Rectangular sealing part manufacturing method

A manufacturing method and sealing technology, which are applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve the effect of high efficiency and effective control of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

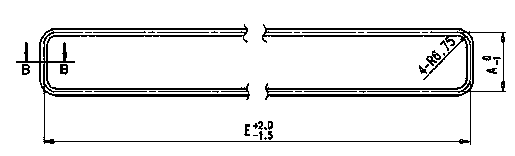

[0021] Draw a drawing of the rectangular seal according to the dimensions of the desired product (see figure 1 ), design a rectangular ring mold according to the drawings, and the height of the mold shall not be greater than that of the cutting equipment (please refer to Figure 4 ) in the width of the nylon column. Vulcanize the rectangular seal 1 that meets the drawings through the existing technology (please refer to figure 2 ), and then superimpose the thickness of the rectangular seal 1 to a certain height and put it into the rectangular sealing ring mold, and the whole heat vulcanization obtains the rectangular sealing ring (please refer to image 3 ), the rectangular sealing ring is put on the slit nylon column by gas propulsion, and finally by adjusting the equipment process parameters, the slitting equipment is used to slit the rectangular sealing ring to obtain a rectangular seal with an accuracy of ±0.05 tolerance accuracy.

[0022] It should be noted that the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com