Winding die positioning assembly of a vertical winding machine

A technology of vertical winding machine and winding mold, which is applied in the direction of coil manufacturing, etc. It can solve the problems of winding mold shaking left and right, the life of winding cup is reduced, and the winding mold is easy to wear, so as to improve winding efficiency and improve The effect of long service life and tidy wire package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

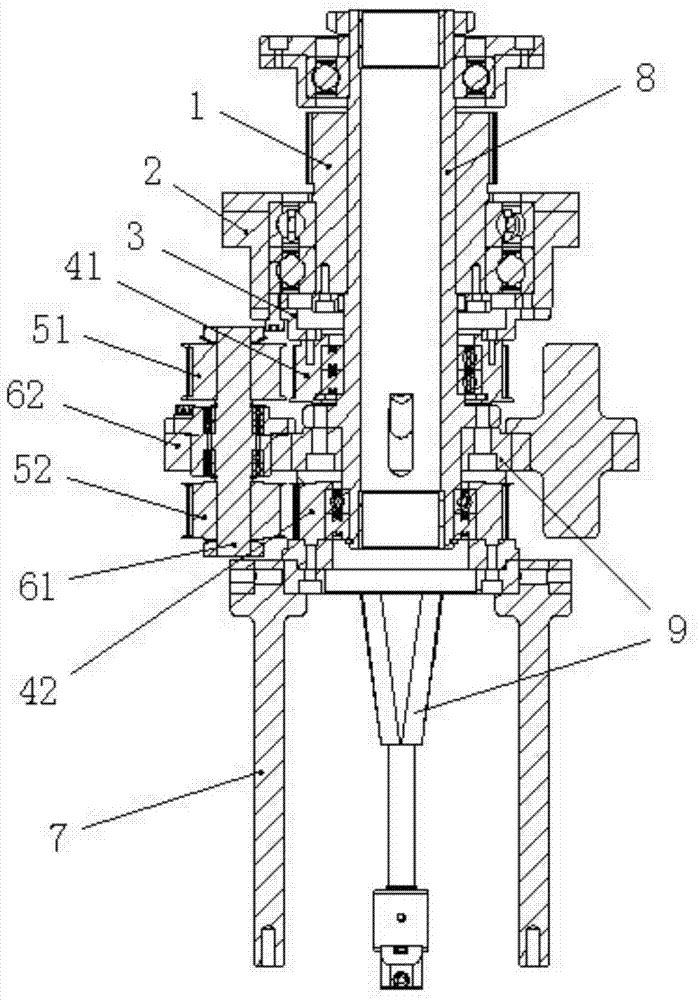

[0015] Such as figure 1 As shown, a winding mold positioning assembly of a vertical winding machine according to the present invention includes a driven synchronous wheel 1, a main winding bearing seat 2, a planetary gear assembly, a mold fixing rod 7, a winding spindle 8 and The winding fly fork 9, the planetary gear assembly includes an upper fixed synchronous wheel 41, a lower fixed synchronous wheel 42, an upper movable synchronous wheel 51, and a lower movable synchronous wheel 52; the main winding bearing seat 2 is fixed on the winding base plate, from The dynamic synchronous wheel 1 is arranged on the main winding bearing seat 2, the driven synchronous wheel 1 drives the winding main shaft 8 to rotate, and the upper part of the winding flying fork 9 cooperates with the winding main shaft 8; the upper fixed synchronous wheel 41 and the lower fixed The synchronous wheel 42 all coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com