Patents

Literature

453results about How to "Avoid working at heights" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

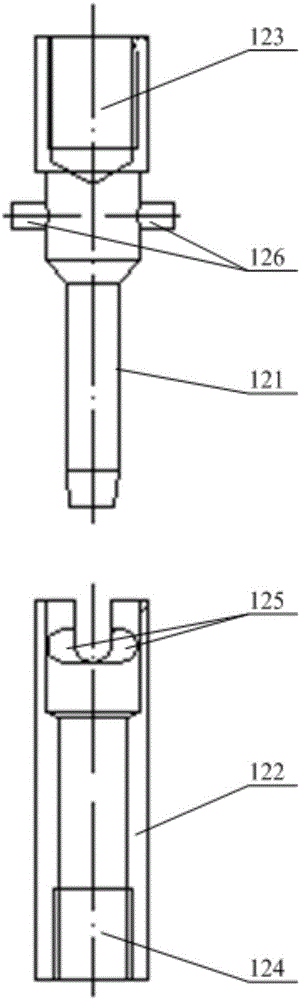

High voltage grounding tool for power maintenance

ActiveCN103531925AImprove securityAvoid safety hazardsLine/current collector detailsMulticonductor cable end piecesGround lineHigh pressure

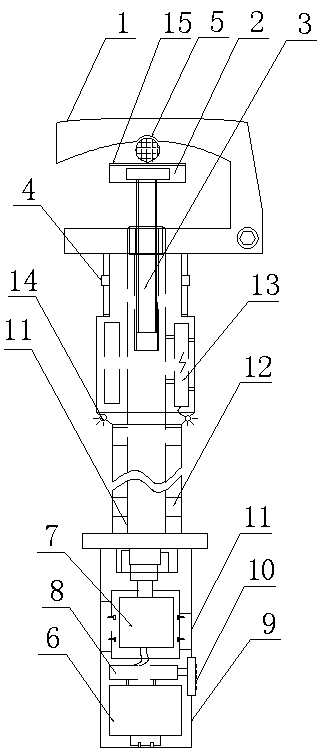

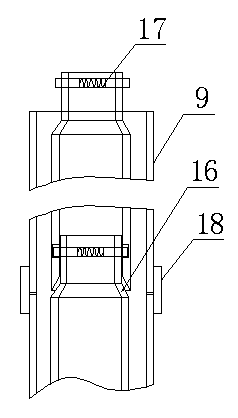

The invention discloses a high voltage grounding tool for power maintenance, which comprises a grounding wire chuck and an operating rod, wherein the wire chuck comprises a C-shaped hanging frame, a wire clamp moving plate and a lifting rod; a connector connected with the C-shaped hanging frame is arranged at the top of the operating rod; the upper end of the lifting rod is connected with the wire clamp moving plate; a driving mechanism connected with the lifting rod is arranged in the operating rod; the operating rod is arranged in a multi-section insertion manner; locking rings are arranged among sections of the operating rod; reducer pipes are arranged among sections of a movable casing pipe; elastic pins or key structures matched with the movable casing pipe are arranged on the reducer pipes. According to the invention, the high voltage grounding tool is hung on a wire by utilizing the C-shaped hanging frame; the wire is clamped by adopting the lifting rod; the wire-off accident is prevented; the low-position safe operation is realized; the potential safety hazard caused by the climbing operation is avoided; the working difficulty is reduced; the working efficiency is improved; the sectional design concept is adopted; the flexible variation of the length of the operating rod is ensured; in the transmission link, the interchangeable connection can be carried out; the effects are obvious.

Owner:STATE GRID CORP OF CHINA +1

Construction method for lifting whole steel structural roof with large span and complicated design

InactiveCN101519913ALow costShorten the construction periodBuilding material handlingIndustrial engineeringBuilding construction

The invention discloses a construction method for lifting whole steel structural roof with large span and complicated design. The method comprises the following steps: (1) dividing the roof into a plurality of lifting units according to the construction requirements and lifting the units independently; (2) completing the preliminary assembly of the lifting units, lifting the units respectively once again to the height near the designed elevation, and then carrying out expanded assembly and lifting at different elevations to the designed elevation of a rack after expanding and assembling all the lifting units into a whole; (3) assembling outdoor racks by units while assembling and lifting indoor racks, and then butting the outdoor racks with the indoor racks respectively; and (4) unloading the racks step by step after butting the indoor racks and the outdoor racks into a whole. The construction method for racks is to carry out assembling and welding on the ground entirely, thereby avoiding aloft work. The method has the advantages of more accurate and convenient positioning, reduction of the cost for erecting the racks and great shortening of total construction period.

Owner:青建集团股份公司

Prefabricated column and precast construction method thereof

ActiveCN104088397AFirmly connectedNo technical quality requirementsStrutsBuilding material handlingArchitectural engineeringRebar

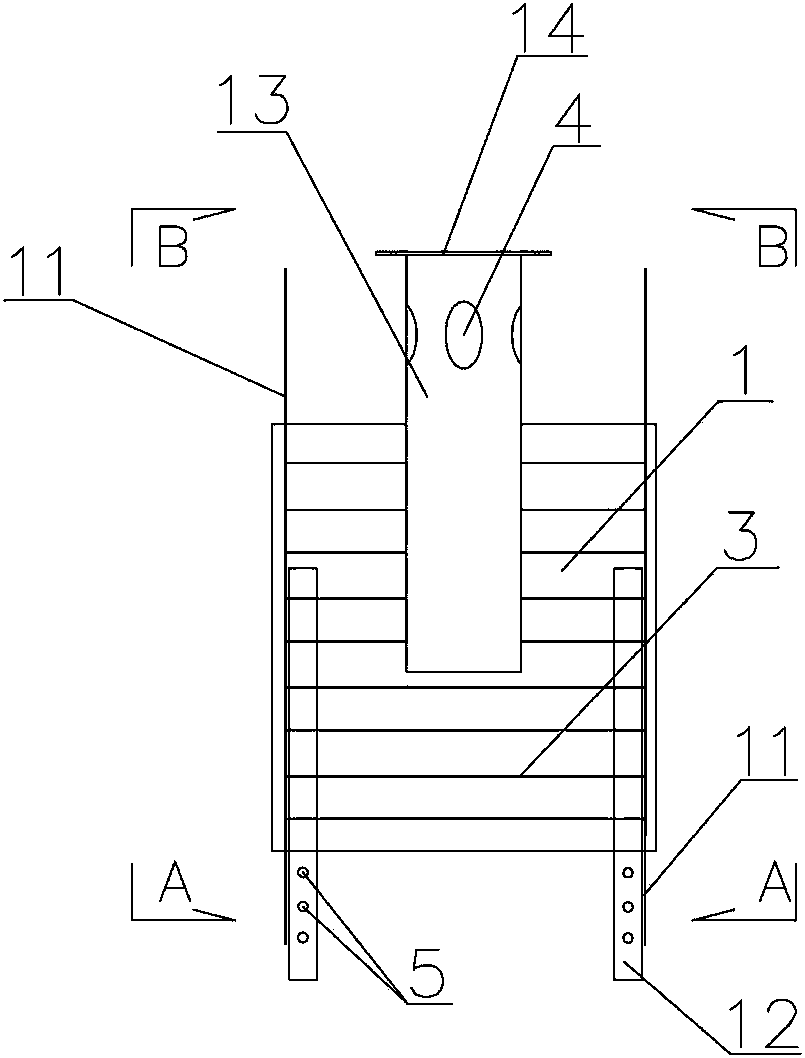

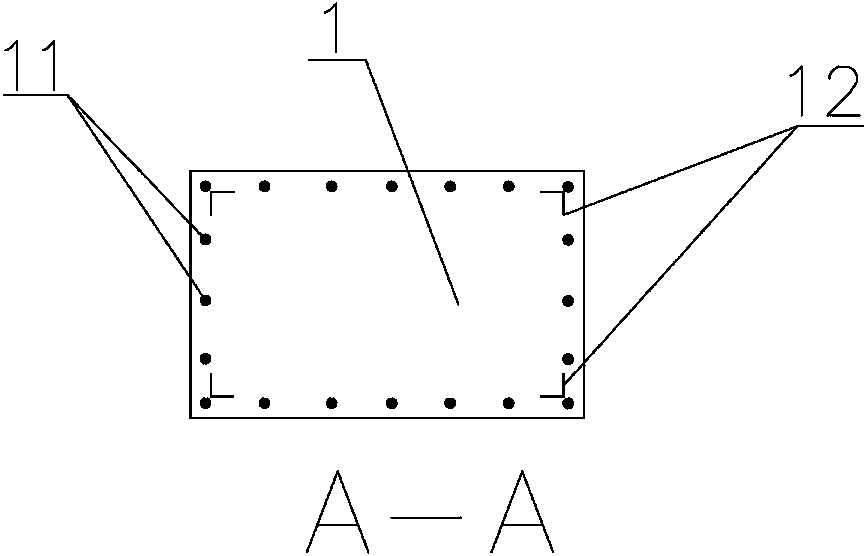

The invention relates to a prefabricated column and a precast construction method. The prefabricated column comprises a lower prefabricated column and an upper prefabricated column matching the lower prefabricated column, a first vertical steel bar extending out of the upper and lower ends of the lower prefabricated column is arranged in the lower prefabricated column, the lower end of the lower prefabricated column is provided with a first connection member, the upper end of the lower prefabricated column is provided with a first steel pipe and a first flange plate welded to the top surface of the first steel pipe, a second vertical steel bar extending out of the upper and lower ends of the upper prefabricated column is arranged in the upper prefabricated column, the upper end of the upper prefabricated column is provided with a second connection member, the lower end of the upper prefabricated column is provided with a second steel pipe and a second flange plate welded to the top surface of the second steel pipe, the top of a second pre-embedded steel pipe is in a butt connection relationship with two auxiliary steel pipes, the first flange plate and the second flange plate are in a butt connection relationship by bolts, the first connection member is connected to the second connection member by threads, and the first vertical steel bar and the second vertical steel bar are bound by stirrups. The prefabricated column can be constructed simply, has a low price, and is suitable for buildings having high floor height and large column sectional area.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

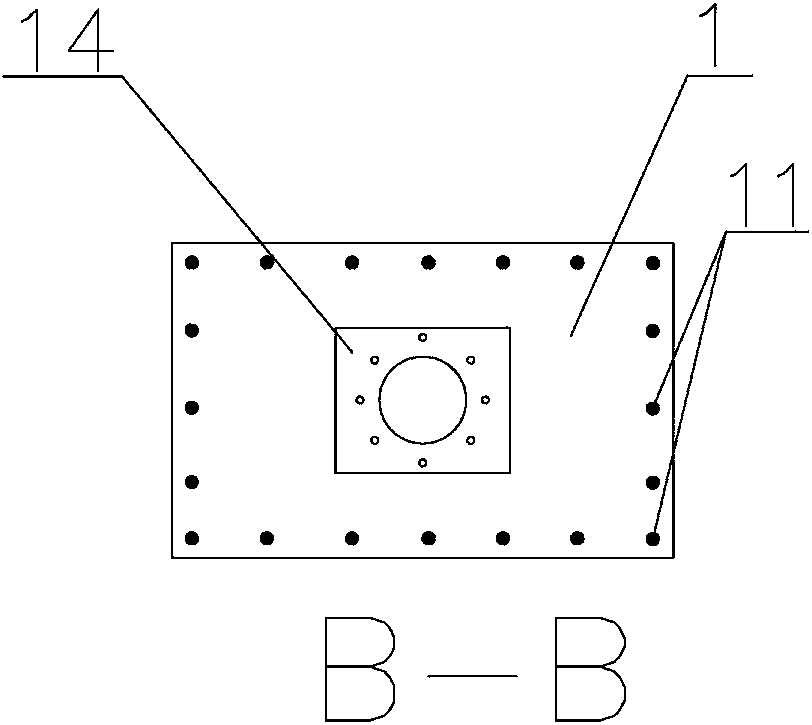

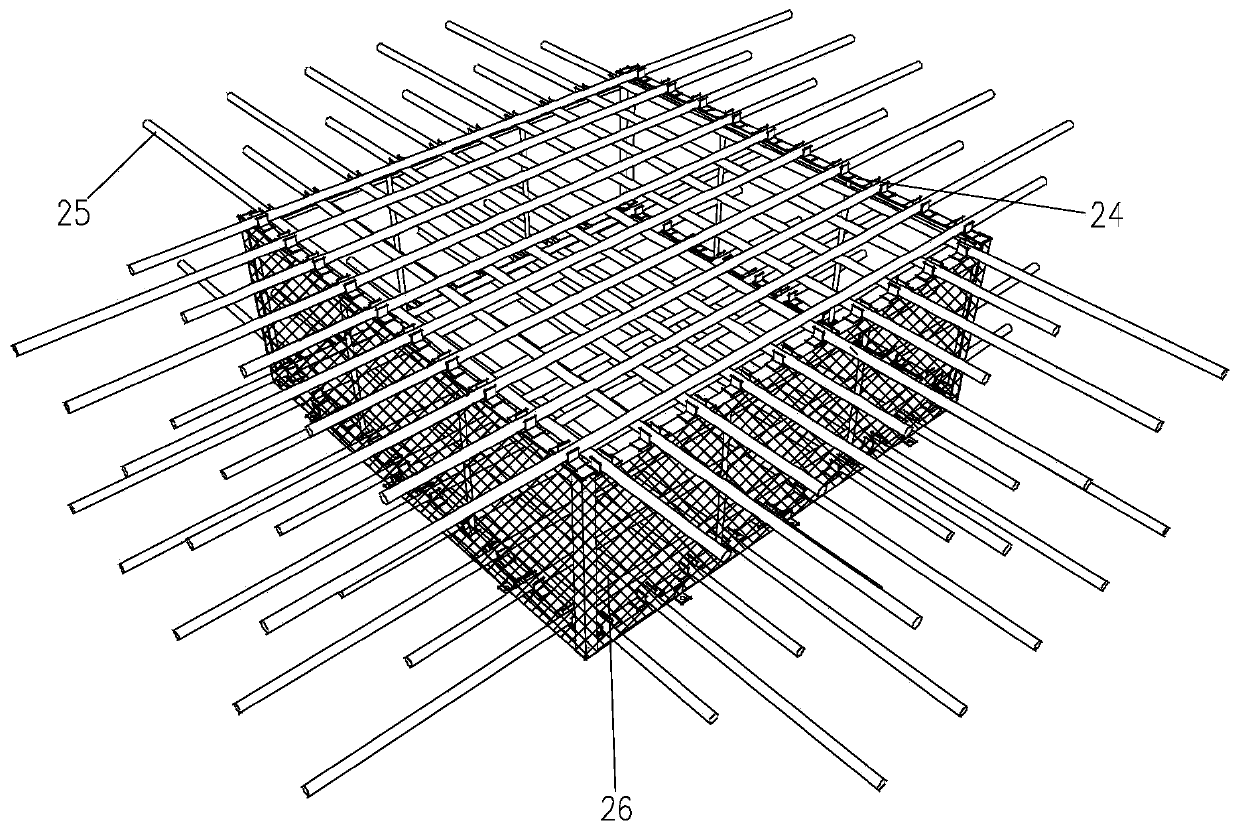

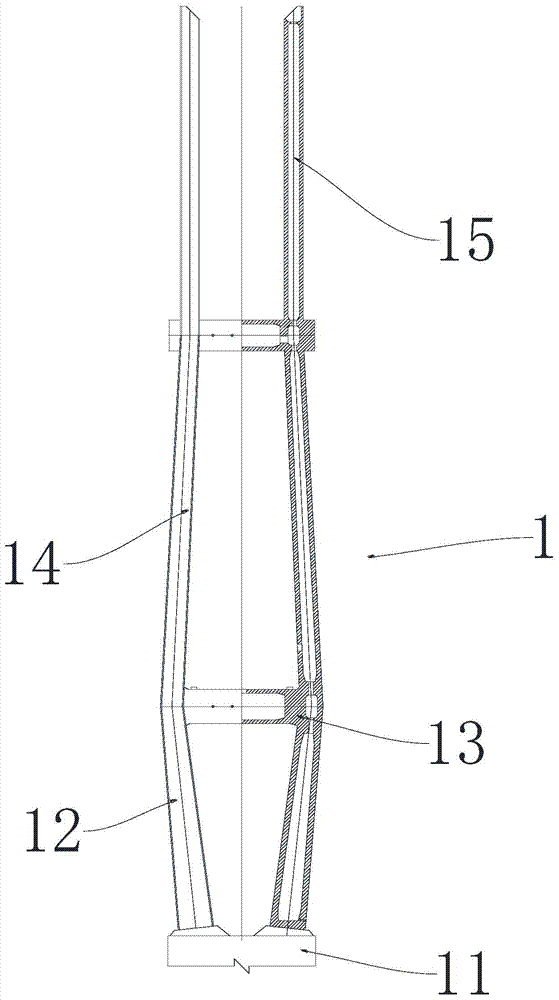

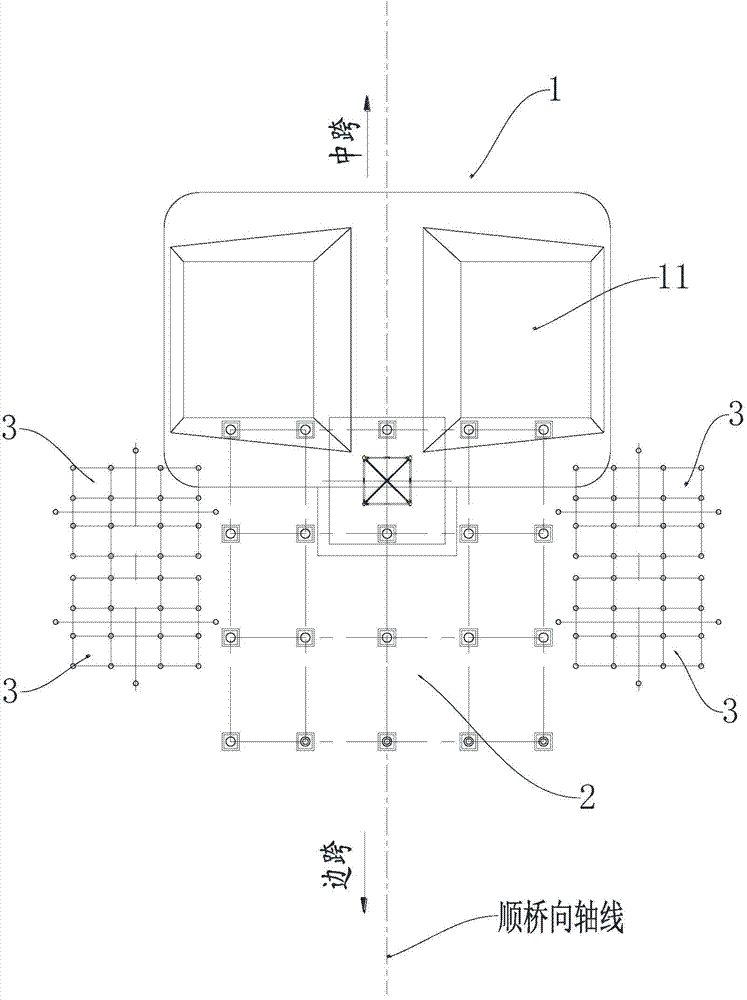

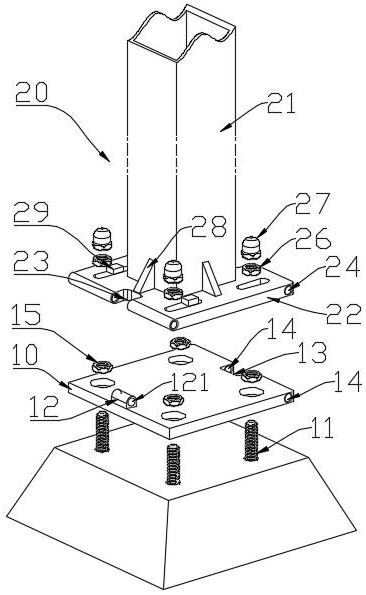

Socket type self-returning multi-section prefabricated pier and assembly method thereof

PendingCN110468694AAvoid working at heightsImprove durabilityBridge structural detailsFoundation engineeringCement slurryEngineering

The invention provides a socket type self-returning multi-section prefabricated pier and an assembly method thereof. The multi-section prefabricated pier comprises a bearing platform and the prefabricated bridge pier, wherein the prefabricated pier comprises a inserting bearing platform section, a plurality of pier body sections, a prestressed tendon, and energy dissipation ribs; the assembly method comprises the following steps that the prefabricated pier is prefabricated; a horizontal assembly method is adopted in a prefabricated factory, and the prestressed tendon is tensioned to enable allthe sections to be connected into a whole; and high-strength non-shrinkage cement slurry is injected into a pier grouting sleeve through grouting holes. On the site, the pier is lifted and is inserted into a pier installing hole, so that a certain gap is kept between the outer wall of the inserting bearing platform section and the inner wall of the pier installing hole; and after the prefabricated bridge pier is positioned, a guide pipe is inserted into the bottom of the gap, the high-strength non-shrinkage cement slurry is injected into the bottom through the guide pipe, and the slurry is discharged from bottom to top until the gap between the inserting bearing platform section and the pier installing hole is completely filled.

Owner:ZHENGZHOU UNIV

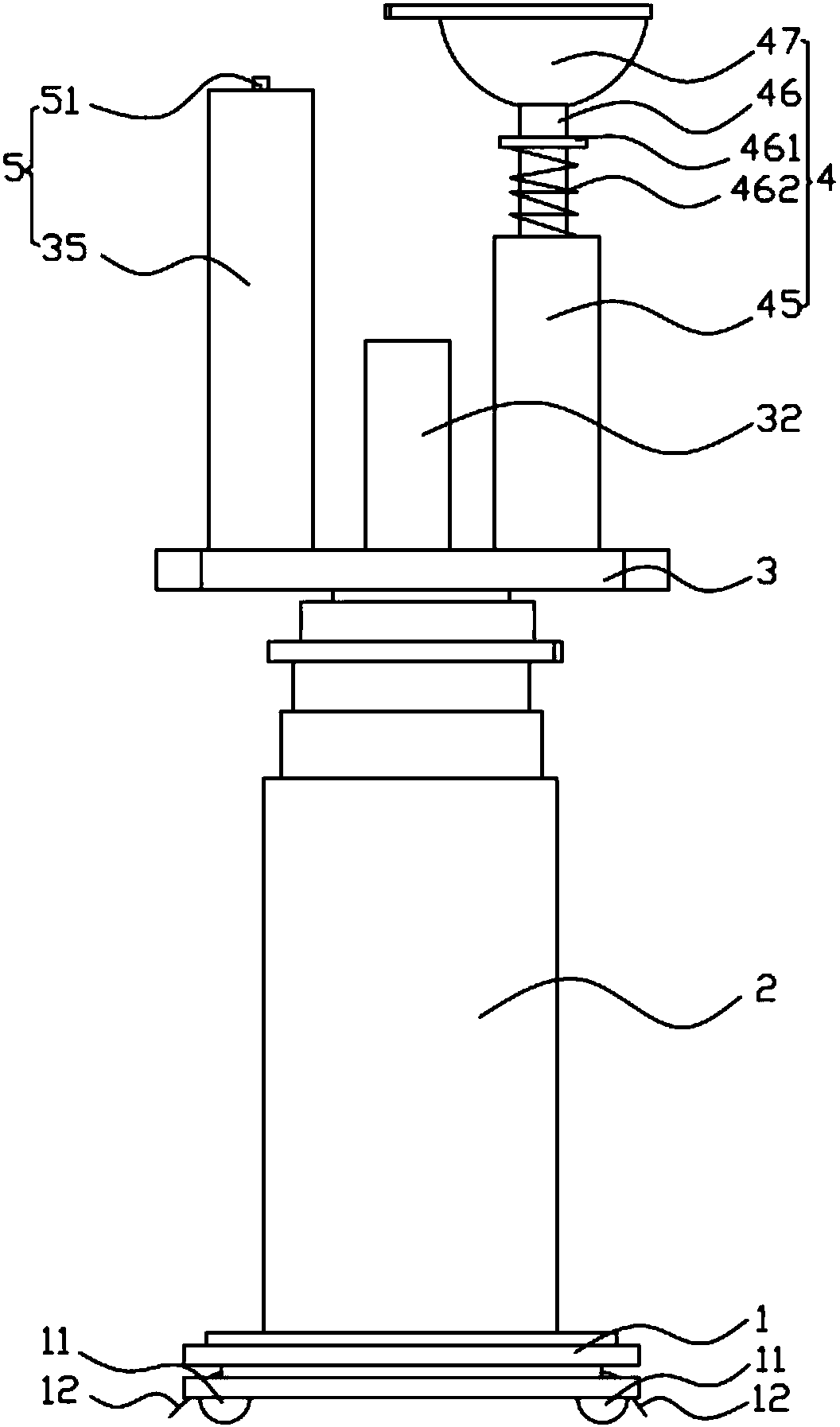

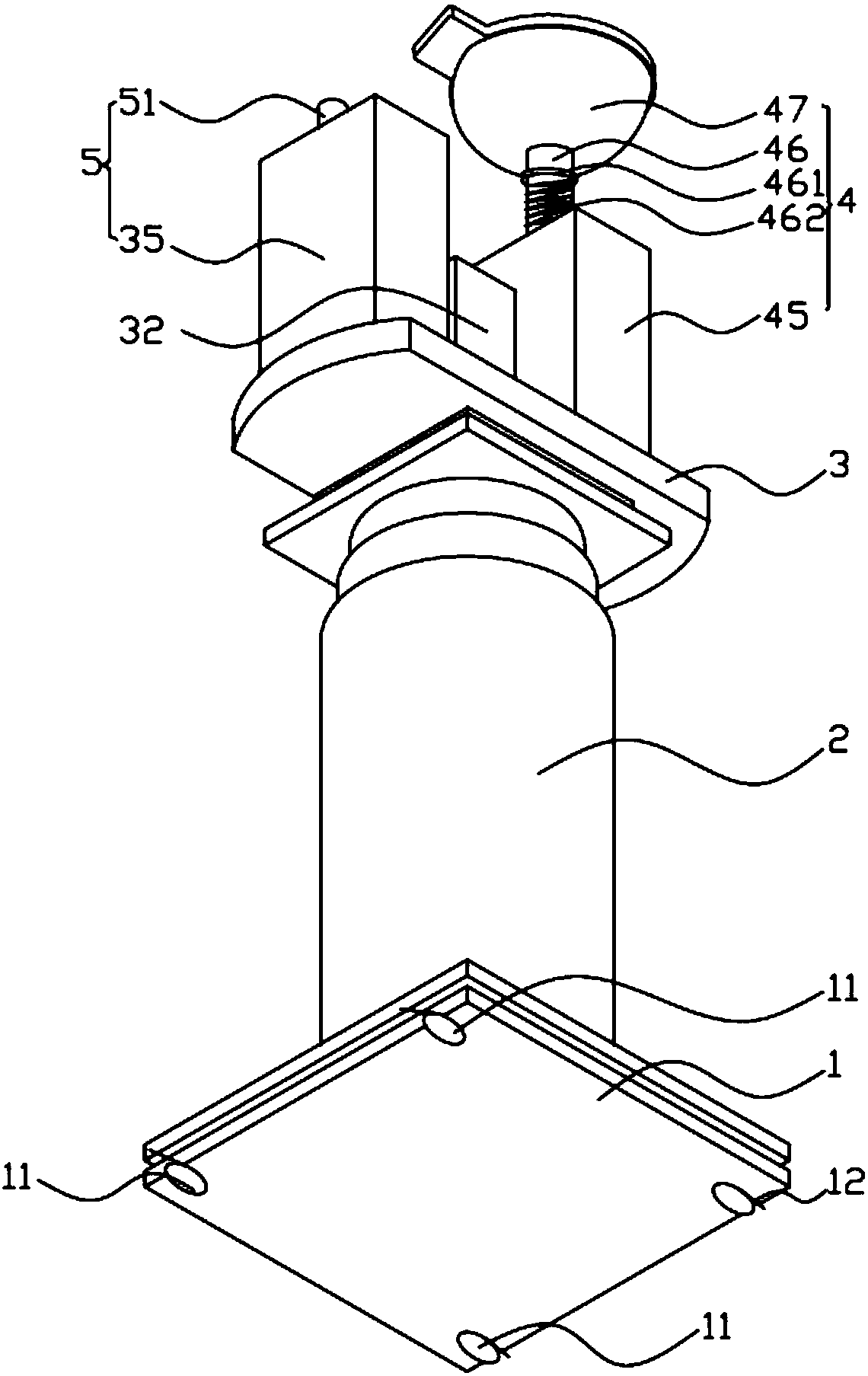

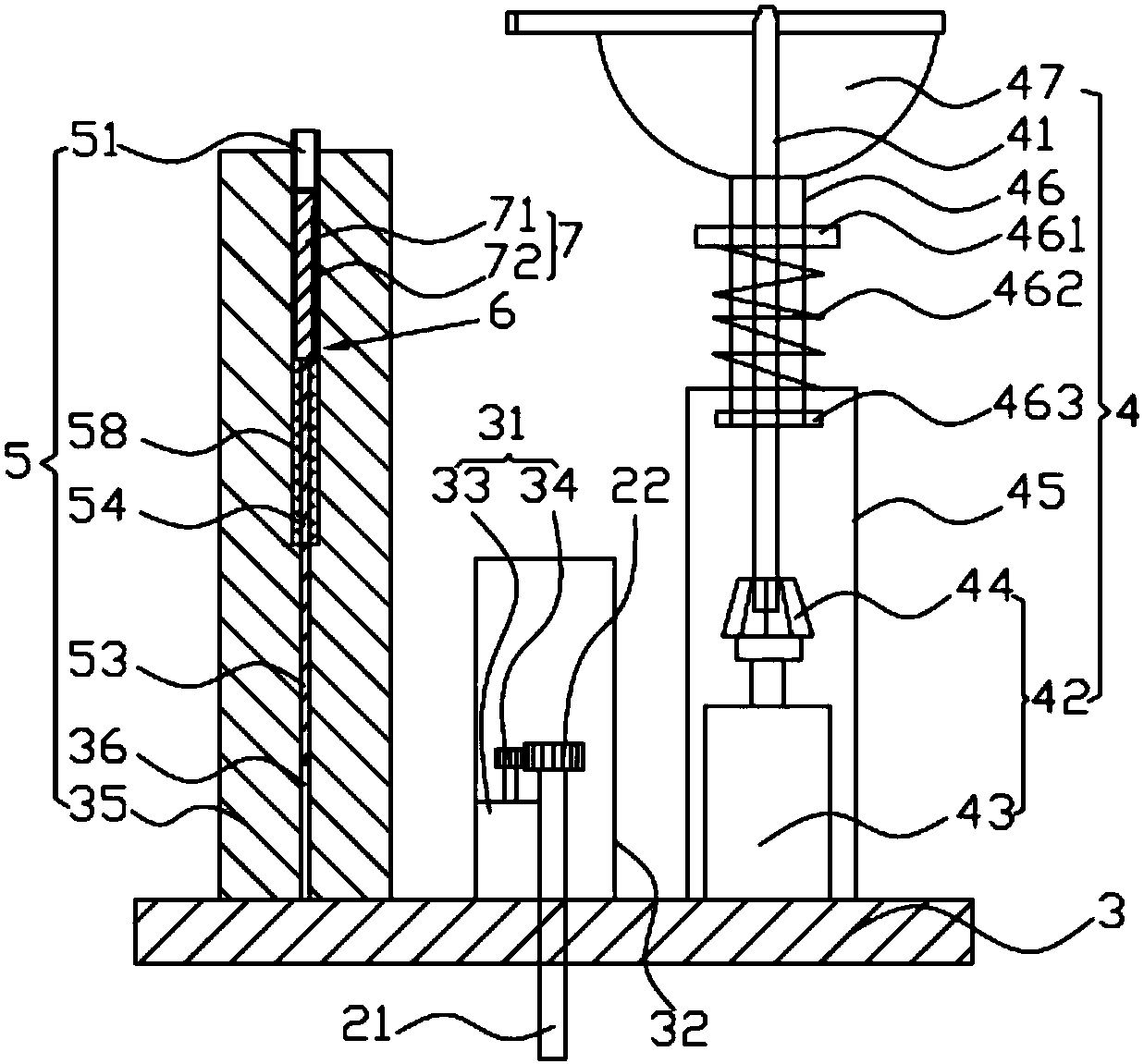

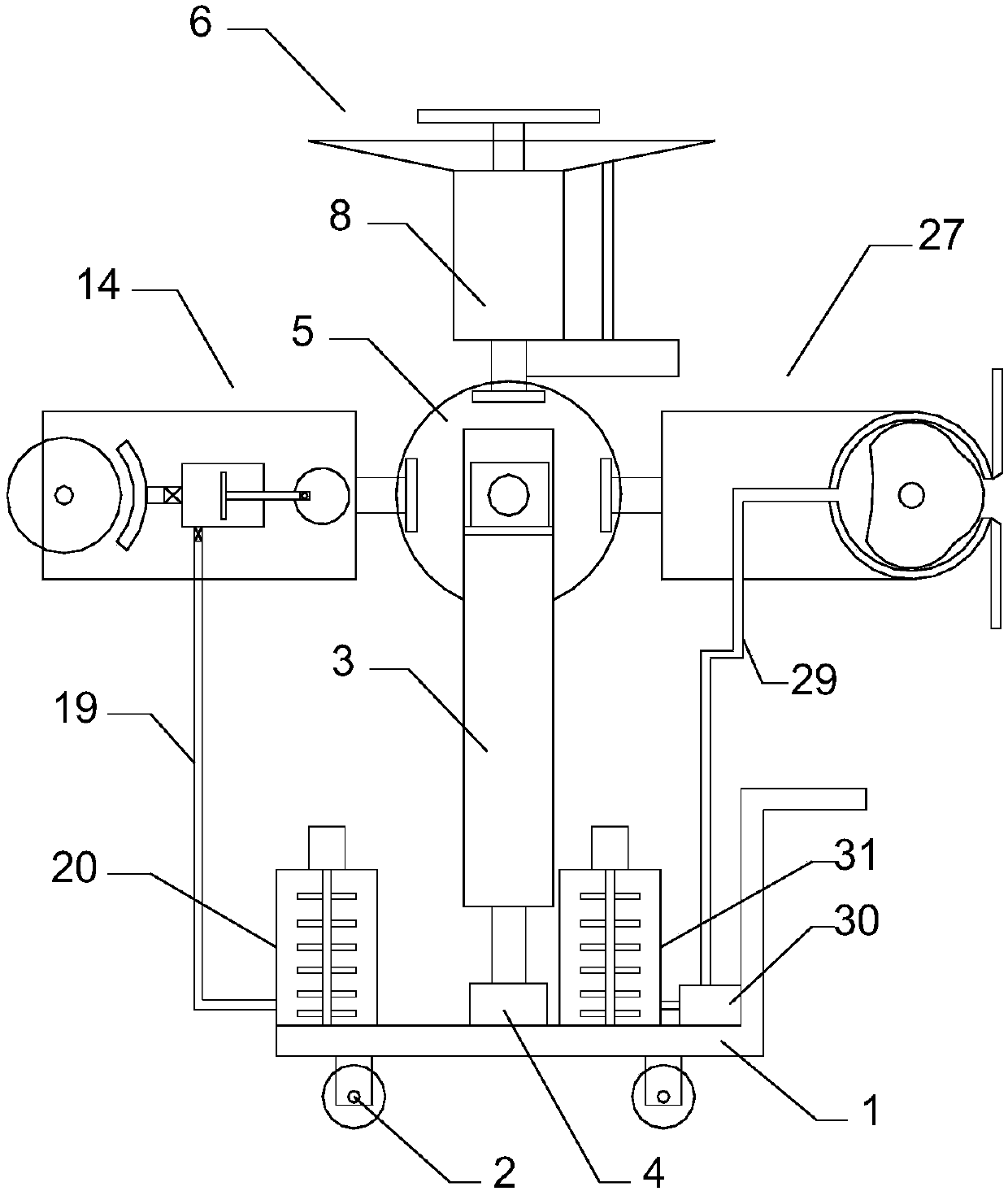

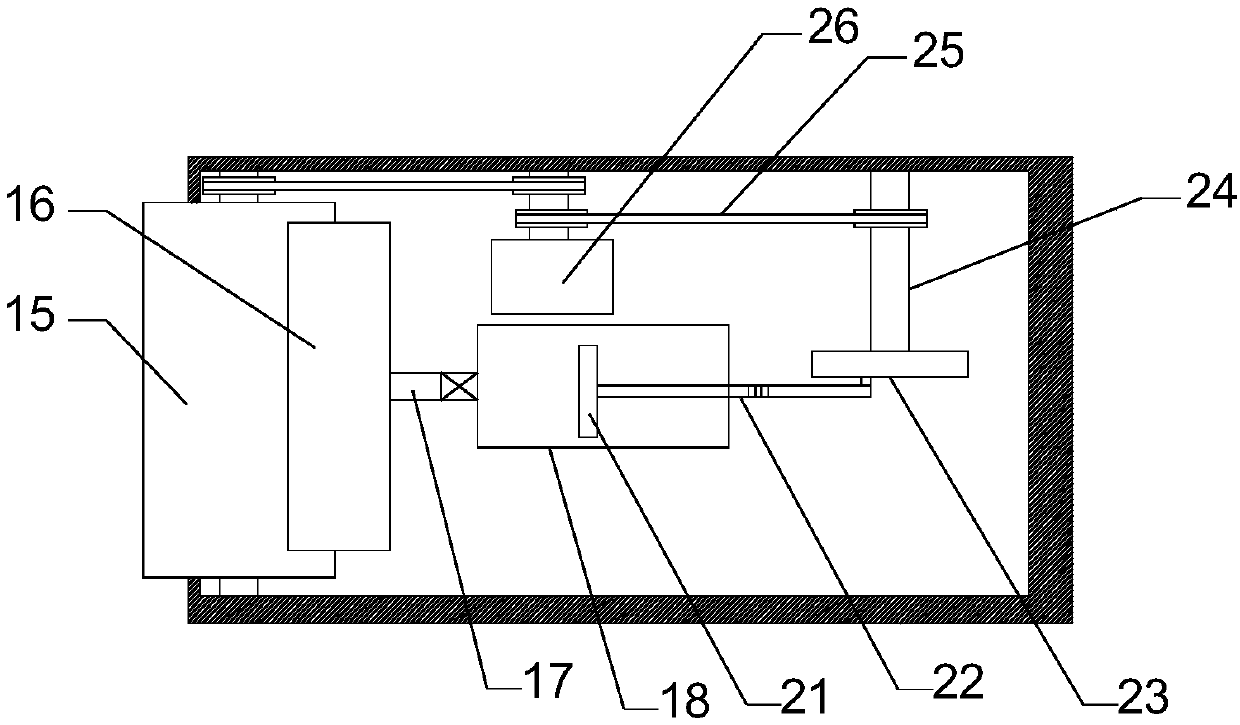

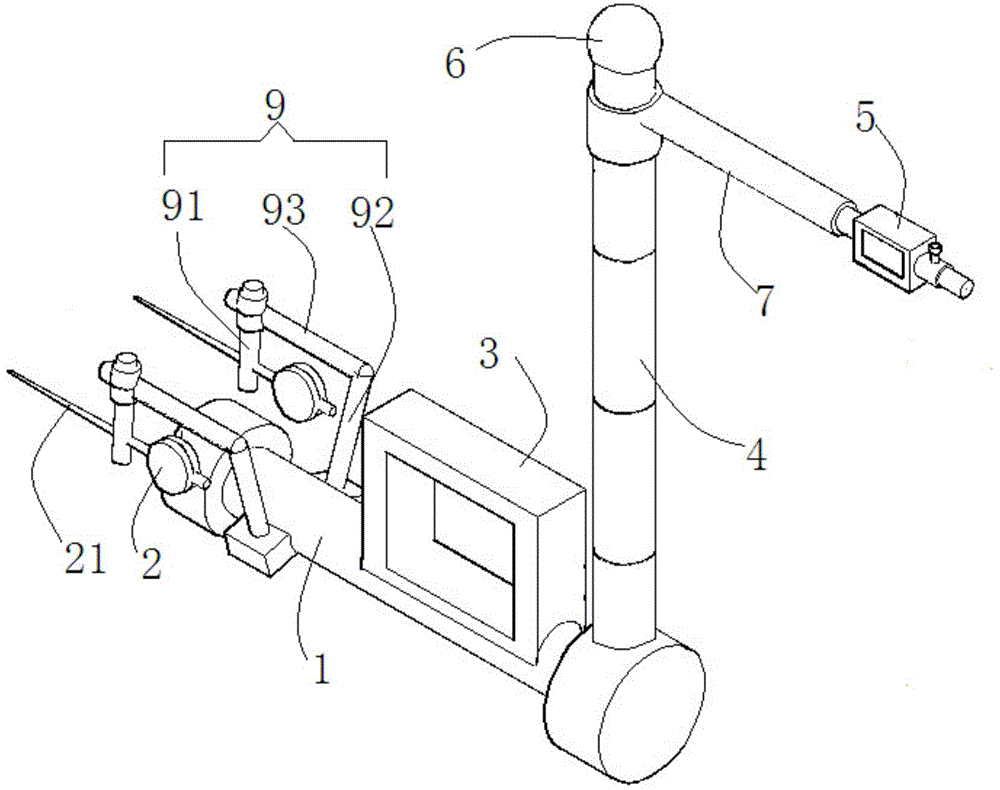

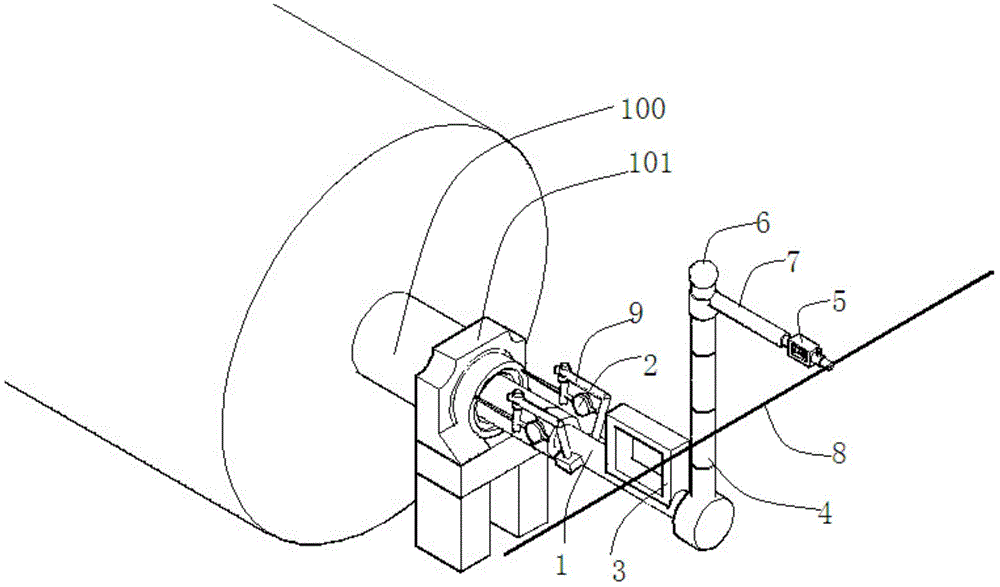

Equipment capable of punching ceiling and mounting expansion bolt conveniently

PendingCN107932052AImprove installation efficiencyFrequent disassemblyMetal working apparatusStone-like material working toolsEngineeringExpansion joint

Equipment capable of punching a ceiling and mounting an expansion bolt conveniently comprises a pedestal; a lifting device is fixedly arranged on the pedestal; the top of the lifting device is rotatably connected with a rotating platform; a drilling device and an expansion bolt mounting device are fixedly arranged on the two sides of the upper part of the rotating platform correspondingly; a cliptype feeding device is inserted into the expansion bolt mounting device; the pedestal is placed on the ground; the lifting device is used for driving the rotating platform to move up and down; the rotating platform is driven by a first driving device to rotate; the drilling device comprises a drill bit; the expansion bolt mounting device comprises a guide pipe; the upper end of the guide pipe is lower than the upper end of the drill bit; an inner hole of the guide pipe only allows a combined piece formed by combining a countersunk bolt and an expansion pipe to pass through; the guide pipe andthe drill bit are arranged on the two sides of the rotating platform symmetrically; an ejection device is fixedly arranged below the guide pipe; the clip type feeding device is internally provided with a plurality of combined pieces; the clip type feeding device is used for conveying the plurality of combined pieces to be between the guide pipe and the ejection pipe sequentially; and the equipmentsimplifies operation, has high efficiency and is safe.

Owner:SHENZHEN STYLE DECORATION

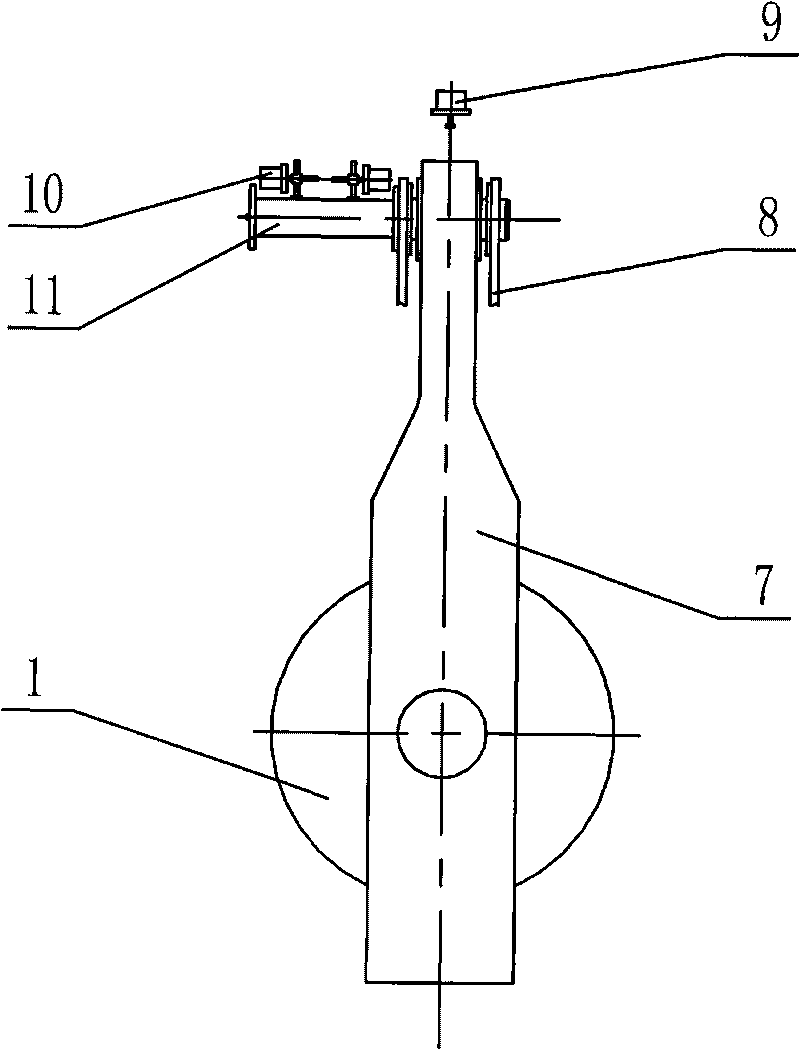

Multiplication-variable hook device

ActiveCN101717038AAvoid working at heightsGood effectLoad-engaging elementsTime efficientEngineering

The invention discloses a multiplication-variable hook device, comprising a hook, a fixed pulley bracket, a movable pullet bracket, a first pulley, a second pulley and a third pulley, wherein the hook is fixed on the movable pullet bracket, the first pulley is fixedly connected with the fixed pulley bracket, the second pulley and the third pulley are symmetrically fixed on the movable pullet bracket, and the second pulley, the first pulley and the third pulley are sequentially wound via a raising line. The hook device overcomes the deficiencies in the prior art, has no need of replacing the hook and putting the raising line through again, and can prominently complete multiplication conversion only by raising the multiplication-variable hook device to a top fixed end and then putting a pin through a pin hole of the top fixed end, thus saving a large amount of manpower, materials and time in particular and greatly enhancing efficiency; in addition, due to the installation of an automatic pin-through device and devices fitted therewith, high-altitude operation by workers is totally avoided so as to prevent the occurrence of accidents.

Owner:杭州国电大力机电工程有限公司

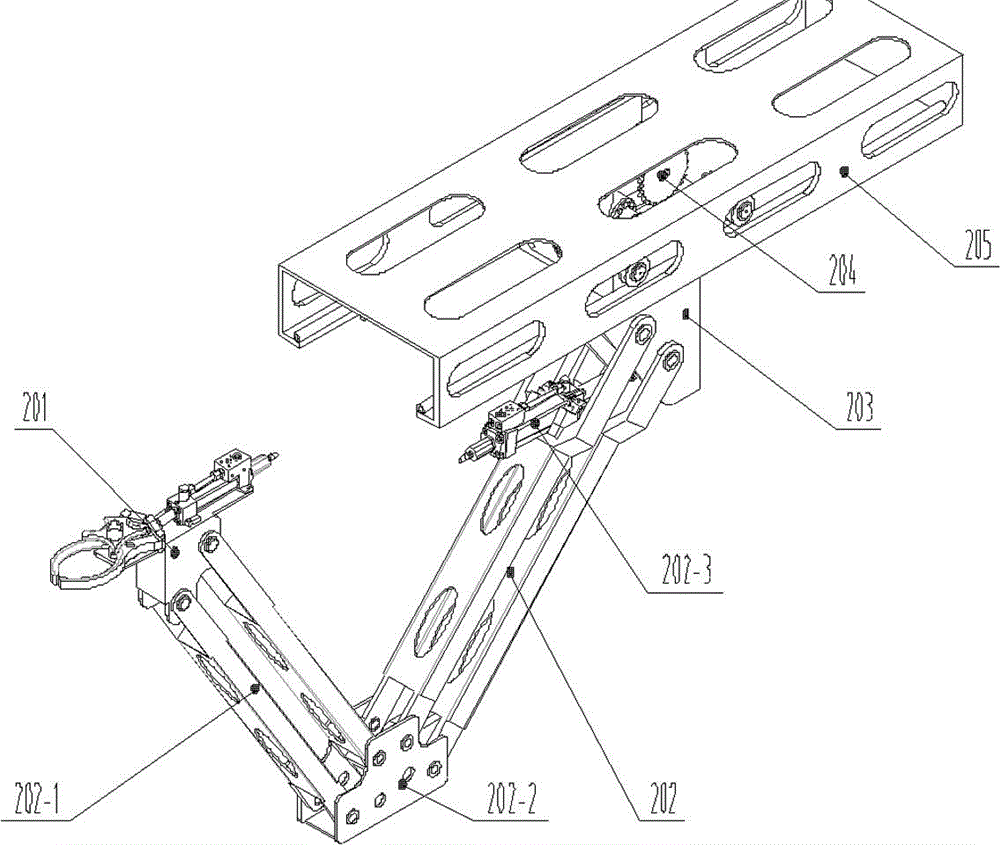

Drill pipe stand storage and fetching device and storage and fetching method

InactiveCN104563918AAvoid working at heightsReduce loadDrilling rodsDrilling casingsRemote controlManipulator

The invention discloses a drill pipe stand storage and fetching device and a drill pipe stand storage and fetching method using the device. The drill pipe stand storage and fetching device mainly consists of a monkey board, a monkey board manipulator, a derrick, a drilling floor manipulator, a drilling floor, a drill pipe stand, an elevator, a traveling system, drill pipe clamping mechanisms, a telescopic arm rod mechanism, a rotary hanging mechanism, a sliding mechanism, a mounting bracket, a sliding trolley, a rotary vertical column, a rotary hanging seat, and sliding guide rails, wherein the traveling system is used for lifting the drill pipe stand to the proper position by the elevator, and the drill pipe clamping mechanisms of the drilling floor manipulator and the monkey board manipulator are used for clamping the drill pipe stand, and are used for lifting the drill pipe stand to the particular position through the telescopic and rotary matching of the telescopic arm rod mechanism, the rotary mechanism and the sliding mechanism, so as to complete the drilling and storage of the drill pipe stand. The drill pipe stand storage and fetching device has the characteristics that the automatic storage and fetching of drill pipe can be realized, the labor intensity of workers is decreased, and the operation safety is improved; the drilling efficiency is improved, the drilling cost is reduced, the remote control is performed, and the automation degree of the operation is improved.

Owner:CHINA PETROCHEMICAL CORP +1

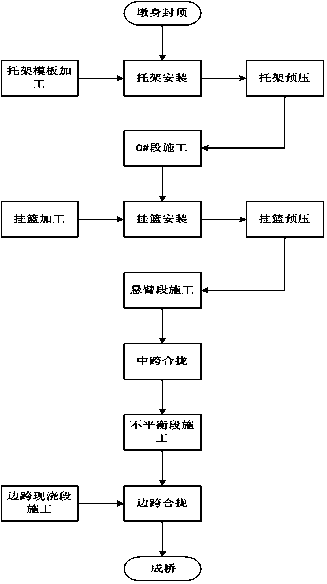

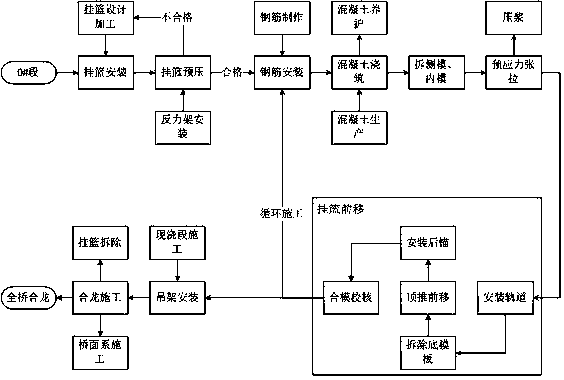

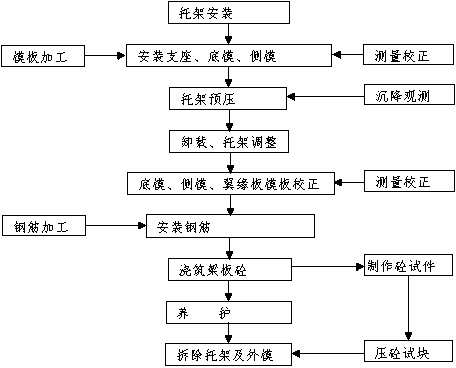

Special construction method for dragging main beam of extra-large bridge

InactiveCN111287095AStrong enoughRigid enoughBridge erection/assemblyBridge materialsPre stressArchitectural engineering

The invention discloses a special construction method for a main beam of a lower dragging extra-large bridge, which comprises the following steps of: S02: 0 # section construction: pouring twice, andforming a support by once pouring; s03, hanging basket construction is conducted, specifically, a hanging basket is moved forwards to the front end of the zero beam section, and the formwork erectingelevation is determined; and erecting a formwork to bind the No.1 beam section steel bars and finish the arrangement of the prestressed pipeline. Aiming at the conditions that the span of a main beamis 200 m, the length of double cantilevers is large, the width-to-span ratio of a box girder is small, and the construction technical difficulty is large when the construction period goes through strong wind seasons and winter, smooth construction is guaranteed, and good practicability is achieved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP +3

Efficient comprehensive wall treatment device

InactiveCN107762116AEfficient mixingEfficient switchingBuilding constructionsPlane surface grinding machinesHydraulic cylinderPulp and paper industry

The invention discloses an efficient comprehensive wall treatment device which comprises a vehicle body. Wheels are arranged at the bottom of the vehicle body, a supporting frame is arranged on the vehicle body, and a first hydraulic cylinder is connected to the bottom of the supporting frame through a piston rod; and a rotating disc is rotationally connected to the position, close to the top, ofthe supporting frame, and a grinding device is arranged above the rotating disc. A grinding wheel and a dust collector are arranged, so that a wall is efficiently ground, dust is collected, and the operation environment and the health of workers are protected; a putty stirring box, an injection cylinder and a scraping plate are arranged, so that putty is uniformly stirred to be fine, the operationefficiency of puttying is improved, and the construction effect is guaranteed; a paint stirring box, a piston cylinder and an injection head are arranged, so that paint is saved, and the constructionefficiency is improved; and the first hydraulic cylinder and the rotating disc are arranged, so that efficient switching of various operating devices is achieved, the functions are diversified, meanwhile, the spatial position of the operating device is adjusted, and climbing operation is avoided.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

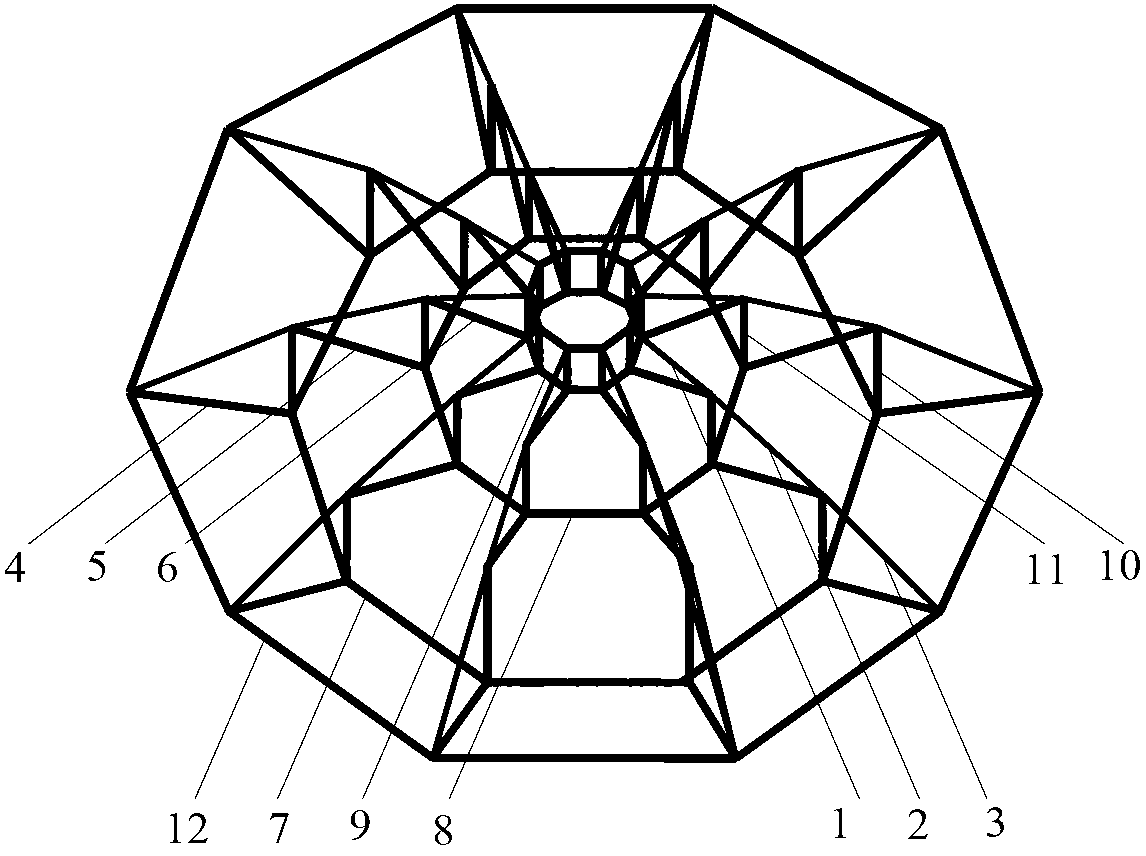

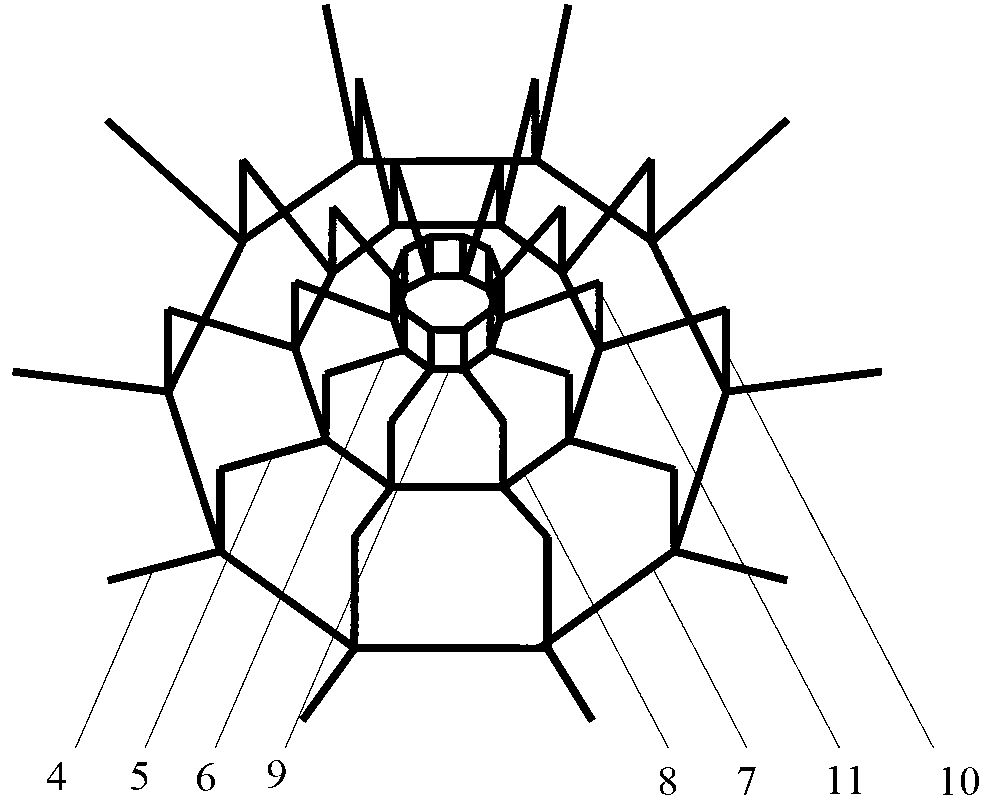

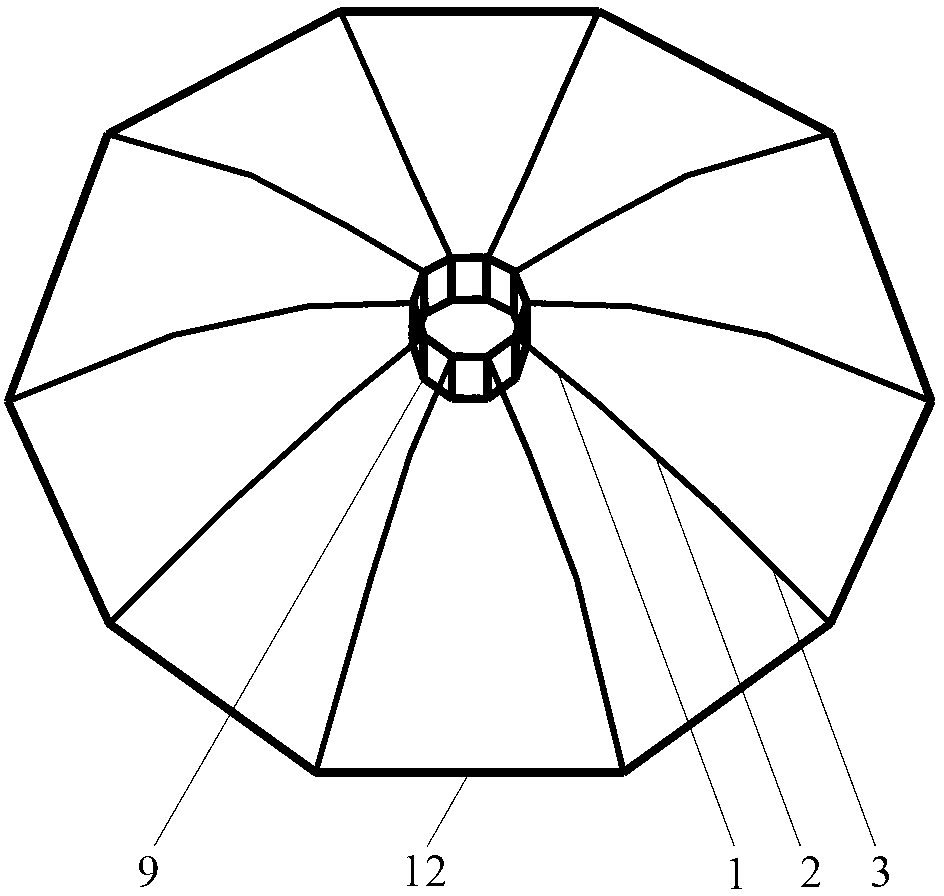

Method for constructing stiff supporting dome structure

InactiveCN103061412AReduce construction difficultyAvoid multiple layers of tensegrityArched structuresVaulted structuresEngineeringRidge

The invention discloses a method for constructing a stiff supporting dome structure, and relates to the field of buildings. The method for constructing the stiff supporting dome structure includes firstly mounting an inner central draw ring and ridge ropes; secondly, mounting inner ring rods, and sequentially mounting inner sway rods and middle struts from top to bottom according to nodes; thirdly, mounting outer ring rods, integrally tensioning and lifting outer ridge ropes and tool ropes of middle sway rods, and mounting the middle sway rods and outer struts; fourthly, integrally tensioning and lifting the outer ridge ropes and tool ropes of outer sway rods and connecting the outer ridge ropes and the outer sway rods with ring beams; fifthly, tensioning the outer ridge ropes so that the appearance of a structure reaches design requirements; and sixthly, laying films to complete construction. The method for constructing the stiff supporting dome structure has the advantages that characteristics such as easiness in positioning of rods of the structure are sufficiently utilized, and the structure is integrally lifted and symmetrically mounted sequentially from inside to outside and from top to bottom according to the nodes and is tensioned and formed at one step; the rods are mounted on the ground or on an operation platform, so that aerial operation is avoided; and the rods are constantly lifted, and are prevented from being tensioned and released repeatedly.

Owner:BEIJING UNIV OF TECH

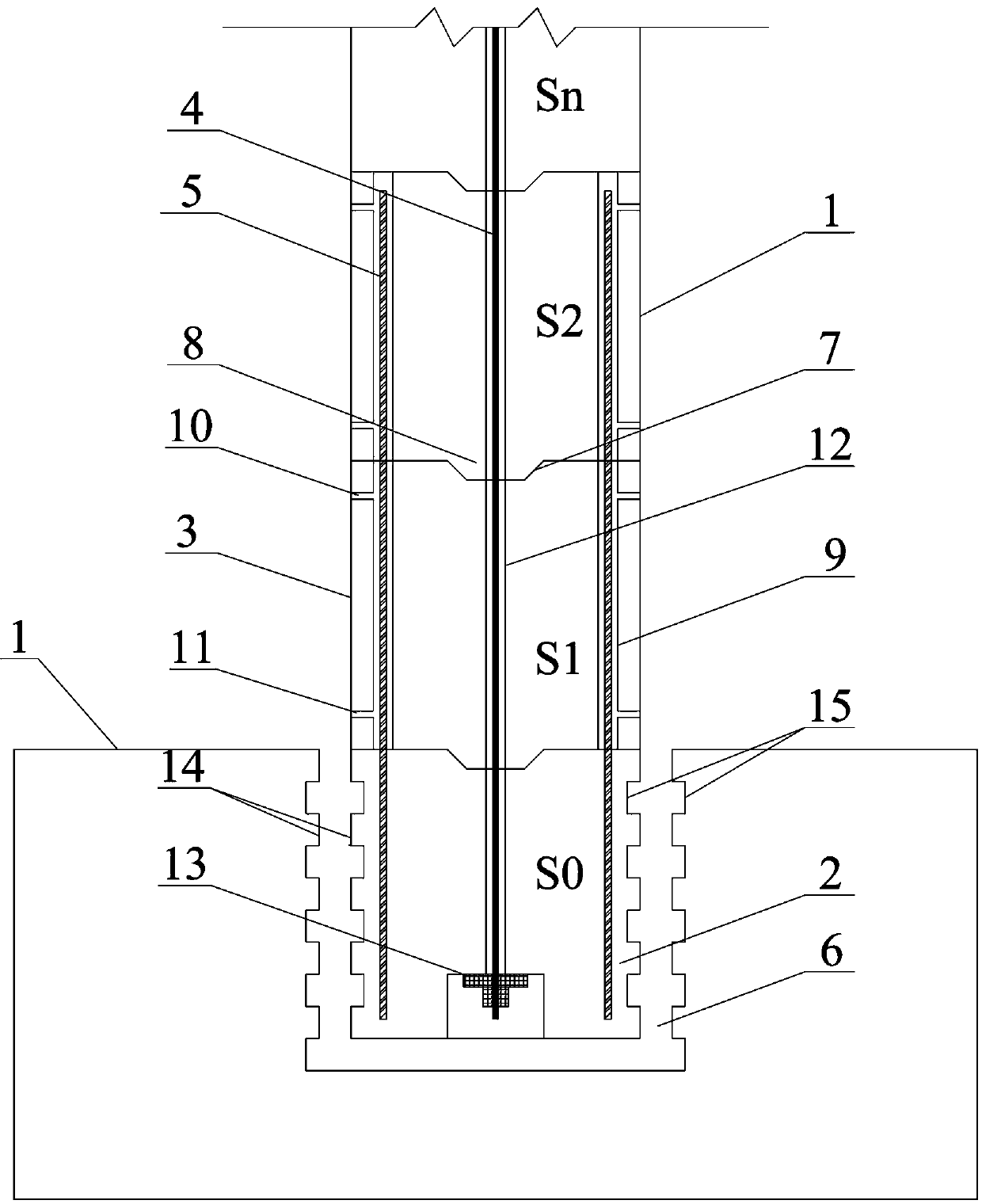

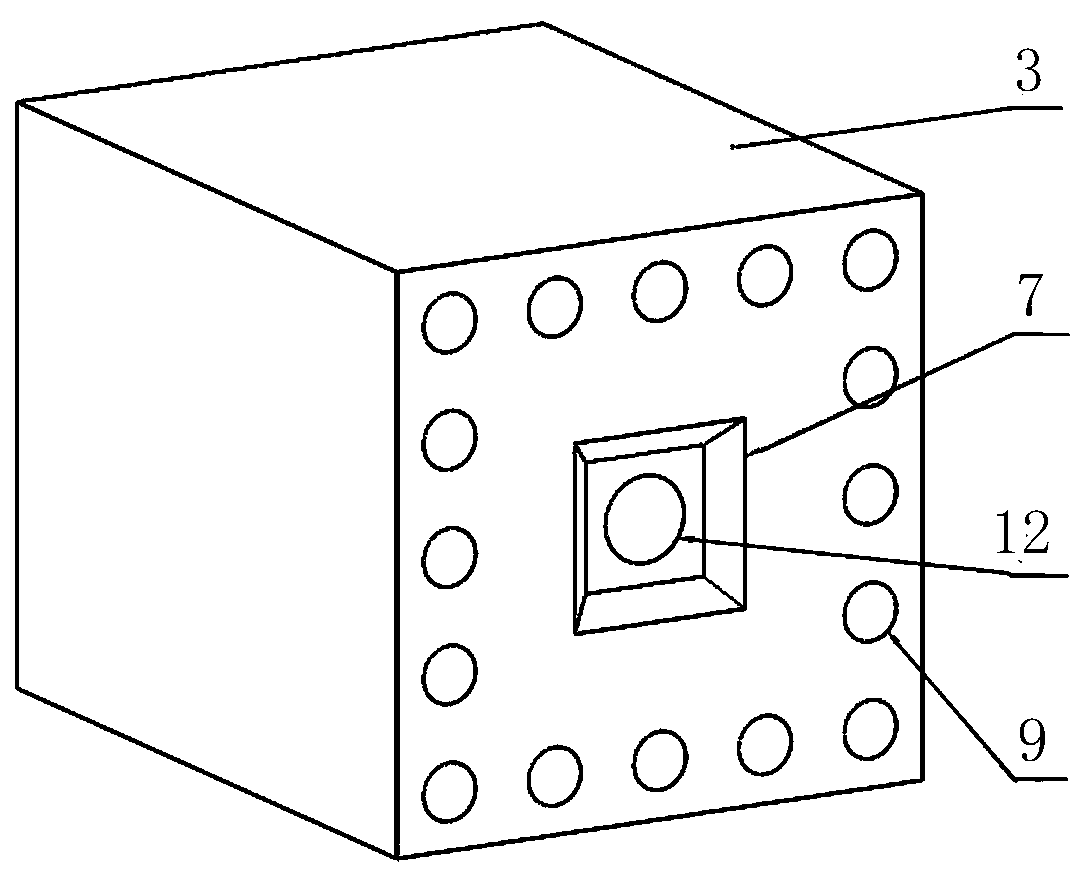

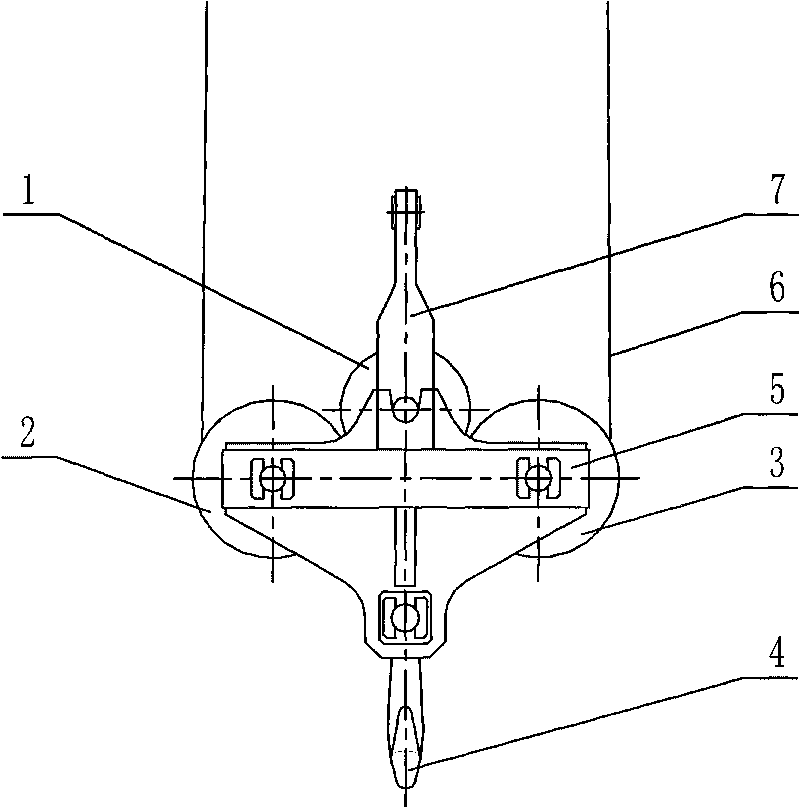

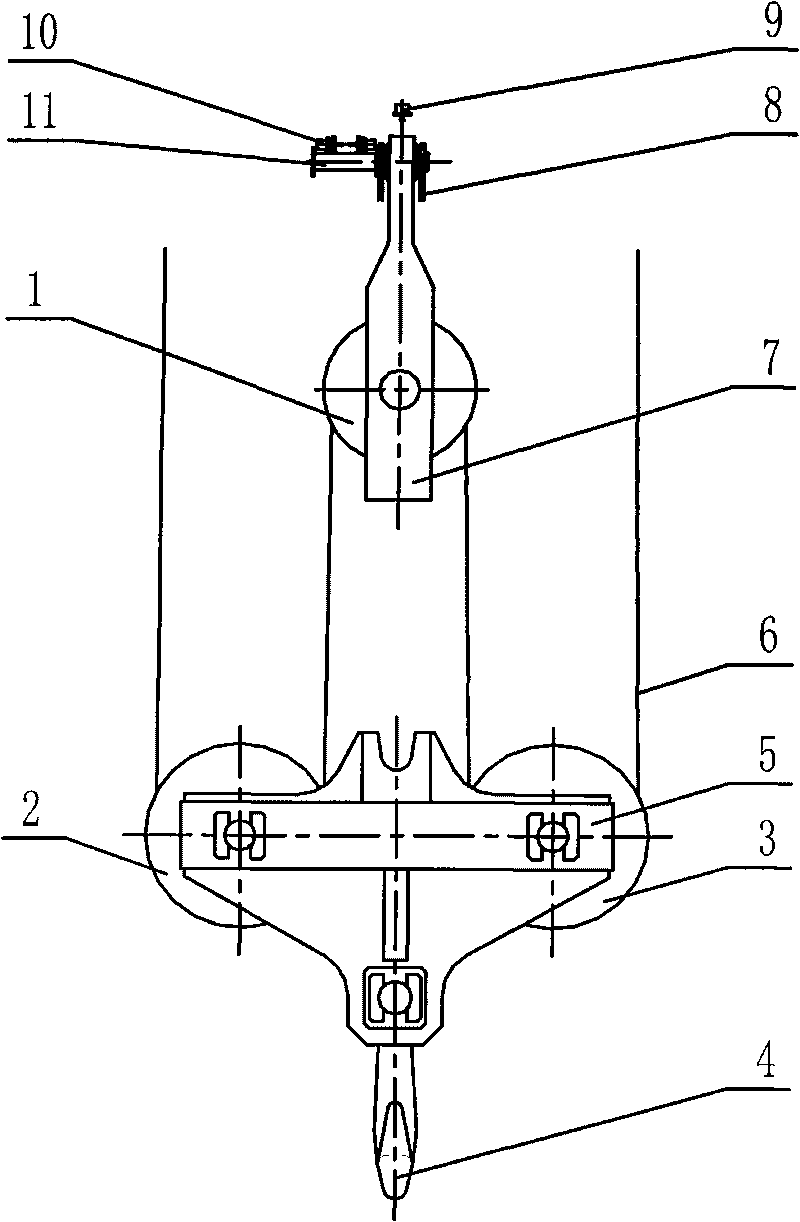

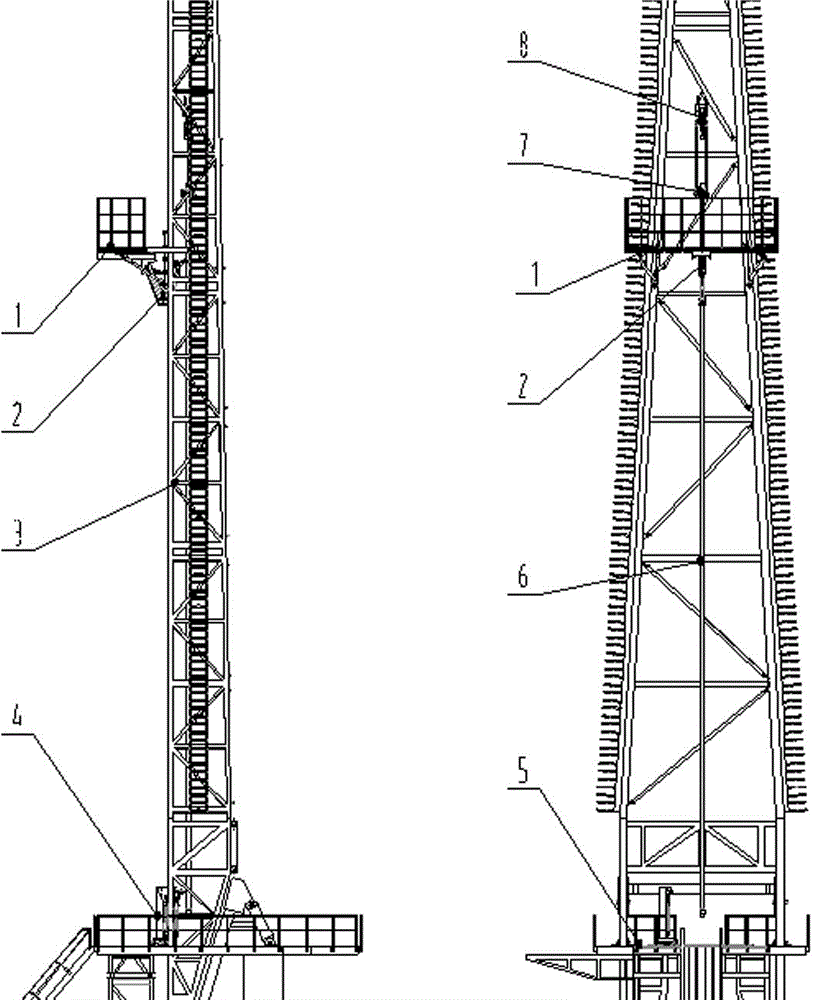

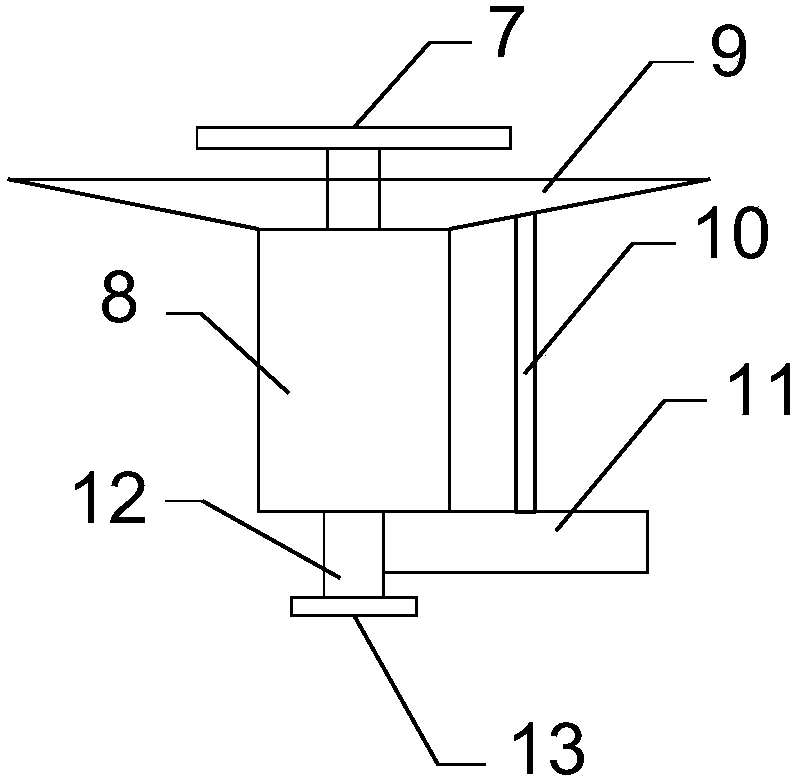

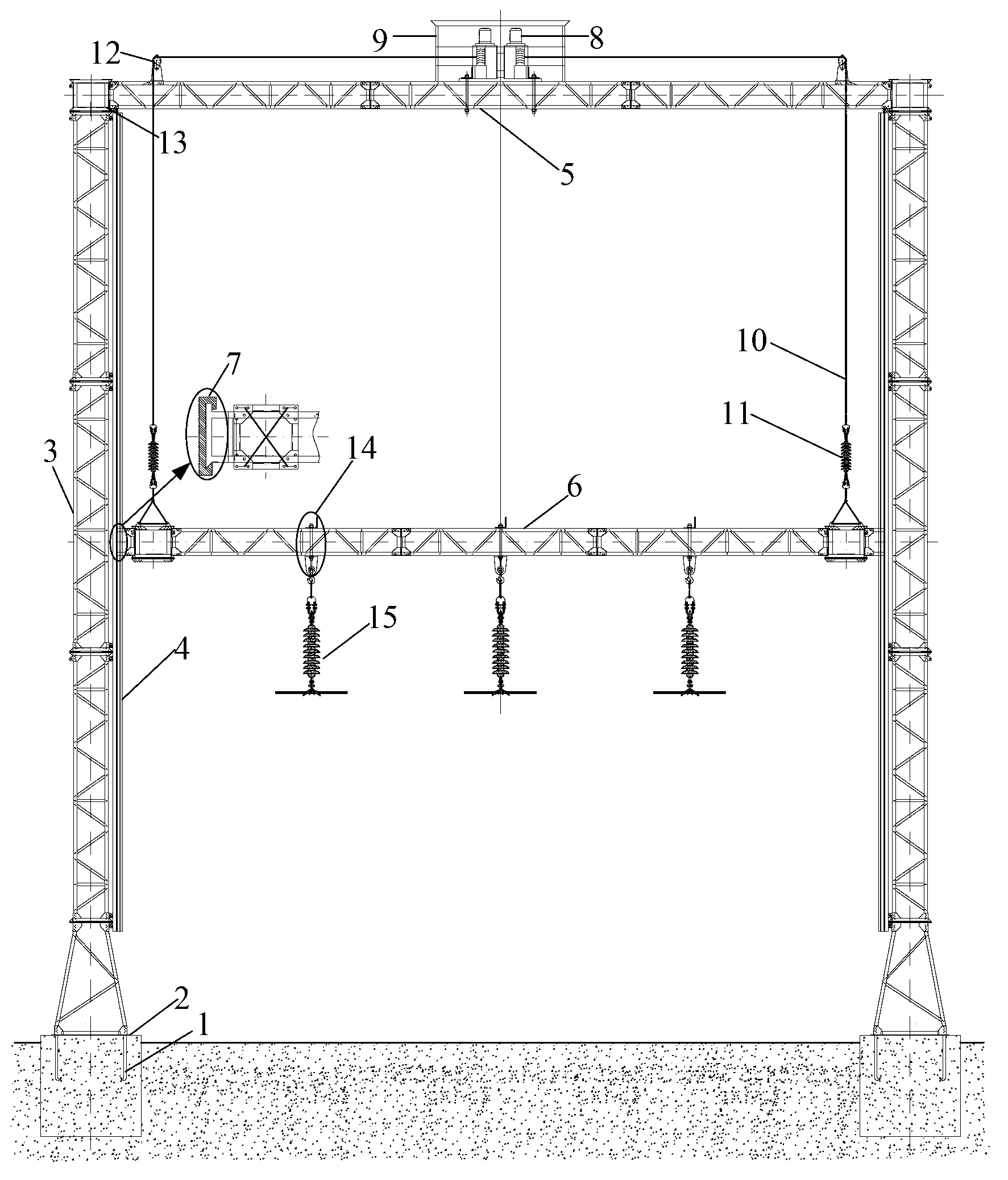

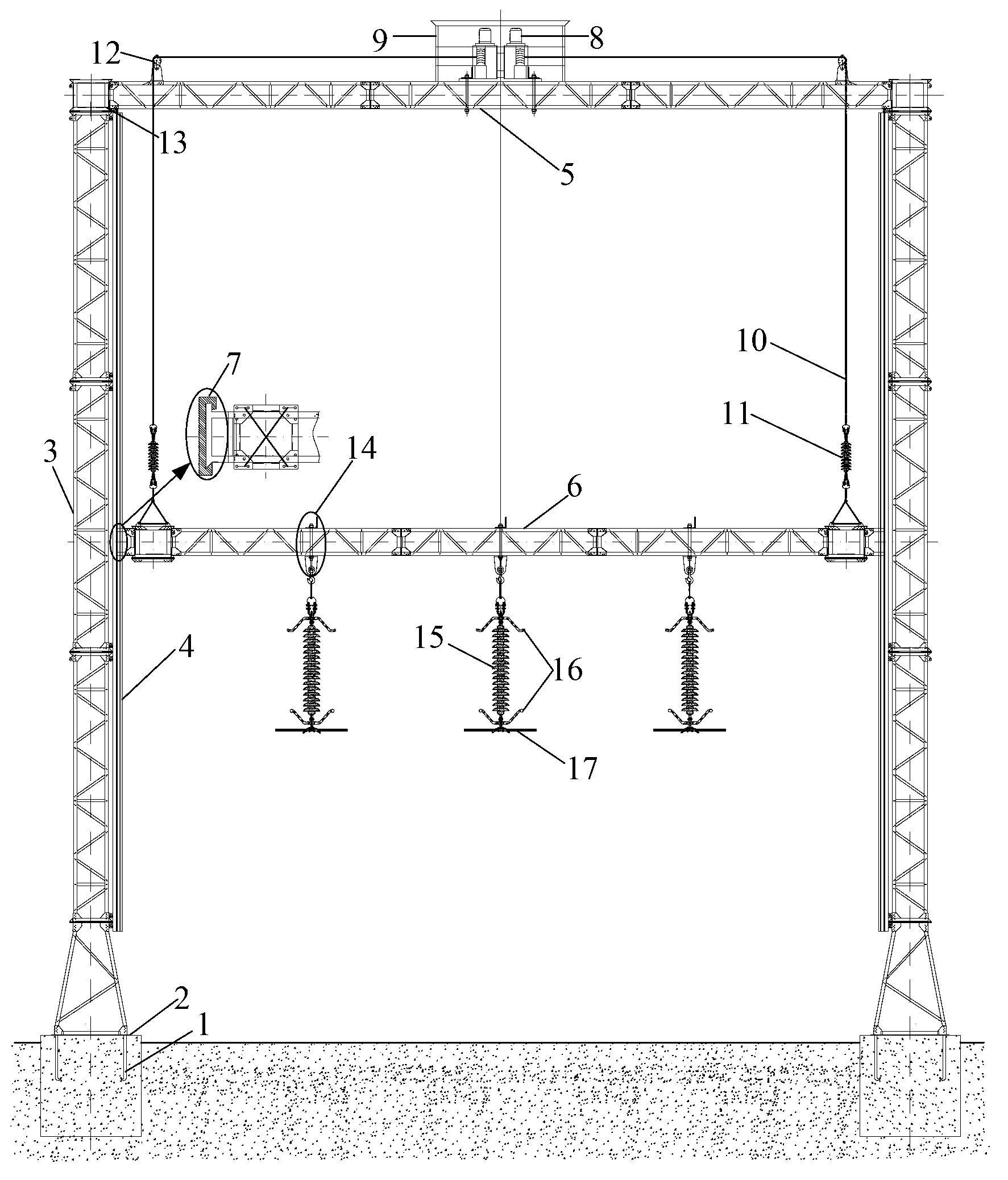

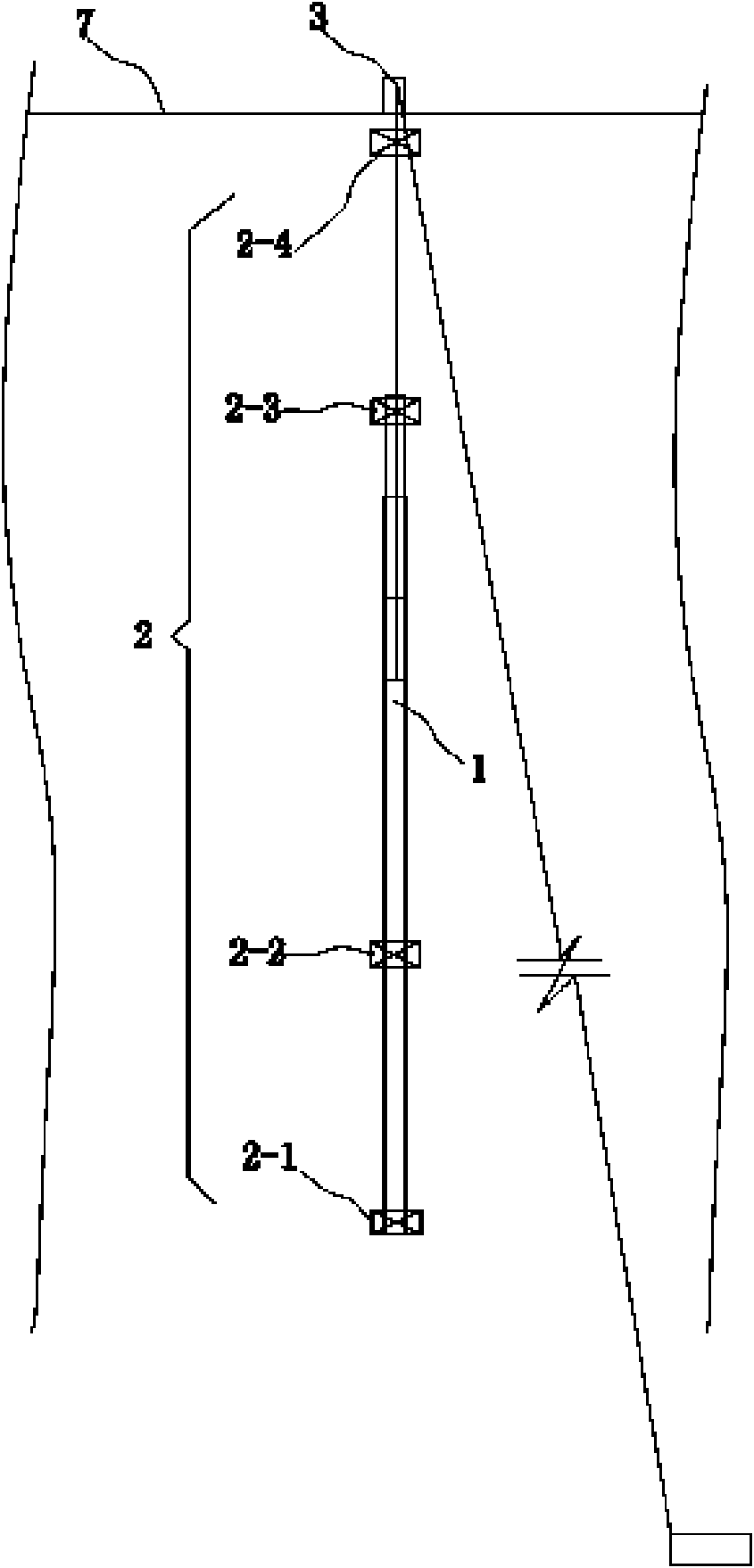

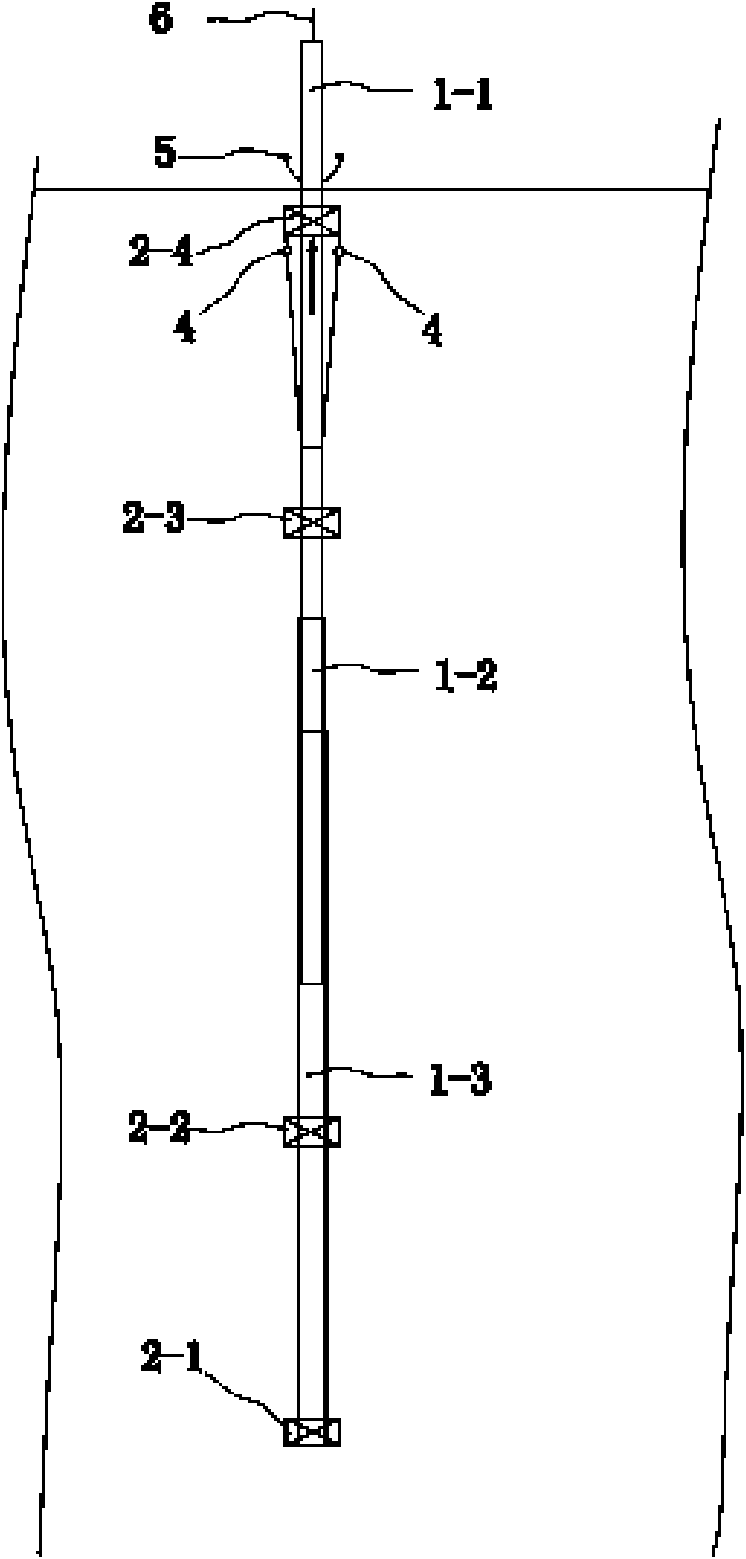

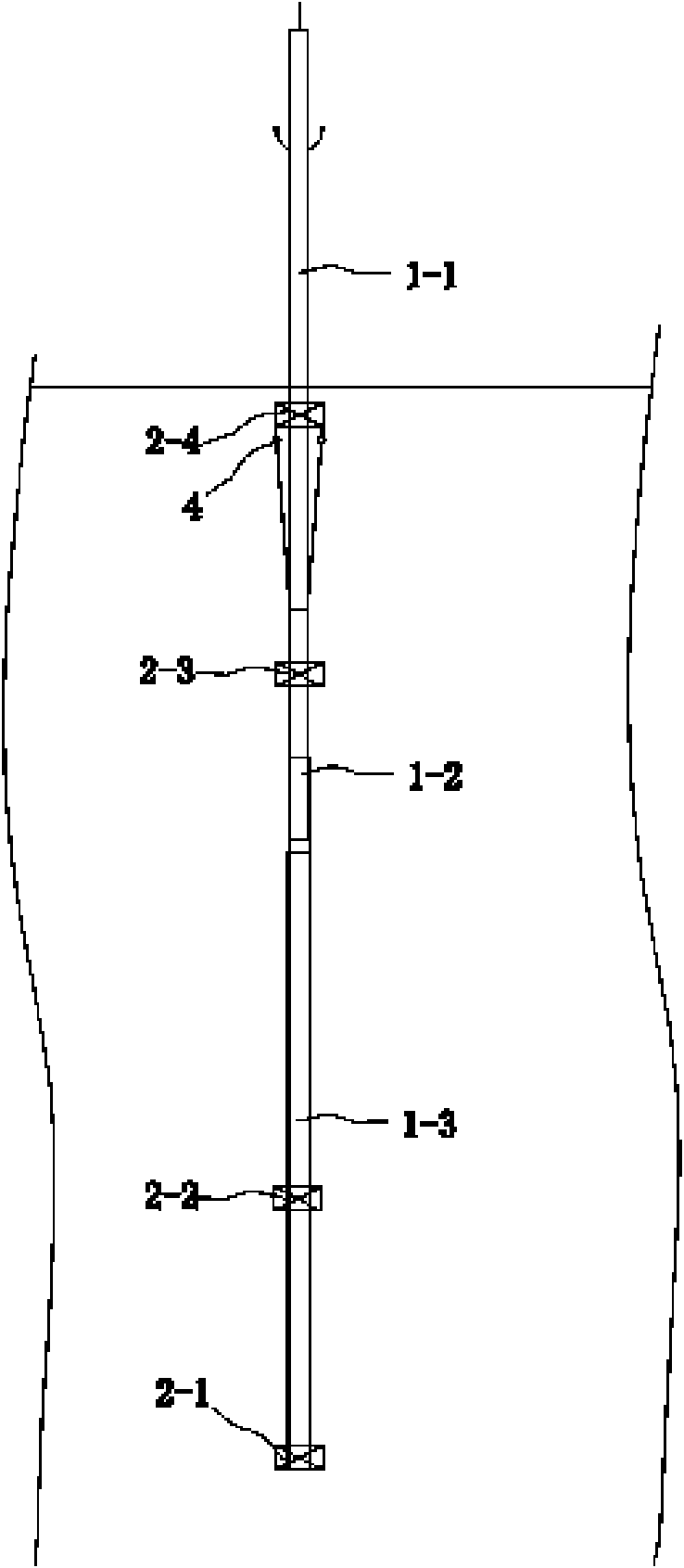

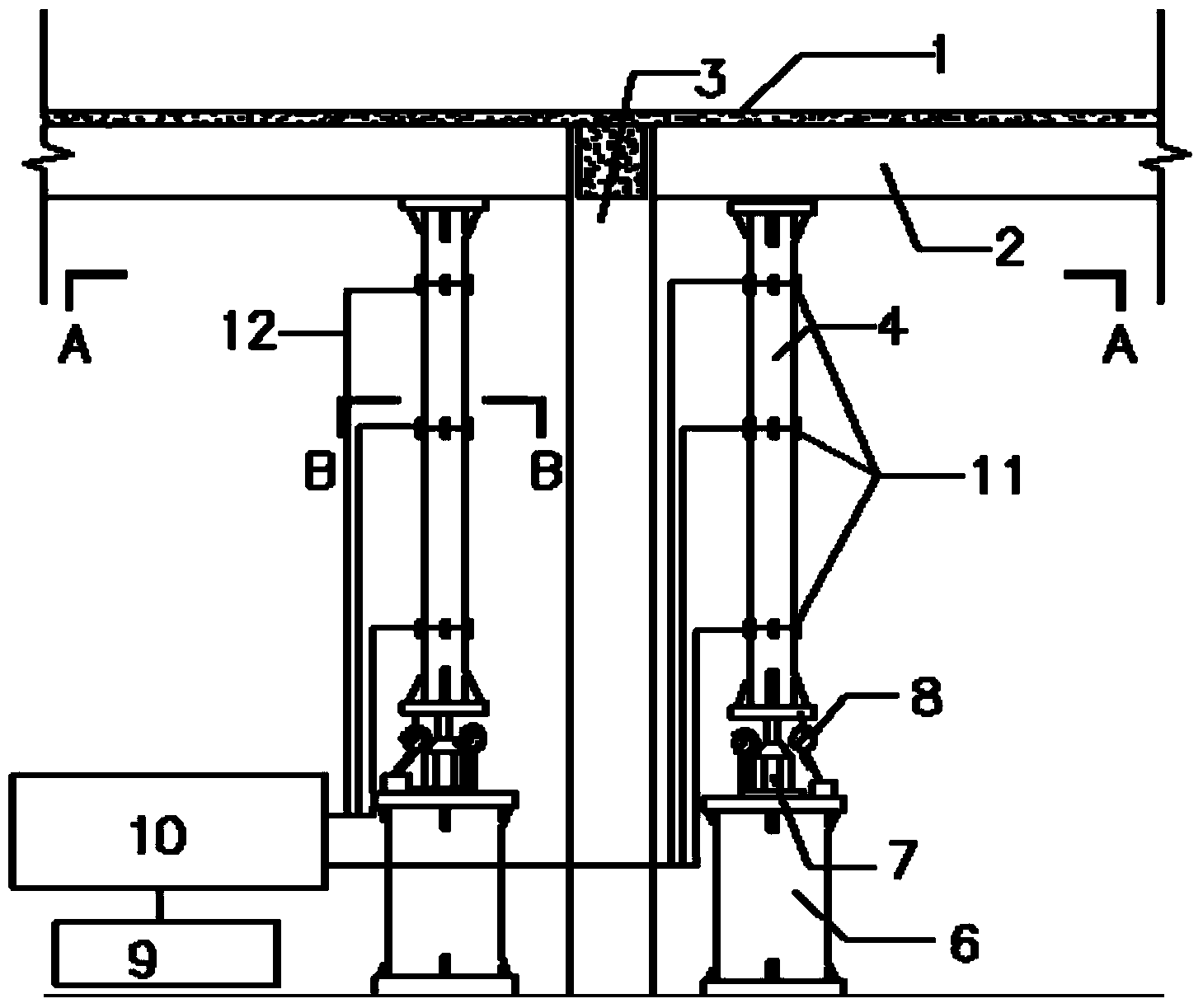

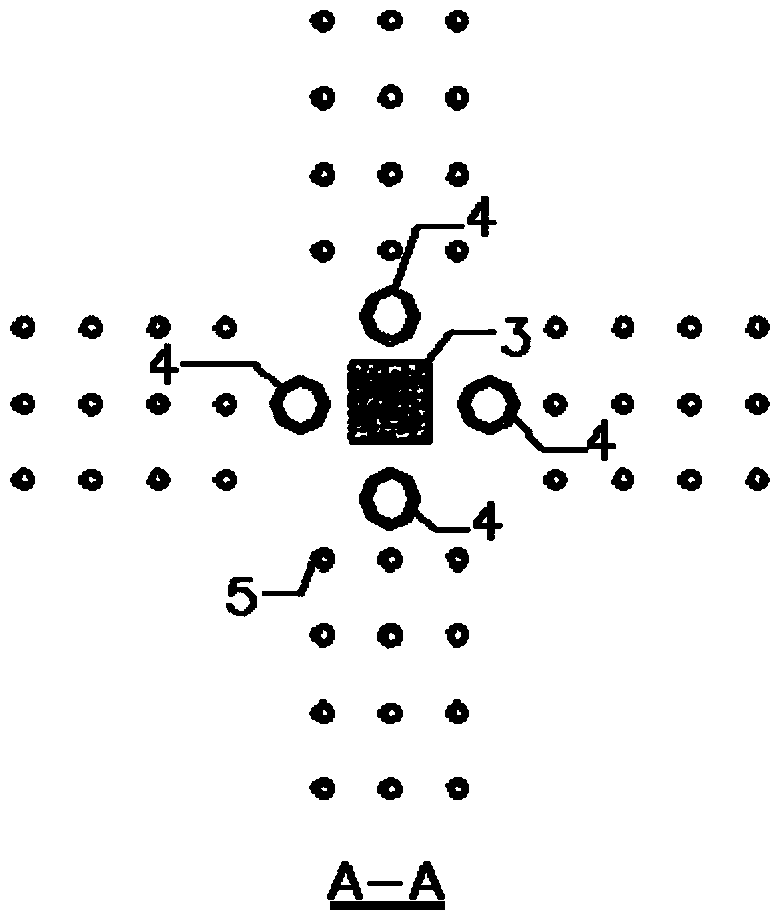

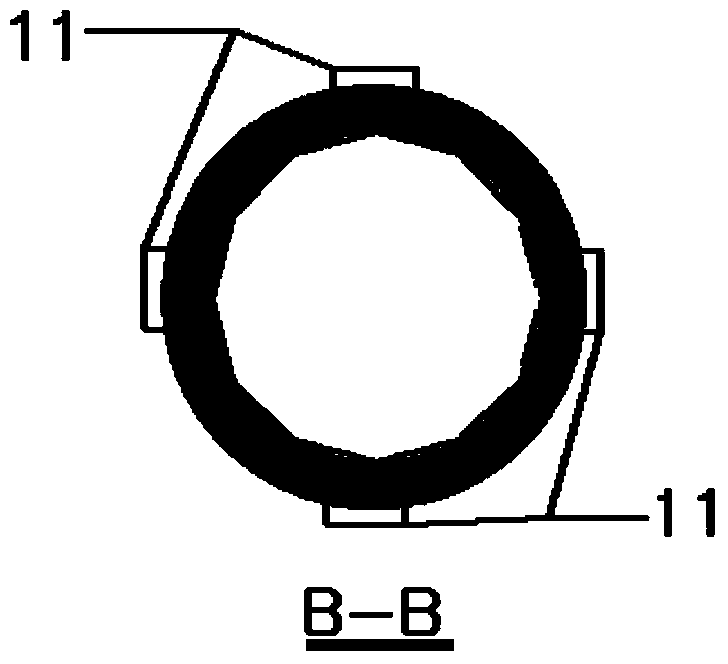

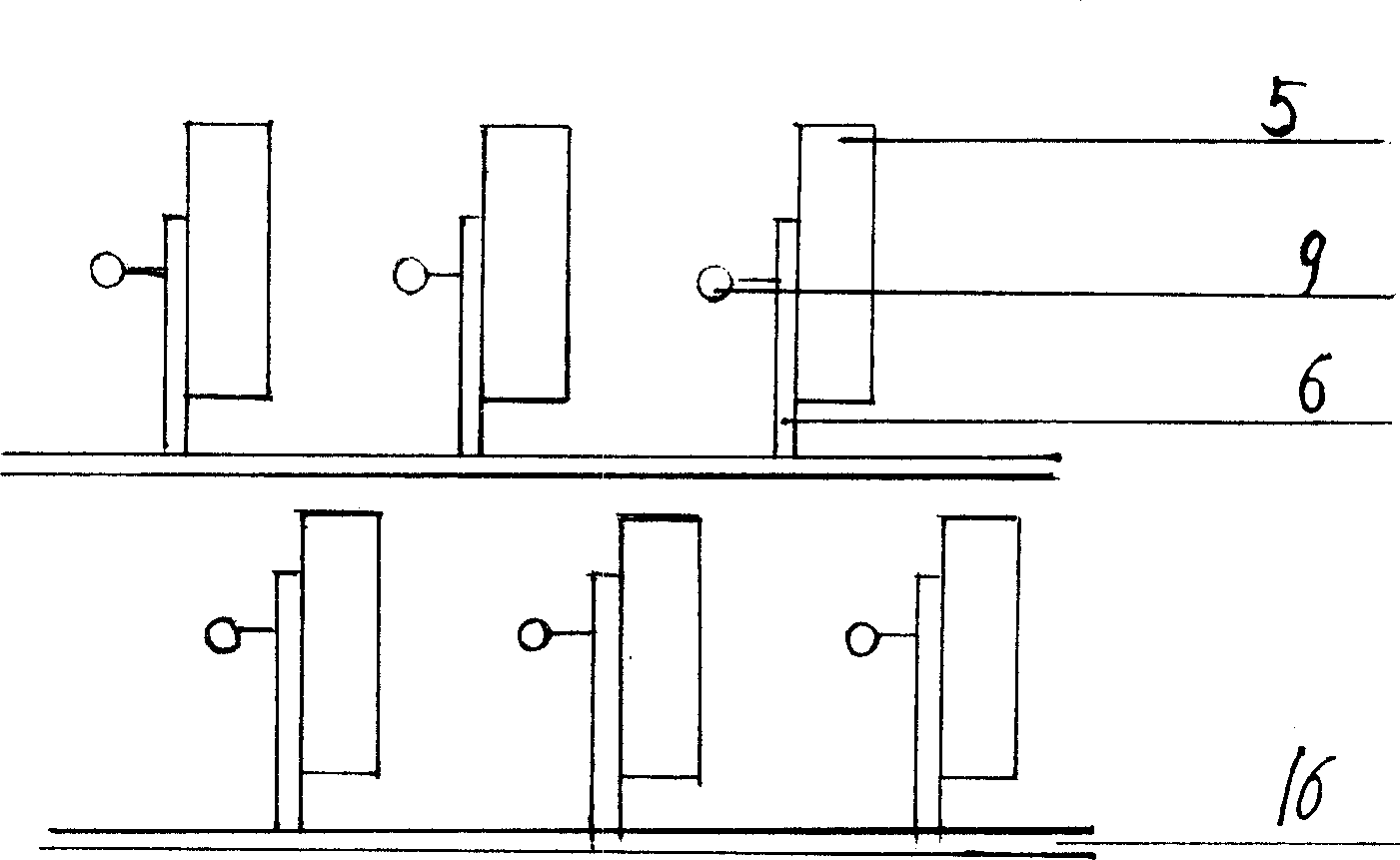

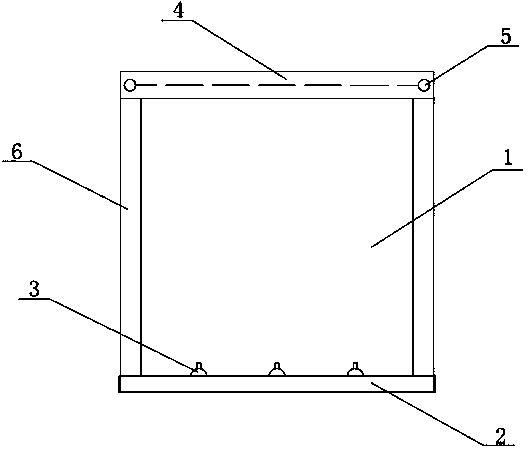

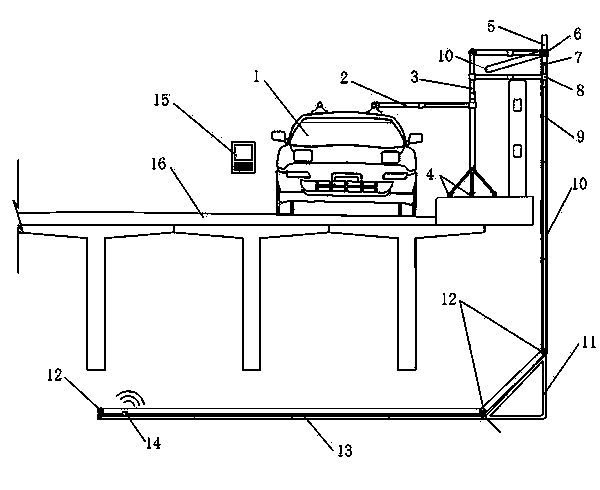

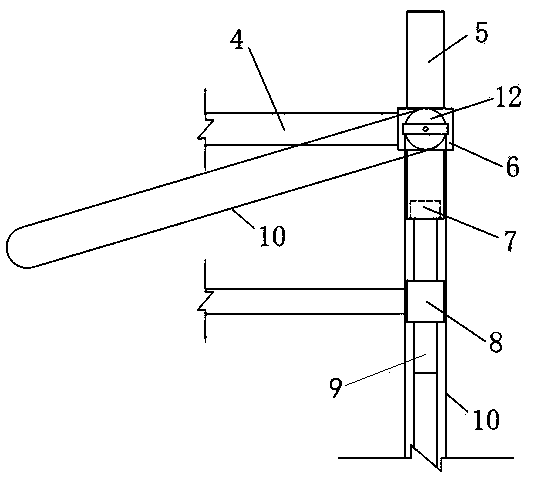

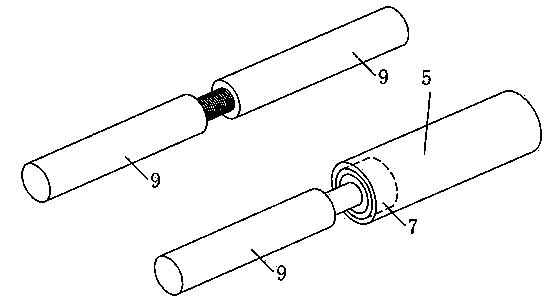

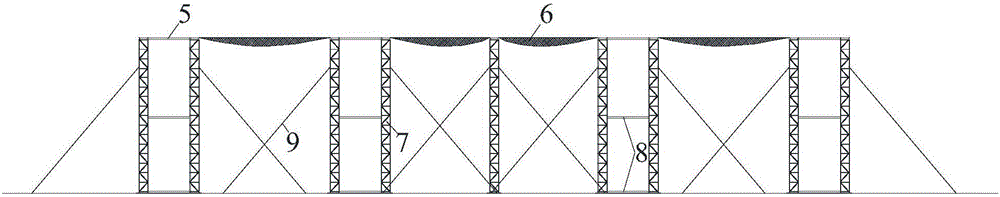

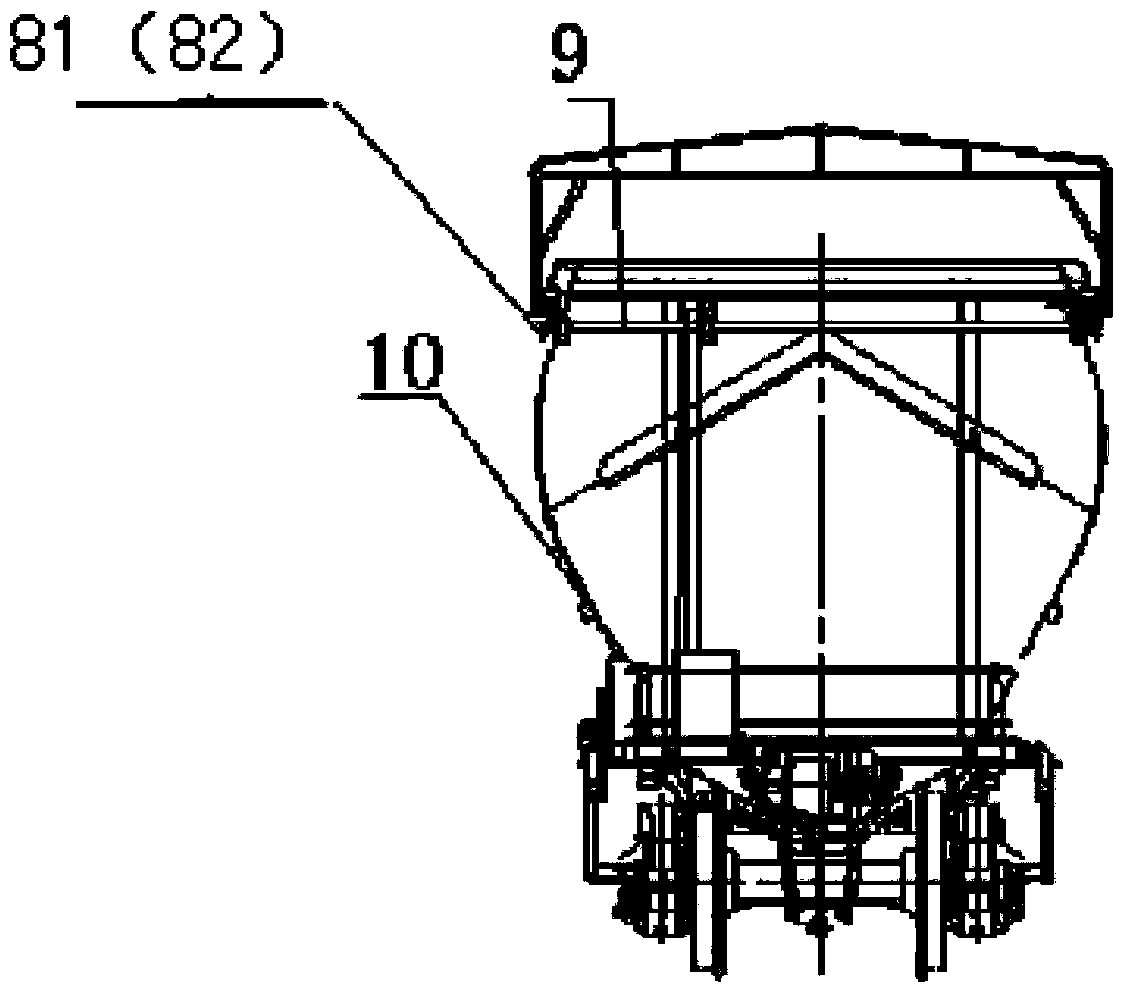

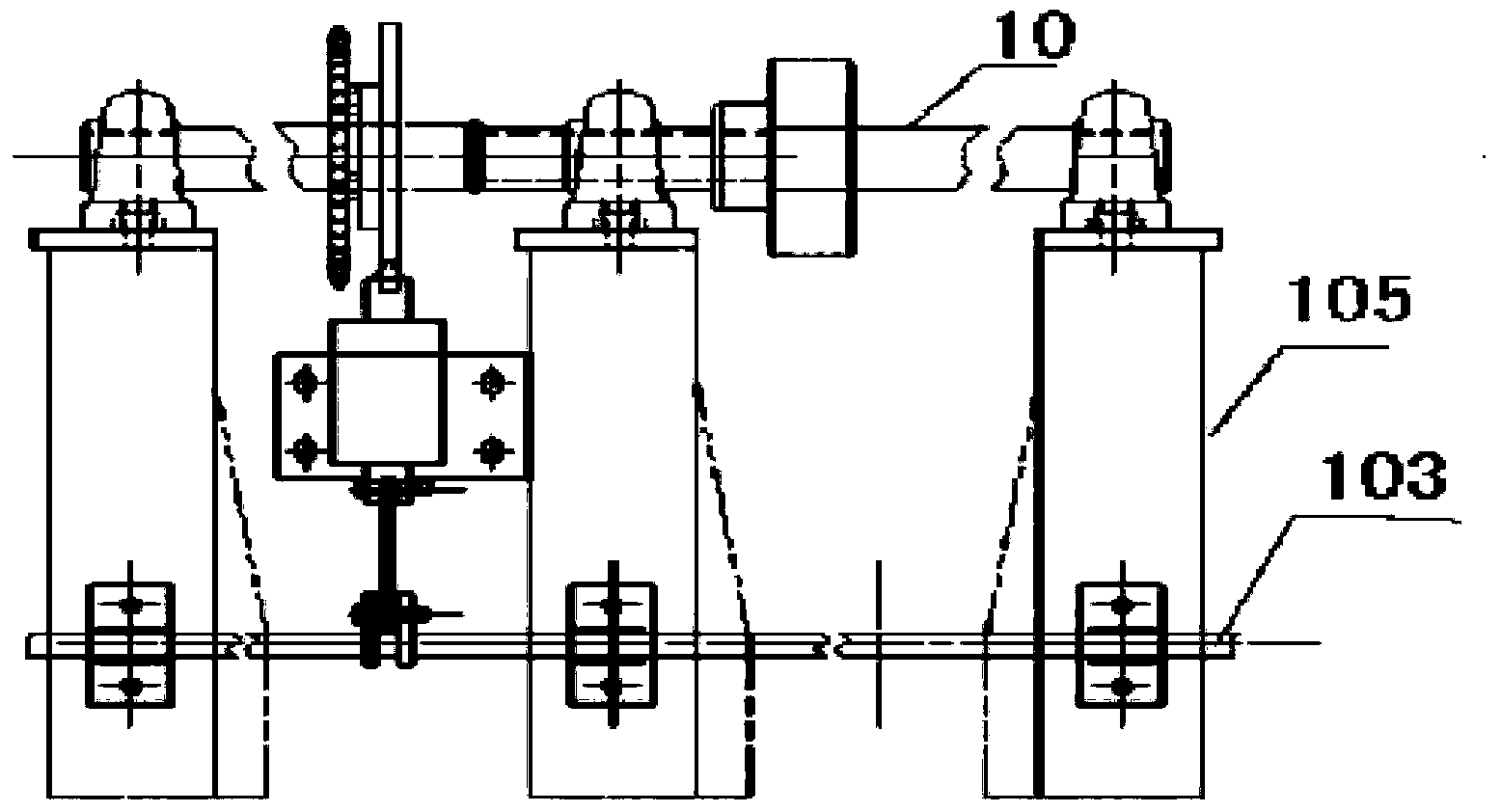

Portable test tower for transmission line insulator string high-voltage performance test

ActiveCN103175998AAvoid working at heightsReduce operational riskTowersMeasurement instrument housingTest powerElectrical performance

Disclosed is a portable test tower for a transmission line insulator string high-voltage performance test. The portable test tower is of a frame structure, bottoms of two supports (3) are fixed together by stone bolts (1) and bases (2) poured by concrete, two synchronous electric hoists (8) with self-locking function are arranged in the middle of a fixing pole arm (5) arranged at the tops of the supports (3), and respectively connected with two ends of a movable pole arm (6) under the fixing pole arm (5) with steel wire ropes (10) through fixing pulleys (12) close to tops of insides of the supports (3), and the movable pole arm (6) and fixing rails (4) arranged inside the supports (3) form guide rail pairs (7). The potable test power for the transmission line insulator string high-voltage performance test is convenient to assemble, and can be used for testing single-string insulator high-voltage performance, and testing interaction of electrical performance among multiphase insulators.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +2

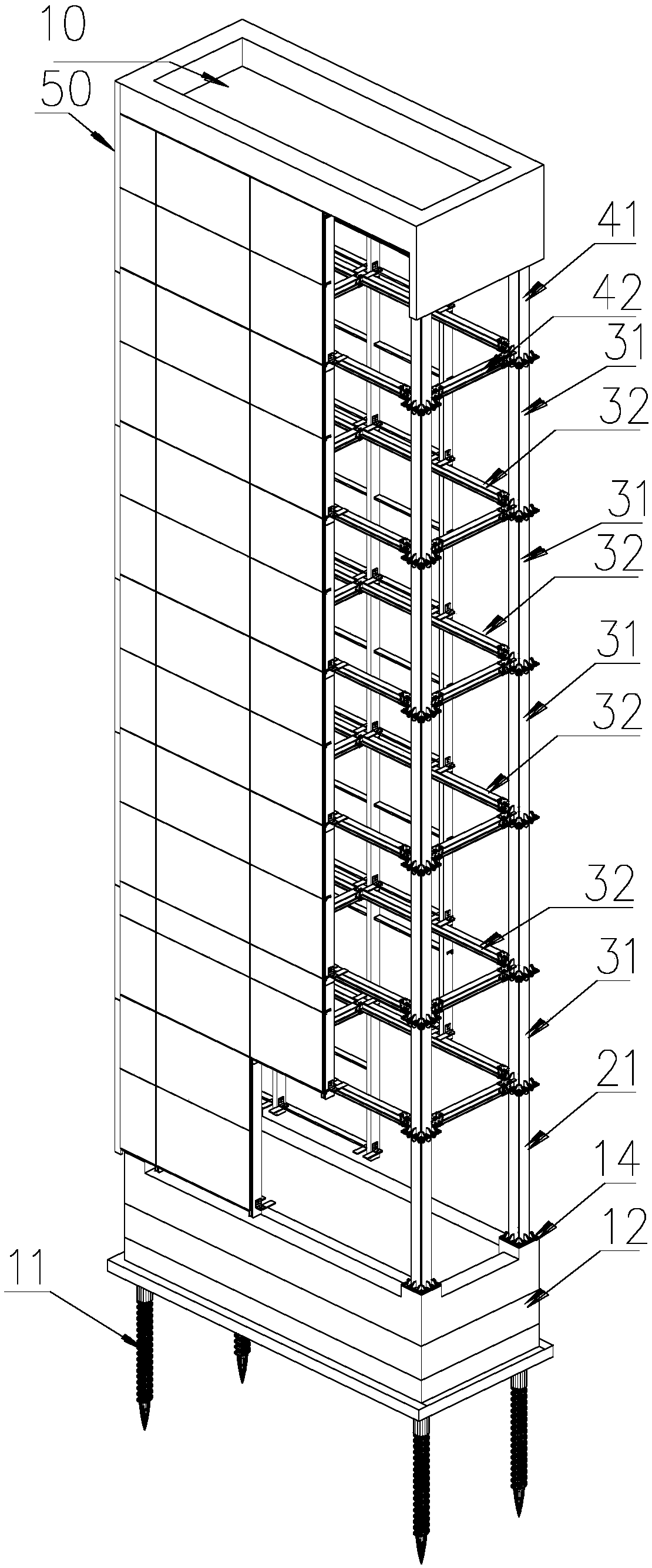

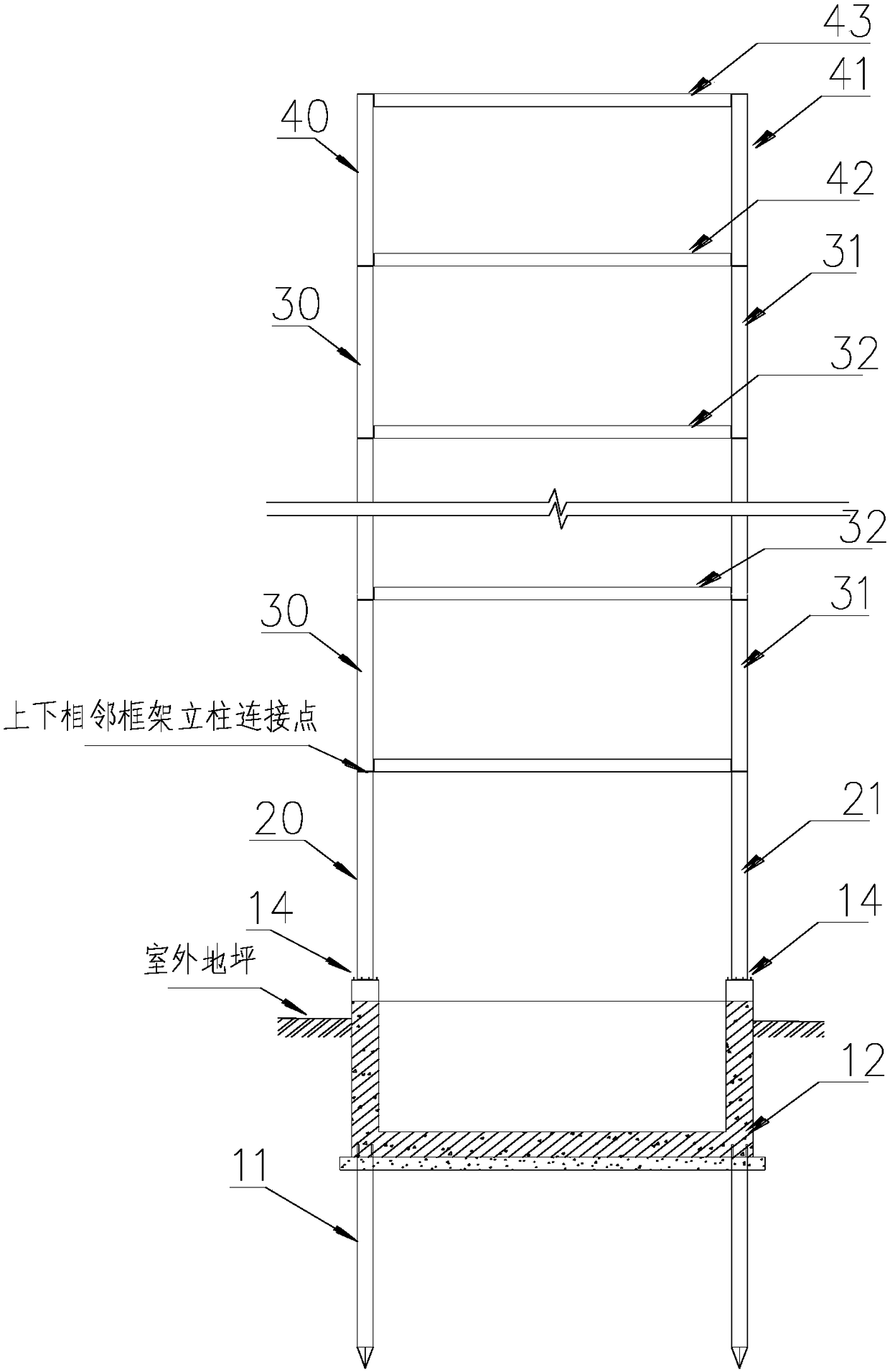

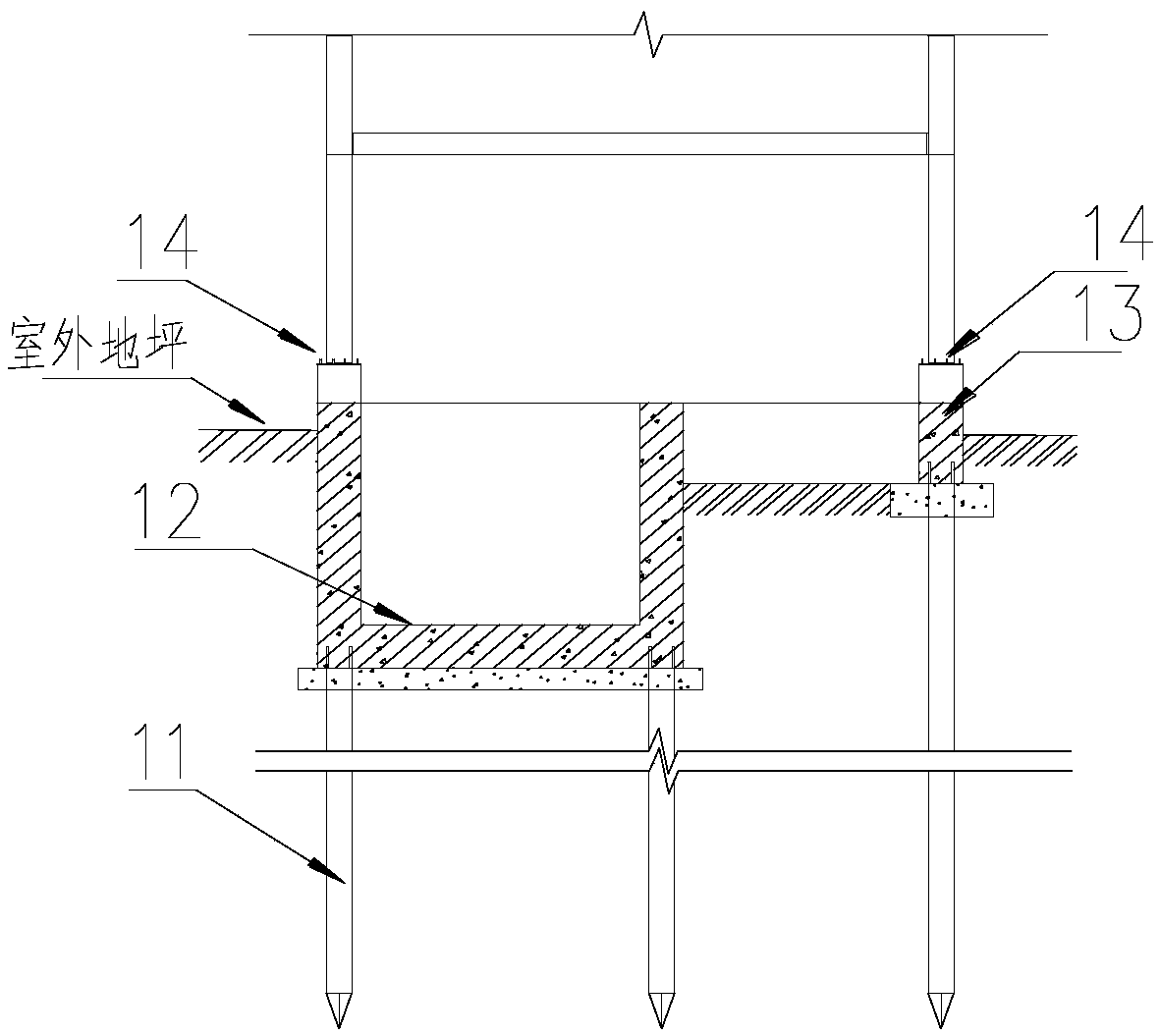

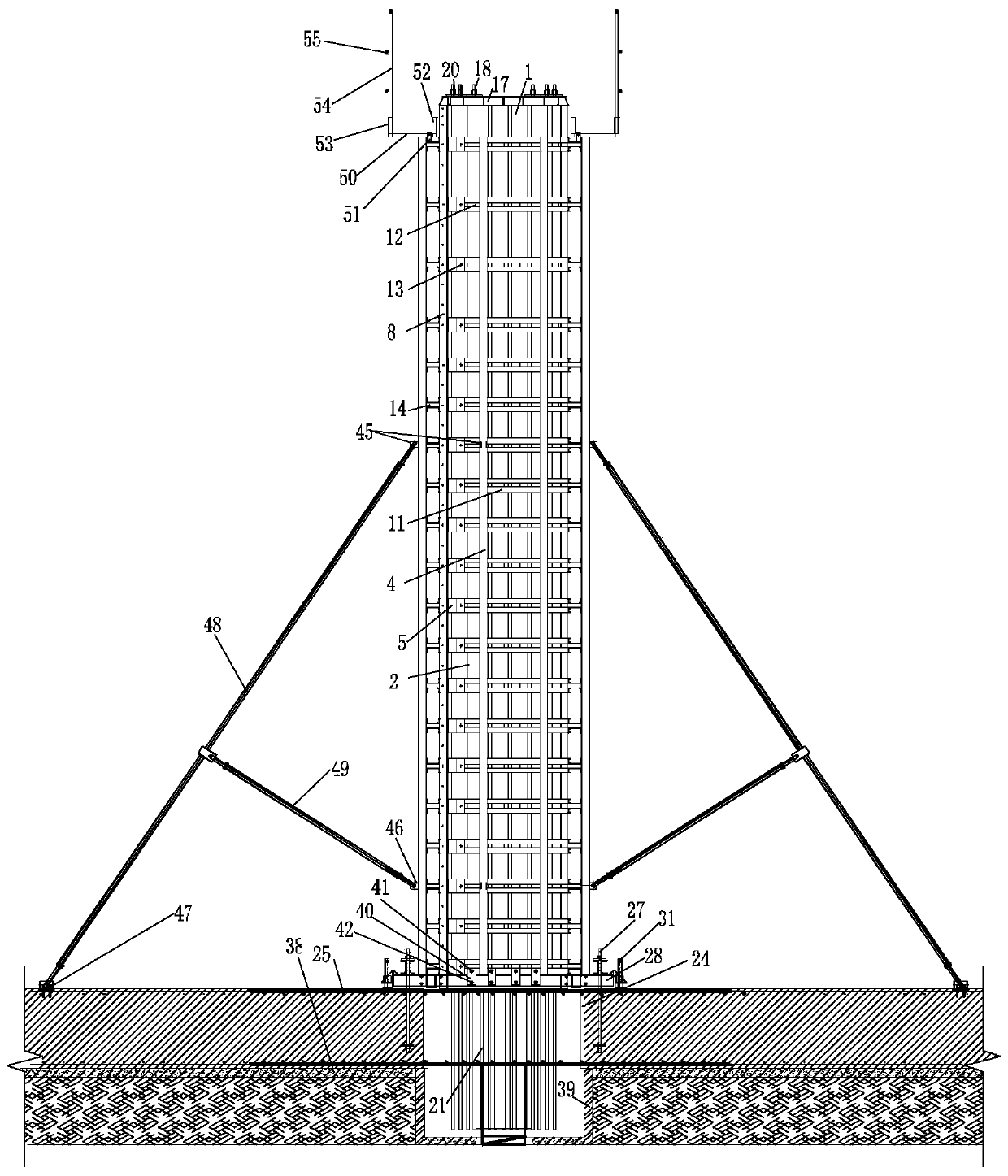

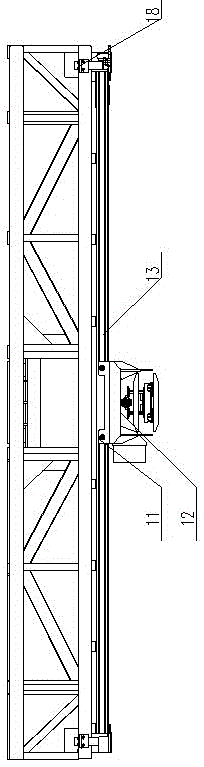

Jacking construction method for assembled-type external elevator shaftway structure

ActiveCN108532769ASmall space constraintsReduce the impactBuilding constructionsFalseworkReinforced concrete

The invention discloses a jacking construction method for an assembled-type external elevator shaftway structure. The jacking construction method comprises the steps that a foundation pit is excavated, and reinforced concrete foundations and pre-buried connecting components are made; a jacking guiding device is mounted on an existing building, and a jacking device is mounted at the bottom of the foundations; a jacking monitoring device is mounted on an assembled elevator shaftway top layer structure unit to conduct jacking operation of the top layer structure unit, the jacking operation stateis monitored in real time, and torsion or inclination of the structure is prevented cautiously; assembling and jacking of structure units of all standard layers are conducted in sequence, and a first-layer structure frame is mounted; equipment is dismounted, and an elevator shaftway and the existing building are connected through flexible connecting components layer by layer; construction of a roof, all layers of floors, partition plates and the first layer is conducted; and finally, an elevator is mounted. By adopting the jacking construction method, the occupied area is small, the period isshort, the efficiency is high, labor force is saved, heavy transportation vehicles and large lifting equipment are not needed, a scaffold does not need to be set up on site, and high-attitude operation and the influence on the daily life of residents can be reduced significantly.

Owner:华城(天津)建筑科技有限公司

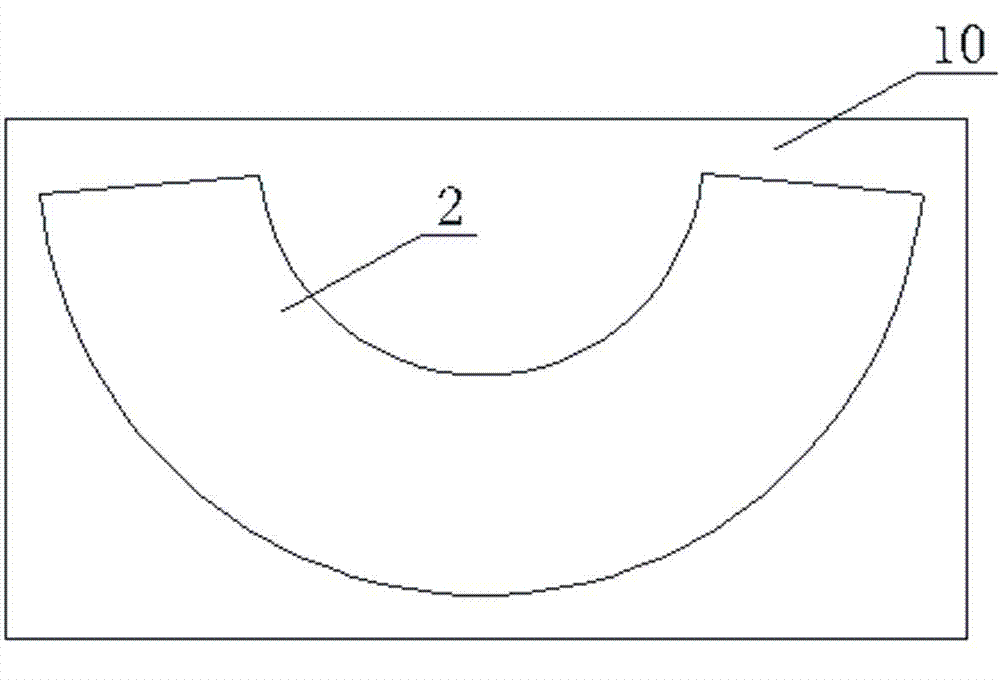

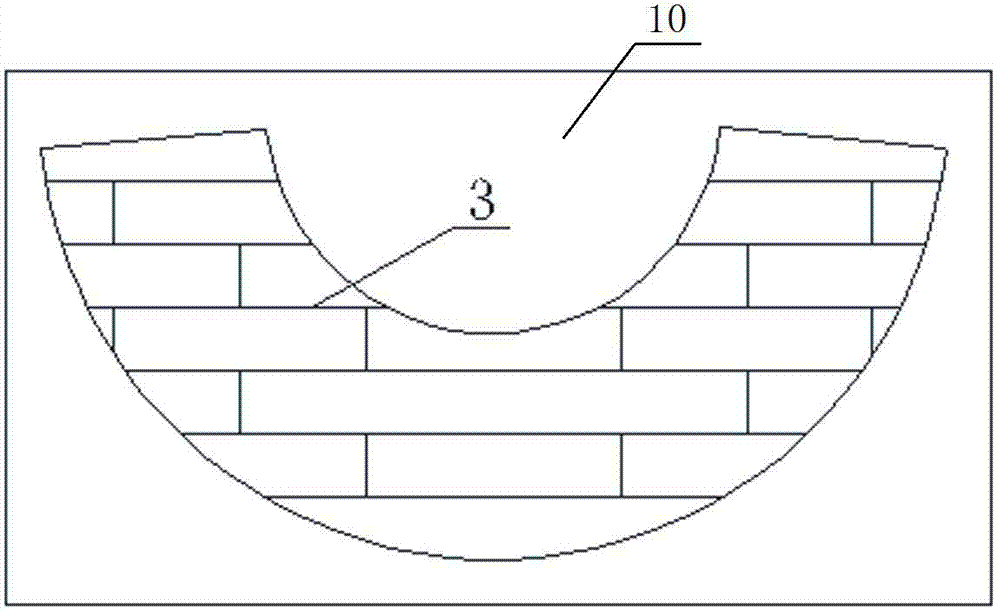

Manufacturing and installing method for upper cone on dry quenching furnace shell

ActiveCN104759856ASimplify the manufacturing processSimplify the installation processCoke quenchingWelding apparatusButt jointQuenching

The invention discloses a manufacturing and installing method for an upper cone on a dry quenching furnace shell. The method includes the following steps that the upper cone on the dry quenching furnace shell is set out into a fan-shaped sample plate, and the outline of the fan-shaped sample plate is drawn on a manufacturing plane according to the practical proportion; a steel plate is fully laid on the outline of the whole fan-shaped sample plate, and a fan-shaped steel plate is formed in a welding mode. Four lifting lugs are arranged on the fan-shaped steel plate, the two middle lifting lugs are connected with a crane lifting hook through steel wire ropes, and the lifting lugs on the two sides are connected with the crane lifting hook through chain blocks and steel wire ropes. After the fan-shaped steel plate is lifted through the crane, three lifting lugs are arranged on the inner side of the fan-shaped steel plate and adjust contracting of the lower end of the fan-shaped steel plate through pulleys, chain blocks and steel wire ropes, and a conical steel plate is formed. The conical steel plate is welded to be manufactured into the upper cone of the dry quenching furnace shell, the upper cone of the dry quenching furnace shell is lifted and is in direct butt joint with the dry quenching furnace shell, and installation is completed. According to the manufacturing and installing method for the upper cone on the dry quenching furnace shell, the upper cone of the dry quenching furnace shell can be integrally spliced on the ground to be used, a temporary platform does not need to be erected, and time, labor and materials are saved.

Owner:CHINA FIRST METALLURGICAL GROUP

Installing method of roof mast

The invention relates to an installing method of a roof mast. The method comprises the following steps: firstly, lifting up a whole steel tube assembly by a windlass; and stopping the windlass when the bottom of the steel tube assembly reaches a base of the lowest place; secondly, connecting a pair of hand-drive block stringers to an outermost layer of steel tube and lifting up or down the steel tube assembly in an alternative working manner in order to fine adjusting the height of the steel tube assembly till the outermost layer of the steel tube is arranged at the base of the lowest place and a base of the lower place, and then keeping the position of the steel tube assembly and welding and fixing the steel tube assembly; connecting the hand-drive block stringers to an innermost layer ofsteel tube in the steel tube assembly, lifting up the innermost layer of the steel tube in an alternative working manner, and stopping the lifting when the length of the sleeved part of the lower endof the innermost layer steel tube and the upper end of an inner layer steel tube sleeved on the innermost layer steel tube is ranged from 0.3-2 m, and then welding and fixing the innermost layer of the steel tube with the inner layer of steel tube; and finally, repeatedly lifting up and welding each remained section of steel tubes sleeved in the outermost layer of the steel tube, and then finishing the installation of the roof mast.

Owner:CHANGZHOU NO 1 CONSTR GRP

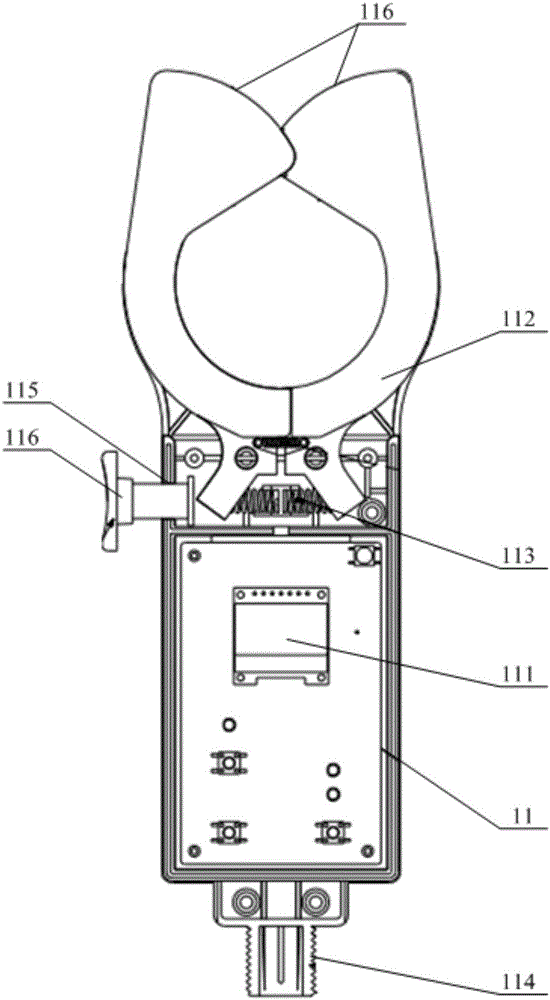

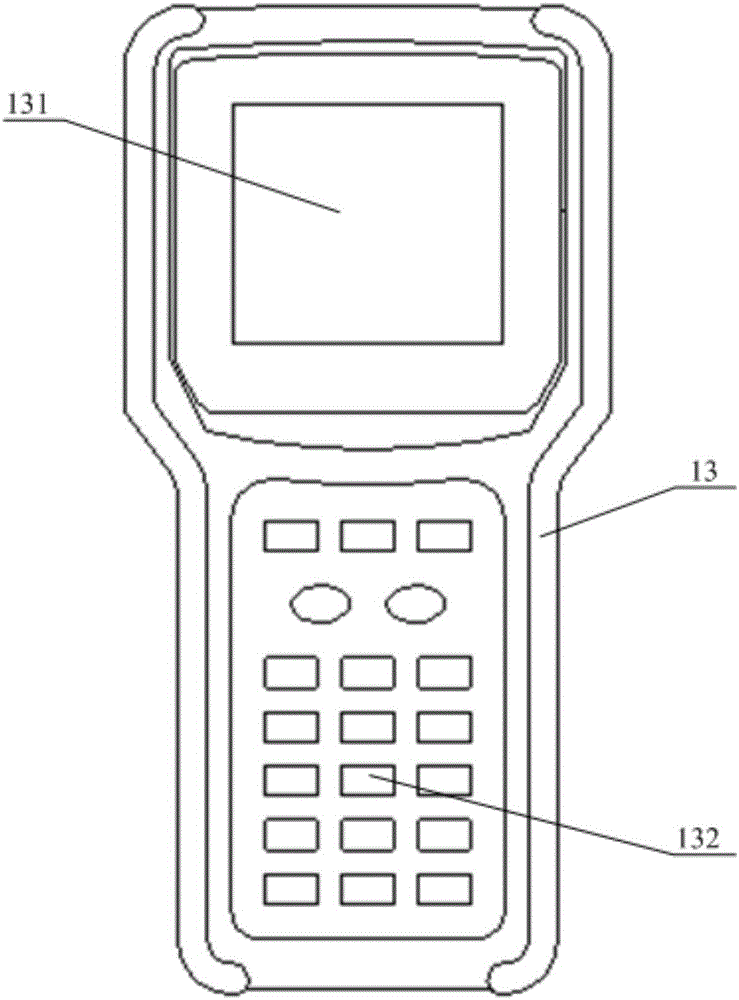

Electric leakage detection device

InactiveCN106370971AAvoid working at heightsAvoid operabilityElectrical testingMeasurement instrument housingEngineeringElectrical and Electronics engineering

The invention discloses an electric leakage detection device. The electric leakage detection device comprises a detection terminal, an insulated extension rod and a control terminal in wireless communication with the detection terminal, wherein an installation connector is connected between the detection terminal and the insulated extension rod; the detection terminal comprises a machine body; a detection module is arranged at the middle part of the machine body; a clamp is retractably arranged at the front end part of the machine body; a reset piece is clamped and connected between the inner end parts of two clamp bodies of the clamp; the control terminal comprises a handheld machine; the handheld machine is provided with a display screen and a keyboard. The electric leakage detection device disclosed by the invention is capable of safely and efficiently implementing electric leakage detection under different working conditions.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +1

Verticality control device for vertical structural column of integral steel platform formwork and construction method

ActiveCN109184172AAvoid uneven forceReduce adverse effectsIncline measurementScaffold accessoriesVertical barEngineering

The invention provides a verticality control device for a vertical structural column of an integral steel platform formwork and a construction method. The verticality control device is arranged on each of the unit formworks in the corners of a rectangular core cylinder. The verticality control device includes two first clamps, two second clamps, two bidirectional deviation correction adjustment components, a tilt sensor, and a computer in a central control room. The two first clamps are arranged at intervals, and sleeve a vertical structural column. The two second clamps respectively sleeve two horizontal connecting rods perpendicularly fixed to the vertical structural column. The two bidirectional deviation correction adjustment components are respectively hinged to the first clamps and the second clamps. The tilt sensor is installed on the top of the vertical structural column. The computer is connected with the tilt sensor. Each bidirectional deviation correction adjustment component includes a connector, an oil cylinder and an oil pump, wherein the connector includes two parallel cross bars and a vertical bar connected between the cross bars, one end of each cross bar is hingedto the corresponding first clamp and the other end is connected with a roller group, the maximum distance from the connecting shaft of the first clamp and the corresponding cross bar to the outer edge of the roller group is greater than the vertical distance between the connecting shaft and the shear wall of the core cylinder, one end of the oil cylinder is hinged to the second clamps and the other end is hinged to the connecting rods, and the oil pump is connected with the oil cylinder through an oil path.

Owner:SHANGHAI CONSTRUCTION GROUP

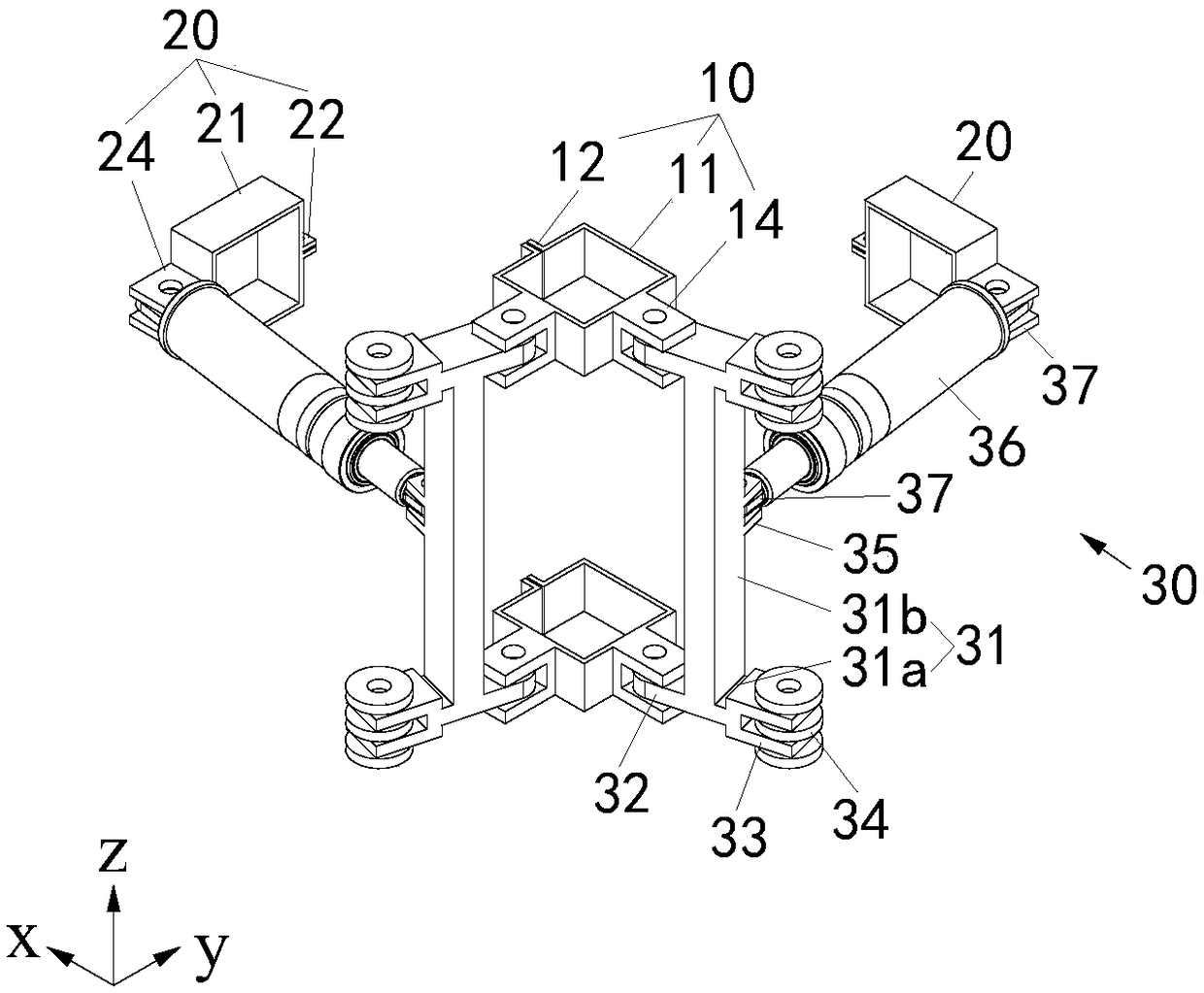

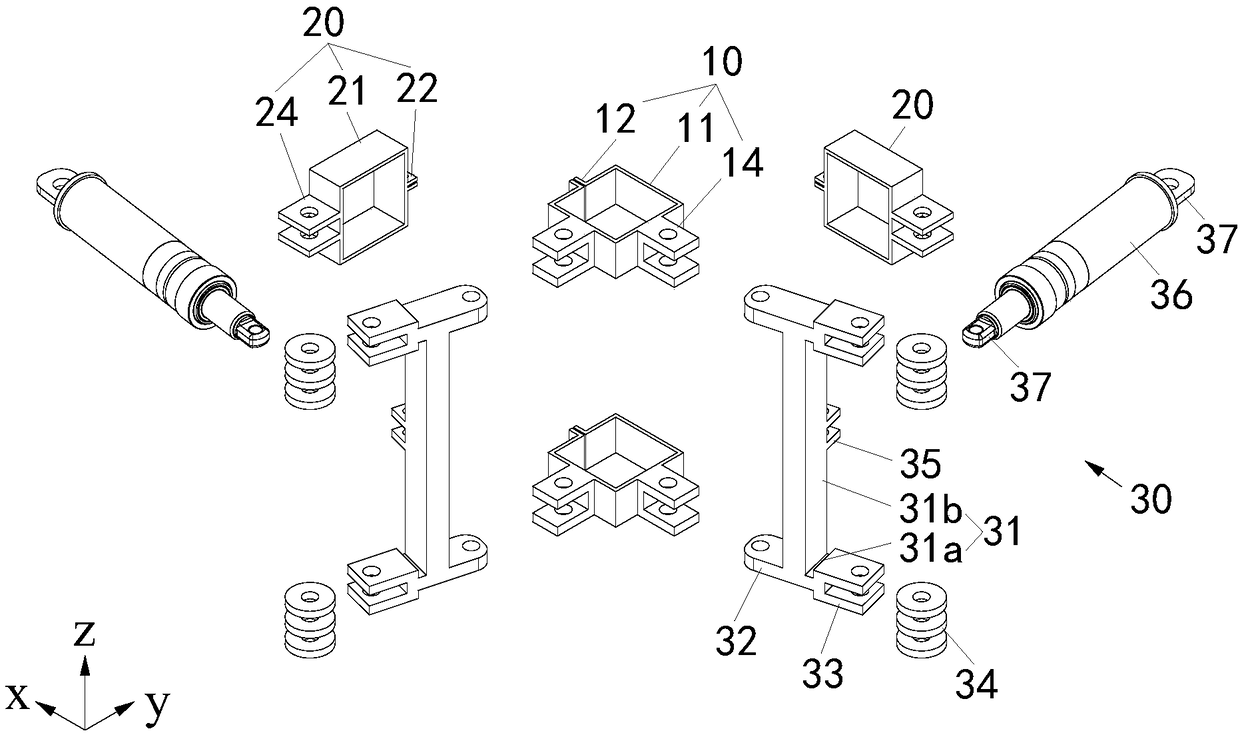

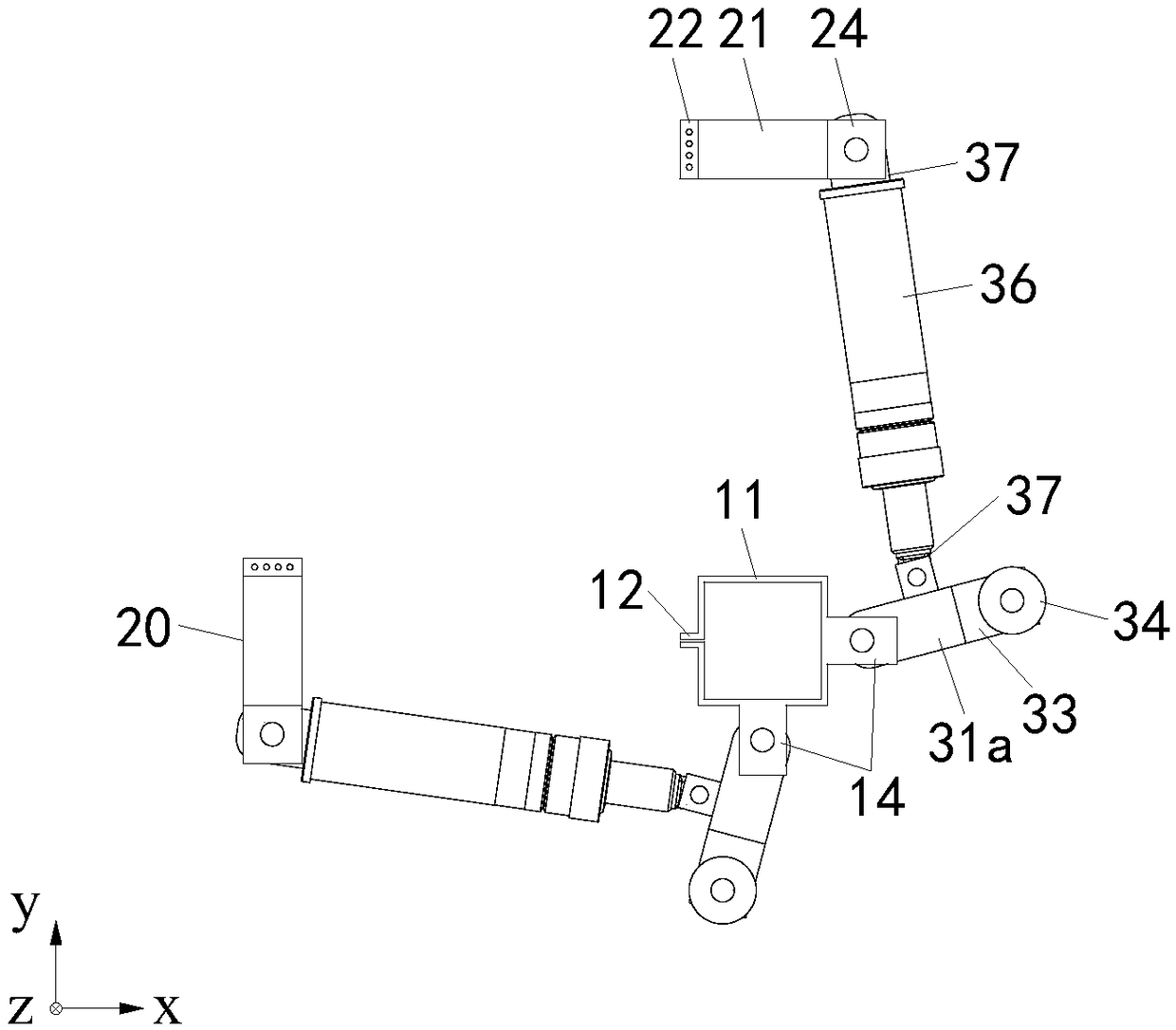

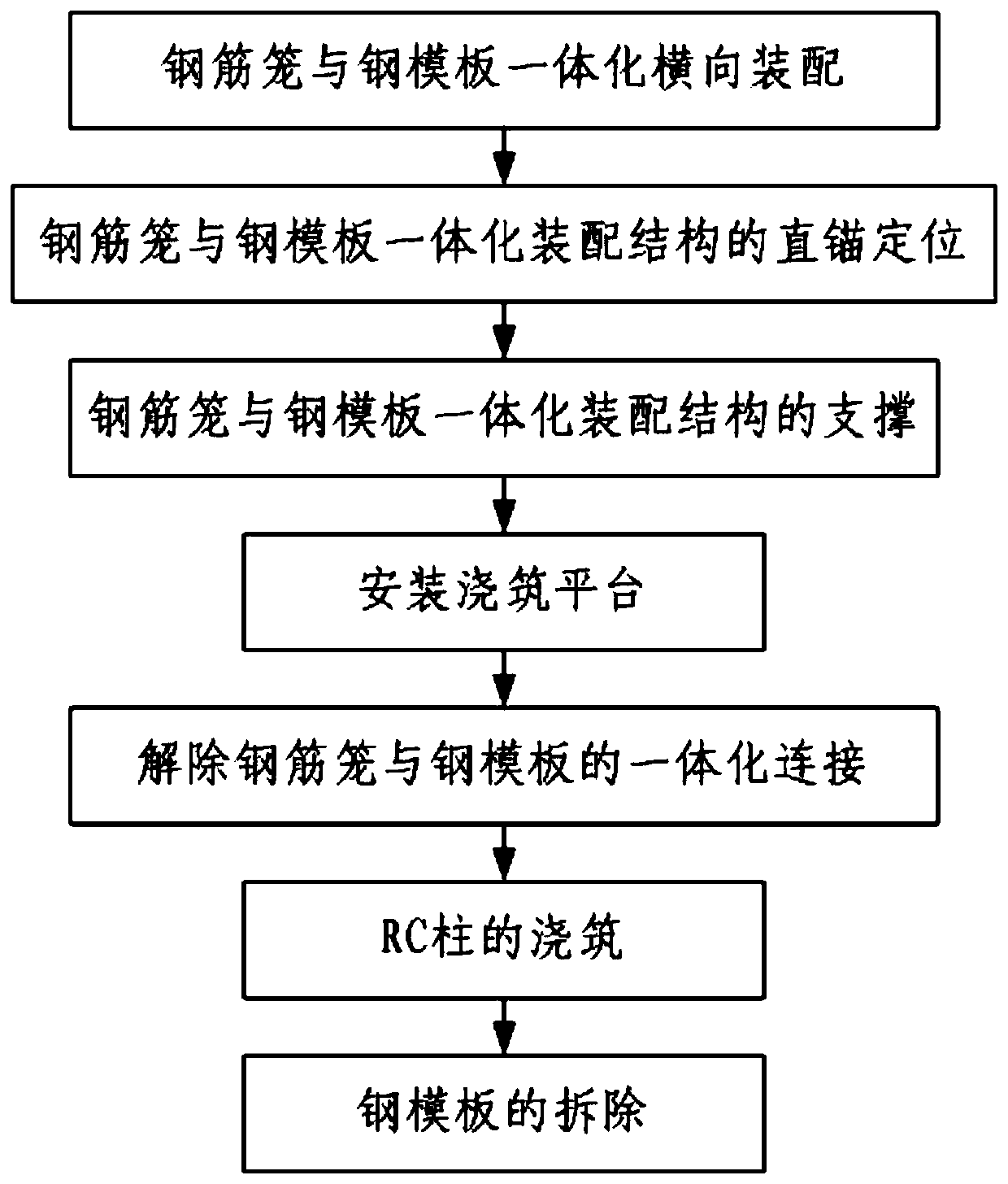

Construction method of semi-fabricated cast-in-place concrete column

ActiveCN110206228AAvoid complex constructionEasy hoisting and positioningStrutsForms/shuttering/falseworksArchitectural engineeringSlurry

The invention discloses a construction method of a semi-fabricated cast-in-place concrete column. The construction method comprises the steps of 1, integrally and transversely fabricating a reinforcement cage and a steel formwork; 2, carrying out straight-anchorage positioning on a reinforcement cage and steel formwork integrated fabricated structure; 3, supporting the reinforcement cage and steelformwork integrated fabricated structure; 4, mounting a pouring platform; 5, removing integrated connection between the reinforcement cage and the steel formwork; 6, pouring the cast-in-place concrete column; and 7, dismantling the steel formwork. The reinforcement cage and the steel formwork are integrally and transversely fabricated, construction of the reinforcement cage and the steel formworkin a construction site is avoided, and high-altitude operation is avoided; meanwhile, overall hoisting and positioning of the reinforcement cage and the steel formwork are facilitated in the later stage; the pouring platform is arranged at the top end of the reinforcement cage and steel formwork integrated fabricated structure in a sleeving mode, so that the integrated connection between the reinforcement cage and the steel formwork is relieved conveniently, and the concrete pouring work of constructors is facilitated; formwork splicing joints are avoided, no slurry leaks, and the cast-in-place concrete column is poured and formed at a time without construction seams.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

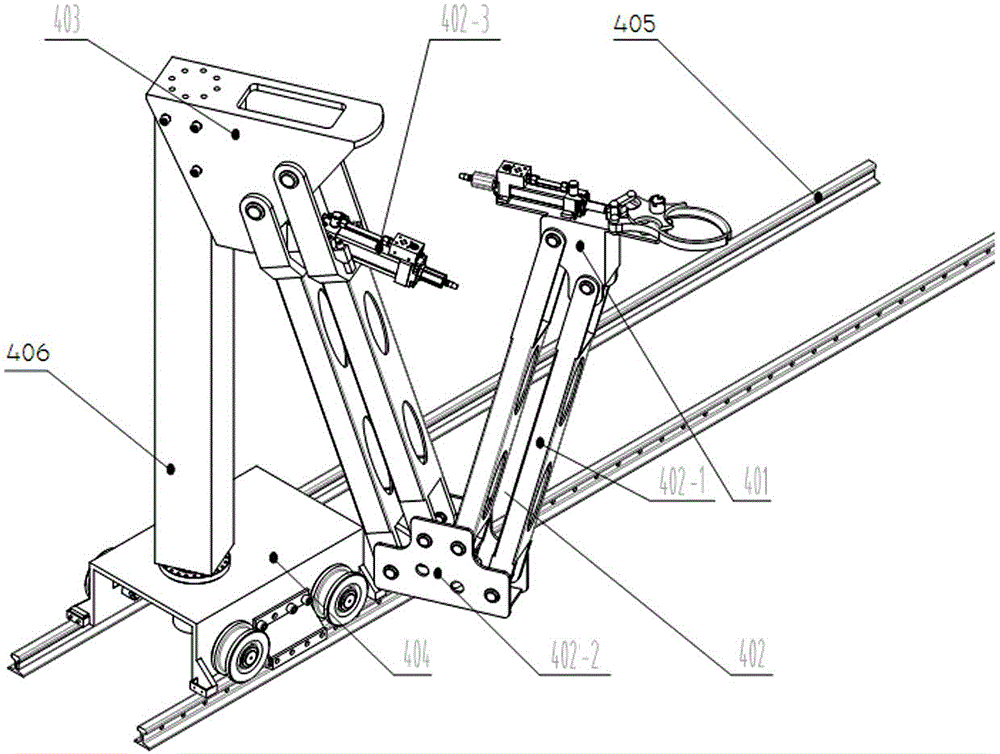

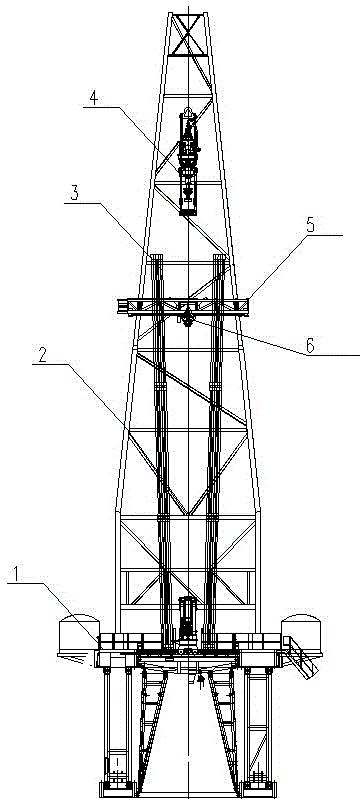

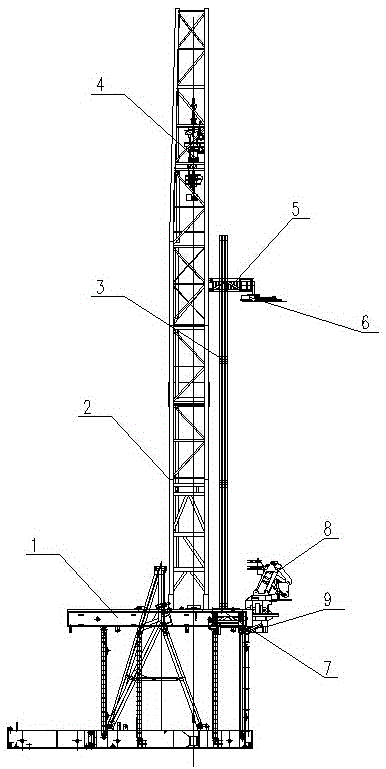

Automatic discharge device for drill strings

InactiveCN105484683AReduce labor intensityReasonable structureDrilling rodsDerricks/mastsManipulatorPetroleum

The invention relates to petroleum drill and exploitation equipment, in particular to an automatic discharge device for drill strings. A top drive is arranged at the top of a derrick, a two-layer platform is arranged in the middle, and a drill floor is arranged at the lower part; a stand platform is connected to the drill floor; an upper manipulator is connected to the two-layer platform and can move on the two-layer platform; a lower manipulator support is connected to the stand platform; a lower manipulator is connected to the lower manipulator support and can move on the lower manipulator support. The device can grip, move and discharge the drill strings automatically, reduces the labor intensity of workers, and is high in mechanical degree, safe to operate and applicable to various drilling platforms.

Owner:中石化四机石油机械有限公司 +1

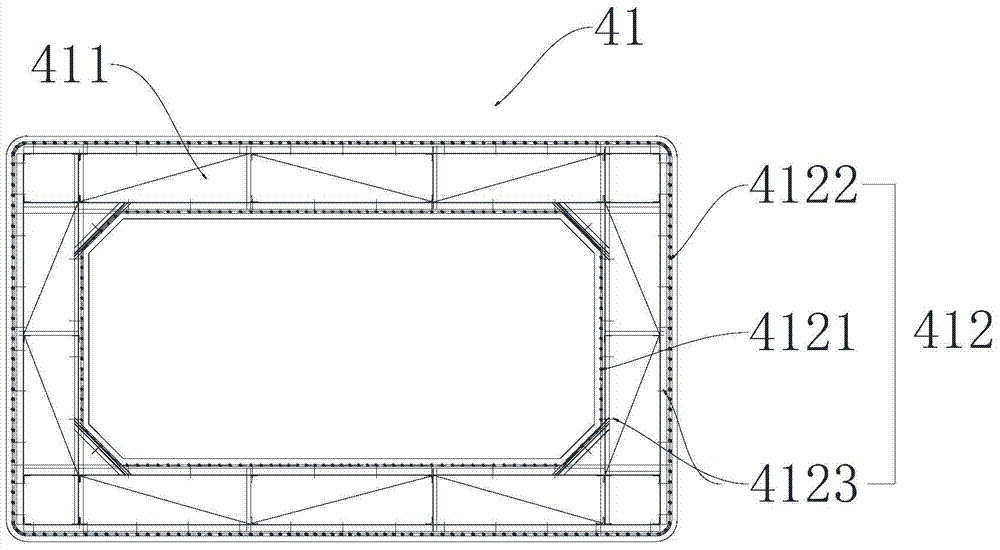

Method for mounting reinforcing steel bars of tower columns of cable-stayed bridge towers

ActiveCN104775364AShorten the timeAvoid working at heightsCable-stayed bridgeBridge structural detailsRebarCable stayed

The invention discloses a method for mounting reinforcing steel bars of tower columns of cable-stayed bridge towers. The method comprises the following steps: (1) arranging a tower crane on one side of a foundation platform of each tower along the axis of a bridge deck, and arranging two assembly jig frames, close to the corresponding tower crane, of each of two sides of the axis of the bridge deck; (2) pre-assembling reinforcing steel bar sections of the tower columns one by one in each assembling jig frame; (3) hoisting the first assembled reinforcing steel bar section as a first reinforcing steel bar section to the top end of the foundation platform of each tower and carrying out aligned connection, and then taking the reinforcing steel bar section as a frame to cast concrete; (4) aligning and connecting a next reinforcing steel bar section to the top end of the reinforcing steel bar section on which the concrete is cast, and taking the newly connected reinforcing steel bar section as a frame to cast concrete; (5) repeating the step (2) and the step (4) till finishing the mounting of the tower columns. According to the method disclosed by the invention, the construction efficiency of tower mounting is effectively improved, the construction quality is also effectively improved, and meanwhile, the construction safety is ensured.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Safe and reliable construction system for replacing columns by sustaining beams supported by columns and construction method for replacing columns by sustaining beams supported by columns

InactiveCN103758359AAvoid instabilityEnsure safetyBuilding repairsArchitectural engineeringTester device

The invention discloses a safe and reliable construction system for replacing columns by sustaining beams supported by the columns and a construction method for replacing the columns by sustaining the beams supported by the columns. The safe and reliable construction system comprises a plurality of supporting structures for replacing the columns by sustaining the beams supported by the columns, a computer, a static strain tester and a plurality of strain gauges, wherein each supporting structure for replacing the columns by sustaining the beams supported by the columns comprises a support, a base, a jack and a dial indicator; the bases are arranged on the ground; each jack is arranged on the corresponding base; the jack is provided with the corresponding support which is used for supporting the beams; each base is provided with the corresponding dial indicator for measuring supporting jacking amount; the outer wall of each support is provided with the corresponding strain gauges; each strain gauge is connected with the static strain tester of the corresponding supporting structure for replacing the columns by sustaining the beams supported by the columns through a corresponding signal line; and each static strain tester is connected with the corresponding computer. Loads of the columns are completely born by the supporting structures in a construction process of replacing the columns by sustaining the beams supported by the columns, and deformation of the beams is accurately controlled. Moreover, in a column load unloading process, stress of the supporting structures can be monitored in real time, and the supporting structures are ensured to be safe all the time. In a construction process, the structure stress of the safe and reliable construction system is clear, the deformation of the beams is controllable, and the construction process is safe and reliable.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

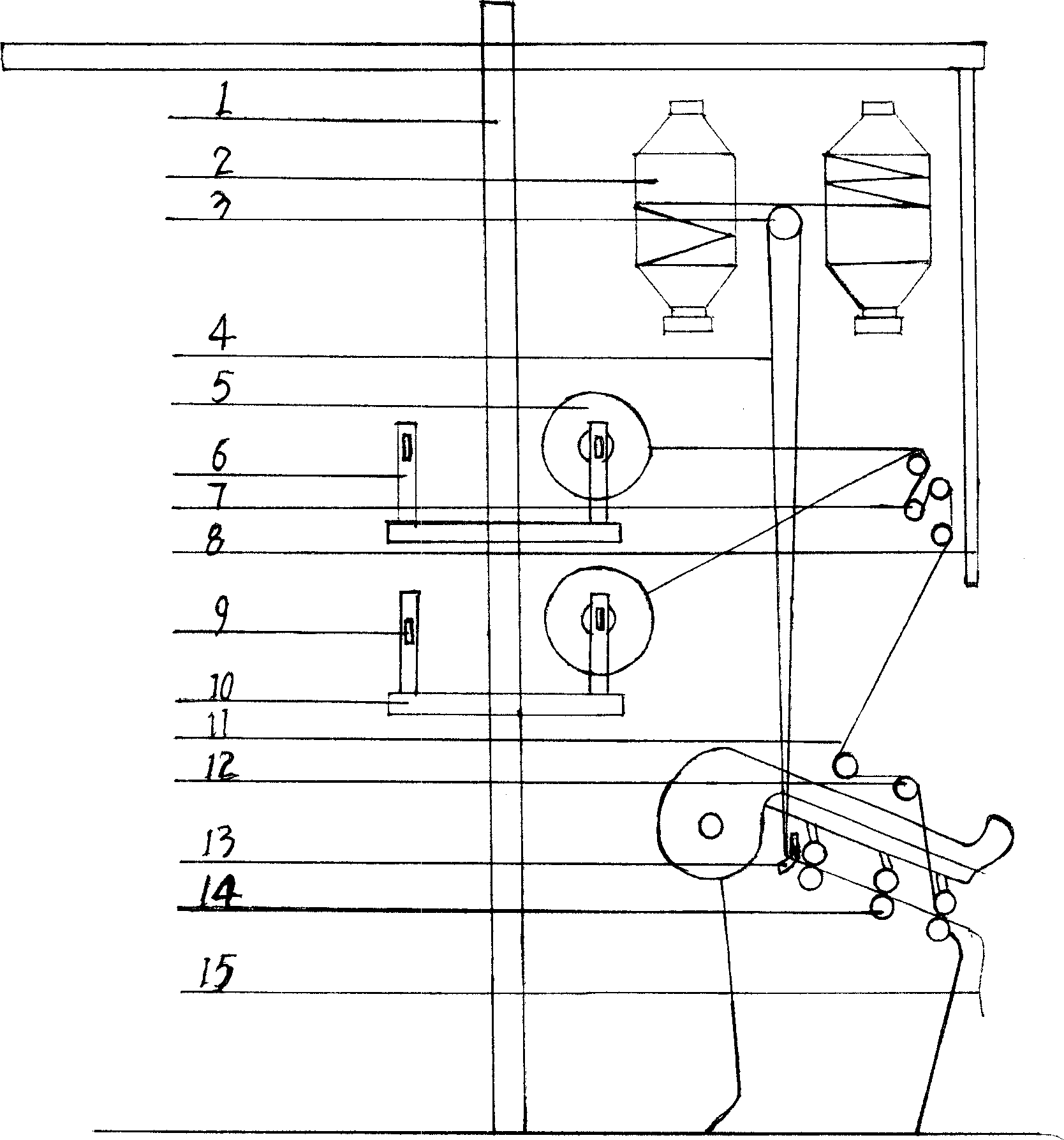

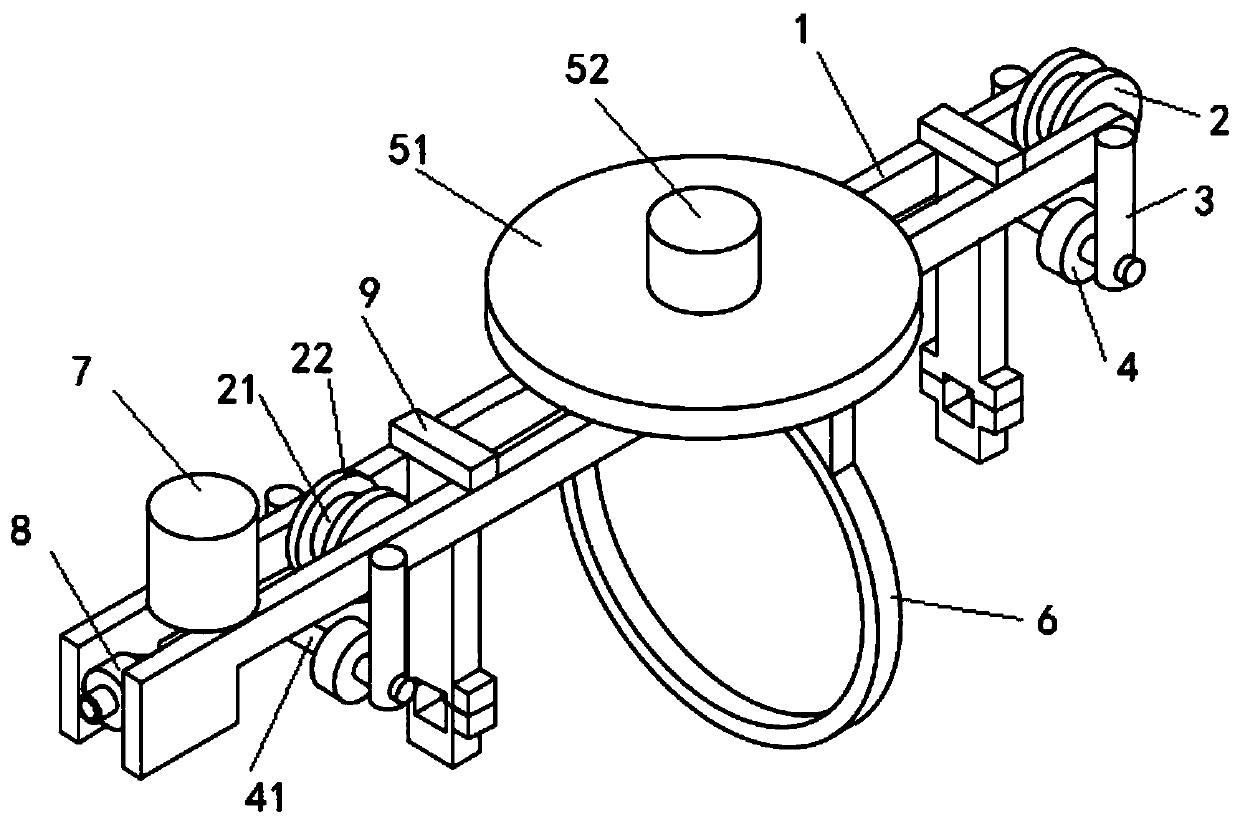

Under ring spindle device for spinning filament covered yarn

InactiveCN1824854AEasy to operateImprove ergonomics and yarn qualityContinuous wound-up machinesYarnEngineeringFilament yarn

The invention relates to a down locating circle ingot spinning filament lapping yarn device that belongs to lapping yarn technology field. It is made up of roving supporting structure, filament cake supporting structure, four bar strain structure, and spinning frame stretching structure. The filament cake supporting structure is located under the spinning frame. The roving of the roving supporting structure is actively connected to the spinning frame stretching structure. The filament of the filament cake supporting structure connects to the spinning frame stretching structure. The advantage of the invention is that the efficiency and quantity would be improved, the waste of filament and cotton would be decreased, and consumption would be declined; the structure is simplified and the cost is lowered, etc.

Owner:烟台金源纺织科技有限公司

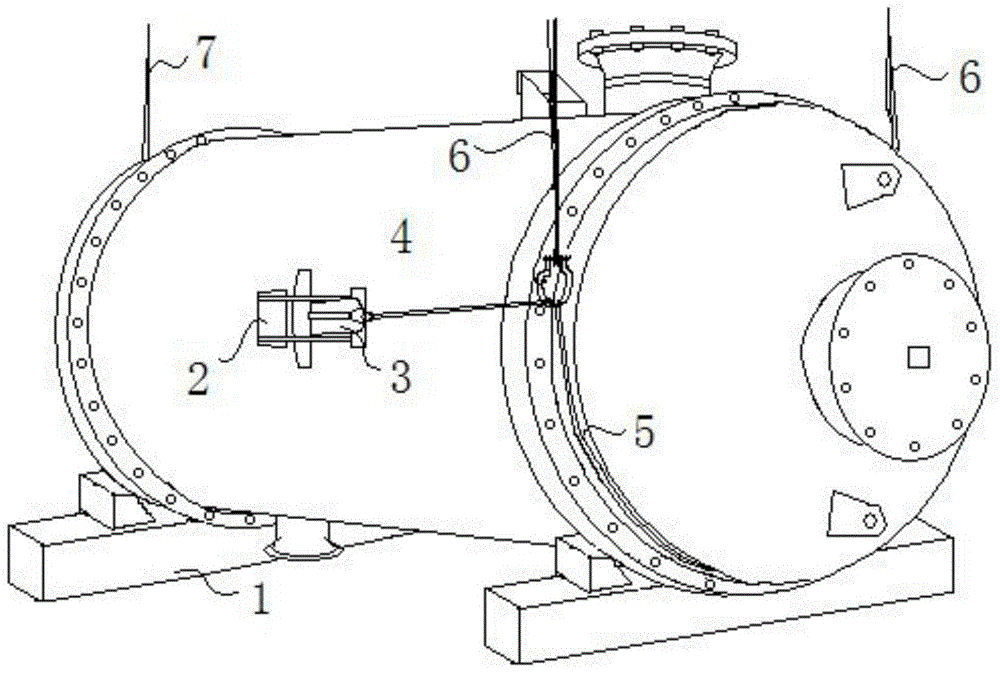

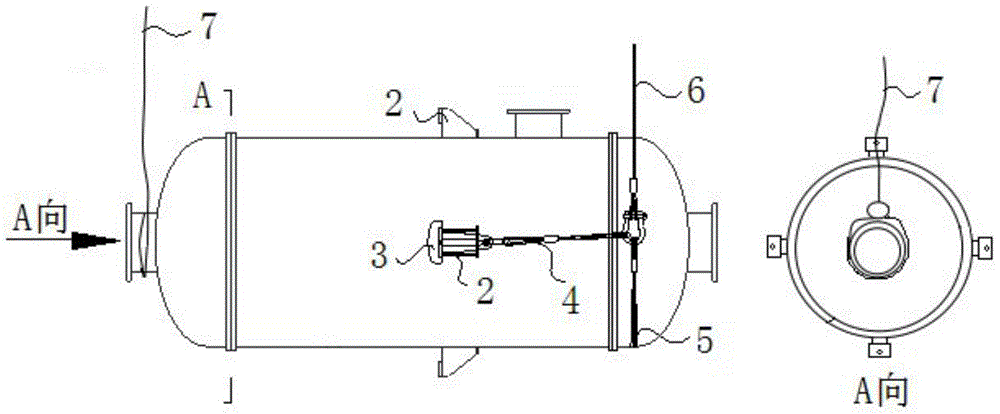

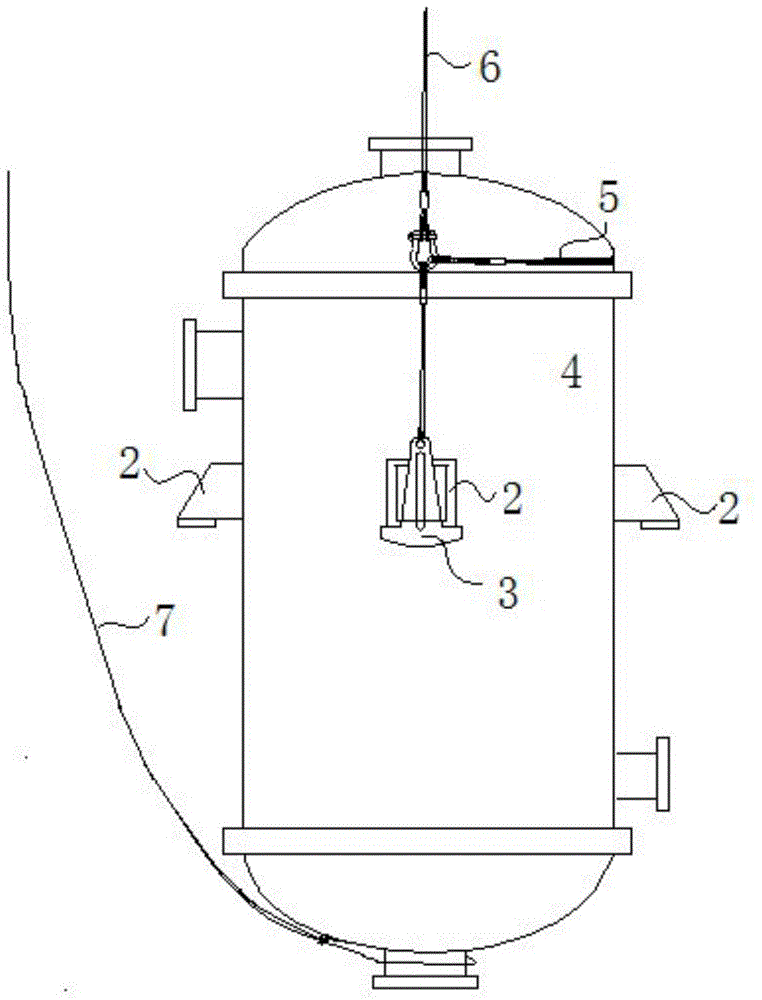

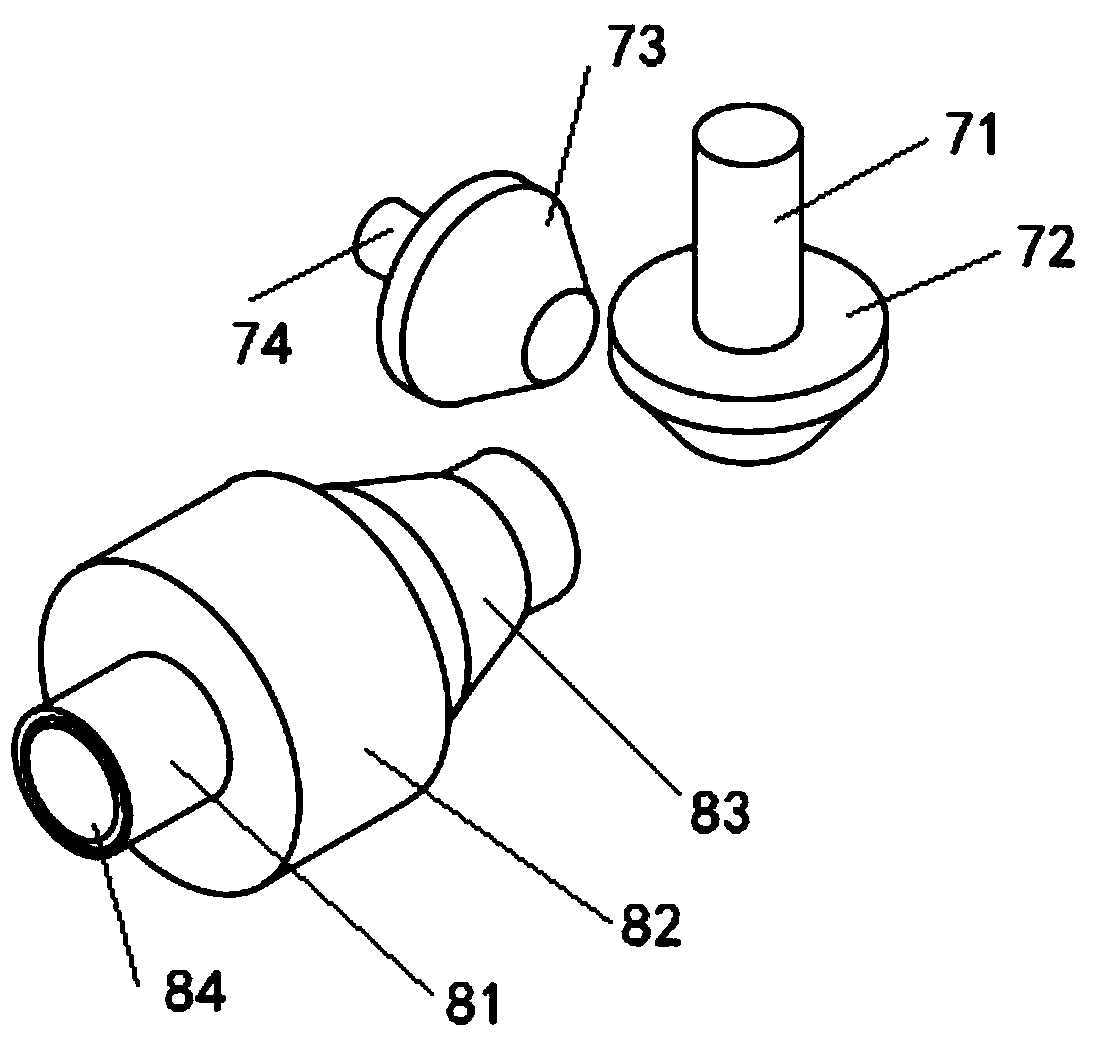

Method for rapidly hoisting suspended type vertical vessel

The invention discloses a method for rapidly hoisting a suspended type vertical vessel, and belongs to the field of equipment hoisting. The hoisting method comprises steps as follows: equipment enters a field and is unloaded; a lifting appliance system is suspended; the equipment is hoisted; the equipment is in place; and the equipment is aligned and fixed, and the lifting appliance is removed, wherein the lifting appliance system comprises slings and anchor lifts; each anchor lift comprises an anchor hanging part and a penetrating part which are mutually perpendicular to form a T shape; a ring clamping hole is formed in one end, far away from the anchor hanging part, of each penetrating part and used for being connected with the slings; the slings comprise connecting slings used for connecting the anchor lifts and main slings, a bottom carrying sling used for bearing head raising force of the suspended vertical vessel as well as main slings connected with the connecting slings and the bottom carrying sling, the length of the bottom carrying sling is equal to the half perimeter of the outer wall of the top of the suspended type vertical container, and the connecting slings are located above the horizontal line. The defect of a conventional hoisting method is overcome, and the suspended type vertical vessel is safely, rapidly, conveniently and economically hoisted.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Aging-resistant flame-retardant power cable mobile detection platform

ActiveCN110487817AEasy to observeEasy to analyzeMaterial analysis by optical meansPower cableEngineering

The invention discloses an aging-resistant flame-retardant power cable mobile detection platform, which comprises two parallel main frame rods. Two ends of the two main frame rods are connected through a lead device; and the main frame rod is fixedly provided with a stabilizing disc, a fixing ring, stretching rods and front driving structures. When the cable is detected, the cable is clamped by aguide wheel and a pressing wheel at the end of the main frame rod, so that the cable in the detection platform is in a tight state. Two stretching rods guides the cable to be away from the main framerod, the cable passes through a mounting ring, enough space is thus left around the cable for mounting multiple cameras, and the surface of the cable can be observed in all directions. The front driving structure mounted at one end of the main frame rod drives the whole mobile detection platform to move on a high-altitude cable, a carding tube is driven to rotate, the surface of the cable passingby is cleaned, the impact of surface pollutants on observation results is reduced, the detection platform moves on the cable by the self power, and long-time high-altitude operation by a worker is avoided.

Owner:安徽上造智能设备科技有限公司

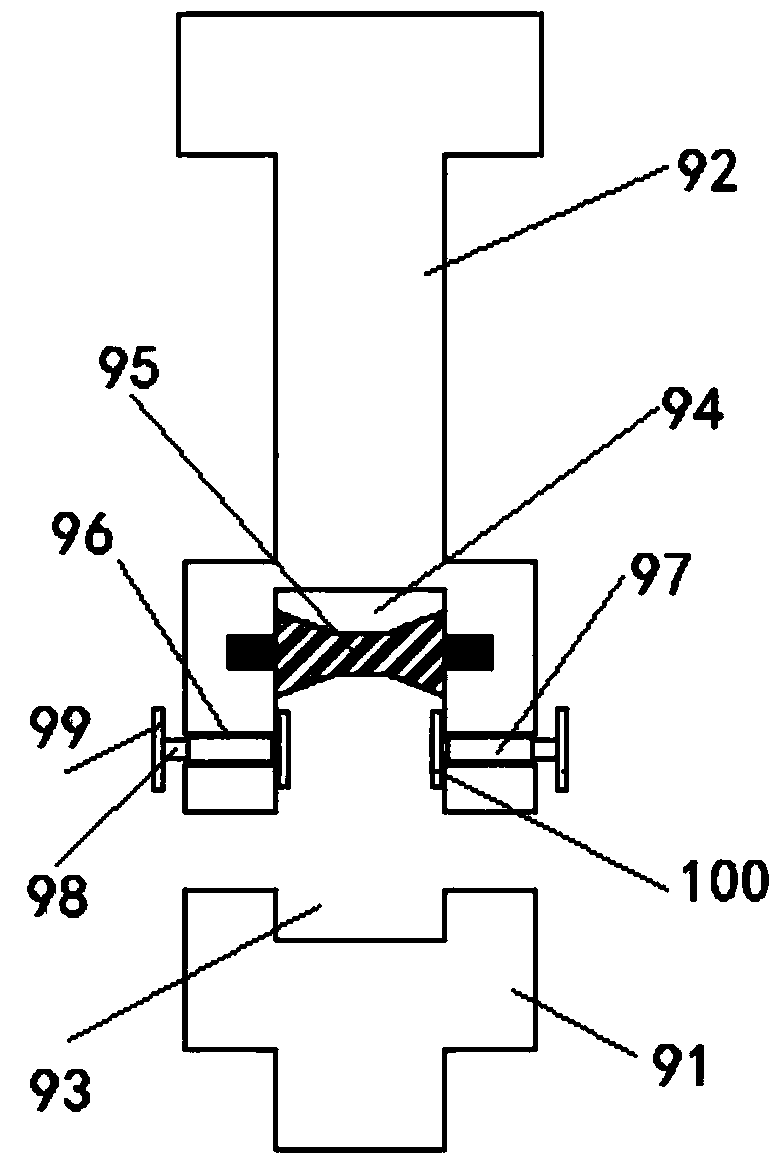

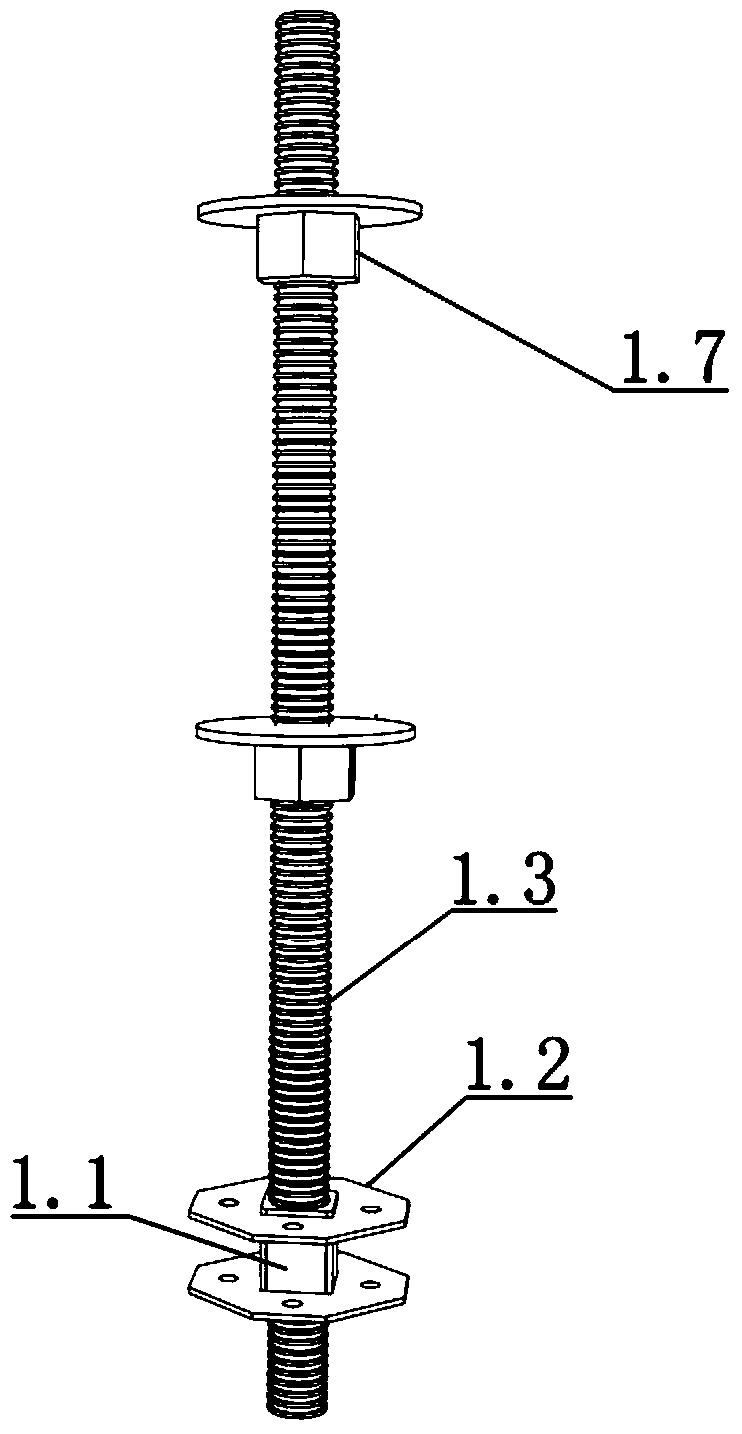

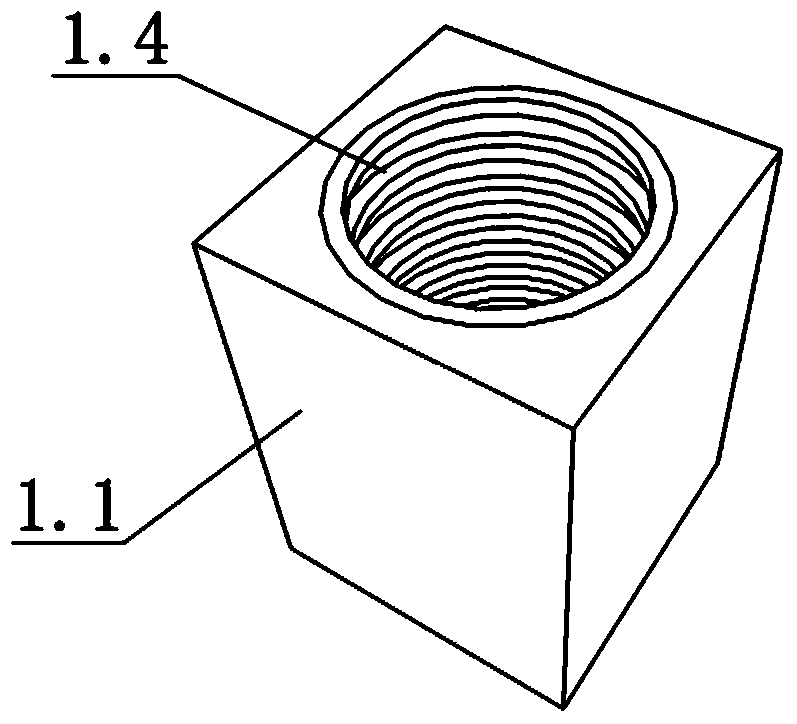

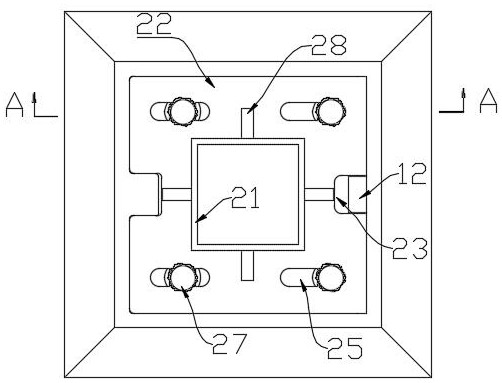

Screw pin clamping plate joints, independent frame, independent mold frame and construction method of independent mold frame

ActiveCN104295084AAvoid working at heightsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringSafe operation

The invention provides screw pin clamping plate joints, an independent frame, an independent mold frame and a construction method of the independent mold frame. Each screw pin clamping plate joint is formed by combining a joint core, a clamping plate and a screw pin. The independent frame is a framework unit formed by combining and connecting four vertical rods, eight transverse rods and the four screw pin clamping plate joints or is a splicing framework formed by splicing two or more framework units. The independent mold frame comprises the independent frame, templates and positioning rods. According to the crew pin clamping plate joints, the independent frame, the independent mold frame and the construction method, general accessories are connected to form the plane frame or the stand, the purpose that an integrated mold frame device is formed by combining the frame serving as the mold and the stand serving as the body is achieved, and according to the concrete construction process characteristics, the integrated device is formed through combination and is constructed through big mechanization hoisting. The independent mold frame serves as an auxiliary construction circulation device and is simple, convenient and fast to use, flexible, practical and multiple in purpose and function, the overall process circulation construction of whole preassembling, carrying, hoisting, positioning, sizing, mold assembly, and demolding is finished in a mechanization mode, the carrying frequency is reduced, safe operation is achieved, the loss is avoided, economization and environmental protection are achieved, and precise construction is achieved.

Owner:朱宏宇

Light-emitting type digital display furnace roller precision measurement device

ActiveCN106323142AImprove online detection efficiencyReduce labor costsAngles/taper measurementsIncline measurementMeasurement deviceEngineering

A light-emitting type digital display furnace roller precision measurement device provided by the present invention comprises an examination shaft, dial indicators, a frame-type gradienter, a connection swinging rod and a digital display dial indicator. The two dial indicators are connected with the examination shaft movably, the center lines of the measuring rods of the dial indicators are parallel with the shaft center line of the examination shaft, and the frame type gradienter is arranged on the outer circumferential wall of the examination shaft. One end of the examination shaft is connected with a roller shaft of a furnace roller detachably and coaxially, and the other end is connected with the lower end of the connection swinging rod vertically. A contact type indicating lamp is arranged on the upper end face of the connection swinging rod, the upper end of the connection swinging rod is connected with a cross bar connected with the digital display dial indicator, and a switch circuit of the contact type indicating lamp is connected with the digital display dial indicator and a reference steel wire separately. The light-emitting type digital display furnace roller precision measurement device can measure the efficiency and the precision, enables the labor intensity of workers to be reduced, can eliminate the potential safety hazards, and can effectively relieve the problem that there is not existed enough time to overhaul a travelling crane annually.

Owner:MCC BAOSTEEL TECH SERVICE

Glass curtain wall easy to clean

InactiveCN103669660AAvoid working at heightsSpray all overWallsCleaning using toolsWater storage tankMechanical engineering

The invention relates to the technical field of building auxiliary appliances, in particular to a glass curtain wall easy to clean. The glass curtain wall comprises a glass plate which is fixed onto a wall bracket. The bottom of the glass plate is provided with a water storage tank which is provided with water spouts with openings facing upwards. A scraper is arranged above the glass plate and fixed inside the same through universal driving shafts, and two sides of the glass plate are provided with moving slideways. According to the technical scheme of the glass curtain wall easy to clean, the outer wall of the glass curtain wall can be effectively and easily cleaned, and convenience is brought to users.

Owner:CHONGQING CHENGSHUO TECH

Bridge inspection device capable of transmitting videos in real time

InactiveCN104195943AAvoid working at heightsImprove securityBridge structural detailsBridge inspectionEngineering

A bridge inspection device capable of transmitting videos in real time comprises a telescopic support, a connection rod, pulleys, ropes and a camera. The middle of the telescopic support is connected with the connection rod, and the other end of the connection rod is fixed to a car. An upper clamping opening and a lower clamping opening are formed in the upper end of the telescopic support, a vertical turning rod is placed into the upper clamping opening and locked and connected through the upper clamping opening, and a vertical supporting rod is arranged in the lower clamping opening in a sleeved mode and locked and connected through the lower clamping opening. The bottom of the vertical supporting rod is connected with a horizontal rod through a triangular frame, and the horizontal rod is provided with a track. A camera supporting sliding block is arranged in the track in a sleeved mode. The horizontal rod, the vertical supporting rod and the vertical turning rod are all provided with the pulleys and the ropes. The camera supporting sliding block is connected with the ropes and can slide on the track along with the ropes. According to the bridge inspection device, work high above the ground is avoided. The bridge inspection device has the advantages that the safety is high, the economy performance is good, complete coverage of the inspection range is achieved, real-time transmitting, recording and tracing can be achieved, the weight is light, disassembly and assembly are easy, carrying is convenient and operation is flexible.

Owner:江西中煤建设集团有限公司

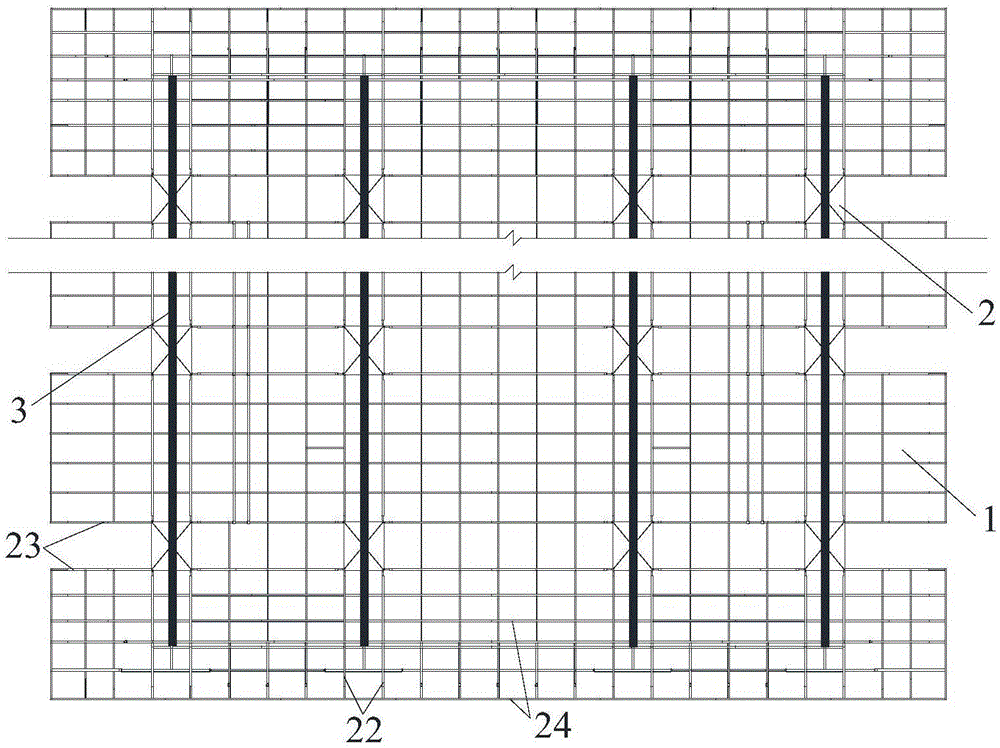

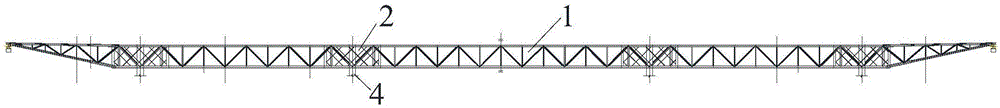

Sectional sliding roof steel truss assembling method

ActiveCN106760561AConstruction organization is convenientAvoid working at heightsGirdersJoistsPistonRoof window

The invention relates to a sectional sliding roof steel truss assembling method. The method is characterized by including the following steps of building a construction platform (5), preparing steel truss basic component units (24), installing first piston shoes (20) and second piston shoes (21), installing support trusses (2), installing longitudinal main trusses (22), installing transverse main trusses (23), lifting, assembling and transversely connecting the steel truss basic component units (24), sliding sectional steel trusses (1), putting the sectional steel trusses (1) in position, assembling the other sectional steel trusses (1), sliding the other sectional steel trusses (1), putting the other sectional steel trusses (1) in position, connecting transverse rods among the sectional steel trusses (1), disassembling second piston shoes (21) and sliding rails (3), and disassembling the construction platform (5). The method belongs to the field of steel structure engineering, roof steel trusses are prepared in sections and put in position by sliding, the problems that roof window construction time of an existing operating railway is short and difficulty of the construction is large are effectively solved, the construction efficiency is improved, and when applied in practical engineering, the method can obtain good technical and economic benefits.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY

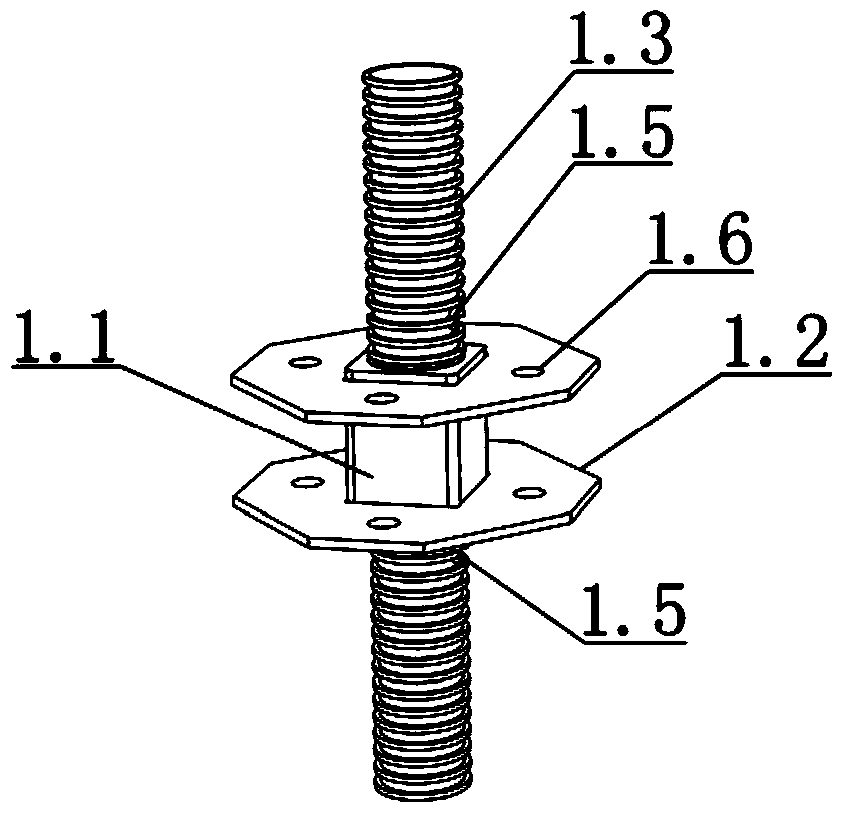

Lamp post and mounting method thereof

InactiveCN111750306AReduce installation costsEasy to operateLighting support devicesTowersAnchor boltEngineering

Owner:四川嘉灿城市家具科技有限公司

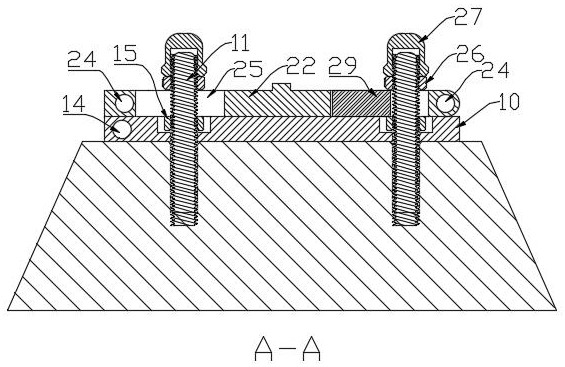

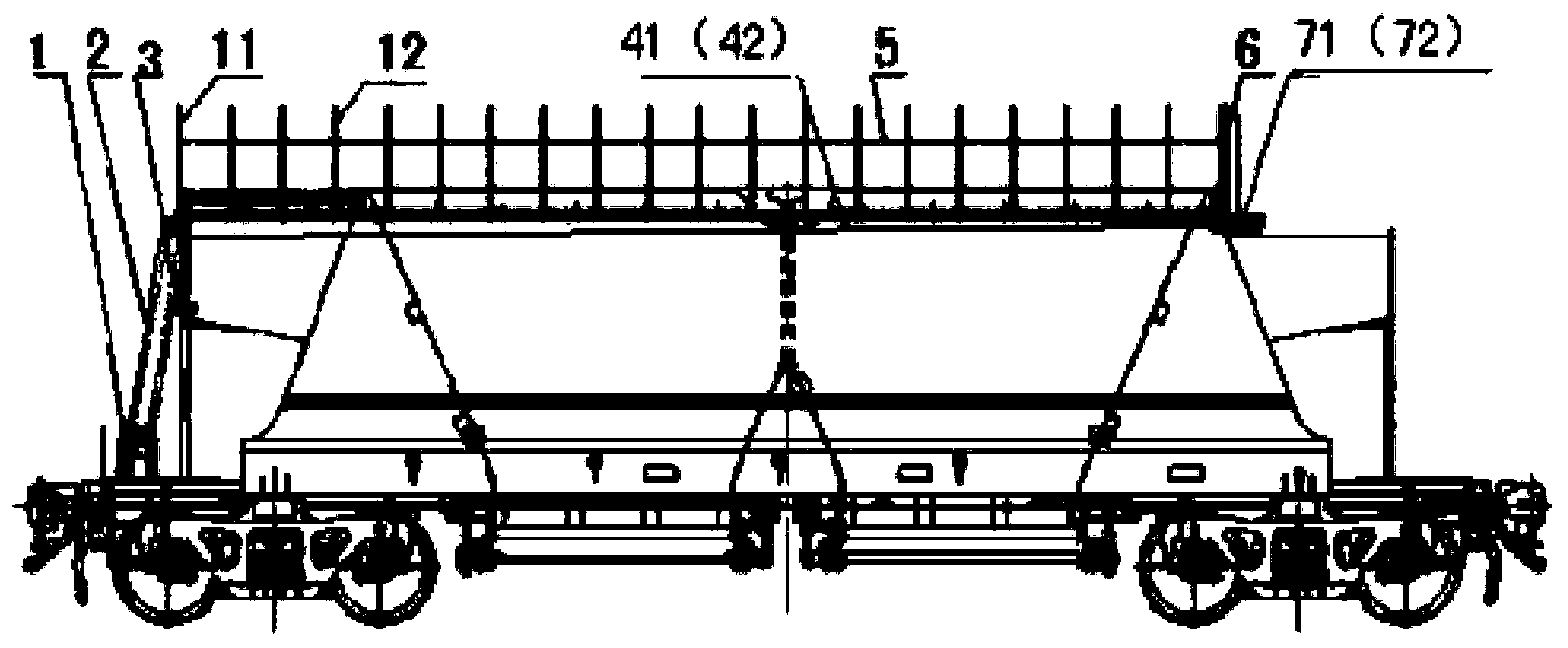

Canopy of railway wagon

The invention belongs to the technical field of railway wagons and particularly relates to a canopy of a railway wagon. The canopy comprises a transmission device and a canopy device, wherein the canopy device comprises a fixed frame, a plurality of movable frames and a layer of folding type canvas; the fixed frame and each movable frame are connected by adopting a dragging rope; the fixed frame is fixed at the top part of one end of the wagon; each movable frame consists of a skeleton and a pulley; the skeleton comprises a cross beam, a left supporting leg and a right supporting leg; the lower parts of the two supporting legs of the skeleton are respectively connected with one pulley block by a connecting plate; a plurality of left-side guide-rail lifting seats and right-side guide-rail lifting seats are respectively welded on upper-side beams along the left side and the right side of the wagon at equal intervals, and are connected with a left guide rail and a right guide rail by bolts; the pulley block of each movable frame slides on the corresponding guide rail. The canopy has the advantages that a folding type telescopic structure is adopted, the weight is light, the installation is easy and the operation is easy; the extension and retraction of the canopy are realized by adopting a chain steel rope to drag the pulleys to slide along the guide rails; the high-altitude operation is avoided and the safety is improved.

Owner:CRRC YANGTZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com