Method for constructing stiff supporting dome structure

A construction method and tooling cable technology are applied in the dome roof structure, arch structure, building components and other directions, which can solve the problems of increasing construction difficulty, tension asymmetry, and construction trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

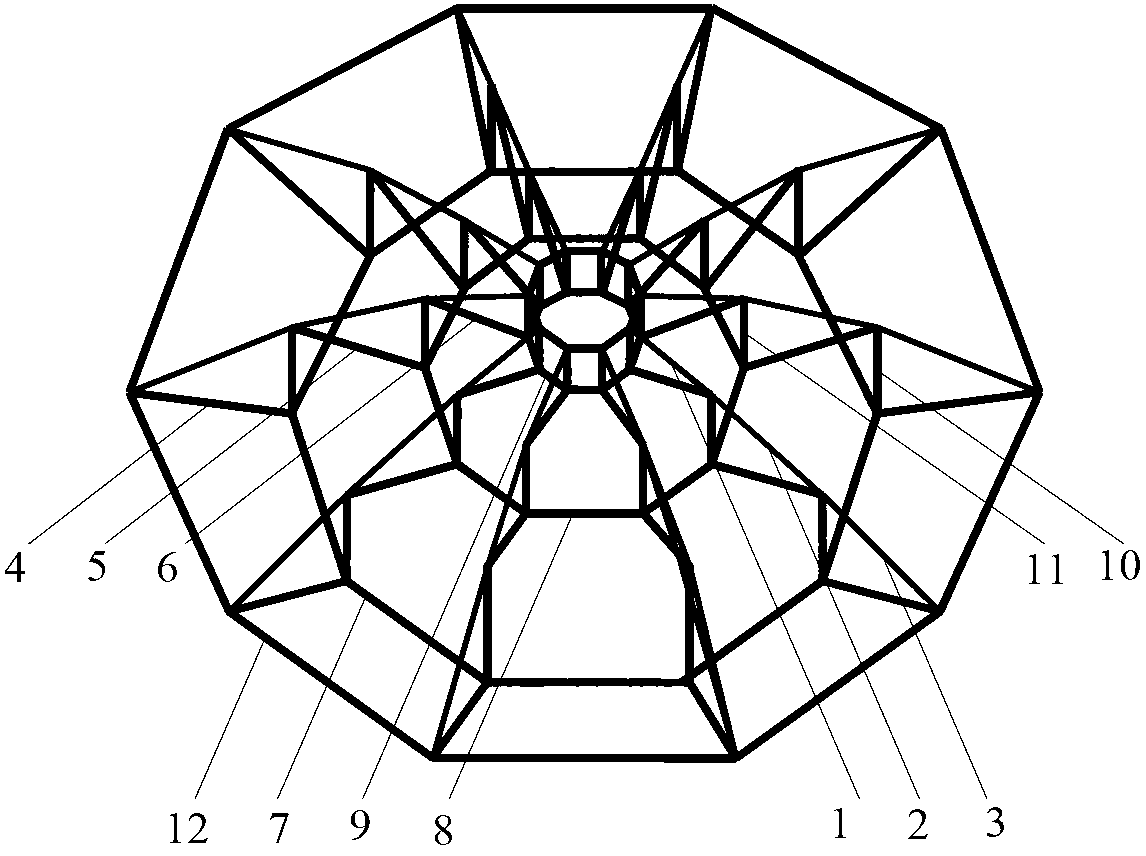

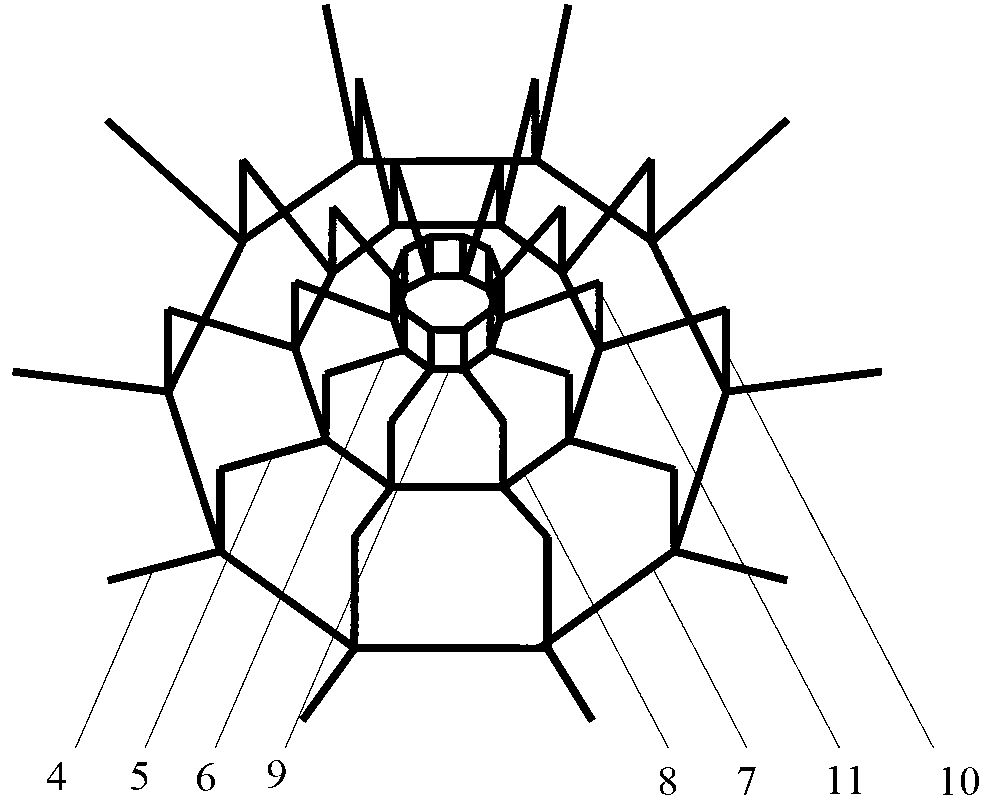

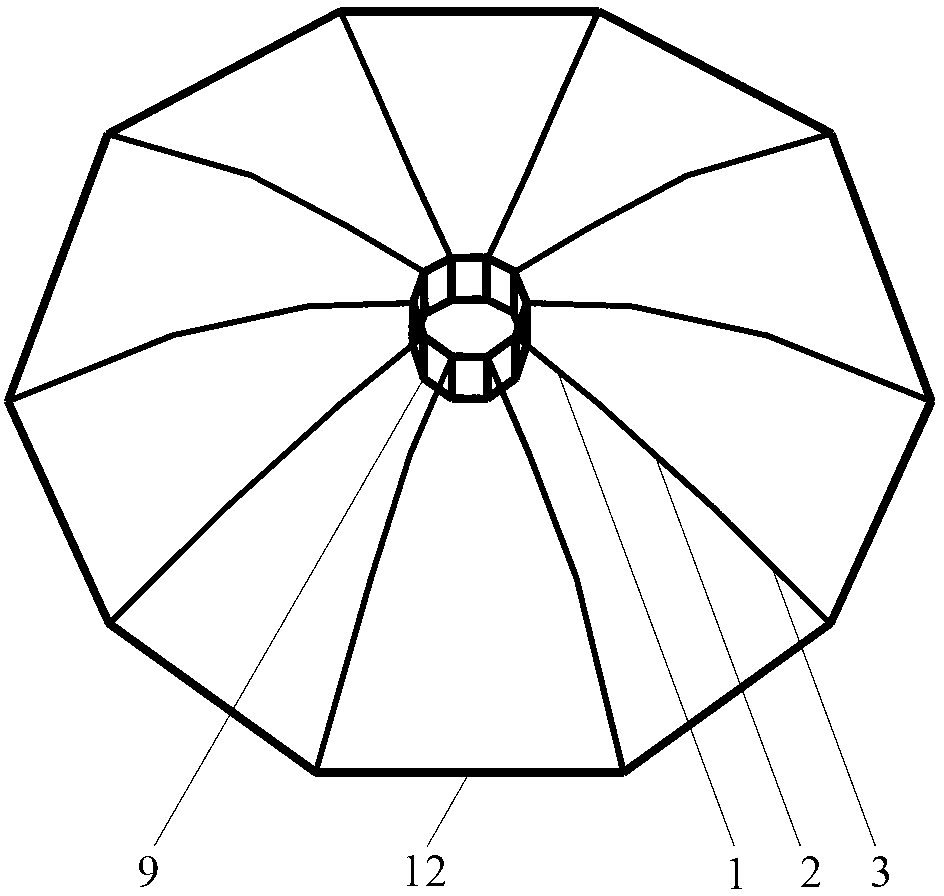

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the construction forming process of this embodiment is as follows: the first step is to install the center inner pull ring 9, connect the upper end of the inner ridge cable 1 with the upper ear plate 13 of the center inner pull ring 9, and install and connect the inner ridge cable 1 and the middle ridge cable. 2. The outer ridge cable 3 is connected with the ring beam 12 through the tooling cable. The lower end of the inner oblique rod 6 is connected with the lower ear plate 14 of the center inner pull ring 9 . which is figure 1 , Figure 5 and Figure 6The central inner pull ring, the inner notochord 1, the middle notochord 2, the outer notochord 3 and the inner oblique rod 6. The specific installation method is as follows: first set up the operation platform, then install the welding center inner pull ring 9 at the central position of the center site, correspond the ear pl...

Embodiment 2

[0040] Such as figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, the construction method of this embodiment is the same as that of Embodiment 1, except that the outer contour lines of the outer ring rod 7, the inner ring rod 8 and the ring beam 12 are elliptical.

Embodiment 3

[0042] Such as figure 1 , Figure 5 , Figure 6 and Figure 8 As shown, the construction method of this embodiment is the same as that of Embodiment 1, except that the outer contour of the ring beam 12 is polygonal. Outlines of the outer ring rod 7, the inner ring rod 8 and the central inner pull ring 9 are all polygonal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com