Laser leveling device for stone maintenance and grinding

A laser and stone technology, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem of not being able to ensure the smoothness of stone materials, and achieve convenient operation and improve flatness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

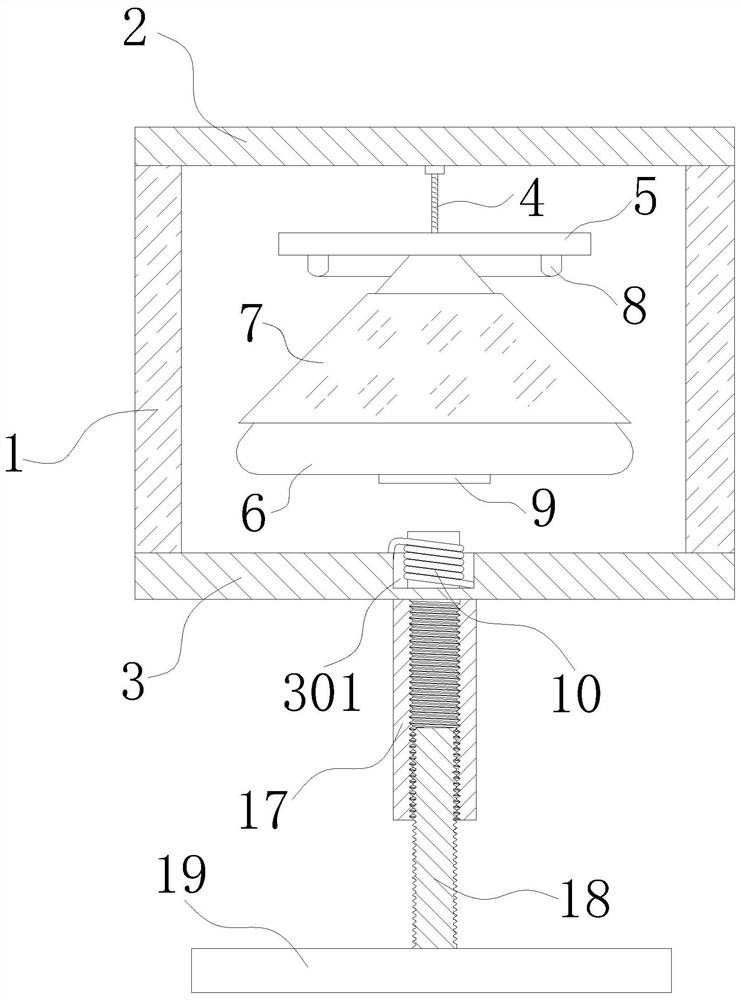

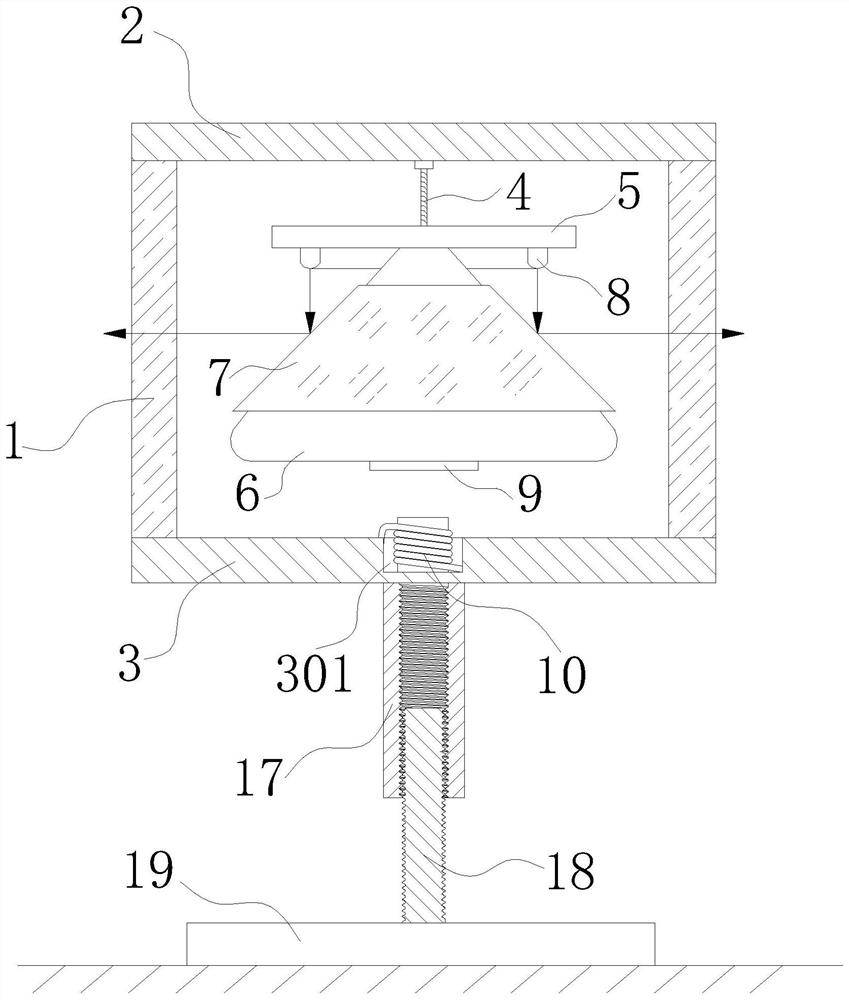

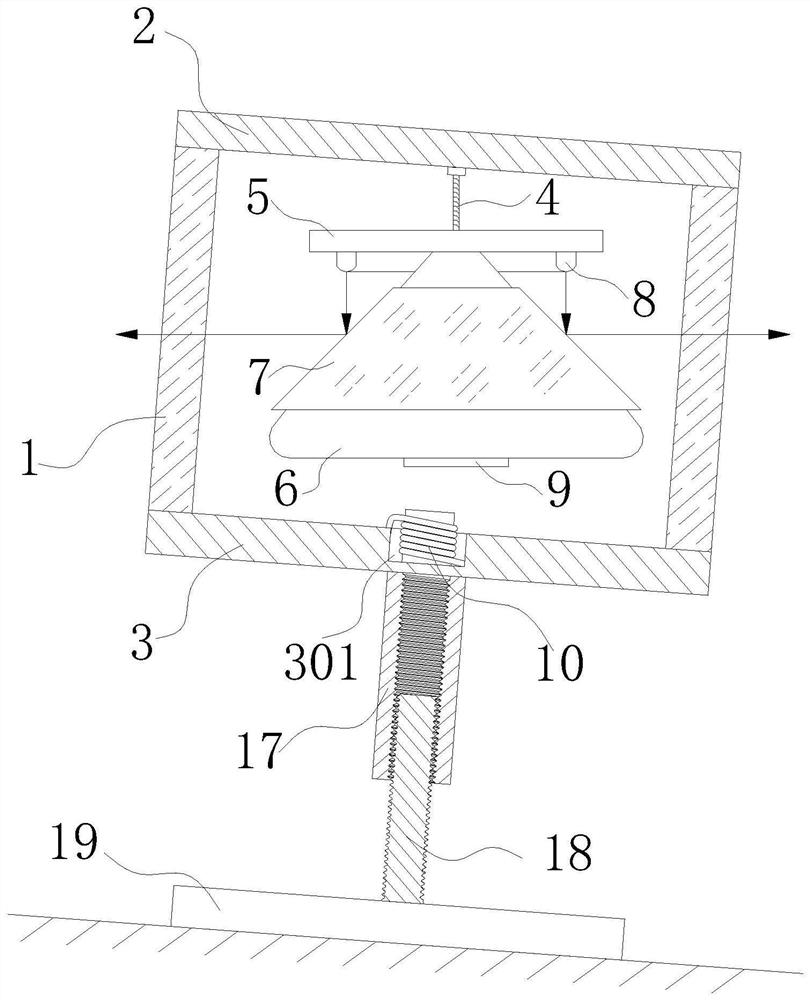

[0035] see Figure 1-5 Shown is a laser leveling device for stone maintenance and polishing, which is a laser leveling device for stone maintenance and polishing to assist the polishing machine to ensure the flatness of the stone surface during polishing. Specifically, a laser leveling device for stone maintenance and polishing includes a glass cylinder 1 , a rope 4 and a cone 6 .

[0036] The glass cylinder 1 is a transparent cylindrical empty cylinder, and the outside of the glass cylinder is provided with a scale. The scale provided on the outside of the glass cylinder can pass through the glass cylinder 1 when the device is placed on an inclined plane. The scale corresponding to the laser spot of the laser spot calculates the inclination angle of the inclined surface, which is convenient for later processing of the place; the upper end surface of the glass cylinder 1 is fixedly provided with an upper top plate 2, and the bottom end surface of the upper top plate 2 is conne...

Embodiment 2

[0045] Another laser leveling device for stone maintenance and grinding differs from that of Embodiment 1 in that: Figure 8 As shown, the upper top plate 2 is evenly provided with air inlets 201, and the inside of the air inlets 201 is fixedly provided with a filter layer 20, and the lower base plate 3 is provided with an air outlet 302, and the air outlet 302 is fixedly provided with a fan 21, so that Regularly turn on the fan 21, then the air outside the space formed by the glass cylinder 1, the upper top plate 2 and the lower bottom plate 3 will enter the interior through the air inlet 201 after being filtered by the filter layer 20, and then be discharged through the air outlet 302, which can Blow off the dust and impurities attached to the surface of the mirror 7 to prevent the laser light from being parallel to the horizontal plane after reflection and affecting the polishing effect.

Embodiment 3

[0047] Another laser leveling device for stone maintenance and grinding differs from that of Embodiment 1 in that: Figure 9 As shown, the diameters of the upper top plate 2 and the lower bottom plate 3 are larger than the diameter of the glass cylinder 1, and the upper end surface of the lower bottom plate 3 is fixedly provided with a lifting and shrinking cylinder 22. The lifting and shrinking cylinder 22 is composed of a plurality of concentric circles with different diameters The outermost cylinder of the lifting and shrinking cylinder 22 is provided with a handle 23, the material of the outermost cylinder of the lifting and shrinking cylinder 22 is iron, and the bottom end surface of the upper top plate 2 is provided with a permanent magnet 24, so that when not in use During installation, the lifting and shrinking cylinder 22 can be wrapped around the outside of the glass cylinder 1 to prevent the outside of the glass cylinder 1 from being damaged due to bumping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com