Movable type connecting device for reverse construction method steel tube column and reinforcement cage

A connection device and steel pipe column technology, which is applied in water conservancy projects, artificial islands, sheet pile walls, etc., to achieve the effects of convenient operation, simple construction and high operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

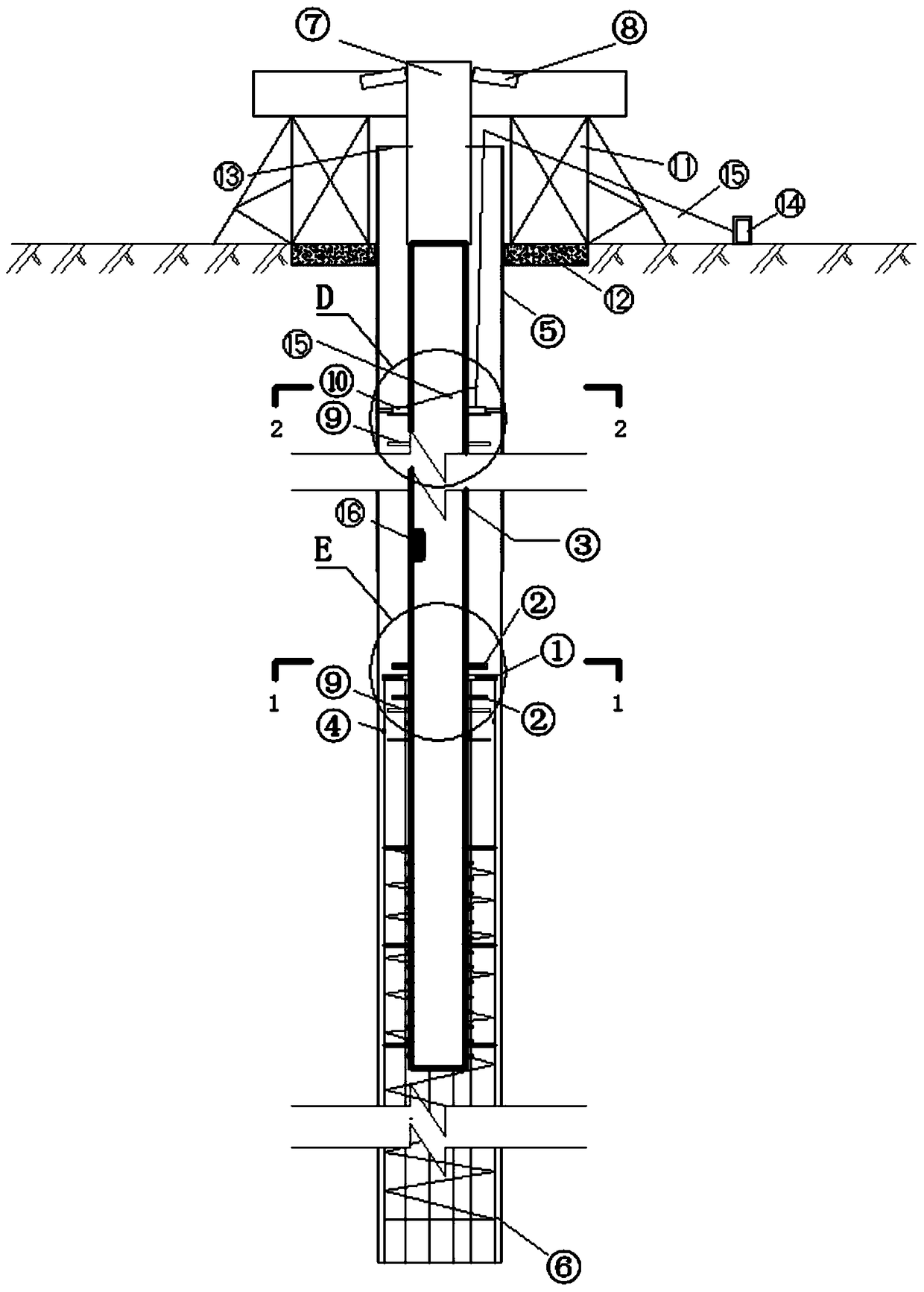

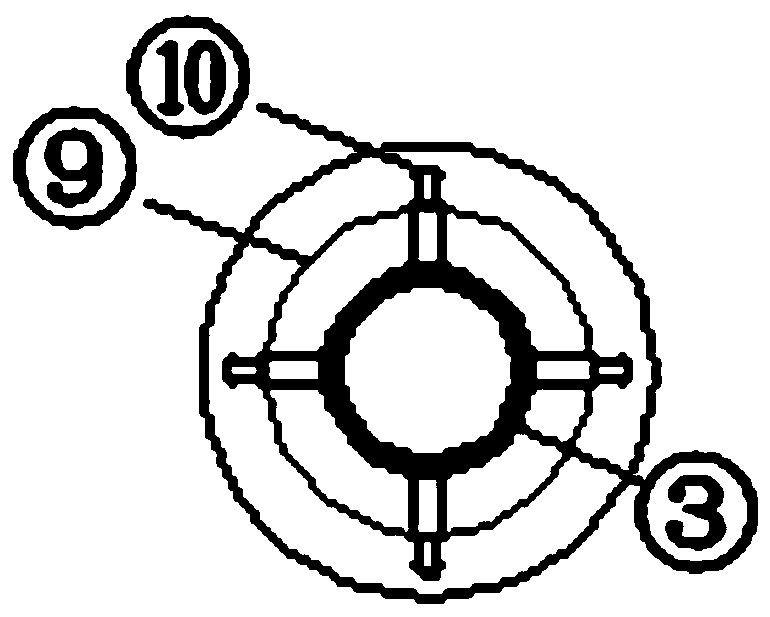

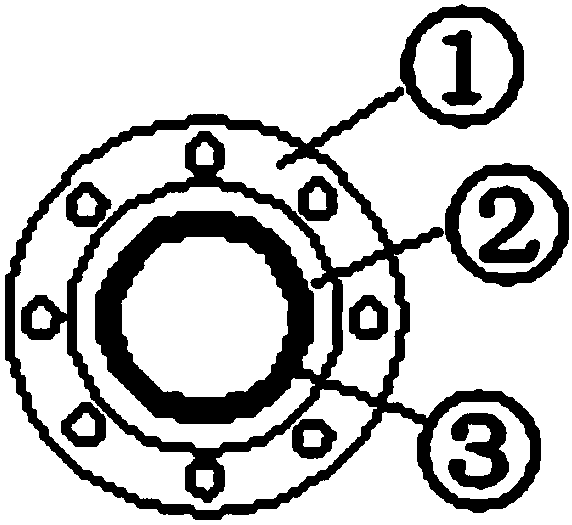

[0018] Referring to each figure, the upper part of the reinforcement cage 6 is fixed with a reinforcement sleeve 4, and the upper port of the reinforcement sleeve 4 is fixed with a front guard plate 1 with a middle hole, and the steel pipe column 3 passes through the middle hole in the middle part of the front guard plate 1, so that the two The connection of the former is suspended and limited. The upper outer wall of the steel pipe column 3 is fixed with a pair of spaced upper and lower limit plates 2. The front guard plate 1 is located between the upper and lower limit plates 2 and the center of the front guard plate 1 The size of the hole is smaller than the diameter of the upper and lower limit plates, and the reinforcement cage 6 and the reinforcement sleeve 4 are located in the all-steel casing 5 in the construction state. In the adjustment state, the reinforcement sleeve 4 of the reinforcement cage 6 can have a certain radial adjustment gap in the all-steel casing 5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com