Automatic discharge device for drill strings

An automatic discharge and drill string technology, applied in the direction of support devices, drill pipes, drill pipes, etc., can solve the problems of complex stress, unfavorable drilling rig transformation, small working radius, etc., to achieve a reasonable overall structure, improve drilling efficiency, and mechanization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

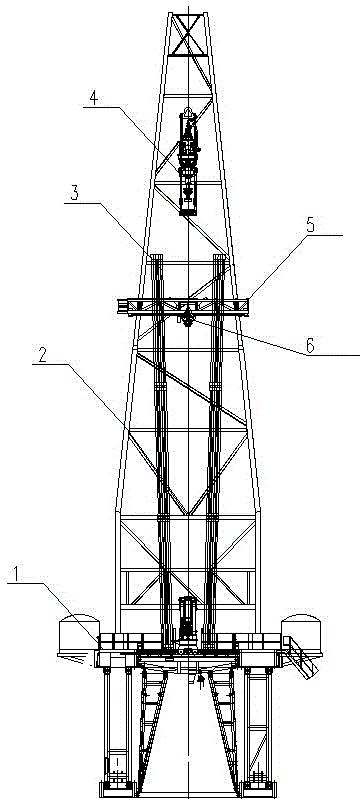

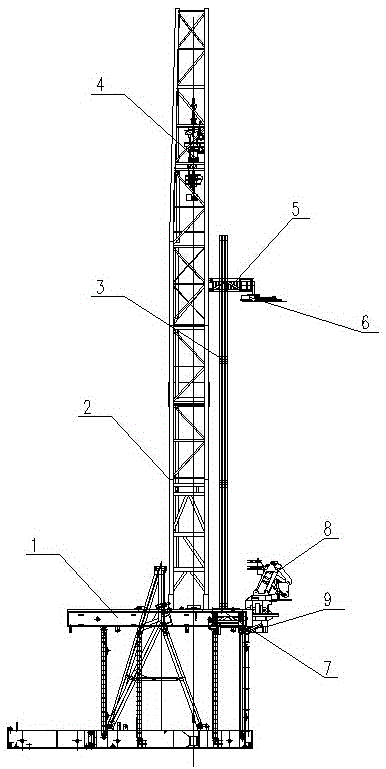

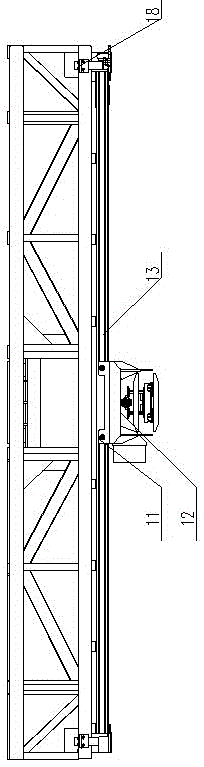

[0022] Figure 1-2 Middle: There is a second-floor platform 5 in the middle of the derrick 2, a drill floor 1 at the lower part, and a top drive 4 drooping at the top. The upper manipulator 6 is welded on the second-floor platform 5, and the upper manipulator 6 can move on the second-floor platform. 7 is connected on the drill floor 1, the lower manipulator bracket 9 is connected to the vertical heel platform 7 through a pin shaft, the lower manipulator 8 is connected to the lower manipulator bracket 9 through a pin shaft, and the upper manipulator 6 rings the upper part of the vertical heel 3, and the lower manipulator The lower part of the vertical root 3 is covered with 8 rings, so that the vertical root 3 is lifted and moved on the lower manipulator support 9 and the working area when moving covers the entire vertical heel platform 7, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com