Preparation method of force responsiveness nanometer magnitude photonic crystal materials

A photonic crystal and responsive technology, applied in optics, optical components, instruments, etc., can solve the problems of difficulty in preparing nanometer-scale photonic crystals, limited precision level of photonic crystals, poor structure controllability, etc., and shorten the preparation cycle , short preparation cycle, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

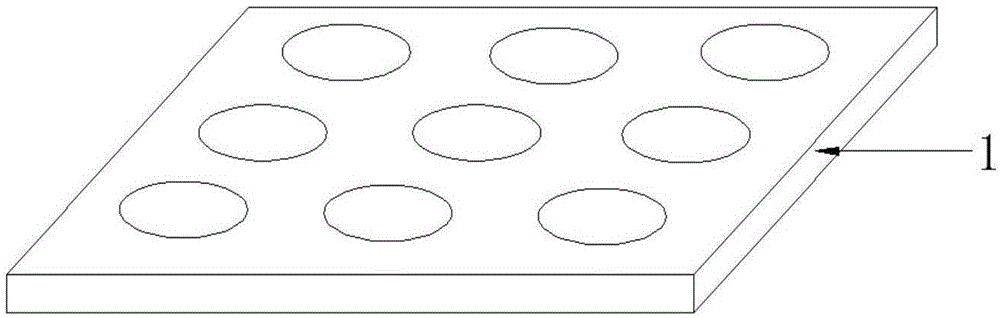

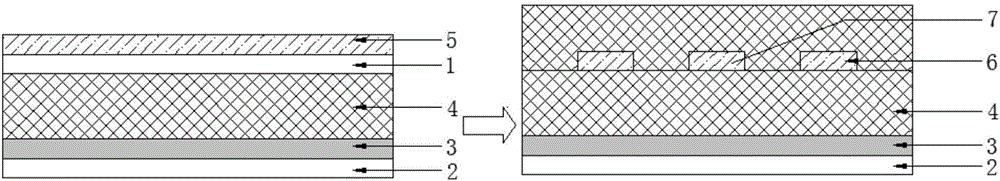

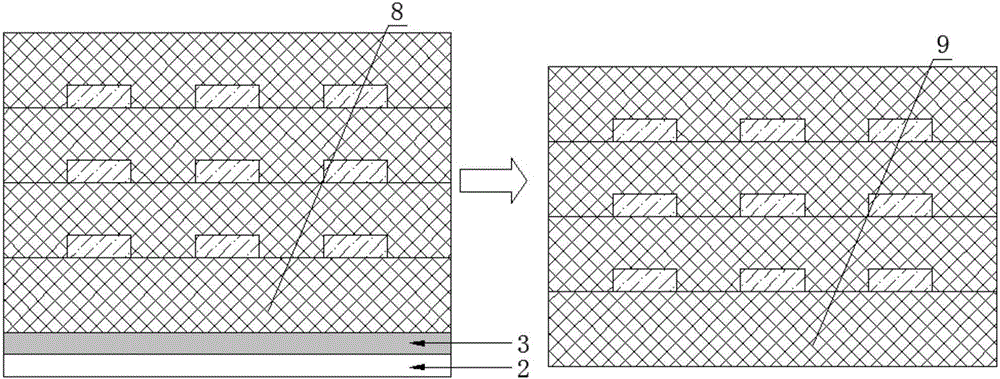

[0045] 1. Such as figure 1 As shown, the preparation steps of the quartz template with photonic crystal pattern are as follows:

[0046] (1) According to actual needs, pre-design the structural parameters of the photonic crystal, mainly including: the surface structure is a hexagonal columnar lattice, the lattice period is 200nm, the diameter of the convex column is 100nm, and the height of the convex column is 150nm. The effective area is 20×20mm 2 .

[0047] (2) According to the structural parameters of the above photonic crystals, design the structural parameters of the quartz template, mainly including: the surface structure is a hexagonal columnar hole array, the lattice period is 200nm, the diameter of the columnar holes is 100nm, and the height of the columnar holes is 150nm , The effective area is 20×20mm 2 .

[0048] (3) Take a quartz substrate (25mm×25mm in size), use electron beam lithography technology to expose the quartz substrate and the photoresist on the quartz subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com