Bead string nailing and sanding machine

A nail sanding machine and bead string technology, applied in jewelry, clothing, grinders, etc., can solve the problems of low nailing efficiency and difficult nailing, and achieve the effect of improving efficiency, solving nailing difficulty and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

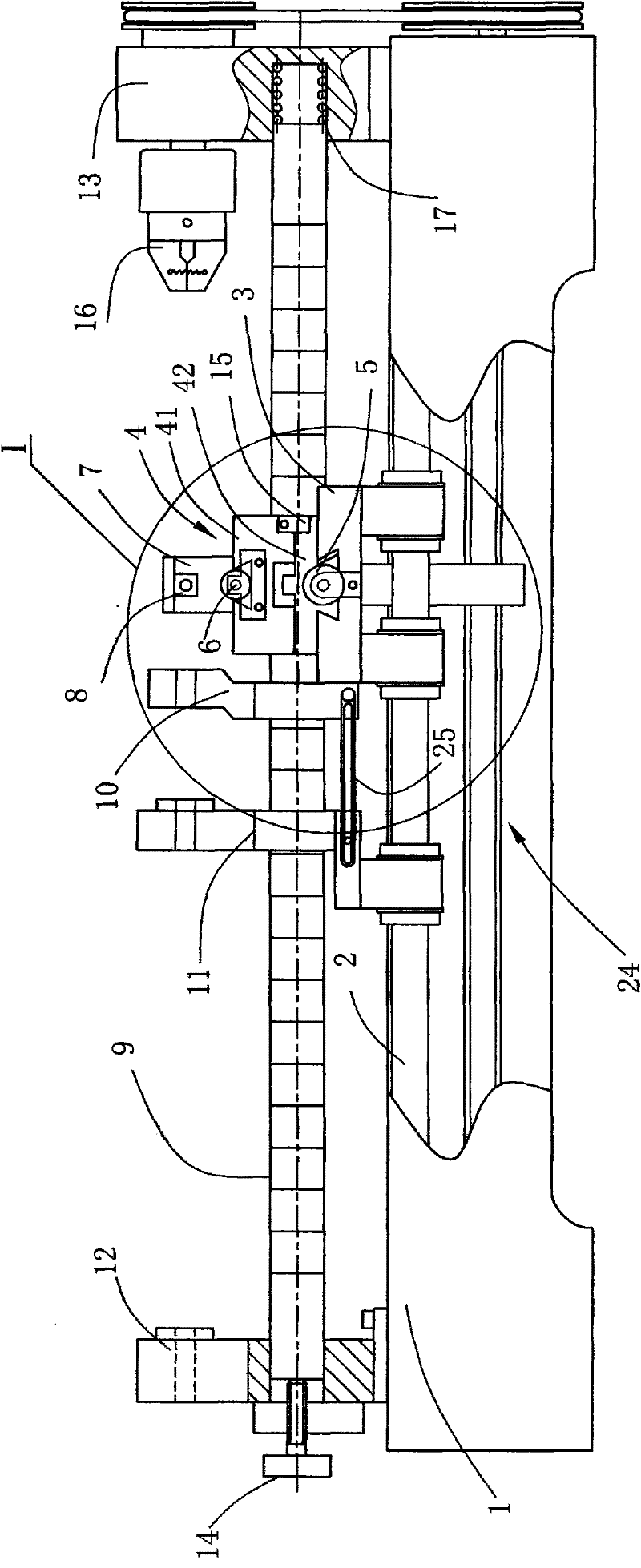

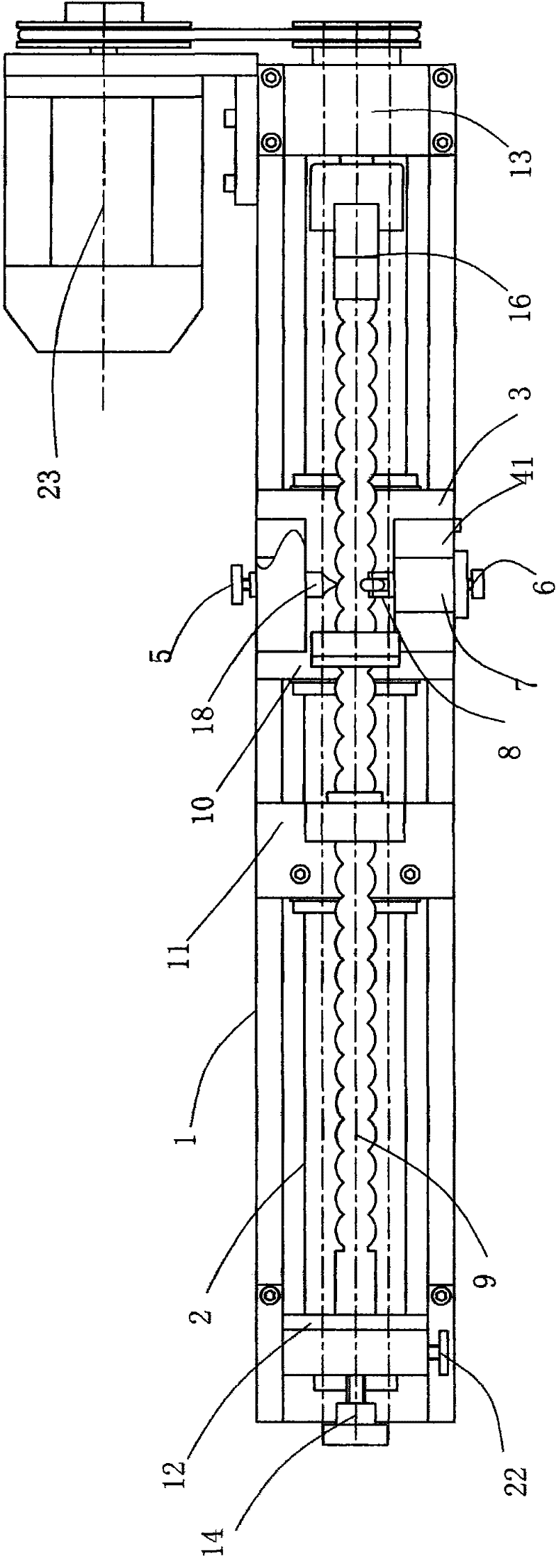

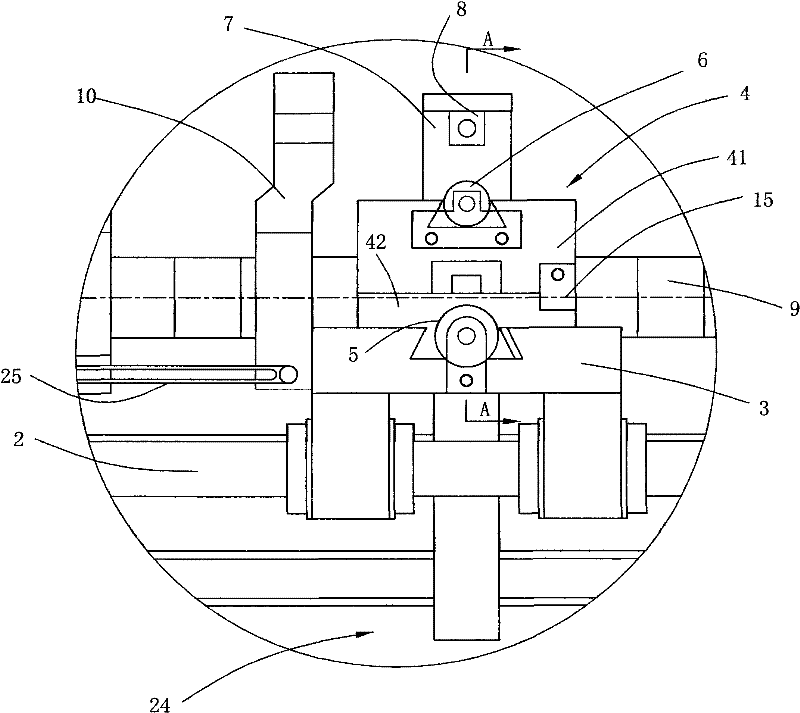

[0020] A kind of bead string nail sand machine, such as figure 1 , figure 2 and image 3 As shown, it includes: a frame 1, on which a chuck seat 13 and a tailstock 12 are installed, on which a chuck 16 driven by a first power unit 23 is rotatably mounted, and the The tailstock 12 is provided with a guide sleeve for supporting the bead string, the guide sleeve is coaxially arranged with the chuck 16; the slide seat 3 driven by the second power unit is slidably installed on the On the longitudinal track 2, the longitudinal track 2 is arranged on the frame 1, the first power unit 23 and the second power unit are motors, and the first power unit 23 drives the collet through a pulley transmission 16 rotation, the second power unit drives the sliding seat 3 to slide through the screw nut mechanism 24, and of course, the second power unit can also drive the sliding seat 3 to slide through the synchronous belt transmission;

[0021] Form 9, the two sides of the form 9 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com