Composite easily-cracking front cover opened in one side and making method of composite easily-cracking front cover

A composite material and front cover technology, used in the storage of ammunition, weapon accessories, ammunition, etc., can solve the problems of ground personnel and equipment damage, potential safety hazards, and a large number of fragments, and achieve the elimination of potential safety hazards, good compactness, Consistent effect of breaking cover pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

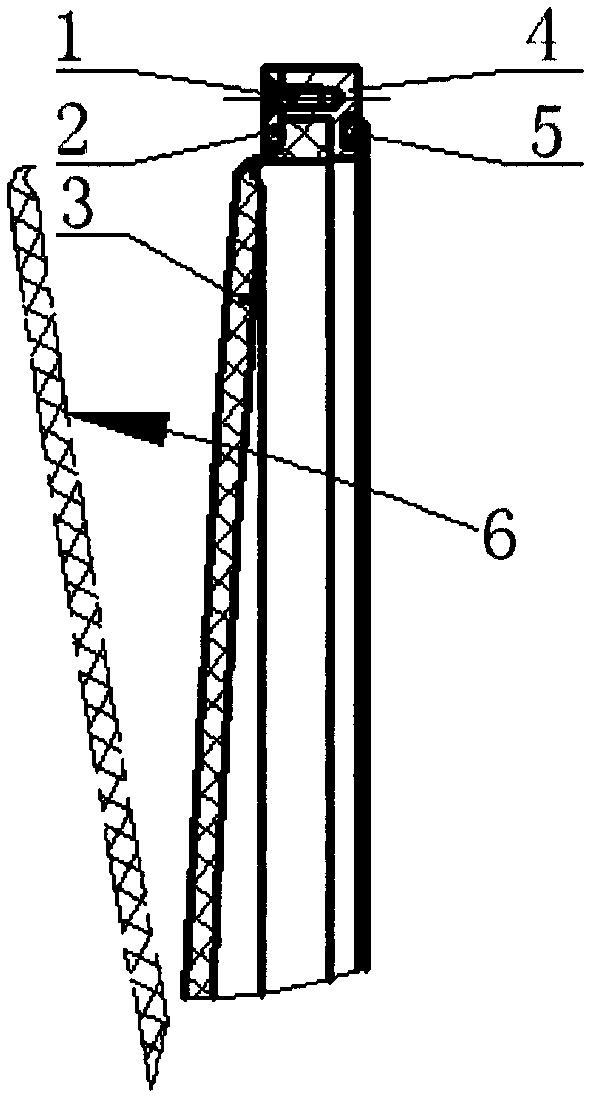

[0019] Such as figure 1 As shown in the figure, it is a composite material easy-to-crack front cover that can be opened on one side. The front cover in the figure includes screws 1, pressure plate 2, cover body 3, cover frame 4, sealing ring 5, indication of the direction of breaking the cover 6, and thickening layer of the cover body 7 , steel wire 8, anti-falling off fixing screw 9. Put the sealing ring 5 into the cover frame 4, then put the cover body 3 into the cover frame 4 coated with polysulfide sealant, press the cover body firmly with the pressure plate 2 and screw the cover body 3 and the cover frame 4 through the screw 1 , Pressing plate 2 is locked.

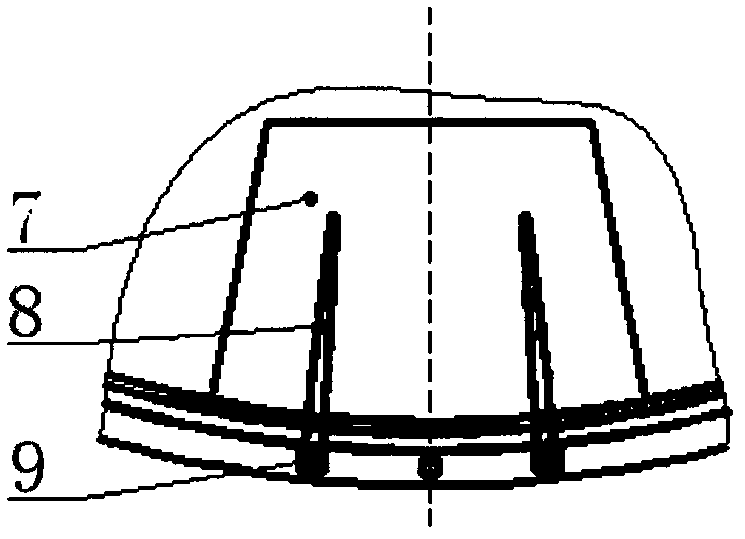

[0020] Such as figure 2 As shown, it is a partial reinforcement structure diagram of the front cover, and the steel wire 8 is connected to the cover 3 through the anti-falling fixing screws 9 and connected to the cover thickening layer 7 .

[0021] Such as figure 1 , figure 2 As shown, the cover frame 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com