Miniature pipe jacking construction method for ecological comprehensive pipe gallery project

A technology of integrated pipe gallery and construction method, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve problems such as discontinuity, and achieve the effects of good accuracy and safety, simple operation, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

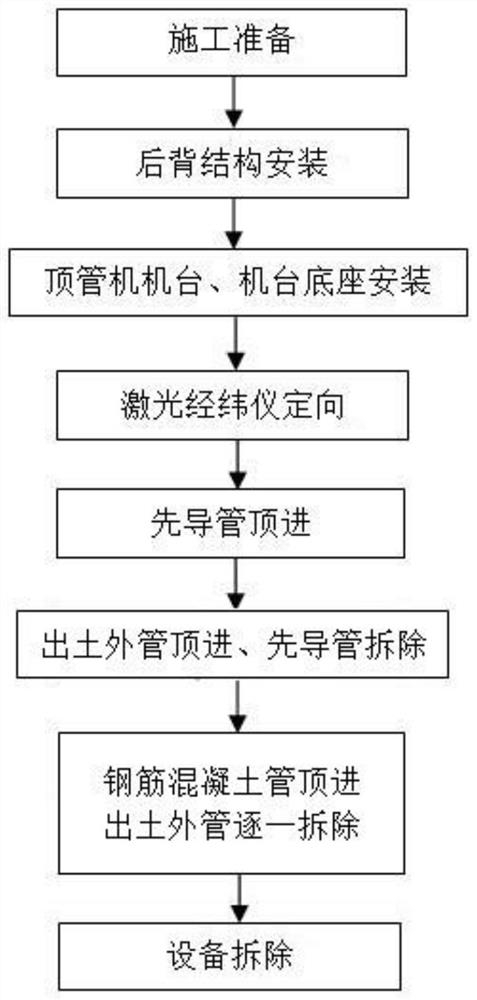

[0048] combine figure 1 As shown, a micro-pipe jacking construction method for an ecological comprehensive pipe gallery project includes the following construction steps:

[0049] Step 1. Installation and commissioning of the micro pipe jacking machine, including the setting and construction of the back structure of the micro pipe jacking. The central axis of the inlet pipeline adjusts the height and level of the base of the machine and is fixedly installed at the bottom of the well. The machine base of the pipe jacking machine is installed on the base of the machine to connect the hydraulic oil circuit. The front end of the device can be detachably connected to the pilot tube, start the equipment to determine whether the equipment is working normally;

[0050] Step 2, laser theodolite orientation, place the laser theodolite on the center line of the pipeline in the working well, adjust the slope of the laser theodolite, and make the laser theodolite project on the pilot pipe...

Embodiment 2

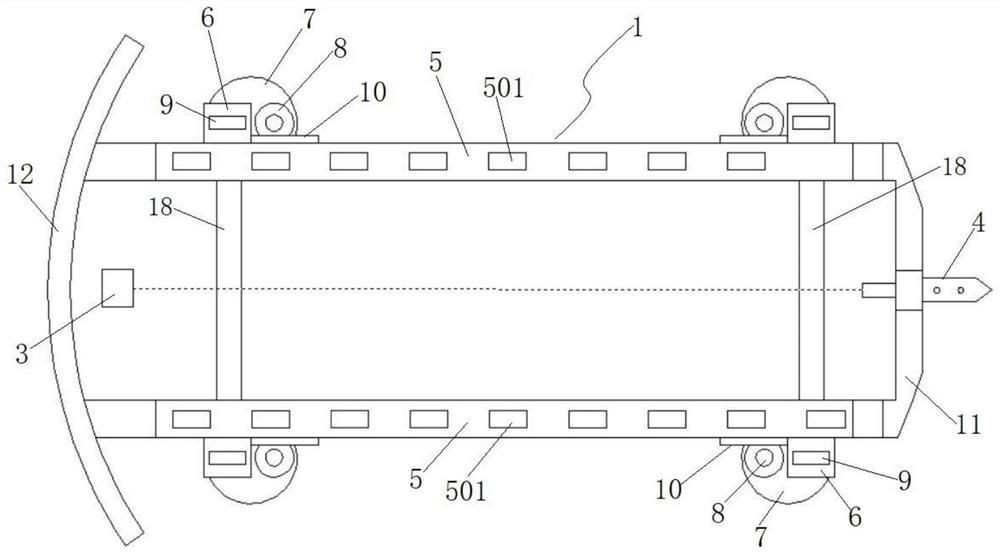

[0070] This embodiment provides a machine base structure and a specific construction process of Step 1.

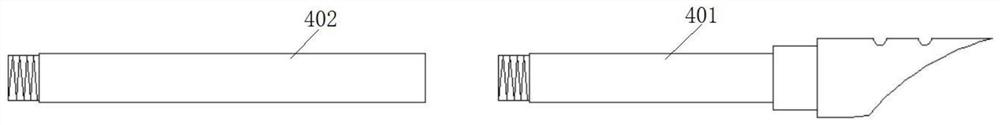

[0071] Such as figure 2 As shown, the machine base 1 includes a pair of cross bars 5 arranged in parallel, and a pair of adjustable support frames 6 are respectively arranged under the pair of cross bars 5; the ends of the support frames 6 are provided with supporting feet 7. A number of adjusting pads 16 are provided under the support feet 7, and anchors 8 for fastening are also provided on the support feet 7; suspension rings 9 are respectively provided above the support frame 6; the cross bar 5 is provided with a number of vertical installation holes 501 at intervals, and the pipe jacking machine platform 2 is detachably installed on the cross bar 5 and the installation holes 501; a pair of ends of the cross bar 5 A connecting rod 11 is also detachably provided, and a horizontal connecting hole is provided in the middle of the connecting rod 11, and the pilot pipe 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com