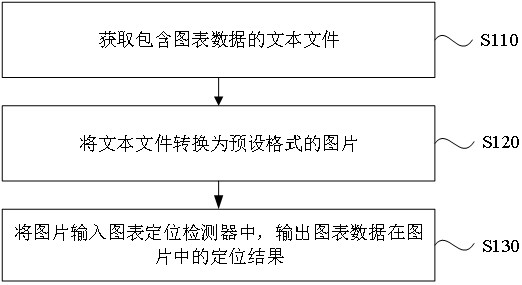

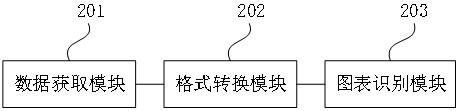

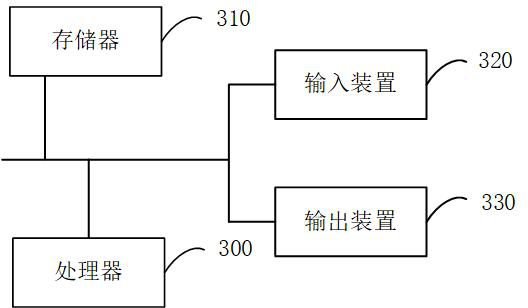

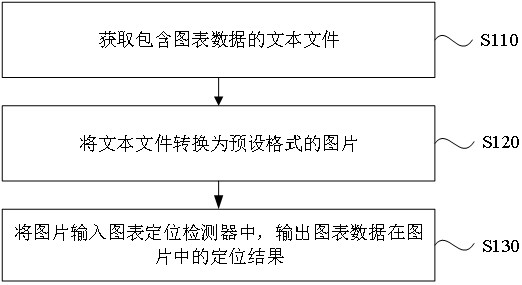

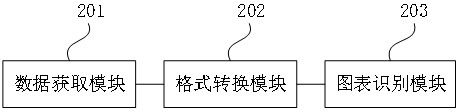

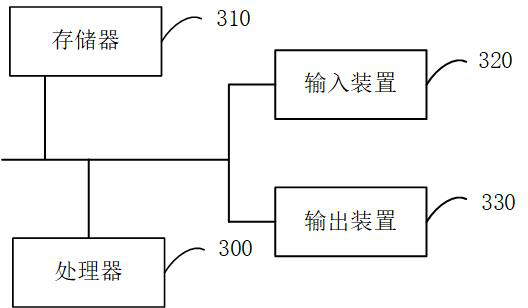

A method, device, device and storage medium for chart recognition

ActiveCN114155547BGuaranteed robustnessHigh precisionCharacter and pattern recognitionNeural architecturesSample graphData set

The invention discloses a chart recognition method, device, equipment and storage medium. The method includes: acquiring a text file containing chart data; converting the text file into a picture in a preset format; inputting the picture into a chart positioning detector, and outputting The positioning result of the chart data in the picture; wherein, the chart positioning detector is obtained by training a preset neural network through a sample data set containing sample chart data. The text file containing chart data in the present invention can be a text file of any format and type, and converting the text file into a picture avoids the need to use a standard protocol to parse the text to locate the chart position in the prior art. If the picture is directly input into the pre-trained chart positioning detector, the positioning result of the chart data in the picture can be directly output, which can solve the problem that the existing technology is inefficient in identifying charts from text files and the accuracy of identifying charts is low. question.

Owner:珠海盈米基金销售有限公司

Chart identification method and device, equipment and storage medium

ActiveCN114155547AGuaranteed universalityGuaranteed robustnessCharacter and pattern recognitionNeural architecturesSample graphData set

The invention discloses a chart recognition method and device, equipment and a storage medium. The method comprises the steps that a text file containing chart data is acquired; converting the text file into a picture in a preset format; inputting the picture into a chart positioning detector, and outputting a positioning result of the chart data in the picture; wherein the chart positioning detector is obtained by training a preset neural network through a sample data set containing sample chart data. The text file containing the chart data can be a text file of any format type, the text file is converted into the picture, the operation that in the prior art, a normative protocol needs to be used for analyzing the position of a text positioning chart is avoided, the converted picture is directly input into the pre-trained chart positioning detector, and the positioning accuracy of the chart positioning detector is improved. Therefore, the technical problems that the efficiency of identifying the chart from the text file is low and the accuracy of identifying the chart is low in the prior art can be solved.

Owner:珠海盈米基金销售有限公司

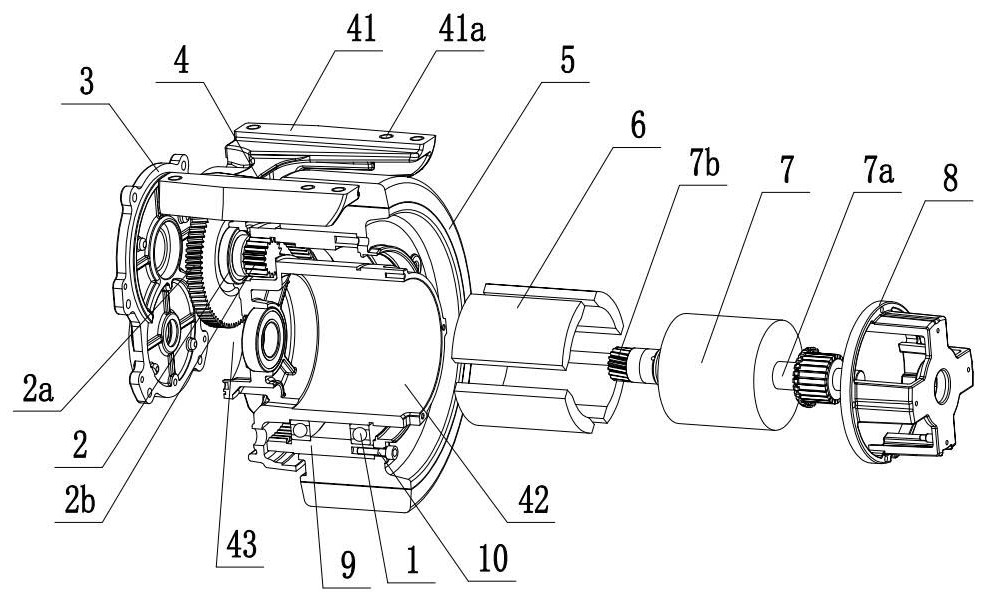

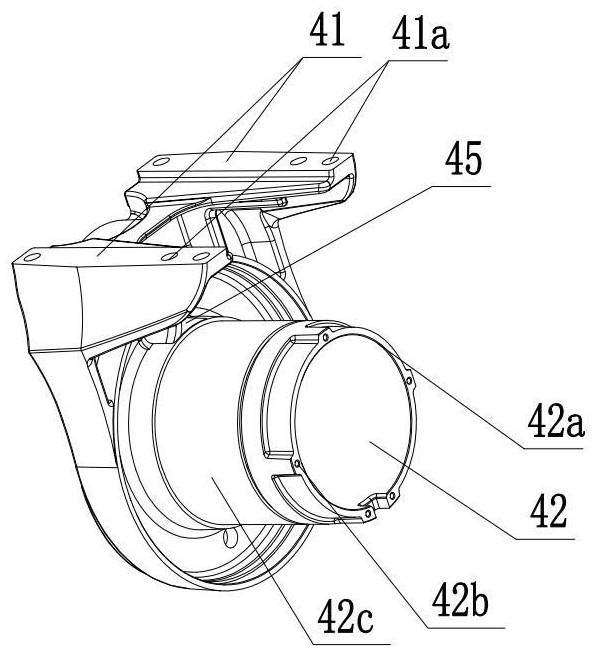

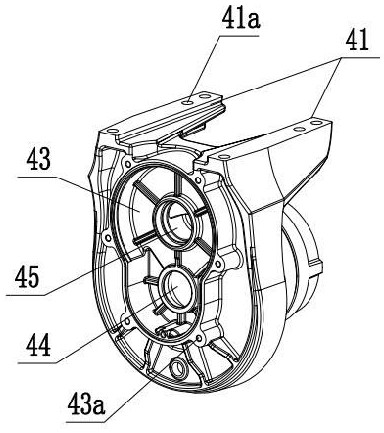

Highly-integrated electric driving wheel

PendingCN113119713AInnovative designReasonable structureMotor depositionMechanical energy handlingElectric driveEngineering

The invention discloses a highly integrated electric driving wheel, and belongs to the technical field of movable equipment driving wheels. The electric driving wheel is provided with an integrated support, one side of the integrated support is provided with a power cavity, a stator assembly is mounted in the power cavity, the other side of the integrated support is provided with a speed reduction cavity, a part of or all gear bodies are mounted in the speed reduction cavity, a shaft hole is formed between the speed reduction cavity and the power cavity, a rotating shaft of a rotor assembly penetrates through the shaft hole and then is meshed and matched with the gear body to form transmission connection, and the outside of the integrated bracket extends outwards to form an integrated mounting platform. According to the technical scheme, the highly-integrated integrated support has the functions of a motor shell, a reduction gearbox body, an installation support and the like, the effects of greatly reducing parts, shortening the assembly process route, reducing the comprehensive error of a machining size chain and the like are achieved, the part precision, the product performance and the consistency of batch products are effectively controlled, the rotation radius of the electric driving wheel is reduced to the maximum extent so as to save the installation space, vibration, noise and other adverse factors caused by assembly errors are effectively avoided, and the comprehensive performance of equipment is improved.

Owner:恒业智能驱动(杭州)股份有限公司

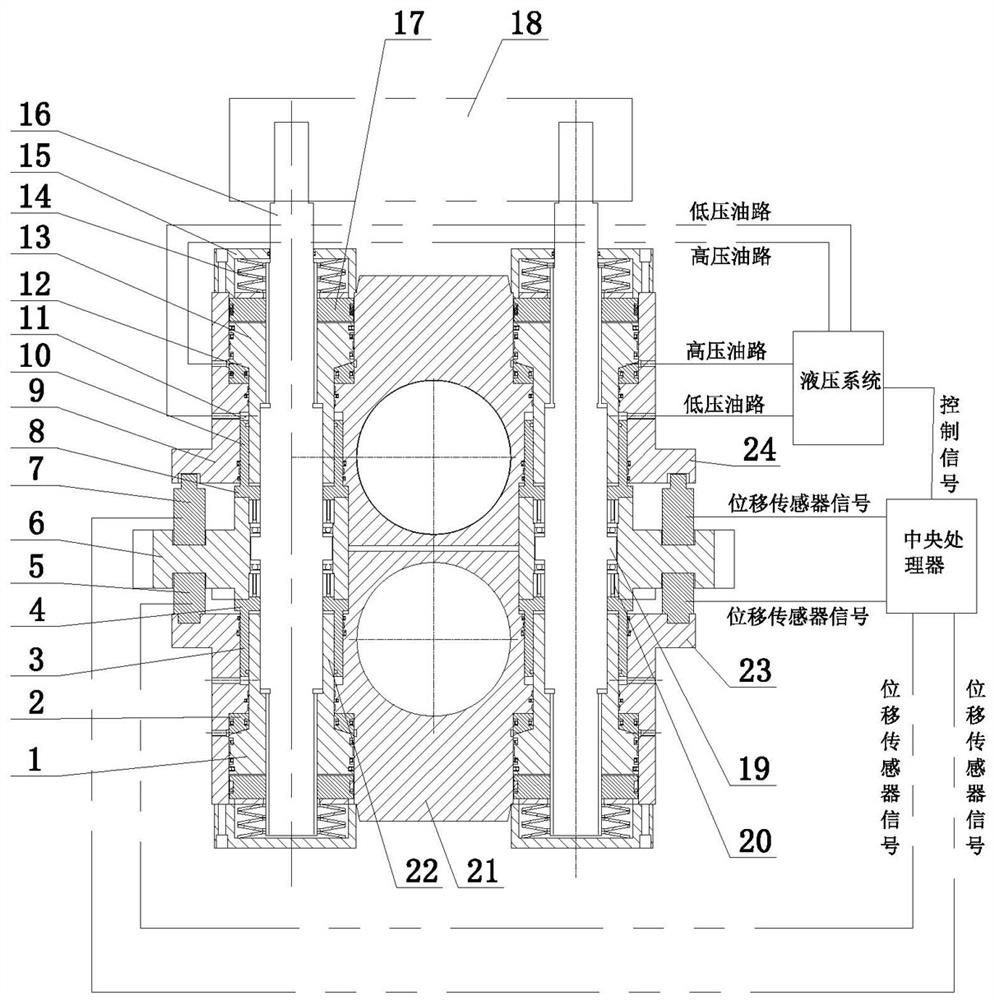

Short-stress rolling mill capable of automatically adjusting prestress of roll gaps

PendingCN112058914AControl precisionEffective control of precisionMetal rolling stand detailsMetal rolling arrangementsScrew threadRolling mill

The invention belongs to the technical field of steel rolling equipment, particularly relates to an improvement of a short-stress rolling mill structure, and provides a short-stress rolling mill whichis capable of automatically adjusting the prestress of roll gaps, and is high in machining precision and high in production efficiency. The short-stress rolling mill comprises a pull rod arranged ina rack body and axially fixed, wherein an upper roller box and a lower roller box are arranged on the upper side and the lower side of the rack body respectively; an upper main nut is arranged in theupper roller box; a lower main nut is arranged in the lower roller box; and the pull rod is connected between the upper main nut and the lower main nut through right-hand threads and left-hand threads. The short-stress rolling mill is characterized in that main oil cavities are formed between the upper part of the upper roller box and the lower part of the upper main nut and between the lower partof the lower roller box and the upper part of the lower main nut, and oil return disc springs of the main oil cavities are arranged between the pull rod and the upper roller box and between the pullrod and the lower roller box; and a prestress system of the pull rod and a real-time roller box distance monitoring system are arranged on the rack body.

Owner:SHENYANG DALU LASER TECH

A device for increasing material manufacturing rigid insulation tile body

ActiveCN108608721BEffective control of precisionUniform densityAdditive manufacturing apparatusCeramic shaping apparatusThermal insulationStructural engineering

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of one-side opening composite material easy-to-crack front cover and its manufacturing method

The invention relates to a missile launcher technology. In order to solve the problems of easy embrittlement during long-term storage of an easily-cracking front cover and potential safety hazards due to a large quantity of fragments after the cover is broken after launched, the invention provides a composite easily-cracking front cover opened in one side and a making method of the composite easily-cracking front cover. Compared with the prior art, the composite easily-cracking front cover has the advantages and the beneficial effects of light weight, high strength and good compaction due to the adoption of a composite, and can ensure that the front cover structure is more reasonable in performance and is greatly improved in sealing property; and made by adopting a mold, the composite easily-cracking front cover has the advantages of capability of effectively controlling precision and ensuring that cover breaking pressures are consistent, rapidness, high efficiency and stable quality; and an opened cover body can not be separated from the launcher so as to eliminate potential safety hazard caused by scattering broken fragments after the cover is opened. The composite easily-cracking front cover is formed through medium-temperature curing, can be reliably used under the condition of high-temperature and low-temperature environments, and is difficult in embrittling and cracking.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

Process method for bending and forming straight-through vehicle frame inner beam with hole

The invention discloses a process method for bending and forming a straight-through vehicle frame inner beam with a hole. The original process mode that only part of a plug welding hole is formed in the inner beam is changed, and is not equal to the vehicle frame loading efficiency through the process method that an inner beam hole is drilled in a sleeving manner after the inner beam and the outerbeam are embedded. By improving the process of realizing all hole sites of the inner beam and bending, the purposes of improving the precision of a hole system after the inner beam is formed and thealignment precision of the hole system after the inner beam and the outer beam are embedded, reducing the working strength of the inner beam of the sleeve drill and improving the working efficiency are achieved.

Owner:SHIYAN XIANCHI AUTOMOBILE FRAME

Preparation method of a force-responsive nanoscale photonic crystal material

ActiveCN106226847BSimple processShort preparation cycleOptical elementsPhotonic crystal structureCurrent technology

The invention discloses a method for preparing a force-responsive nanoscale photonic crystal material. Electron beam lithography technology and reactive ion etching technology are used to etch a nanoscale pattern according to pre-designed photonic crystal structure parameters. The rigid template is used as the filling template, the highly elastic gel with excellent mechanical properties is used as the matrix material, and the viscoelastic polymer is used as the filling material. By filling the template, the pre-designed photonic crystal pattern is "transferred" to the viscose In elastic polymers, nanoscale, structure-controllable and force-responsive photonic crystal materials are prepared through steps such as spin coating and stacking. Compared with the prior art, the preparation method of the present invention has the characteristics of simple process, short process, easy control of process parameters, reusable template, high product precision level, stable and reliable quality, and low cost.

Owner:SHANDONG UNIV OF SCI & TECH

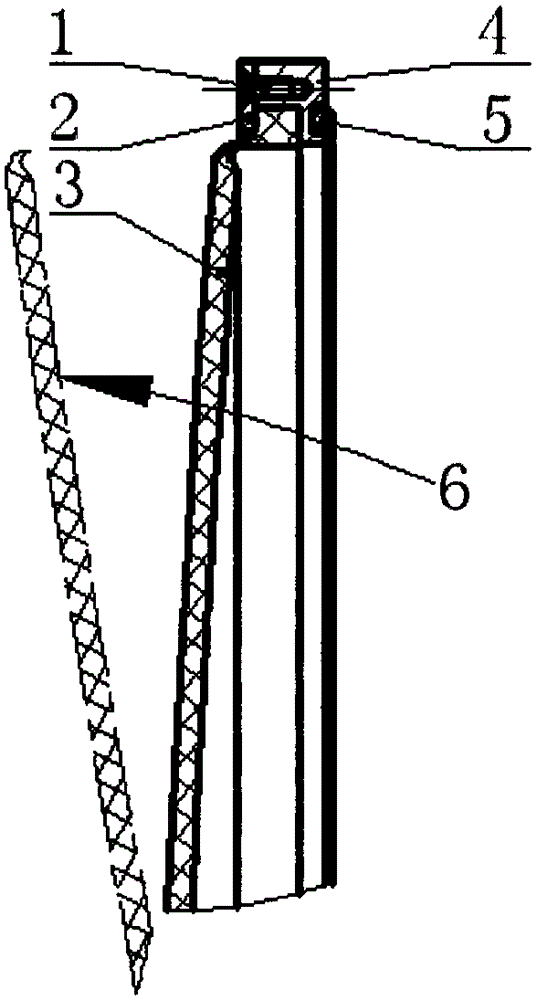

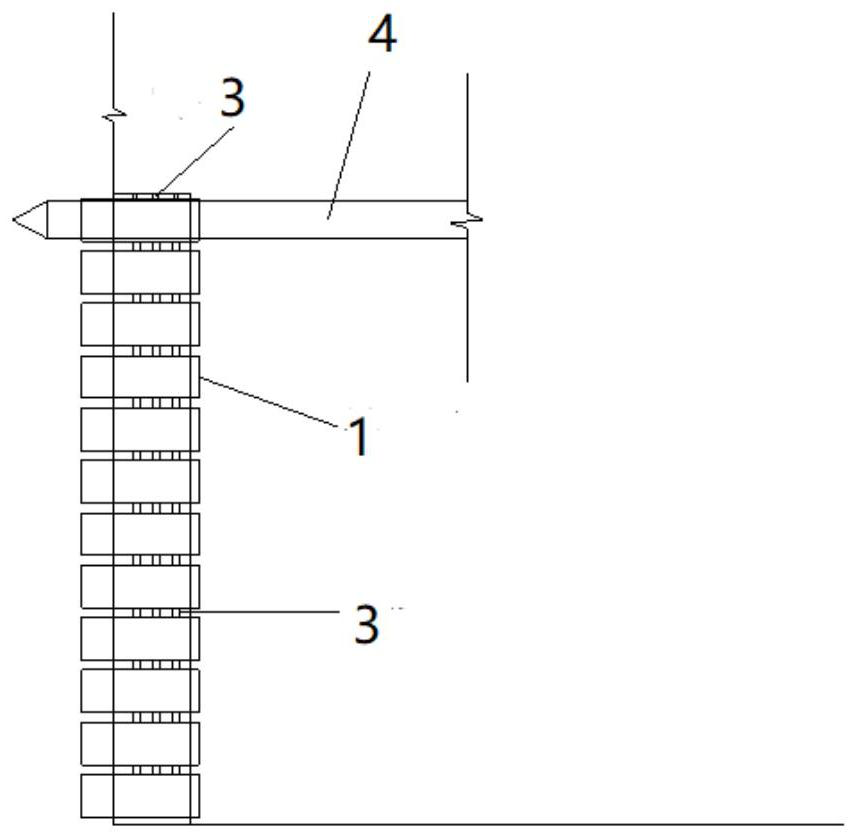

Tunnel underground excavation pipe shed guide pipe drilling construction precision control method

PendingCN114658449AGuaranteed integrityEnsure stabilityUnderground chambersTunnel liningStructural engineeringPipe

The invention discloses a tunnel underground excavation pipe shed guide pipe drilling construction precision control method. The method comprises the following steps that S1, a guide wall is installed; s2, a working platform is erected, a drilling machine is in place, and it is ensured that the axis of a drilling rod of the drilling machine is matched with the axis of an orifice pipe; s3, drilling is conducted, specifically, the height of a drilling machine platform is determined according to the adjustable range of a drilling machine and the drilling sequence, and due to the fact that the drilling sequence of the drilling machine is conducted from the high hole site to the low hole site, the position of the platform is gradually lowered from top to bottom correspondingly; s4, auxiliary positioning is conducted through a laser demarcation device, deviation adjustment is conducted in the drilling process of the pipe roof pipe, and one-time positioning adjustment is conducted on a section of pipe roof pipe to be drilled; s5, a support is adjusted, and the drilling deviation of the pipe roof pipe is adjusted by adjusting the support; and S6, a stop-grouting plug is installed. The problem can be effectively solved by adopting a method for assisting precision control through the laser demarcation device, and the overall precision when the pipe shed pipe is drilled into the guide pipe is guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com