Canopy of railway wagon

A railway freight car and canopy technology, which is applied to railway car body parts, transportation and packaging, etc., can solve the problems of insufficient pressure gas in the train pipe, extremely high rigidity requirements of the chain, affecting the braking effect of the train, etc. Avoid high-altitude work, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

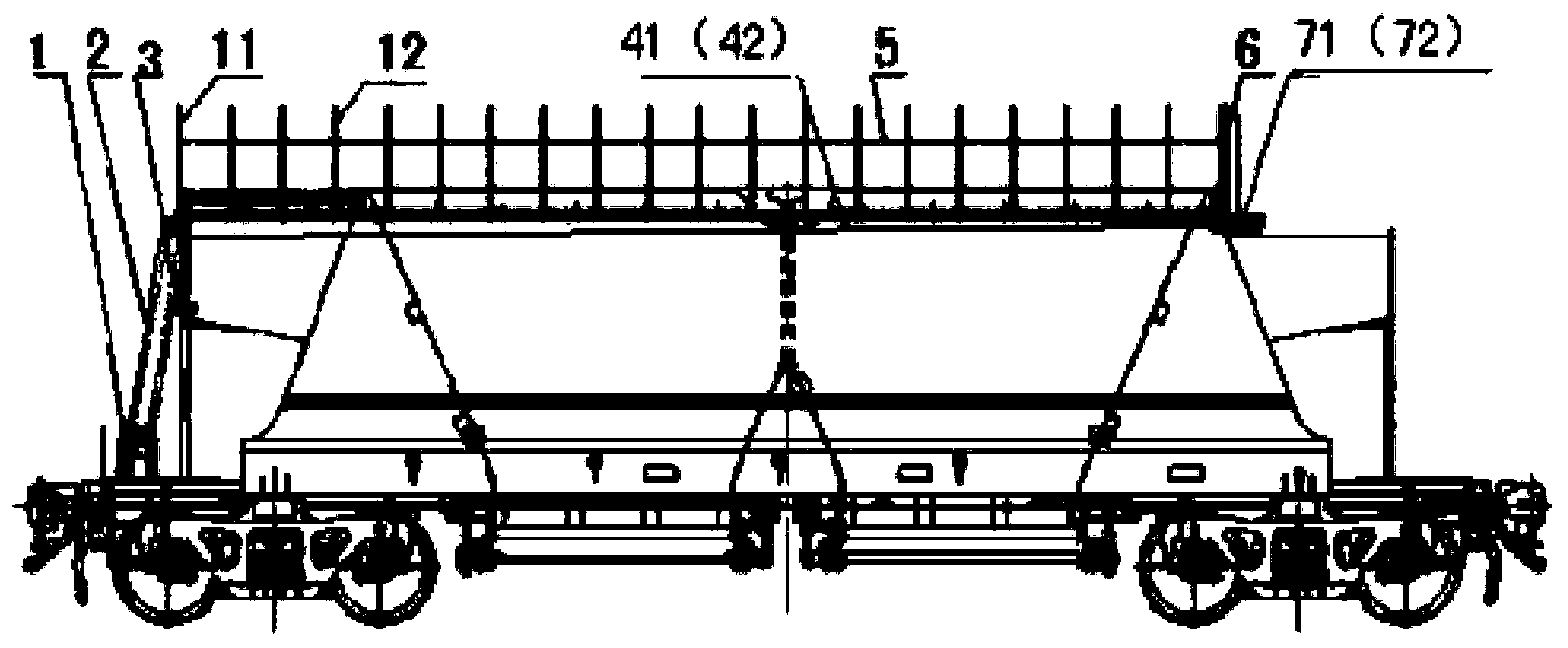

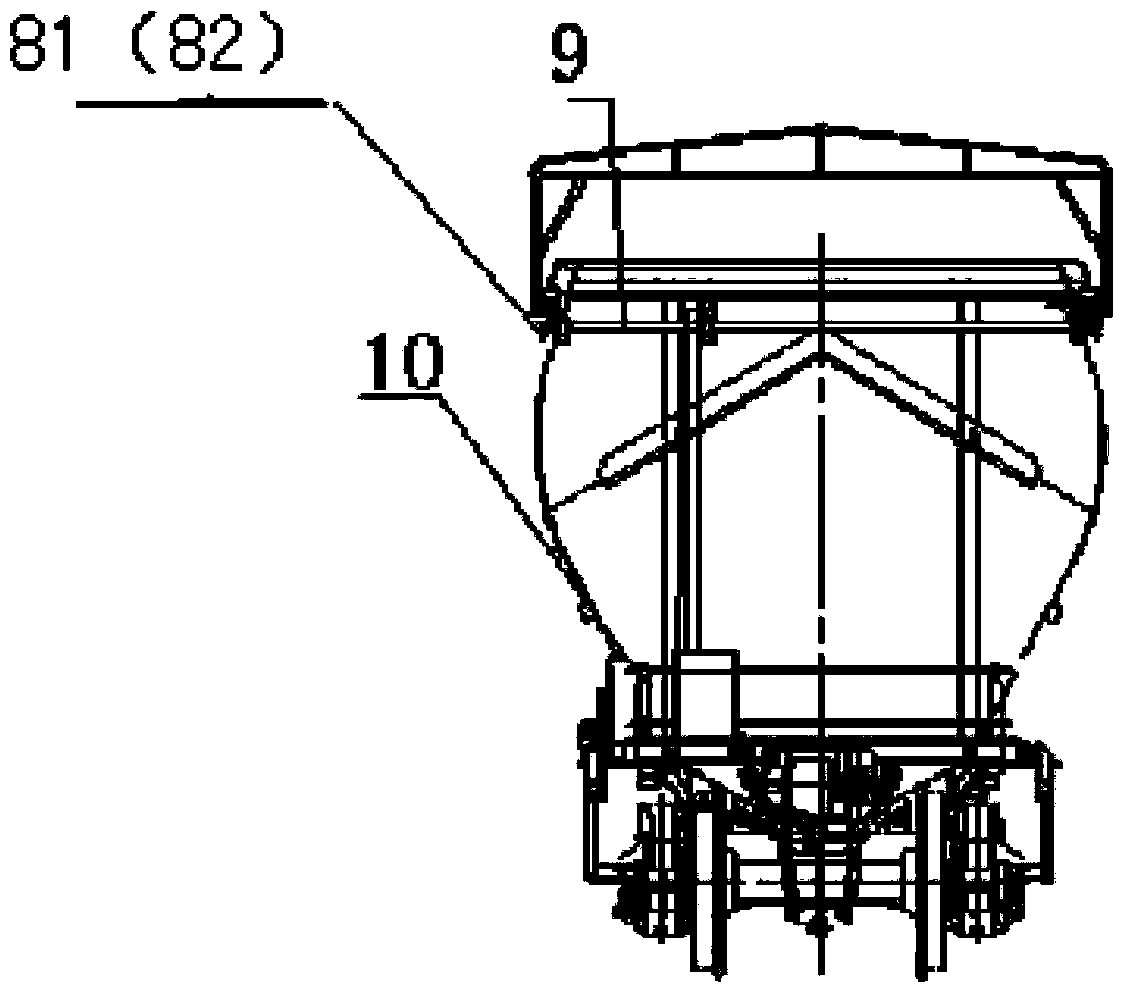

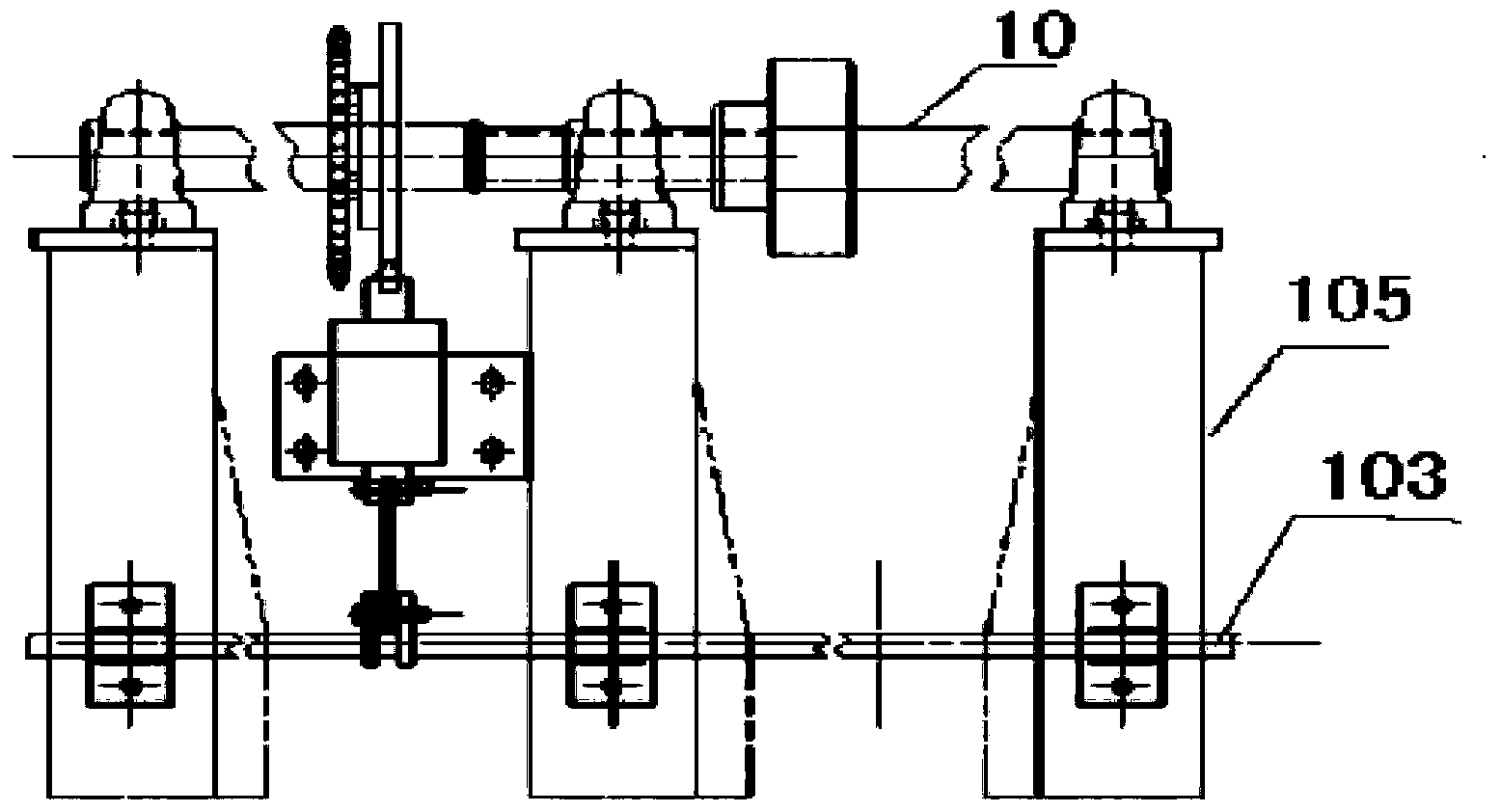

[0023] Such as figure 1 Shown, the embodiment of the present invention provides a kind of roof of railway wagon, comprises transmission device and roof device, and roof device comprises a fixed frame 11, a plurality of movable frames 12 and covers fixed frame 11, a plurality of movable frame 12 tops With one deck of folding canvas on both sides, a traction rope 5 is adopted between the fixed frame 11 and each movable frame 12 to connect, certainly also can adopt a plurality of traction ropes 5 to connect respectively between each frame, as long as the traction rope can be guaranteed 5. Under traction, all the movable frames 12 can keep the same direction of motion relative to the fixed frame 11; Figure 6 and Figure 7 As shown, the movable frame 12 includes a skeleton 600 and a block of pulleys. The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com