Patents

Literature

60results about How to "Avoid hoisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

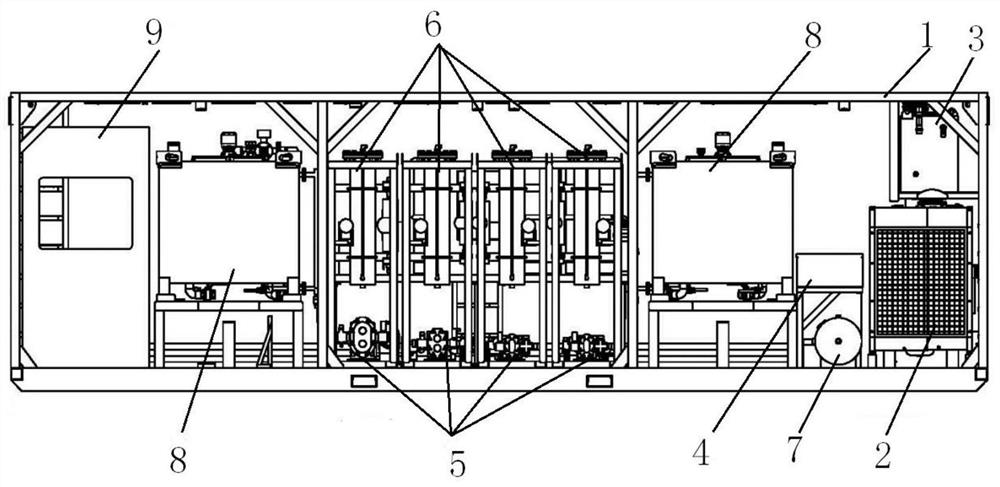

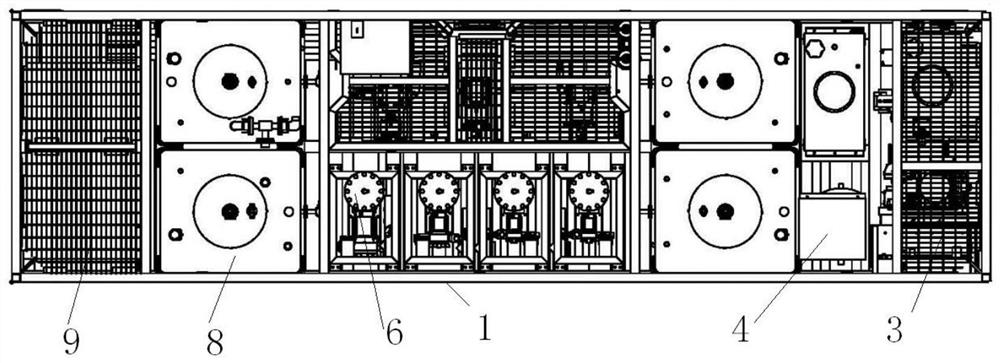

Full-automatic liquid adding device for fracturing construction and adding calibration method

PendingCN112196508AStable structureStructure, stable installationMass flow measurement devicesTransportation and packagingTransfer caseControl engineering

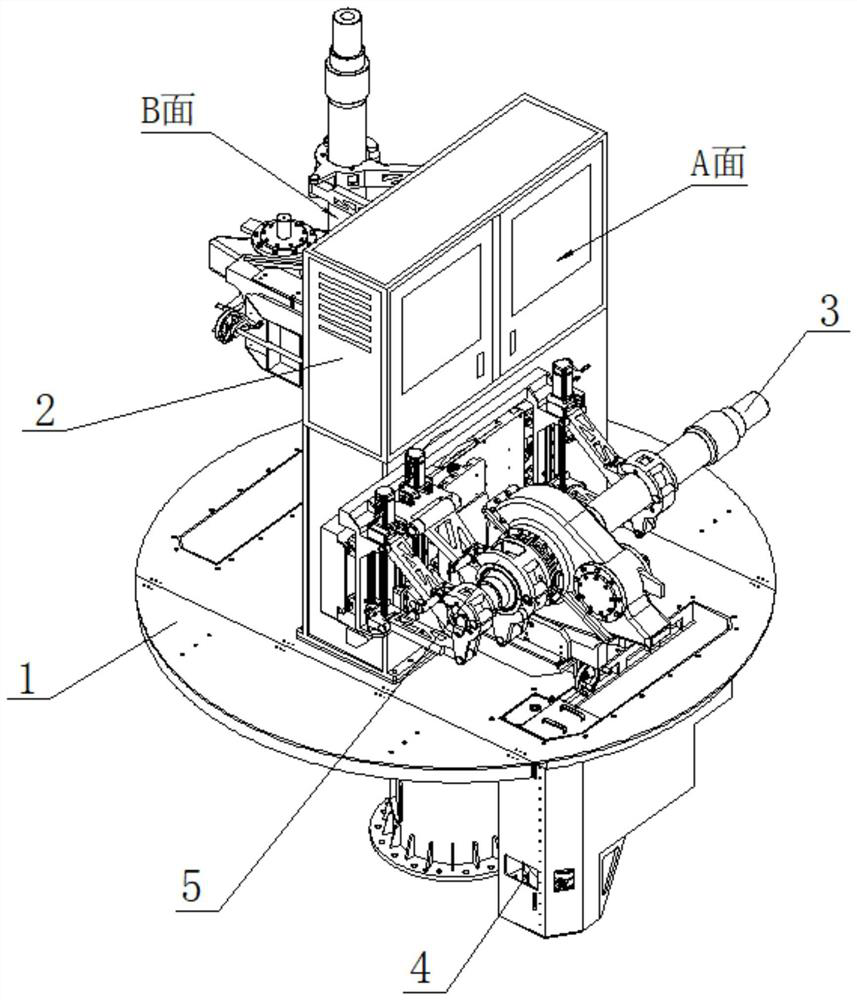

The invention belongs to the technical field of fracturing construction mechanization, and particularly provides a full-automatic liquid adding device for fracturing construction and an adding calibration method. The full-automatic liquid adding device comprises a prying frame, an engine, a transfer case, a hydraulic device, a liquid adding pump, a metering calibration tank, a liquid additive tank, a liquid supply pump and a control unit, wherein the input ends of the engine, the transfer case and the hydraulic device are sequentially connected; the output end of the hydraulic device is connected with the liquid supply pump and the liquid adding pump; the liquid supply pump is connected with an inlet of the liquid additive tank; an outlet of the liquid additive tank is sequentially connected with inlets of the metering calibration tank, the liquid adding pump and the liquid additive tank; the control unit is electrically connected with the engine, the transfer case, the hydraulic device, the liquid adding pump, the metering calibration tank, the liquid supply pump and the liquid additive tank; and the current situation that in the fracturing construction process, the liquid additive adding precision is large in adding difficulty and discontinuous is avoided, the mechanization and automation degree of fracturing construction is improved, meanwhile, the construction quality and potential safety hazards are effectively eliminated, and the construction success rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Construction method for hoisting heavy type ultrahigh steel member

InactiveCN103774854AEasy to fixFlexible adjustmentBridge erection/assemblyBuilding material handlingSteel columnsMaterials science

The invention discloses a construction method for hoisting a heavy type ultrahigh steel member. The construction method comprises the following steps: a, lofting the member; b, pre-burying foundation bolts; c, hoisting steel columns; d, correcting the steel columns; e, mounting column bracings; f, hoisting steel girders; g. mounting high-strength bolts. The construction method has the advantages of simple and convenient construction, short construction period, safety and reliability.

Owner:ZHEJIANG DONGCHI STEEL STRUCTURE

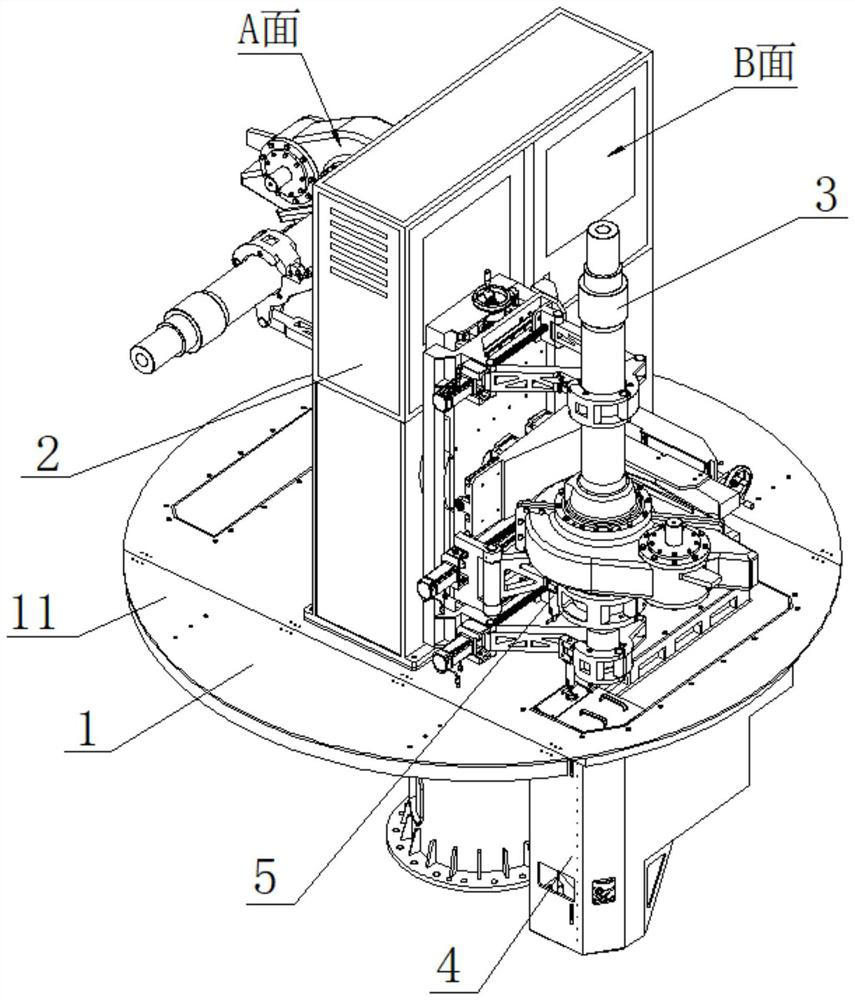

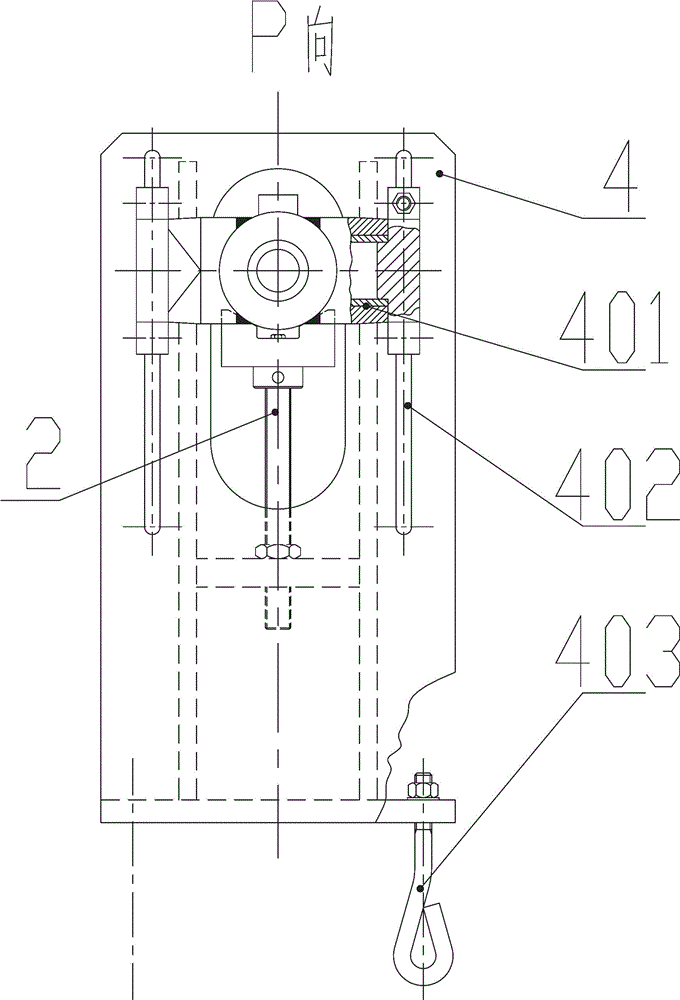

Hanging device

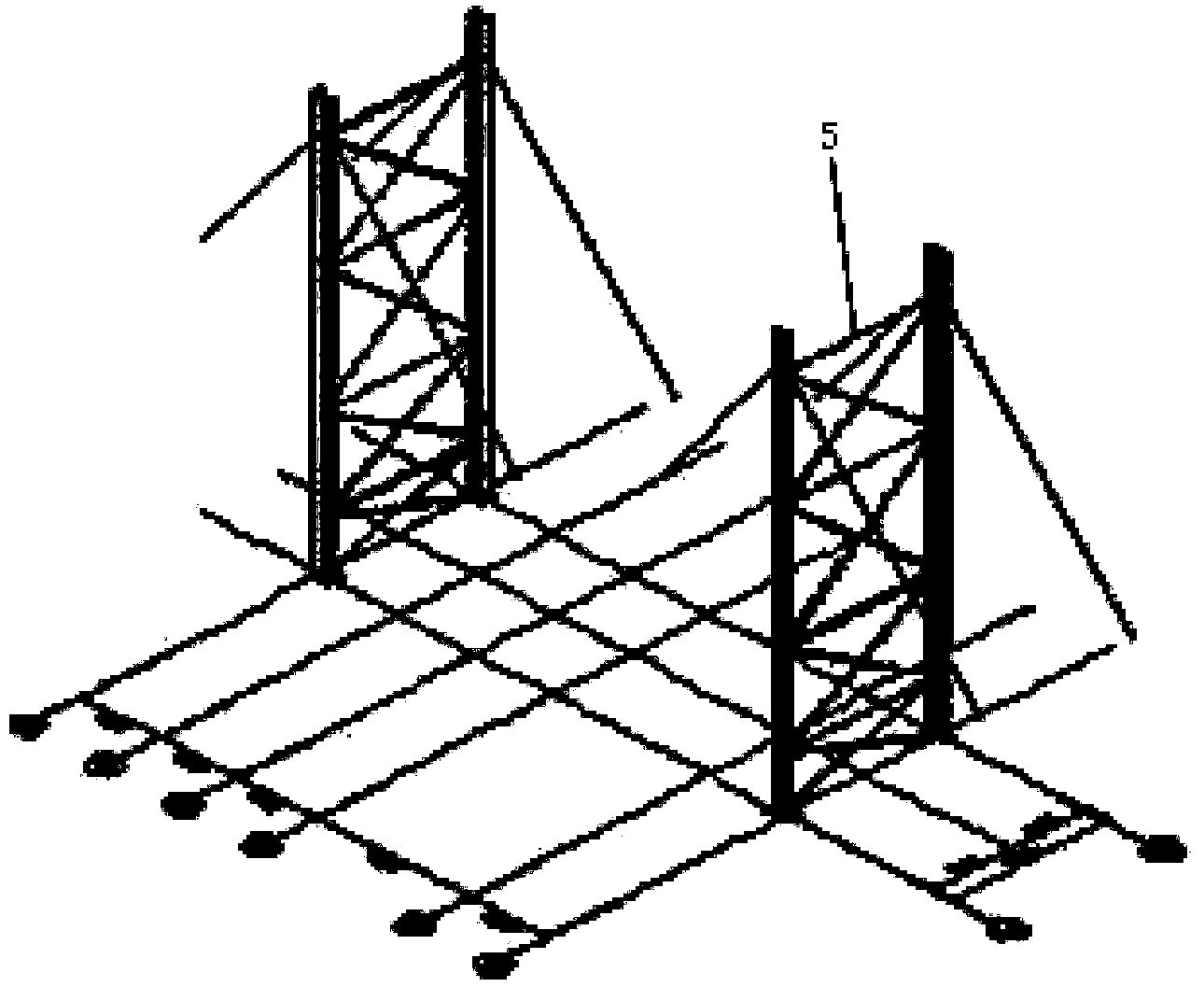

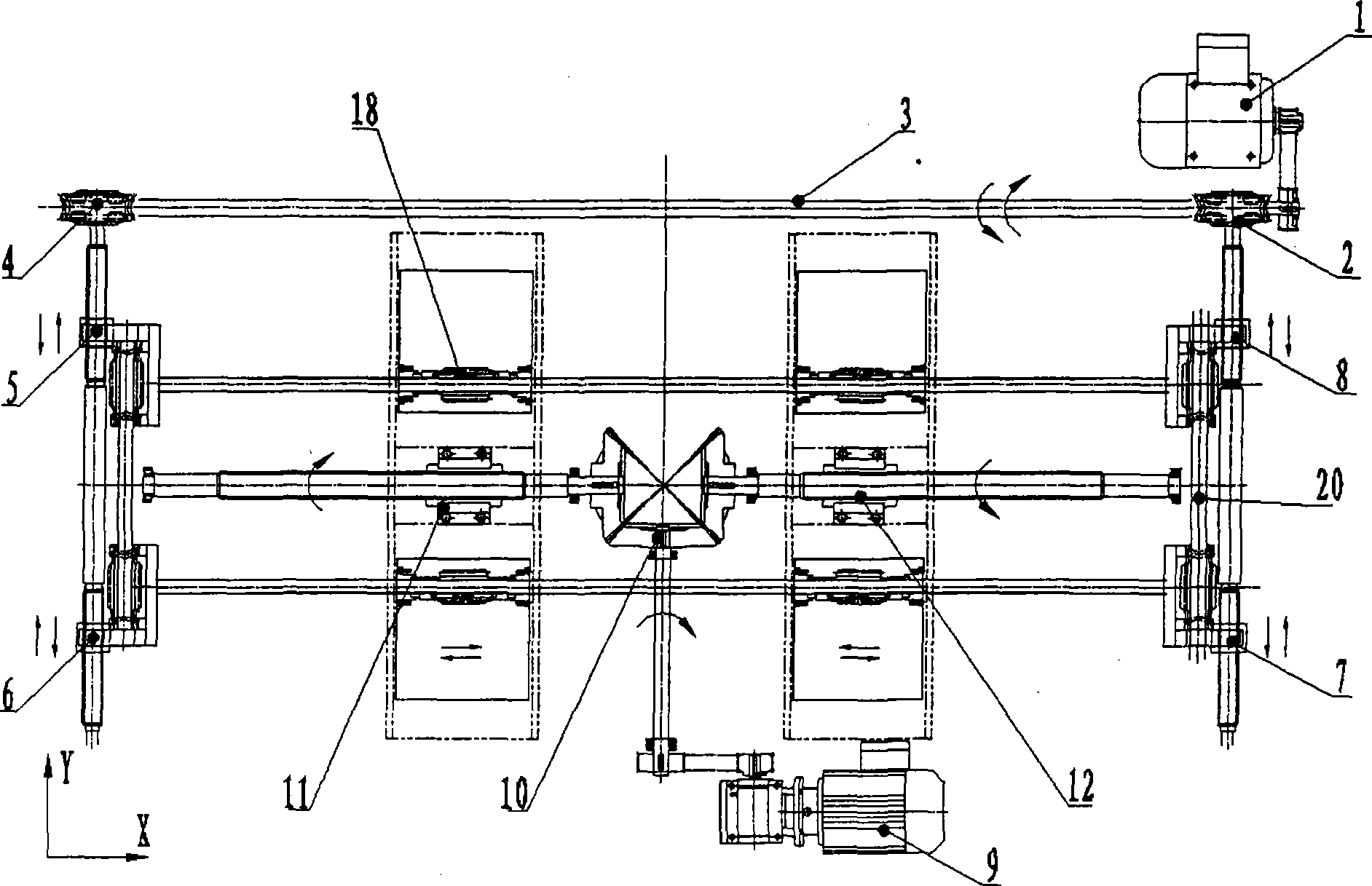

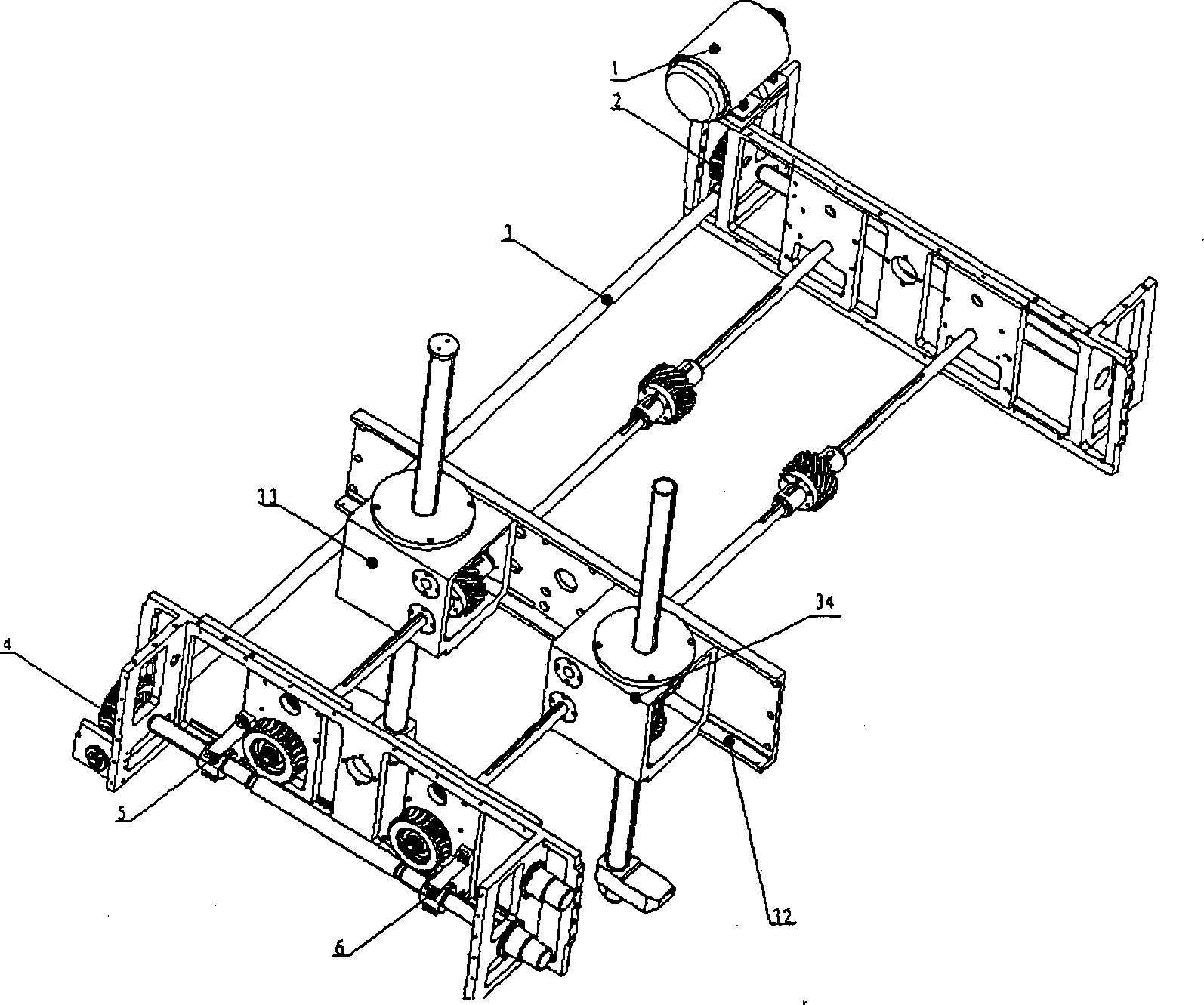

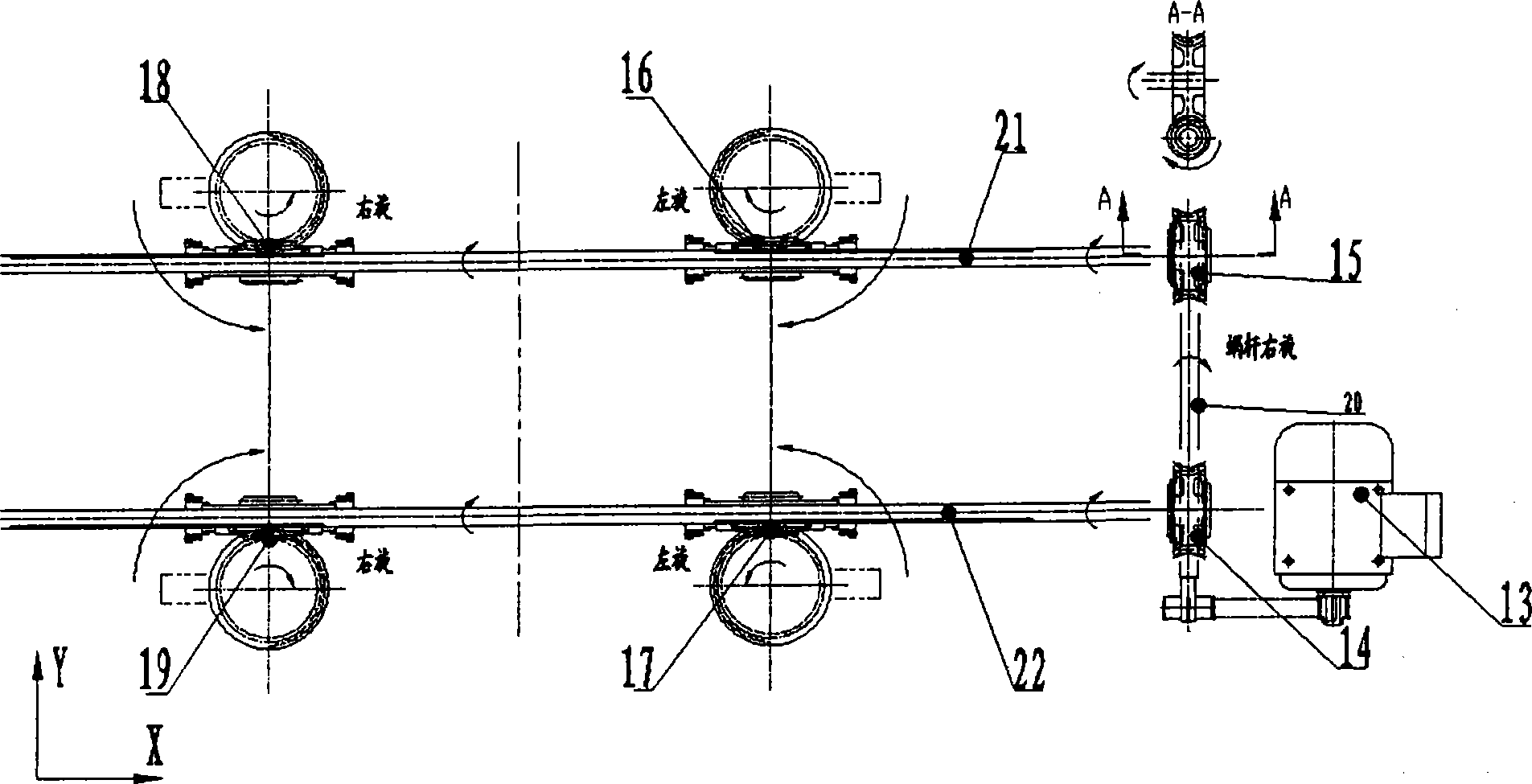

InactiveCN101445189AAvoid hoistingAchieve standardizationLoad-engaging elementsConveyor partsRotational degrees of freedomEngineering

The invention relates to a hanging device which comprises a front and back mobile system, a left and right mobile system, a lifting system and a rotating system. A left sliding frame, a right sliding frame, the front and back mobile system, the left and right mobile system, the lifting system and the rotating system are mounted on a machine frame; the suspension hook of the hanging device has four freedom degrees which are left and right mobile freedom degree (X direction), front and rear mobile freedom degree (Y direction), lifting freedom degree (Z direction) and rotating freedom degree (rotating around the Z direction) respectively. The invention has the advantages that each suspension hook has four freedom degrees; and the position of the suspension hook is adjusted according to the demands of a suspension point. The handing device can solves the suspension of a majority of trusses to achieve the standardization.

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

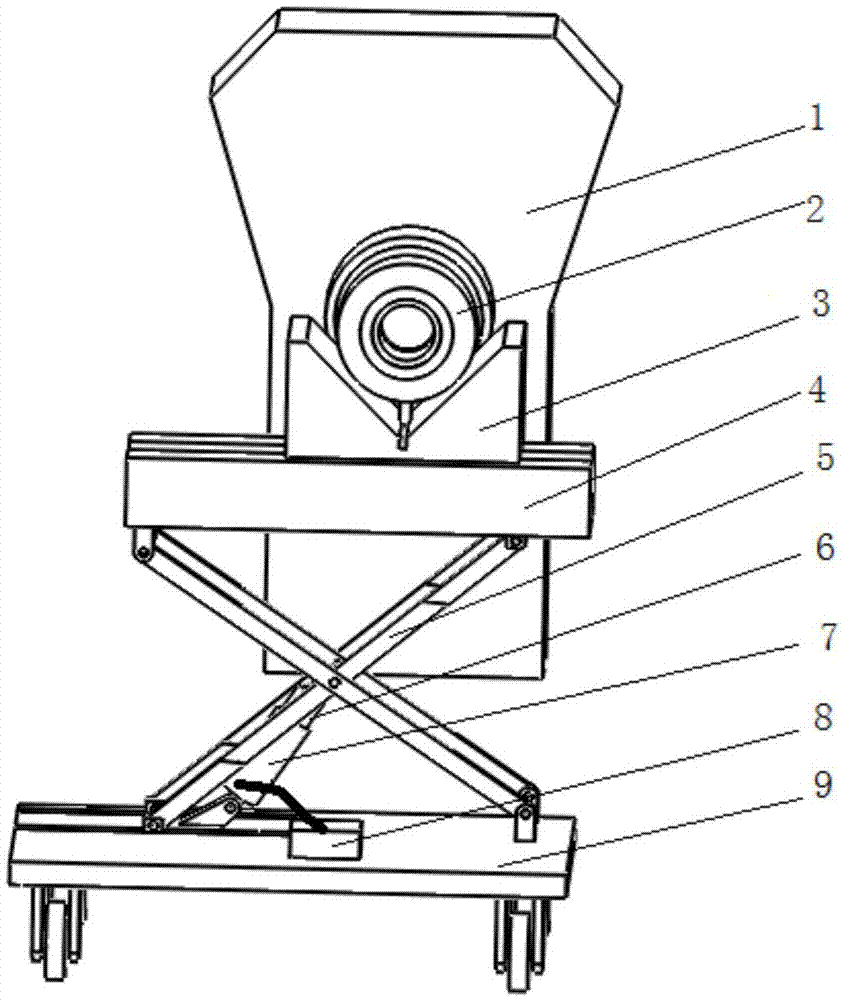

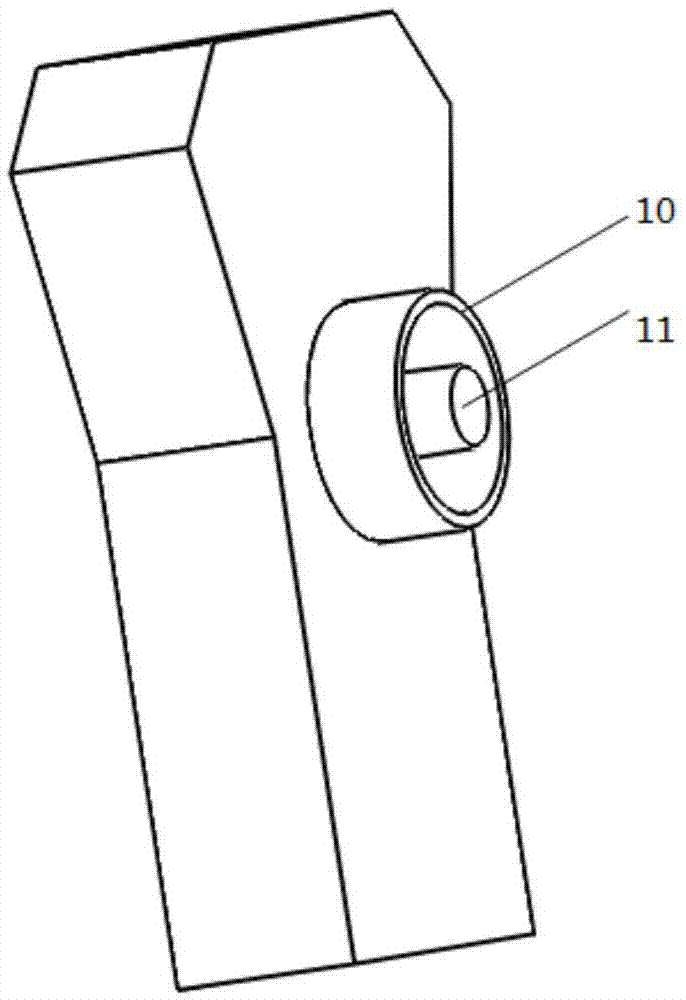

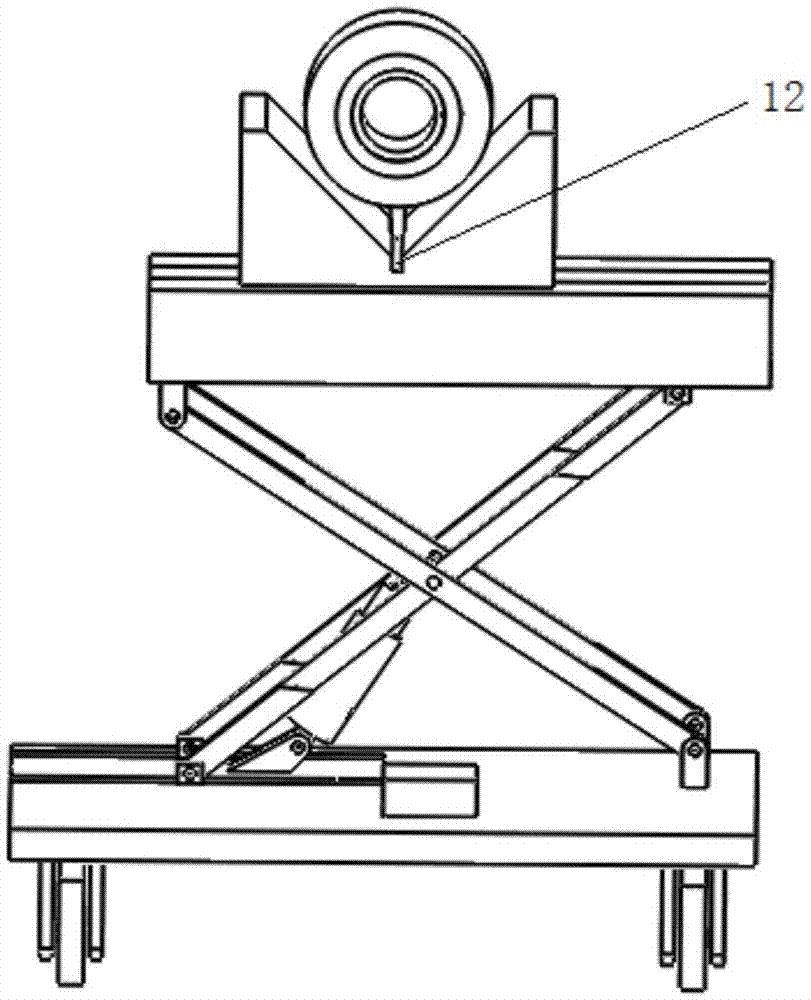

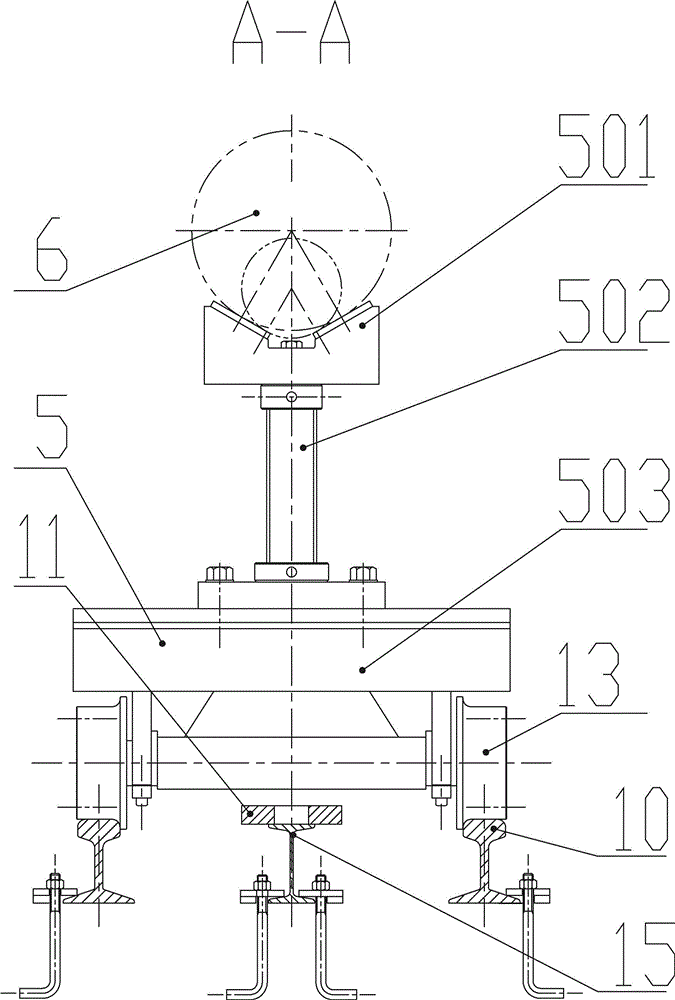

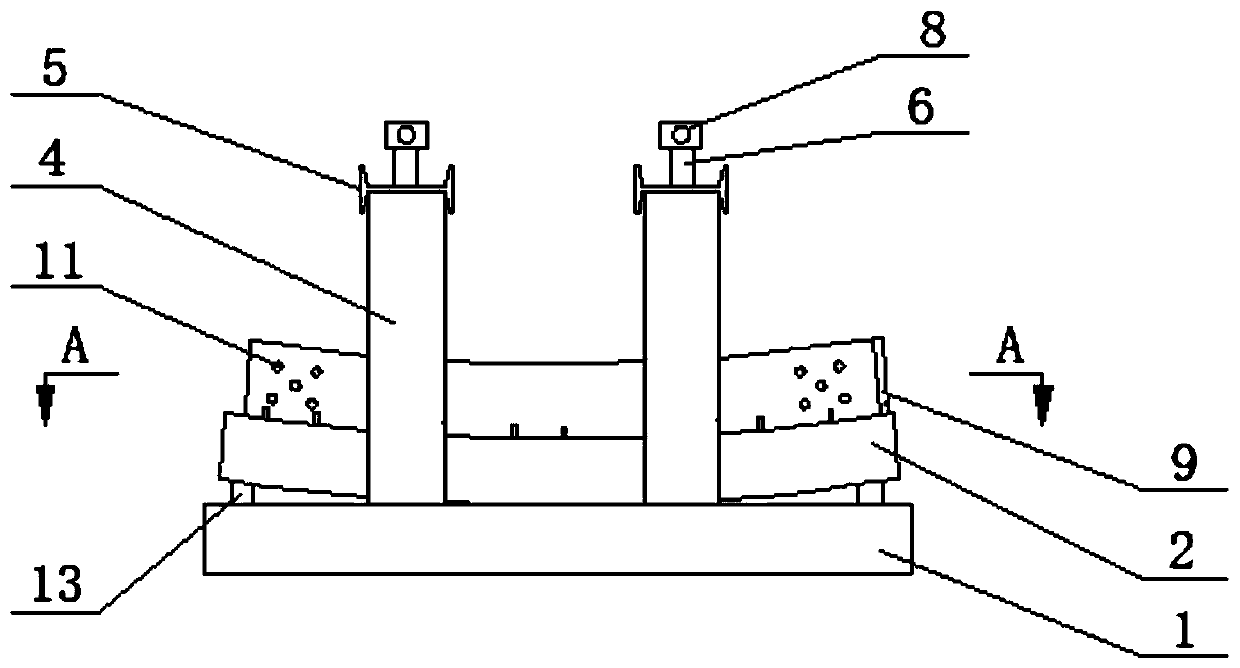

Support platform for installing and disassembling diesel engine crankshaft vibration reducer

ActiveCN105436869AAutomatic centeringAchieve phase lockCrankshaftsMetal working apparatusEngineeringMechanical engineering

The invention discloses a support platform for installing and disassembling a diesel engine crankshaft vibration reducer. The support platform comprises an axial V-shaped groove for supporting the vibration reducer, a horizontal movable table, and a hydraulic lifting device positioned below the horizontal movable table; a first slide block extends below the axial V-shaped groove; and a first chute matched with the first slide block for use is formed in the horizontal movable table. The support platform for installing and disassembling the diesel engine crankshaft vibration reducer has such advantages as simple structure, convenience for operation, high installation efficiency and good safety, supports and fixes the vibration reducer, enhances the balance of the vibration reducer in the installation process, and prevents the lifting of the vibration reducer; and the transverse motion of the axial V-shaped groove and a lifting mechanism can realize automatic centering of an inner hole of the vibration reducer and the axis of a crankshaft in all directions so as to quickly finish the coaxiality matching of the inner hole of the vibration reducer and the crankshaft.

Owner:JIANGSU UNIV OF SCI & TECH

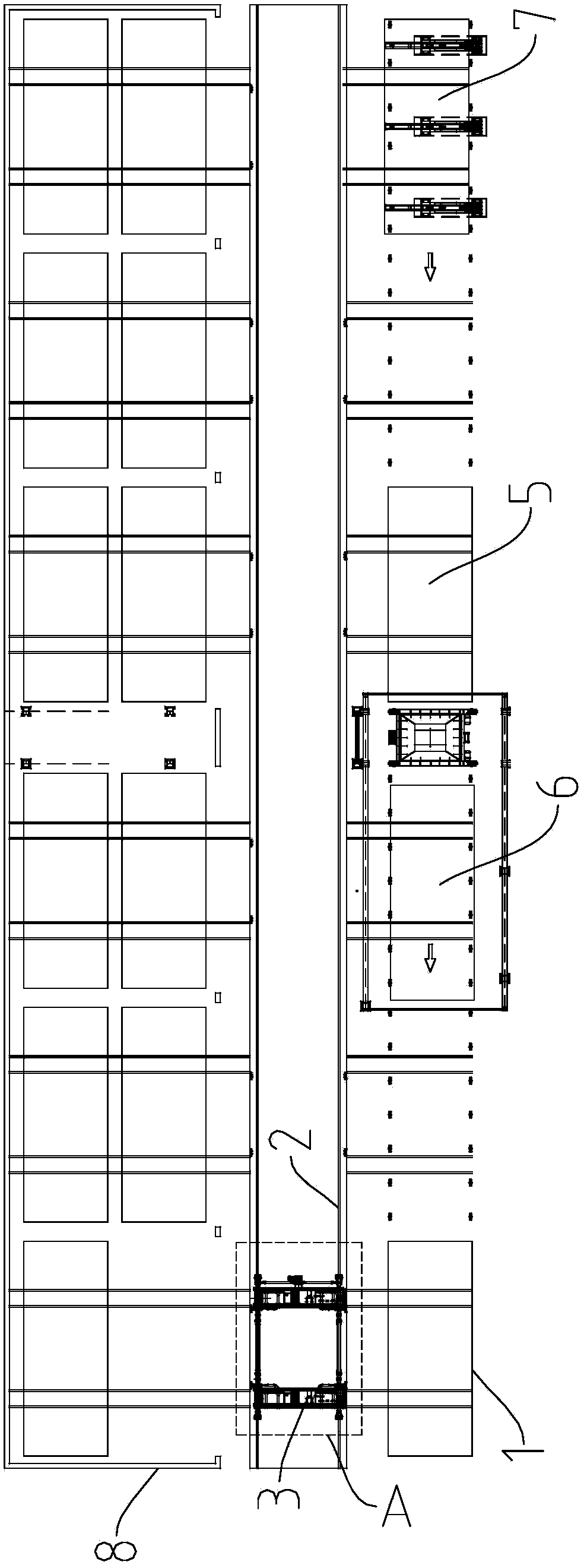

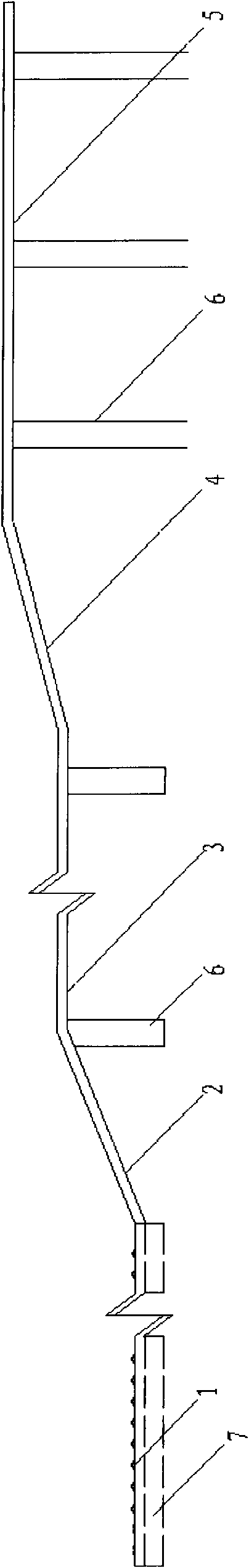

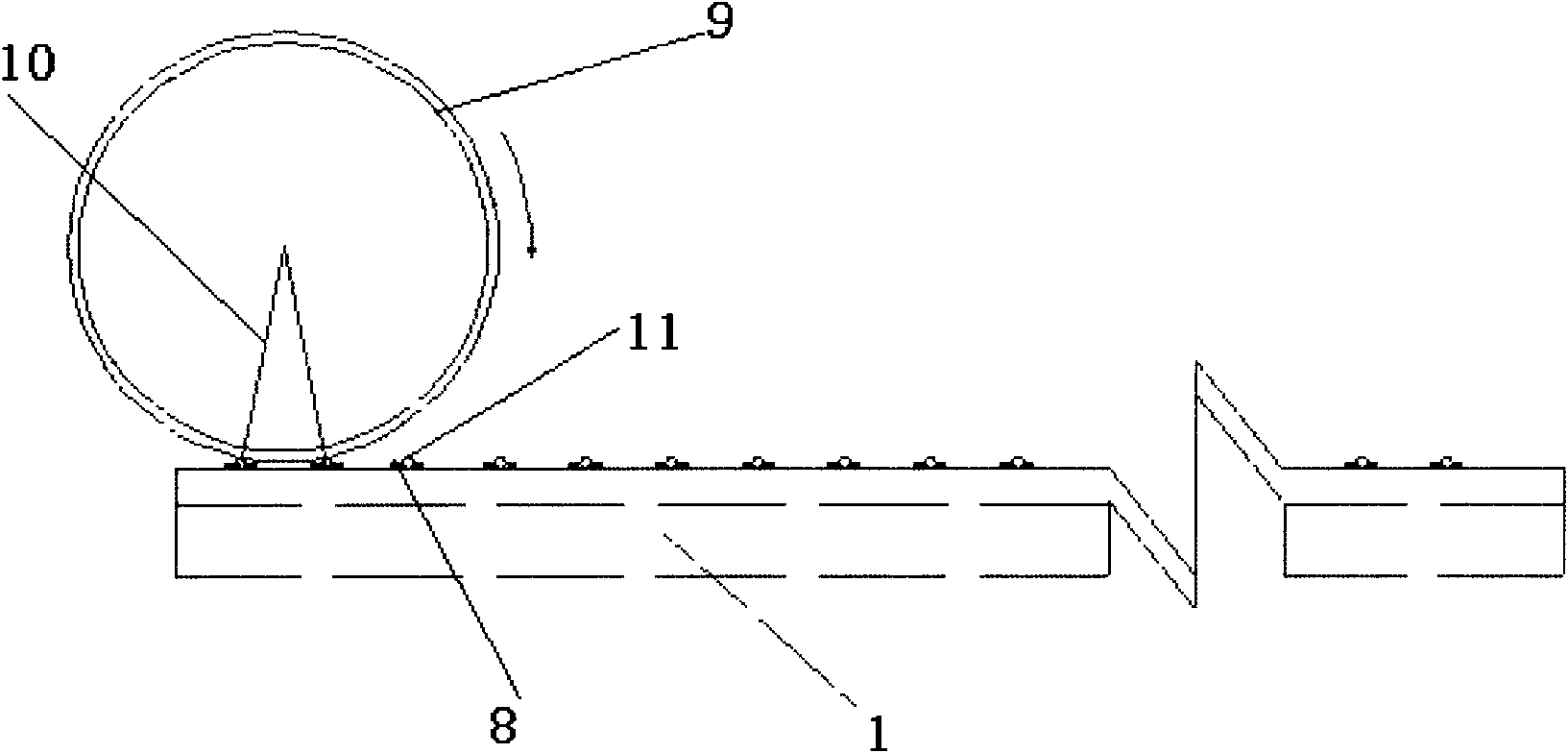

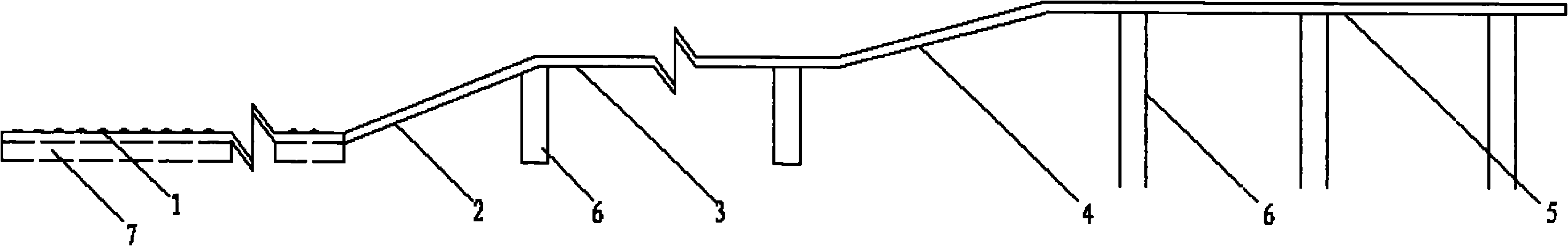

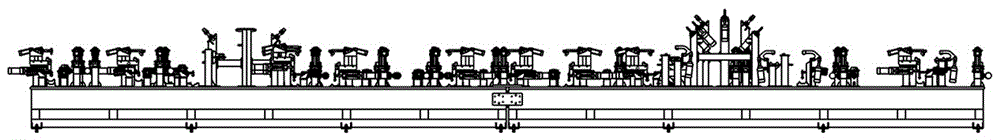

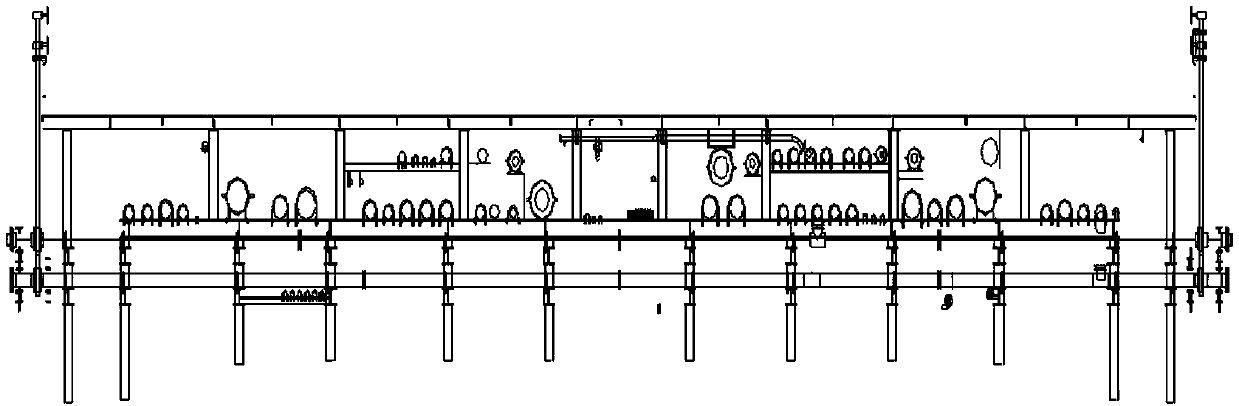

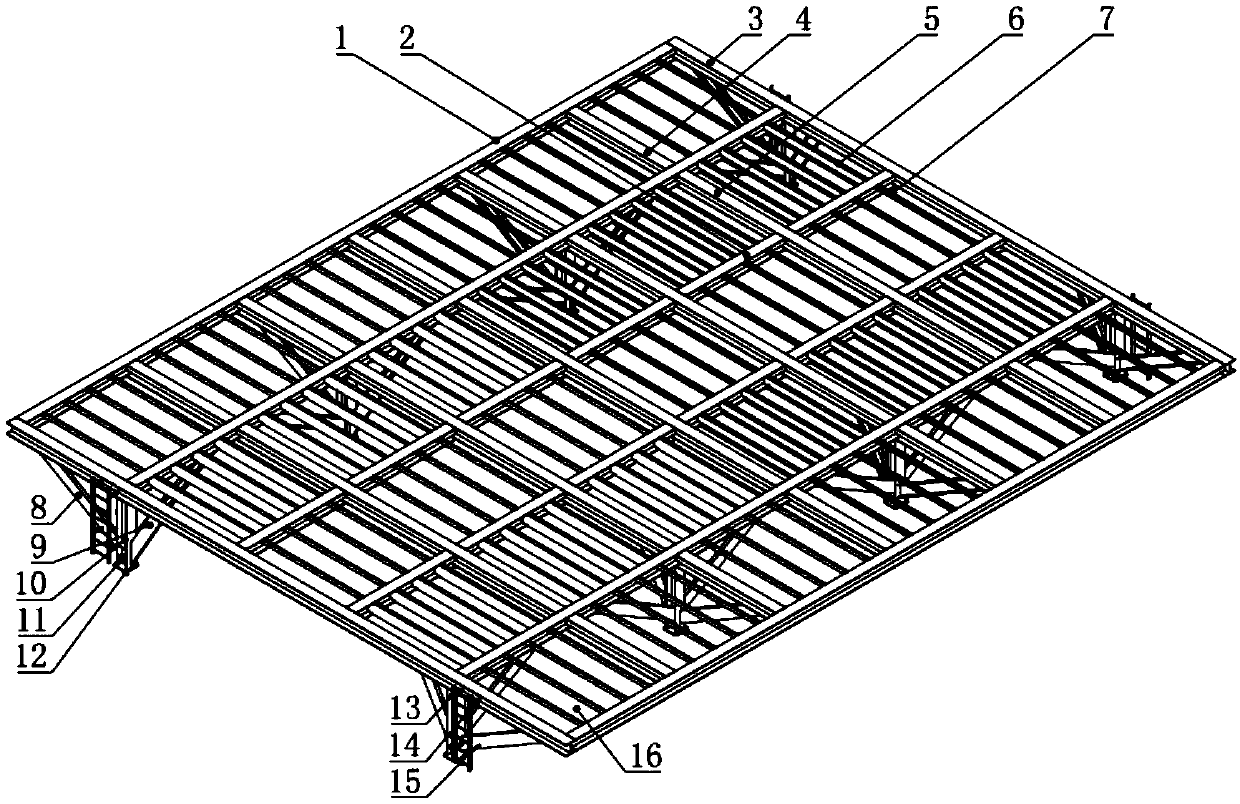

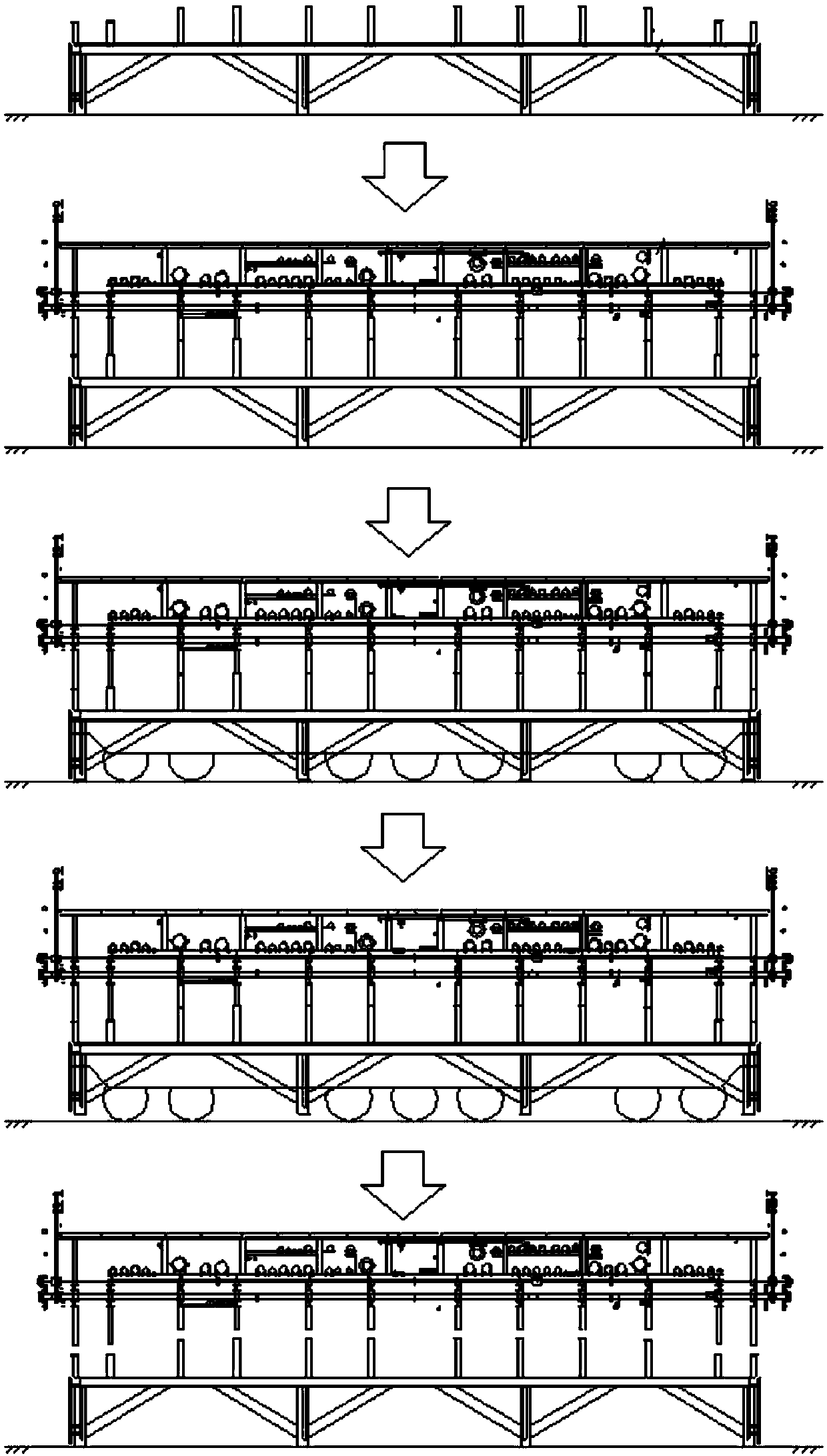

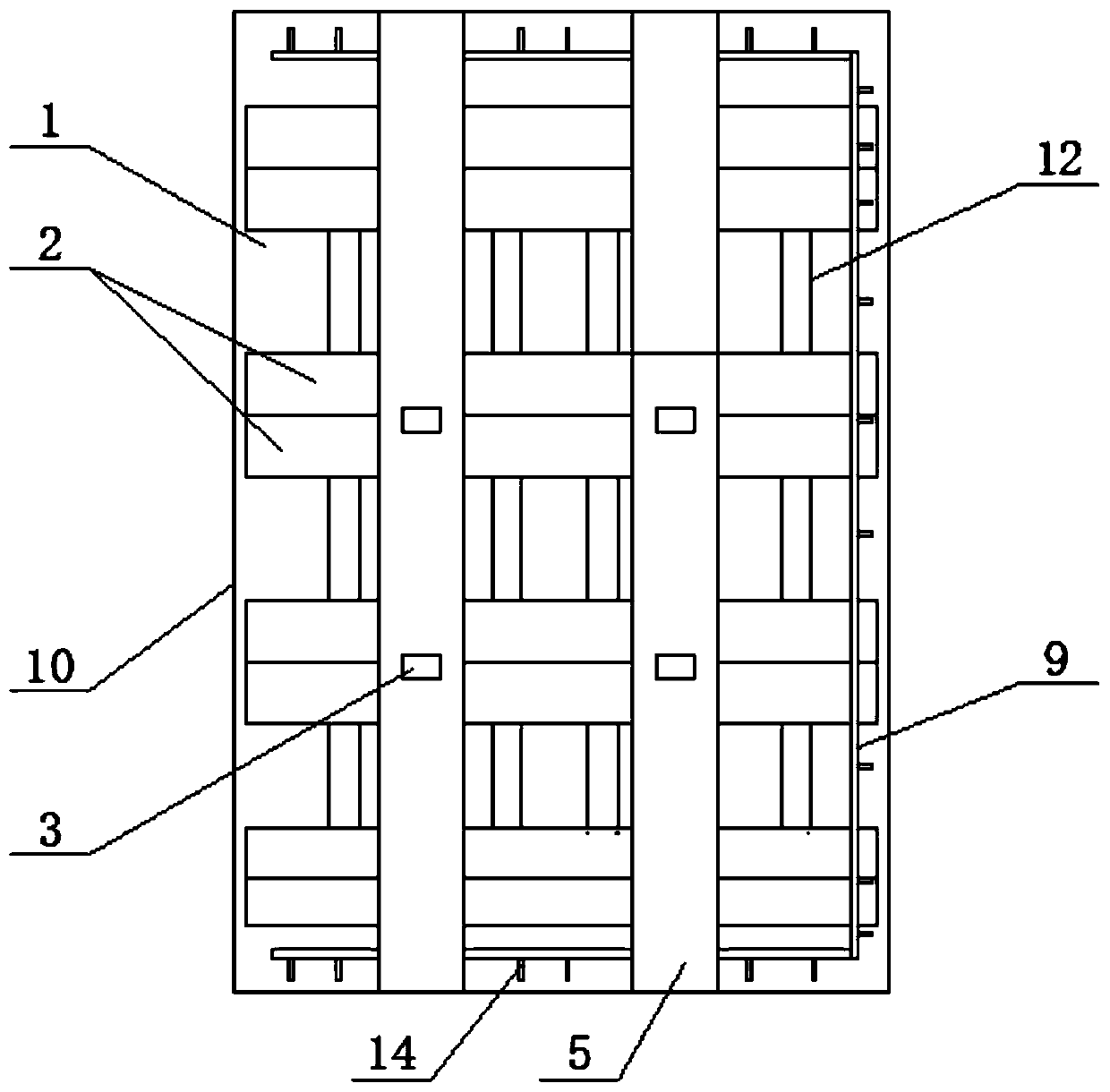

Semi-automatic fixed die table PC component production system

The invention discloses a semi-automatic fixed die table PC component production system. The system comprises a die table, an operation station and a maintenance station, wherein the operation station and the maintenance station are used for placing the die table. The PC component production system further comprises first guide rails and one or more walking trolleys. The walking trolleys are movably arranged along the first guide rails and used for moving the die table between the operation station and the maintenance station in a reciprocating mode. Each walking trolley comprises a jacking carrying mechanism used for carrying the die table. According to the technical scheme, the trolleys with the jacking carrying mechanisms are used for driving the die table to move between the stations in the reciprocating mode, frequent hoisting is avoided, and the labor intensity of an operator is greatly lowered. In addition, the number of hoisting devices can be effectively decreased, the occupied space of the hosting devices is reduced, and the semi-automatic fixed die table PC component production system has giant advantages and good popularization prospects.

Owner:彭译萱

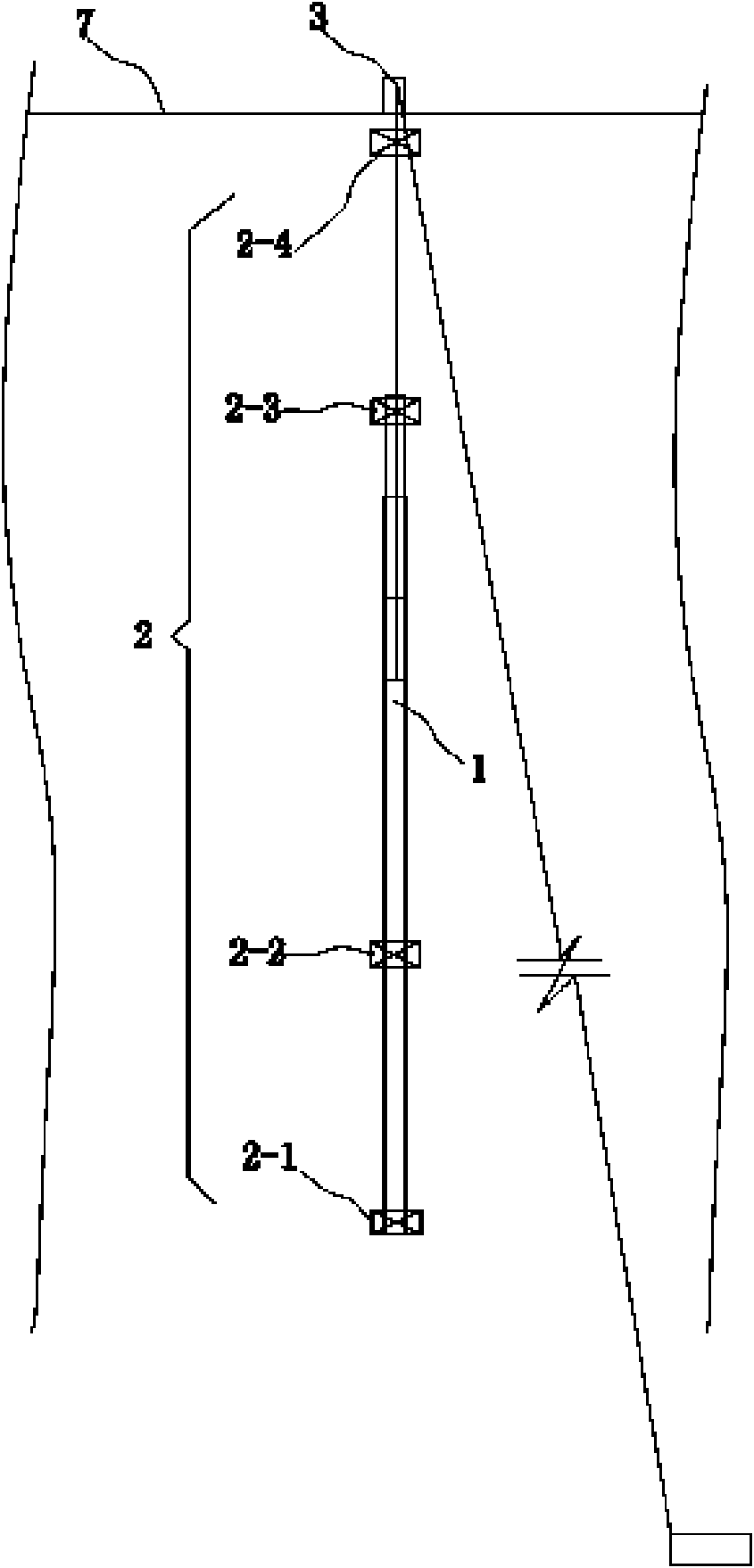

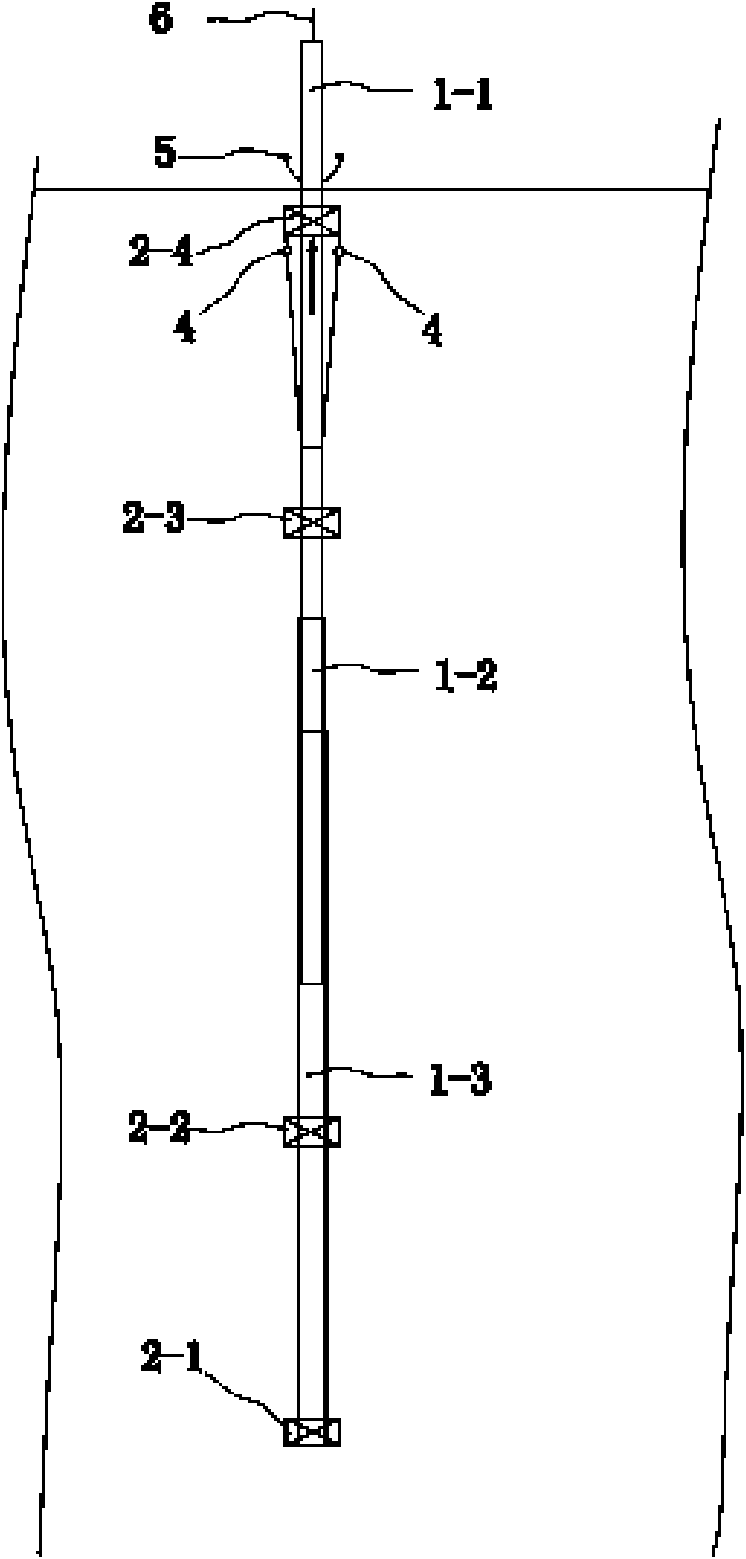

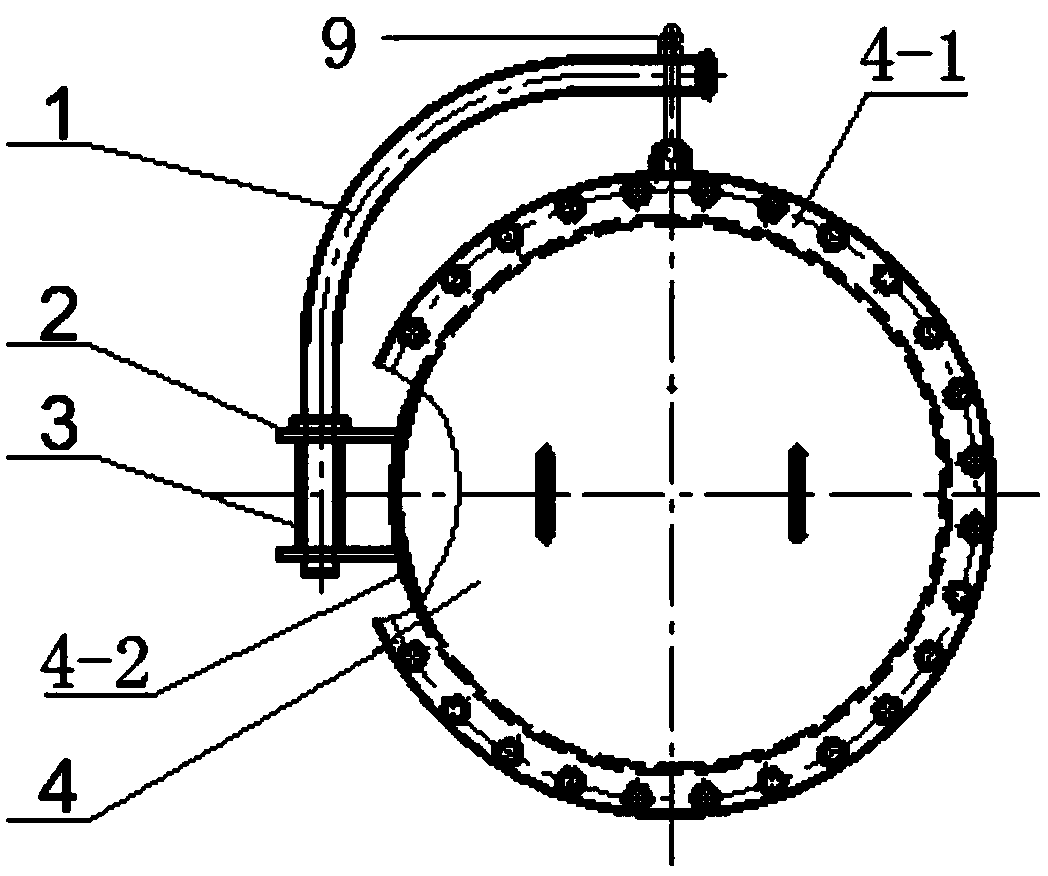

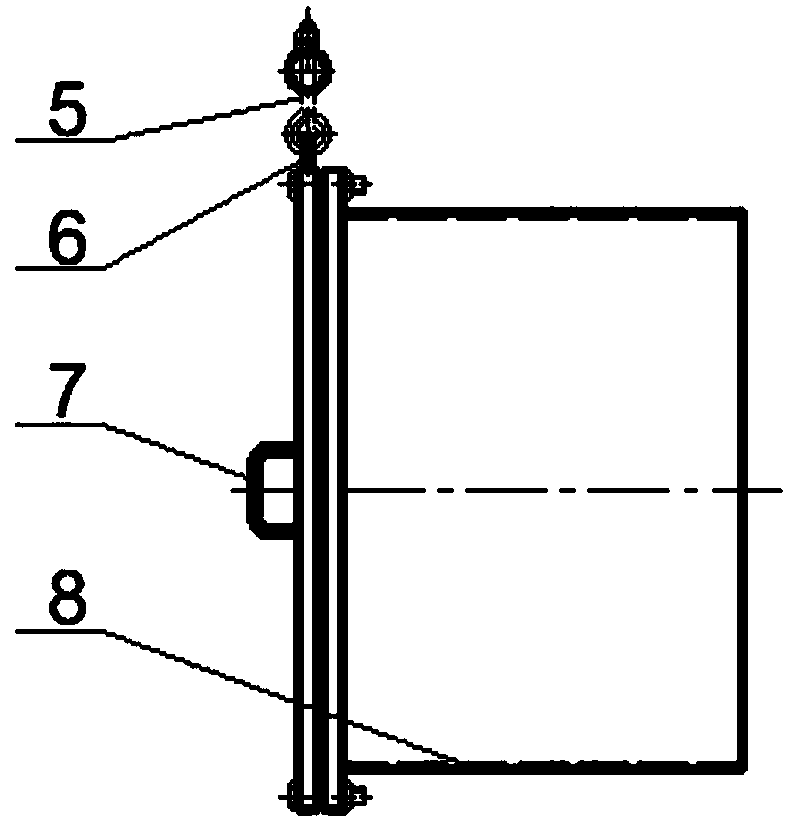

Installing method of roof mast

The invention relates to an installing method of a roof mast. The method comprises the following steps: firstly, lifting up a whole steel tube assembly by a windlass; and stopping the windlass when the bottom of the steel tube assembly reaches a base of the lowest place; secondly, connecting a pair of hand-drive block stringers to an outermost layer of steel tube and lifting up or down the steel tube assembly in an alternative working manner in order to fine adjusting the height of the steel tube assembly till the outermost layer of the steel tube is arranged at the base of the lowest place and a base of the lower place, and then keeping the position of the steel tube assembly and welding and fixing the steel tube assembly; connecting the hand-drive block stringers to an innermost layer ofsteel tube in the steel tube assembly, lifting up the innermost layer of the steel tube in an alternative working manner, and stopping the lifting when the length of the sleeved part of the lower endof the innermost layer steel tube and the upper end of an inner layer steel tube sleeved on the innermost layer steel tube is ranged from 0.3-2 m, and then welding and fixing the innermost layer of the steel tube with the inner layer of steel tube; and finally, repeatedly lifting up and welding each remained section of steel tubes sleeved in the outermost layer of the steel tube, and then finishing the installation of the roof mast.

Owner:CHANGZHOU NO 1 CONSTR GRP

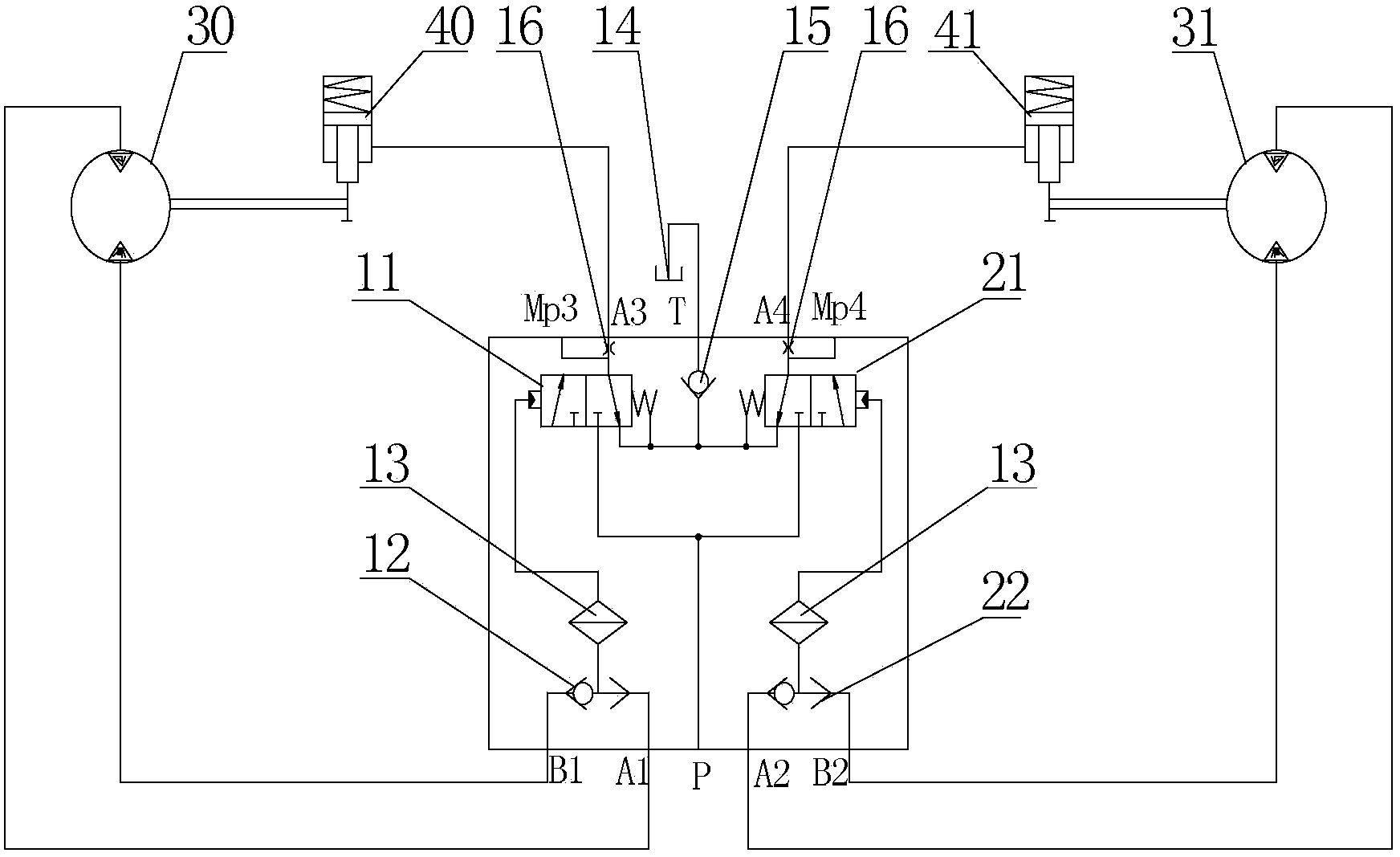

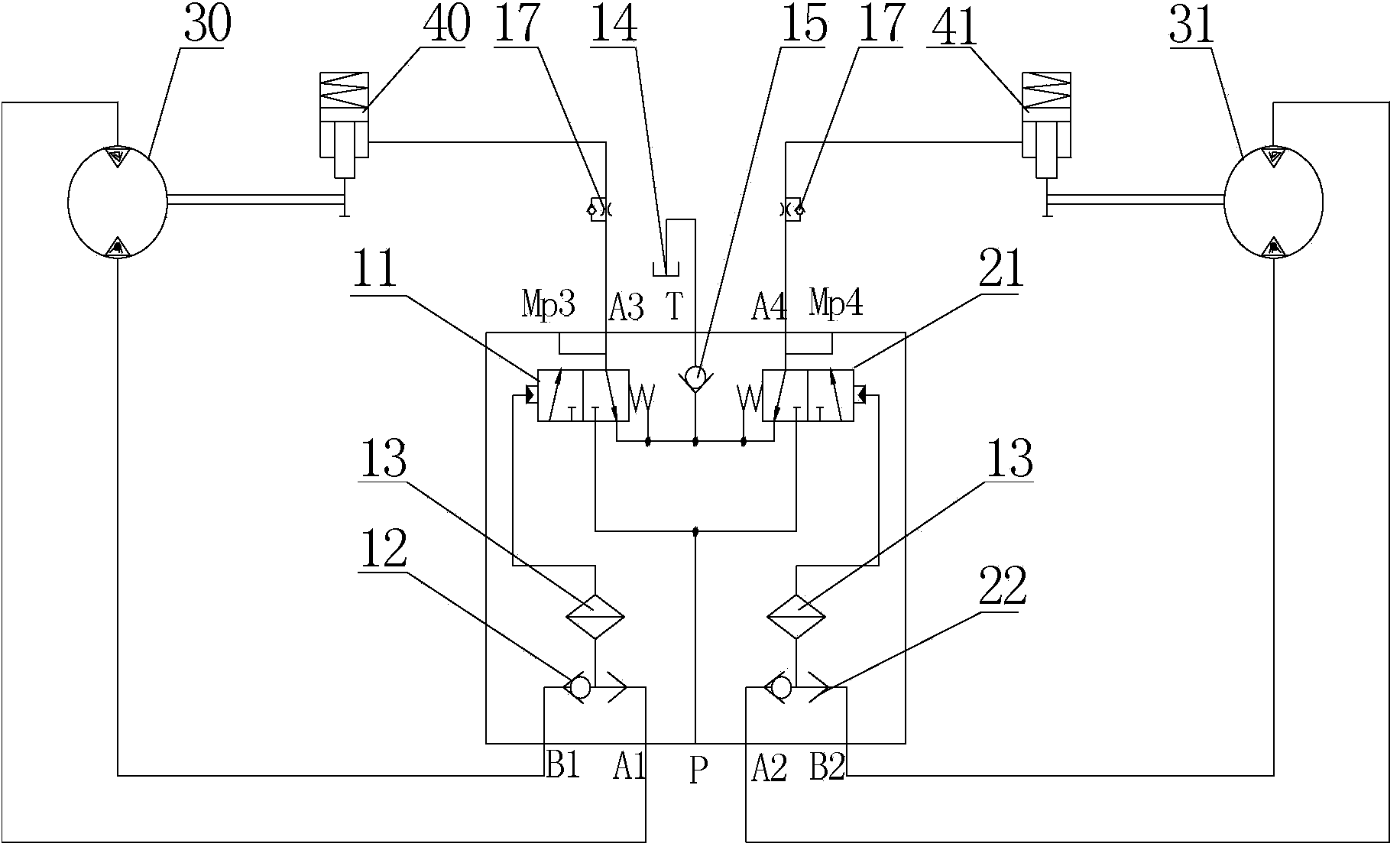

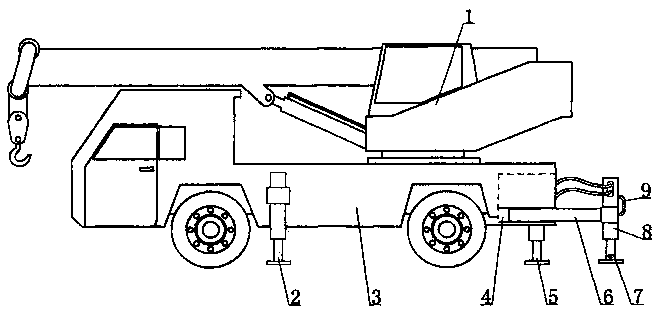

Control valve, hydraulic control system of winch brake and crane

ActiveCN103641023AAlleviate hoisting vibration phenomenonExtended opening timeServomotor componentsHoisting equipmentsControl systemFuel tank

The invention discloses a control valve used for a winch brake, a hydraulic control system of the winch brake and a crane. The control valve comprises a valve body, a first reversing valve is integrated in the valve body, a first oil port, a second oil port and a third oil port are formed outside the valve body, the first oil port is used for being communicated with a pressure oil line with constant external pressure, the second oil port is used for being communicated with a hydraulic oil tank, and the third oil port is used for being communicated with a control oil cylinder of a first winch brake; when the first reversing valve is positioned in the first working position, the first oil port and the third oil port are communicated; and when the first reversing valve is positioned in the second working position, the second oil port and the third oil port are communicated. The special oil ports and oil passages communicated with the pressure oil line with constant external pressure are arranged in the control valve disclosed by the invention, opening and closing of the brake are controlled through the pressure oil line with constant pressure; and in the control mode, pressure for controlling opening and closing of the brake is comparatively constant, the oil line pressure cannot be influenced by loads completely, and a chattering phenomenon during winch hoisting can be effectively relieved.

Owner:XUZHOU HEAVY MASCH CO LTD

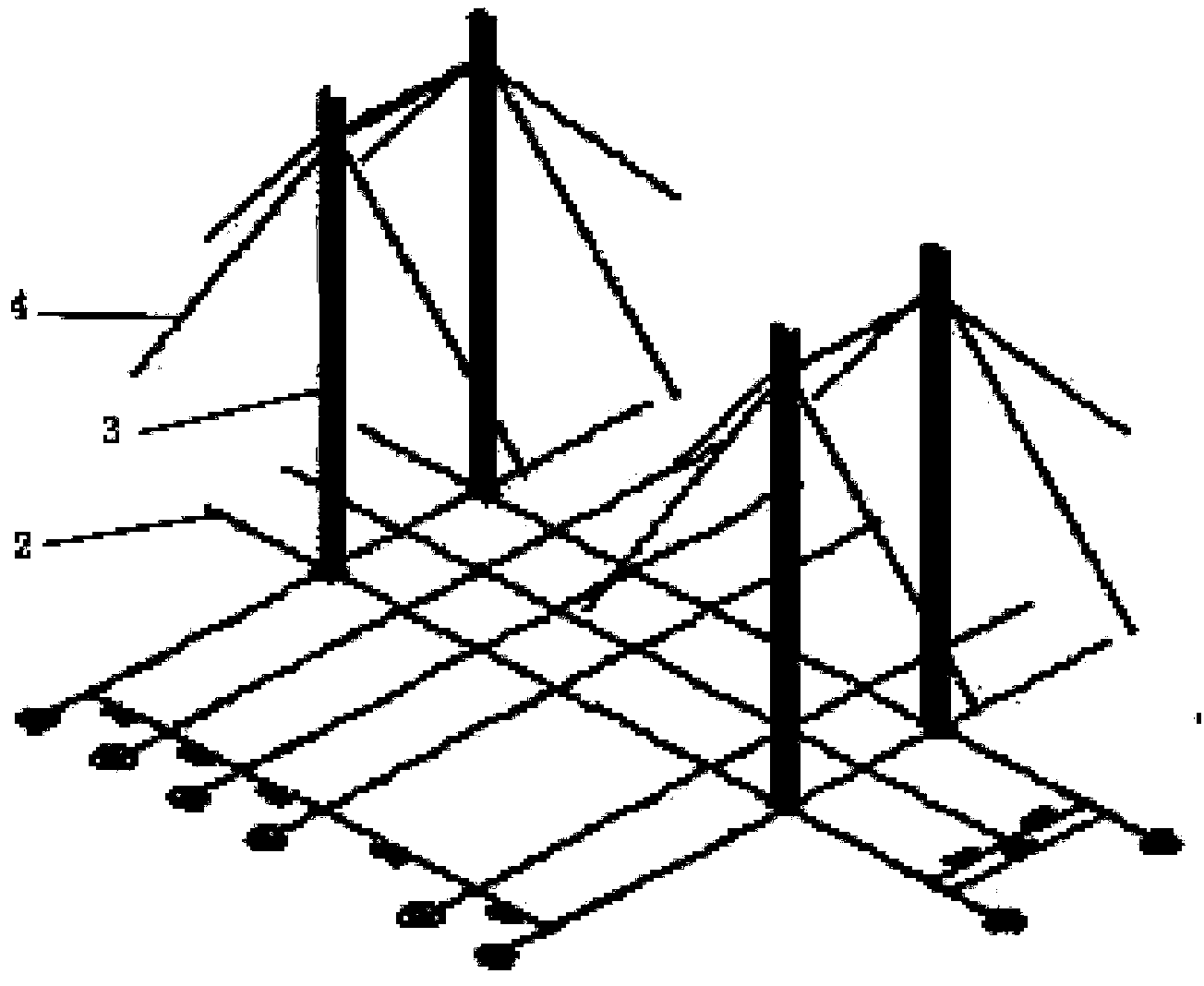

Method for producing steel reinforcement cage by using setting die

ActiveCN102094417AThe production process is simpleEasy constructionBulkheads/pilesRebarMechanical engineering

The invention discloses a method for producing a steel reinforcement cage by using a setting die, comprising the following construction steps of: (1) placing the processed steel reinforcement cage on a plurality of parallel frameworks arranged at intervals, wherein main reinforcement positioning clamps are respectively and equidistantly arranged on each framework; (2) placing a reinforcing rib corresponding to one main rib at the top end of the steel reinforcement cage along the radial direction, welding the main ribs with the reinforcing ribs and intersecting the reinforcing ribs at the center of the steel reinforcement cage and welding into a whole; (3) fully welding various main ribs of the steel reinforcement cage and then pushing the main ribs into a binding frame by rolling a roll carriage; fixing one end of a hooping on a main rib at the top end of the steel reinforcement cage at the initial end of the binding frame; and then backward rolling the steel reinforcement cage to ensure that the hooping is closely hooped on the steel reinforcement cage; and (4) pushing the bound steel reinforcement cage to a finished product frame through the rolling frame and finally carrying out the inspection and acceptance. The method provides a construction platform for producing the welding and the binding of the steel reinforcement cage and is quick and convenient for construction; the production procedures are greatly simplified; a production streamline is formed; and the construction period is effectively shortened.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

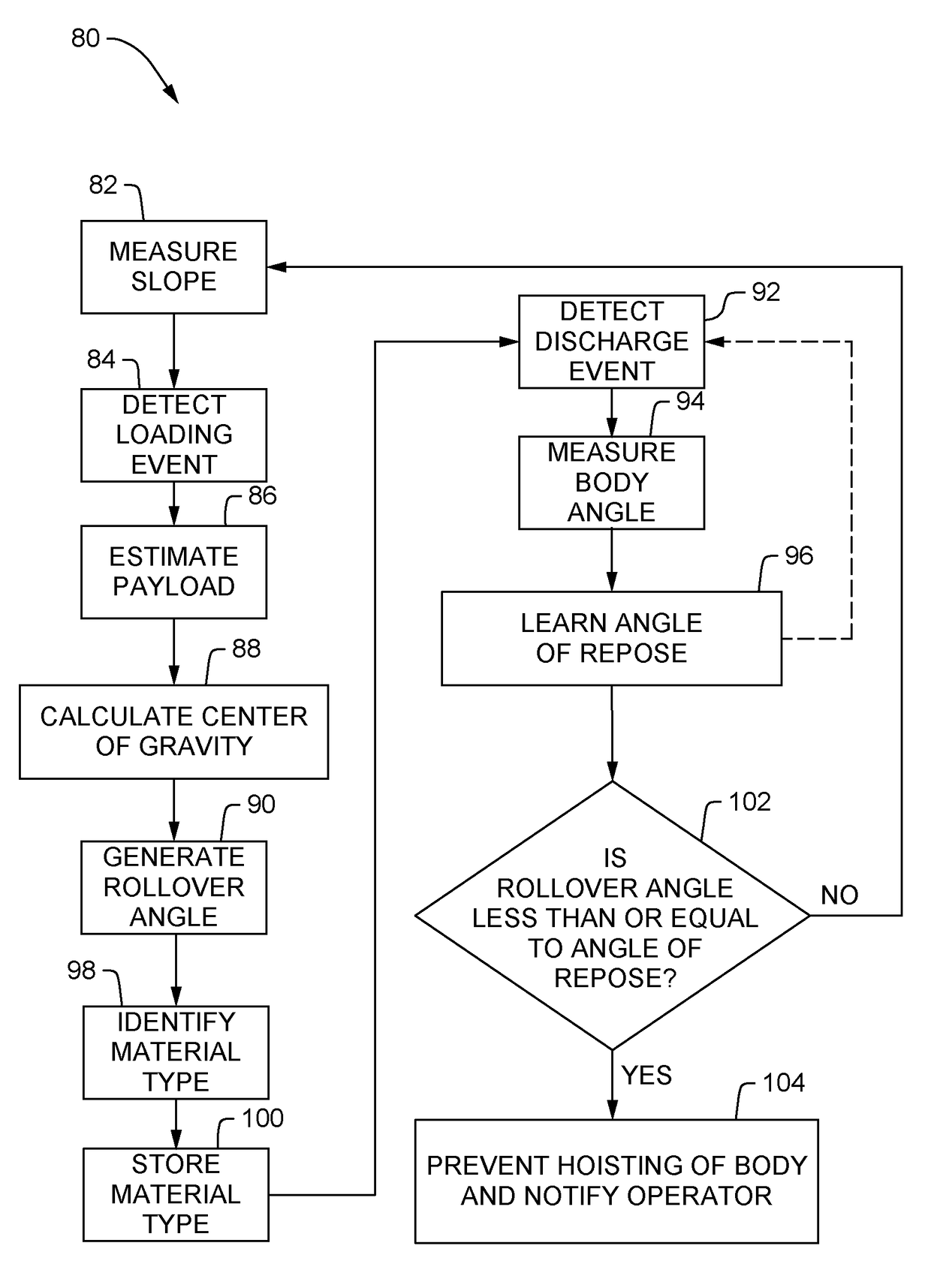

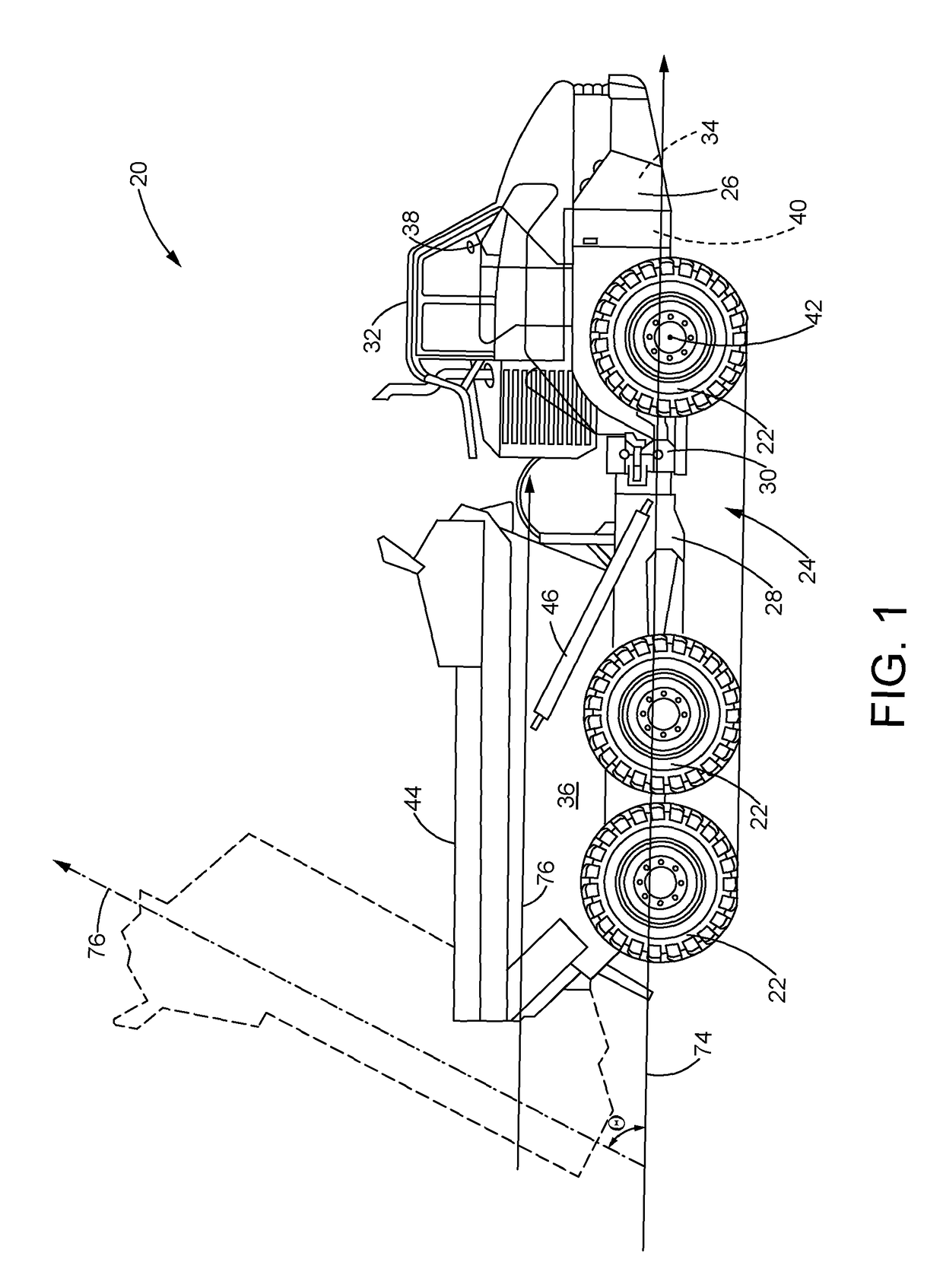

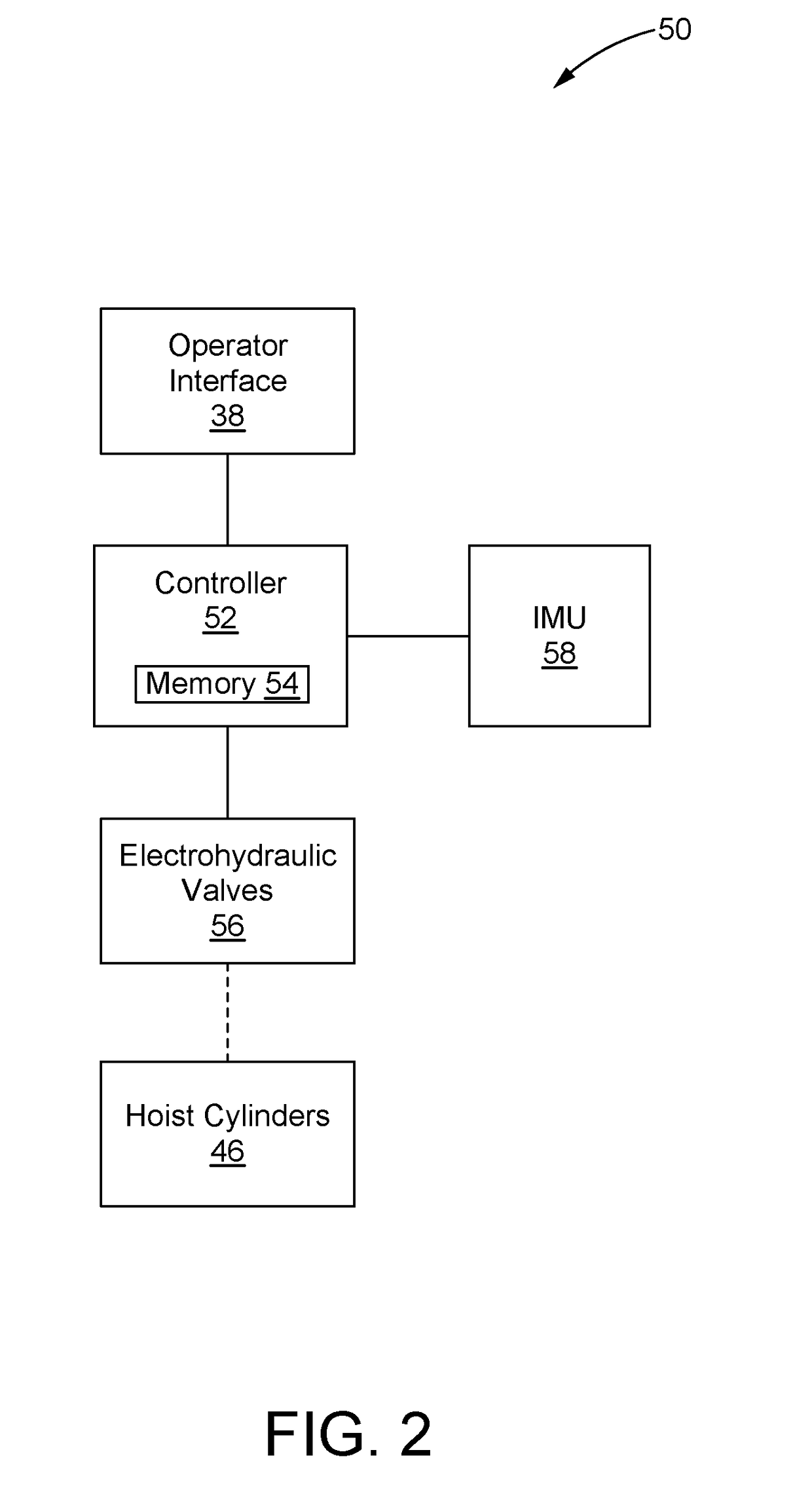

Angle of repose detector for hauling machines

ActiveUS9952115B2Prevent rolloverAvoid hoistingVehicle testingStatic/dynamic balance measurementBody anglePhase detector

A rollover prevention system for a machine is disclosed. The rollover prevention system may include an inertial measurement unit (IMU) configured to detect a discharge event of a payload material from the machine and measure a body angle of the machine. The rollover prevention system may further include a controller in communication with the IMU. The controller may be configured to determine an angle of repose of the machine based on the detected discharge event and the measured body angle.

Owner:CATERPILLAR INC

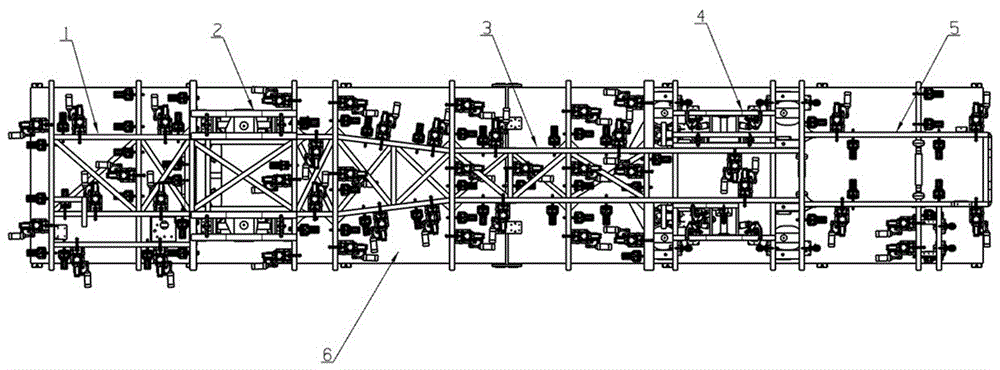

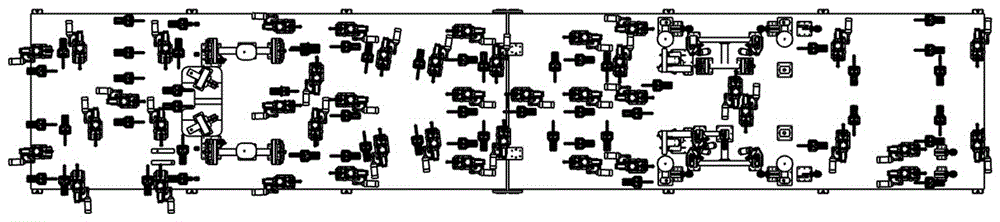

Full-load passenger car frame overall positioning and clamping tool

InactiveCN106736190AImprove product qualityIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelVehicle frame

The invention discloses a full-load passenger car frame overall positioning and clamping tool. The full-load passenger car frame overall positioning and clamping tool comprises a tool underbed assembly, a main body tool assembly, a front axle critical component tool assembly, a rear axle critical component tool assembly, a double-layer beam tool positioning assembly and a gas circuit control system. The tool underbed assembly is formed by welding U-steel to a steel plate, and after aging treatment is conducted, the upper surface of the steel plate is subjected to milling and serves as a positioning block installation datum plane. Accessories such as a thrust rod support, a gasbag installation base plate and a stable rod support which are located on the portions of a front axle and a rear axle and are high in position precision requirement are all positioned through special positioning devices. A pneumatic fixture, linear slide rails and the like which are applied to the tool are all standard parts. All positioning and clamping devices are arranged to be beneficial for automatic demolding of a whole car frame. Clamping and loosening of an air cylinder are controlled by a gas circuit through a two-position five-way valve, in order to ensure gas circuit cleanness and pressure stableness, a gas source adjusting device is installed at an inlet of the gas circuit, automatic production is achieved, the production benefit of car frame welding is increased, and the production quality of products is guaranteed.

Owner:厦门伟特思科技股份有限公司

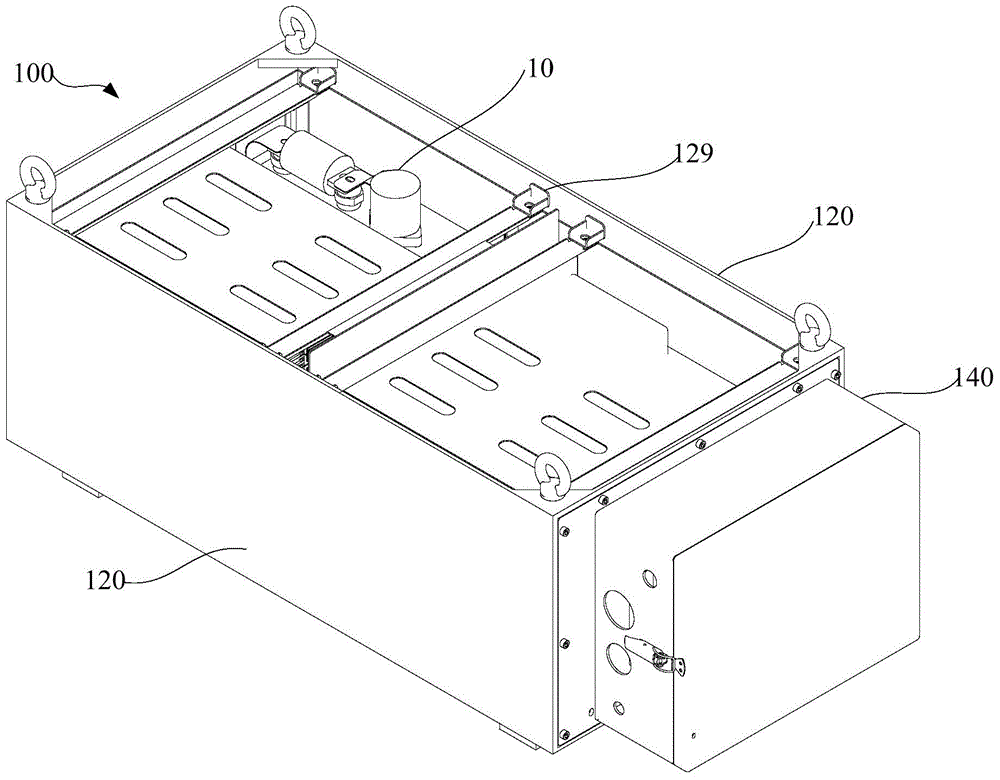

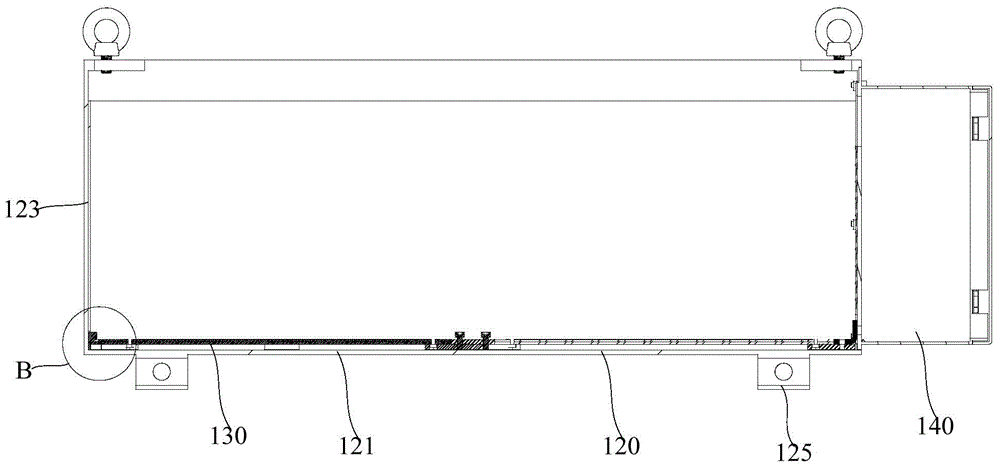

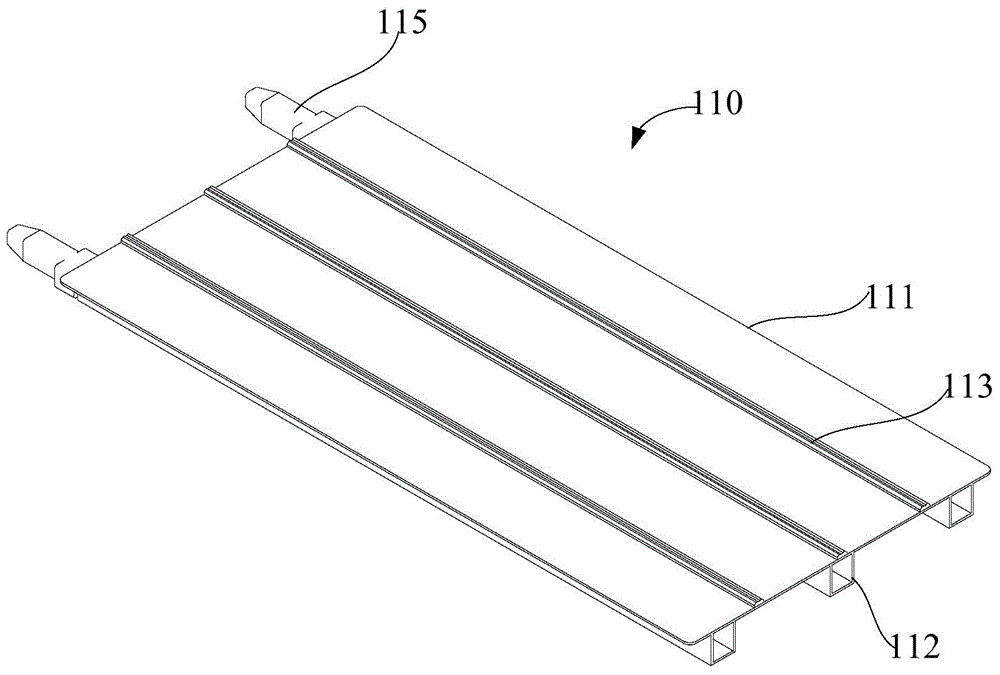

Battery pile mounting structure

ActiveCN104576991APrecise positioningAvoid hoistingCell component detailsPalletElectrical and Electronics engineering

The invention relates to a battery pile mounting structure, which comprises a battery box, a pallet and a control box, wherein the pallet is used for bearing the battery pile, and the control box is used for being electrically connected with the battery pile. The battery box consists of a bottom surface and a side wall, an opening is formed in the side wall, the control box is arranged in the opening, the bottom surface, the side wall and the control box define a box body, the pallet enters the box body from the opening, and the control box and the battery box are detachably connected. A guiderail is arranged on the bottom surface of the battery box and extends towards the opening, a guide channel matched with the guiderail is formed in the side surface, towards the bottom surface, of the pallet, the guiderail enters from one end of the guide channel, the pallet slides along the guiderail and drives the battery to enter the box body. According to the battery pile mounting structure, the battery pile assembly can slide inside the battery box from the opening of the battery box. Then, the control box is arranged in the opening, so that the battery pile is contained in the battery box so as to position the battery pile assembly. The battery pile assembly is prevented from being manually hoisted into the battery box from the upside of the battery box, and the operation is convenient, and the accurate positioning of the battery pile assembly in the battery box can be guaranteed.

Owner:SHENZHEN CLOU ELECTRONICS

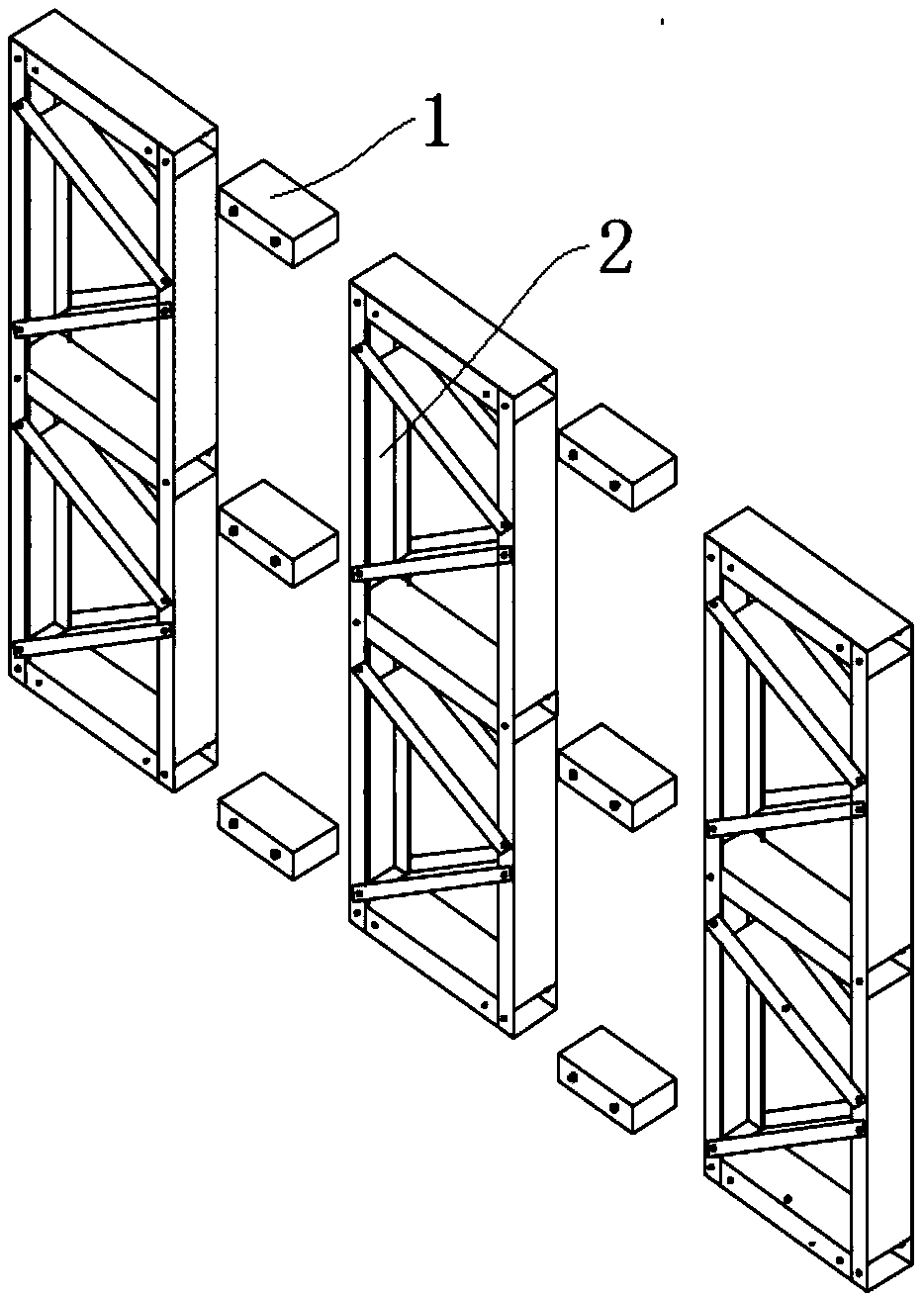

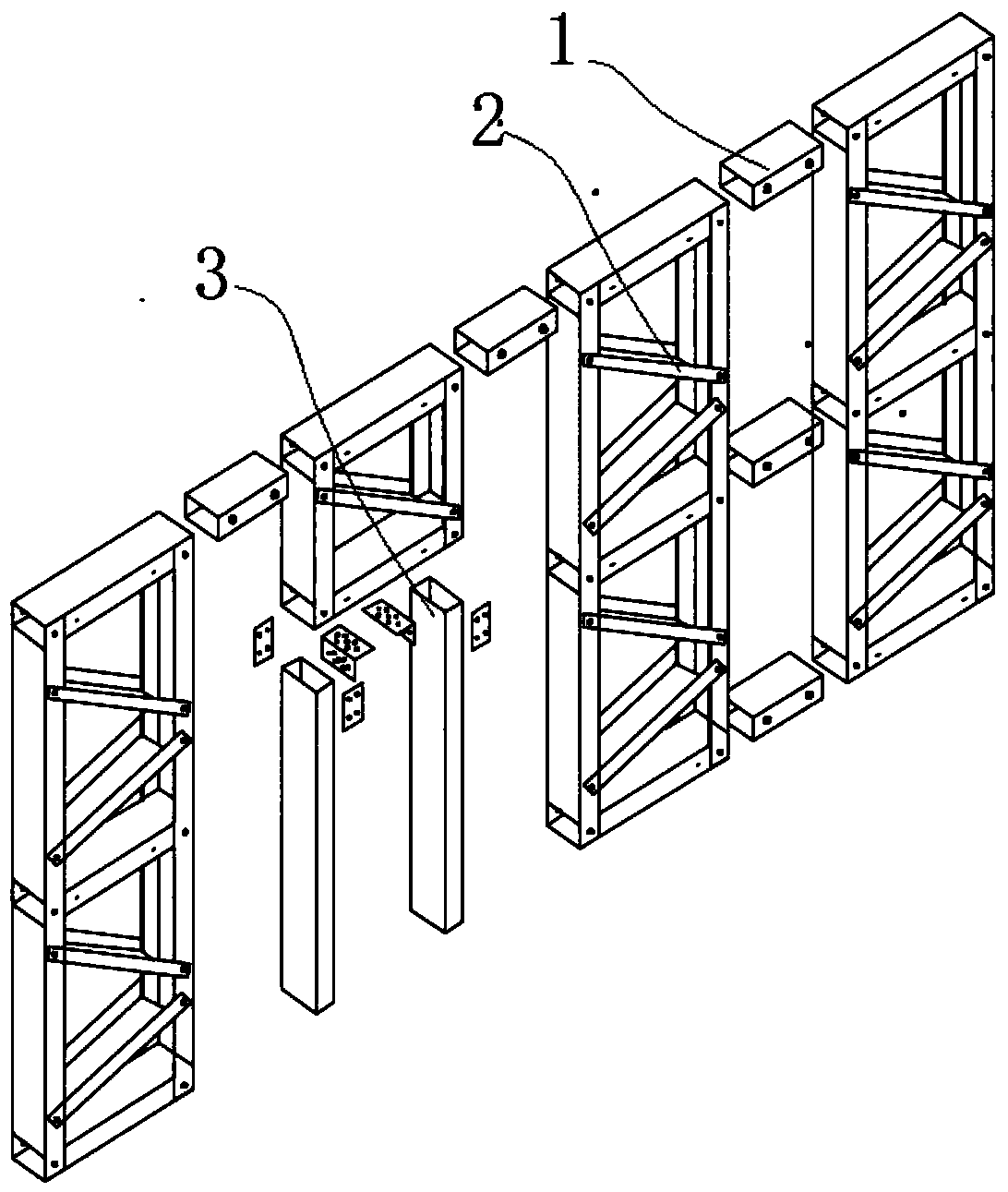

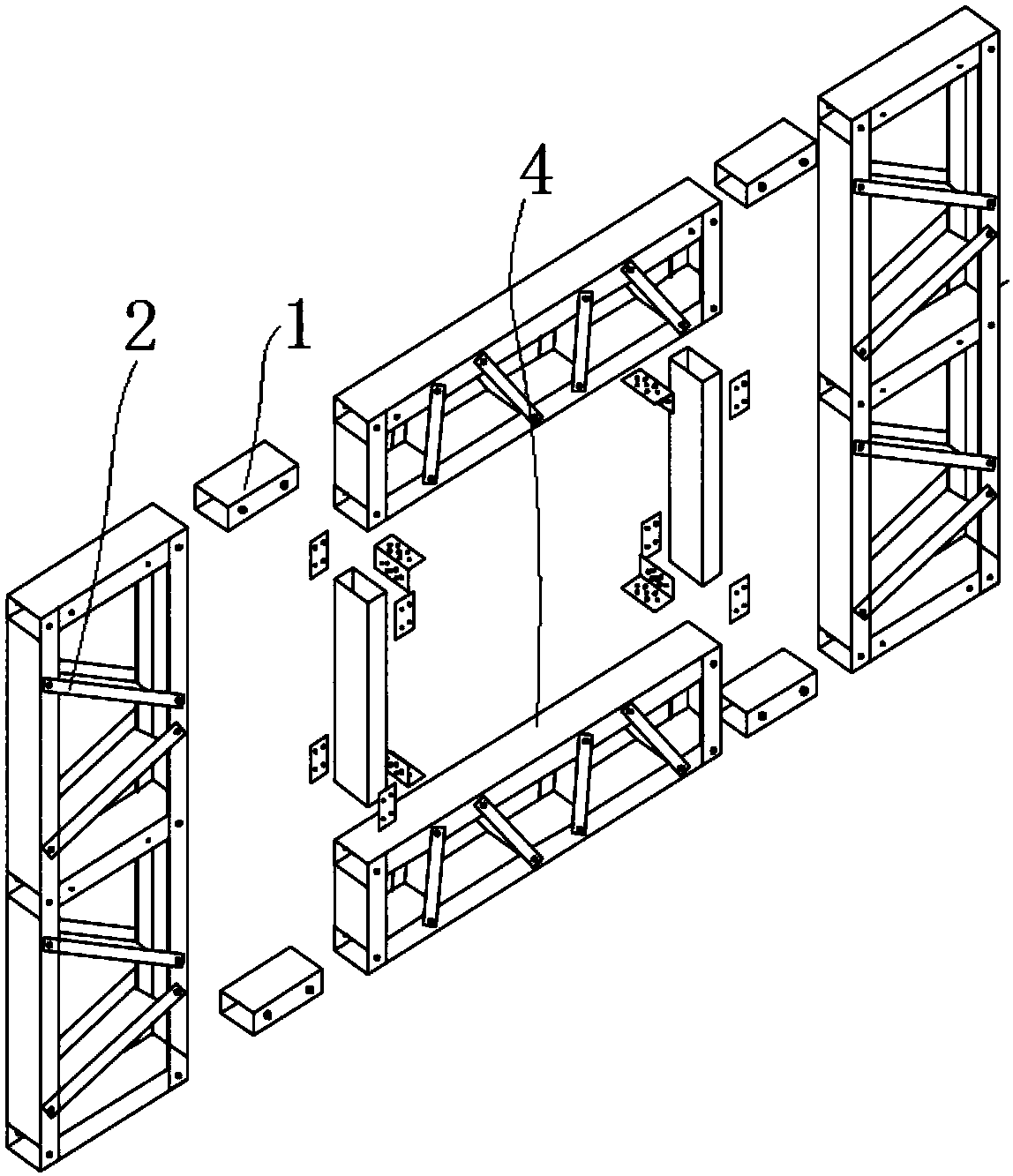

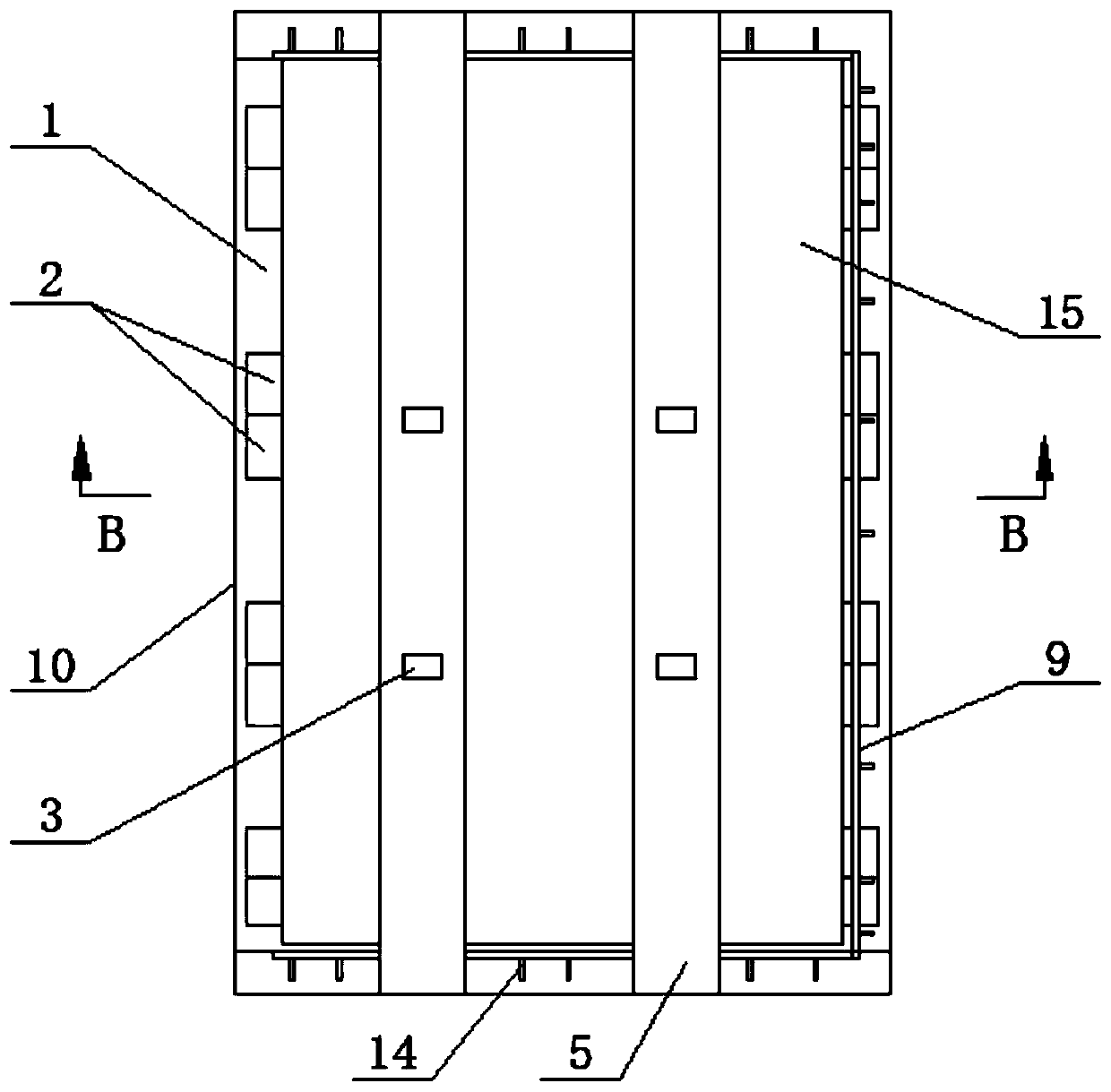

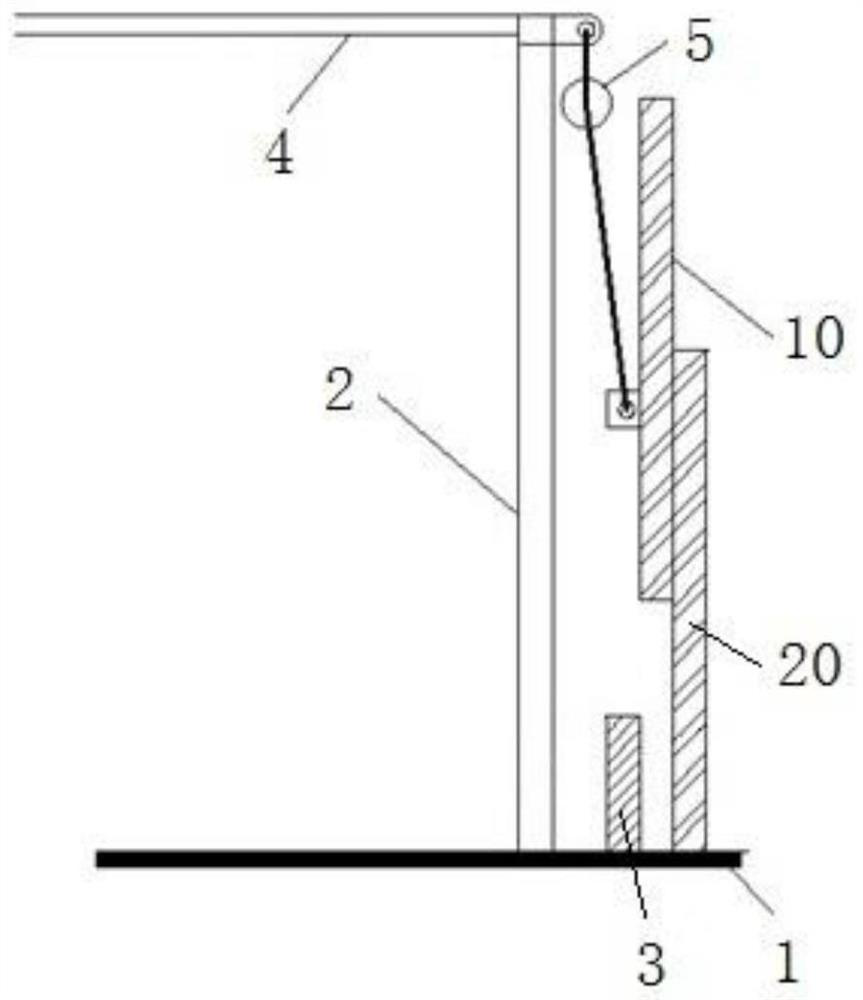

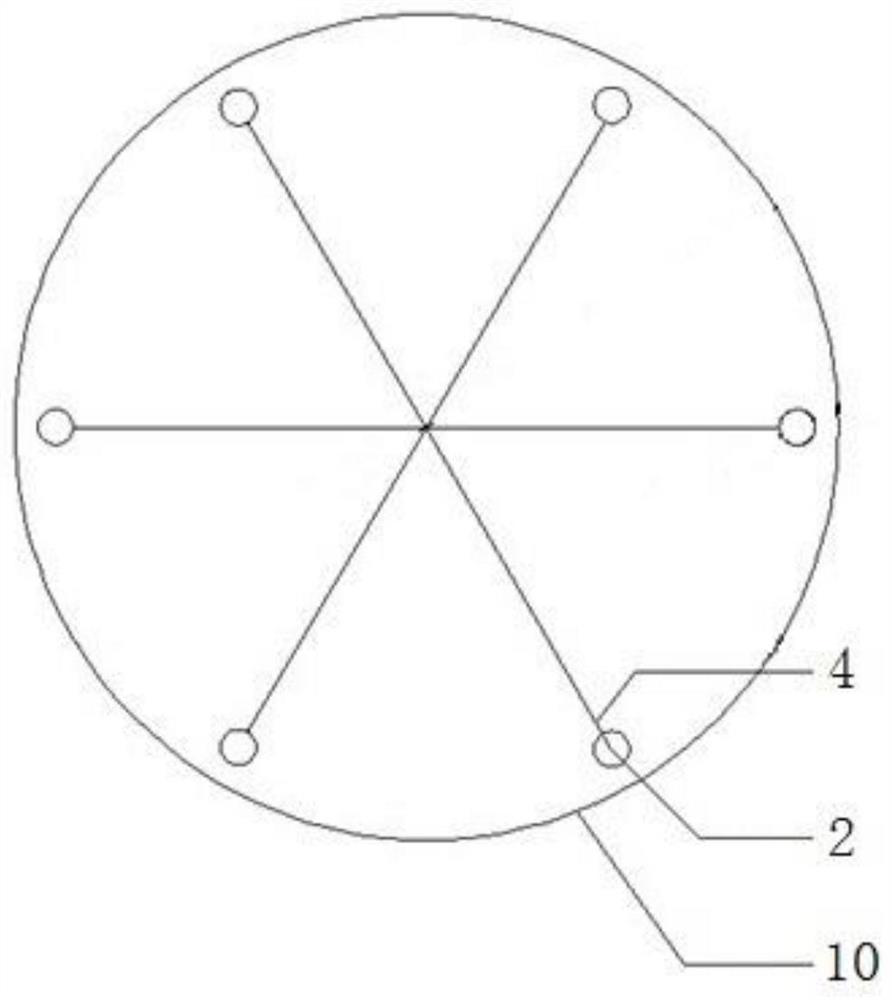

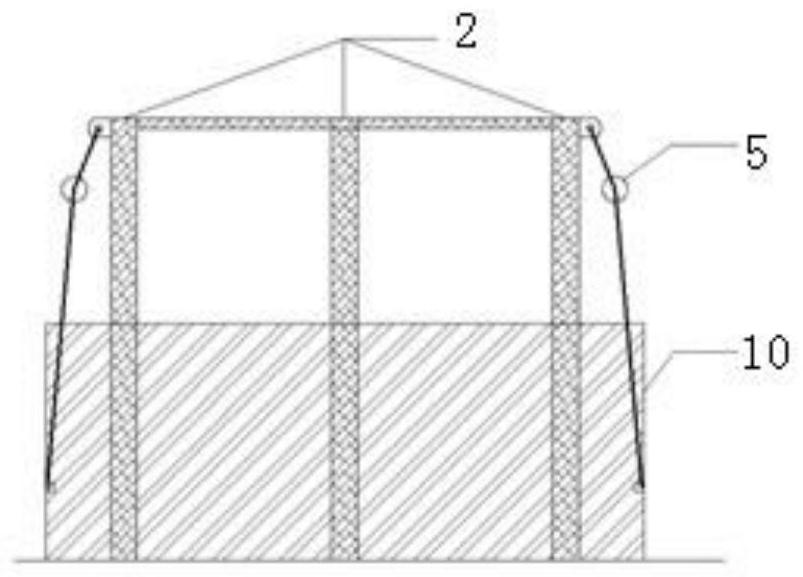

A spliced light steel wall board and a light steel building composed of the light steel wall board and the light steel building

Owner:JIANGSU HUADA INTEGRATED HOUSING

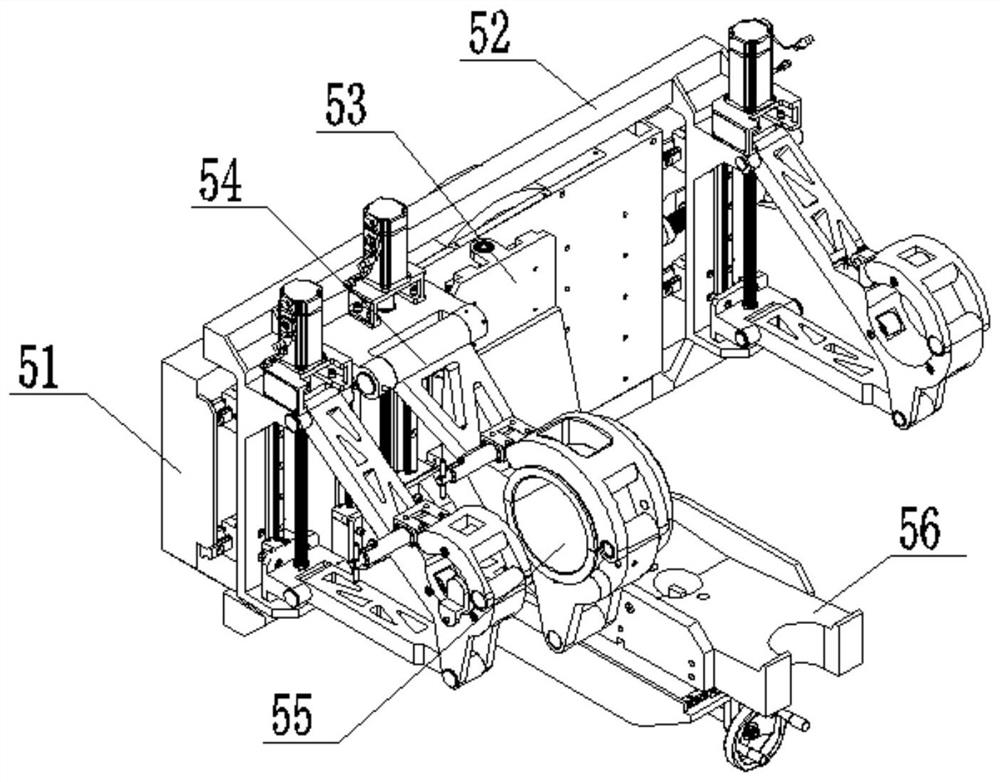

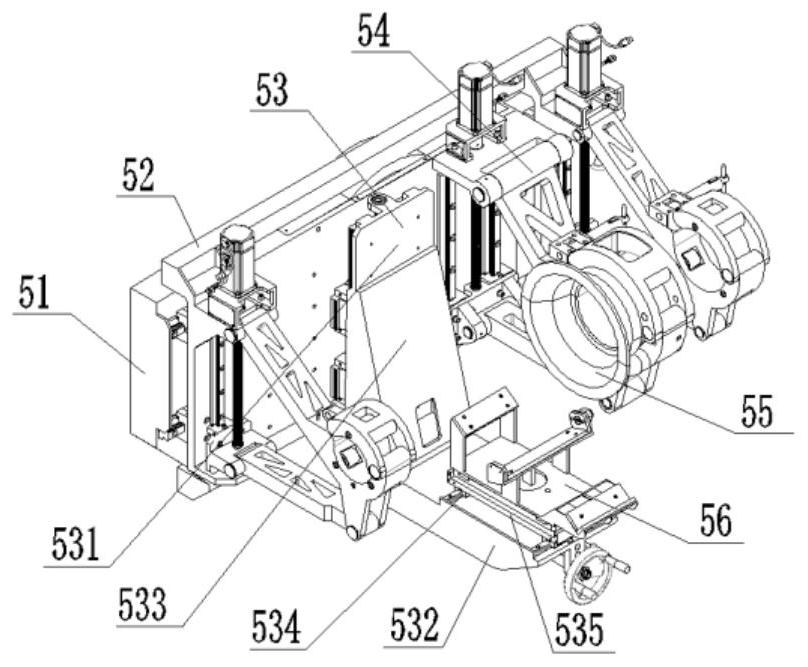

Clamping method and system for overhauling short shaft side gearbox of motor train unit based on AGV (Automatic Guided Vehicle)

PendingCN114516005AShorten the lifting timeSave manpower and material resourcesWork holdersElectric/hybrid propulsionGear wheelMachine

The invention discloses an AGV-based motor train unit short shaft side gear box overhauling and clamping method and system. The method comprises the steps that a turnover machine and a gear box positioning and clamping unit return to zero for self-inspection; the AGV conveys the gear box workpiece on the short shaft side to a box closing operation station and takes the gear box workpiece in place; the robot presses the torque value on the short shaft side end face of the gearbox and then returns to the zero position; a gearbox vertical lifting unit is installed on the short shaft side of a gearbox workpiece and fixed, a transverse moving unit is started to eliminate the gap value between a box body on the short shaft side of the gearbox workpiece and the gearbox vertical lifting unit, and a gearbox positioning and clamping unit on the short shaft side is controlled to rotate anticlockwise so that the gearbox workpiece can be in a vertical posture; the automatic jacking unit assists in adjusting the large gear bearing clearance of the gear box workpiece until the gear box workpiece is qualified; after the small gear enters the box and the clearance of the small gear is measured, the short shaft side gear box positioning and clamping unit is controlled to rotate clockwise, so that a gear box workpiece is in a horizontal posture; and through integrated and automatic operation, the workpiece hoisting cost is saved, and the working efficiency is improved.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

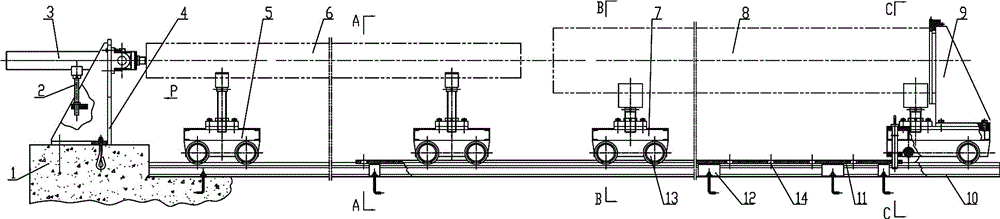

Horizontal cylinder assembling mechanism of hydraulic oil cylinder

ActiveCN104972286AEasy to adjustThe adjustment process is safe and reliableMetal working apparatusHydraulic cylinderCylinder block

The invention discloses a horizontal cylinder assembling mechanism of a hydraulic oil cylinder. The horizontal cylinder assembling mechanism comprises a cylinder pushing support provided with a pushing oil cylinder. Two tracks are laid on a foundation on the right side of the pushing oil cylinder and fixed to the foundation through track fixing devices. Two piston rod supporting trolleys used for supporting a piston rod to be assembled are arranged on the left sides of the tracks. An oil cylinder supporting trolley for supporting an oil cylinder to be assembled and a cylinder body supporting and positioning trolley are arranged on the right sides of the tracks in sequence. A supporting track is installed between the two tracks and fixedly provided with a positioning plate. The horizontal cylinder assembling mechanism is a novel guide rail type hydraulic oil cylinder horizontal cylinder assembling special device developed for solving the problem that to prevent sealing scratching in the hydraulic cylinder assembling process, assembling is difficult. The horizontal cylinder assembling mechanism is widely applied to comprehensive assembly of hydraulic cylinders which are different in diameter and length and are provided with different internal structures. According to the horizontal cylinder assembling mechanism, the hydraulic cylinder oil cylinder assembling efficiency is greatly improved, the labor intensity is relieved, and the using frequency of crown blocks is reduced.

Owner:HUBEI LIDI MACHINE TOOL

Construction method of chemical ship pipe collecting area unit

The invention relates to a construction method of a chemical ship pipe collecting area unit, which comprises two layers of brackets, two layers of pipelines and a platform, wherein a bottom layer of brackets, a bottom layer of pipelines, an upper layer of brackets, an upper layer of pipelines and the platform are respectively arranged from bottom to top, the construction method comprises the following steps of: constructing a pipe collecting area unit on a special bracket; arranging a column type jig which simulates the height of T rows of main decks of the pipe collecting area on the specialbracket as a bracket for supporting the pipe collecting area unit; and placing the special bracket on a unit construction site, after the construction of the pipe collecting area unit is finished, transporting the special bracket to a dock or a berth area through a flat car under the condition of not taking off the tire, so that the pipe collecting area unit is directly hoisted on the ship. According to the method, the hoisting of the whole unit is avoided, the limitation of hoisting capacity is avoided, the integrity of the unit is greatly improved while the whole weight of the unit is improved, and the deformation of the unit from the hoisting belt is effectively avoided.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

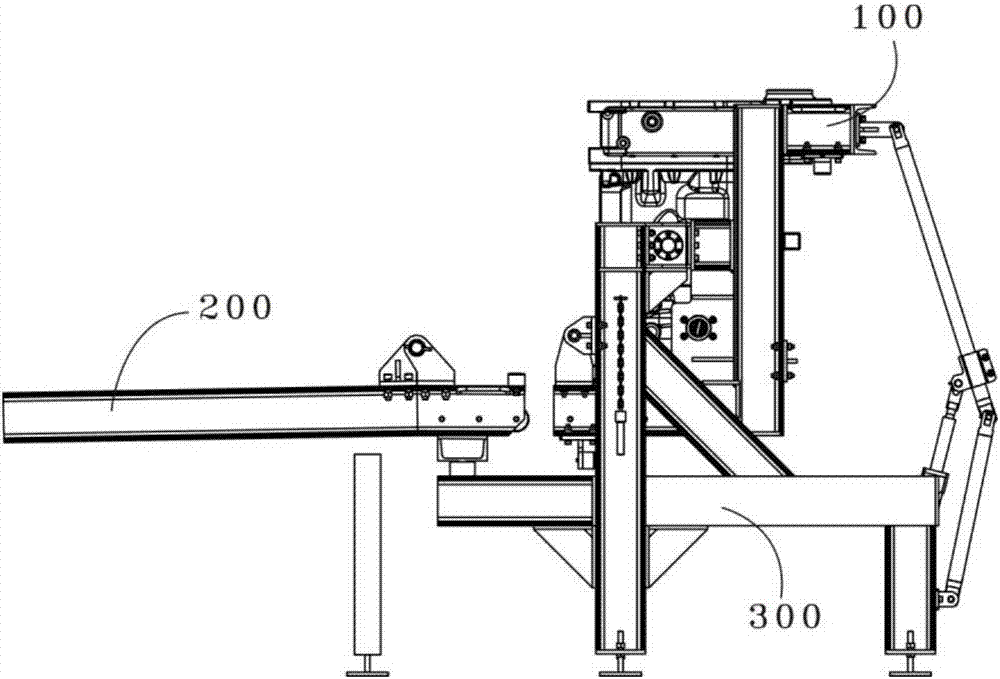

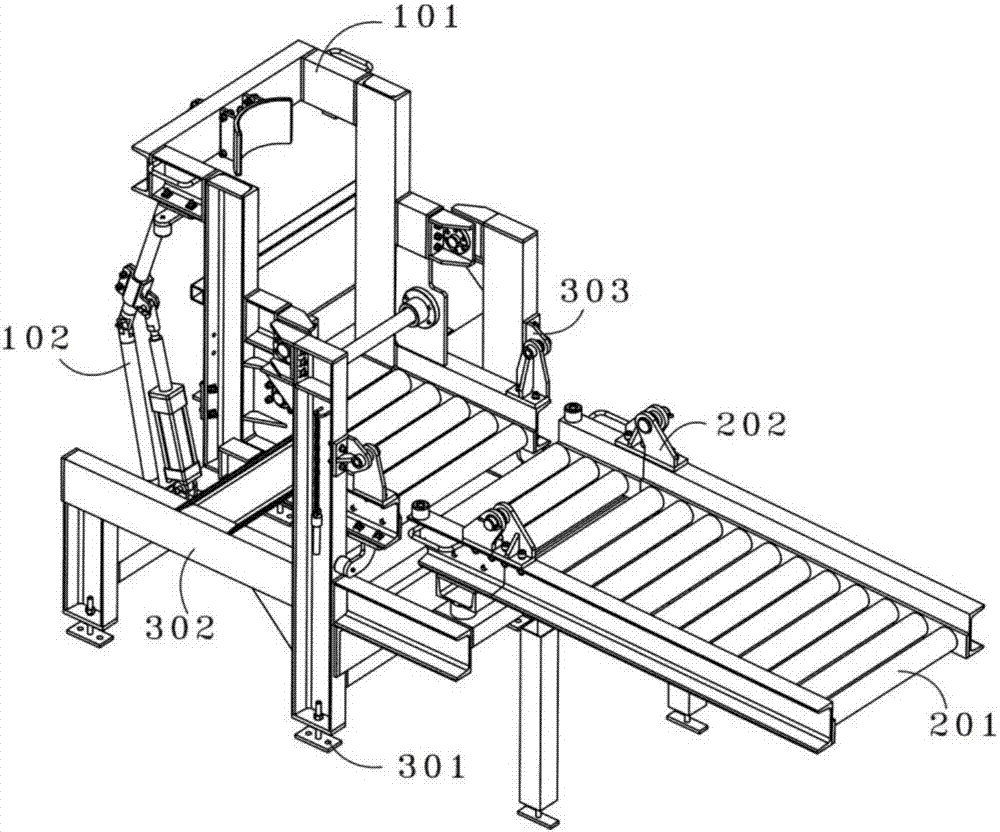

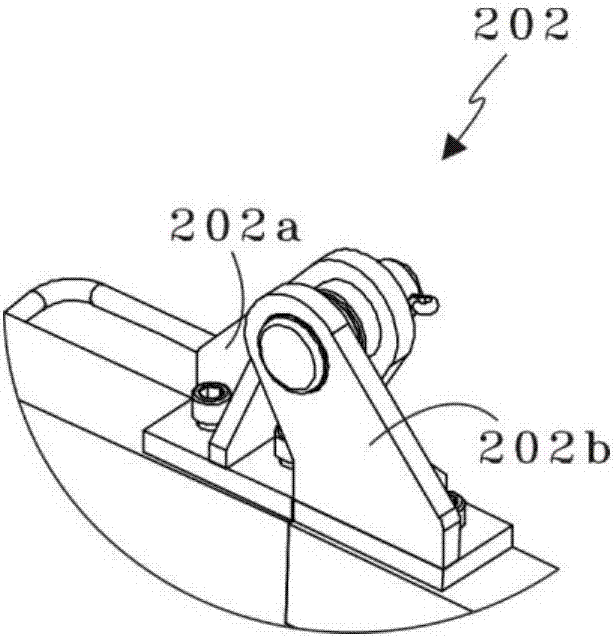

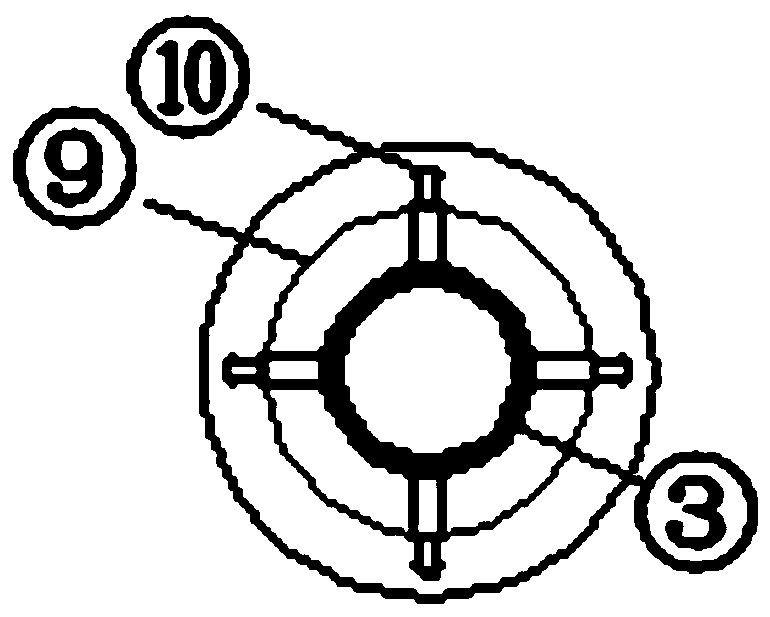

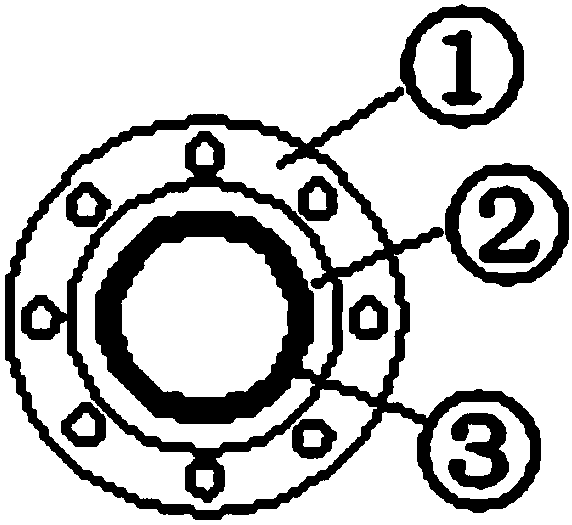

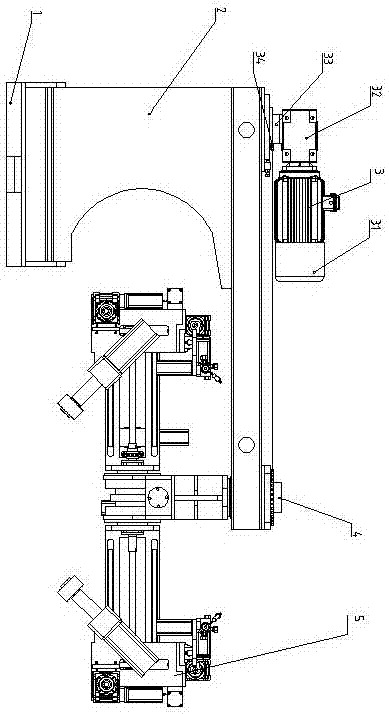

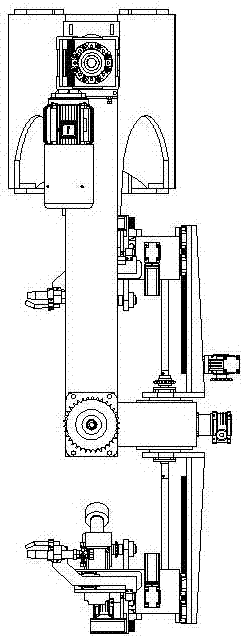

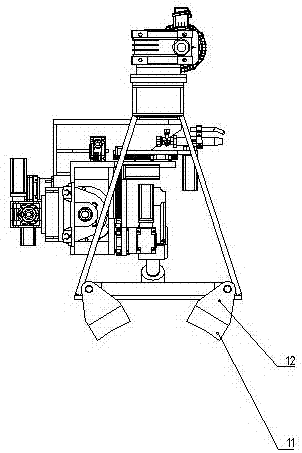

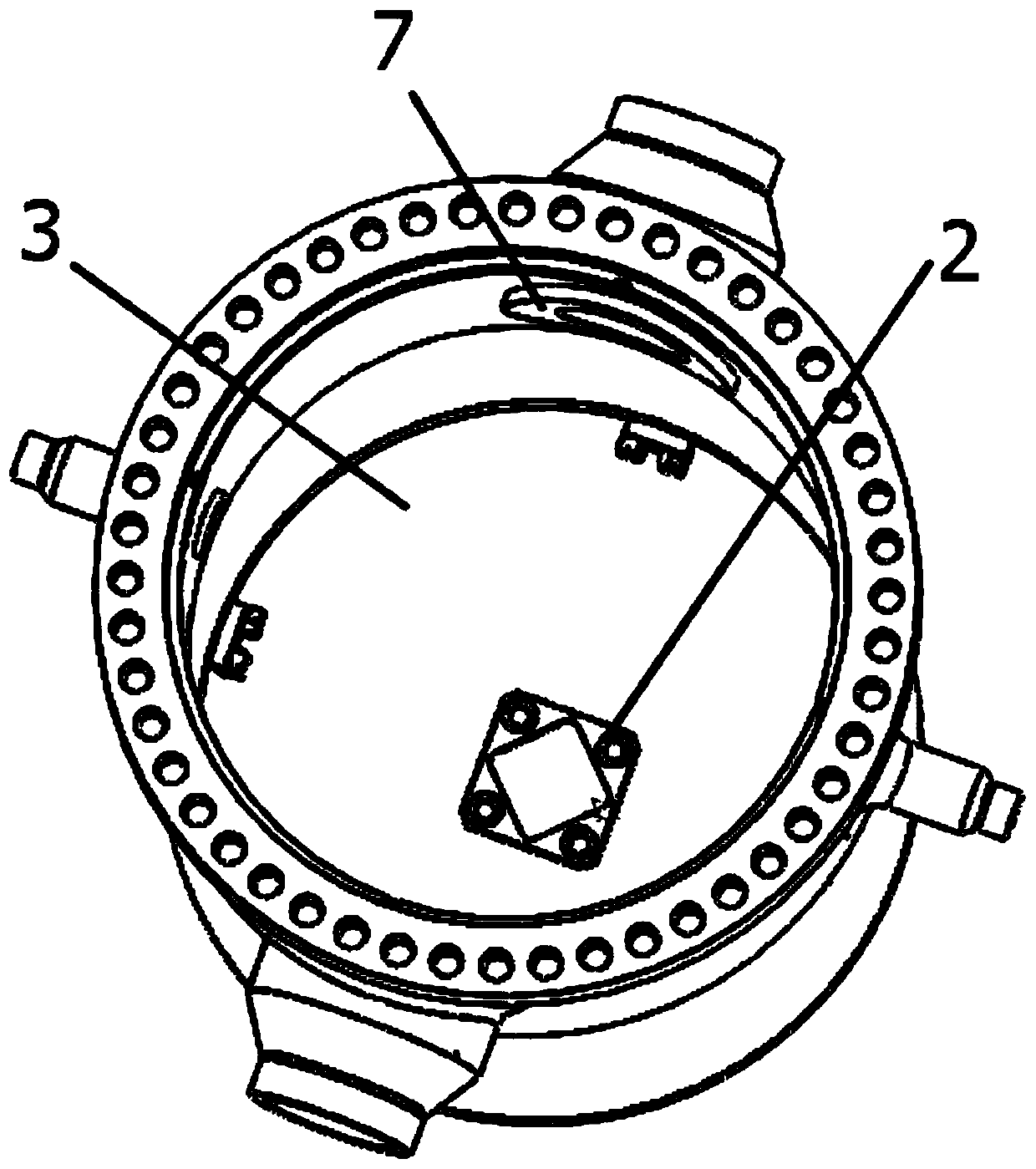

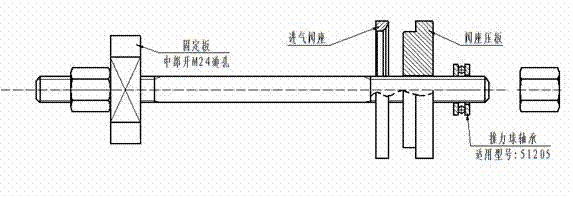

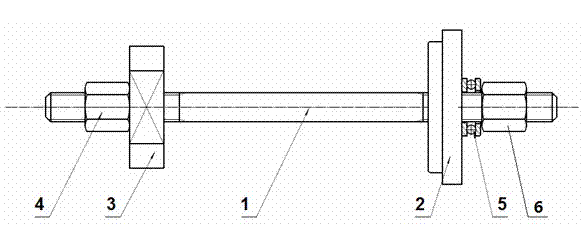

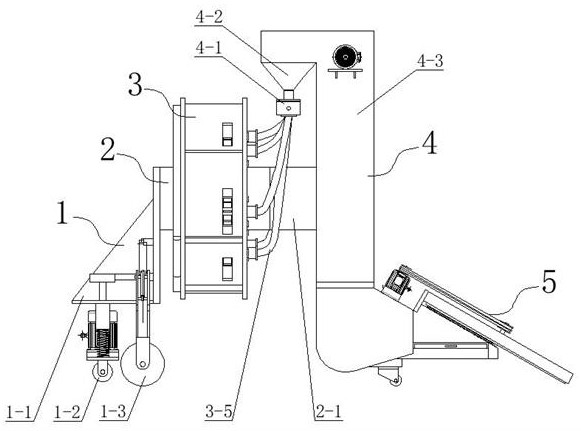

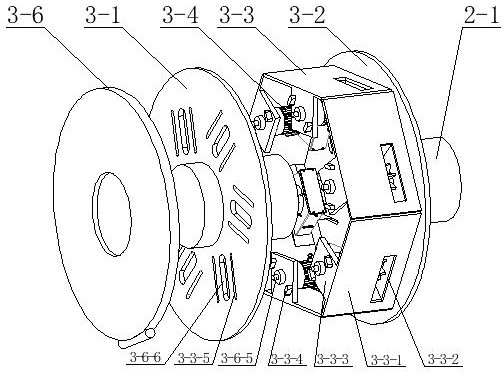

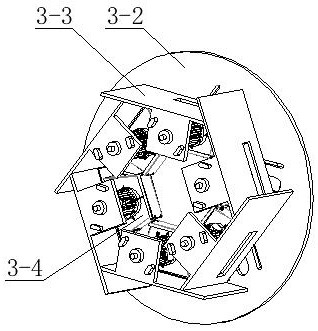

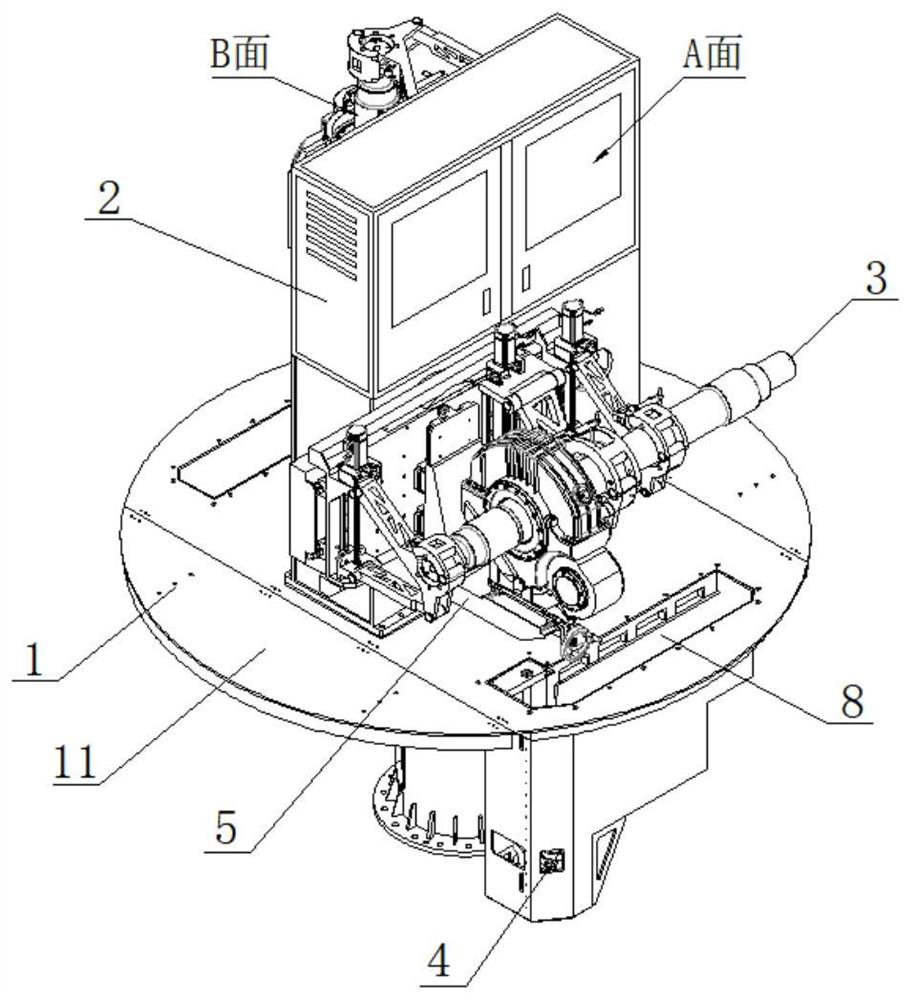

Portable turnover device for transfer case assembling

The invention discloses a portable turnover device for a transfer case assembling. The portable turnover device comprises a turnover table assembly, a roller bed delivery assembly, and a fixing assembly, wherein the turnover table assembly comprises supporting pieces and connecting pieces, and the connecting pieces are connected with the supporting pieces and a fixing support. The roller bed delivery assembly comprises rolling pieces and hinging pieces, the hinging pieces are divided into first hinging pieces and second hinging pieces, and the first hinging pieces are arranged on two sides of each rolling piece correspondingly; and the fixing assembly is connected with the turnover table assembly and the roller bed delivery assembly. The portable turnover device for the transfer case assembling has the beneficial effects that by additionally arranging a limiting shaft, no slippage happening in the transfer case turnover process is guaranteed, driving pieces and connecting rod pieces cooperate together to provide power for turnover, the whole turnover process is compact and stable, and reliable guarantees are provided for the transfer case to change stations and conduct a next assembly process; and meanwhile, the complicated lifting and leveling operation are avoided, labor burdens of workers are reduced, the assembly efficiency of the transfer case is improved, and the advantage of the mechanical assembly method is reflected.

Owner:JIANGSU UNIV OF SCI & TECH

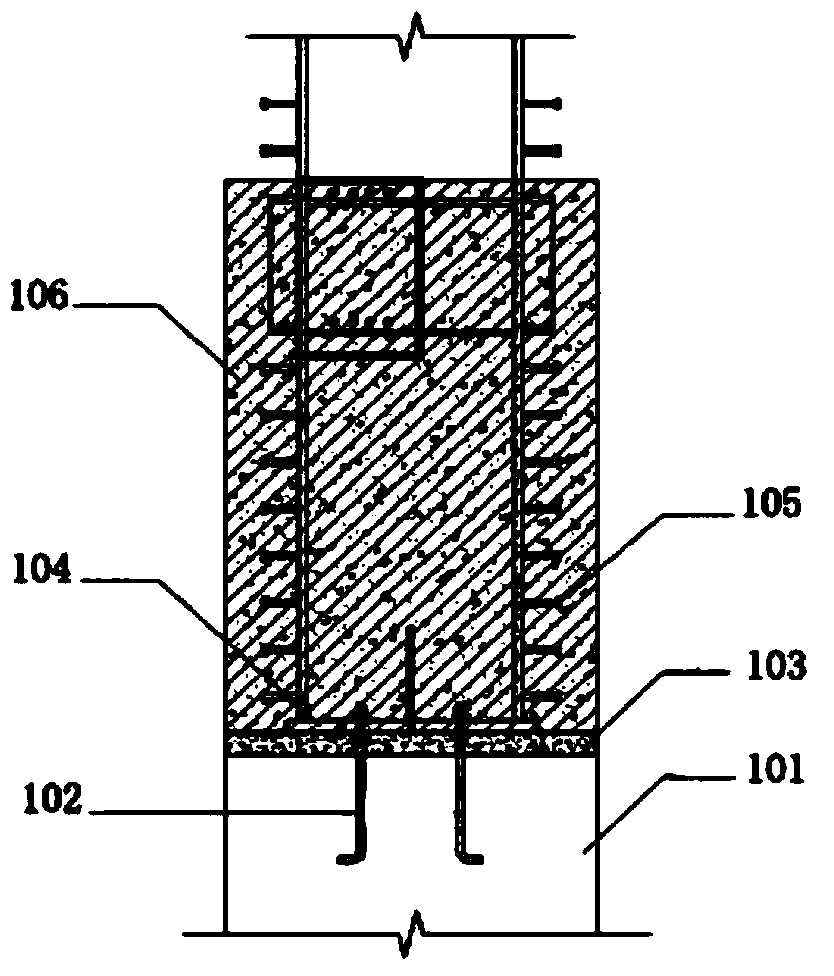

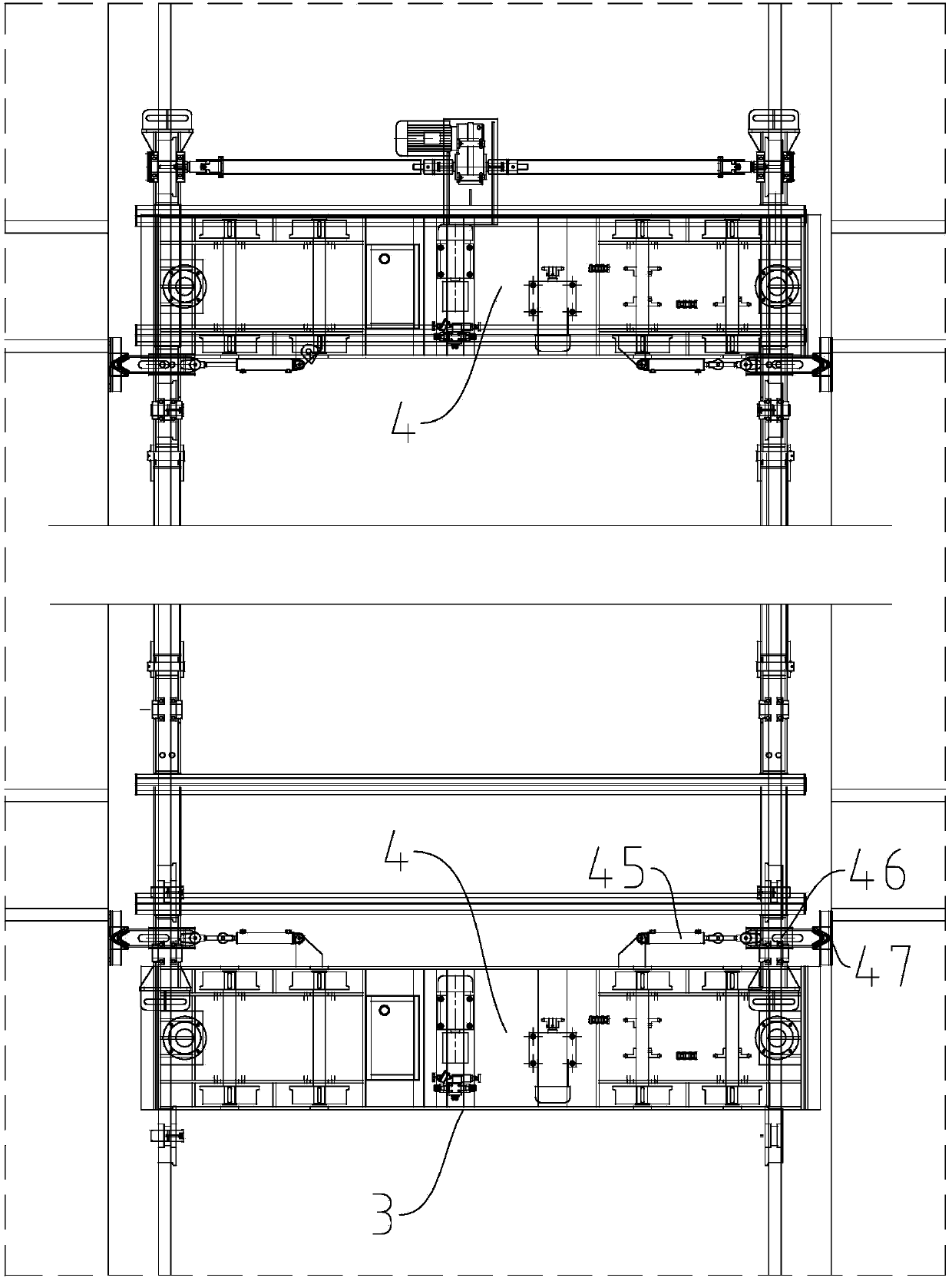

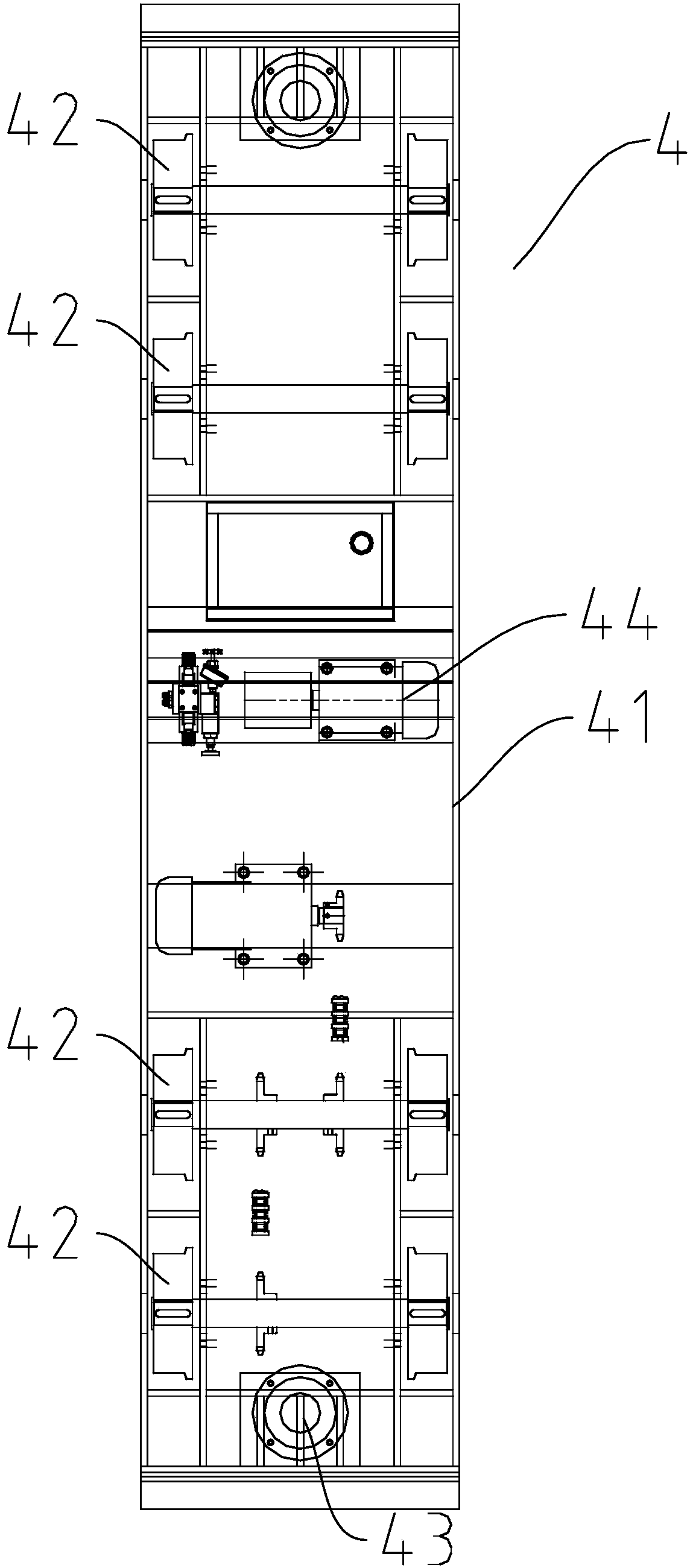

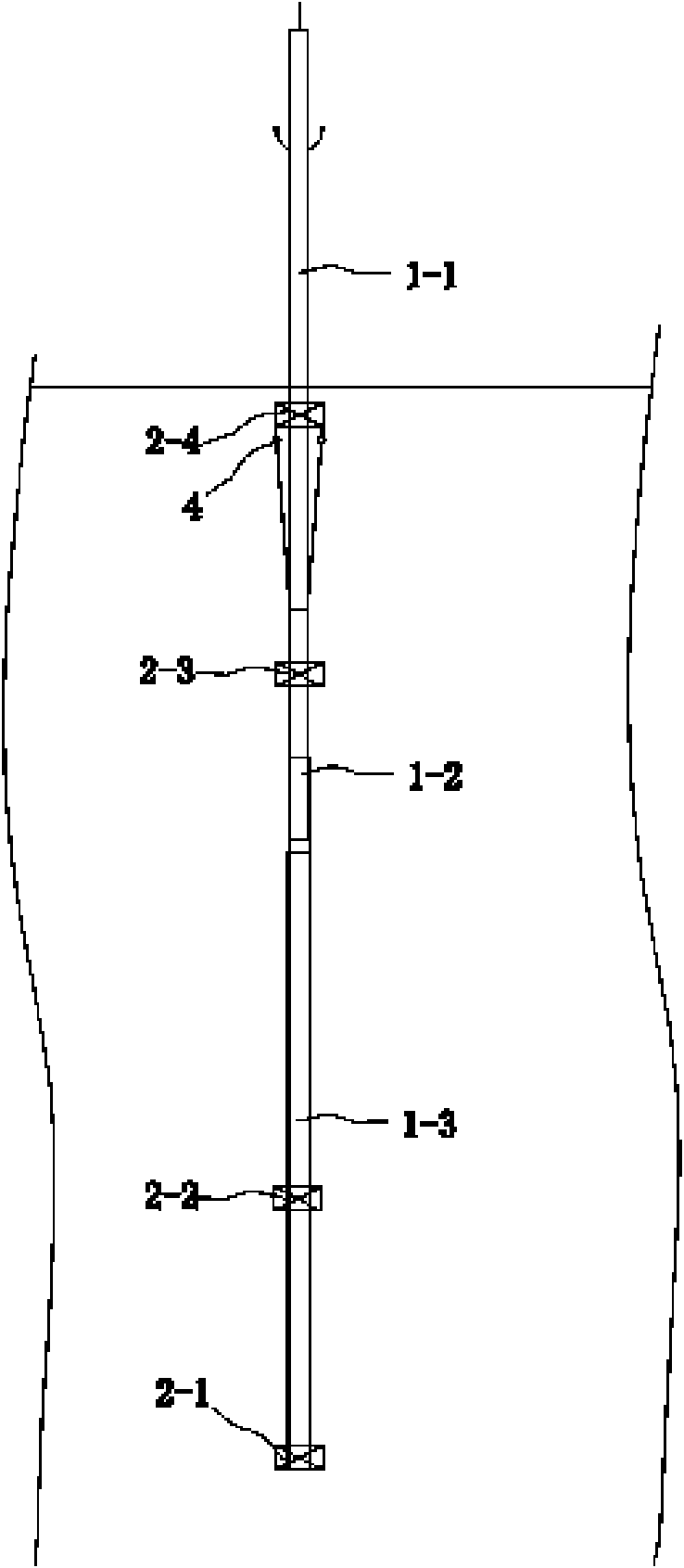

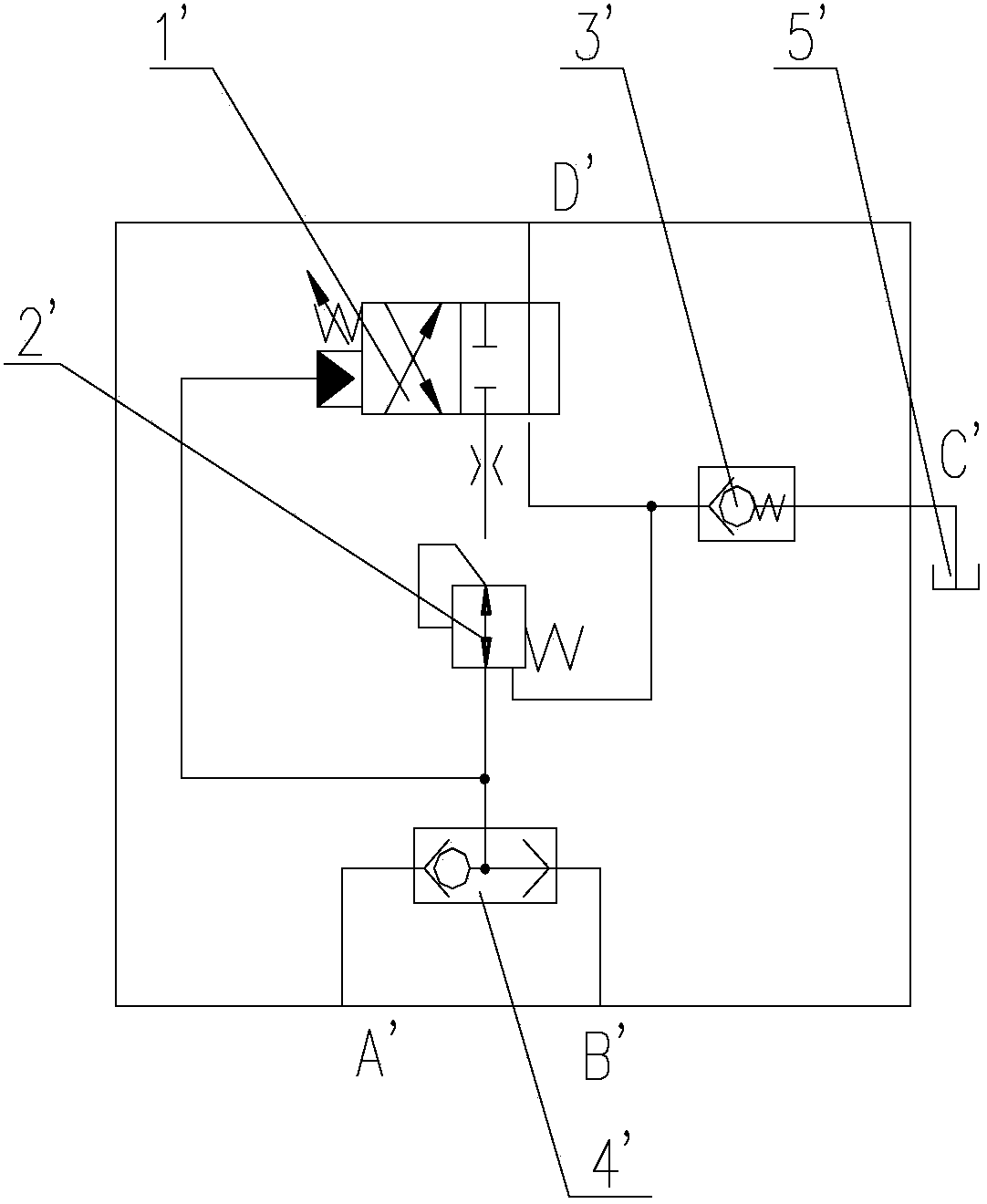

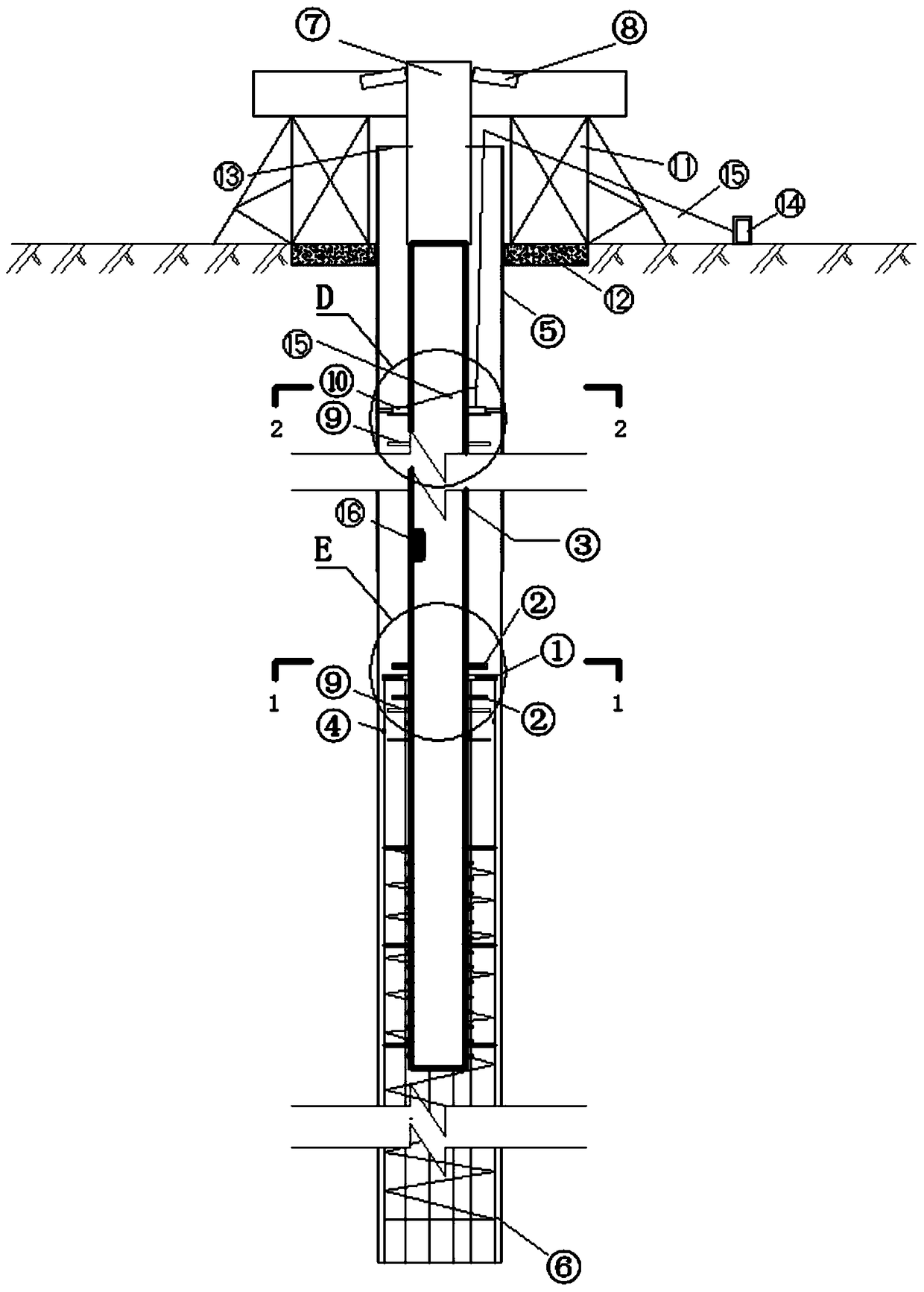

Movable type connecting device for reverse construction method steel tube column and reinforcement cage

PendingCN109372015AEasy to adjustPrecise positioningArtificial islandsExcavationsMovable typeEngineering

The invention discloses a movable type connecting device for a reverse construction method steel tube column and a reinforcement cage, belongs to the an engineering device of the underground space development reverse construction method foundation pit engineering field, and particularly relates to a movable type connecting device for the steel tube (structure) column and the reinforcement cage. The movable type connecting structure is characterized in that a reinforcement sleeve is fixedly arranged on the upper part of the reinforcement cage, wherein the upper port of the reinforcement sleeveis fixedly equipped with a protecting aligning plate with a middle hole; the steel tube column passes through the middle hole of the protecting aligning plate; a pair of upper and lower spaced limiting plates is fixedly arranged on the outer wall of the upper part of the steel tube column; the protecting aligning plate is positioned between upper and lower limiting plates, and the dimension of themiddle hole of the protecting aligning plate is smaller than diameters of the upper and lower limiting plates; and the reinforcement cage and the reinforcement sleeve are positioned in an all-steel protective barrel in a construction state. The movable type connecting device is simple in structure, is high in operation precision, is convenient to operate, and can realize construction in a pile hole with or / without underground water, so that connecting, hoisting and mounting of the steel tube (structure) column and the reinforcement cage can be solved, and regulating and positioning for perpendicularity in a steel tube (structure) column core mounting process are also convenient.

Owner:昆明捷程桩工有限责任公司

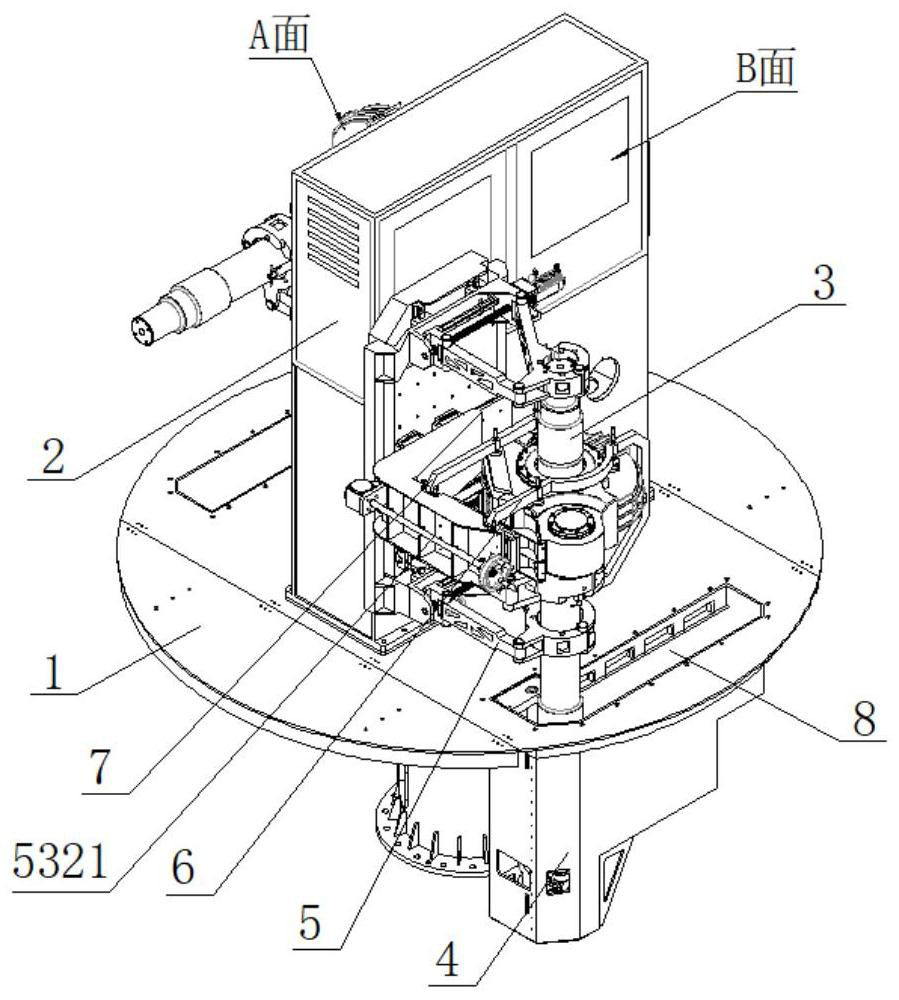

Mobile numerical control cylinder intersecting line groove forming equipment

PendingCN107138959AAvoid hoistingPortable and compactOther manufacturing equipments/toolsMetal working apparatusPolishingEngineering

The invention discloses mobile numerical control cylinder intersecting line groove forming equipment, and relates to the field of cylinder intersecting line pipe joint unloading groove cutting equipment. The forming equipment comprises a frame, a rotating power device, a rotating device, a groove polishing device and a numerical control system; the frame serves as an overall bracket of the equipment; the rotating power device, the rotating device and the groove polishing device are connected in sequence and arranged on the frame; an electromagnetic absorbing device is arranged at the bottom of the frame; during working, the numerical control system is started; the frame is absorbed on workpieces; and under driving by the rotating power device, the groove polishing device rotates along with the rotating device to realize formation and polishing of round holes and grooves of workpiece cylinder intersecting lines. The forming equipment integrates groove cutting and polishing as a whole, is high in automation degree, saves the labor force, greatly improves the working efficiency, and is small in structure and low in duty; and the forming equipment is fixed on the workpieces in the working process without considering the equipment floor problem to achieve higher convenience.

Owner:泰安九和智能设备有限公司

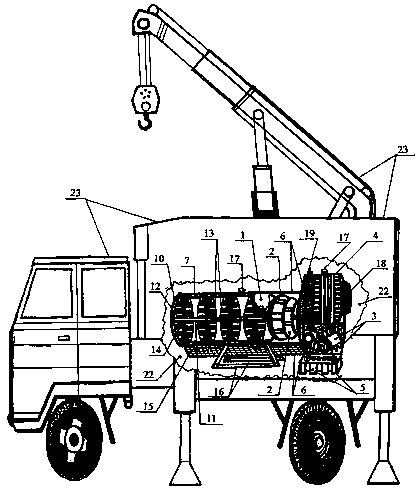

Lifting method for installing large-scale power equipment

InactiveCN108545631ALifting accessory structureImprove installation efficiencyCranesPower equipmentEngineering

The invention discloses a lifting method for installing large-scale power equipment, and the lifting method comprises the following steps: S1, a first motor and a second hydraulic device work to suspend a suspension arm; S2, a first hook at the end of a first wire rope is used to hang large electrical equipment accessory, a second hook at the end of a second wire rope is used to hang large electrical equipment accessories; S3, a third hydraulic device can be used to lift a support plate structure, and a worker can stand on a support plate to perform height lifting work; and S4, a frame structure arranged at the top of the support plate is used to control left-right adjustment of a second traction mechanism by a servo drive device, and the second traction mechanism is used for lifting a tool and a component for lifting movement. The lifting method improves the installation efficiency, avoids multiple times of movement and suspending and lifting of the device, and a simple lifting elevator structure is formed. The worker can stand on the support plate for lifting, the method is convenient for installation and construction, reduces the carrying pressure of the worker working at height, and improves the safety performance.

Owner:河南中盟电气设备有限公司

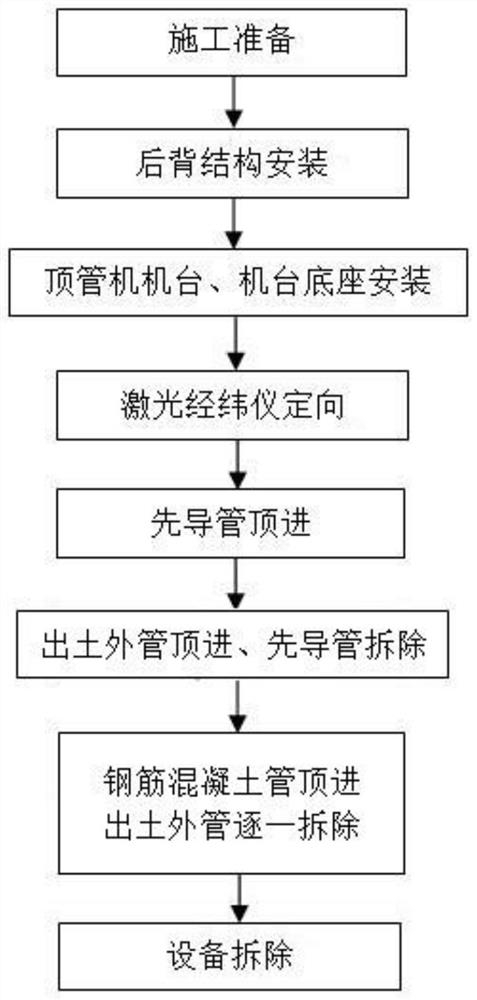

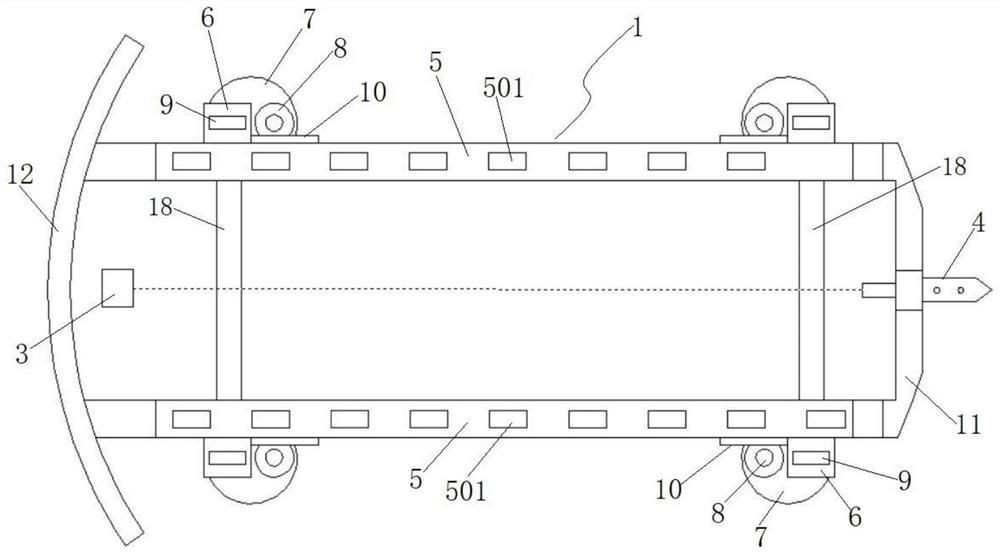

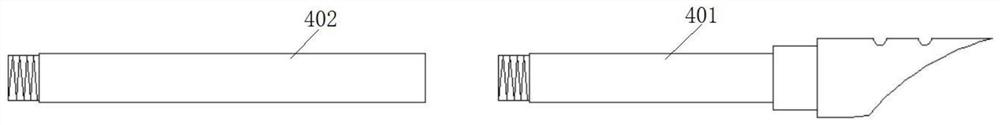

Miniature pipe jacking construction method for ecological comprehensive pipe gallery project

ActiveCN113338985AHigh pipe jacking efficiencyImprove accuracyMining devicesUnderground chambersEnvironmental resource managementReinforced concrete

The invention discloses a miniature pipe jacking construction method for ecological comprehensive pipe gallery engineering, which comprises the following construction steps: step 1, mounting and debugging a miniature pipe jacking machine, step 2, orienting a laser theodolite, step 3, jacking a pilot pipe, step 4, jacking an unearthed outer pipe, step 5, jacking a spiral cutter head, step 6, jacking a reinforced concrete pipe, and step 7, dismounting equipment. In the pipe jacking construction process, each section of pilot pipe and each section of unearthed outer pipe are sequentially dismantled in the receiving well, and the spiral cutter head, the pipe jacking machine table and the machine table base are dismantled in the working well. The miniature pipe jacking construction method for the ecological comprehensive pipe gallery project is easy to operate, high in pipe jacking efficiency, quite convenient and rapid to install and detach, good in pipe jacking accuracy and safety and suitable for rapid construction of urban ecological comprehensive pipe galleries.

Owner:葛洲坝集团生态环保有限公司

Platform tool and method for enabling equipment to enter cabin

InactiveCN113525624ASolve the drifting distance problemShorten the construction periodWaterborne vesselsMarine engineeringStructural engineering

The invention discloses a platform tool and method for enabling equipment to enter a cabin, and belongs to the technical field of ships. The platform tool for enabling the equipment to enter the cabin comprises a bearing platform, the bearing platform is arranged on one side of an outer plate, the first end of the bearing platform is fixedly arranged on a ship, the second end extends towards the side away from the ship, a hoisting device can place the equipment at the second end of the bearing platform, and the equipment can enter a cabin opening from the first end of the bearing platform. According to the method for enabling the equipment to enter the cabin, the platform tool for enabling the equipment to enter the cabin is used for auxiliary installation. According to the platform tool and method for enabling the equipment to enter the cabin, by arranging the bearing platform and the hoisting device, the equipment can be hoisted to the bearing platform, then the equipment is transferred into the cabin through the bearing platform, the number of detachable plates is reduced, the hoisting device can be adopted for assisting in enabling the equipment to enter the cabin from the detachable plate of an outer plate, the workload is reduced, and the cost is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Nuclear power station reactor internals anti-breaking assembly bottom plate measuring method

InactiveCN111310300AAvoid repeated disassemblyAvoid hoistingGeometric CADDesign optimisation/simulationNuclear powerThree dimensional measurement

The invention belongs to the field of nuclear power equipment installation, and particularly relates to a method for measuring the distance between a CAP1400 nuclear power station reactor internals anti-breaking assembly bottom plate and a pressure vessel bottom sealing head. The method includes: collecting three-dimensional measurement points of the sealing surface and the bottom end socket of the pressure vessel, establishing a pressure vessel coordinate system, and fitting the outline of the bottom end socket; collecting three-dimensional measurement points of a reactor internal top flangeand an anti-breaking assembly bottom plate, establishing a reactor internal coordinate system, and fitting the outline of the anti-breaking assembly bottom plate; hoisting the reactor internals into apressure vessel, adjusting, collecting three-dimensional measurement points of flanges at the tops of the reactor internals, and fitting actual axes; and importing the reactor internals model into apressure vessel coordinate system, adjusting the model according to the actual axis position, and calculating the distance between the bottom plate and the bottom seal head. The method has the beneficial effects that a person does not need to enter the limited space for measurement, hoisting in and hoisting out of the reactor internals are reduced by one time respectively, mounting and dismountingof the anti-breaking assembly are reduced by one time respectively, and the hoisting and limited space operation safety risk and the part damage risk are reduced.

Owner:国核示范电站有限责任公司

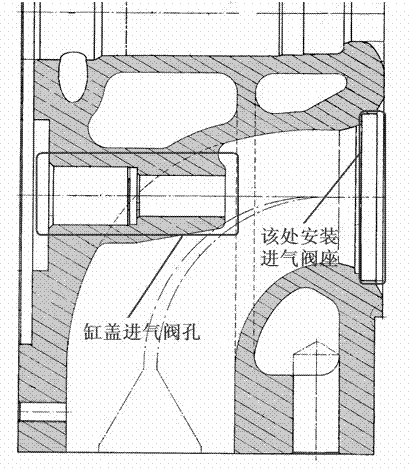

Device and method for mounting valve seat

The invention discloses a device for mounting a valve seat. The device comprises a pull rod, of which two ends are provided with screw threads, wherein the two ends of the pull rod are provided with a fixing plate and a pressing plate respectively; and a first gland nut and two second gland nuts are arranged on the outer side of each of the fixing plate and the pressing plate, and are used for fixing each of the fixing plate and the pressing plate at each of the two ends of the pull rod. During mounting, the pull rod passes through an air inlet valve hole in a cylinder cover; the nuts and the fixing plate are arranged on the side opposite to the valve seat to fix the pull rod; and the gland nuts and the pressing plate are arranged on the valve seat side to mount the valve seat in a valve seat hole in the cylinder cover in a squeezed manner. The mounting process for the valve seat is simplified greatly, and the mounting time is reduced, so that the valve seat mounting operation is relatively safe; and the device is particularly suitable for mounting the valve seats of air inlet valves of PC26-type cylinder covers.

Owner:HUDONG HEAVY MACHINERY

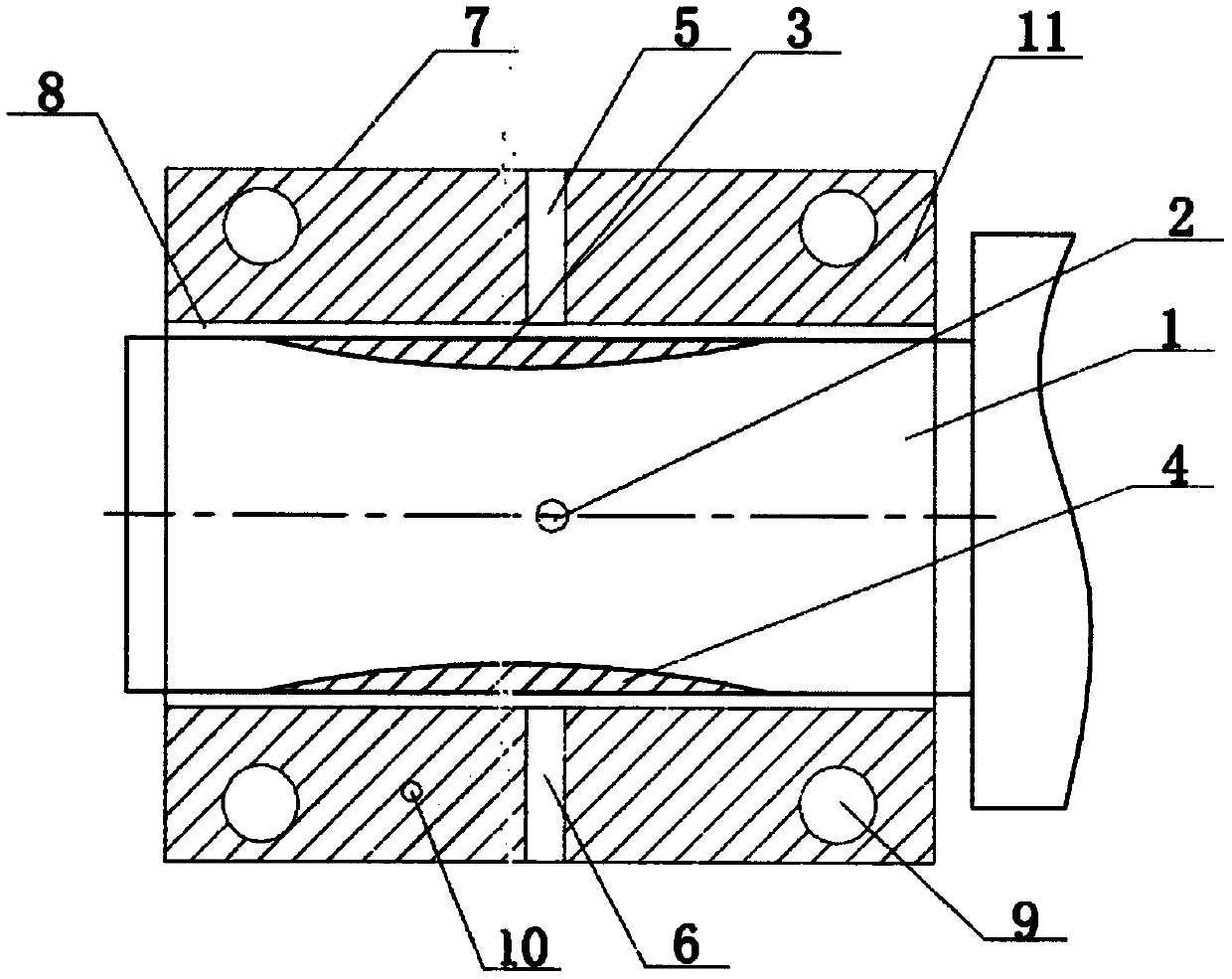

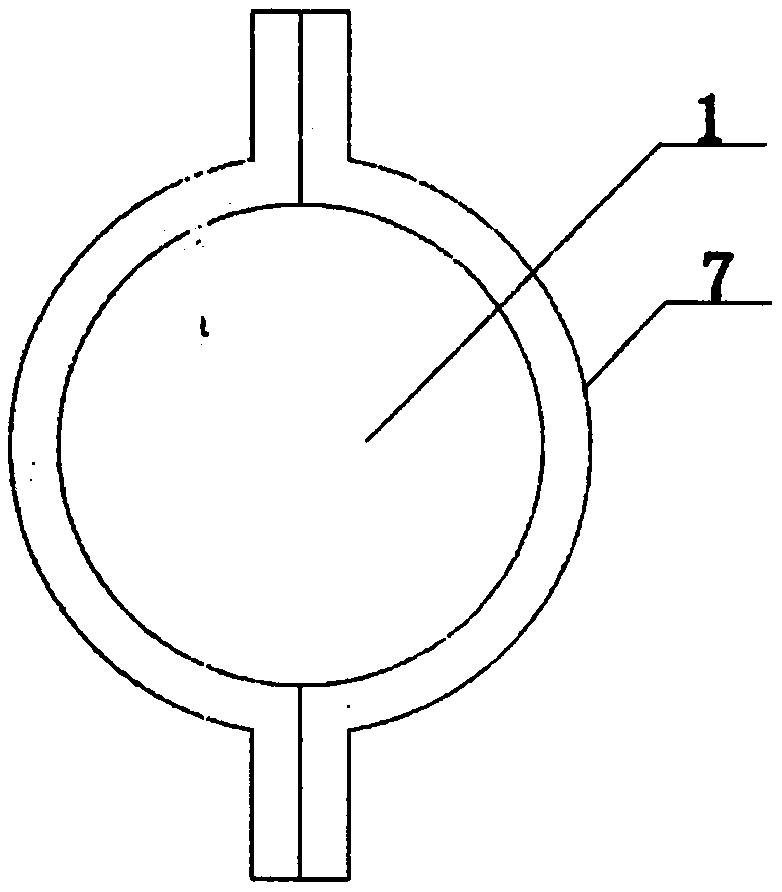

Abraded bearing position repairing device

The invention discloses an abraded bearing position repairing device, relates to the bearing abrasion repairing technology field, and especially relates to the abraded bearing position repairing device. The device comprises a bearing installation position, an upper abrasion bearing position, a lower abrasion bearing position, an upper injection hole, a lower injection hole, a grinding tool shell,a repairing layer for an abrasion position, a bolt hole, a positioning hole and a filling portion. The bearing installation position is located in the grinding tool shell, the upper abrasion bearing position is arranged on an upper side of the bearing installation position, the lower abrasion bearing position is arranged on the lower side of the bearing installation position, and the repairing layer for the abrasion position is arranged above the upper abrasion bearing position. After the technical scheme is adopted, the device has advantages that equipment does not need to be disassembled, repair welding is not needed, and disassembling, hoisting and transportation of the equipment can be avoided; machining cost is reduced, and time is shortened; a grinding tool is adopted for forming, heat is not generated, there is no deformation, precision is high, and abrasion resistance is good; and a new shaft does not need to be replaced and cost is low.

Owner:唐山市康泰工贸有限公司

Swinging structure and swinging method of steel pipe inner wall derusting machine

ActiveCN113070818AAvoid hoisting steel pipesImprove efficiencyAbrasive machine appurtenancesAbrasive blasting machinesElectric machineryEngineering

The invention belongs to the technical field of derusting machines, and particularly relates to a swinging structure and a swinging method of a steel pipe inner wall derusting machine. The swinging structure comprises a swinging motor, a swinging disc, a swinging disc sliding block, a swinging rod and a swinging rod groove, the swinging motor is fixedly arranged in a frame body cylinder, and a rotating shaft of the swinging motor is fixedly connected with the swinging disc; and the swinging disc sliding block is eccentrically arranged on the swinging disc, the swinging disc sliding block is arranged in the middle of the swinging rod in a sliding manner, the upper end of the swinging rod is rotationally arranged at the axis of the frame body cylinder, the lower end of the swinging rod penetrates through the swinging rod groove and then is connected with a front baffle, and the swinging rod groove is formed in the frame body cylinder. The swinging structure serves as a key part and is applied to the steel pipe inner wall derusting machine.

Owner:杭州泓林科技有限公司

A rotary pipeline device

ActiveCN106946147BNo storage space requiredNo need for temporary storage spaceFlanged jointsLoad-engaging elementsEngineeringFlange

The invention discloses a rotary pipeline device. The rotary pipeline device comprises a rotary flange cover, shaft bases, a sleeve, a lifting lug, a lifting hook and an arc lifting arm, wherein the rotary flange cover is formed by a rotary cover and a flange, the flange is mounted on an opening of a pipeline, a handle is mounted in the middle of the rotary cover, the rotary cover is connected with the flange through a bolt, one side of the rotary cover is rotatably connected with one side of the flange, an arc opening is formed in one side of the rotary cover, and the rotary cover can rotate horizontally; the shaft bases are welded to one side of the flange, and the two shaft bases are symmetrically mounted based on the center axis of the flange; the sleeve is welded to one side of the flange and perpendicularly mounted between the two shaft bases; the lifting lug is welded to the top of the rotary cover, and a first round hole is formed in the middle of the lifting lug; the lifting hook is mounted above the lifting lug and formed by a perpendicular section and a lifting ring section integrated with the perpendicular section, and the lifting ring section penetrates through the first round hole; one end of the arc lifting arm penetrates through the sleeve and is rotatably mounted in the sleeve, and the other end of the arc lifting arm is rotatably mounted at the end of the perpendicular section. The rotary pipeline device has the advantages of solving the problem of hoisting during overhaul and the problem that no temporary storage space is needed for the disassembled flange cover.

Owner:DATANG ENVIRONMENT IND GRP

Automatic positioning and clamping system and method for overhauling long shaft side gearbox of bullet train set

ActiveCN114516349AHigh degree of automationImprove work efficiencyWork holdersRailway transportControl systemElectrical control

The invention discloses an automatic positioning and clamping system and method for overhauling a long shaft side gearbox of a bullet train set. The system comprises a double-station upender, an electrical control system, a long shaft side gearbox positioning and clamping mechanism, a pull rod clearance adjusting outer side tool, a pull rod clearance adjusting inner side tool, a cover plate opening and closing mechanism and a center mechanism. The long-axis side gearbox positioning and clamping mechanism comprises a clamp body back plate, a horizontal transverse moving mechanism, a vertical lifting sliding seat, a gearbox supporting arm, a gearbox vertical lifting tool, a long-axis side gearbox lower box body positioning and clamping tool and a vertical lifting sliding seat locking handle. Seamless combination of the lower box body of the gear box, the large gear shaft and the bearing seats on the two sides is ensured through the vertical lifting sliding seat. Accurate positioning of the gearbox in the front-back direction and the left-right direction is ensured through the lower box body positioning and clamping profiling tool; the cover plate opening and closing mechanism is driven by the lead screw elevator and the motor to be automatically opened and closed. The electric control system controls the center mechanism to act to achieve automatic adjustment of the gear box bearing clearance.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

Arc-shaped formwork and moulding bed rapid machining and assembling equipment

PendingCN110788546AReduce gapGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesScrew threadRapid tooling

The invention provides arc-shaped formwork and moulding bed rapid machining and assembling equipment, and belongs to the technical field of vertical shaft one-time assembling and manufacturing. The equipment comprises a base and a moulding bed jacking and pressing mechanism arranged on the base. The moulding bed jacking and pressing mechanism comprises shaping plates with the shapes of the upper surfaces matched with the shape of the bottom face of a moulding bed and cambered surface jacking mechanisms arranged above the shaping plates. The cambered surface jacking mechanism comprise supports,cross beams, jacking lead screws and pressing blocks. The supports are oppositely arranged at the two ends of the shaping plates, the top ends of the supports are higher than the upper end faces of the shaping plates, the cross beams stretch across the shaping plates to be fixed to the supports at the two ends of the shaping plates, threaded holes are formed in the cross beams, the jacking lead screws penetrate through the threaded holes of the cross beams, and the lower ends of the jacking lead screws are connected with the pressing blocks. Steel plates can be pressed into the designated radian through the moulding bed jacking and pressing mechanism, a moulding bed bottom plate and the shaping plates are better attached, moulding bed side plates can be rapidly positioned through mouldingbed side plate positioning mechanisms, the positioning time of the side plates and limiting plates is shortened, the labor intensity of workers is reduced, and the efficiency of manufacturing the moulding bed with the arc-shaped bottom face is greatly improved.

Owner:CHINA COAL FIRST CONSTR

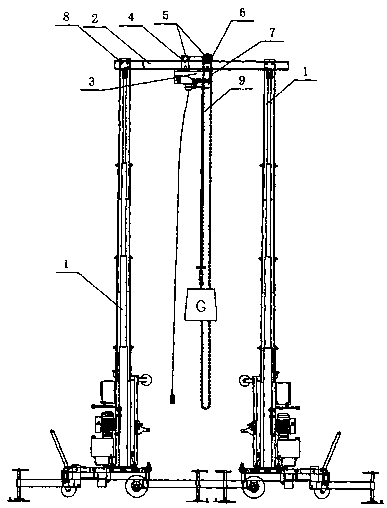

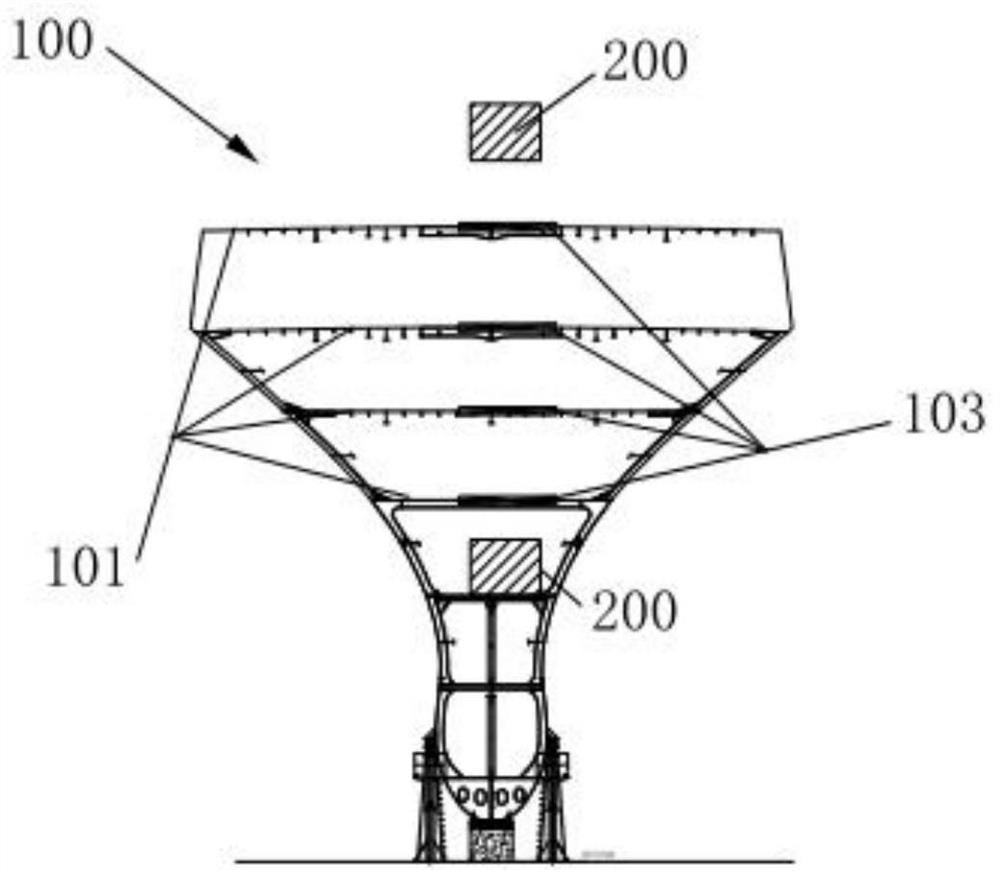

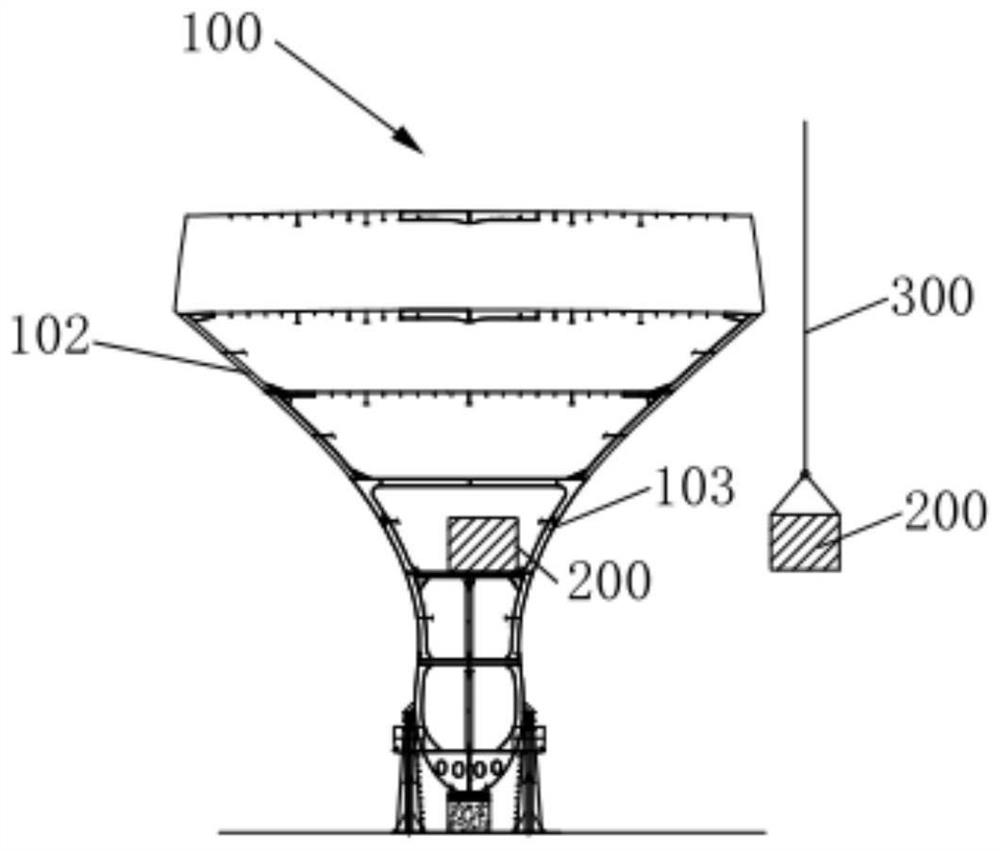

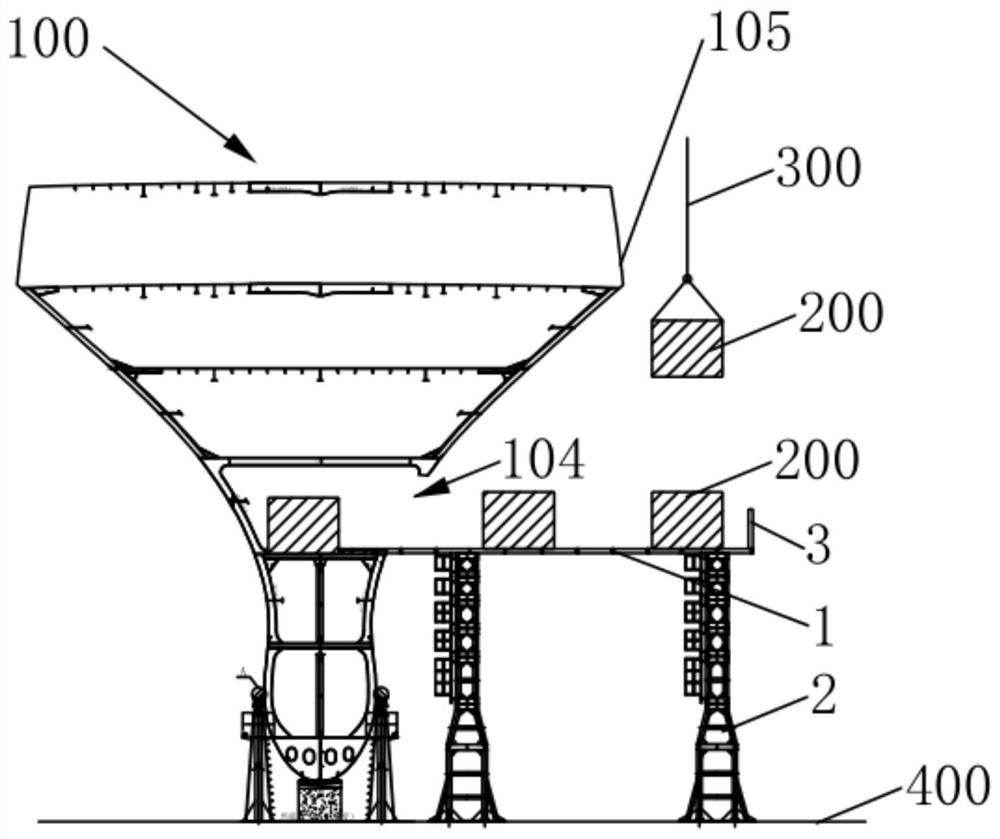

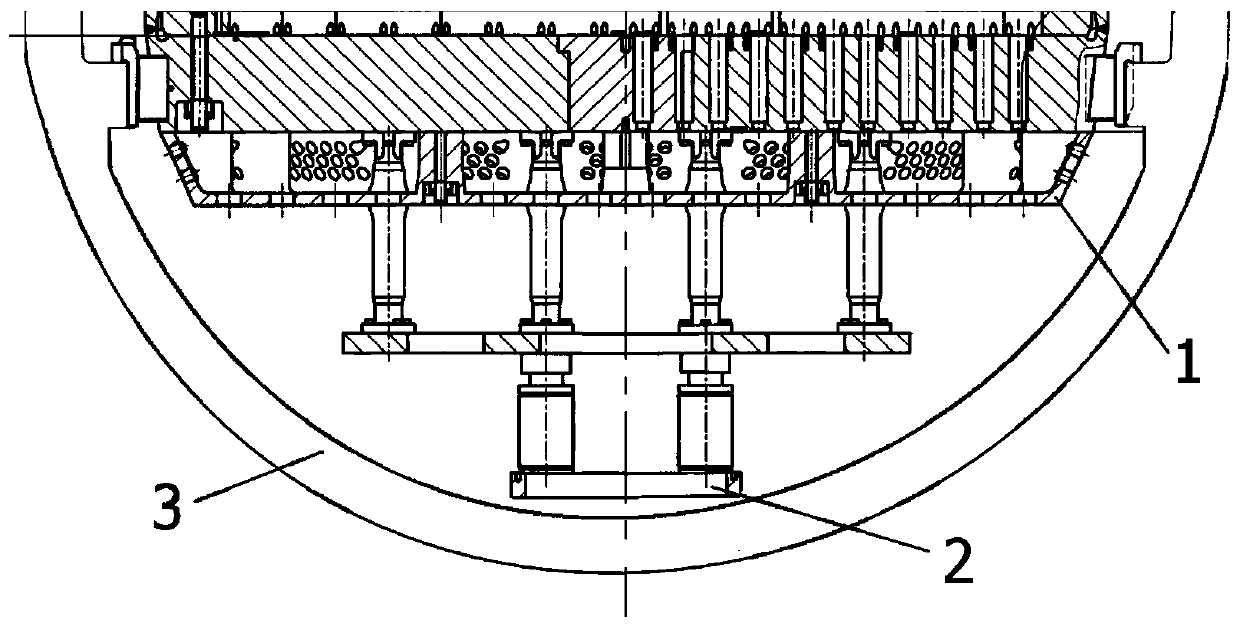

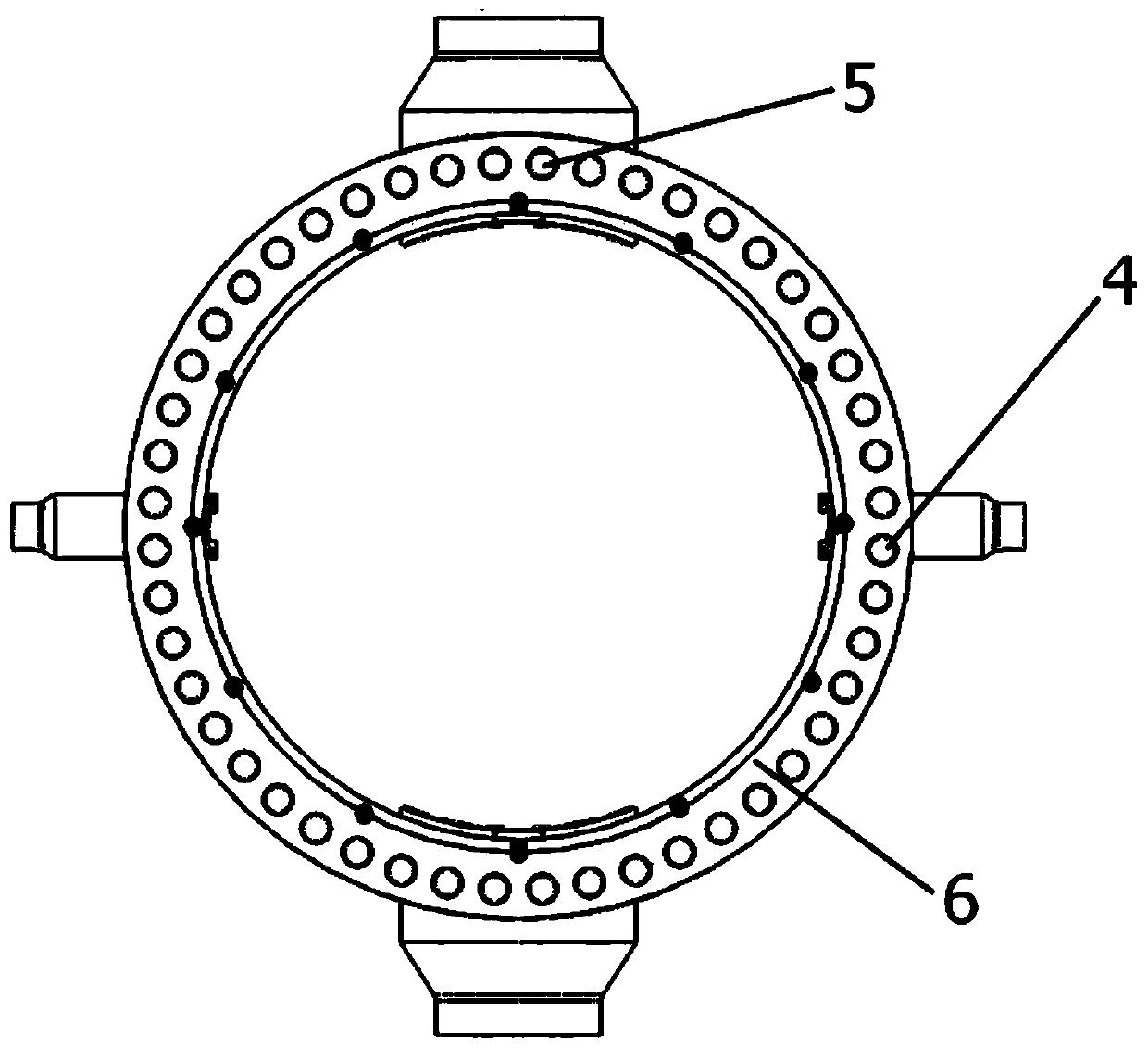

Large standing tower inverted installation device and inverted construction method

The invention provides a large standing tower inverted installation device and inverted construction method. According to the inverted installation device, a side column in the inverted installation device is arranged on a base, lifting equipment is arranged on the side column and used for lifting a tower body wall plate, and a limiting plate is arranged on the base and located on the inner side of the tower body wall plate to be installed in use. According to the method, after the layer of tower body wall plate is welded on the inverted installation device, the tower body wall plate is liftedby the lifting equipment, so that the next layer of tower body wall plate is conveniently installed below the lifted tower body wall plate, a large crane is not required to be used for installing a large standing tower, the space is saved, welding operation of the tower body wall plates is completed on the inverted installation device, namely the welding operation is completed on a flat ground, high-altitude operation is avoided, the personal safety of operators is guaranteed, compared with the high-altitude operation, the flat ground operation is higher in efficiency, an installation and construction period of the large standing tower is shortened, and the installation efficiency of the large standing tower is improved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY NO 9 GRP

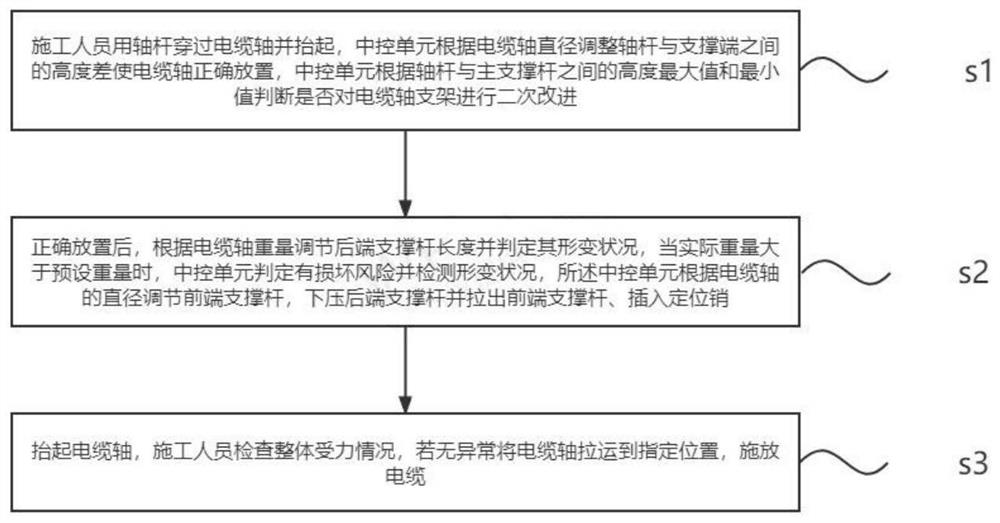

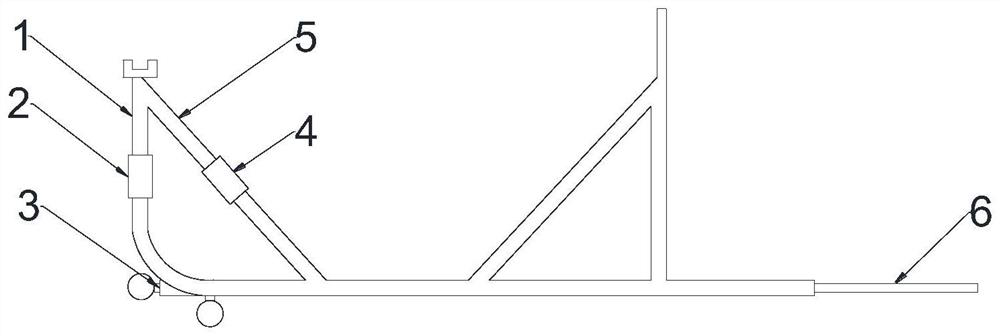

Construction method of movable lever type cable shaft bracket

PendingCN114583633AIncrease castImprove efficiencySuspension arrangements for electric cablesApparatus for overhead lines/cablesStructural engineeringElectric cables

The invention relates to the technical field of cables, in particular to a movable lever type cable shaft support construction method which comprises the steps that s1, a constructor uses a shaft rod to penetrate through a cable shaft and lift up the shaft rod, and a central control unit adjusts the height difference between the shaft rod and a supporting end according to the diameter of the cable shaft so that the cable shaft can be correctly placed; the central control unit judges whether secondary improvement is carried out on the support or not according to the maximum value and the minimum value of the height between the shaft rod and the main supporting rod; s2, the central control unit adjusts the rear end supporting rod according to the weight of the cable shaft and judges the deformation condition of the rear end supporting rod, when the actual weight is larger than the preset weight, the central control unit judges that the damage risk exists and detects the deformation condition, the front end supporting rod is further adjusted according to the diameter of the cable shaft, the rear end supporting rod is pressed downwards, the front end supporting rod is pulled out, and a positioning pin is inserted; and s3, the cable shaft is lifted, a constructor checks the overall stress condition, and if no abnormity exists, the cable shaft is conveyed to a designated position, and the cable is released. The working efficiency is obviously improved; and the construction cost is reduced.

Owner:内蒙古送变电有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com