Short-stress rolling mill capable of automatically adjusting prestress of roll gaps

A short stress rolling mill, automatic adjustment technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of large size deviation, change of roll gap distance, and inability to maintain constant prestress, etc. Achieve the effect of large rolling force and effective control of product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

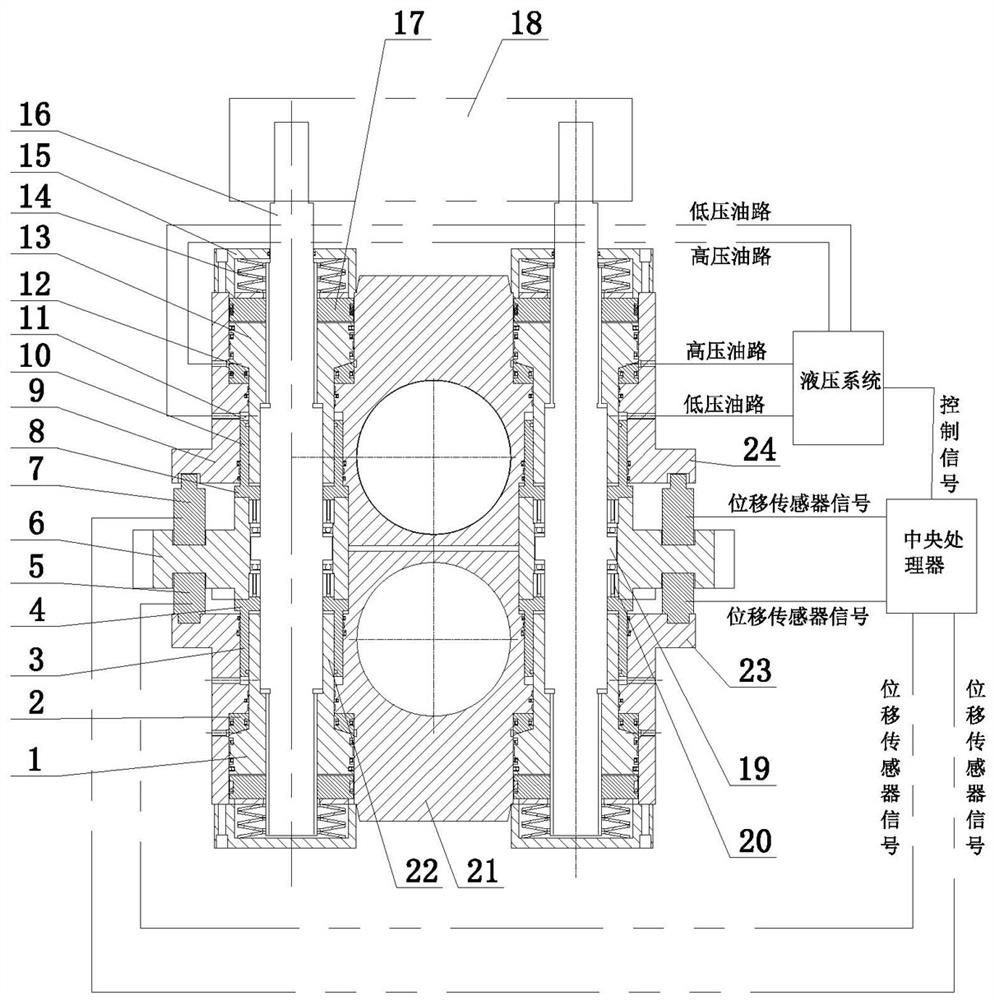

[0017] The present invention comprises that the pull rod 16 is axially fixedly arranged in the frame body 6, the upper and lower sides of the frame body 6 are respectively provided with an upper roller box 9 and a lower roller box 21, and the upper roller box 9 is an upper main nut 13, Inside the lower roll box 21 is the lower main nut 1, and the upper main nut 13 and the lower main nut 1 are connected to the pull rod 16 through positive and negative threads. It is characterized in that: the upper part of the upper roller box 9 and the lower part of the upper main nut 13 Between, and between the lower part of the lower roller box 21 and the upper part of the lower main nut 1, a main oil chamber 12 is arranged, and the oil return of the main oil chamber 12 is arranged between the tie rod 16 and the upper roller box 9, and the lower roller box 21 Disc spring 14; the frame body 6 is provided with a prestressing system of pull rod 16 and a real-time monitoring system for the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com