Patents

Literature

34results about How to "Guaranteed not to shake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

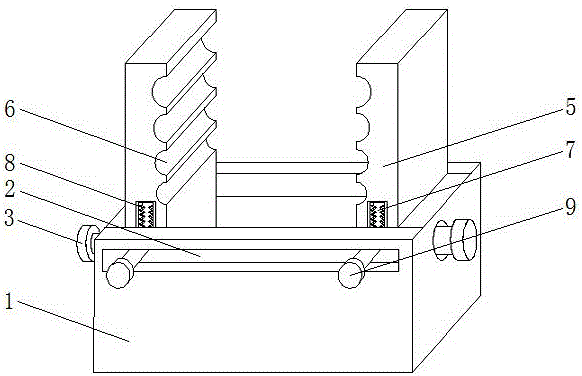

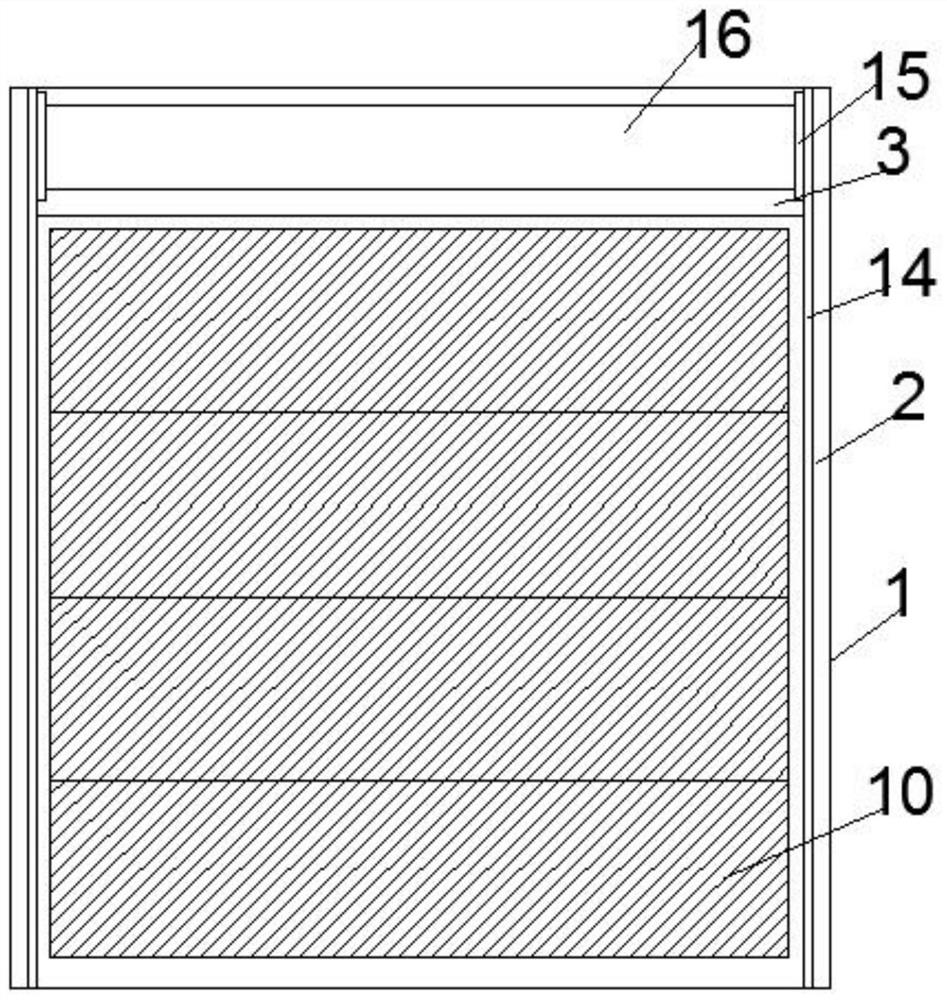

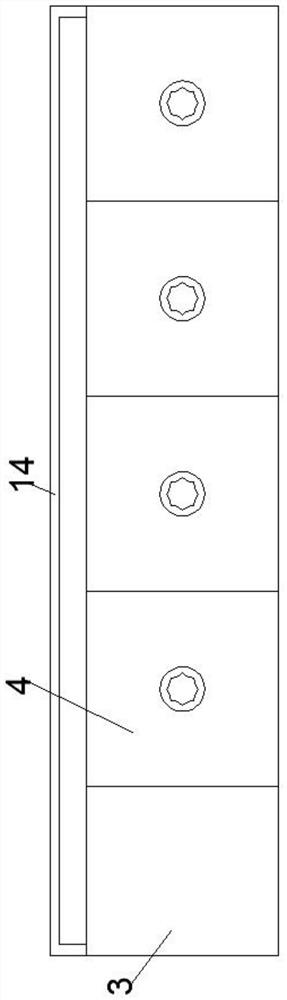

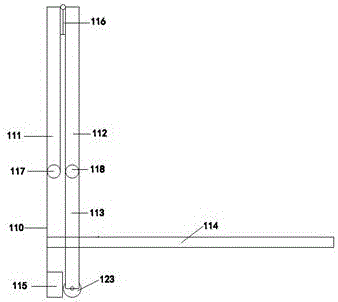

Mold clamping device

InactiveCN105798120AEasy to processEasy installation and clampingShaping toolsPressesEngineeringSlide plate

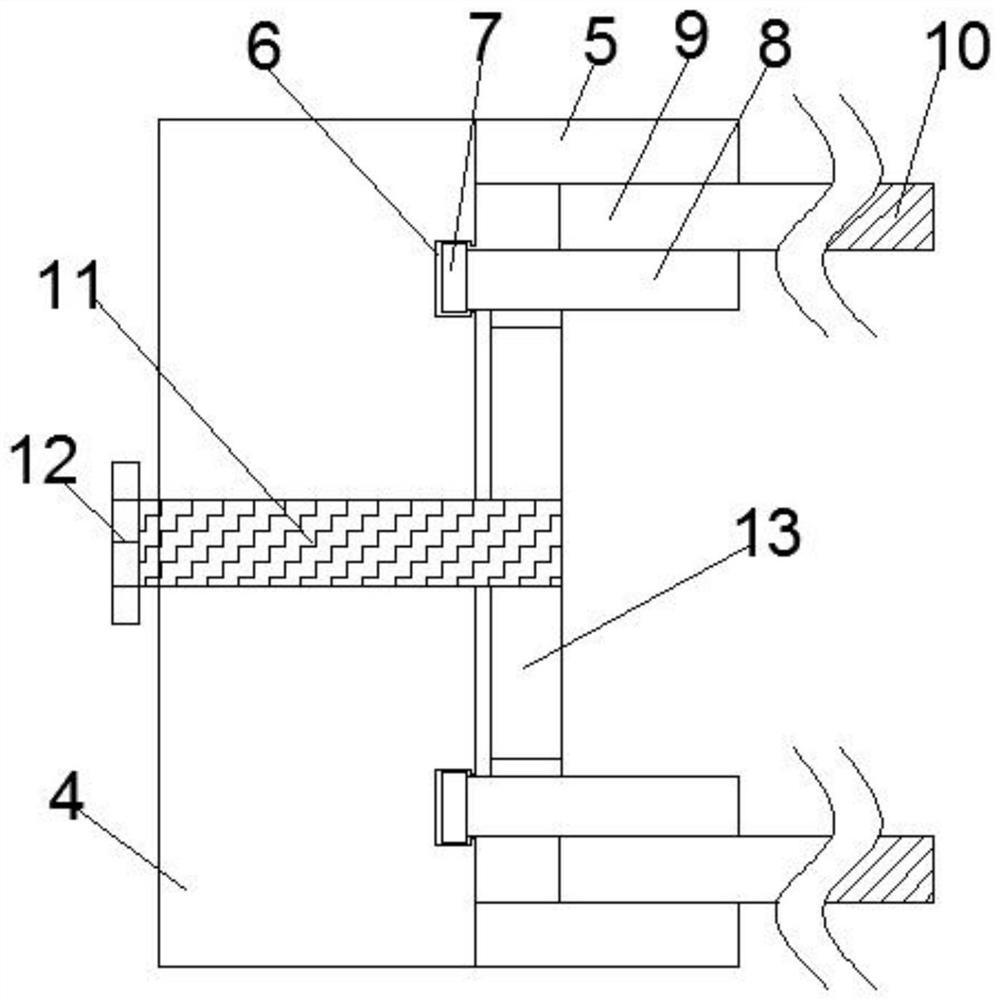

The invention discloses a mold clamping device. The mold clamping device comprises a base; a rectangular hole is formed in the front surface of the base; first bolts are respectively arranged on two sides of the base; the ends of the first bolts penetrate through the side surface of the base, and extend into the base; a slide plate is arranged in the base, and is provided with chutes; two clamping plates are arranged on the slide plate; the clamping plates are positioned in the chutes, penetrate through the top of the base, and extend above the base; and one sides, near the inner wall of the base, of the clamping plates are in threaded connection with the ends of the first bolts extending into the base. The mold clamping device can clamp different molds through setting first grooves to widen the application range, can move the clamping plates left and right through setting the first bolts to conveniently mount and clamp the molds, and can move the clamping plates up and down through setting second bolts to achieve the fine adjustment effect of the molds and convenience for machining.

Owner:CHANGZHOU JINCHENGYU HARDWARE

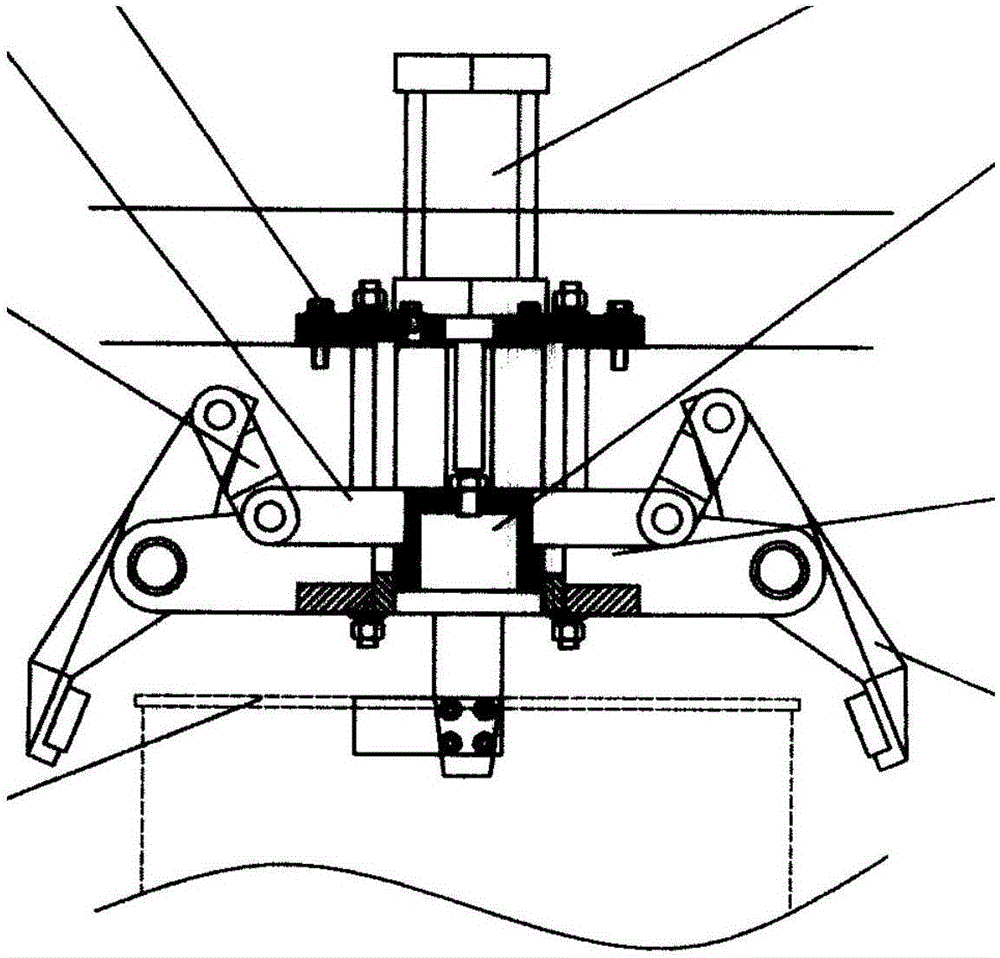

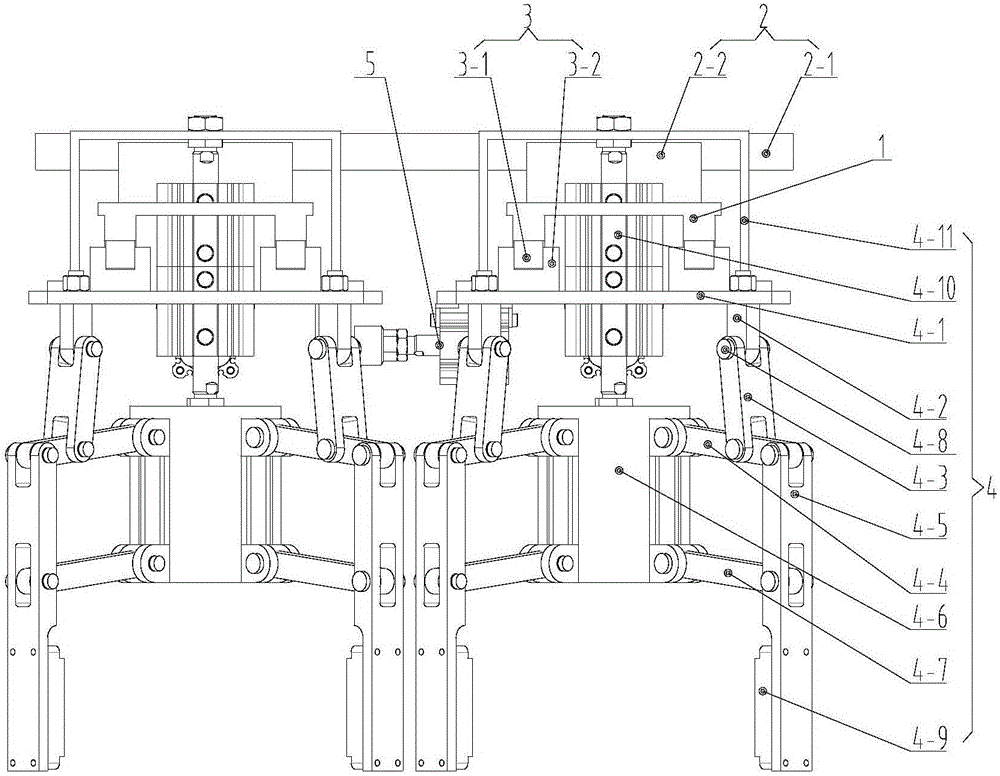

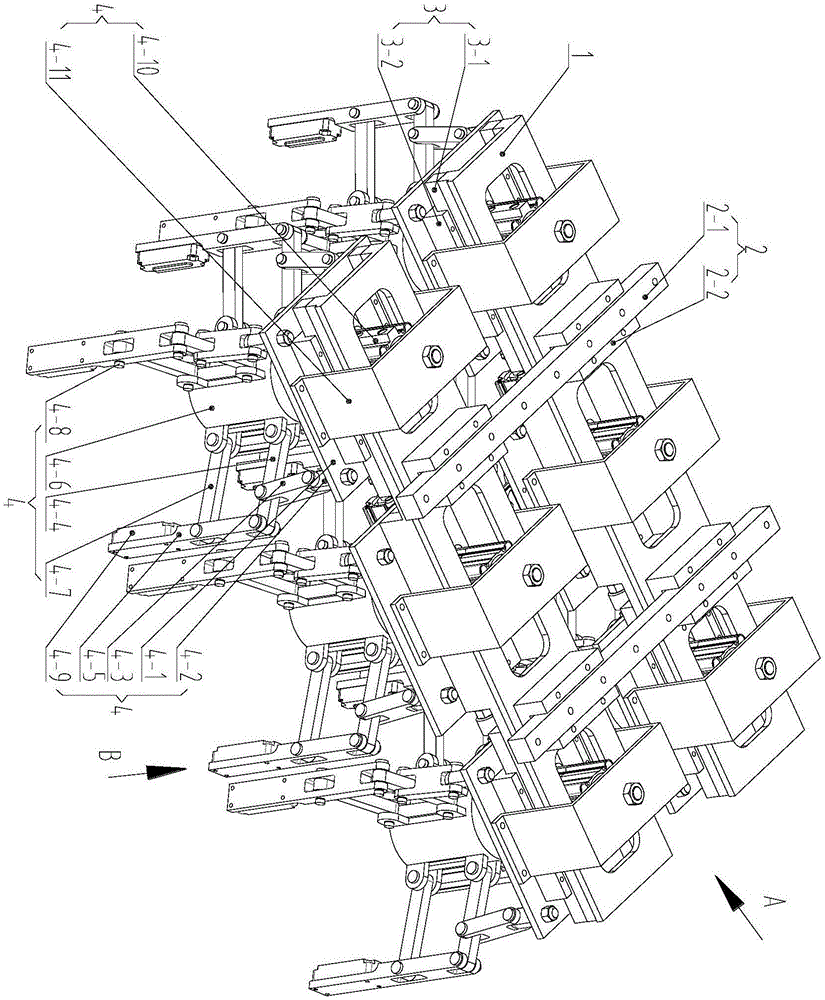

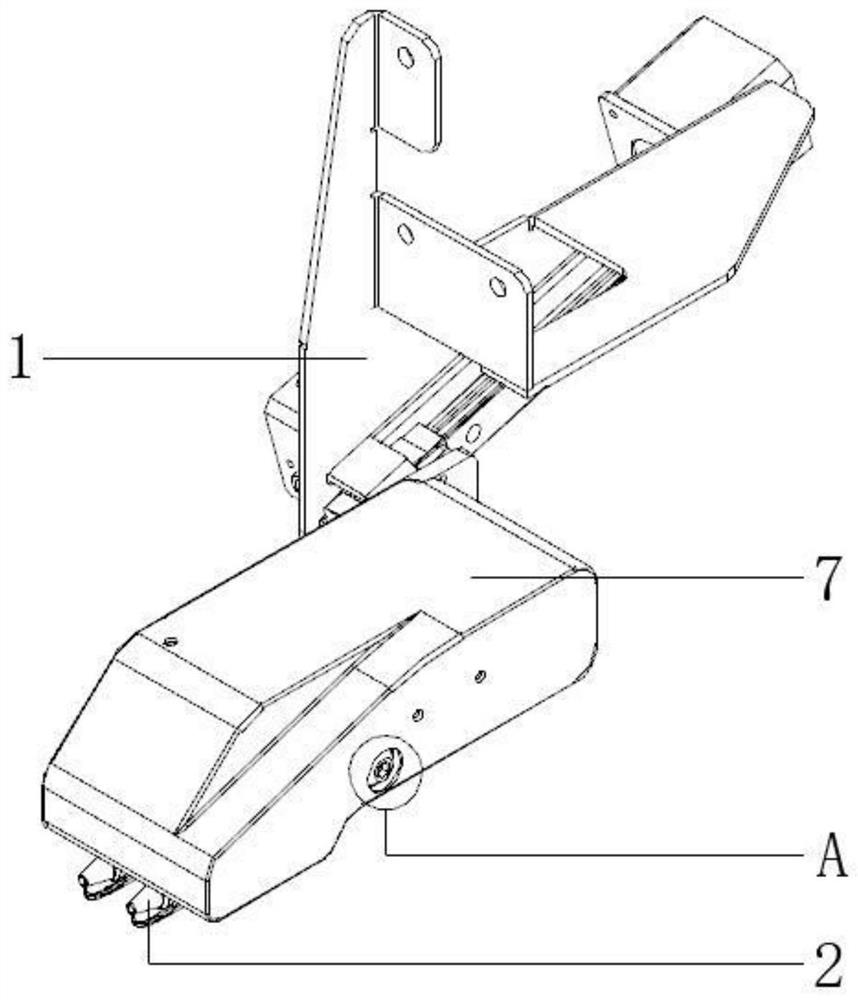

Gripping device of stacker

The invention discloses a gripping device of a stacker. The gripping device comprises supporting frames, heavy load mobile groups, light load mobile groups, gripping groups and distance adjusting air cylinders. Barrels are clamped through air bags, it is guaranteed that the cylindrical barrels do not swing in the gripping process, and the appearances of the barrels are prevented from being damaged; meanwhile, parallel four-bar mechanisms are used for the gripping device, jaws are perpendicular to one another all the time in the gripping process, and space is saved to the maximum degree. In addition, air cylinders for carrying out gripping actions are designed in two strokes, and the device can be compatible with two kinds of cylindrical barrels of different diameters.

Owner:BEIJING AREOSTANARD NEW TECH +1

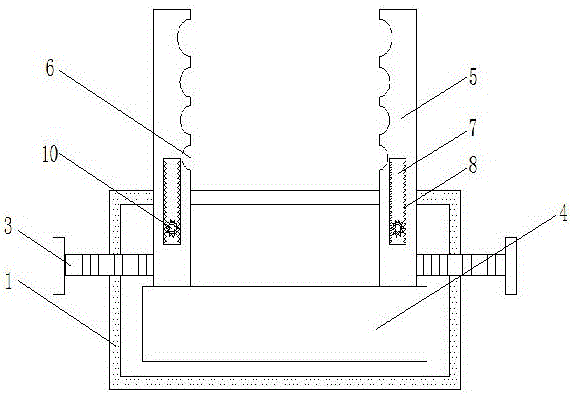

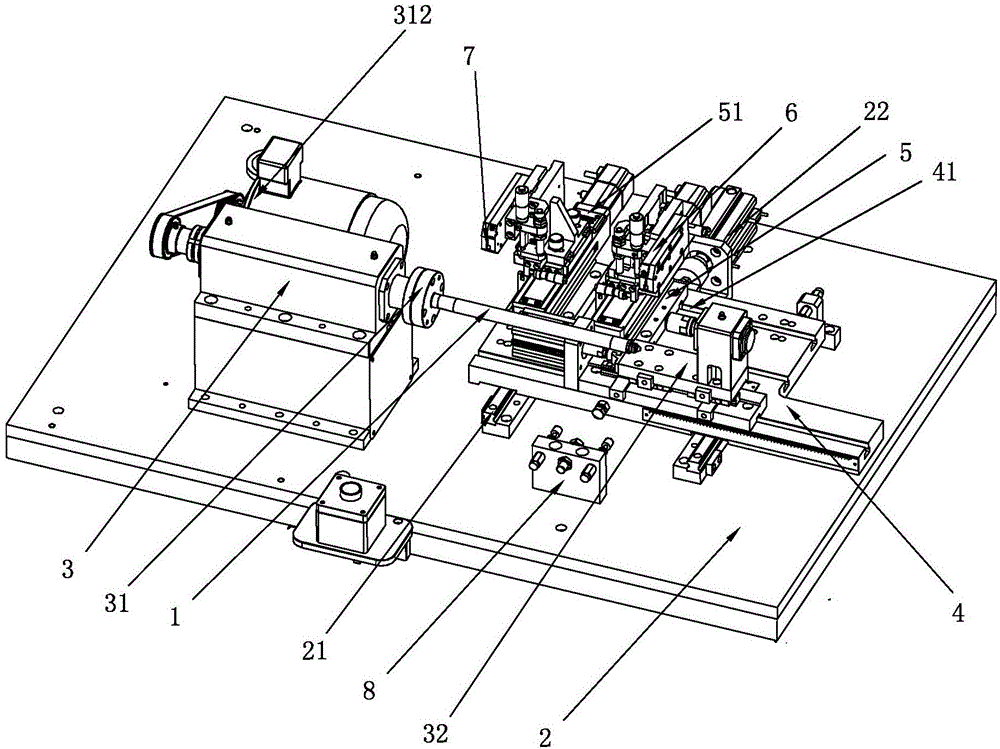

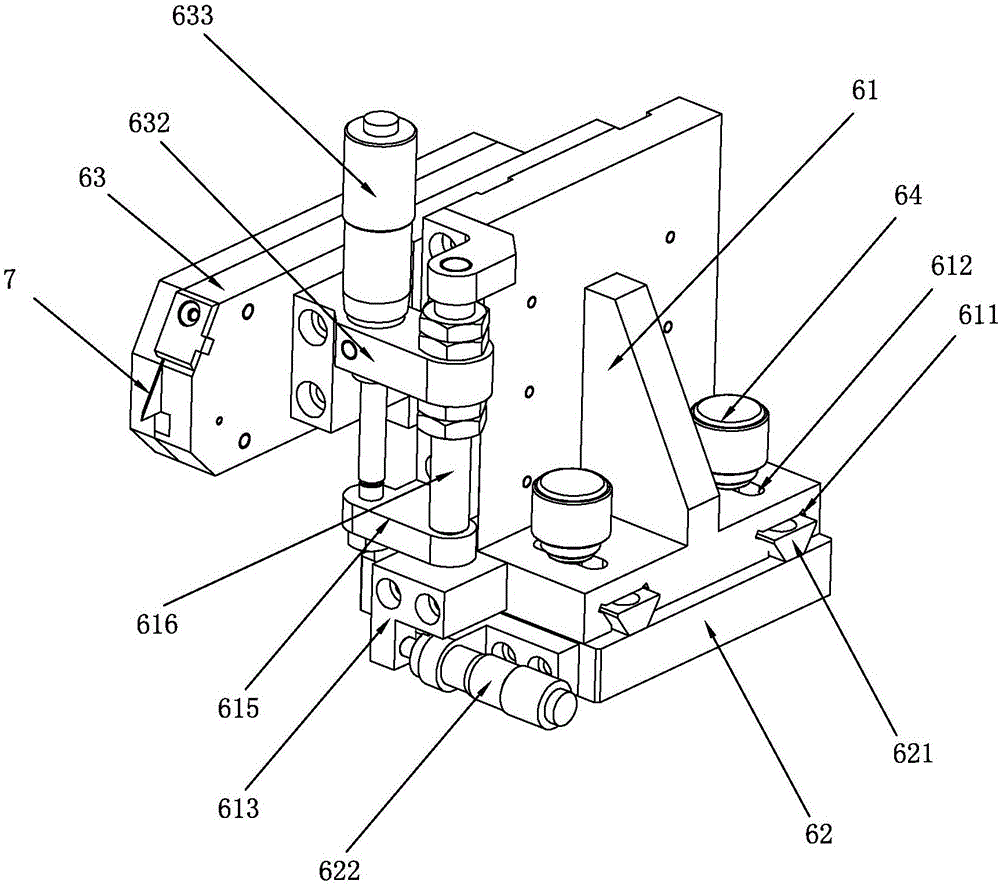

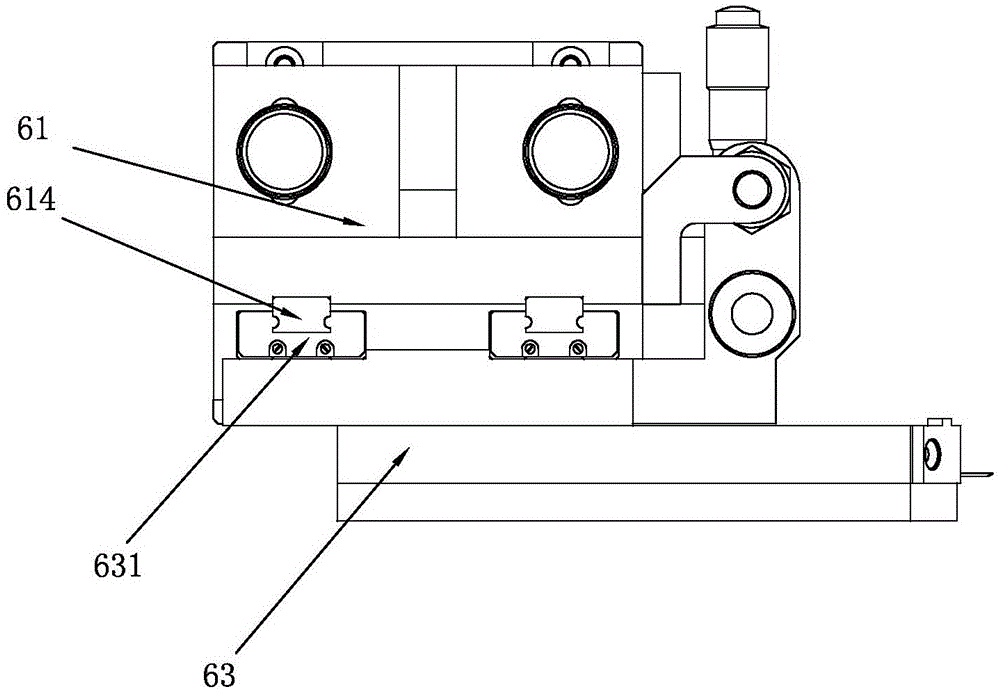

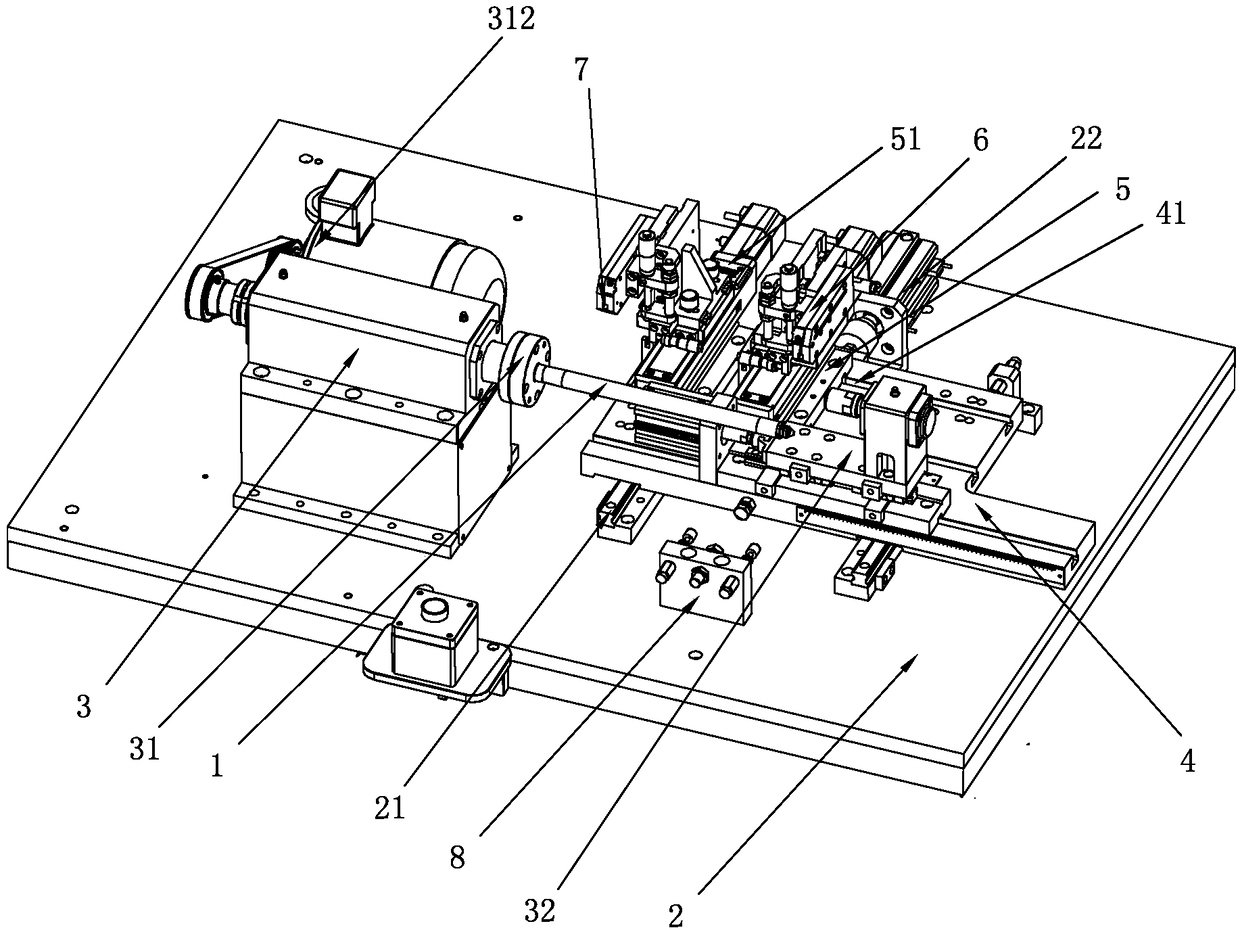

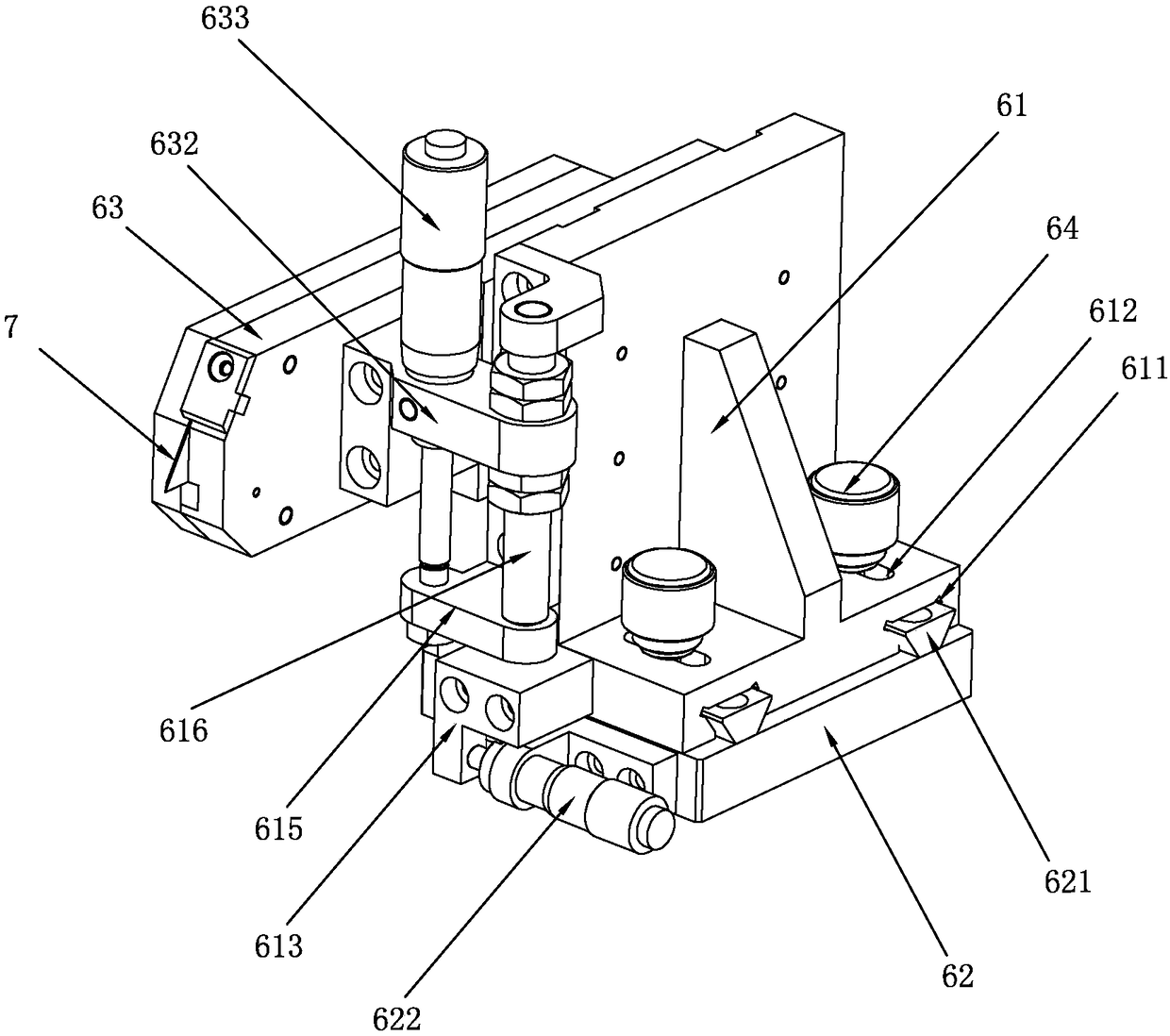

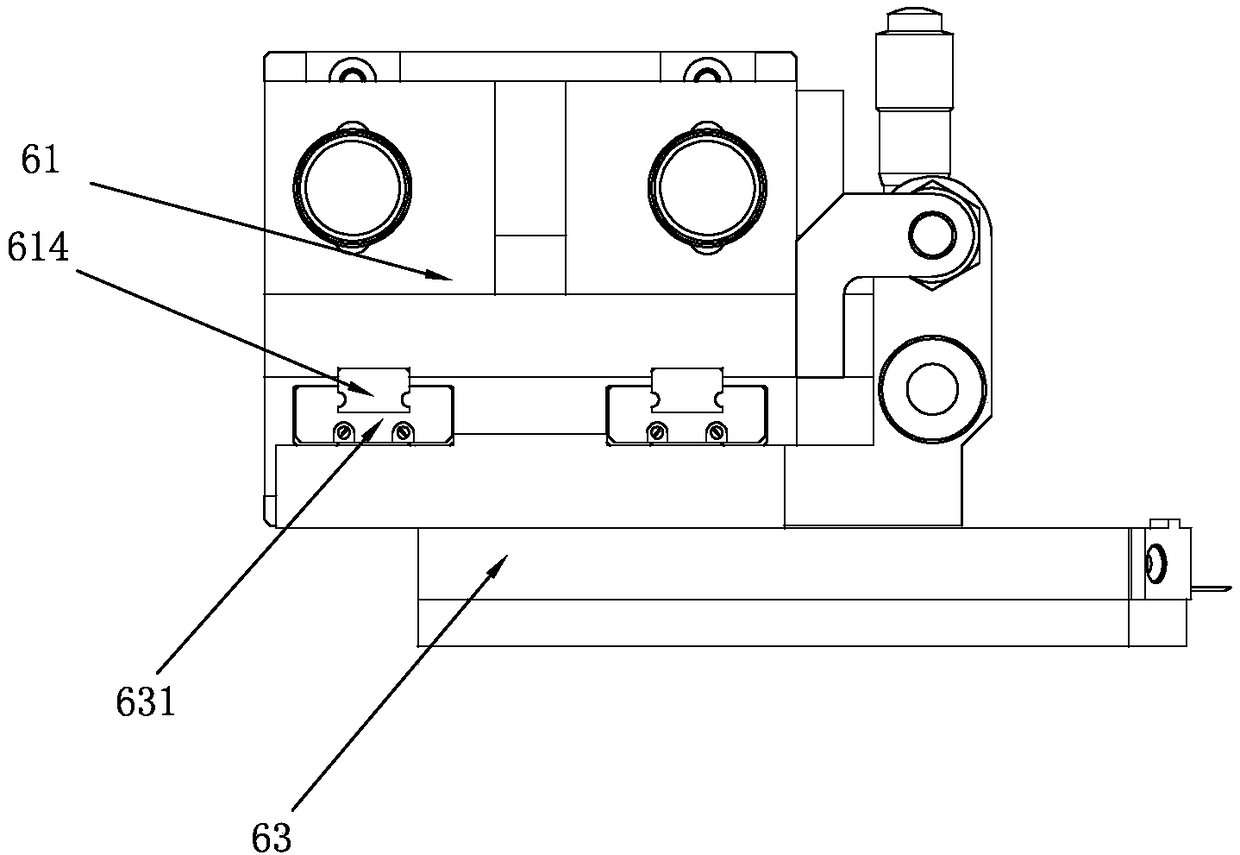

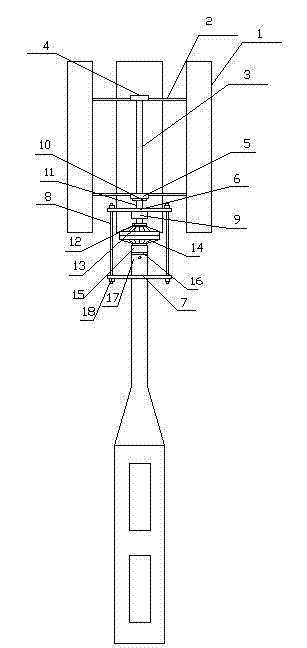

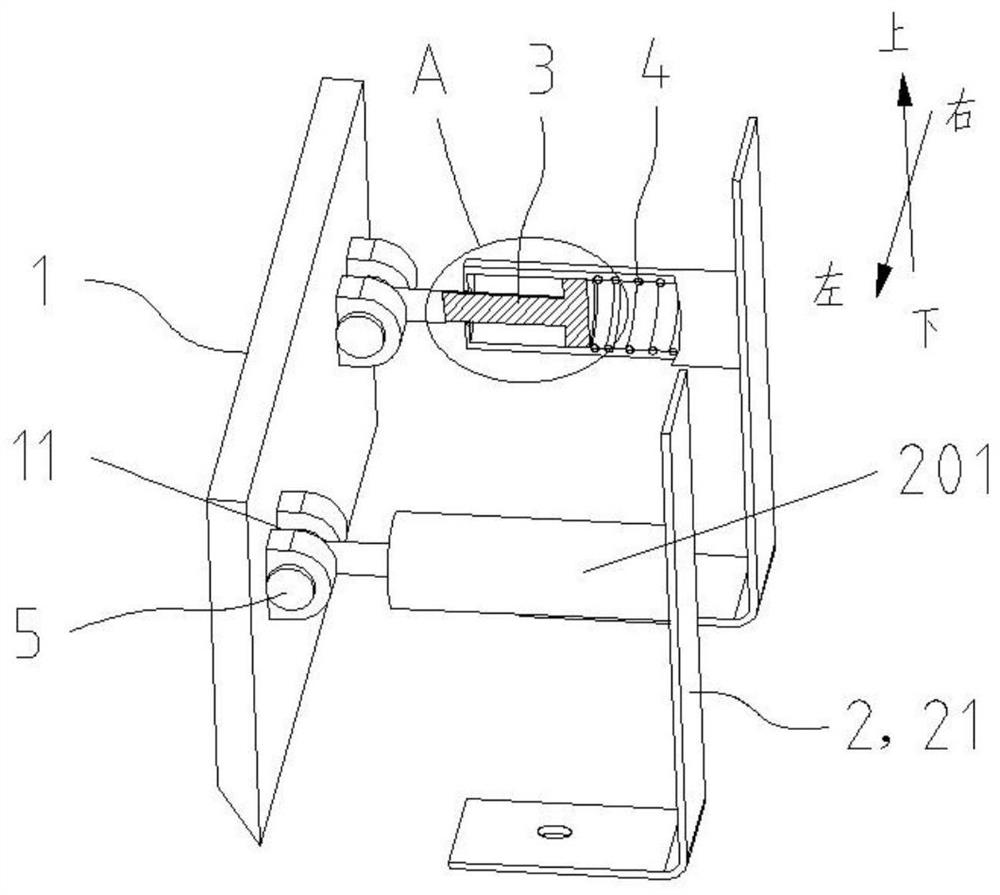

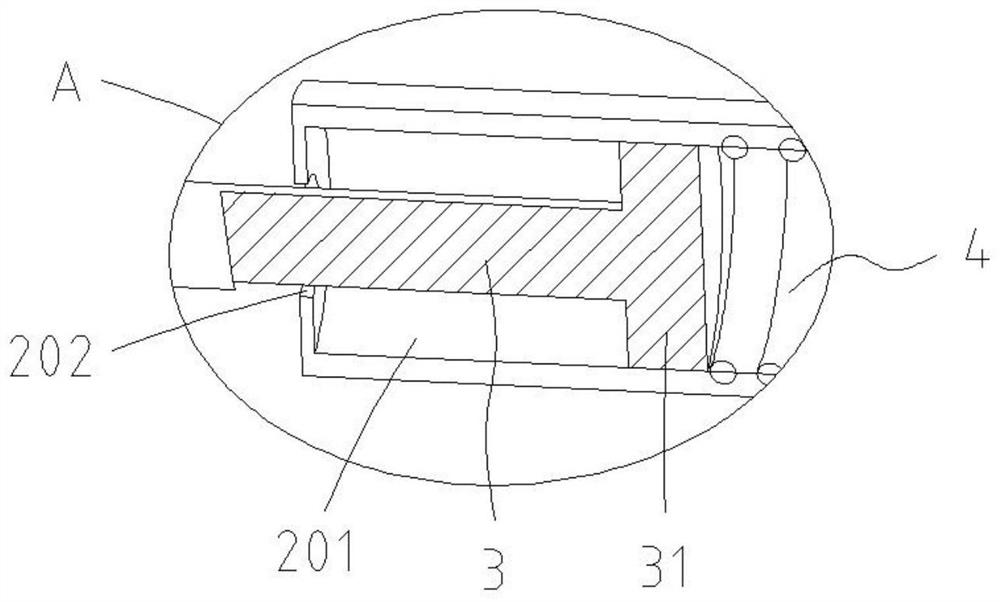

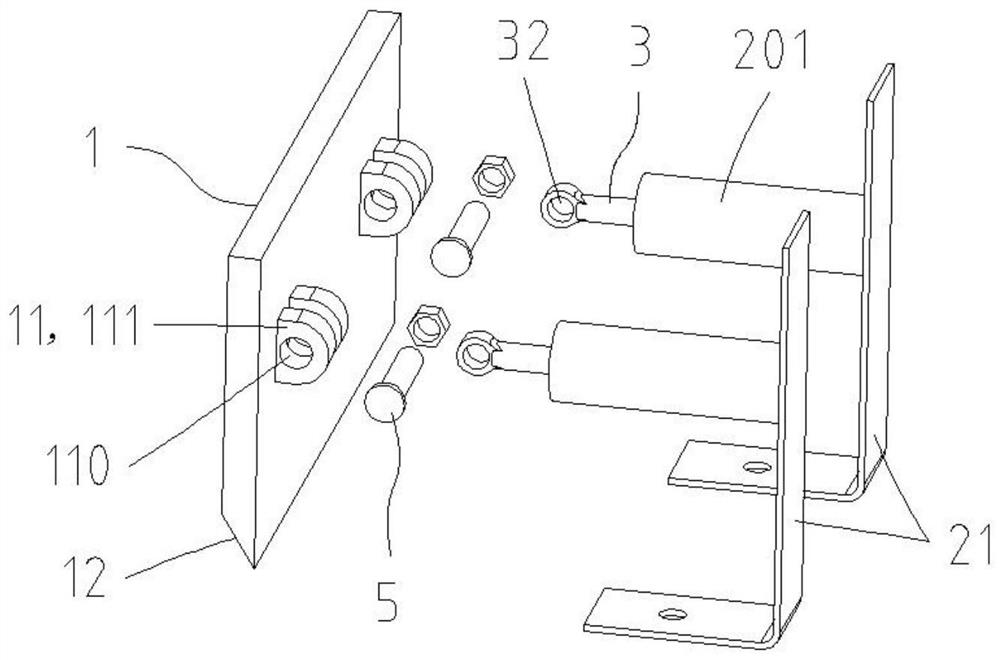

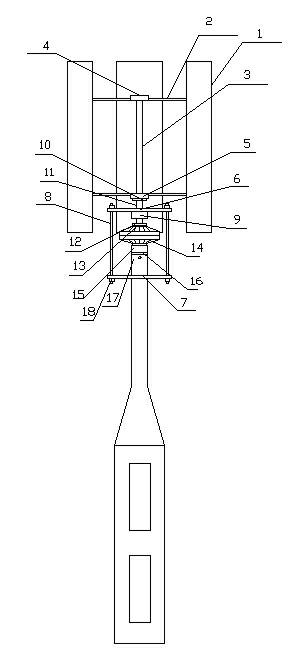

Polyimide (PI) pipe cutting machine

ActiveCN106142170AGuaranteed not to shakeStable cutting sizeMetal working apparatusEngineeringMechanical engineering

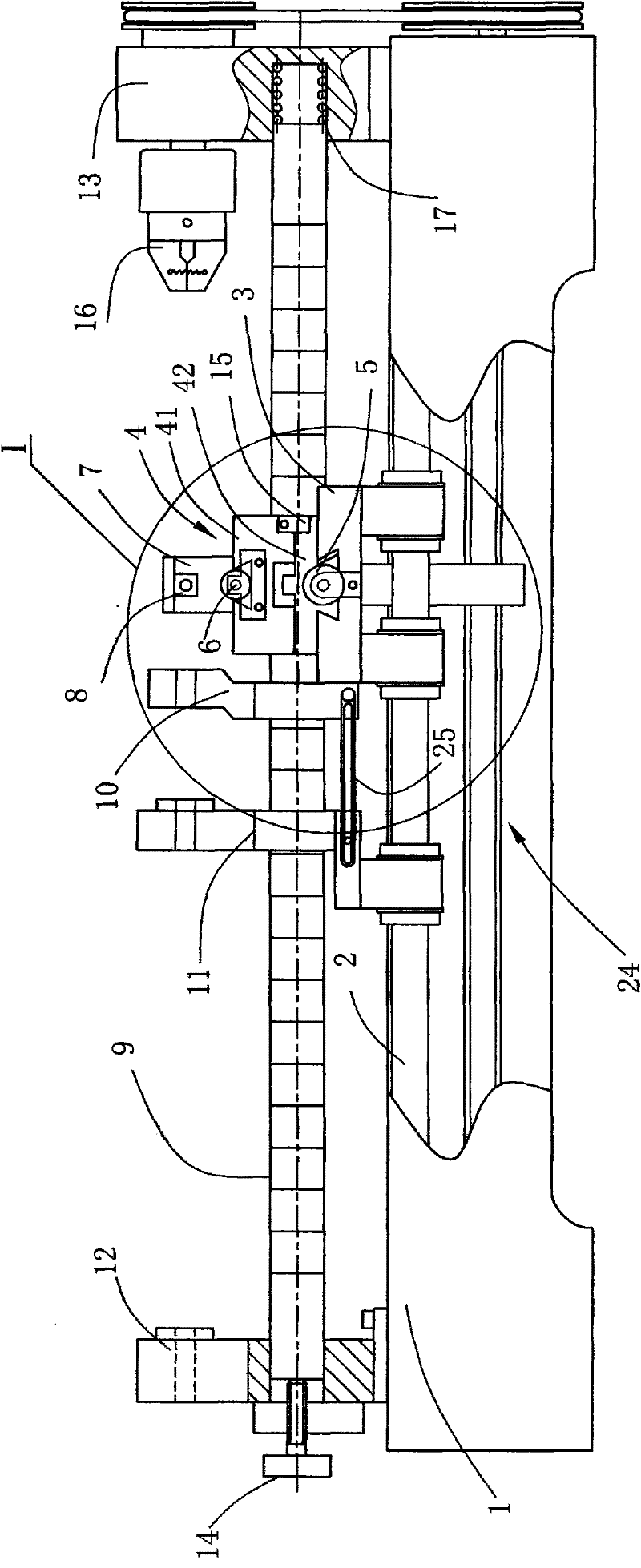

The invention discloses a polyimide (PI) pipe cutting machine. The PI pipe cutting machine comprises a workbench and a clamping mechanism for clamping a workpiece and driving the workpiece to rotate, the workbench is provided with a first Y-axis slideway and a base air cylinder, a base is arranged on the first Y-axis slideway in a sliding mode, an X-axis guide slot is formed in the base, at least one group of knife rest bases are installed in the X- axis guide slot in a sliding mode, each knife rest base is provided with a Y-axis electric sliding table, a knife rest is arranged on each Y-axis electric sliding table in a sliding mode, and each knife rest is provided with a blade. According to the PI pipe cutting machine, a workpiece to be cut is placed on the clamping mechanism and the workpiece to be cut is driven to rotate, the base is quickly pushed to the preset position by the base air cylinder, the blades of the knife rests are driven by the Y-axis electric sliding tables to slide to the workpiece, and the workpiece is cut into pieces. The clamping mechanism enables the workpiece not to waggle, the blades and the workpiece are always kept in a vertical state stably, the cutting size is stable, and the edges of the workpiece are neat and have no burrs after being cut.

Owner:珠海市技嘉科技有限公司

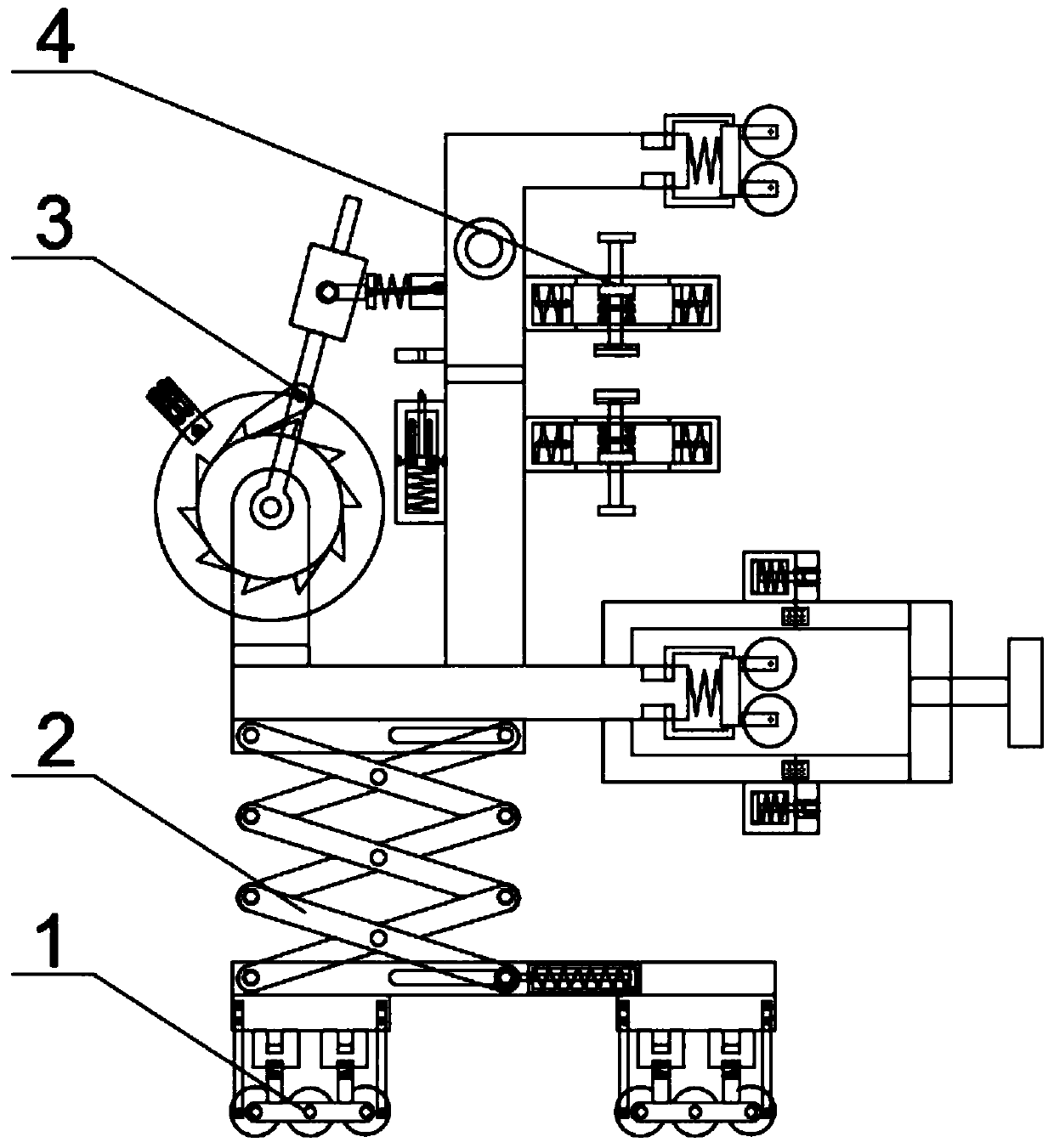

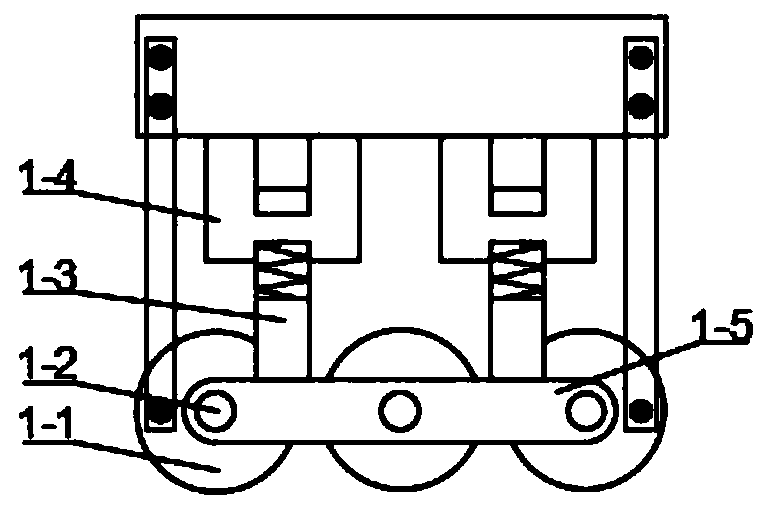

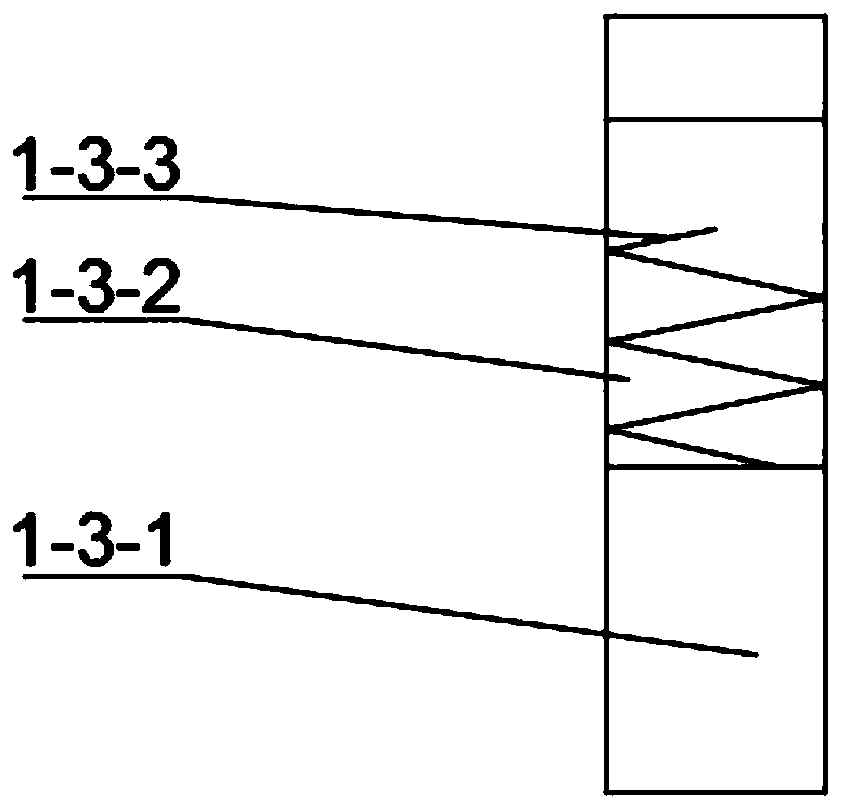

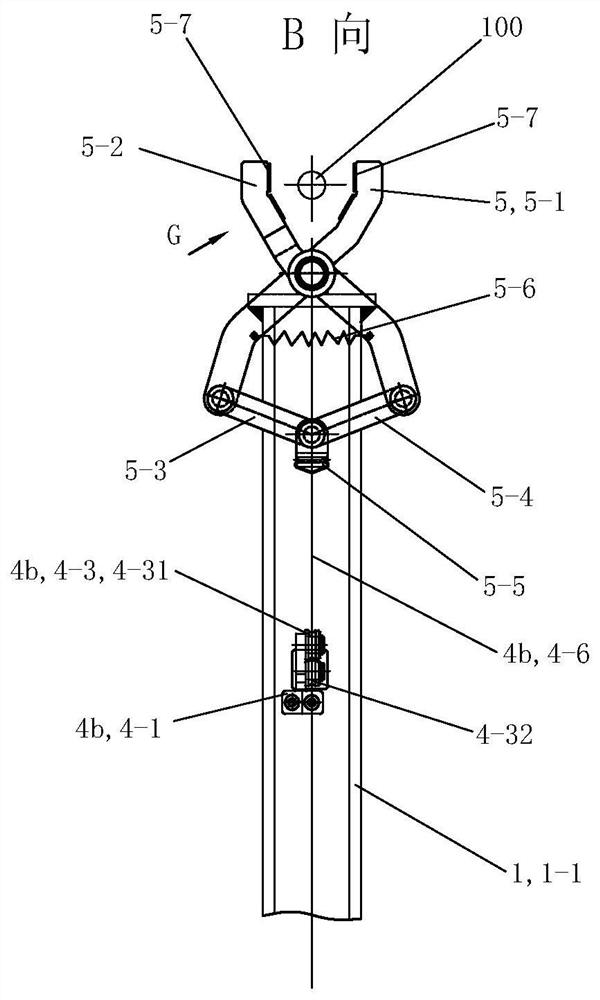

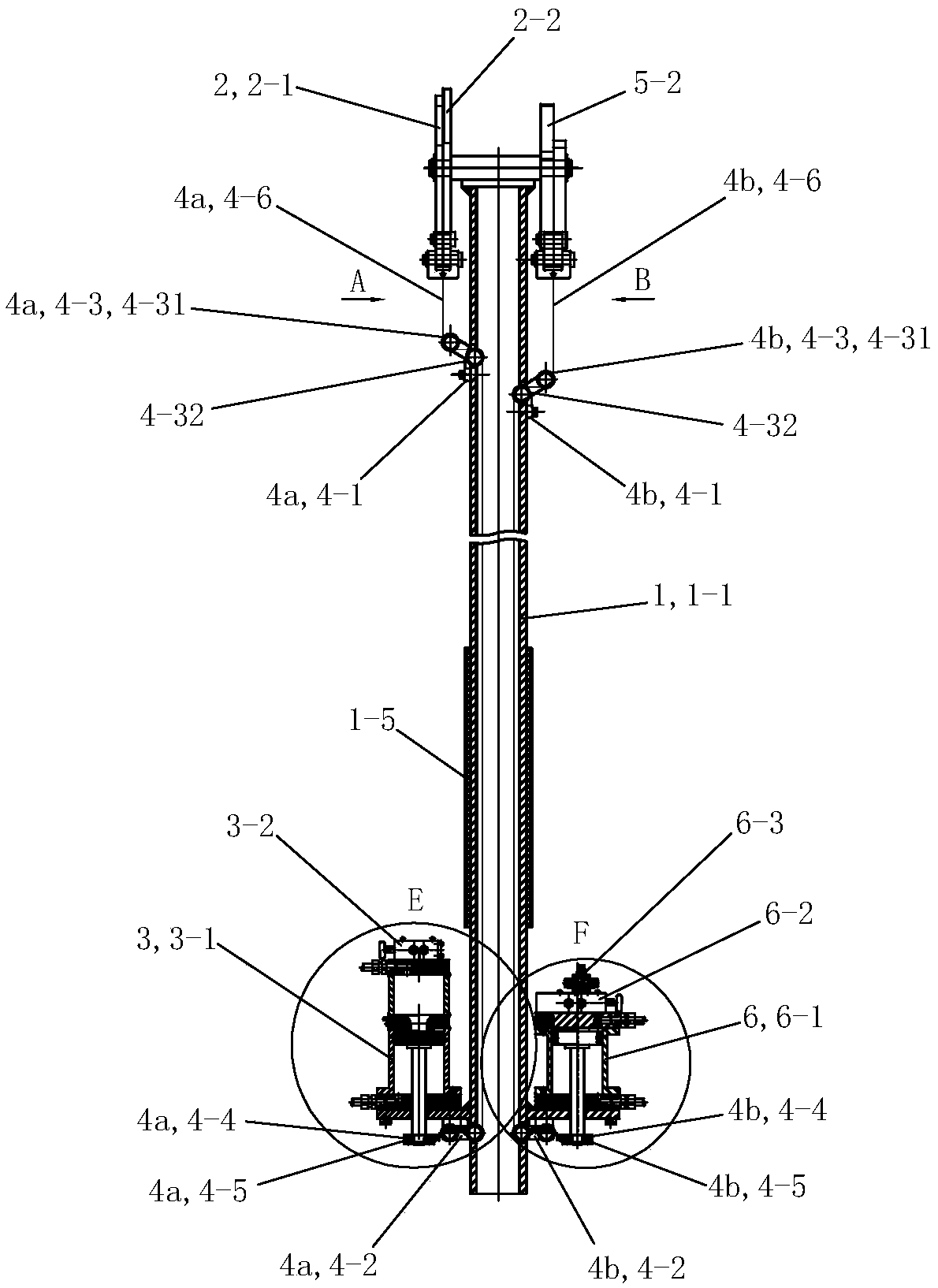

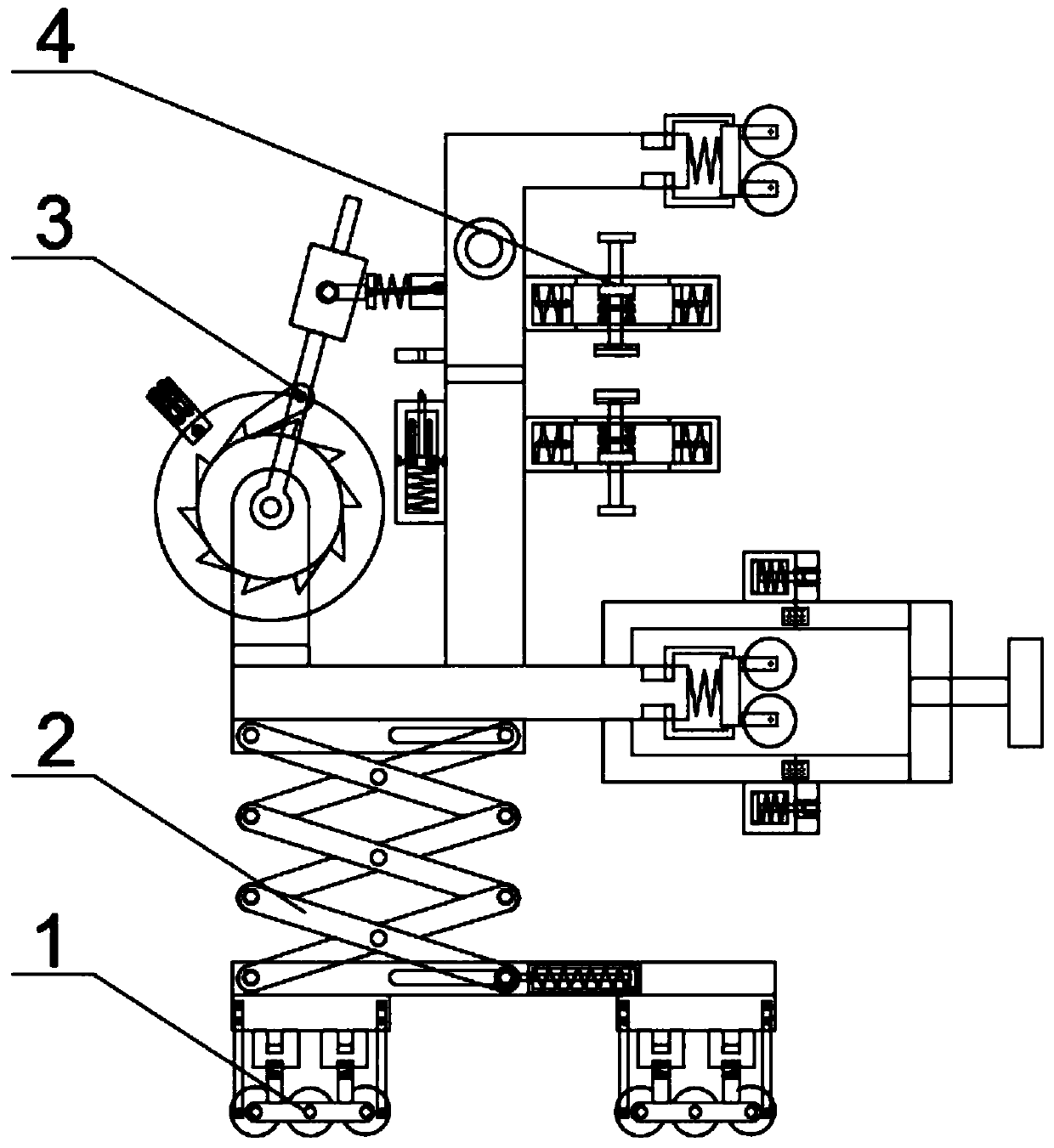

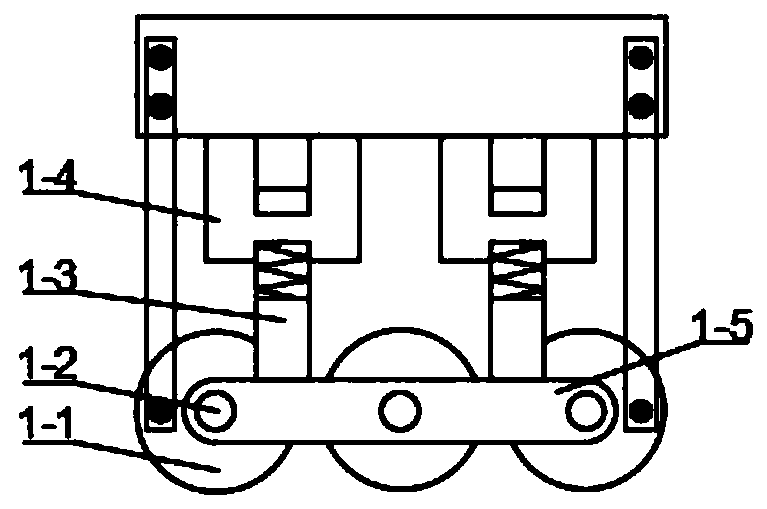

Power system stringing auxiliary device

ActiveCN109818299AReduce vibrationChange heightApparatus for removing/armouring cablesApparatus for overhead lines/cablesElectricityElectric power system

The invention relates to a stringing auxiliary device, in particular to a power system stringing auxiliary device. The power system stringing auxiliary device comprises a damping parking wheel mechanism, an elevating locking mechanism, a tensioning and wire cutting mechanism, and a cable peeling mechanism. The vibration of the device can be reduced in the moving process of the device; the device is capable of parking, capable of changing height, and capable of locking a telegraph pole; it is guaranteed that the device does not shake; the device can clamp a cable, the device can tension the cable, the device can cut the cable, and the device can peel the cable; the damping parking wheel mechanism is welded to the lower portion of the elevating locking mechanism; the tensioning and wire cutting mechanism is welded to the upper portion of the elevating locking mechanism; and the cable peeling mechanism is welded to the right side of the tensioning and wire cutting mechanism.

Owner:浙江正嘉建设有限公司

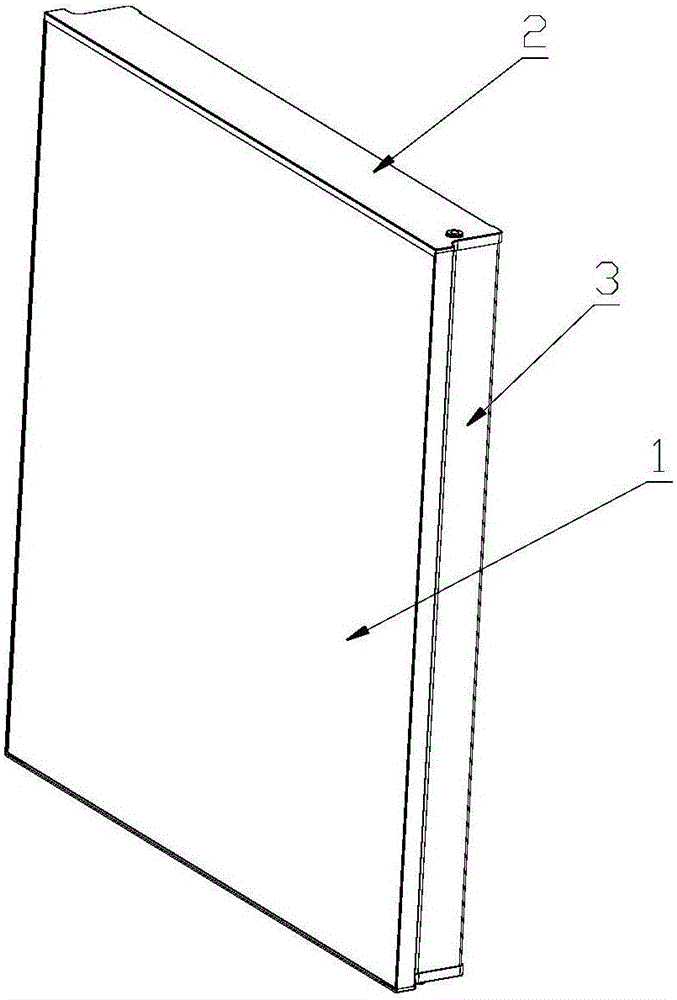

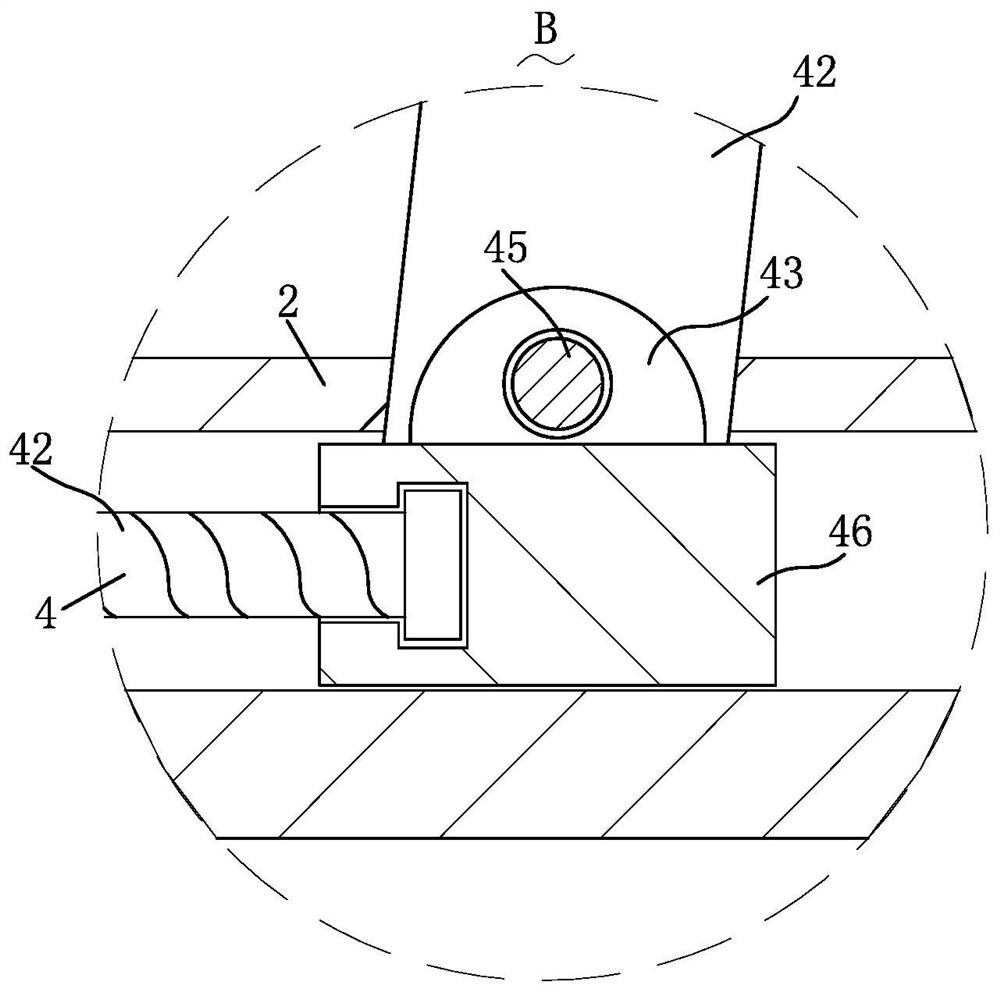

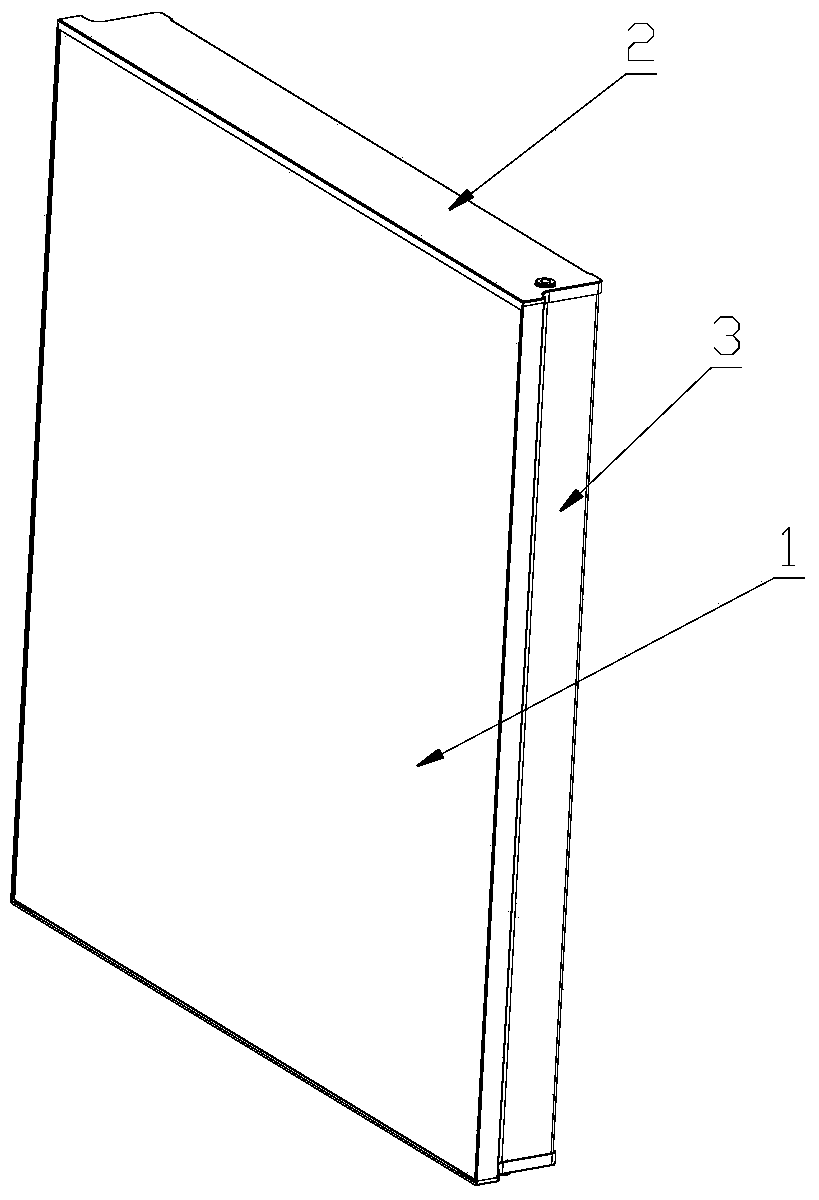

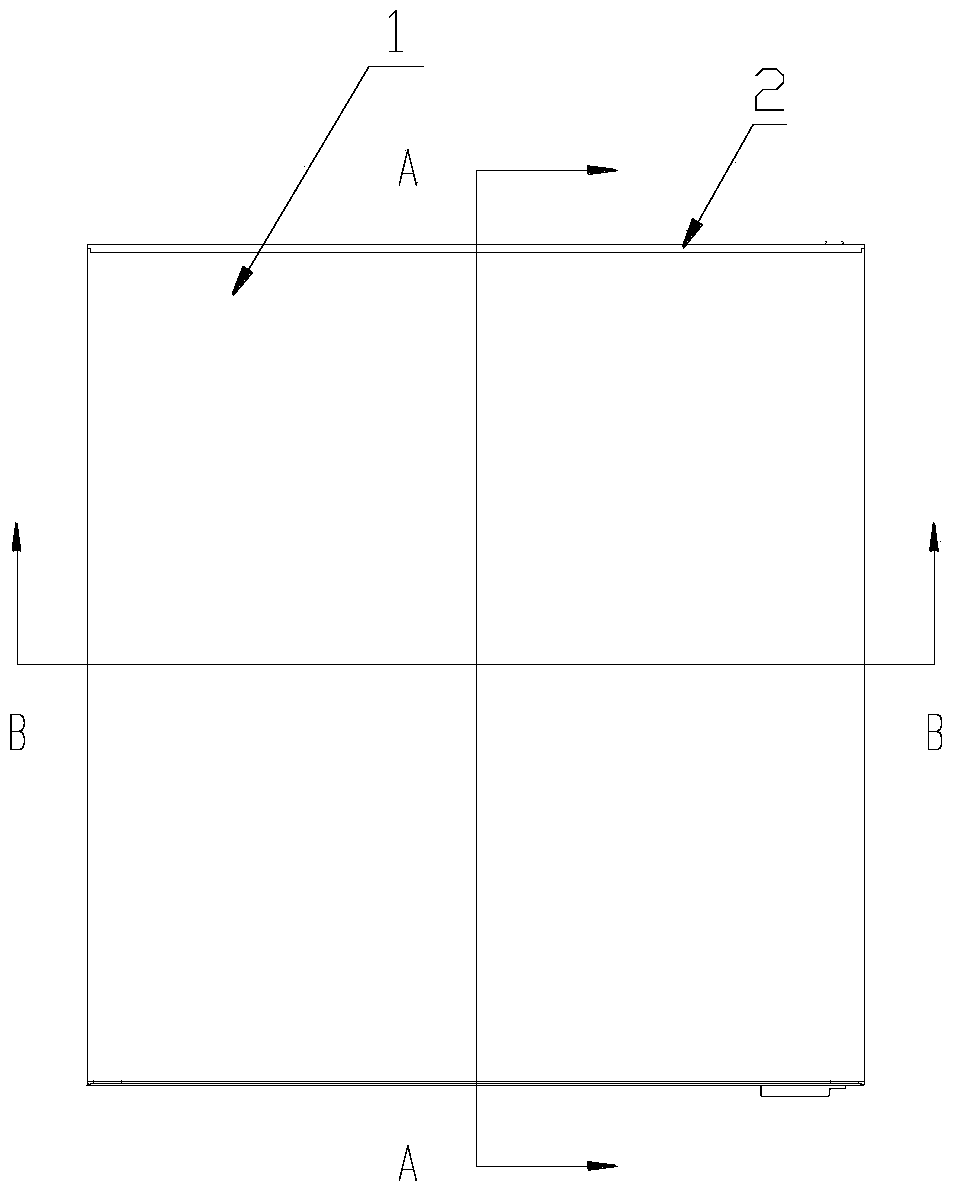

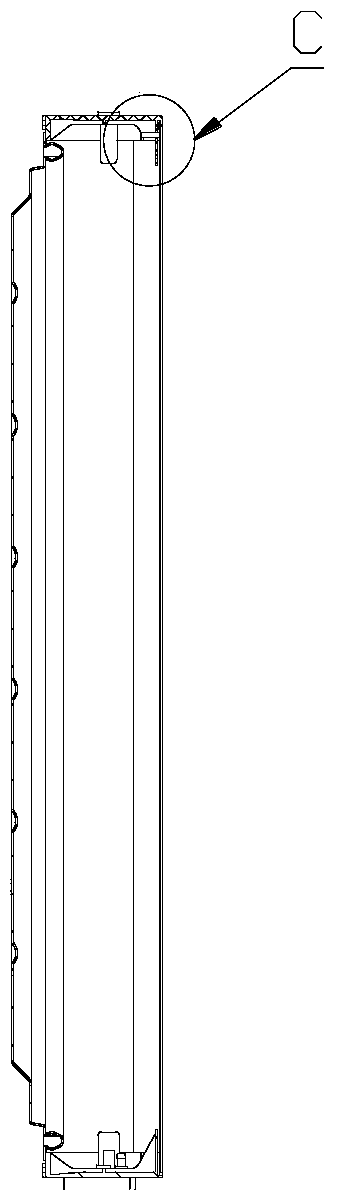

Door body assembly of refrigeration equipment and refrigeration equipment

ActiveCN106123456AEasy to installShake notLighting and heating apparatusCooling fluid circulationClamp connectionEngineering

The invention relates to a door assembly of refrigeration equipment and refrigeration equipment. The door assembly of the refrigeration equipment includes a glass door shell or a metal door shell. The main body of the metal door shell is a plane plate, and an end cover is also included. In the length direction and on the outer surface of the end cover, a long strip with an L-shaped cross-section is extended outward. A groove for clamping the flat plate is formed between the long strip and the outer surface of the end cover. The metal door shell is installed on the end cover by snap-fitting of the groove, or the glass door shell is bonded to the outer surface of the end cover by an adhesive. When installing the metal door shell, the plane plate is clamped with the groove, and the columns on both sides of the metal door shell are engaged with the end cover and the joint provided on the end cover, and the metal door shell is installed on this end; the cover; and When the glass door shell is installed, the glass door shell can be bonded to the outer surface of the end cover through an adhesive, and finally one end cover can fix two kinds of door shells.

Owner:HEFEI HUALING CO LTD +1

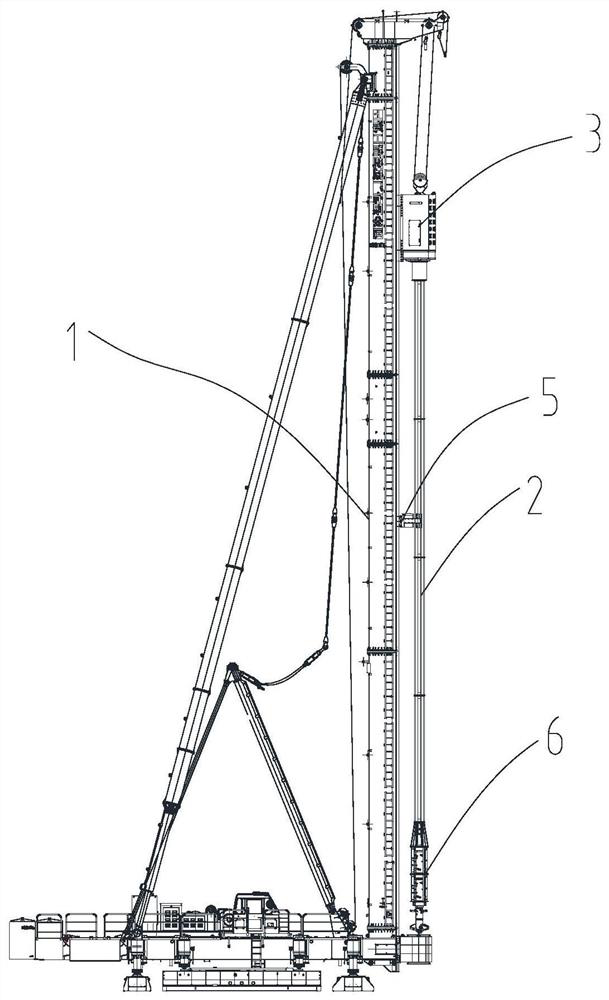

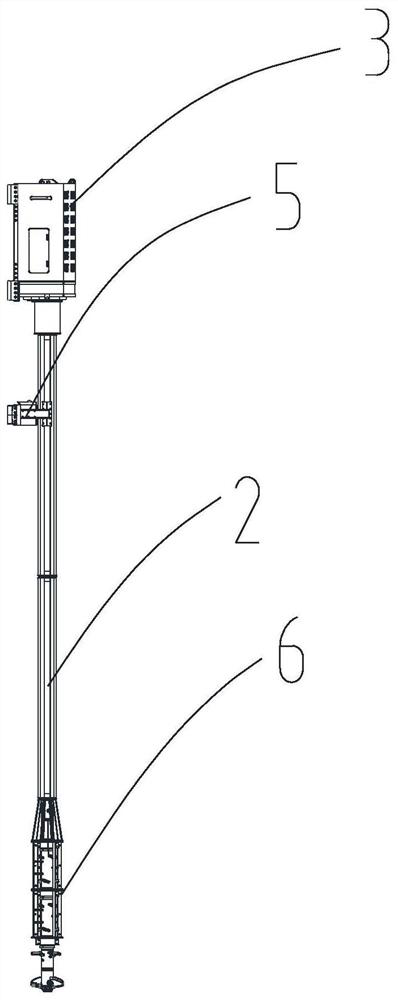

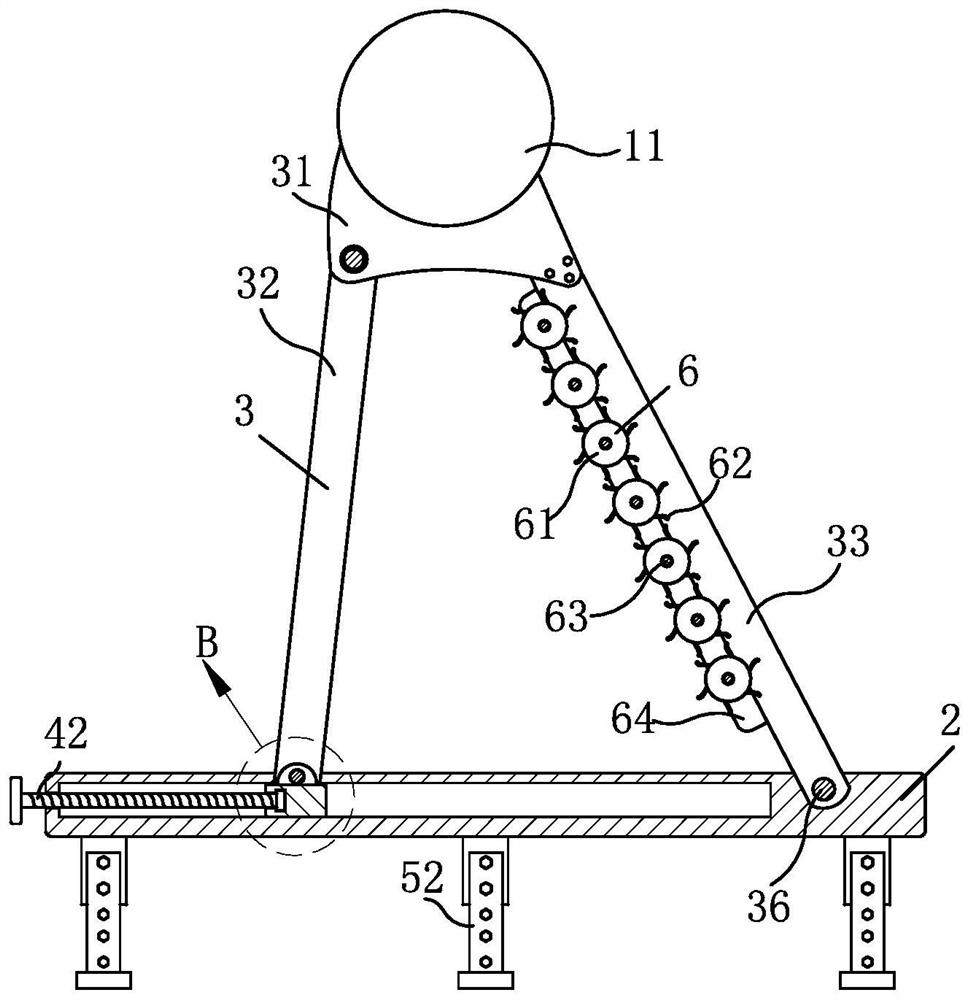

Pile planting construction device

PendingCN111945728AGuaranteed vertical drillingGuaranteed piling accuracyDerricks/mastsDirectional drillingAgricultural engineeringStructural engineering

The invention provides a pile planting construction device. The pile planting construction device comprises a pile frame, wherein a drill rod is arranged on the pile frame, and a power device is arranged at the top of the drill rod. The pile planting construction device is characterized in that a hollow stirring cage is arranged at the lower end of the drill rod; the part, provided with stirring blades, of a stirring shaft at the lower end of the drill rod is located in the stirring cage; fixed blades are arranged in the stirring cage; the fixed blades and the stirring blades on the stirring shaft are arranged in a staggered mode; the drill rod drives the stirring shaft to rotate to cut a stratum; and an outer-layer sleeve and the stirring cage are fixed together and do not rotate. According to the pile planting construction device, the stirring cage is arranged, so that the front end of the drill rod does not shake, and vertical downward drilling in the drilling process is guaranteed.The fixed blades and the stirring blades interact within the range of the stirring cage, cement slurry is fully stirred, and the pile forming effect is good.

Owner:SHANGHAI STRONG FOUND ENG

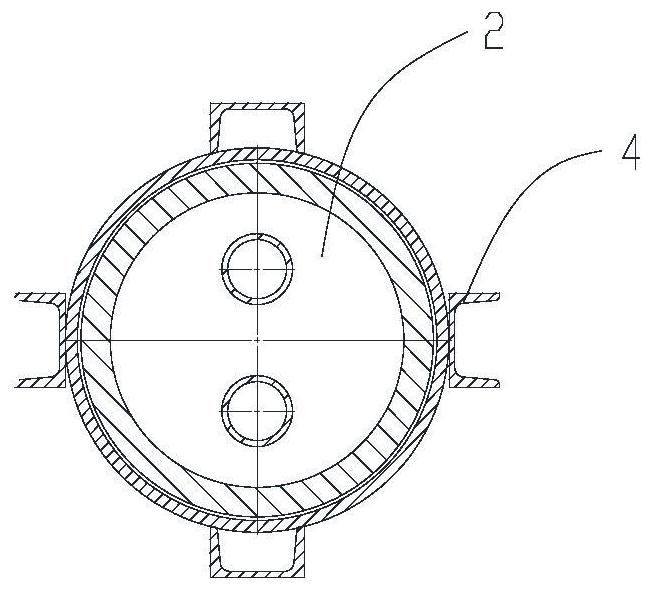

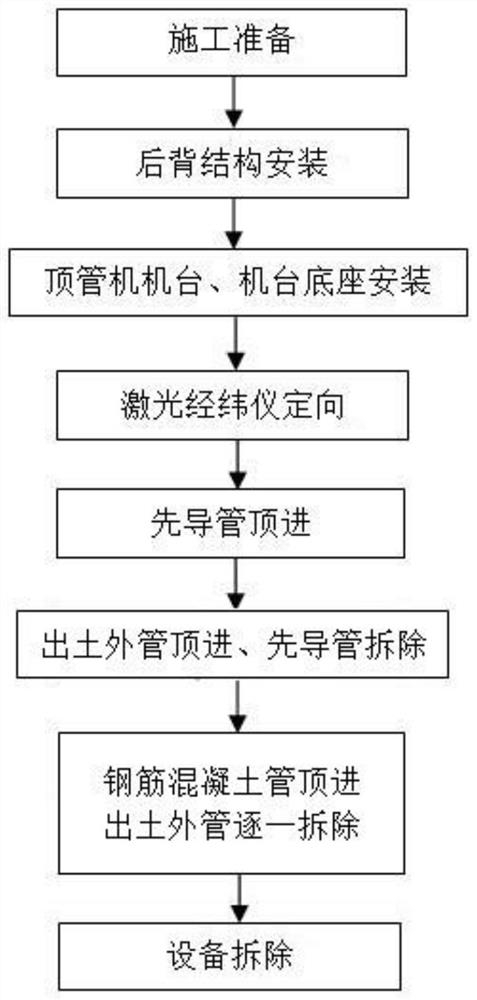

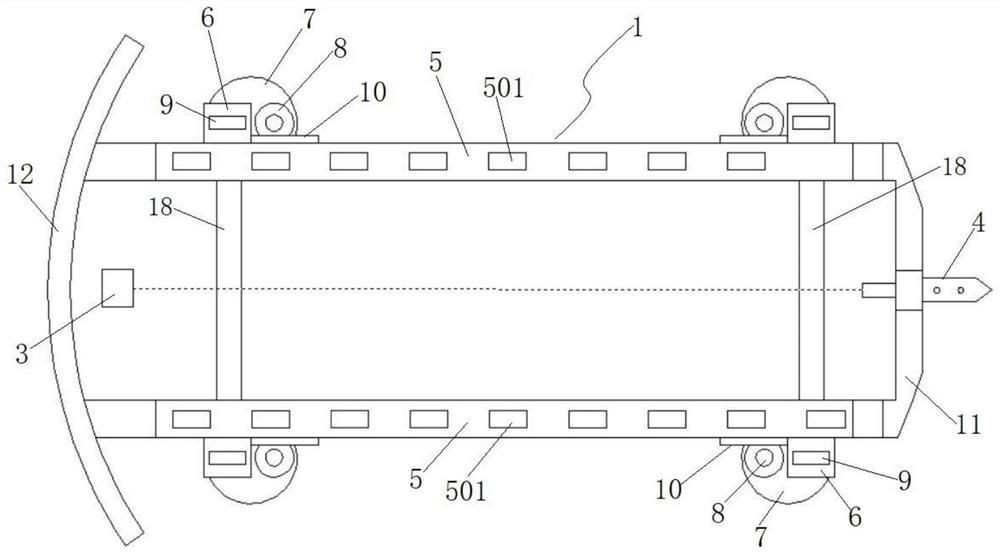

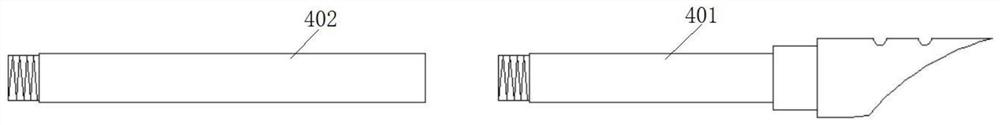

Miniature pipe jacking construction method for ecological comprehensive pipe gallery project

ActiveCN113338985AHigh pipe jacking efficiencyImprove accuracyMining devicesUnderground chambersEnvironmental resource managementReinforced concrete

The invention discloses a miniature pipe jacking construction method for ecological comprehensive pipe gallery engineering, which comprises the following construction steps: step 1, mounting and debugging a miniature pipe jacking machine, step 2, orienting a laser theodolite, step 3, jacking a pilot pipe, step 4, jacking an unearthed outer pipe, step 5, jacking a spiral cutter head, step 6, jacking a reinforced concrete pipe, and step 7, dismounting equipment. In the pipe jacking construction process, each section of pilot pipe and each section of unearthed outer pipe are sequentially dismantled in the receiving well, and the spiral cutter head, the pipe jacking machine table and the machine table base are dismantled in the working well. The miniature pipe jacking construction method for the ecological comprehensive pipe gallery project is easy to operate, high in pipe jacking efficiency, quite convenient and rapid to install and detach, good in pipe jacking accuracy and safety and suitable for rapid construction of urban ecological comprehensive pipe galleries.

Owner:葛洲坝集团生态环保有限公司

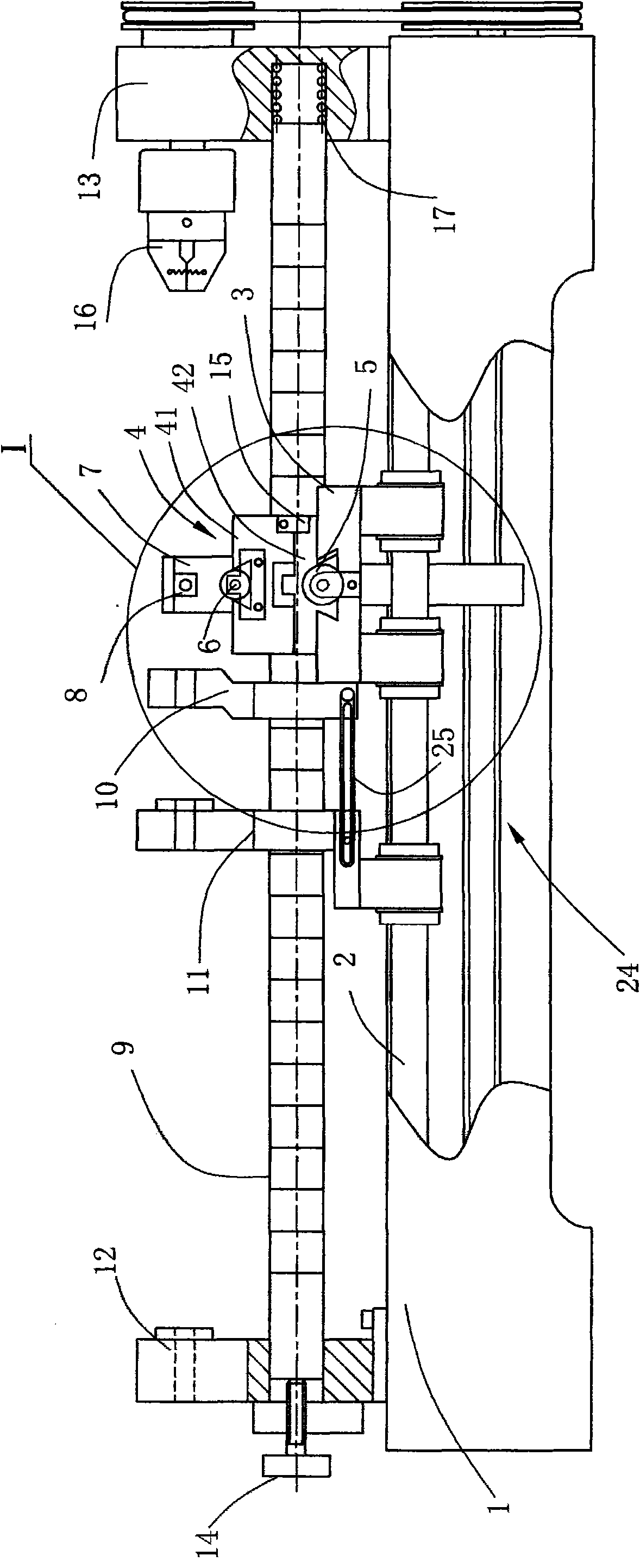

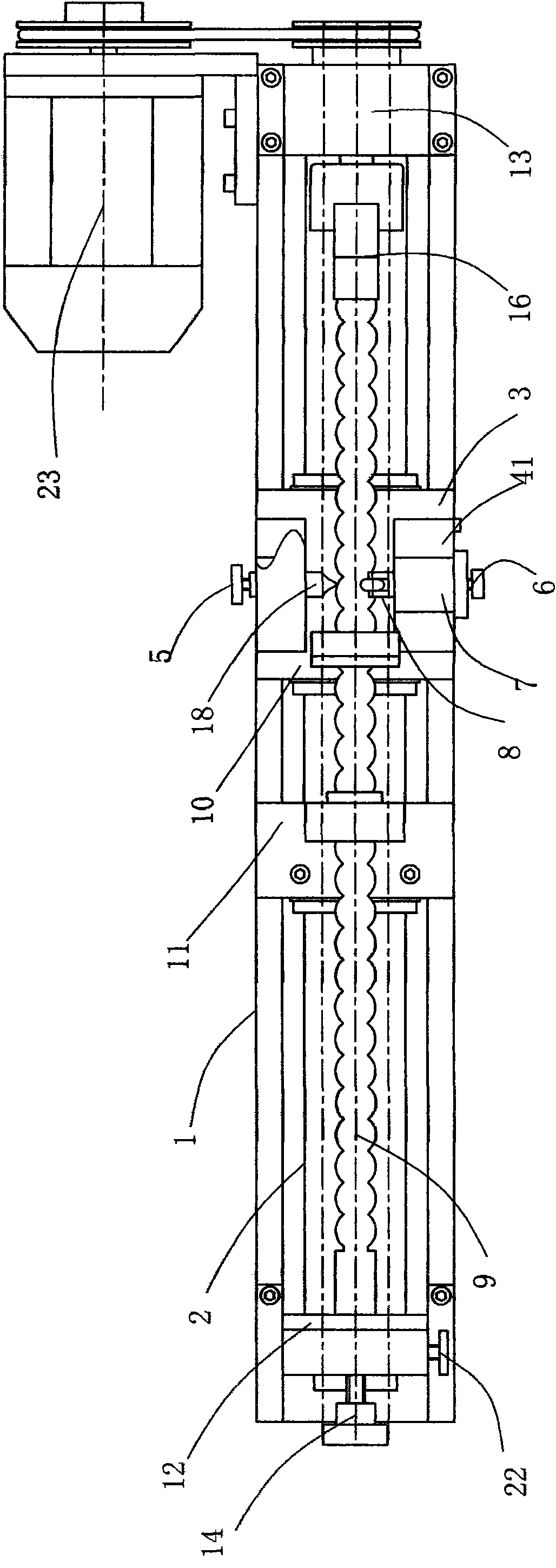

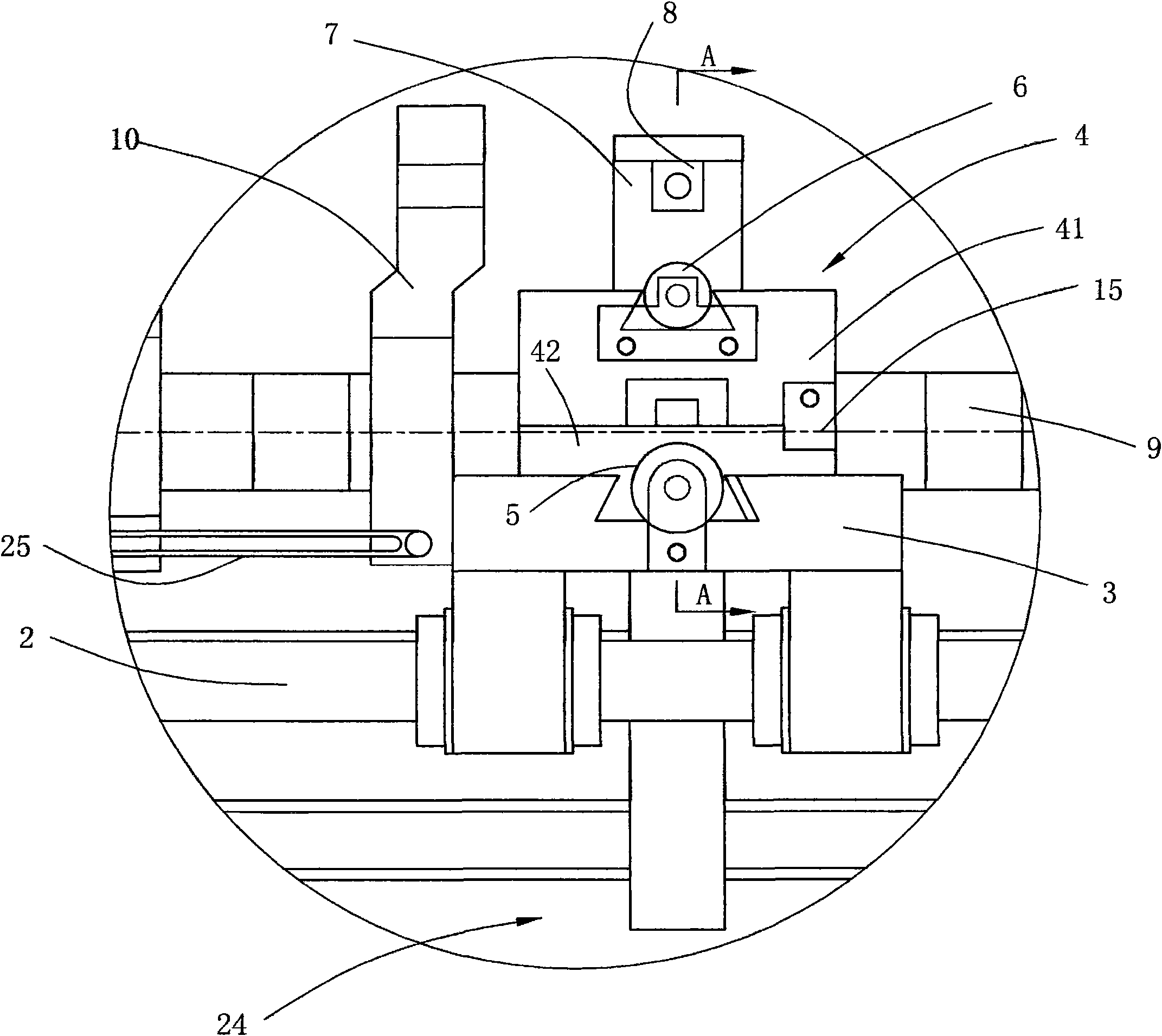

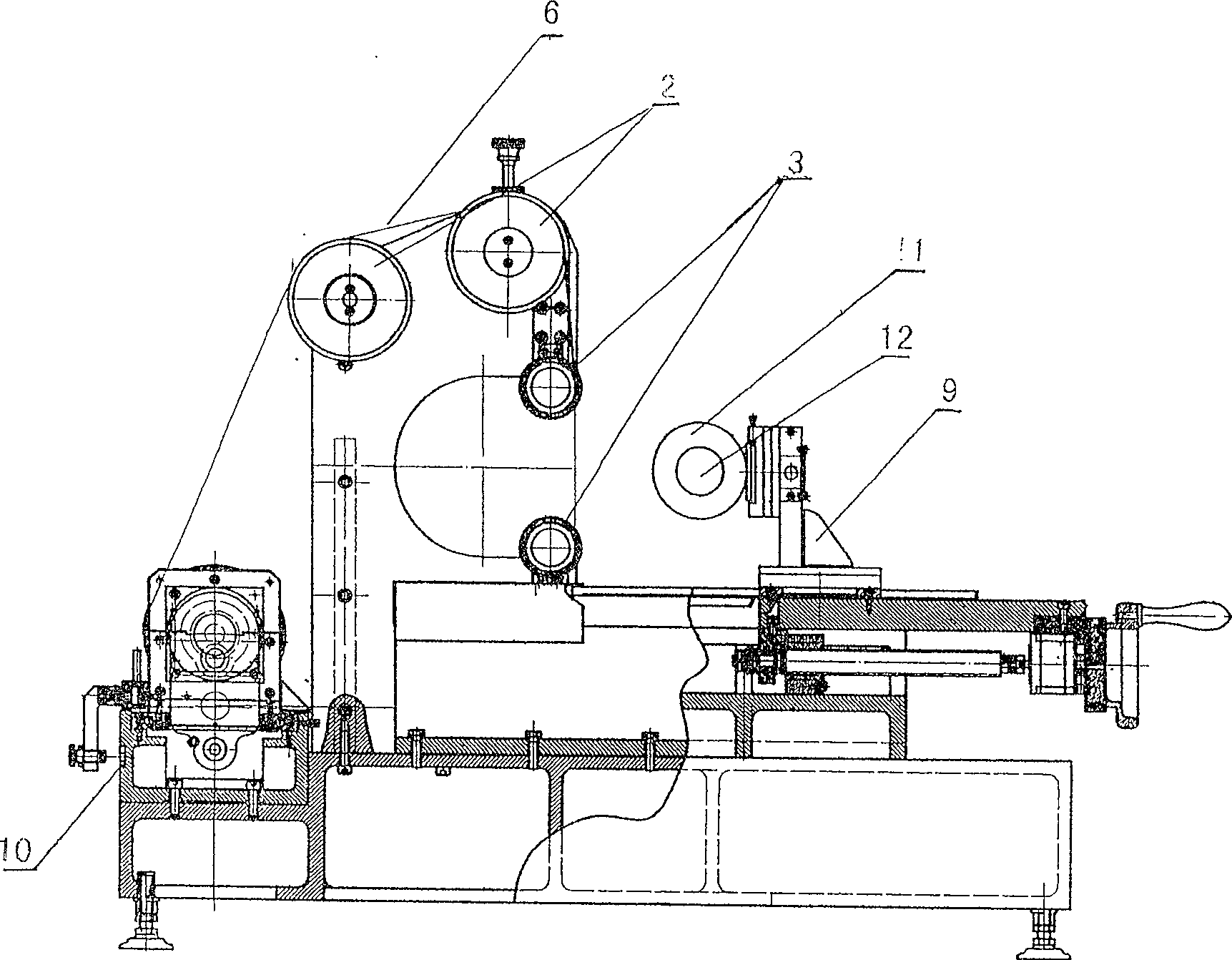

Bead string nailing and sanding machine

ActiveCN101829939AImprove efficiencyQuality improvementSpherical surface grinding machinesJewelleryEngineeringExplorator

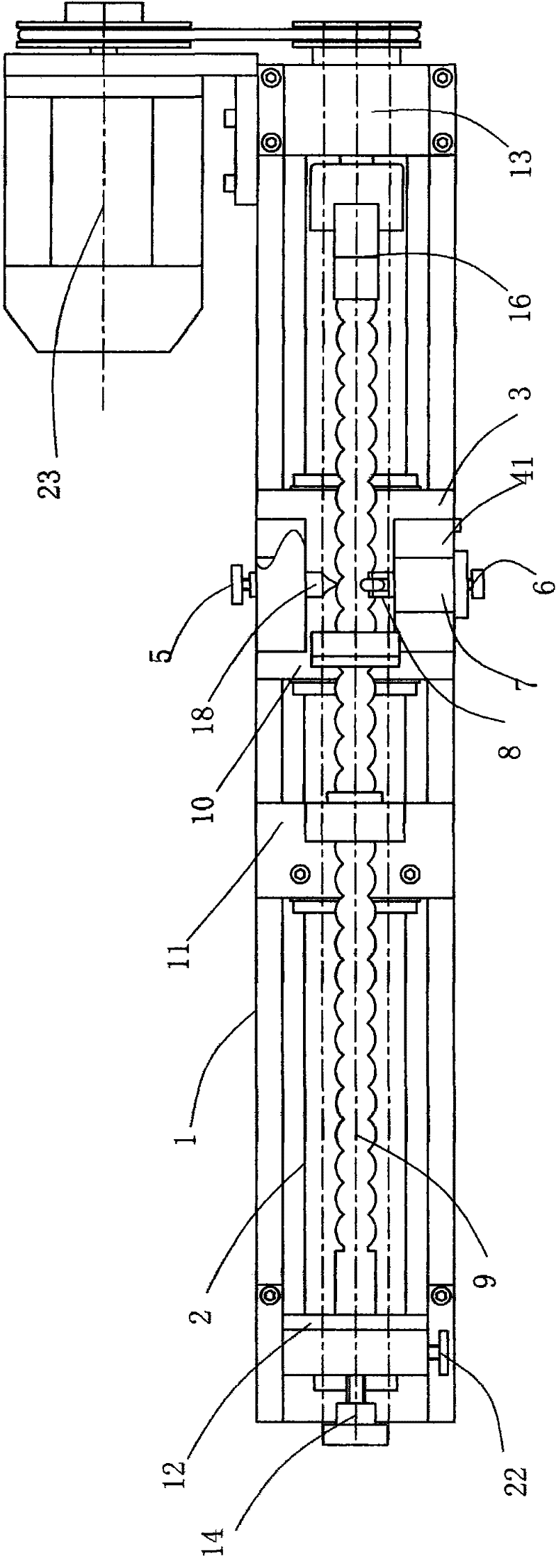

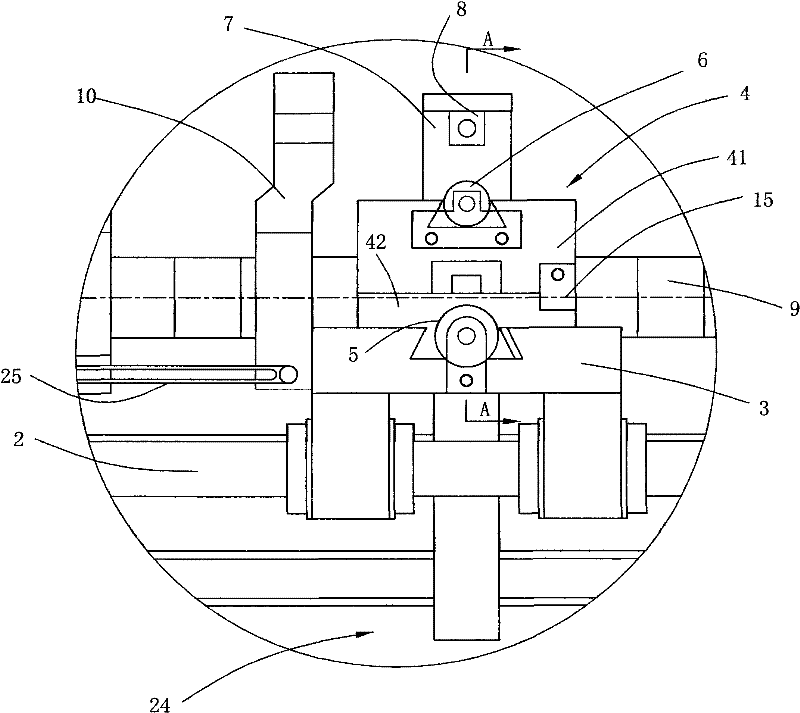

The invention discloses a bead string nailing and sanding machine which comprises a stand, a clamping head seat, a tail seat, a slide seat, an explorator, two contact knives and two nailing and sanding knife seats, wherein the clamping head seat and the tail seat are arranged on the stand; the clamping head seat is rotatably provided with a clamping head driven by a first power device, and the tail seat is provided with a guide sleeve coaxial with the clamping head; the slide seat is driven by a second power device and slidably arranged on a longitudinal rail on the stand; both side surfaces of the explorator are respectively provided with profiling ripples adaptive to bead strings, and the explorator is arranged between the clamping head seat and the tail seat; a longitudinal explorator regulating mechanism is arranged between the explorator and a mounting part corresponding to the explorator; the two contact knives are arranged at both sides of the explorator and respectively fixed on a contact knife seat, and a first transverse regulating mechanism is arranged between the contact knife seats and the slide seat; the two nailing and sanding knife seats are respectively provided with a nailing and sanding knife, and the nailing and sanding knife seats are arranged on the contact knife seats; and a second transverse regulating mechanism is arranged between the nailing and sanding knife seats. The nailing and sanding machine can be used for quickly and conveniently nailing and sanding the bead strings, thereby the nailing efficiency and the nailing quality are improved.

Owner:SHANDONG MOKINGRAN JEWELRY

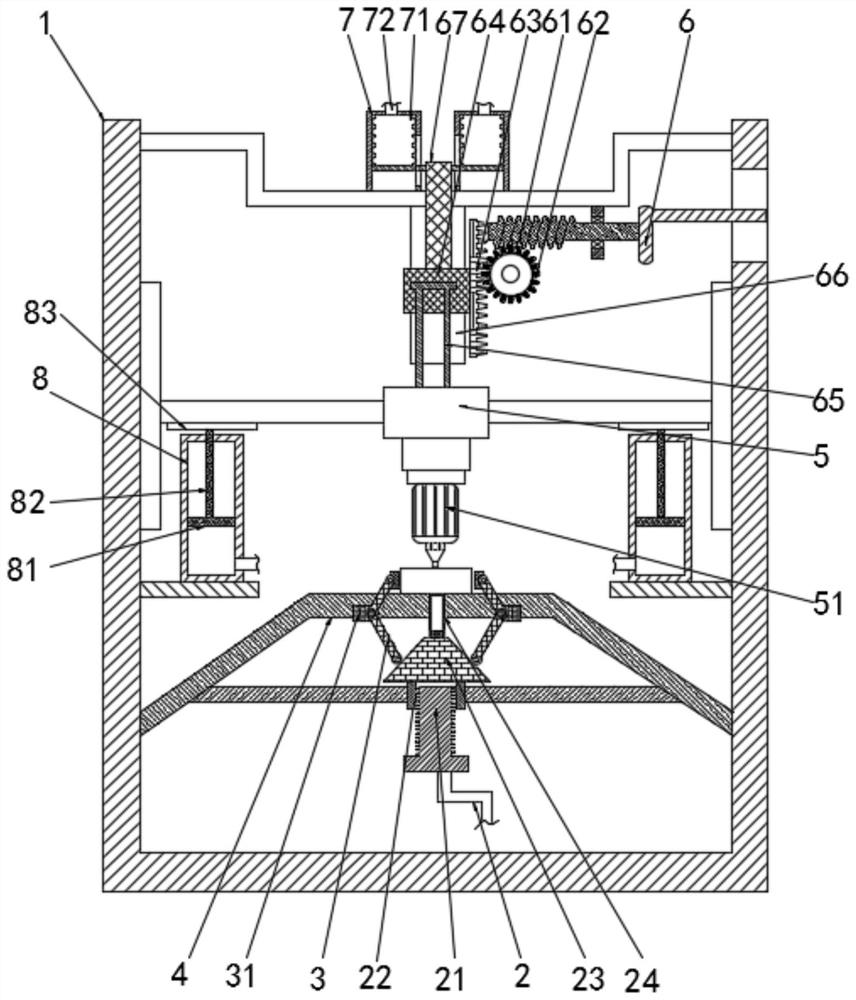

Steel structure punching auxiliary device capable of adjusting punching depth

PendingCN113182555AFixed firmlyGuaranteed not to shakePositioning apparatusBoring/drilling componentsDrill holeEnvironmental geology

The invention relates to the technical field of steel structure punching, and discloses a steel structure punching auxiliary device capable of adjusting the punching depth. The steel structure punching auxiliary device capable of adjusting the punching depth comprises a device main body frame and an operation table, wherein a drilling machine is arranged above the operation table, a driving device is arranged on the drilling machine, and a threaded rod is arranged at the upper part of the device main body frame; a gear is arranged below the threaded rod, a toothed rod is arranged on the left side of the gear, a sleeve is fixedly connected to the left side of the toothed rod, and a connecting piece is arranged between the sleeve and the driving device. According to the steel structure punching auxiliary device capable of adjusting the punching depth, the longest distance that the driving device drives the drilling machine to move downwards is not changed, the threaded rod drives the gear to rotate clockwise when the drilling depth needs to be reduced, the tooth rod on the left side of the gear moves upwards along with the gear, the tooth rod moves upwards to drive the sleeve to move upwards, and the sleeve moves upwards to drive the connecting piece and the driving device to move upwards, so that the drilling depth is reduced when the drilling machine moves downwards, and the effect of adjusting the drilling depth is achieved through the structure.

Owner:王琛哲

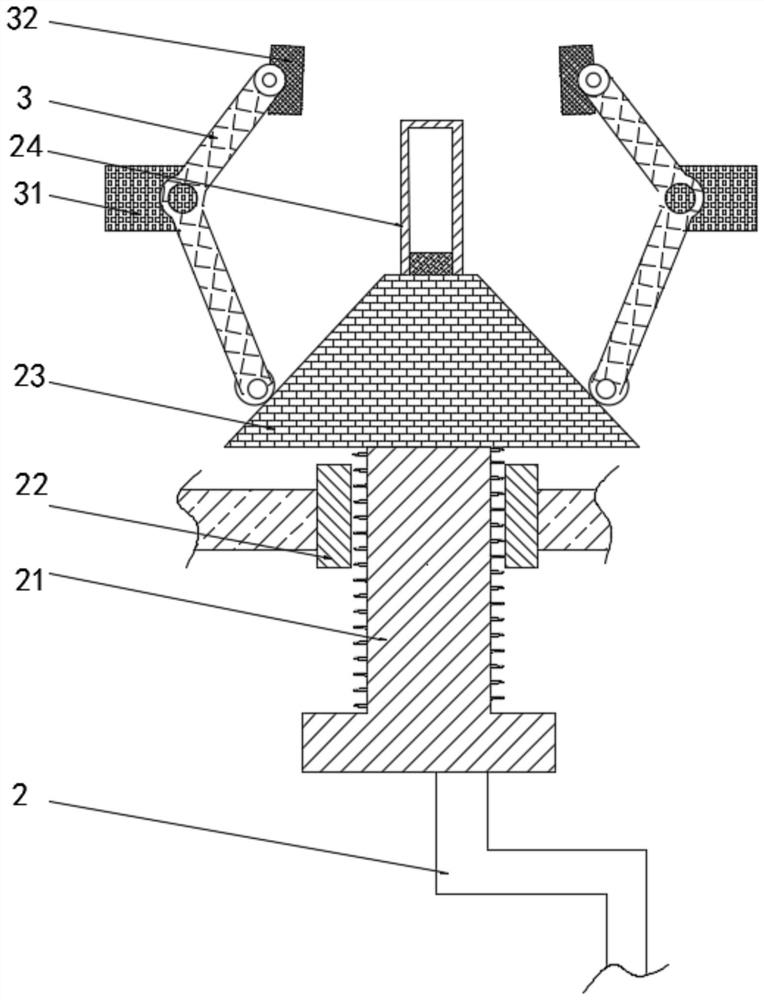

A wind-proof solar water heater support device

ActiveCN111351241BAchieve installationImprove stabilitySolar heating energyMoving/orienting solar heat collectorsExposure sunlightSolar water

The invention relates to the field of solar water heaters, in particular to a strong wind-proof solar water heater support device, including a heating mechanism, a support plate, a support mechanism, a drive mechanism, an installation mechanism and a cleaning mechanism; a drive mechanism is installed horizontally inside the support plate, In addition, one end of the driving mechanism is rotationally connected to the supporting mechanism, and the other end of the supporting mechanism is rotationally connected to the supporting plate, and the heating mechanism is fixed to the top of the supporting mechanism through nuts. During installation, the heating mechanism and the supporting mechanism can be changed by rotating the driving mechanism. The angle between the support plates maximizes the exposure of the heating mechanism to sunlight, which is beneficial to heating the water and is easy to operate; there are two sets of installation mechanisms at the bottom of the support plate, and several installation mechanisms can slide on the bottom of the support plate , and the installation mechanism itself can be stretched, which is convenient for installation on the roofs of houses with different slopes in rural areas, and increases the stability of the overall structure.

Owner:广东启程新能源科技有限公司

Door body assembly of refrigeration equipment and refrigeration equipment

ActiveCN106123456BEasy to installShake notDomestic cooling apparatusLighting and heating apparatusClamp connectionEngineering

The invention relates to a door body assembly of refrigeration equipment and the refrigeration equipment. The door body assembly of the refrigeration equipment comprises a glass door shell or a metal door shell and further comprises end covers, wherein the main body of the metal door shell is a flat panel; a long strip-shaped plate with an L-shaped section extends out from the outer side surface of each end cover in the length direction of the end cover, a groove for clamping the flat panel is formed between each long strip-shaped plate and the outer side surface of the corresponding end cover, and the metal door shell is installed on the end covers through clamping connection of the flat panel and the grooves or the glass door shell is bonded on the outer side surfaces of the end covers through a bonding agent. When the metal door shell is installed, the flat panel and the grooves are in clamped connection, stand columns on the two sides of the metal door shell are connected with the end covers and combination portions arranged on the end covers, and the metal door shell is installed on the end covers. When the glass door shell is installed, the glass door shell can be bonded on the outer side surfaces of the end covers through the bonding agent. Finally, the two door shells can be fixed through the same kind of end covers.

Owner:HEFEI HUALING CO LTD +1

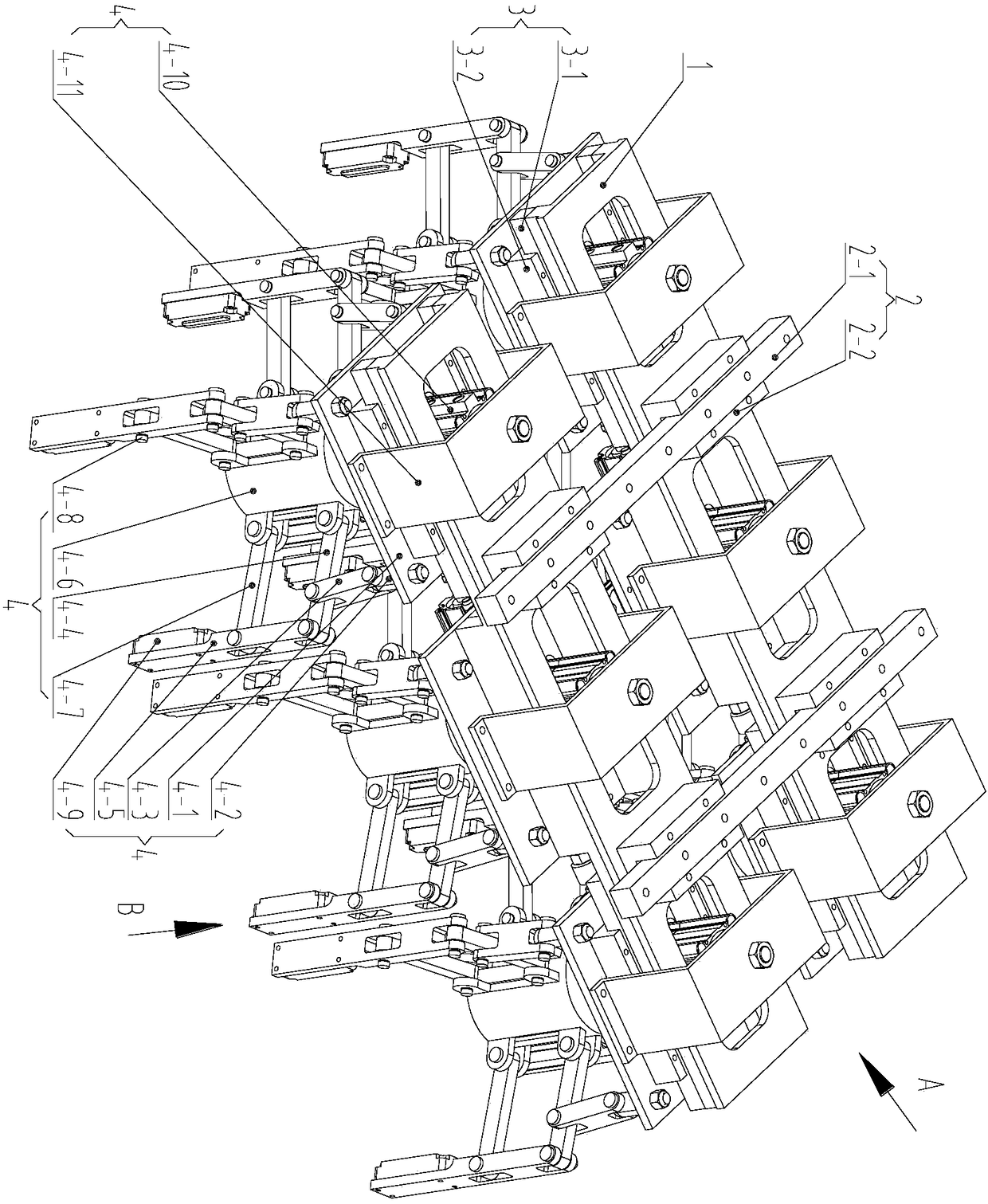

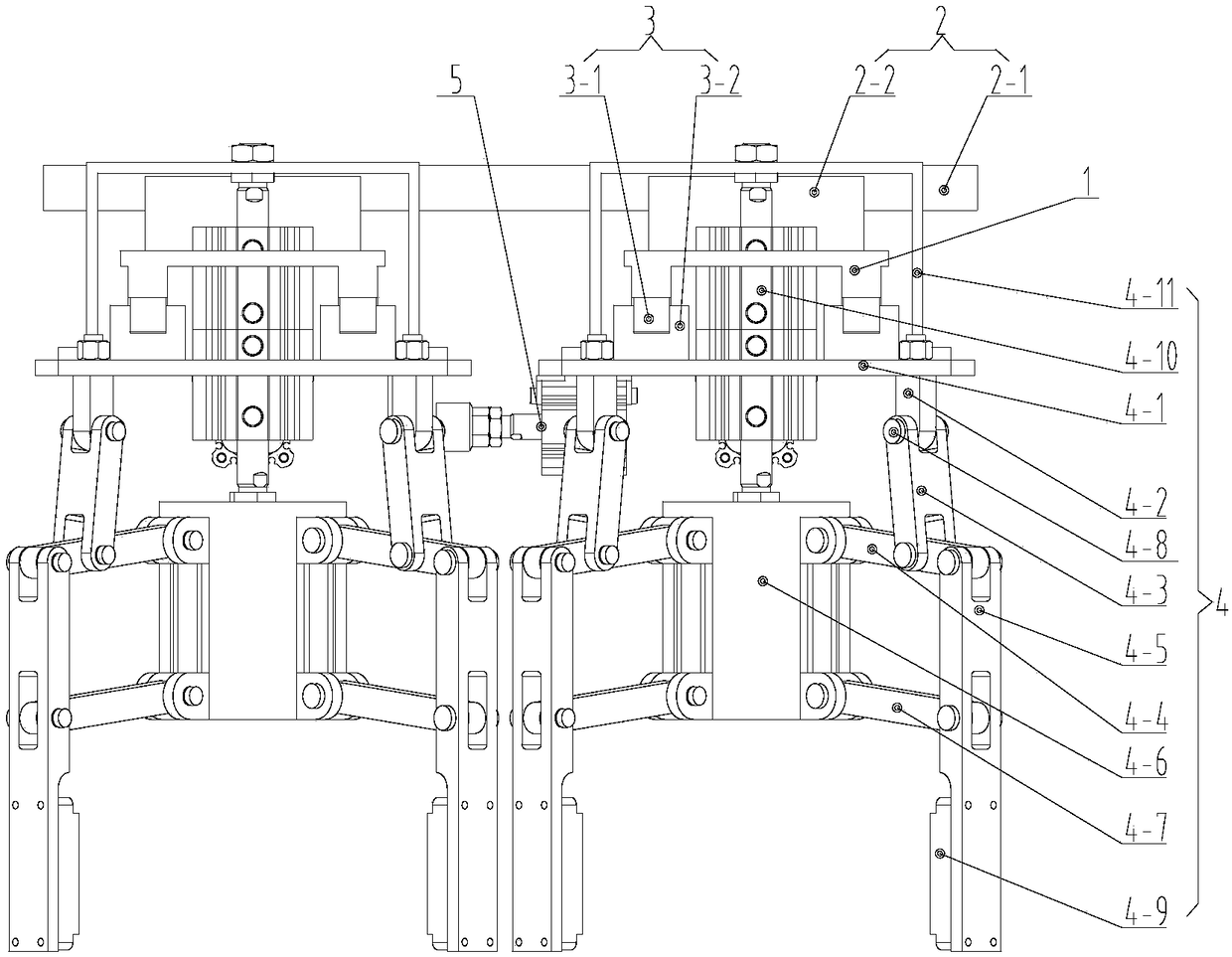

A grabbing device for a palletizer

ActiveCN106081644BAvoid destructionGuaranteed not to shakeConveyorsGripping headsPalletizerEngineering

The invention discloses a gripping device of a stacker. The gripping device comprises supporting frames, heavy load mobile groups, light load mobile groups, gripping groups and distance adjusting air cylinders. Barrels are clamped through air bags, it is guaranteed that the cylindrical barrels do not swing in the gripping process, and the appearances of the barrels are prevented from being damaged; meanwhile, parallel four-bar mechanisms are used for the gripping device, jaws are perpendicular to one another all the time in the gripping process, and space is saved to the maximum degree. In addition, air cylinders for carrying out gripping actions are designed in two strokes, and the device can be compatible with two kinds of cylindrical barrels of different diameters.

Owner:BEIJING AREOSTANARD NEW TECH +1

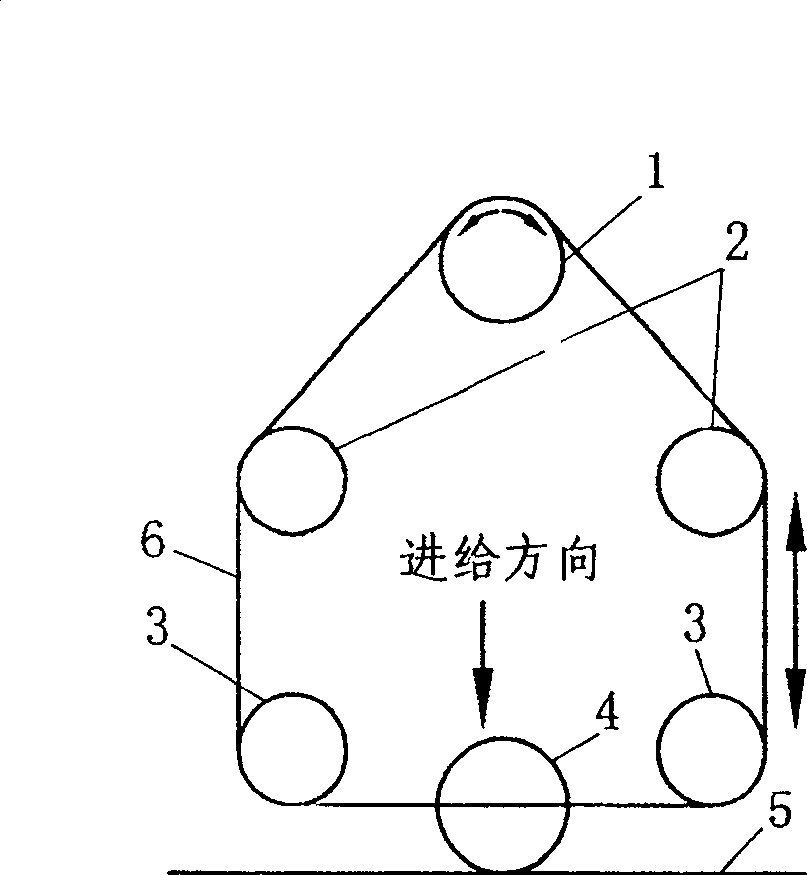

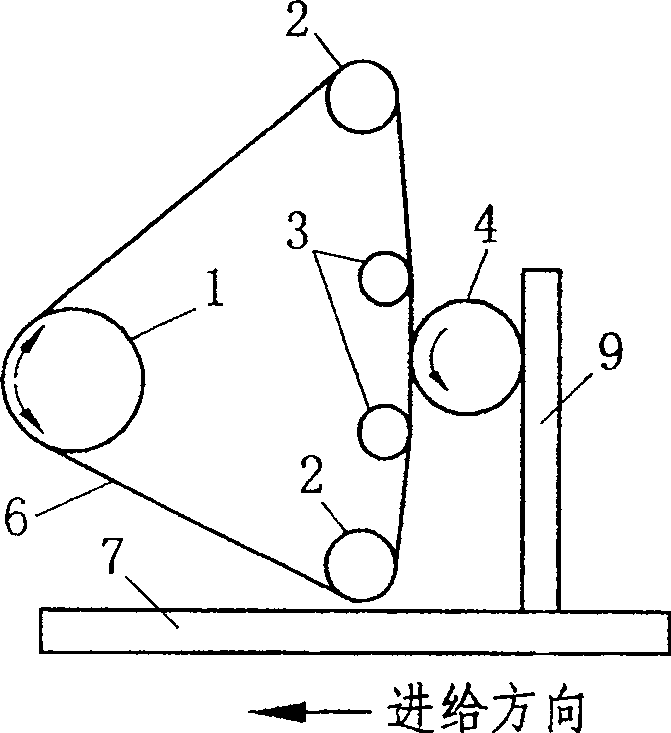

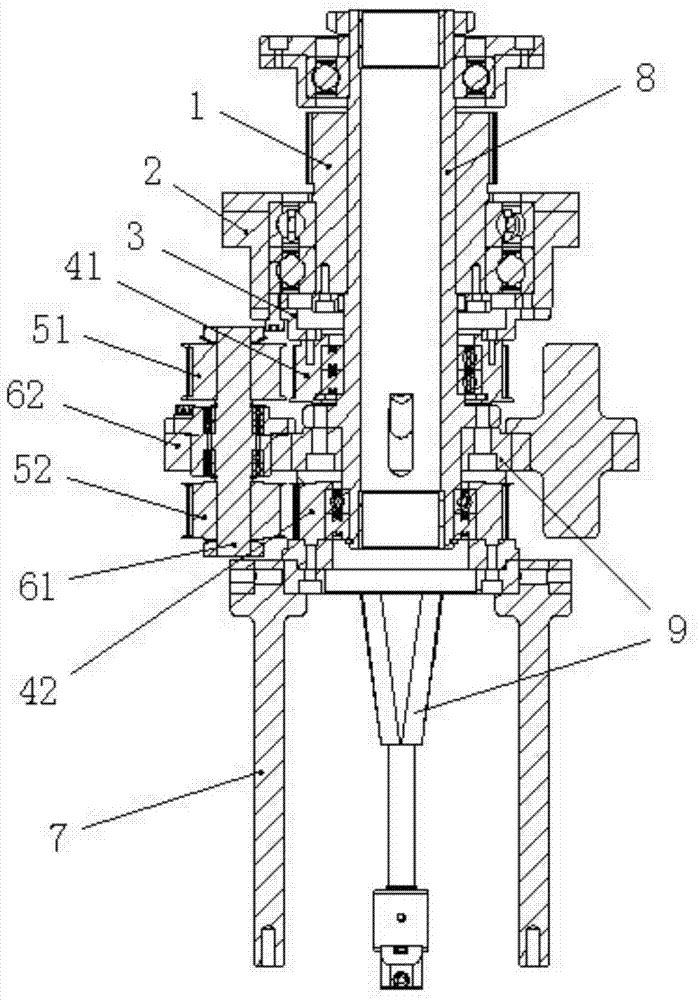

Apparatus for rotating point cutting large size silicon-carbide crystal

InactiveCN100480015CGuaranteed not to shakeIncrease cutting spaceFine working devicesMetal working apparatusMaterials processingControl theory

An apparatus for cutting large-size SiC crystal by the moving dots is composed of base, sensor, sawing diamond string, pneumatic tension roller, working rollers, DC servo motor and 2D fixture mechanism consisting of rotary manipulator and step motor. A horizontal angle regulating turn-table is linked on a Y-axis moving platform. A vertical angle regulating turn-table is linked on said horizontal angle regulating one. Said step motor is fixed to an adjustable supporting plate.

Owner:张革 +1

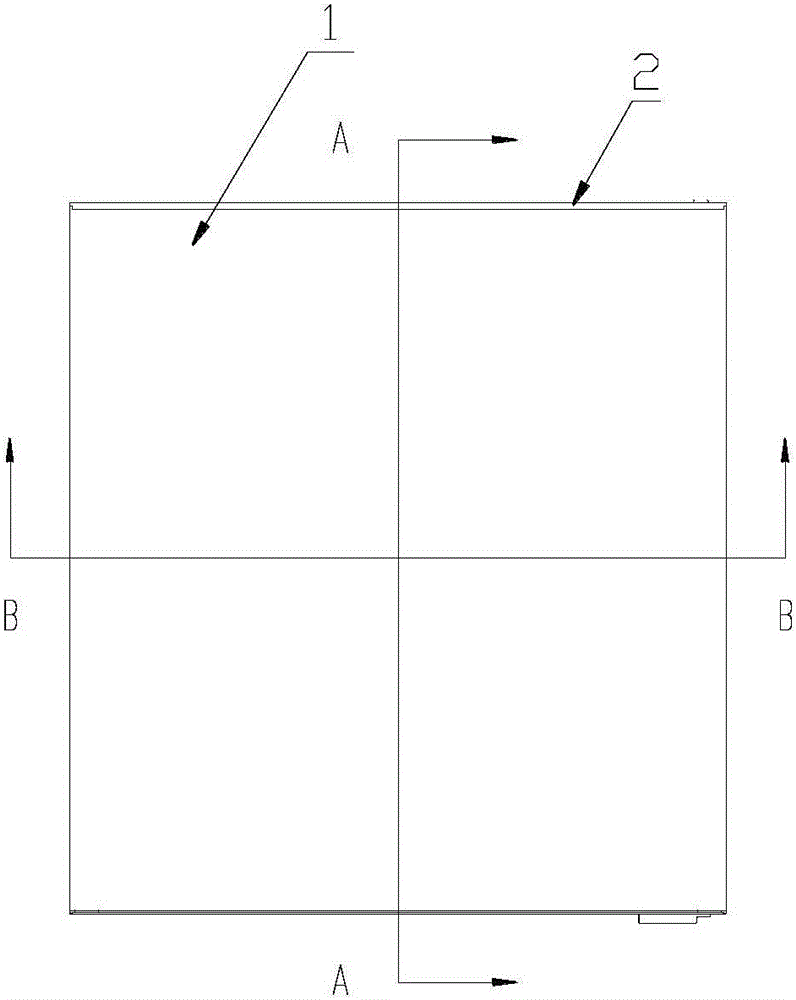

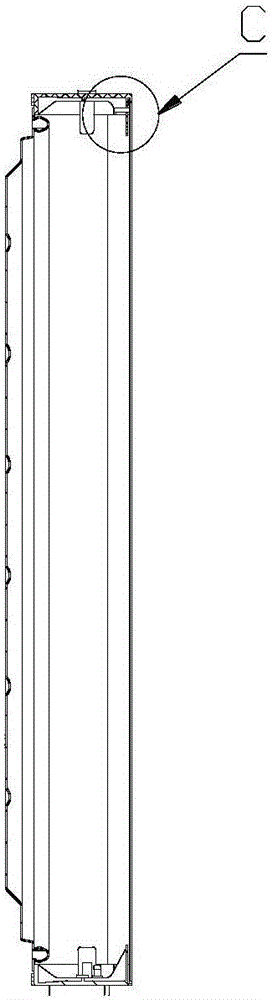

Photovoltaic module frame

InactiveCN112600502AGuaranteed not to shakeEasy to cleanPhotovoltaicsPhotovoltaic energy generationStructural engineeringMechanical engineering

Owner:JAYU DOOR & WINDOW & CURTAIN WALL XUZHOU CO LTD

Bead string nailing and sanding machine

ActiveCN101829939BImprove efficiencyQuality improvementSpherical surface grinding machinesJewelleryExploratorTailstock

The invention discloses a bead string nailing and sanding machine which comprises a stand, a clamping head seat, a tail seat, a slide seat, an explorator, two contact knives and two nailing and sanding knife seats, wherein the clamping head seat and the tail seat are arranged on the stand; the clamping head seat is rotatably provided with a clamping head driven by a first power device, and the tail seat is provided with a guide sleeve coaxial with the clamping head; the slide seat is driven by a second power device and slidably arranged on a longitudinal rail on the stand; both side surfaces of the explorator are respectively provided with profiling ripples adaptive to bead strings, and the explorator is arranged between the clamping head seat and the tail seat; a longitudinal explorator regulating mechanism is arranged between the explorator and a mounting part corresponding to the explorator; the two contact knives are arranged at both sides of the explorator and respectively fixed on a contact knife seat, and a first transverse regulating mechanism is arranged between the contact knife seats and the slide seat; the two nailing and sanding knife seats are respectively provided with a nailing and sanding knife, and the nailing and sanding knife seats are arranged on the contact knife seats; and a second transverse regulating mechanism is arranged between the nailing and sanding knife seats. The nailing and sanding machine can be used for quickly and conveniently nailing and sanding the bead strings, thereby the nailing efficiency and the nailing quality are improved.

Owner:SHANDONG MOKINGRAN JEWELRY

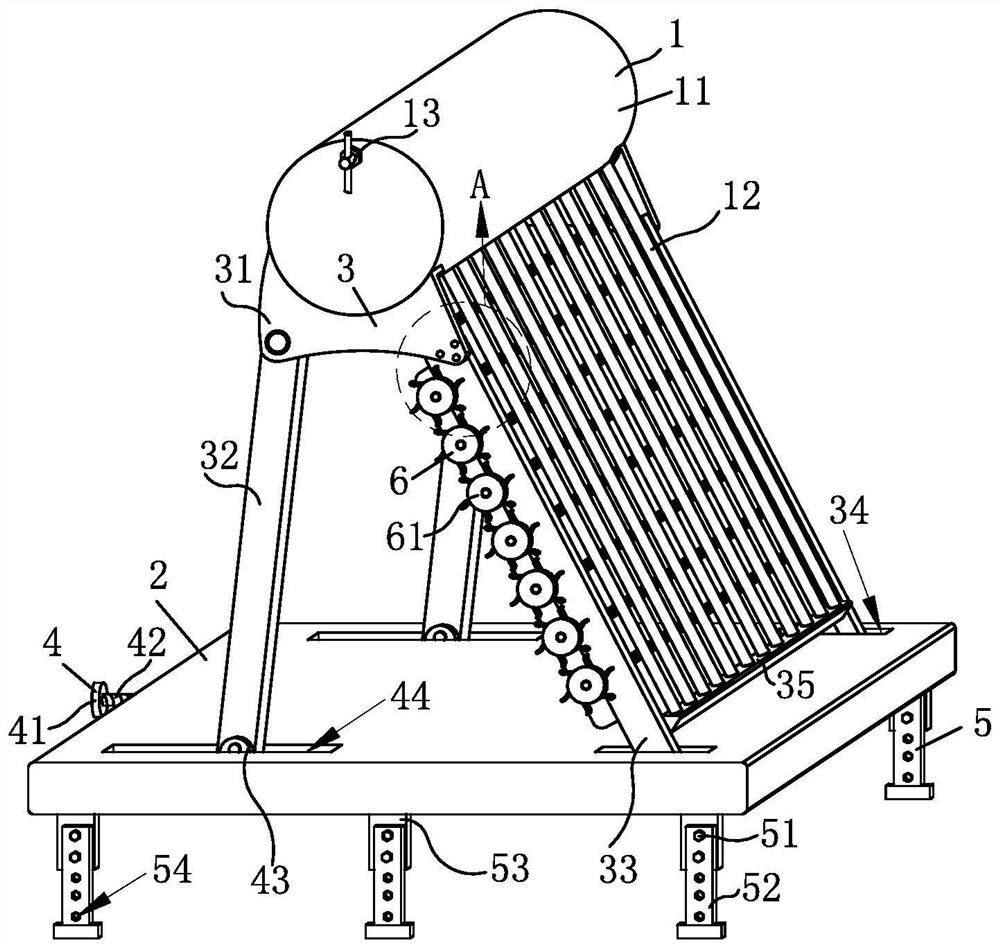

Dried fruit conveying device

InactiveCN107487735ALarge storage capacityGuaranteed not to shakeLifting framesRubber materialEngineering

The invention discloses a dried fruit transportation device, which comprises a device base, the lower end surface of the device base is connected to rollers through a support rod with lifting function, a positioning rod is respectively arranged on both sides of the rollers, and the upper end surface of the device base is one One side is fixedly connected to the first support rod, and the other side is rotatably connected to the second support rod. The upper end of the first support rod is rotatably connected to the dried fruit storage frame, and the upper end of the second support rod is arranged in the installation groove on the dried fruit storage frame. The inner wall of the groove is inlaid with an anti-loose block made of rubber material, one end of the dried fruit storage frame is connected to the lap block, and the lap block is provided with a spherical lap groove, and one end of the device base is connected to The rod connects to the spherical support block which fits into the lap groove. The dried fruit transportation device of the present invention has the advantages of large storage capacity, convenient unloading and the like.

Owner:TONGCHENG GUNIUBEI AGRI DEV

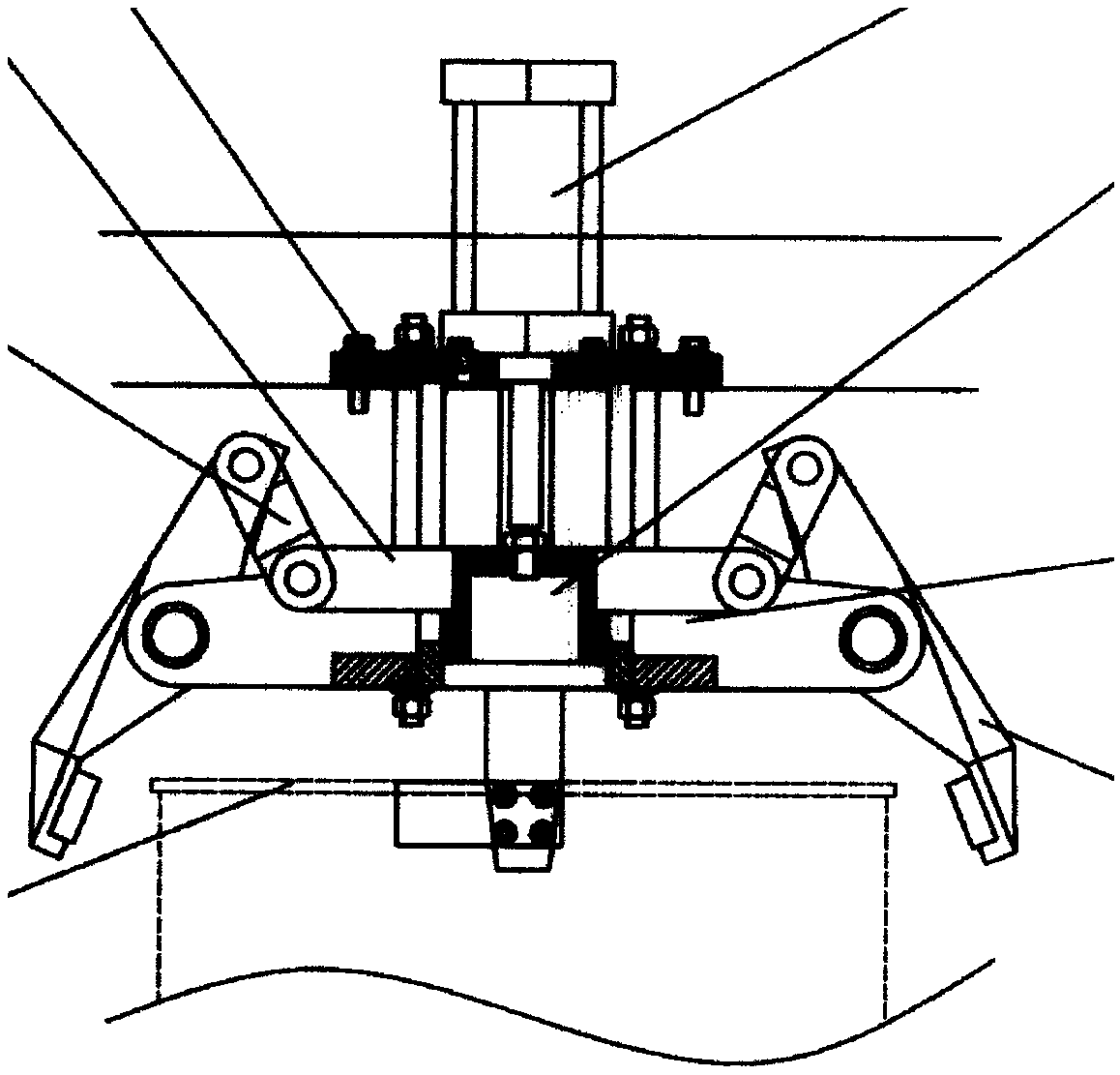

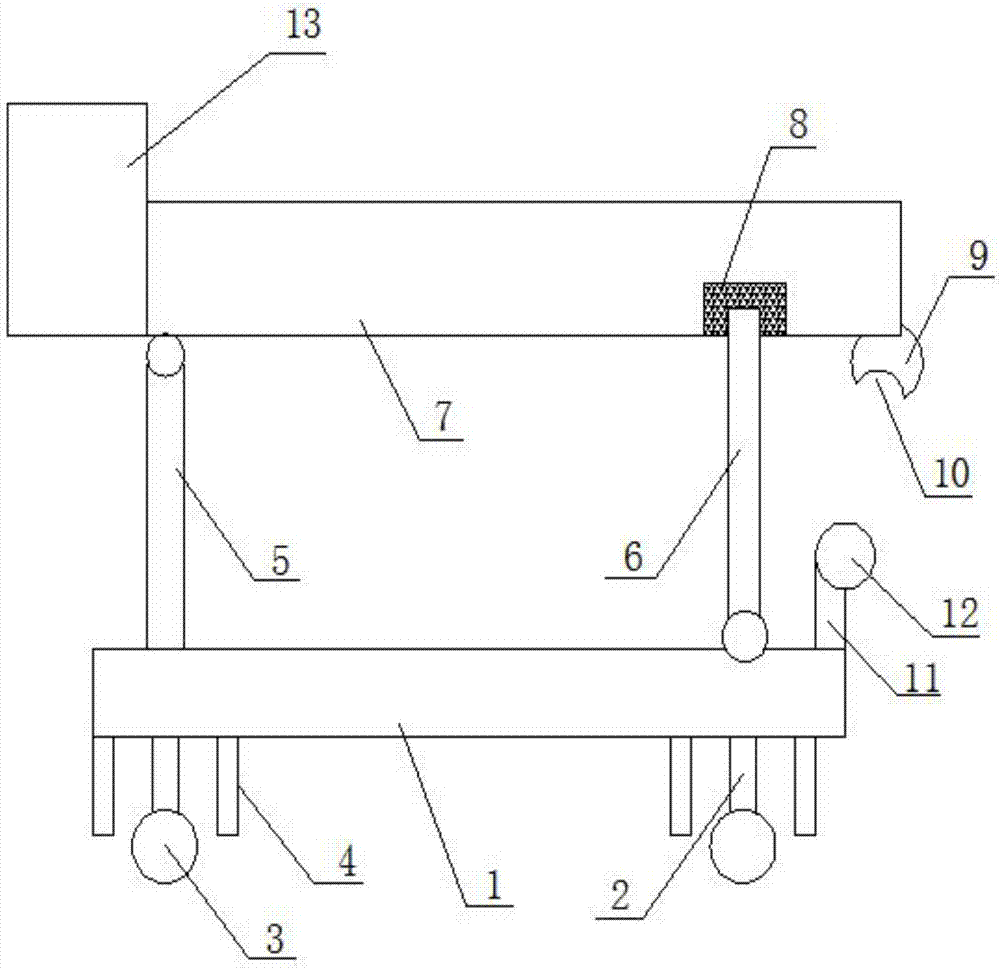

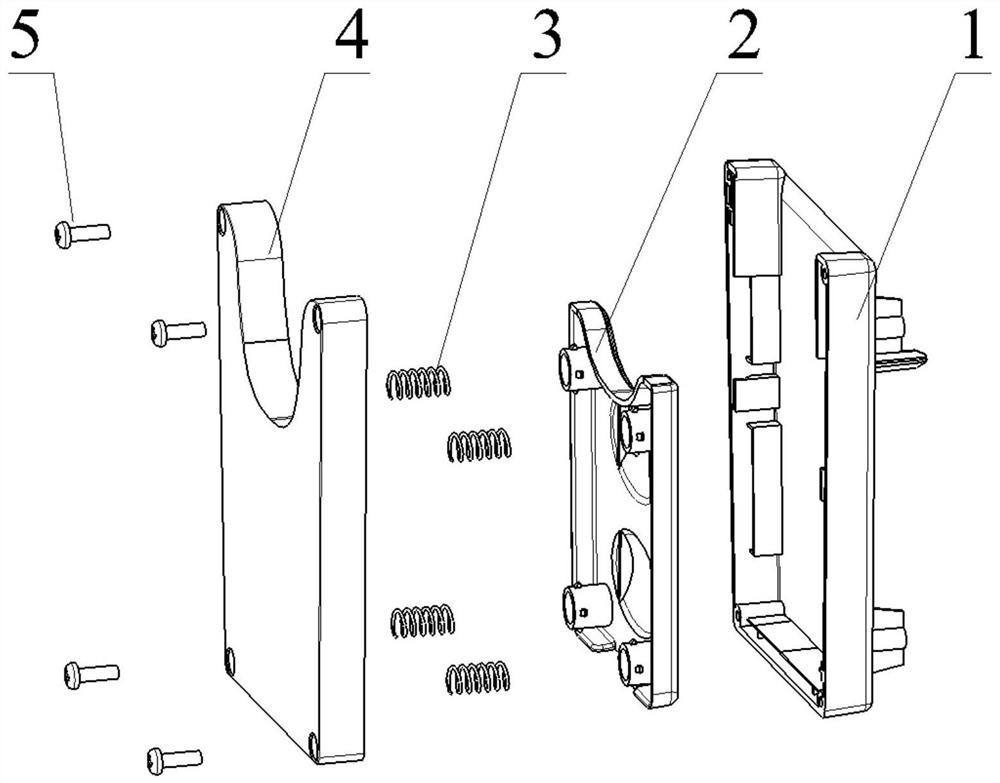

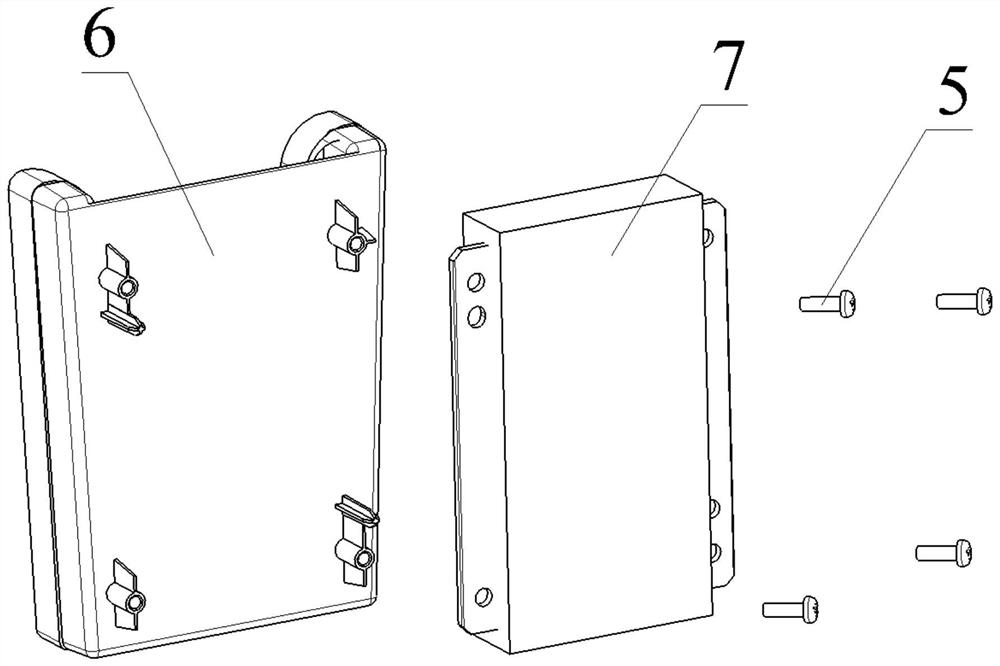

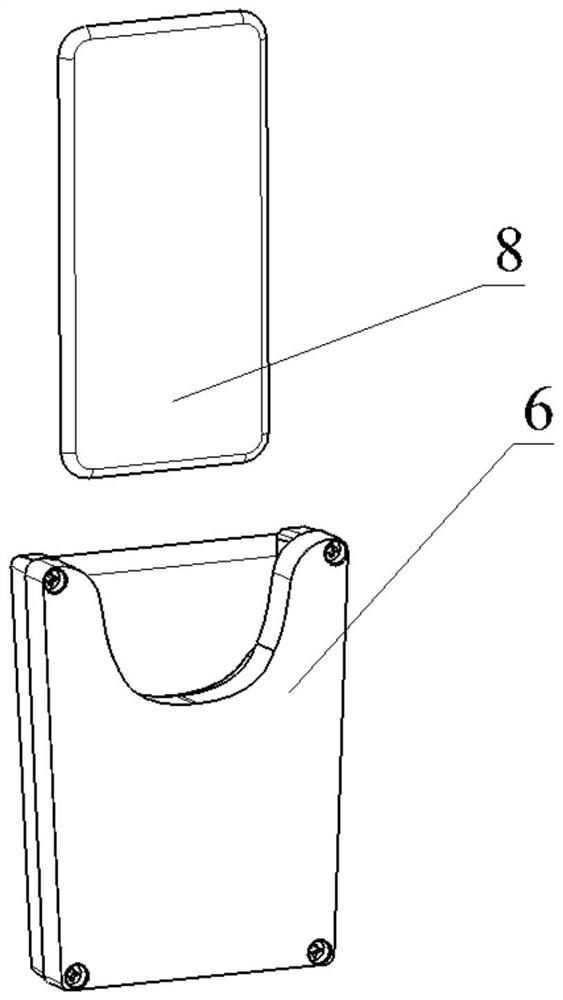

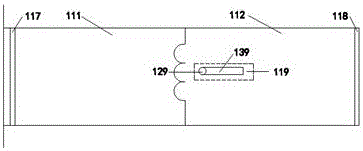

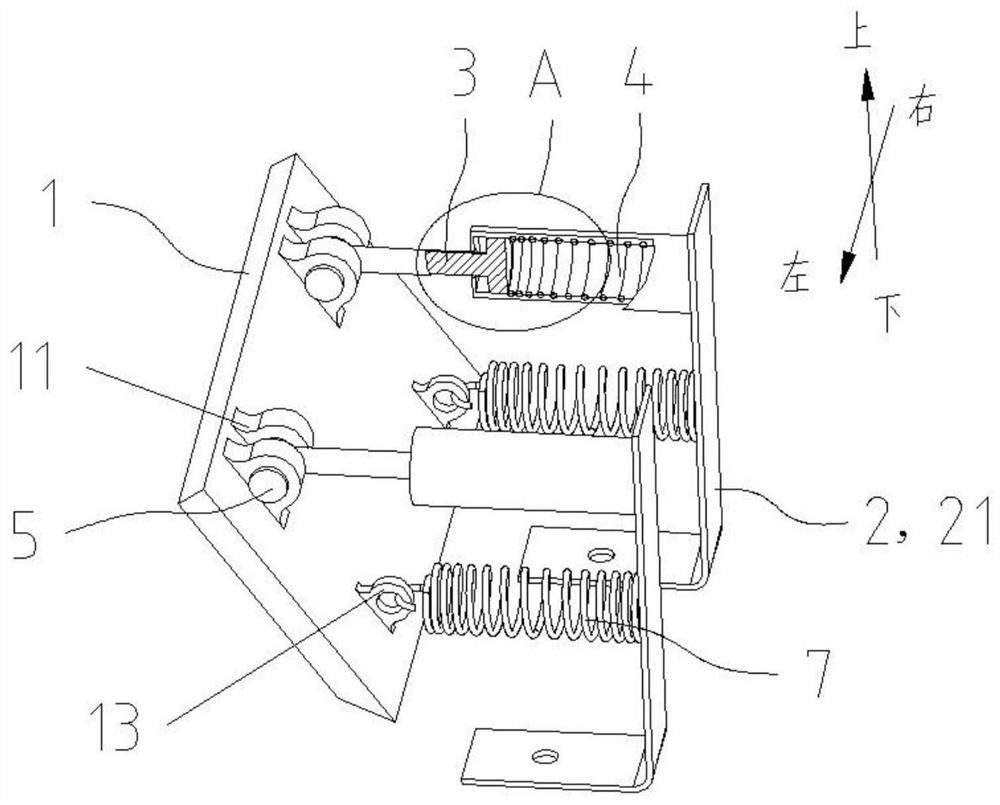

Wireless charging clamping mechanism and wireless charger

PendingCN113067377AGuaranteed fixed effectGuaranteed not to shakeBatteries circuit arrangementsElectric powerInductive chargingElectrical and Electronics engineering

The invention discloses a wireless charging clamping mechanism and a charger. The wireless charging clamping mechanism comprises a bottom shell, a clamping plate and an upper cover. The rubber material on the clamping plate is in contact with the surface of the mobile phone, and the mobile phone can be fixed without sliding down or shaking left and right after the mobile phone is inserted in place by means of the elastic force of the rubber and the displacement of the clamping plate. The elastic force formed by the deformation of the rubber on the clamping plate causes the reverse elastic force of the spring to the clamping plate, so that the clamping plate and the bottom shell form a cavity capable of accommodating mobile phones with different thicknesses, the thickness of the cavity can be changed along with the expansion and contraction of the spring, the mobile phones are ensured to be vertically placed and are not easy to shake, the optimal charging position is achieved, and the charging efficiency of the wireless charging device is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

pi pipe cutting machine

ActiveCN106142170BGuaranteed not to shakeStable cutting sizeMetal working apparatusKnife bladesKnife holder

The invention discloses a polyimide (PI) pipe cutting machine. The PI pipe cutting machine comprises a workbench and a clamping mechanism for clamping a workpiece and driving the workpiece to rotate, the workbench is provided with a first Y-axis slideway and a base air cylinder, a base is arranged on the first Y-axis slideway in a sliding mode, an X-axis guide slot is formed in the base, at least one group of knife rest bases are installed in the X- axis guide slot in a sliding mode, each knife rest base is provided with a Y-axis electric sliding table, a knife rest is arranged on each Y-axis electric sliding table in a sliding mode, and each knife rest is provided with a blade. According to the PI pipe cutting machine, a workpiece to be cut is placed on the clamping mechanism and the workpiece to be cut is driven to rotate, the base is quickly pushed to the preset position by the base air cylinder, the blades of the knife rests are driven by the Y-axis electric sliding tables to slide to the workpiece, and the workpiece is cut into pieces. The clamping mechanism enables the workpiece not to waggle, the blades and the workpiece are always kept in a vertical state stably, the cutting size is stable, and the edges of the workpiece are neat and have no burrs after being cut.

Owner:珠海市技嘉科技有限公司

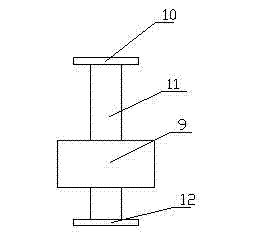

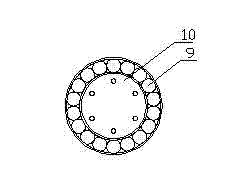

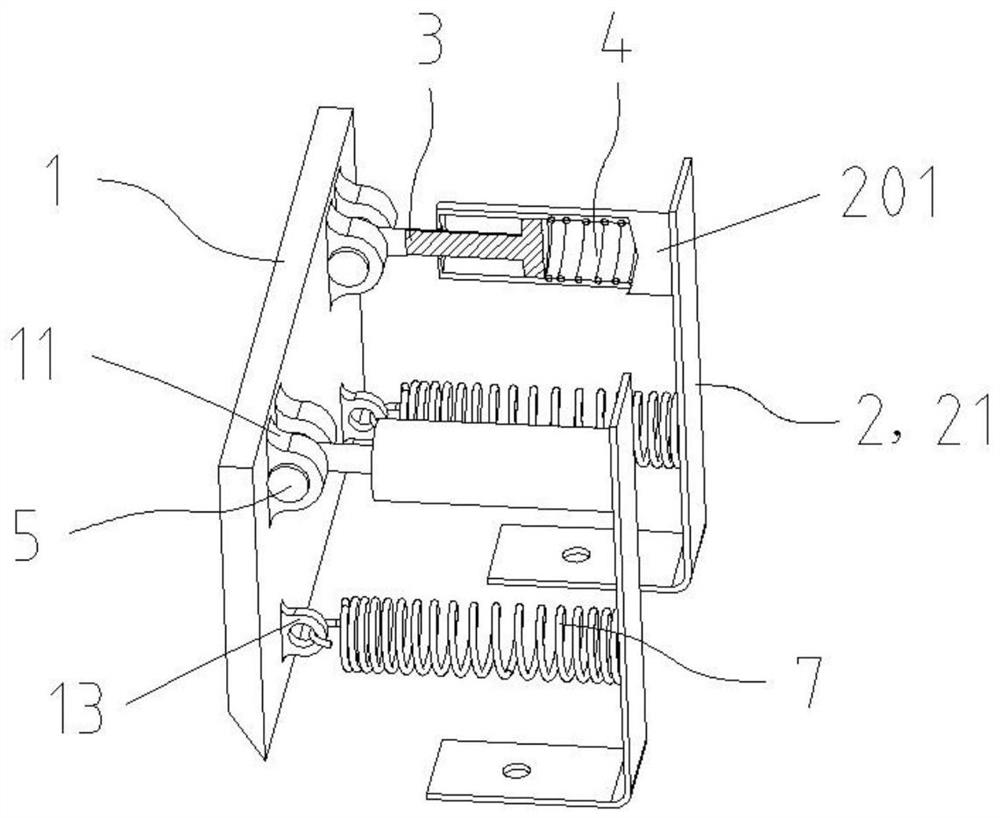

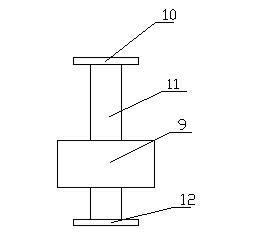

Structure for connecting vertical shaft windmill with power generator

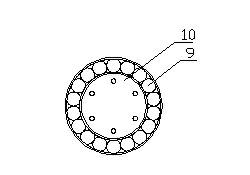

ActiveCN102322406BGuaranteed not to shakeGuaranteed normal operationWind energy generationSupports/enclosures/casingsDrive shaftEngineering

The invention relates to a structure for connecting a vertical shaft windmill with a power generator, which belongs to the technical field of vertical shaft wind power generators. The invention has the technical scheme that the vertical shaft windmill and the power generator are connected together through an aligning bearing mechanism and are vertically arranged, wherein the aligning bearing mechanism comprises an aligning bearing (9), a driving shaft (11), a driving shaft upper flange (10) and a driving shaft lower flange (12); the driving shaft is matched with the aligning bearing; the driving shaft upper flange is arranged at the upper part of the driving shaft and is connected with the vertical shaft windmill; and the driving shaft lower flange is arranged at the lower part of the driving shaft and is connected with the power generator. The structure has the beneficial effects that the action force can be automatically adjusted to be acted on the aligning bearing; the windmill is ensured not to shake by continuously and automatically adjusting the center; and the swing force acted on the power generator is offset by the aligning bearing, so that the power generator and the vertical shaft windmill can be used for automatically adjusting the center, normal operation of the power generator is ensured, and the power generation efficiency is improved.

Owner:TANGSHAN TOYODA TECH

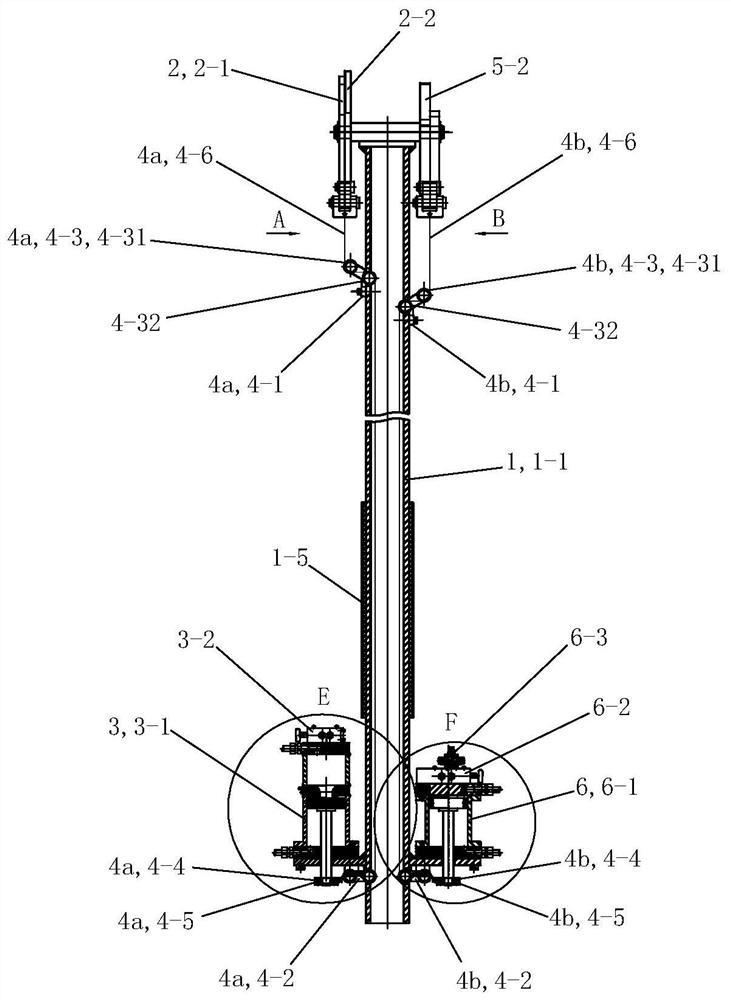

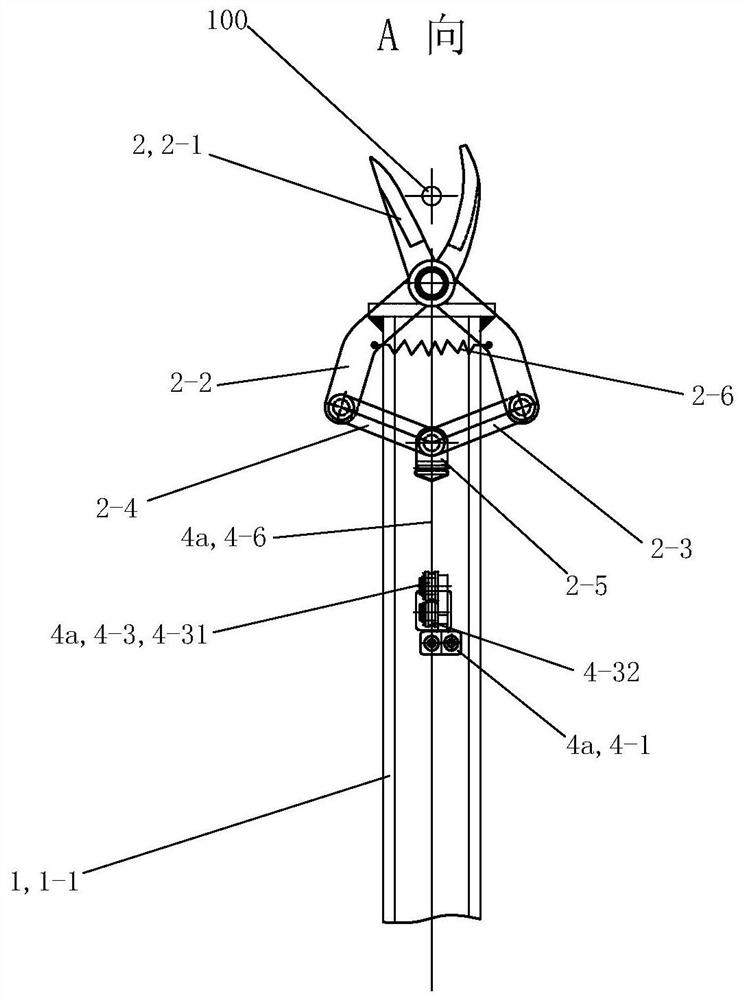

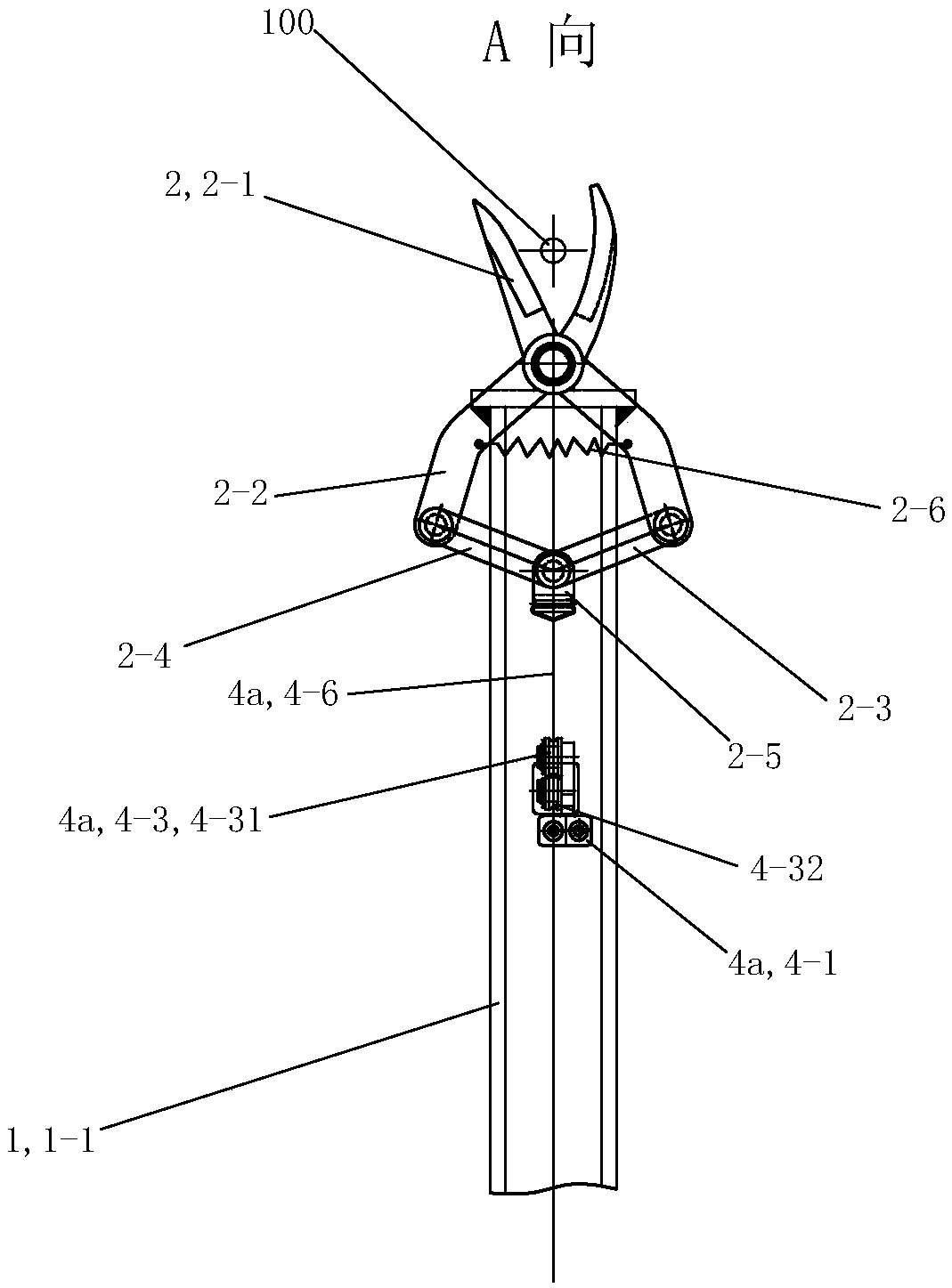

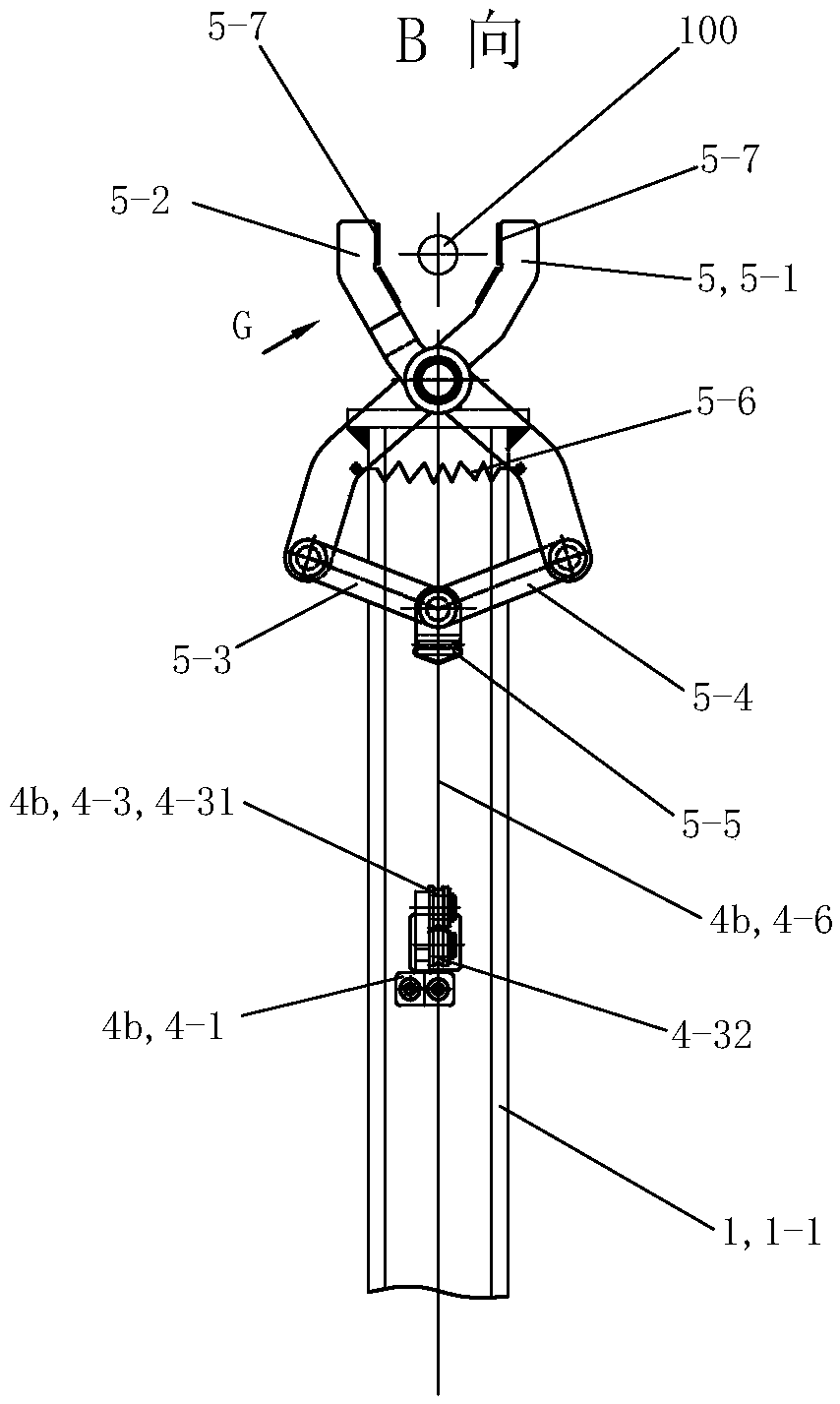

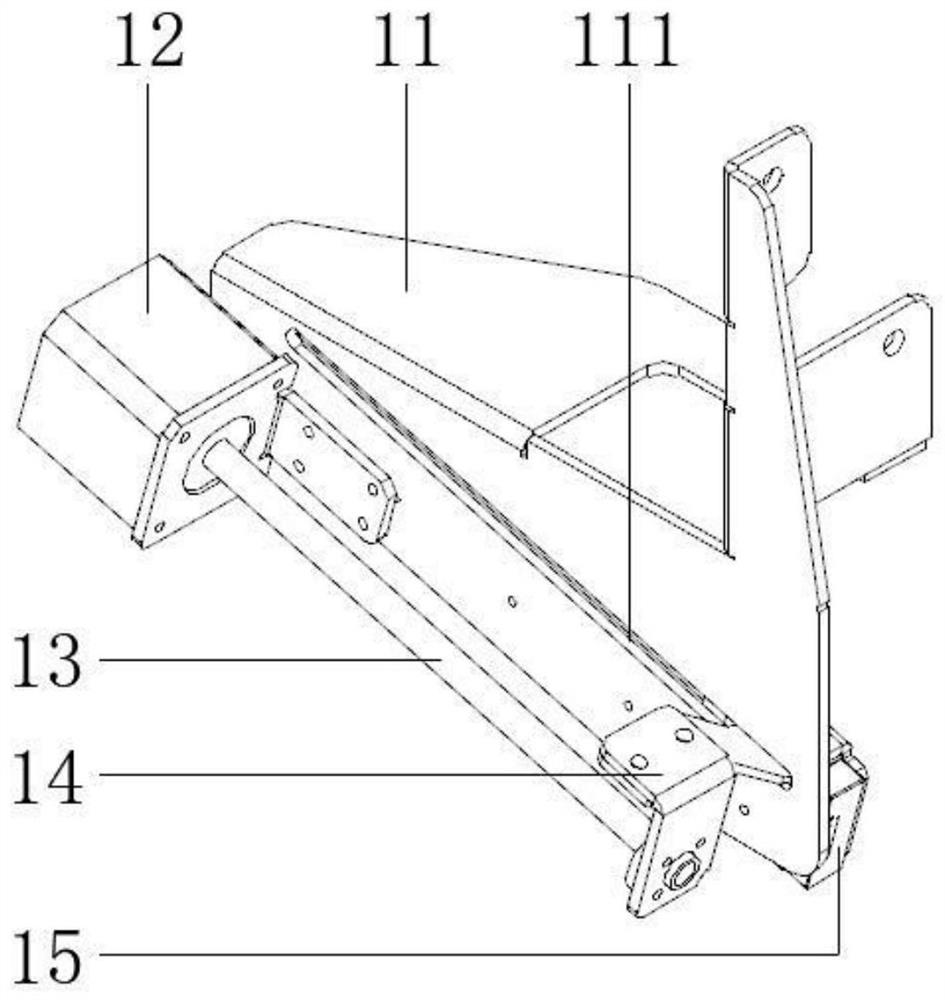

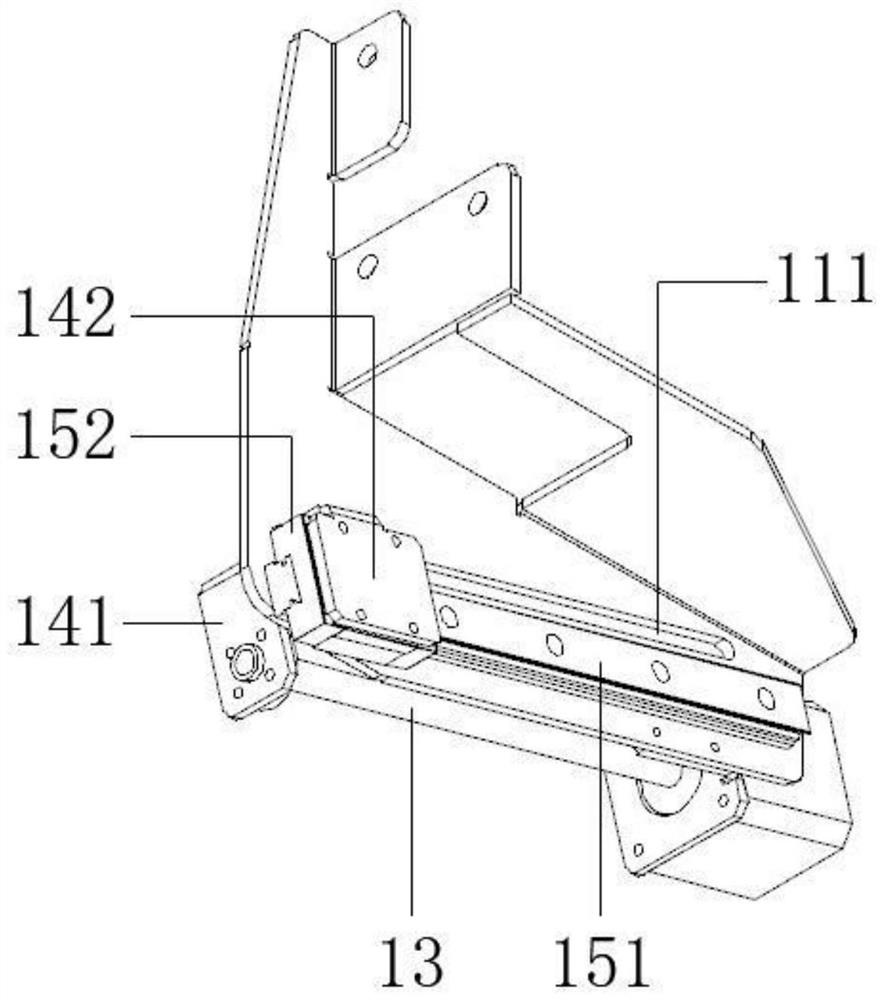

High altitude pruning device

ActiveCN109220288BGuaranteed not to shakeAccurate locationCuttersCutting implementsStructural engineeringMechanical engineering

The invention discloses a high-altitude pruning device, which mainly includes a strut assembly, a cutting assembly, a first driving device, a transmission assembly, a clamping assembly and a second driving device. There are 2 sets of transmission assemblies, the structures of which are the same, and the 2 sets of transmission assemblies are divided into a left transmission assembly and a right transmission assembly according to their left and right positions. The strut assembly includes a strut and a lower mount. The lower mounting seat is welded and fixed on the lower part of the strut. The first driving device is fixedly arranged on the left part of the lower mounting seat. The first driving device drives the front cutter bar and the rear cutter bar of the shearing assembly through the left transmission assembly to perform cutting operations. The second driving device is fixedly arranged on the right part of the lower mounting seat. The front clamping arm and the rear clamping arm of the clamping component are driven by the second driving device through the right transmission component to perform the clamping and positioning operation.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

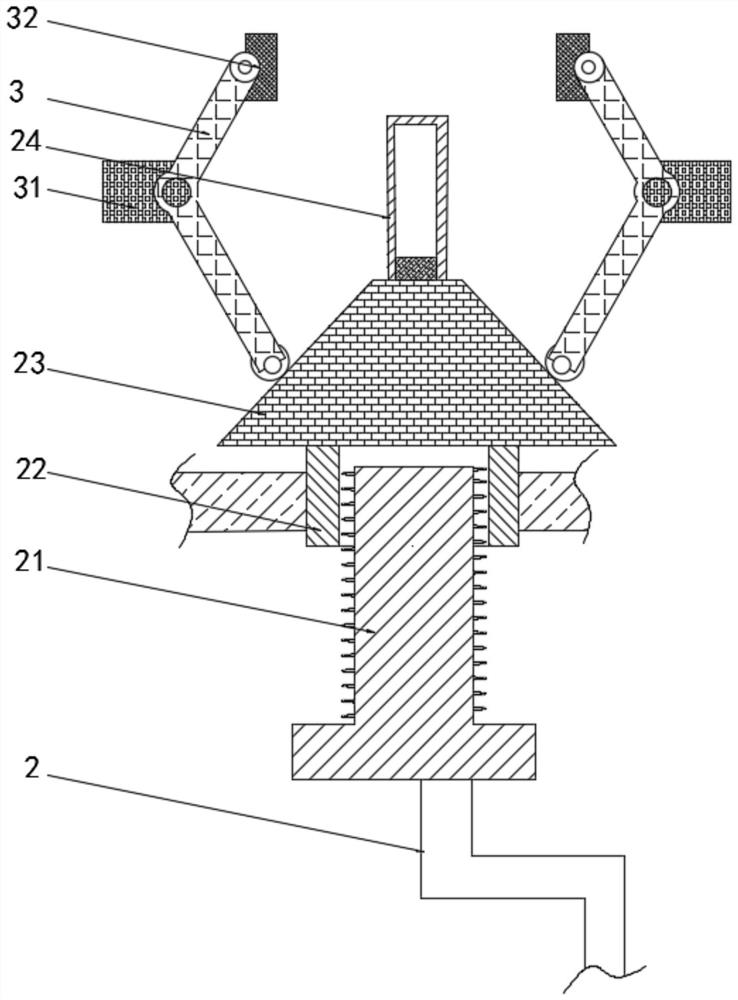

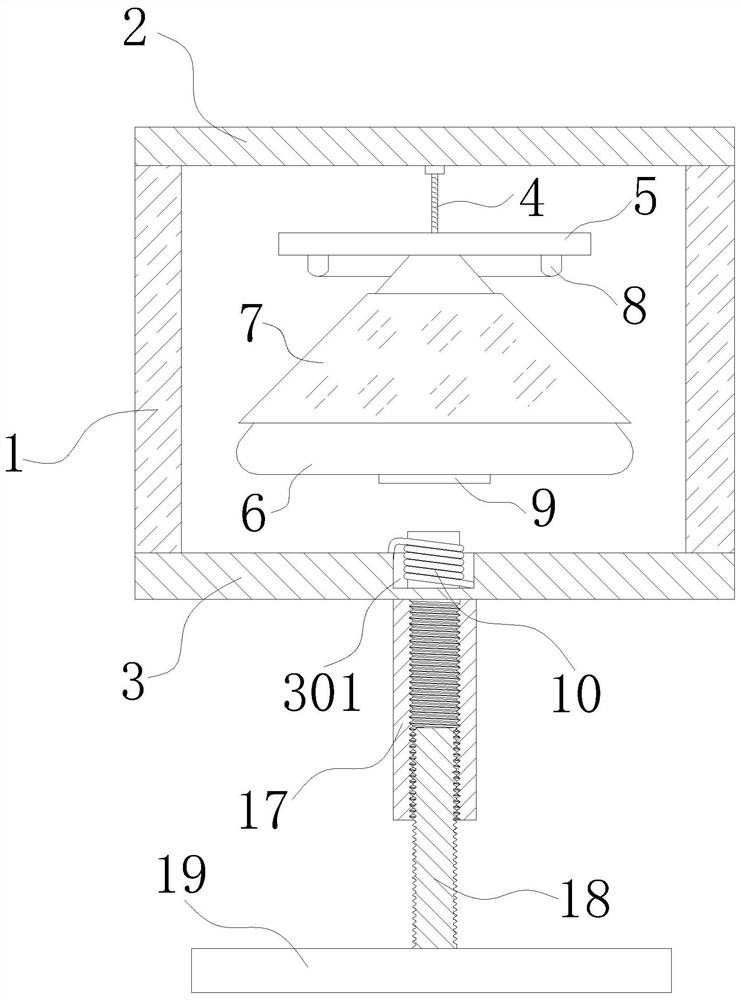

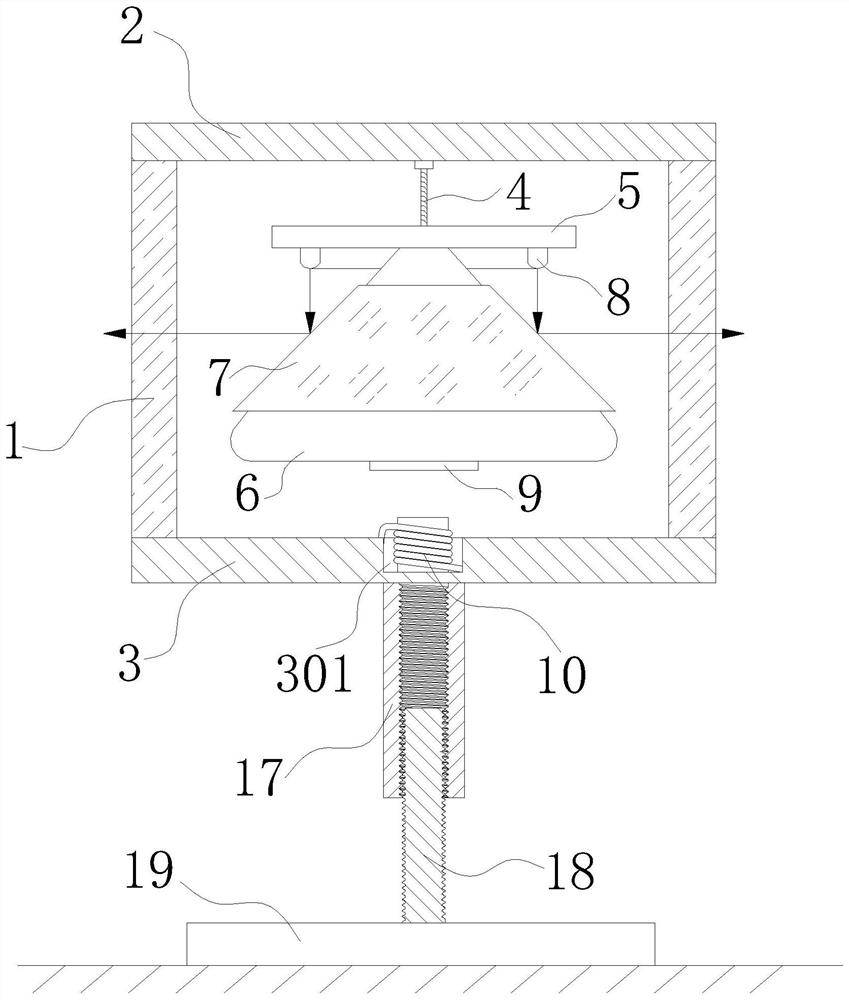

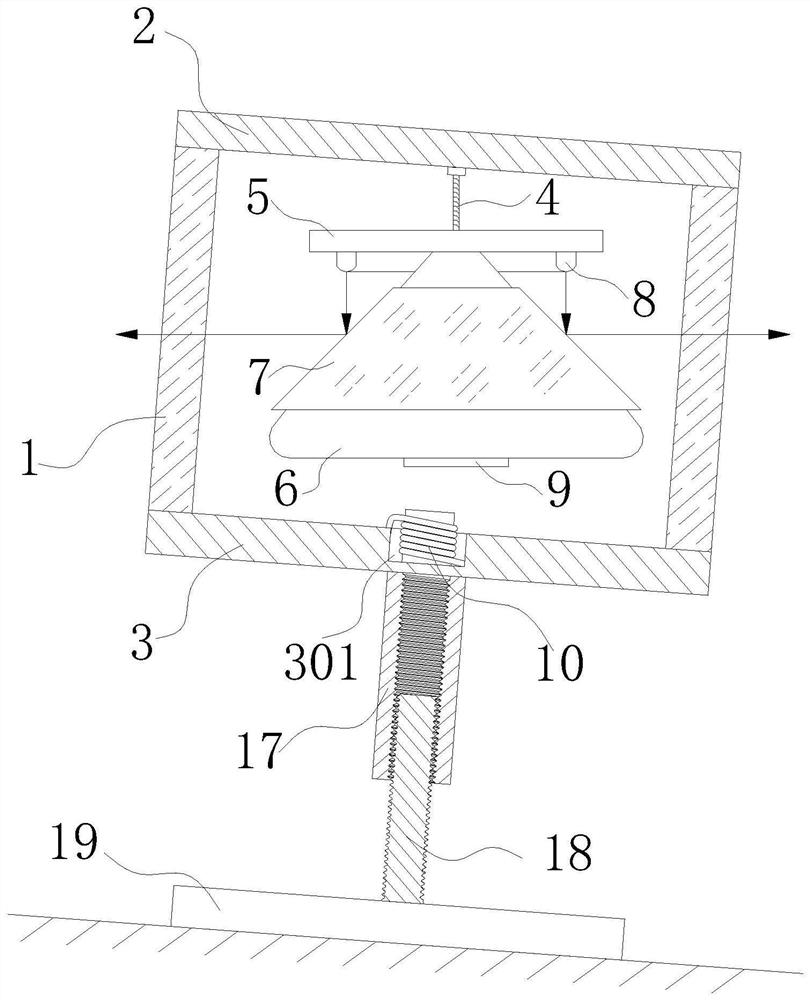

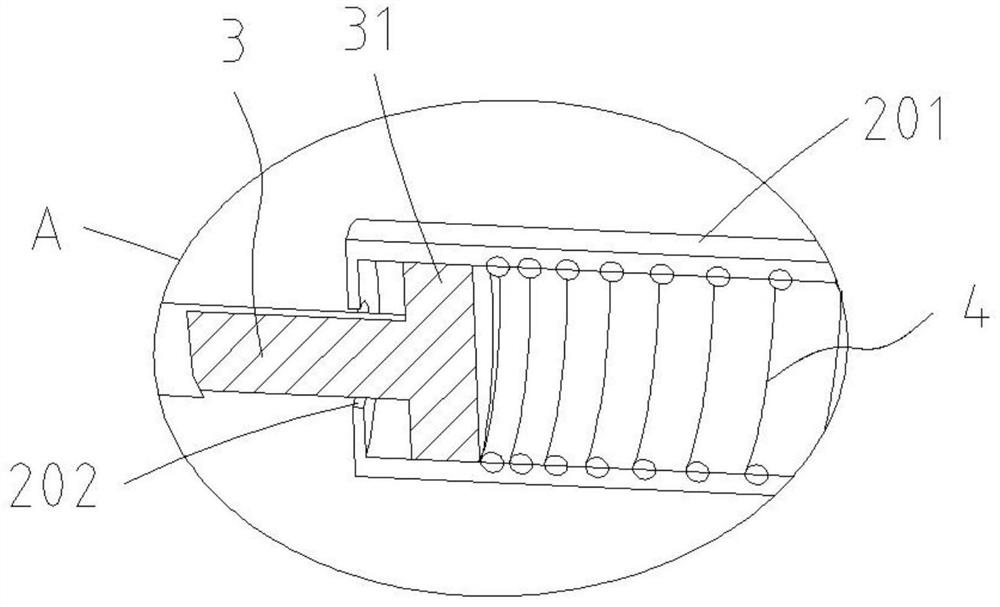

Self-adaptive structure capable of self-adapting to size of embedded hole and embedded cooker

InactiveCN112393286ASimple structureIngenious structureStoves/ranges foundationsDomestic stoves or rangesEngineeringMechanical engineering

The invention discloses a self-adaptive structure capable of self-adapting to the size of an embedded hole and an embedded cooker. The self-adaptive structure comprises a pressure-containing part, a support, pull rods and elastic parts, wherein the support is provided with mounting cavities extending towards the pressure-containing part; an opening facing the pressure-containing part is formed ineach mounting cavity; one end of each pull rod is arranged in one mounting cavity in a telescopic movement manner, and the other end of each pull rod penetrates through the corresponding opening and then is hinged to the pressure-containing part; and each elastic part is installed in one mounting cavity, one end of each elastic part is propped against one surface, facing the corresponding opening,of one mounting cavity, and the other end of each elastic part is connected with or propped against one pull rod. The self-adaptive structure is simple and ingenious in structure; and the pressure-containing part can move within the compression range of the elastic parts, so that the self-adaptive structure can be suitable for an embedding size interval of a certain range segment, automatic adjustment is achieved according to the size of the embedded hole, the self-adaptability is high, and the condition that the cooker does not shake is guaranteed.

Owner:VATTI CORP LTD

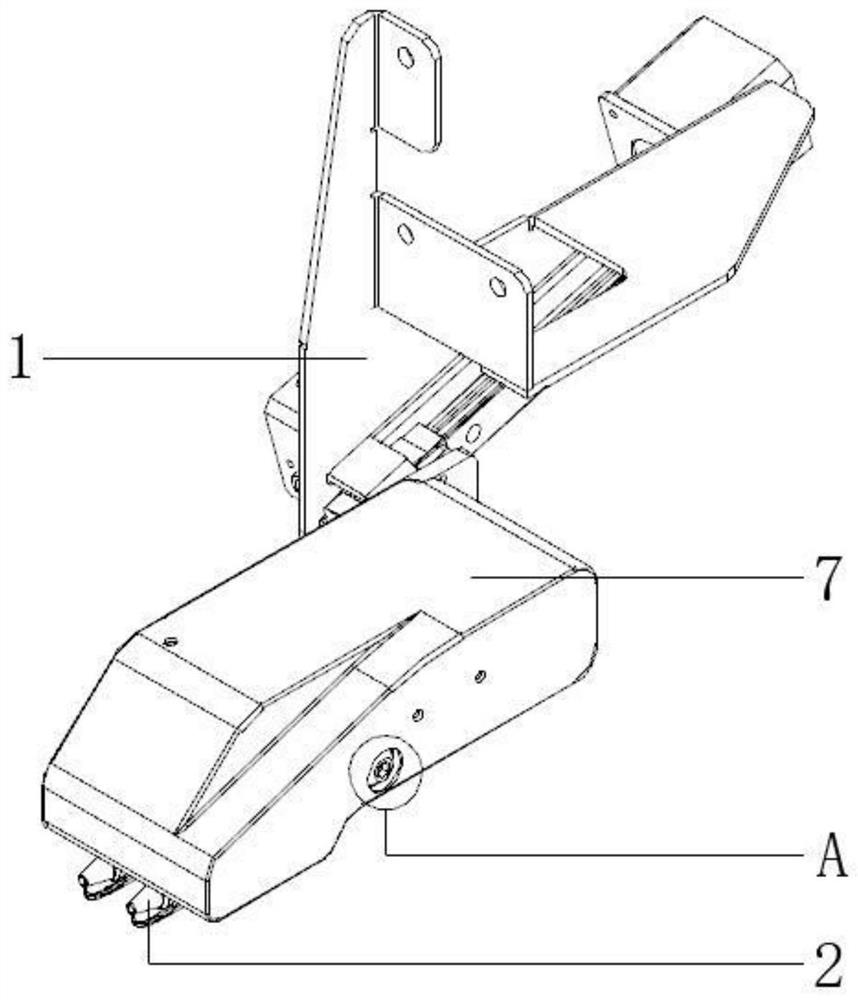

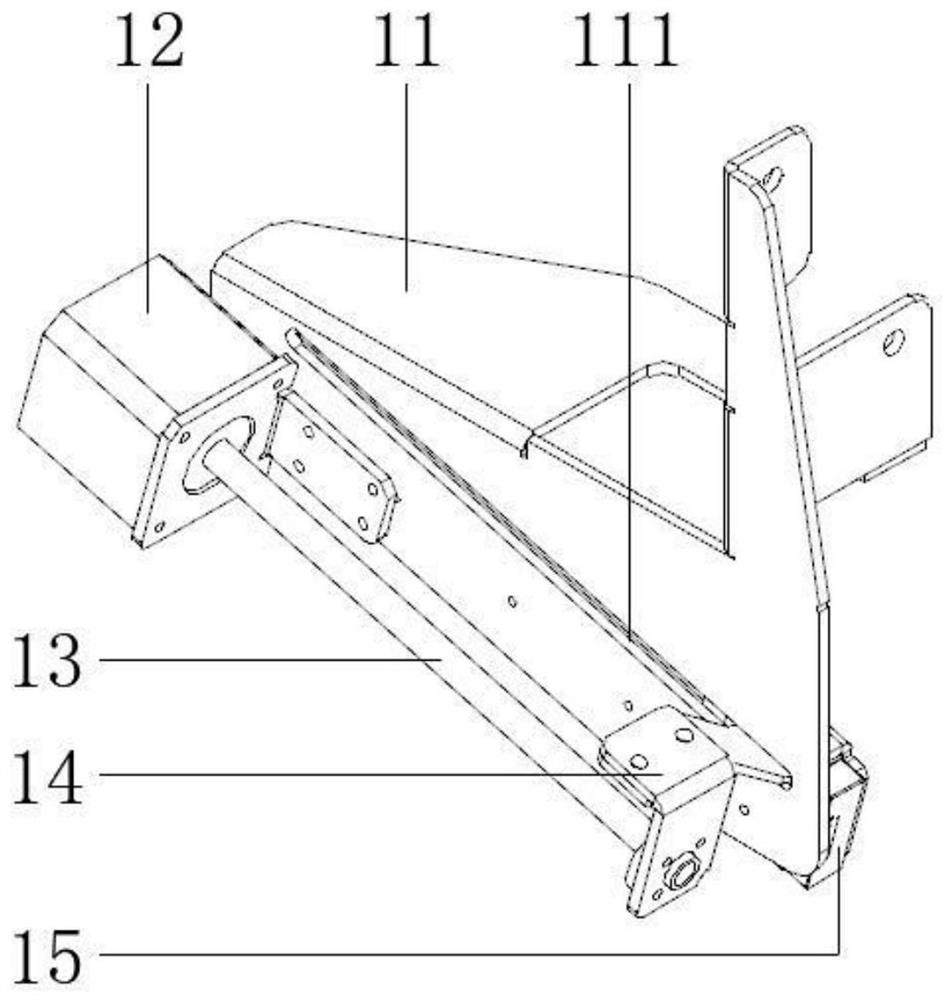

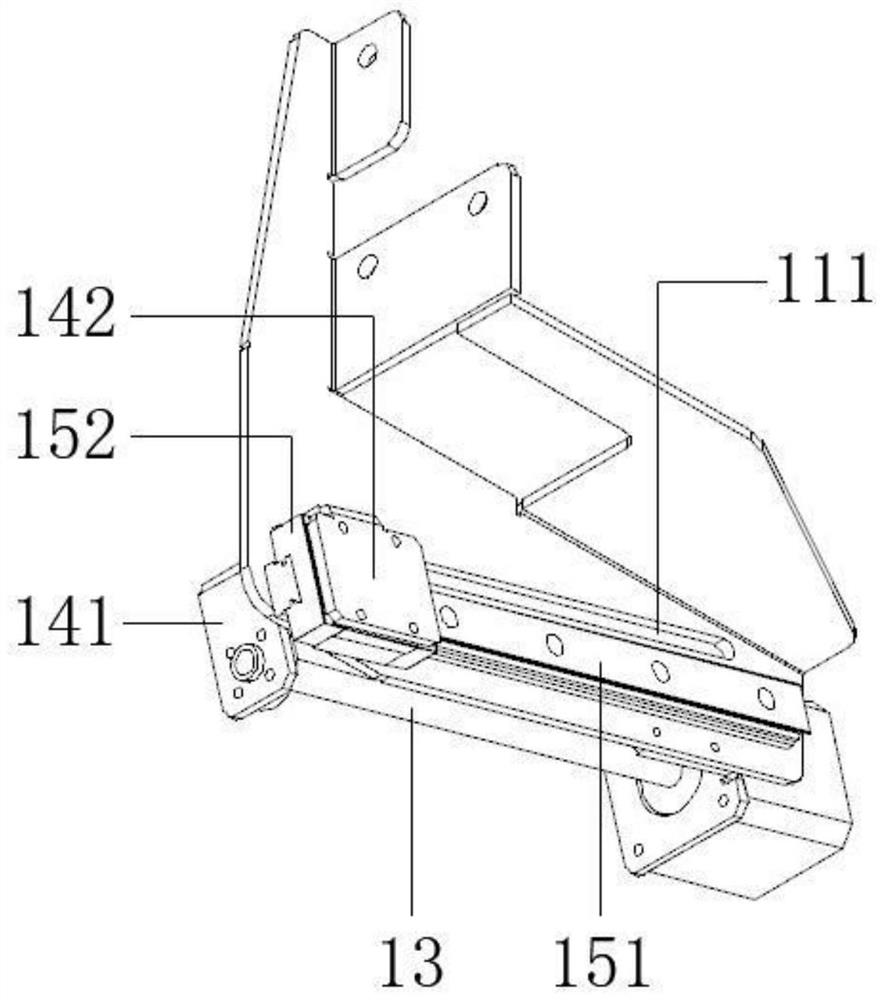

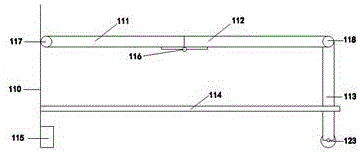

A circular knife device for tape embroidery or rope embroidery

ActiveCN111826932BSmooth cutGuaranteed not to shakeSevering textilesAutomatic machinesStructural engineeringKnife blades

An embodiment of the present invention provides a round knife device for tape embroidery or cord embroidery, which belongs to the technical field of embroidery equipment. The round knife device for tape embroidery or cord embroidery includes: a fixing mechanism; a lifting mechanism, and the lifting mechanism includes : lifting assembly, the lifting assembly includes: lifting base; lifting body; driving base, the driving base is connected with the lifting base; and a circular knife base, the circular knife base and the lifting The base is connected; the knife mechanism, the circular knife mechanism is arranged on the circular knife base, and there is a blade on the circular knife mechanism; and the driving mechanism, the driving mechanism is arranged on the driving base; wherein, and the The driving mechanism acts on the lifting body and the circular knife mechanism respectively, the lifting body is lifted and moved by the driving mechanism, and the blade in the circular knife mechanism is rotated by the driving mechanism. It achieves the technical effect of cutting the embroidery material quickly while maintaining the stability of the rolled embroidery material.

Owner:浙江雨濠智能设备有限公司

Foldable desk for train

The invention discloses a foldable desk for a train. The desk comprises a first desktop, a second desktop, a sliding supporting rod, two limiting guide rails, two pulley blocks, a locking chuck and a plurality of hinges. One edge of the first desktop is fixed to a compartment of the train, and the first desktop and the wall of the compartment are connected through a first fixed pulley; the second desktop and the first desktop are connected through the hinges; the locking chuck is installed on the upper surface of the second desktop; the second desktop and the sliding supporting rod are connected through a second fixed pulley; two metal pulleys are arranged on the lower sides of the two sides of the sliding supporting rod; the sliding supporting rod penetrates through the two limiting guide rails; the distance from the two limiting guide rails to the floor of the compartment of the train is 20-30 cm; the two pulley blocks are installed under the two limiting guide rails and fixed to the wall of the compartment of the train. The desk is simple in structure, convenient to use and high in practicality.

Owner:谭清平

Winding die positioning assembly of a vertical winding machine

The invention discloses a winding mould positioning component of a vertical winding machine. The winding mould positioning component comprises a driven synchronous wheel, a planetary wheel component, a mould fixing rod, a winding spindle and a winding flying fork, wherein the driven synchronous wheel drives the winding flying fork to rotate through the winding spindle; and the planetary wheel component comprises a fixed wheel set and a movable wheel set; the upper part of the fixed wheel set is fixed, and the lower part of the fixed wheel set is connected with the mould fixing rod; and the driven synchronous wheel drives the movable wheel set to revolute around the fixed wheel set through the winding spindle. According to the winding mould positioning component of the vertical winding machine, the mould fixing rod below the winding spindle is fixed by utilizing a planetary gear train structure, so that the mould positioning effect is achieved, the speed of the whole device in operation is greatly increased, the overall efficiency of the whole device in operation is greatly improved, it is ensured that a mould does not shake under the condition of quick winding, the overall action smoothness of the device is improved, the winding efficiency is improved by 25%, no slot jumping in winding is ensured, a wire package is regular, the wear of the winding mould and a winding cup is reduced, and the service life of the mould is prolonged.

Owner:JIANGSU NIDE AUTOMATION TECH

High-altitude pruning device

The invention discloses a high-altitude pruning device, which is characterized by comprises a stay rod component, a shearing component, a first driving device, a transmission component, a clamping component and a second driving device. Two groups of transmission components have the same structure, and the two groups of transmission components are divided into a left transmission component and a right transmission component according to the difference of the left position and the right position of the transmission components. The strut assembly includes a strut and a lower mounting seat. And the lower mounting seat is welded and fixed on the lower part of the brace rod. The first driving device is fixedly arranged on the left part of the lower mounting seat. And the first driving device drives the front cutter bar and the rear cutter bar of the shearing assembly to carry out shearing operation through the left side transmission assembly. And the second driving device is fixedly arrangedon the right part of the lower mounting seat. And the front clamping arm and the rear clamping arm of the clamping assembly are driven by the second driving device through the right side transmissionassembly to carry out clamping positioning operation.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

An auxiliary device for wiring in a power system

ActiveCN109818299BReduce vibrationChange heightApparatus for removing/armouring cablesApparatus for overhead lines/cablesElectric power systemWire cutting

The invention relates to a stringing auxiliary device, in particular to a power system stringing auxiliary device. The power system stringing auxiliary device comprises a damping parking wheel mechanism, an elevating locking mechanism, a tensioning and wire cutting mechanism, and a cable peeling mechanism. The vibration of the device can be reduced in the moving process of the device; the device is capable of parking, capable of changing height, and capable of locking a telegraph pole; it is guaranteed that the device does not shake; the device can clamp a cable, the device can tension the cable, the device can cut the cable, and the device can peel the cable; the damping parking wheel mechanism is welded to the lower portion of the elevating locking mechanism; the tensioning and wire cutting mechanism is welded to the upper portion of the elevating locking mechanism; and the cable peeling mechanism is welded to the right side of the tensioning and wire cutting mechanism.

Owner:浙江正嘉建设有限公司

Circular cutter device for taping embroidery or rope embroidery

ActiveCN111826932ASmooth cutGuaranteed not to shakeSevering textilesAutomatic machinesStructural engineeringKnife blades

An embodiment of the invention provides a circular cutter device for taping embroidery or rope embroidery, and belongs to the technical field of embroidery equipment. The circular cutter device for the taping embroidery or the rope embroidery comprises a fixing mechanism, a lifting mechanism, a circular cutter mechanism and a driving mechanism. The lifting mechanism comprises a lifting assembly, adriving base and circular cutter bases. The lifting assembly comprises a lifting base and a lifting body. The driving base is connected with the lifting base. The circular cutter base is connected with the lifting base. The circular cutter mechanism is arranged on the circular cutter base, and a blade is arranged on the circular cutter mechanism. The driving mechanism is arranged on the driving base. The driving mechanism acts on the lifting body and the circular cutter mechanism, the lifting body can conduct lifting movement through the driving mechanism, and the blade in the circular cuttermechanism can rotate through the driving mechanism. The technical effect that embroidery materials are sheared quickly as the stability of the coiled embroidery materials is kept is achieved.

Owner:浙江雨濠智能设备有限公司

Laser leveling device for stone maintenance and grinding

The invention belongs to the technical field of stone surface polishing, and relates to a laser leveling device for stone maintenance and grinding. The laser leveling device is characterized by comprising a glass cylinder, a rope and a cone. The glass cylinder is a transparent cylindrical hollow cylinder, an upper top plate is fixedly arranged on the upper end face of the glass cylinder, a mounting plate is connected to the bottom end face of the upper top plate through the rope, the joint of the rope and the upper top plate is located in the middle of the upper top plate, and a laser lamp is fixedly connected to the bottom end face of the mounting plate. The small end of the cone is fixedly connected with the bottom end face of the mounting plate, the axis of the cone coincides with the axis of the rope, and the peripheral outer side of the cone is covered with a reflector. A lower bottom plate is fixedly arranged on the bottom end face of the glass cylinder. When in use, the device is placed at a certain place, a laser lamp power source is turned on, laser can be reflected under the reflection effect of the reflector on the cone to form a light beam parallel to the horizontal plane, and the device is matched with a polishing machine for use, so that the flatness of stones is improved, operation is made convenient, and repeated adjustment and measurement are not needed.

Owner:吾尚良品环境服务(上海)有限公司

Self-adaptive structure capable of self-adapting to size of embedded hole and embedded cooker

InactiveCN112393287ARealize automatic adjustmentAdaptableStoves/ranges foundationsDomestic stoves or rangesCookerPhysics

The invention discloses a self-adaptive structure capable of self-adapting to the size of an embedded hole and an embedded cooker. The self-adaptive structure comprises a pressure-containing part, a support, pull rods, elastic parts and at least one traction part, wherein the support is provided with mounting cavities extending towards the pressure-containing part; an opening facing the pressure-containing part is formed in each mounting cavity; one end of each pull rod is arranged in one mounting cavity in a telescopic movement manner, and the other end of each pull rod penetrates through oneopening and then is hinged to the pressure-containing part; each elastic part is mounted in one mounting cavity, one end of each elastic part is propped against one surface, facing the correspondingopening, of one mounting cavity, and the other end of each elastic part is connected with or propped against one pull rod; and two ends of each traction part are connected with the pressure-containingpart and the support separately. The self-adaptive structure disclosed by the invention is simple and ingenious in structure, can be suitable for an embedding size interval of a certain range segment, can achieve automatic adjustment according to the size of the embedded hole, is high in self-adaptability, and further guarantees that the cooker does not shake. In addition, the self-adaptive structure can automatically reset when moving away from the embedded hole.

Owner:VATTI CORP LTD

Structure for connecting vertical shaft windmill with power generator

ActiveCN102322406AGuaranteed not to shakeGuaranteed normal operationWind energy generationSupports/enclosures/casingsDrive shaftEngineering

The invention relates to a structure for connecting a vertical shaft windmill with a power generator, which belongs to the technical field of vertical shaft wind power generators. The invention has the technical scheme that the vertical shaft windmill and the power generator are connected together through an aligning bearing mechanism and are vertically arranged, wherein the aligning bearing mechanism comprises an aligning bearing (9), a driving shaft (11), a driving shaft upper flange (10) and a driving shaft lower flange (12); the driving shaft is matched with the aligning bearing; the driving shaft upper flange is arranged at the upper part of the driving shaft and is connected with the vertical shaft windmill; and the driving shaft lower flange is arranged at the lower part of the driving shaft and is connected with the power generator. The structure has the beneficial effects that the action force can be automatically adjusted to be acted on the aligning bearing; the windmill is ensured not to shake by continuously and automatically adjusting the center; and the swing force acted on the power generator is offset by the aligning bearing, so that the power generator and the vertical shaft windmill can be used for automatically adjusting the center, normal operation of the power generator is ensured, and the power generation efficiency is improved.

Owner:TANGSHAN TOYODA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com