High altitude pruning device

A technology of pruning and driving device, applied in agricultural machinery and implements, gardening, agriculture, etc., can solve the problems of time-consuming, labor-intensive, inconvenient, etc., and achieve the effect of accurate position, convenient operation and stable stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

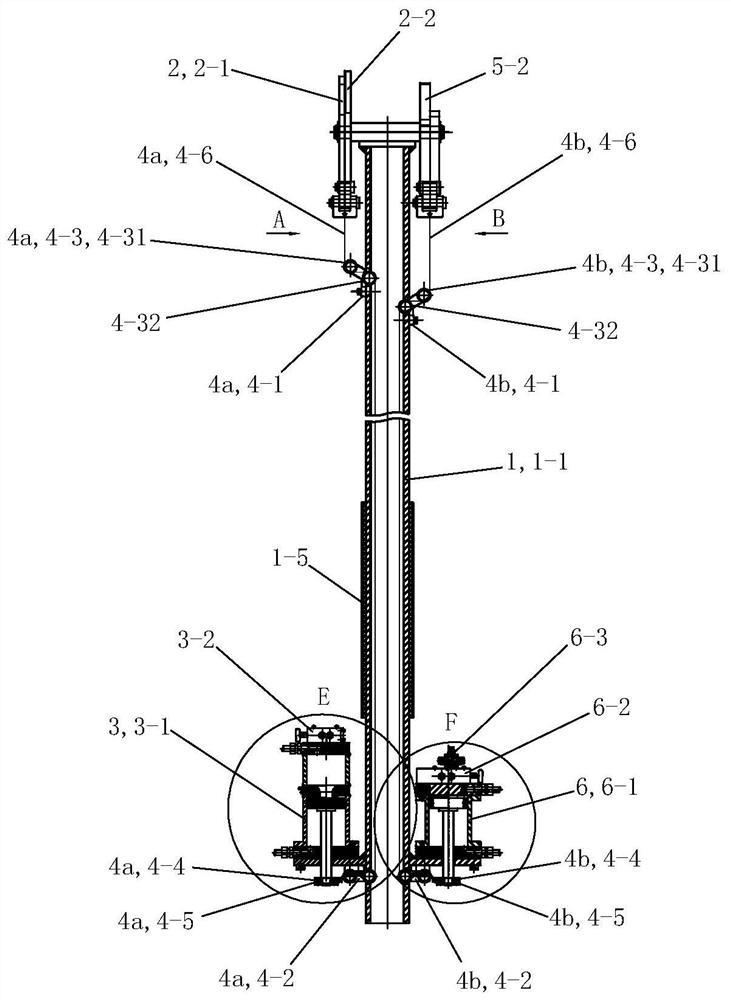

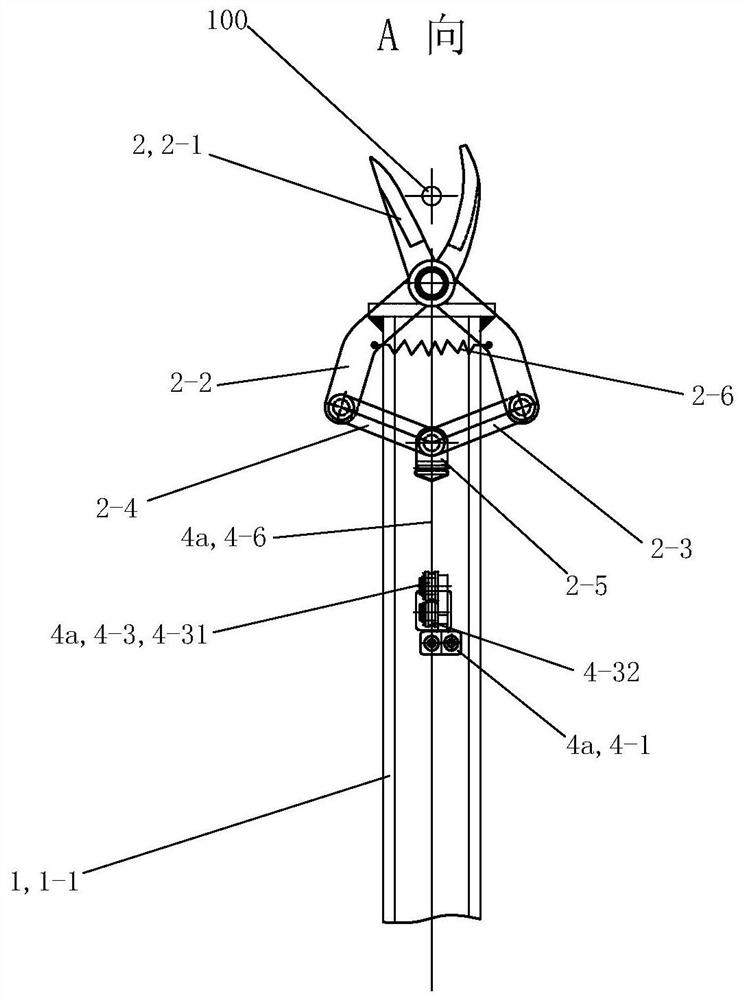

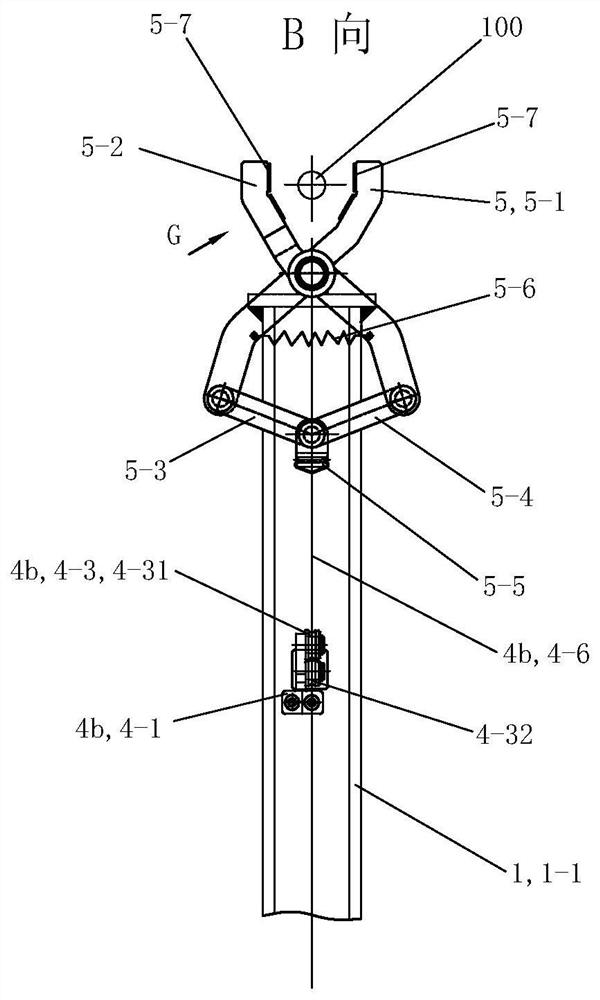

[0067] See Figure 1 to Figure 10 , The high-altitude pruning device of the present invention includes a brace assembly 1 , a cutting assembly 2 , a first driving device 3 , a transmission assembly 4 , a clamping assembly 5 and a second driving device 6 .

[0068] See Figure 1 to Figure 3 and Figure 11 to Figure 14 , The strut assembly 1 includes a strut 1-1, a lower mounting seat 1-2, an upper mounting plate 1-3, an upper mounting shaft 1-4 and a grip sleeve 1-5. The strut 1-1 is made of hard aluminum alloy, and the strut 1-1 is hollow tubular. The upper mounting plate 1-3 is welded and fixedly arranged on the upper end of the strut 1-1. The upper mounting shaft 1-4 is fixedly welded and fixed on the upper mounting plate 1-3 along the radial direction of the strut 1-1, and is arranged along the left and right directions. The lower mounting seat 1-2 is a circular mounting plate, and the center is provided with an installation through hole that runs through it up and down...

Embodiment 2

[0085] The rest of this embodiment is the same as that of Embodiment 1, the difference being that: the strut assembly 1 is also provided with strap rings 1-6 and straps. The strap suspension ring 1-6 is fixedly arranged on the front upper side of the lower mounting base 1-2. When in use, the strap suspension rings 1-6 are fixedly connected with the strap, and the operator carries the strap on his back, which helps to reduce the labor intensity of the operator, and is convenient for weaker operators to hold alone, making it more convenient to use.

Embodiment 3

[0087] The rest of this embodiment is the same as Embodiment 1, except that the second driving device does not include the one-way speed regulating valve 6-3. The fourth interface 6-24 is in airtight communication with the gas source through a corresponding pipeline. The first interface 6-21 of the second two-position five-way manual reversing valve 6-2 is airtightly communicated with the air inlet 6-11 on the second cylinder of the second cylinder 6-1 through a corresponding pipeline. The second interface 6-22 of the second two-position five-way manual reversing valve 6-2 is airtightly communicated with the lower air inlet 6-12 of the second cylinder 6-1 through a corresponding pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com