A rotary pipeline device

A pipeline device and rotary technology, applied in the field of pipelines, can solve the problems of inconvenient maintenance and insecurity, and achieve the effect of preventing deformation and reducing operation strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

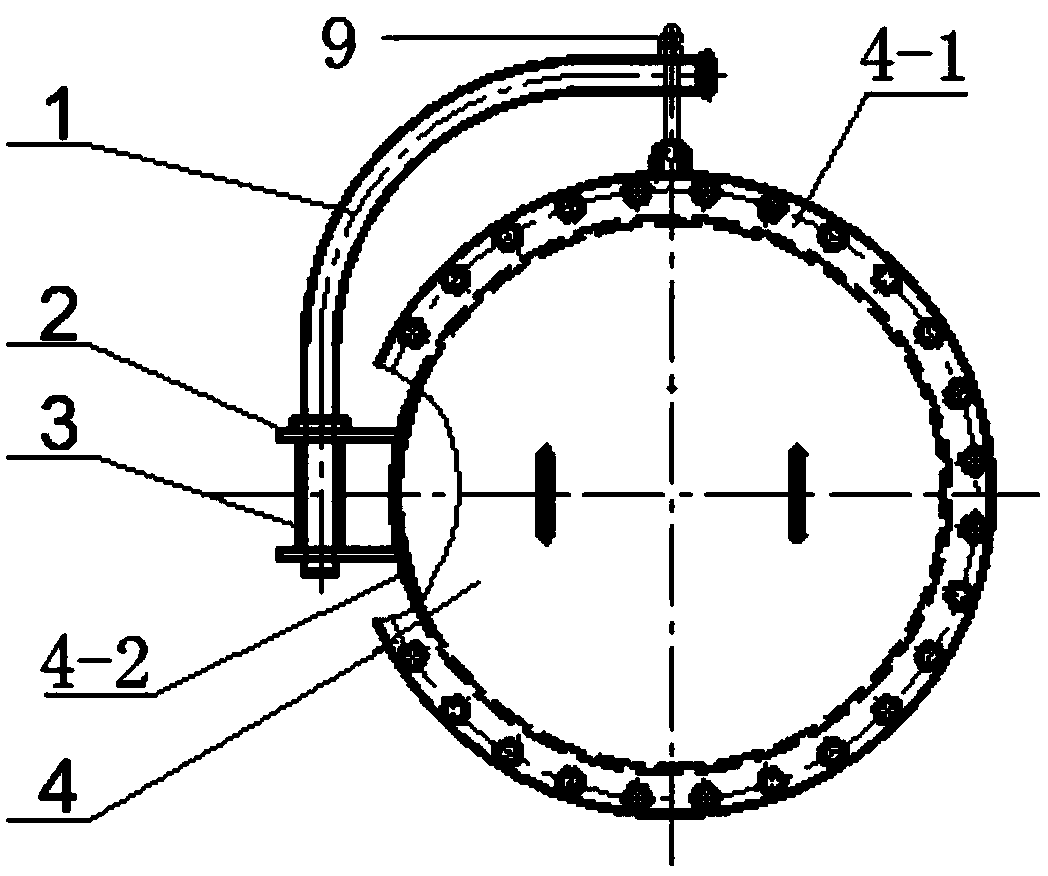

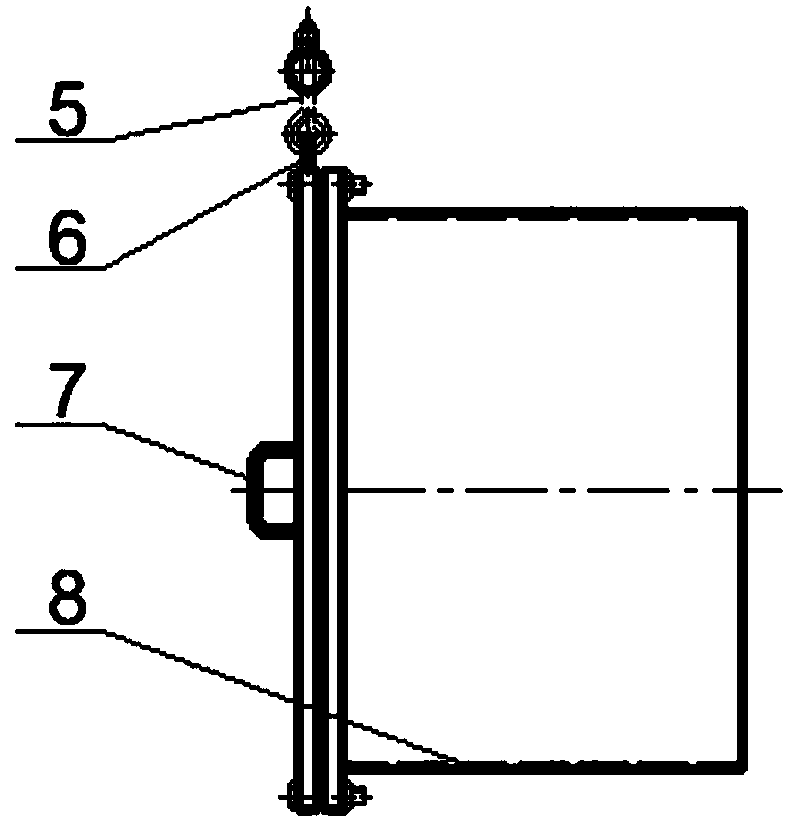

[0028] Example 1, such as Figure 1-2 As shown, a rotary pipeline device according to an embodiment of the present invention includes: a rotary flange cover 4, a shaft seat 2, a sleeve 3 and a suspension mechanism, wherein the suspension mechanism includes a lifting lug 6, a hook 5 and an arc Shaped boom 1.

[0029] The rotary flange cover 4 is installed at the pipe mouth of the pipeline 8. The rotary flange cover 4 is composed of a rotary cover 4-1 and a flange 4-2. The flange 4-2 is installed at the pipe mouth. The middle part of the rotary cover 4-1 is installed The handle 7, the rotary cover 4-1 and the flange 4-2 are fixedly connected by bolts, one side of the rotary cover 4-1 and one side of the flange 4-2 are rotatably connected by a connecting piece, and one side of the rotary cover 4-1 is provided. Arc mouth, rotary cover 4-1 can rotate horizontally.

[0030] The shaft seat 2 is welded and fixed on one side of the flange 4-2, and the two shaft seats 2 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com