Patents

Literature

167 results about "Explorator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

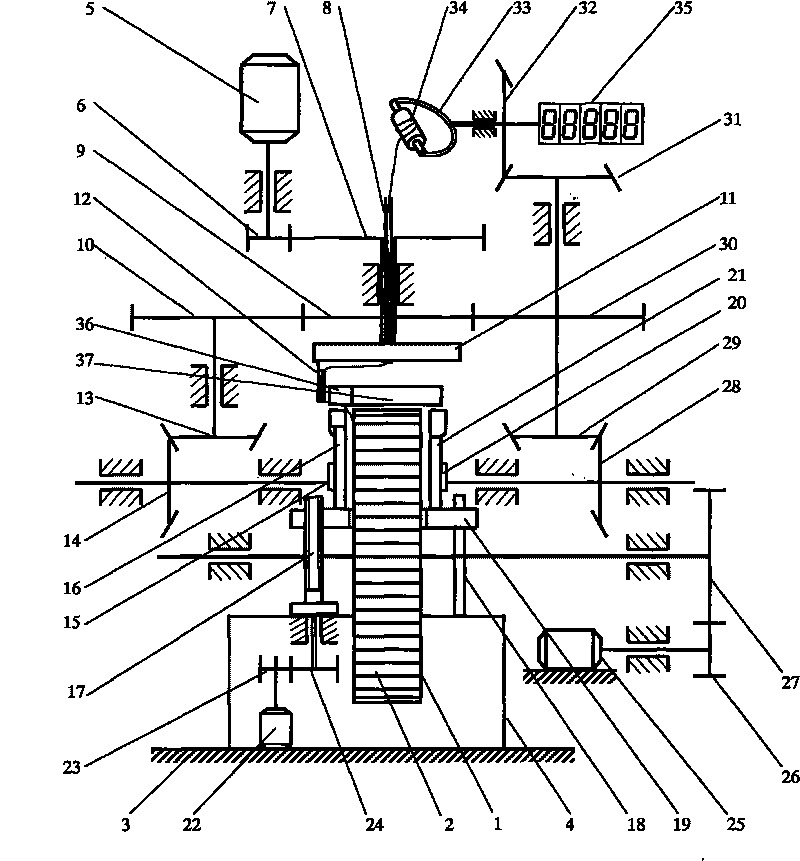

Spring concentricity and verticality measuring meter and its measurement method

ActiveCN101216287AAvoid product qualityHigh measurement accuracyUsing optical meansMeasurement deviceEngineering

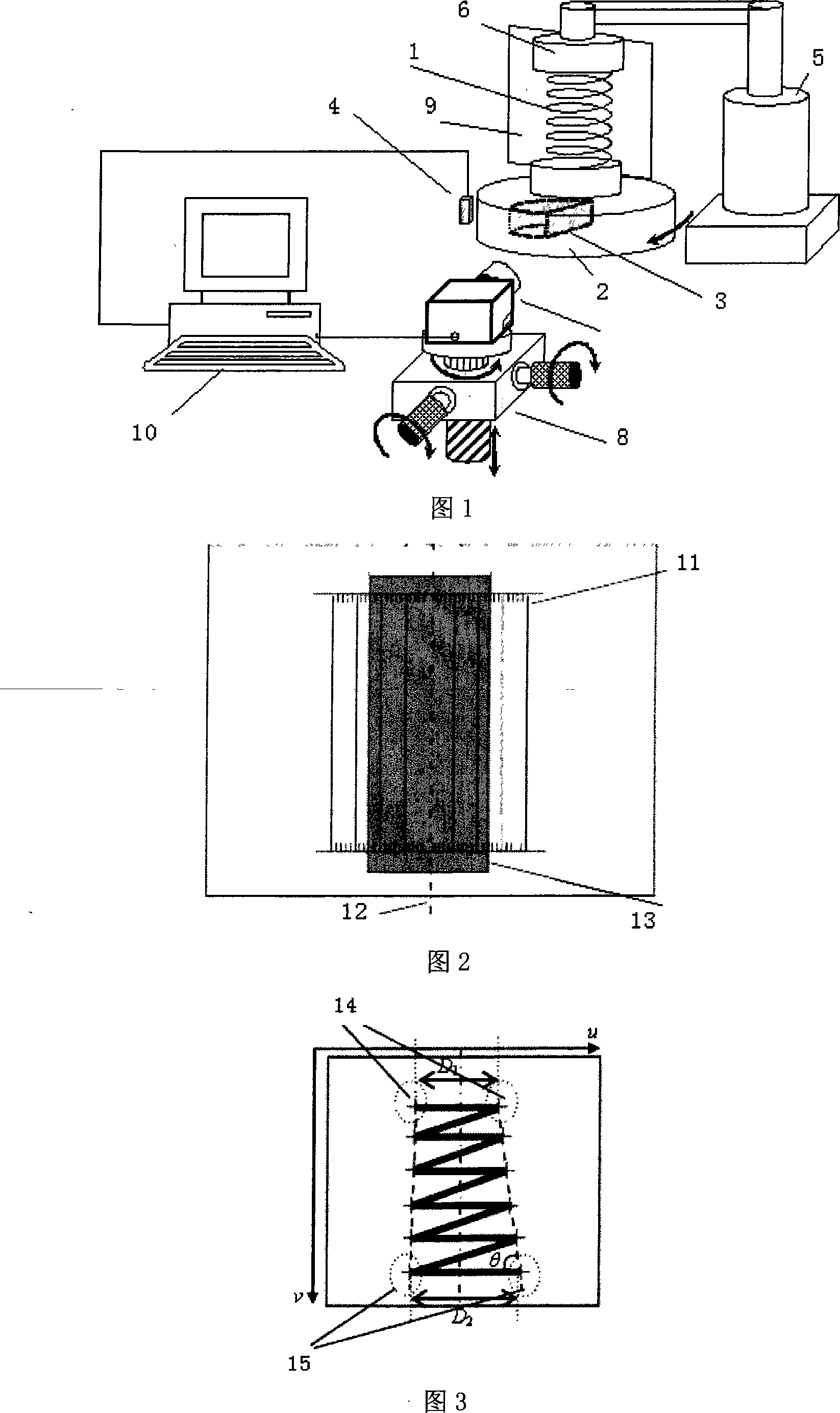

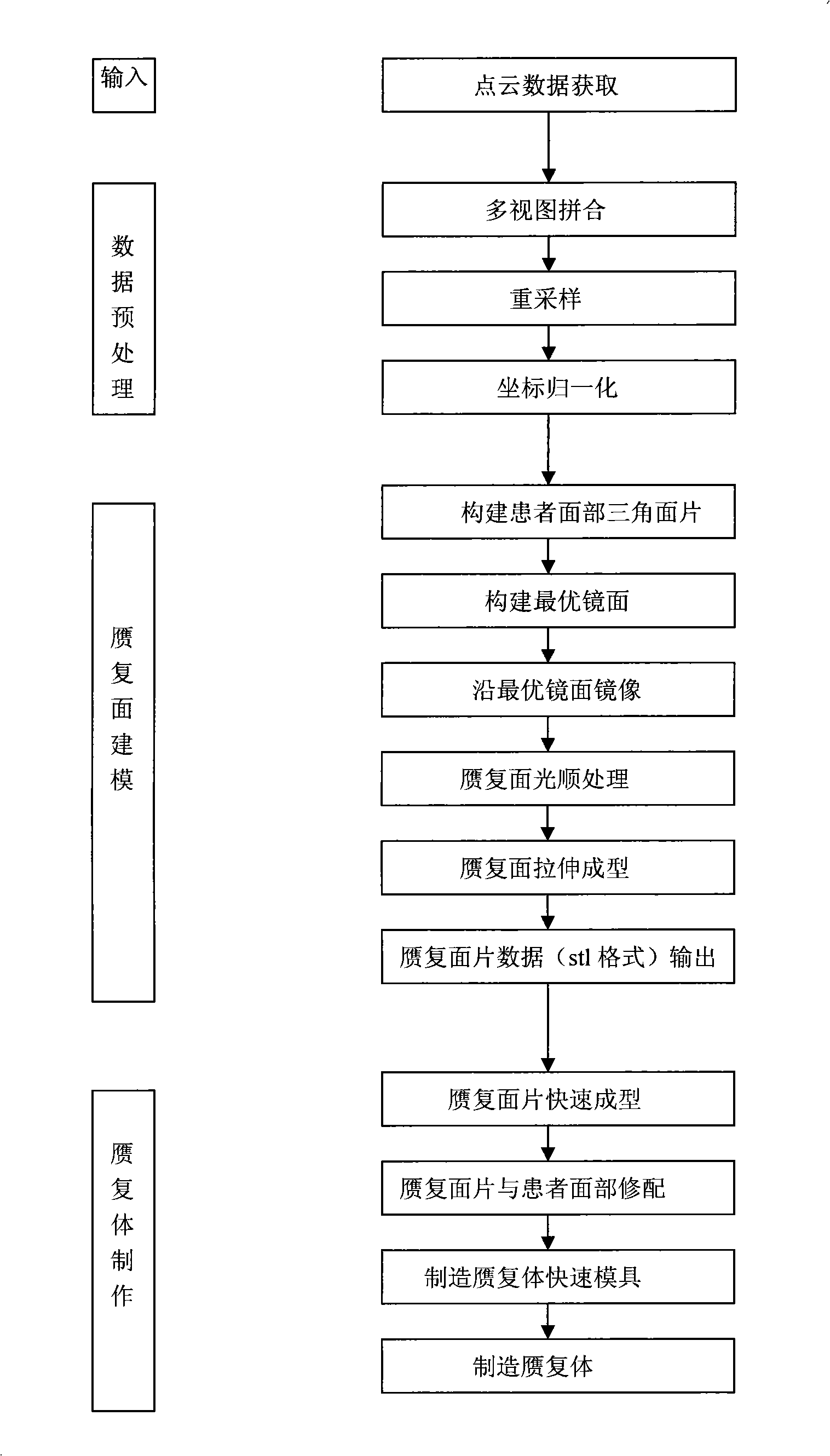

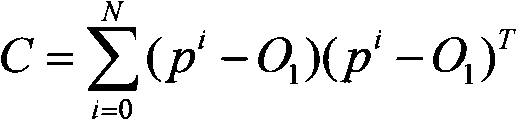

The invention belongs to the technical field of image measurement, particularly relates to a measurement device for measuring concentricity and perpendicularity of a compression spring, which comprises a camera disposed on a cloud platform; a backlight plate disposed opposite to the camera for projecting uniform beam; a rotating base for fixing a spring to be measured; a cylinder and a cylinder head shaft for fixing the spring position and pressing the spring; a cloud platform for adjusting the viewing angle of the camera; and a computer for calculating and measuring the concentricity and perpendicularity of the spring according to the image signal collected by the camera. The invention also provides a method for measuring the concentricity and perpendicularity of the compression spring by utilizing the measurement device. The inventive measurement device can completely replace the measurement manner for measuring the concentricity and perpendicularity of a compression spring during compression spring production process by using an explorator or a contour projection measurement device, and realizes high speed online measurement and quality control of spring production. The inventive measurement device has good measurement accuracy and stability.

Owner:TIANJIN UNIV

Symmetrical character maxillofacial prosthesis producing method based on three-dimensional visual sensation measurement

InactiveCN101292914AImprove production efficiencyImprove the simulation effectBone implantDiagnosticsSelective laser sinteringPoint cloud

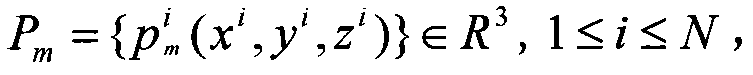

A symmetrical characteristic face prosthesis preparation method based on three-dimensional vision measurement belongs to the technical field of mechanical engineering and medical engineering. The present invention constructs a face triangular surface patch according to the point cloud data of a measured position of the patient face. An initial mirror image surface of the face triangular surface patch is obtained by a mirror image of an initial mirror surface to be optimized and jogged to obtain an optimized mirror surface; then a corresponding perfect part images at a defect part along the optimized mirror surface to be faired with the surrounding triangular surface patch to pick up a required prosthesis surface and a locating explorator surface is manufactured at the same time; the prosthesis surface and the locating explorator surface are respectively stretched into the data of a prosthesis surface patch and a locating explorator surface patch with certain thicknesses, and a selective laser sintering fast forming machine is used for manufacturing the prosthesis surface patch and the locating explorator surface patch; the prosthesis surface patch is used for fitting the face of the patient to manufacture a prosthesis fast mould; a medical silica gel prosthesis is manufactured inside a vacuum mould-duplicating machine. The method of the present invention can be used for obtaining exact defect area information and improves the manufacturing efficiency and the manufacturing precision of the prosthesis obviously.

Owner:SHANGHAI JIAO TONG UNIV

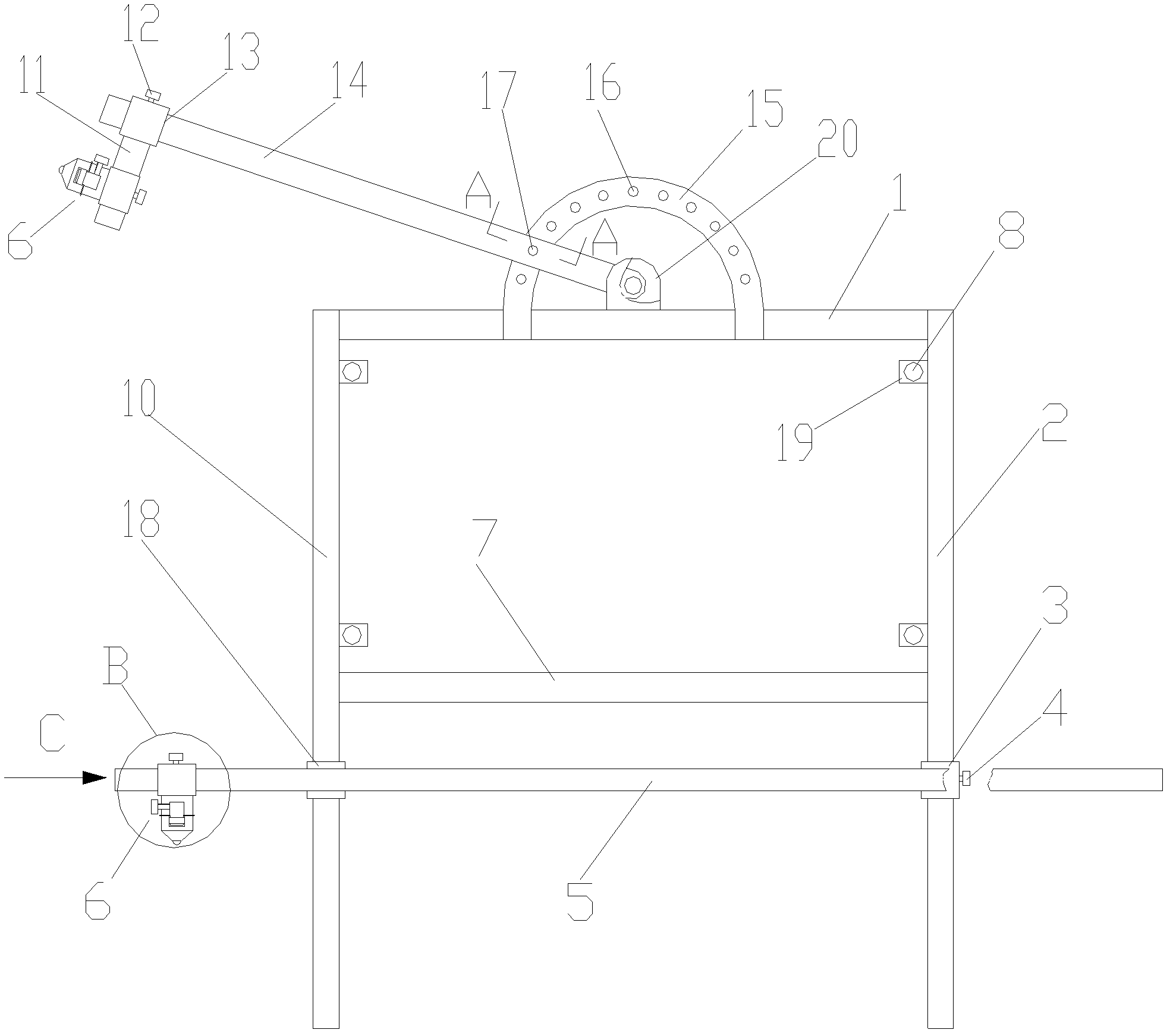

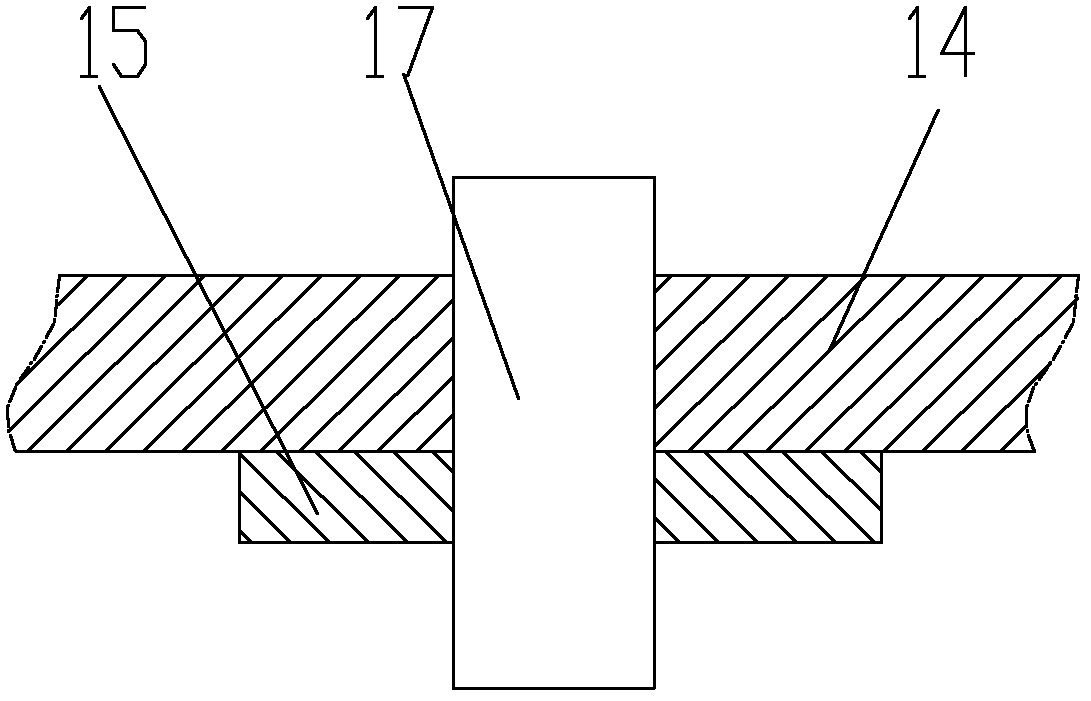

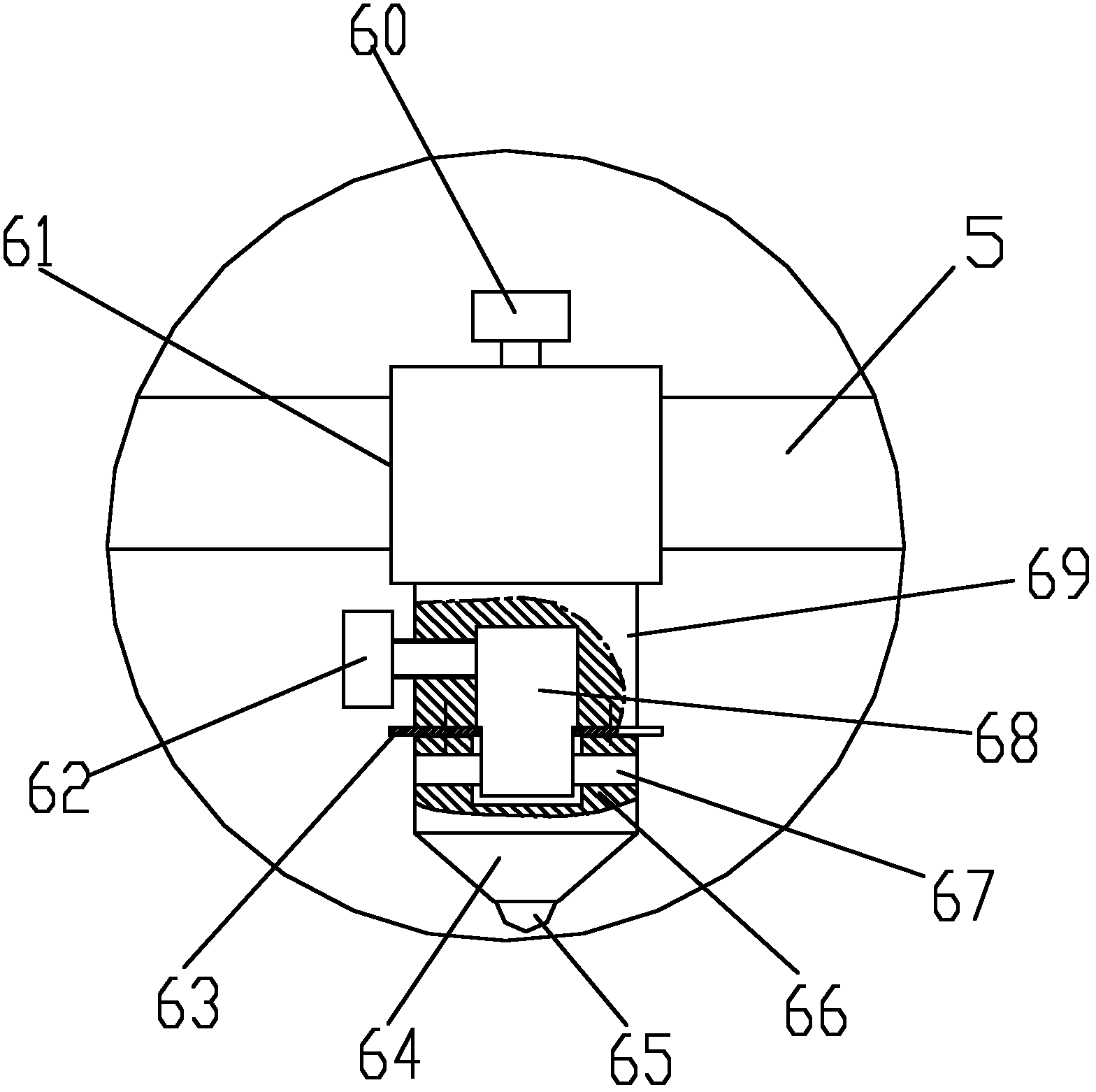

Tunneling embrasure positioning and guiding device and using method thereof

InactiveCN102425981AHigh degree of moldingImprove medication efficiencyBlastingEngineeringService efficiency

The invention discloses a tunneling embrasure positioning and guiding device and a using method thereof. The tunneling embrasure positioning and guiding device comprises a base frame component, a positioning component and an explorator component; the base frame component comprises a portal frame and an arc-shaped frame; the positioning component comprises a horizontal positioning arm and a rocker arm; the explorator component comprises an explorator and an explorator base; the explorator base is fixedly arranged at the horizontal positioning arm or / and the rocker arm in a way that the longitudinal position is adjustable; and the explorator is fixedly arranged on the explorator base in a way that included angles in directions parallel to and vertical to the horizontal positioning arm or / and the rocker arm are adjustable. According to the tunneling embrasure positioning and guiding device and the using method thereof, an embrasure can be positioned, and further, guided drilling on embrasures of different angles can be carried out, an accurate position and drilling direction are provided for operators, and embrasure-drilling accuracy is ensured, so that an expected blasting effect can be obtained, the service efficiency of explosive is ensured to be high when the blasting is carried out, the tunnel forming degree is high after blasting, and the tunneling efficiency is high, further, better security protection can be obtained, and the cost is lowered.

Owner:CHONGQING VOCATIONAL INST OF ENG

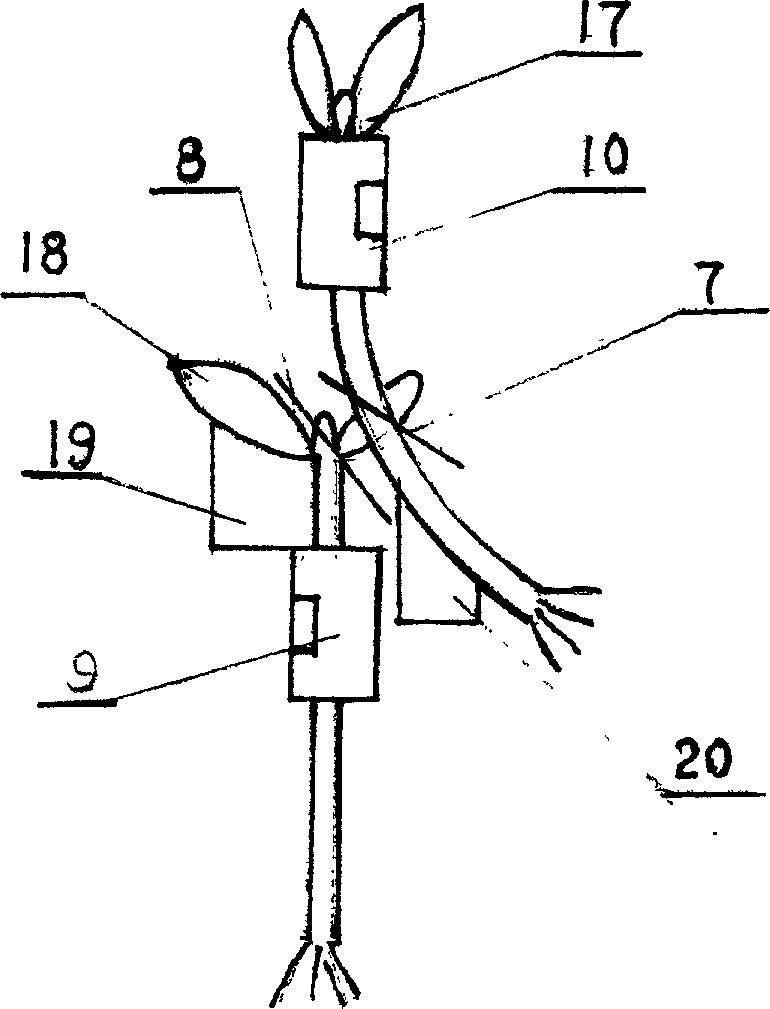

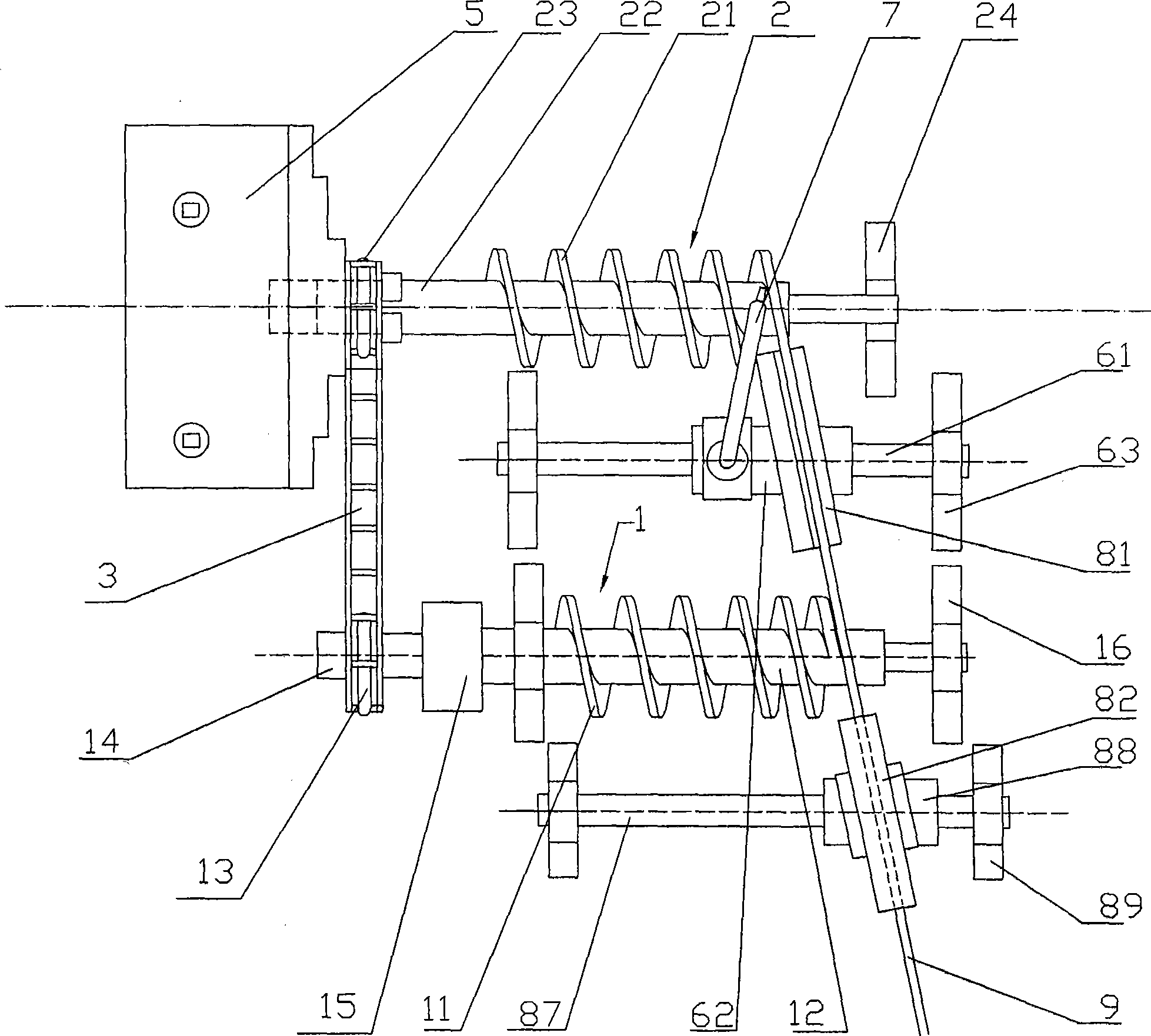

Automatic grafting machine for vegetable

There is disclosed an automatic vegetable grafting machine for vegetable grafting. Its stake clamp, which is on the operating platform, is aligned with the center of the graft clamp. The graft clamp's two explorators positions can be adjusted according to the sprout size; one leaf of stake sprout is relied to the exploratory, and scion stalk is relied to the exploratory and is a little bent. The stake and the graft incision fold automatically because of the two knives relative positions on knife-carrier slide and the graft scion bending. Wherein, compression lever and support swing link are separately joined with frame by means of gemels; the stake clamp swing link and the graft clamp swing link are contacted with cam and are joined with the support by means of gemels, and control opening or shutting of the stake and the graft incision and up-or-down movement of the lifter and the knife carrier. After cutting, the stake and the graft incision ascend along the stake and the scion until the graft stalk is unbend and automatically fold with the stake sprout incision, then the stake clamp and the graft clamp open and graft is completed. The machine has simple structure and high work efficiency of 600 trees per hour.

Owner:HUNAN AGRICULTURAL UNIV

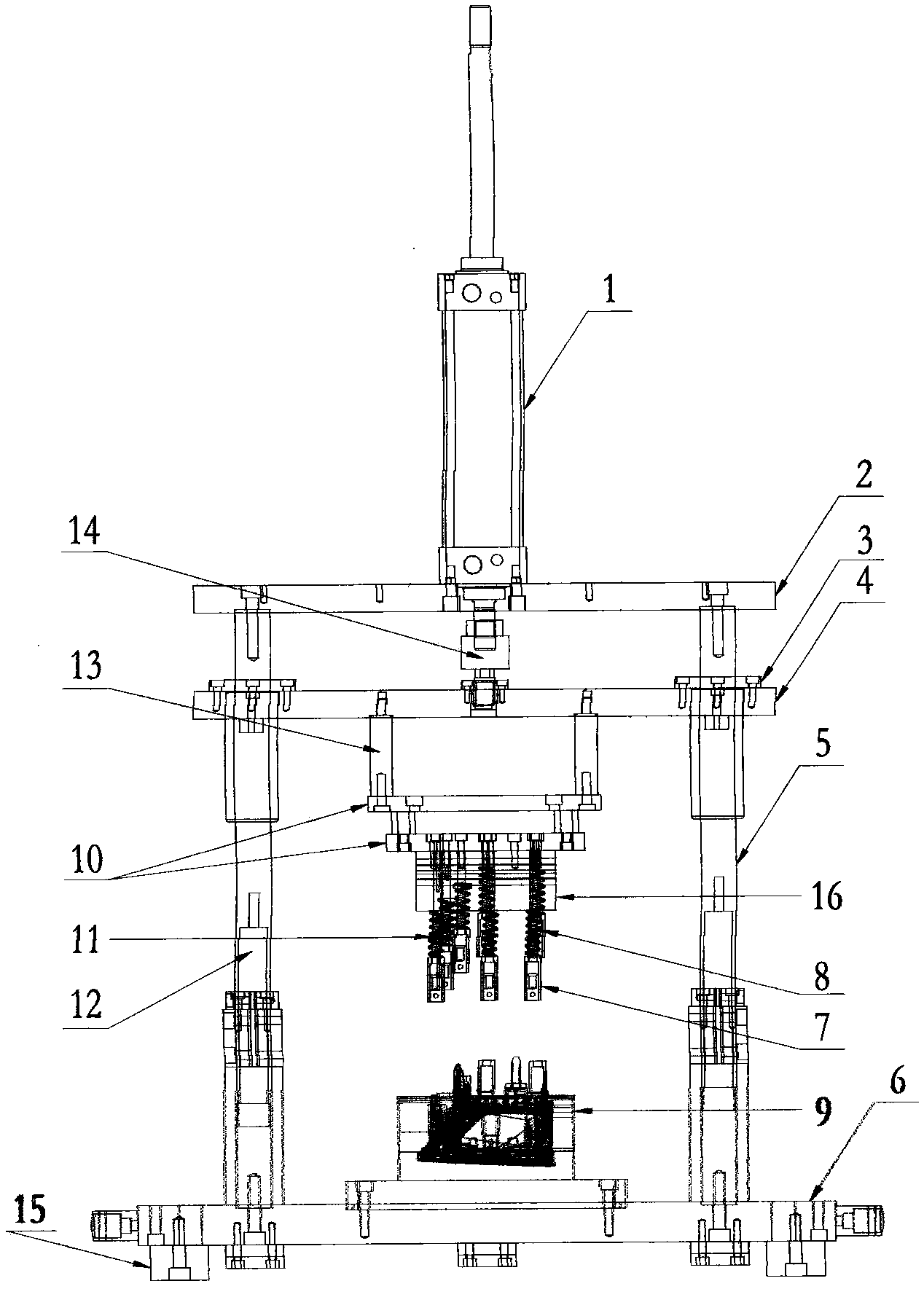

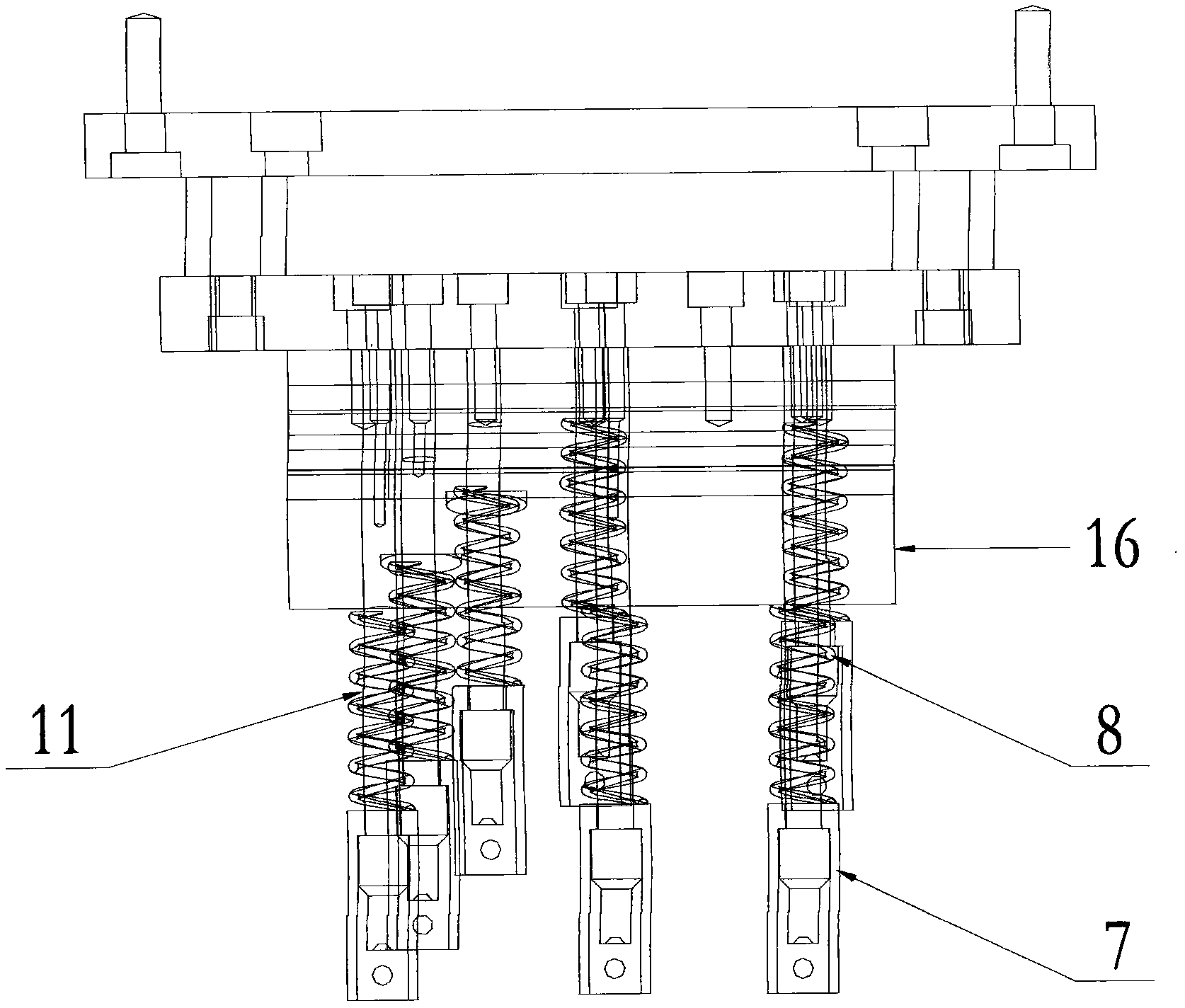

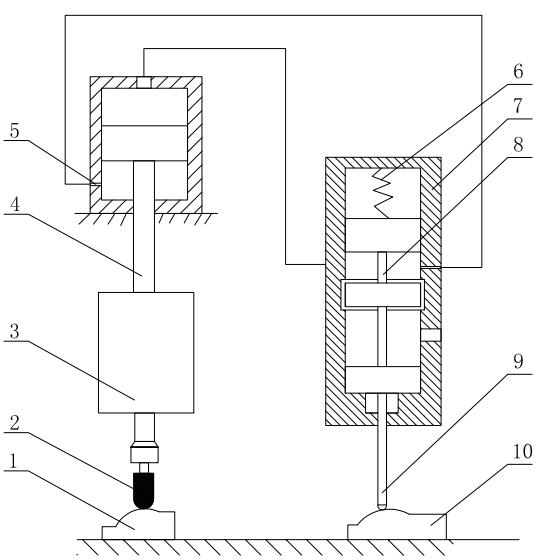

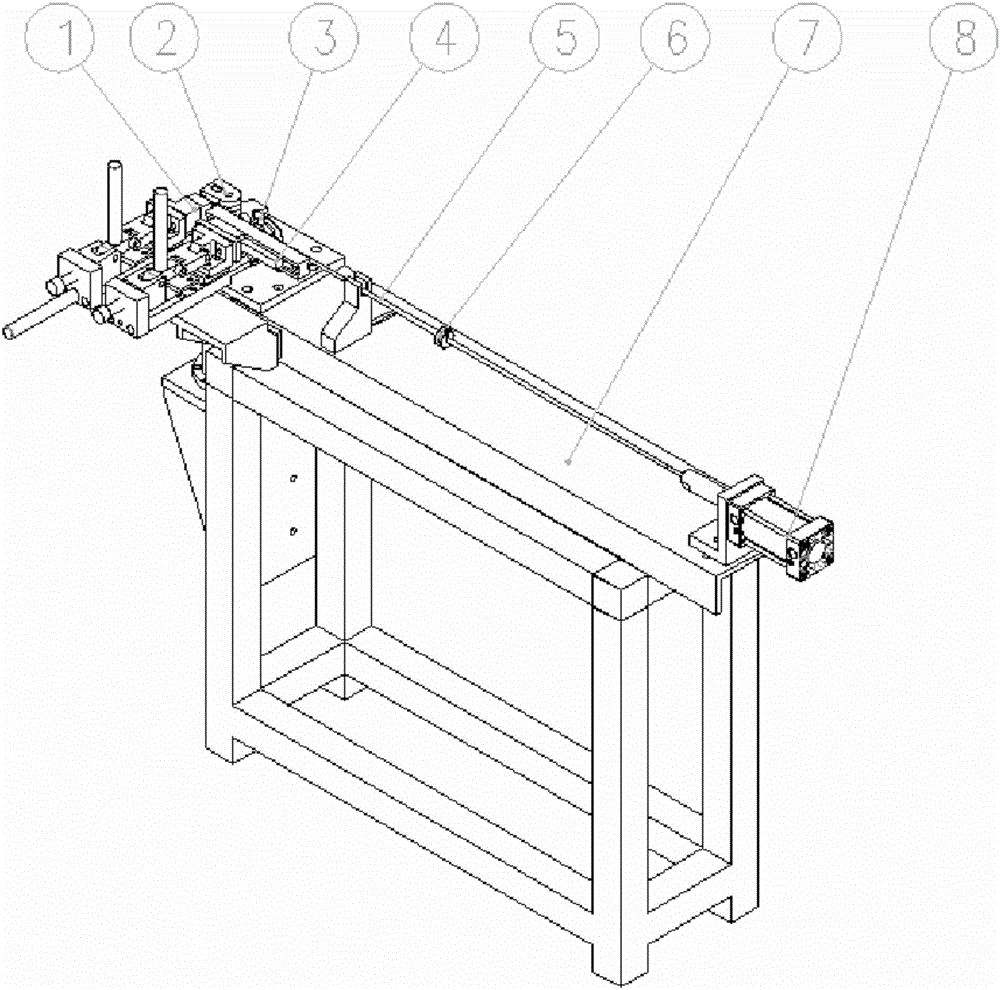

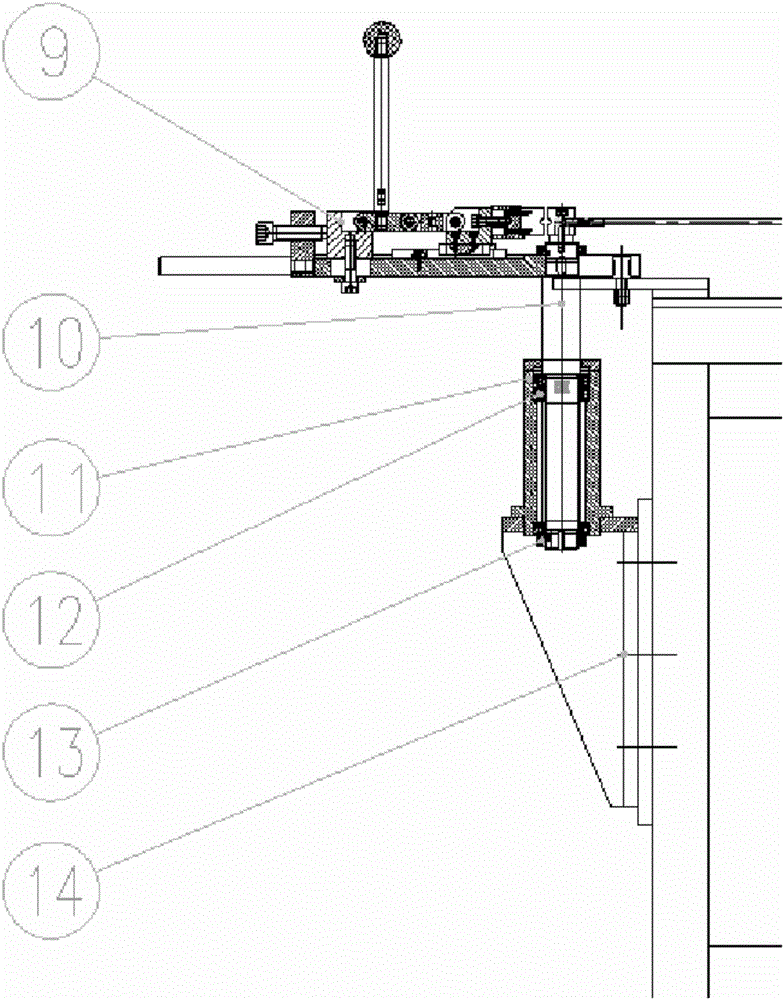

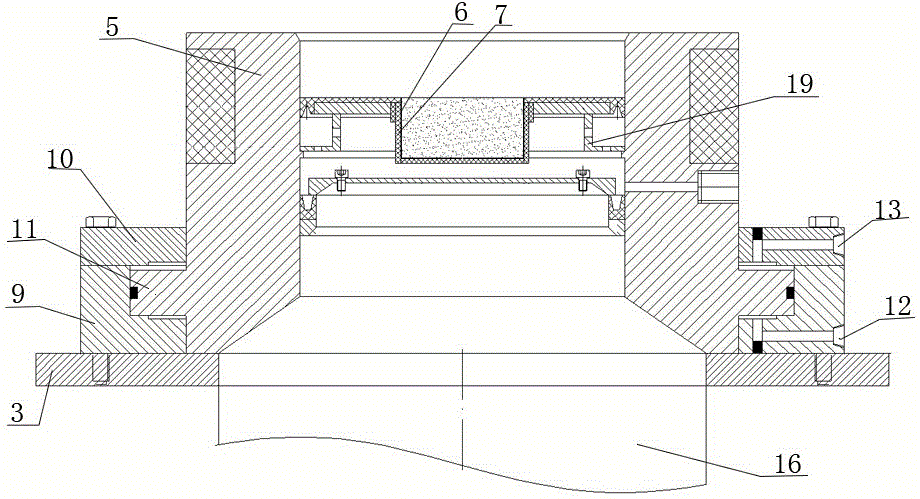

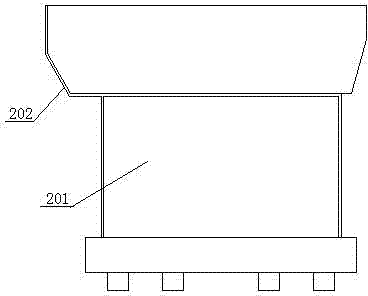

Pre-compressing device

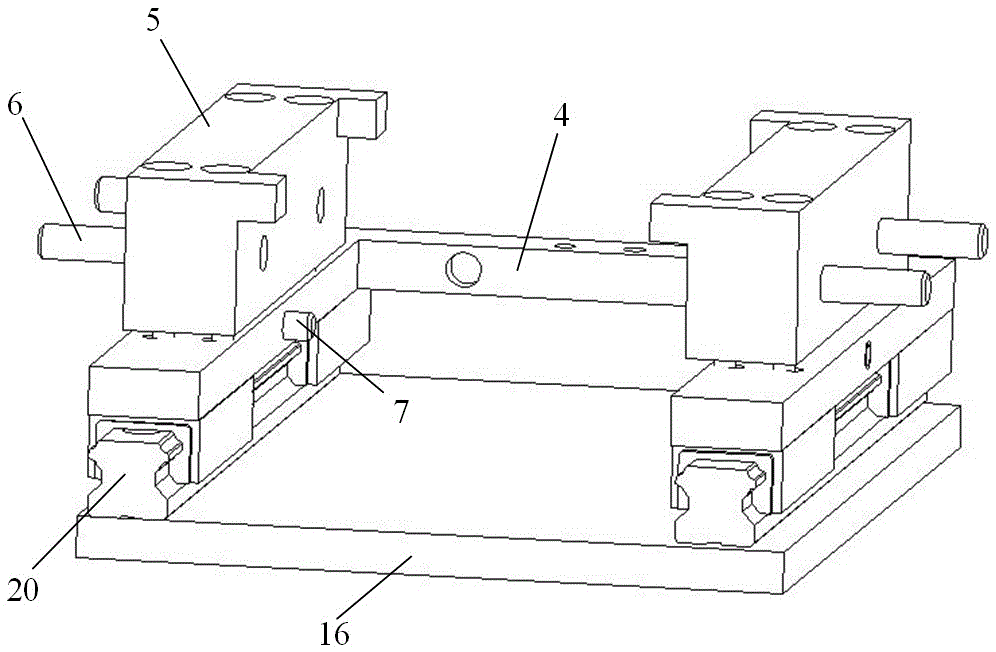

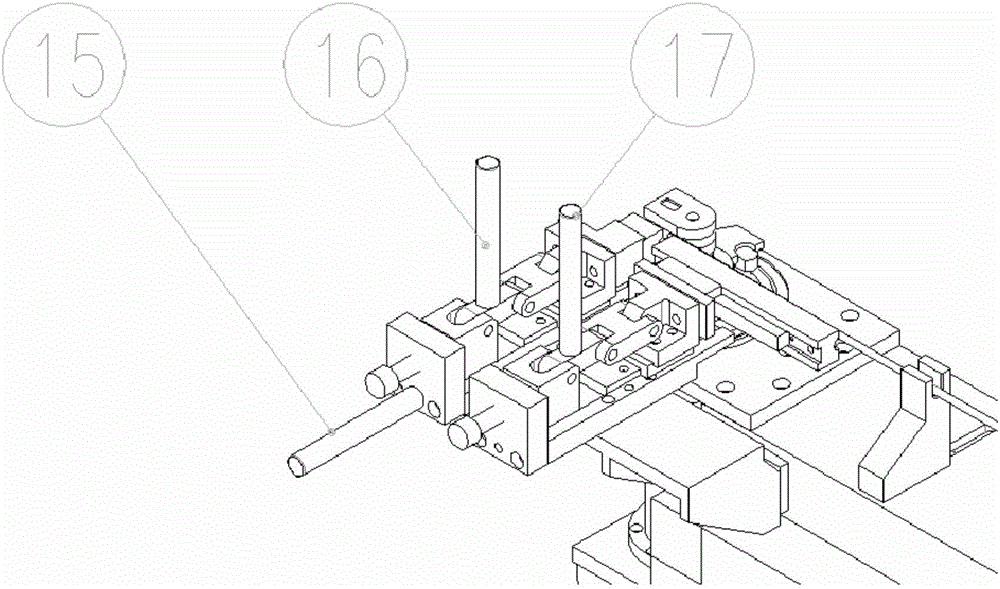

ActiveCN103878520APrevent crushingAvoid scratchesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringExplorator

The invention provides a pre-compressing device. The pre-compressing device comprises a baseplate and a product explorator, and the bottom of the baseplate is provided with support legs. The pre-compressing device is characterized by further comprising a compressing mechanism, a power mechanism and straight guide columns, wherein the compressing mechanism is used for tightly compressing a product and the product exploratory, the power mechanism is used for driving the compressing mechanism to move, the straight guide columns are used for supporting the power mechanism and the compressing mechanism, movable pieces are arranged at joints of the straight guide columns and the compressing mechanism, and the compressing mechanism is driven by the power mechanism to move along the straight guide columns and contacts with a product on the baseplate. By the technical scheme, the pre-compressing device has the advantage that technical effects including precise positioning, simplicity in structure machining, convenience in mounting, small size and space saving are achieved.

Owner:NINGBO CHANGSHENG ELECTRONICS TECH

Hydraulic copy grinding device

The invention relates to a hydraulic copy grinding device. A workpiece and an explorator are both fixed on a workbench; a contact contacts with the explorator; a grinding head contacts with the workpiece; a first hydraulic cylinder is fixed on a rack; the piston of the first hydraulic cylinder is connected with a quick-change working chuck and the grinding head in series; a second hydraulic cylinder is fixed on the rack; one end of a valve plug in the second hydraulic cylinder is connected into the second hydraulic cylinder by a spring, and the other end of the valve plug is connected with the contact; and the first hydraulic cylinder is connected with the second hydraulic cylinder via an oil line. According to the hydraulic copy grinding device, the copy can be stably and accurately realized, the problems of large action force, poor precision and the like of rigid connection can be avoided, so that a thin-wall piece can be successfully grinded and polished, and high-quality surface roughness can be achieved.

Owner:JIANGNAN UNIV

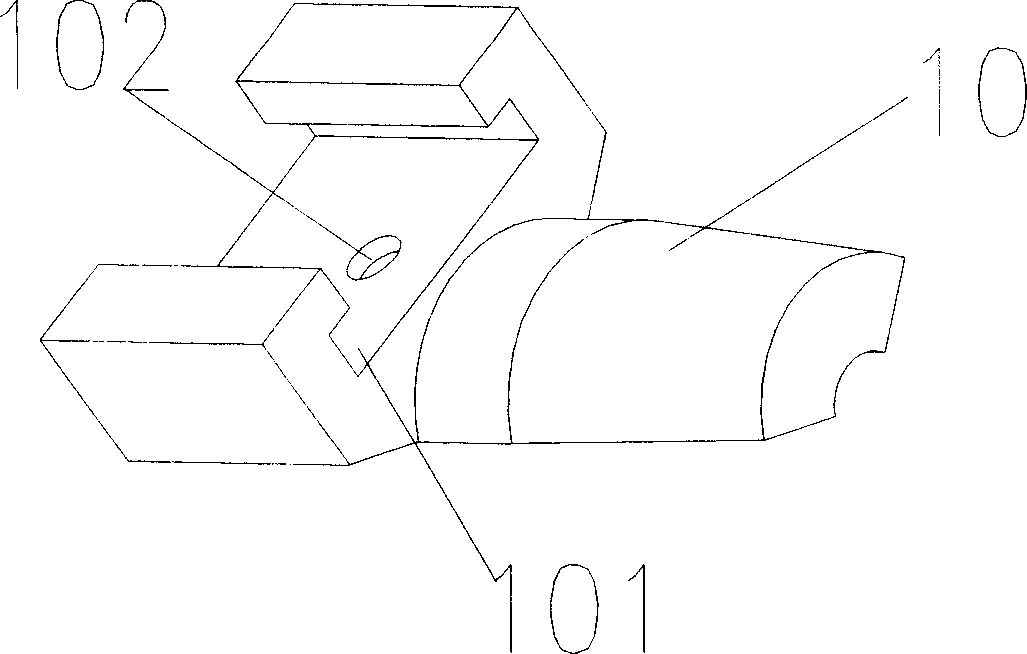

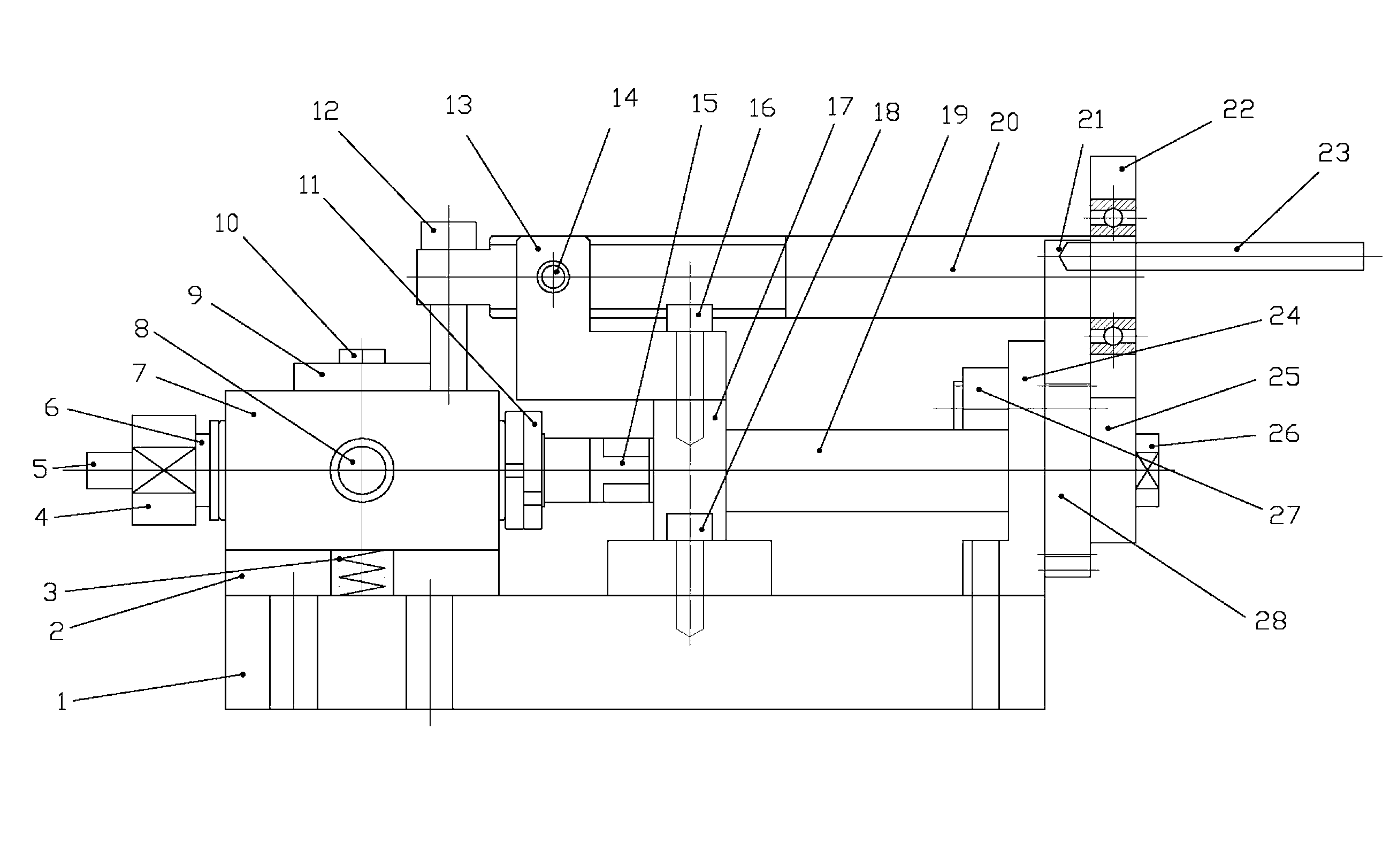

Digital control pipe bending machine

ActiveCN1820869APracticalStrong reliabilityShaping toolsMetal-working feeding devicesEngineeringExplorator

The present invention relates to pipe machining equipment, and is especially one digital controlled pipe bending machine. The digital controlled pipe bending machine includes a control part, a mechanical part and an auxiliary part. The mechanical part includes a frame, a material feeder, a pipe bending unit and a discharging unit. The pipe bending unit includes a circular mold assembly, a sandwich mold, an explorator, and a pusher. The circular mold assembly includes circular mold, circular mold seat and lower pull rod; the sandwich mold is for holding the workpiece and the explorator prevents the bent pipe from springing back.

Owner:GREE ELECTRIC APPLIANCES INC

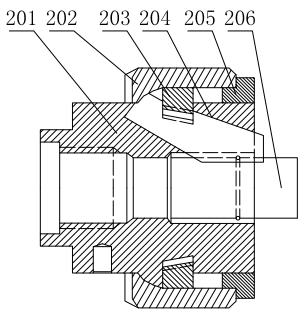

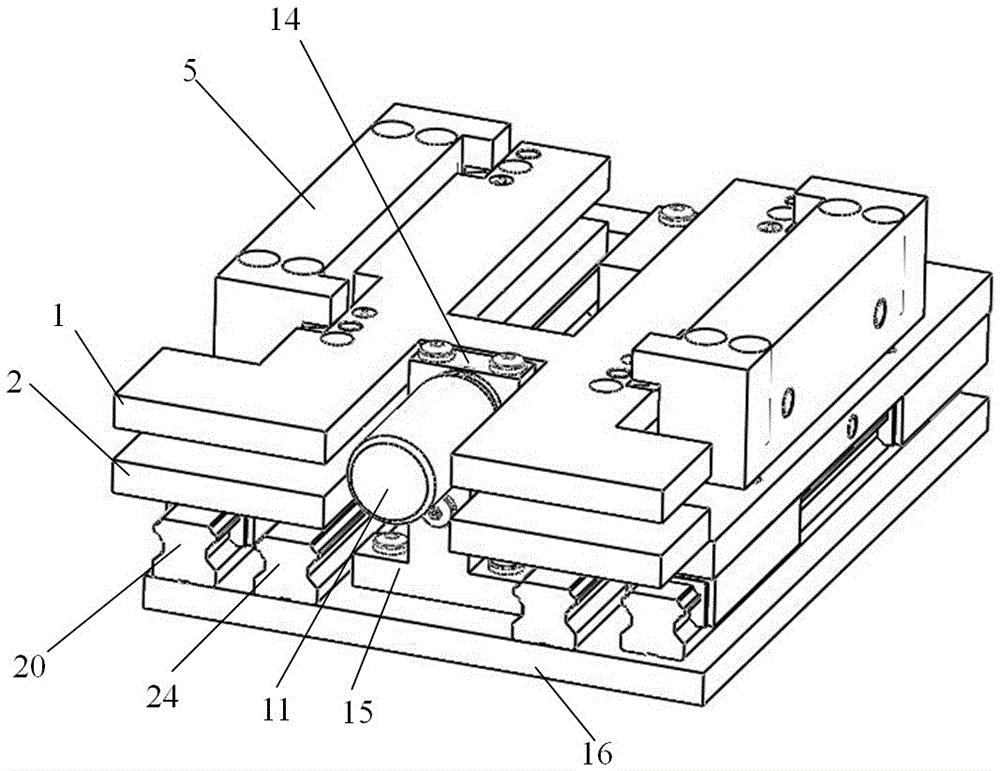

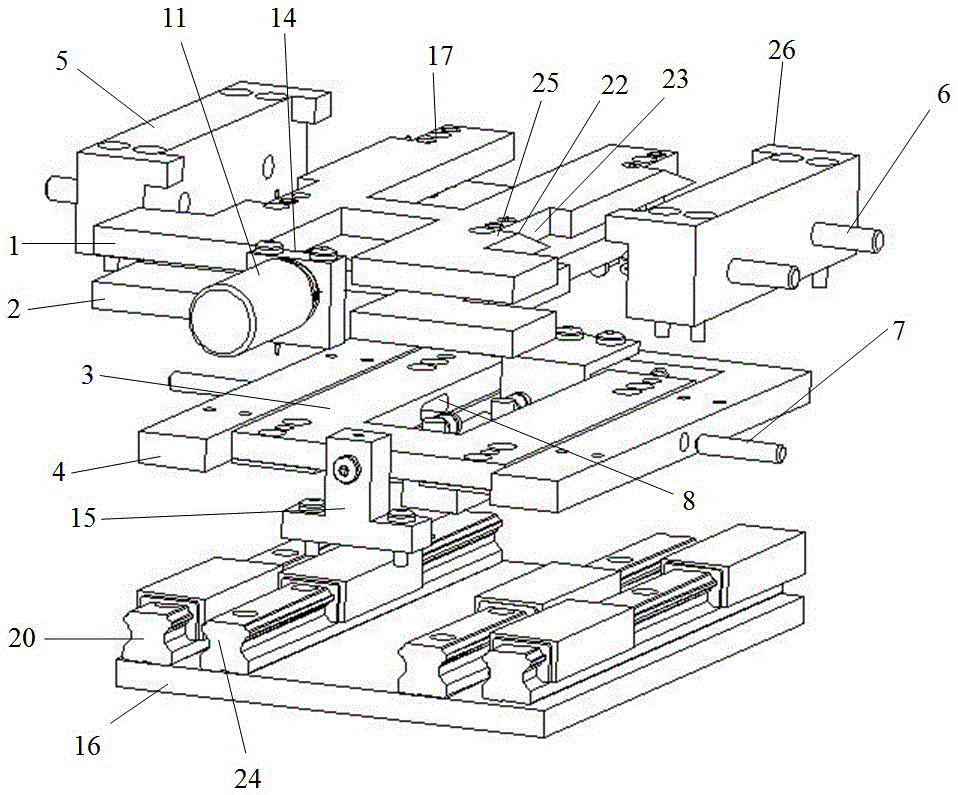

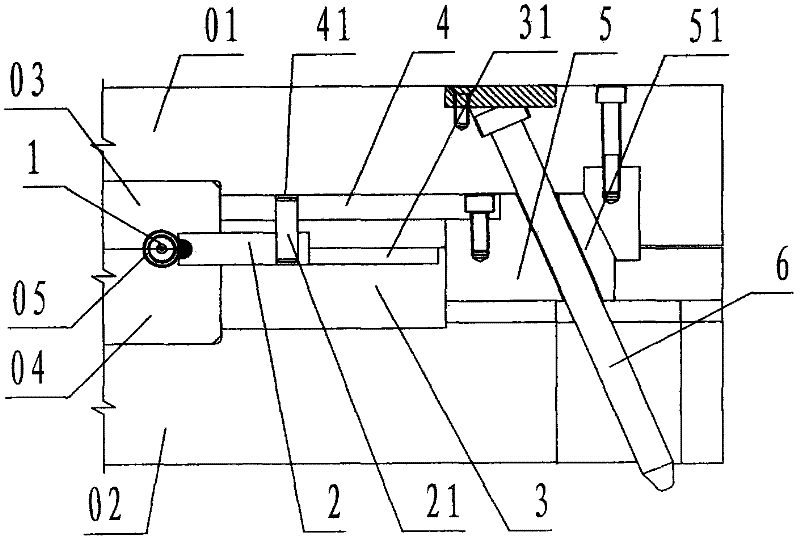

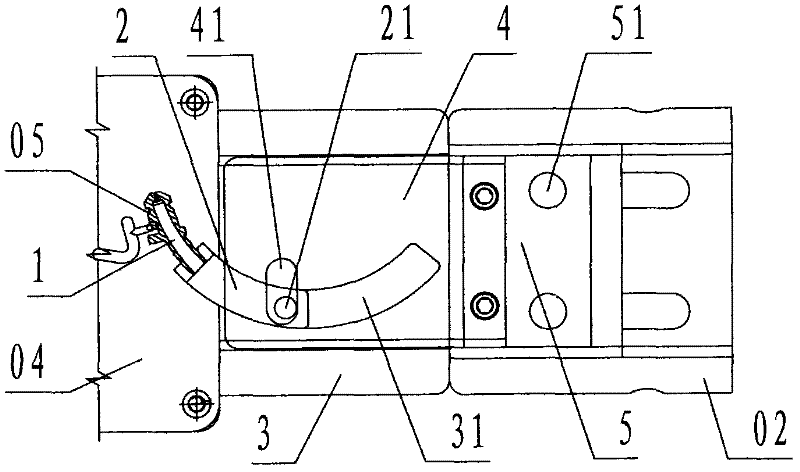

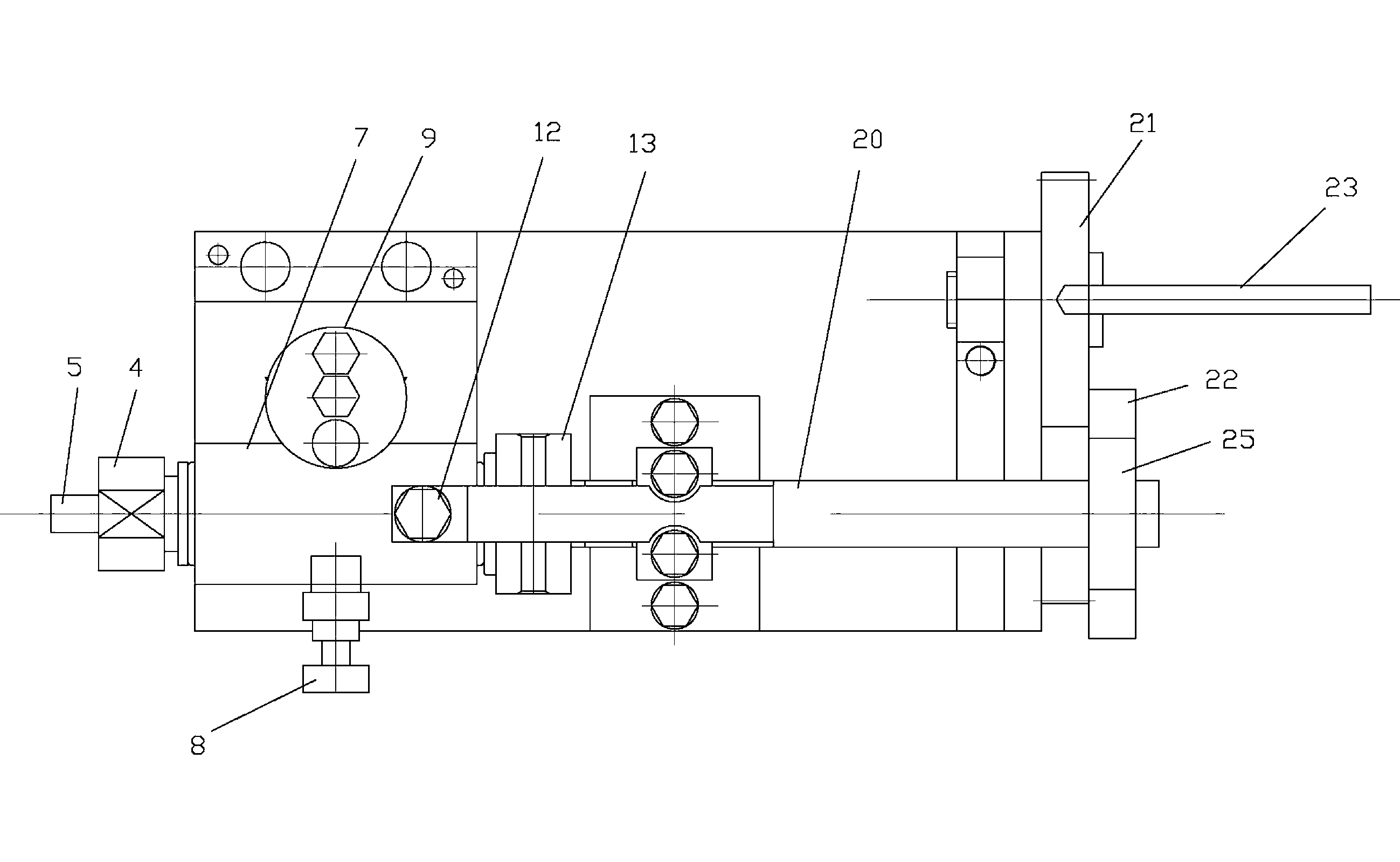

Precise pneumatic clamping mechanical gripper for thin plate type workpiece

ActiveCN105643322AMobile controlConstant clamping forceGripping headsPositioning apparatusEngineeringExplorator

The invention relates to a precise pneumatic clamping mechanical gripper for a thin plate type workpiece. The precise pneumatic clamping mechanical gripper comprises a gripper clamping mechanism, a gripper moving mechanism and an explorator moving mechanism, wherein the gripper clamping mechanism comprises a pair of plate-shaped claws in up-down correspondence, a pair of explorators in left-right correspondence and a positioning mechanism; the gripper moving mechanism comprises a sliding bottom plate and a pair of inner guide tracks; the explorator moving mechanism comprises a U-shaped frame, an air cylinder and a pair of outer guide tracks; the air cylinder is used for driving the pair of explorators to move in a reciprocating manner through the U-shaped frame, and used for controlling the pair of plate-shaped claws to clamp and release in the movement process; meanwhile the pair of claws is moved in a reciprocating manner along the pair of inner guide tracks through the sliding bottom plate. The precise pneumatic clamping mechanical gripper is reasonable in structural design, and all types of action such as overall movement of the mechanical gripper and clamping and release of upper and lower clamping plates of the mechanical gripper can be achieved through the one air cylinder.

Owner:黄山市开发投资集团有限公司

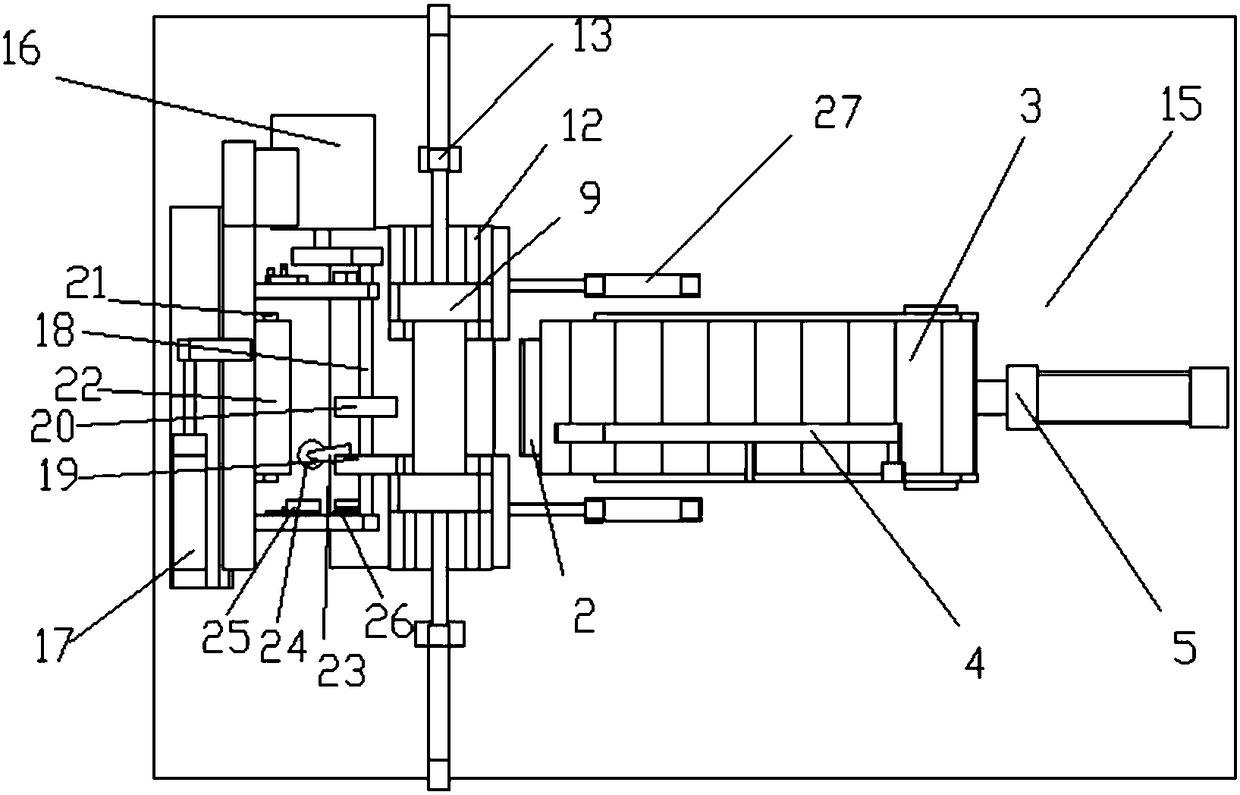

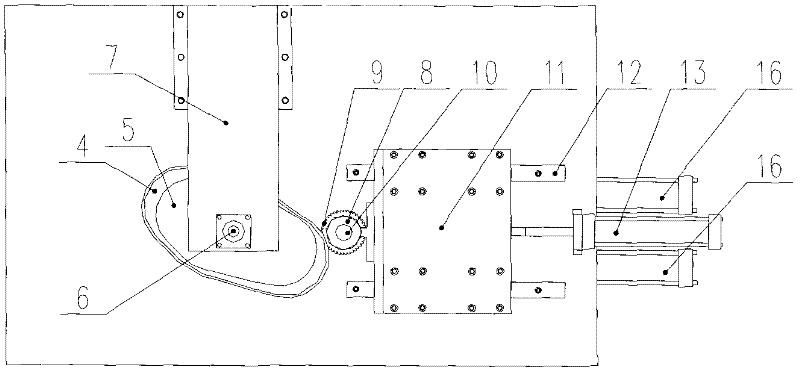

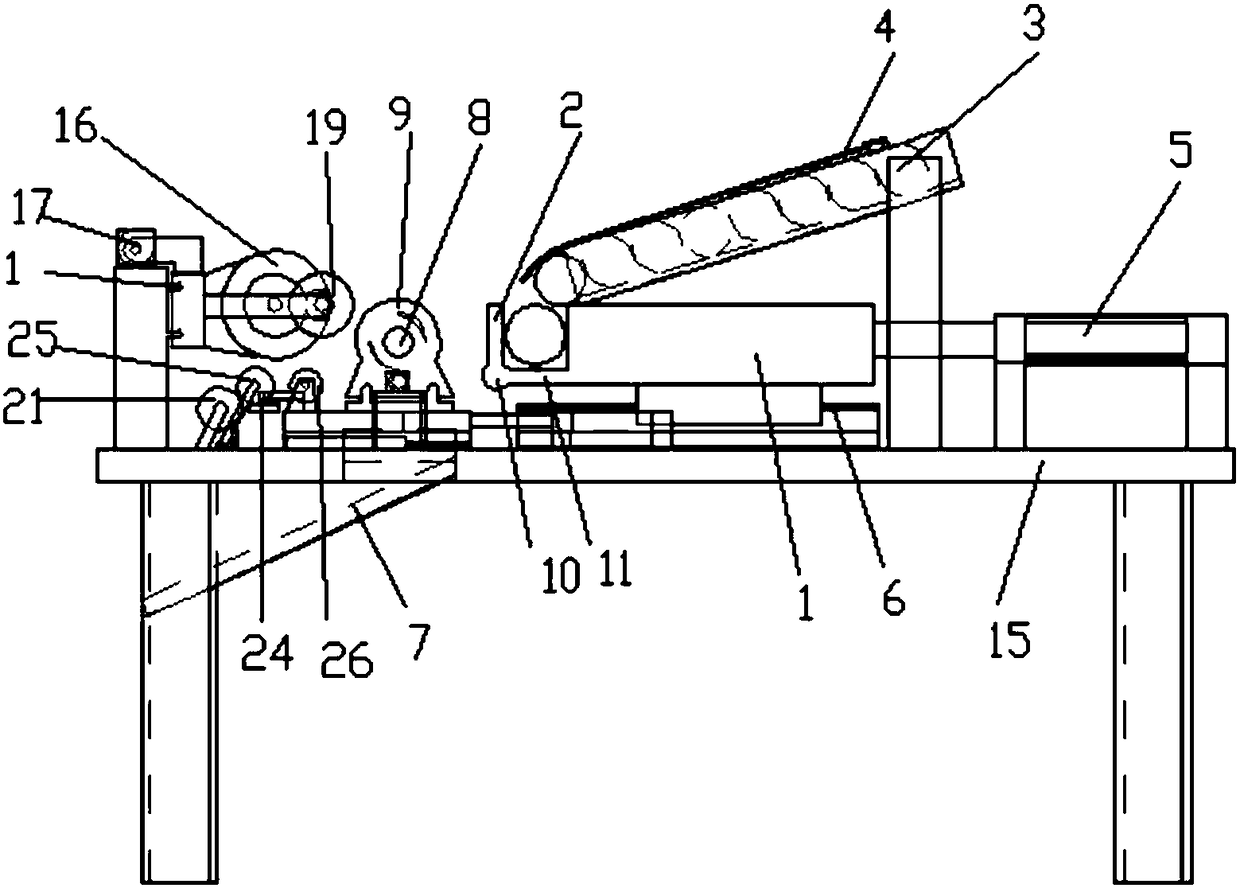

Hammer handle shape machining and polishing device with annular explorator

InactiveCN108311892AImprove processing efficiencyReduce labor costsOther manufacturing equipments/toolsMetal working apparatusExploratorElectric control

The invention relates to the technical field of hammer machining, in particular to a hammer handle shape machining and polishing device with an annular explorator. An electric control box is used forunified control over feeding, clamping, processing and polishing. A blanking device automatically conducts blanking to a conveying device under the effect of the gravity. Automatic conveying, clampingand correction are achieved. A machined hammer handle is conveyed to the position of a machining tool through an explorator cylinder so as to be machined. Meanwhile, the machining distance or the depth is limited through the explorator. A polishing device which coaxially rotates instantly conducts polishing after cutting is completed. Manual operation is not needed in the whole process, so that the machining efficiency is greatly improved, the labor cost is reduced, and the machining precision is high and consistent; and the hammer handle shape machining and polishing device is suitable for large-scale application and popularization.

Owner:SHAODONG HEXIE HARDWARE ELECTROMECHANICAL CO LTD

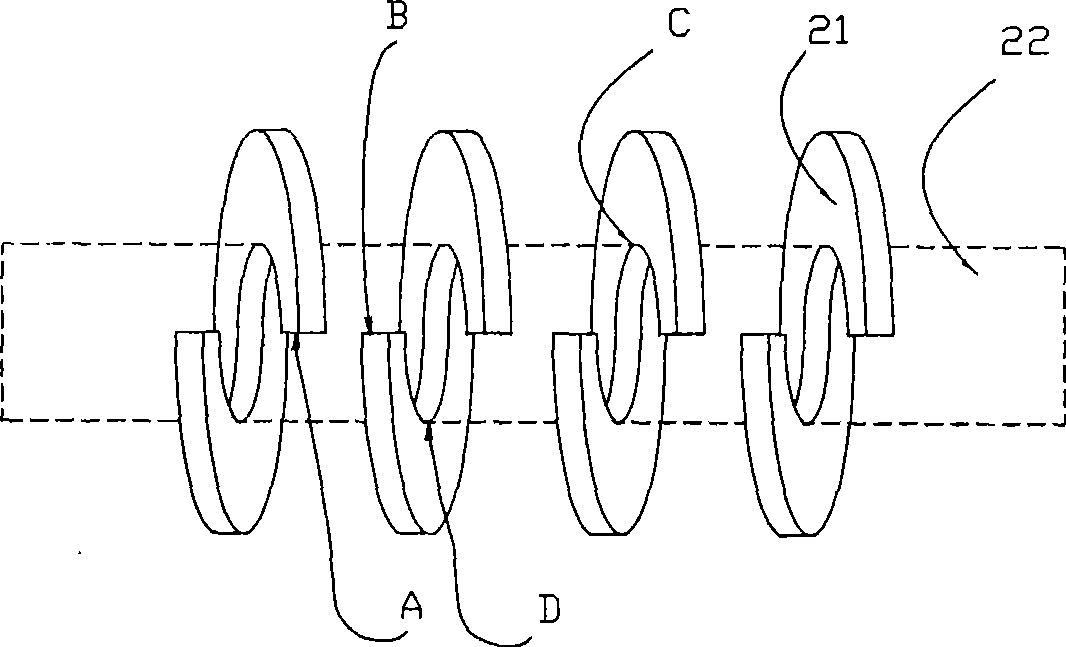

Method and equipment for manufacturing screw rod

The invention relates to a manufacturing method of a screw and manufacturing equipment thereof.. A standard screw is selected as an explorator; the standard screw or the rotation shaft of the screw to be processed are driven by a motor so that the standard screw or the rotation shaft of the screw to be processed can synchronously rotate by a transmission mechanism; a flat steel bar is heated by a welding gun; the edge of the flat steel bar burned to red by the welding gun is distorted and heated along the rotation shaft of the screw to be processed with the rotation of the screw tooth of the standard screw, so as to form the prefabricated screw tooth of the screw; subsequently, the welding rod of the welding gun is aligned to the joint seam between the prefabricated screw tooth and the initial end of the surface of the rotation shaft; the prefabricated screw tooth rotates along the rotation shaft while being welded, thus forming a screw consistent with the standard screw. Compared with the prior art, the method and the equipment overcome the problems that the efficiency is low and the quality is not easy to be ensured as the single ring of screw tooth is welded end to end; furthermore, no rim leftover is generated by a punching ring, the working efficiency is improved by times, and the production cost is obviously reduced.

Owner:赵援宁

Method for processing alnico magnetic sheet

InactiveCN101552130AGuarantee product qualityReduce manufacturing costInductances/transformers/magnets manufactureMagnetic materialsMagnetizationWire cutting

The invention discloses a method for processing an alnico magnetic sheet, which comprises the following steps of: firstly measuring the magnetization direction of an alnico magnet hair dry compact and positioning an S-N center direction; using a high-precision surface grinder for grinding a product meeting the requirement of thickness tolerance and then implementing cutting by wire cutting machine; using an angle explorator for grinding an angle meeting the requirement of tolerance by the high-precision surface grinder; using a mu-meter to pull the product parallelism for controlling the consistency of the products; using a projector to measure the dimension of the product workpiece; removing the burrs and adding walnut powder to a centrifuge for implementing surface processing to the products; adopting multi-chip products for implementing uniform processing and finally conducting uniform cutting and also finishing the last dimension processing on a mold; and using a degausser to eliminate the residual magnetism of the products. The method for processing the alnico magnetic sheet adopts the conventional processing equipments such as surface grinder, wire cutting machine, digital measurement projector, mu-meter, Tesla meter and the like, and also adopts a self-made angle mold and a self-made processing and clamping mold, thereby ensuring the product quality and simultaneously lowering the production cost.

Owner:江苏熙友磁电科技有限公司

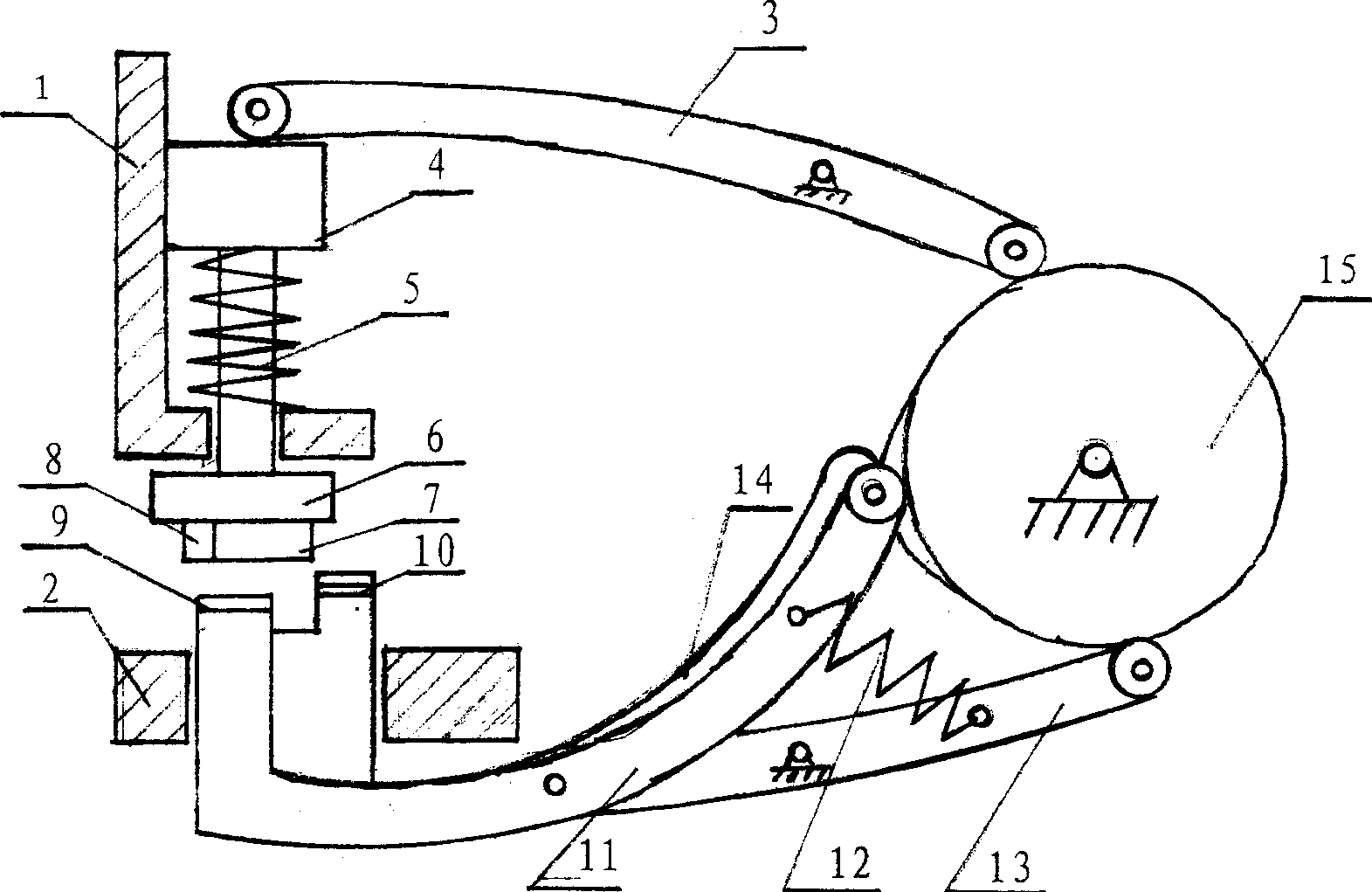

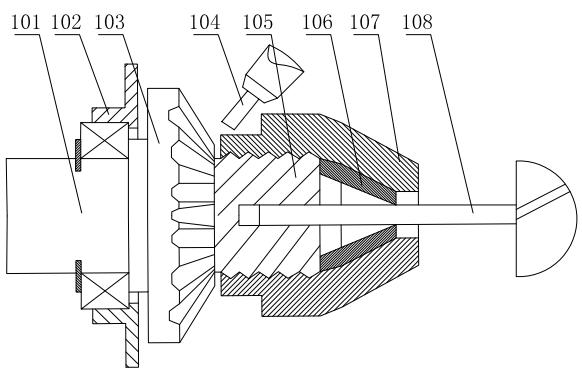

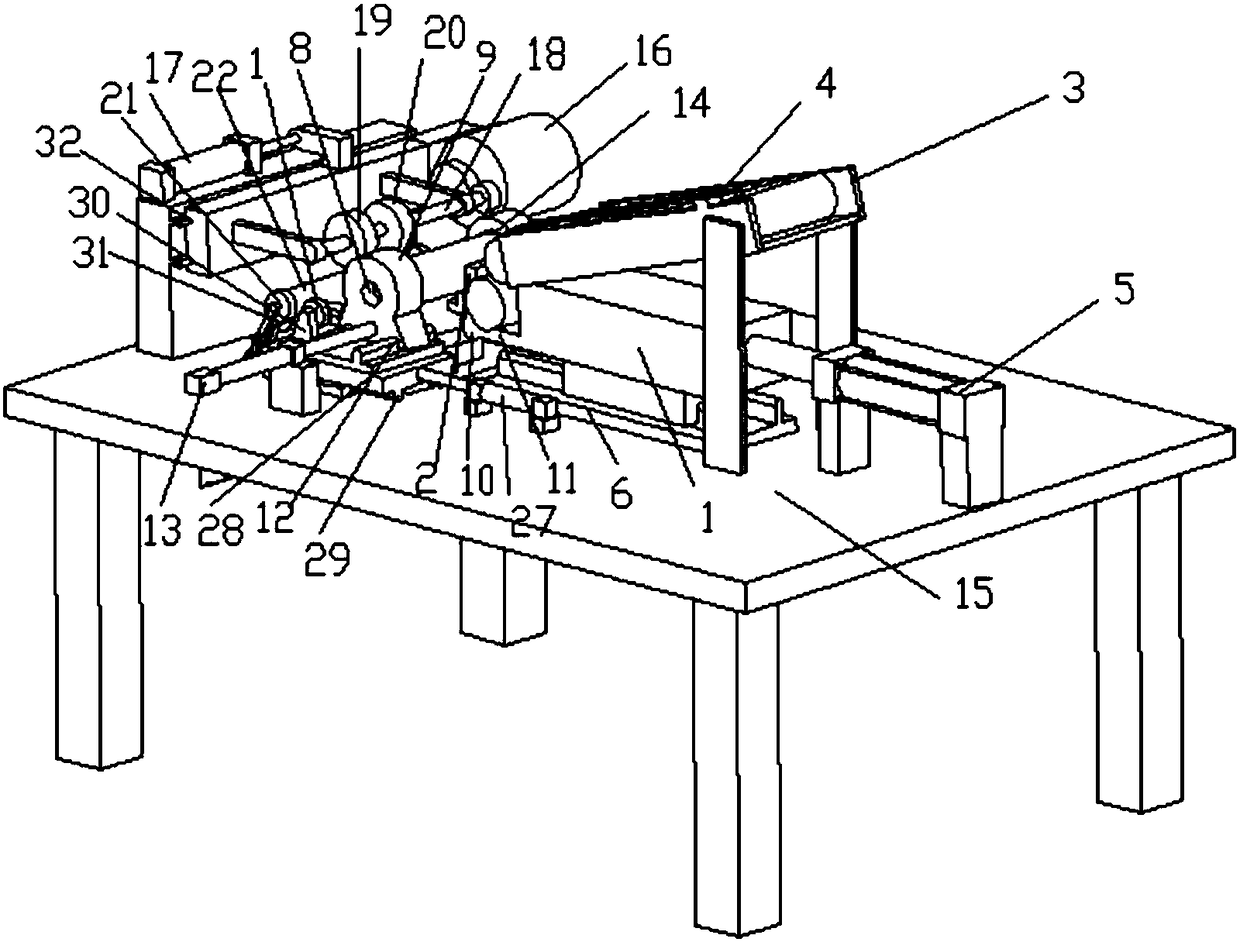

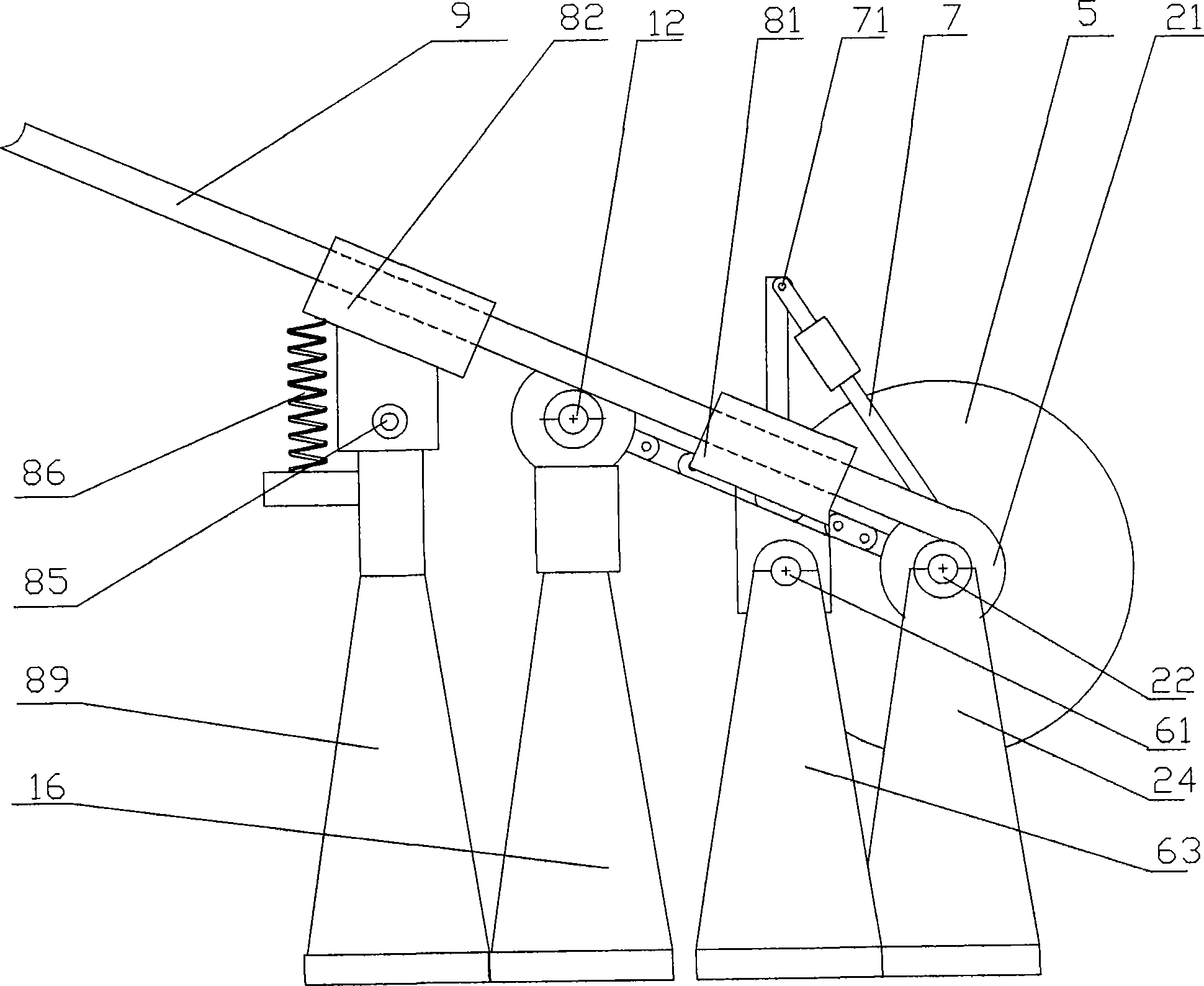

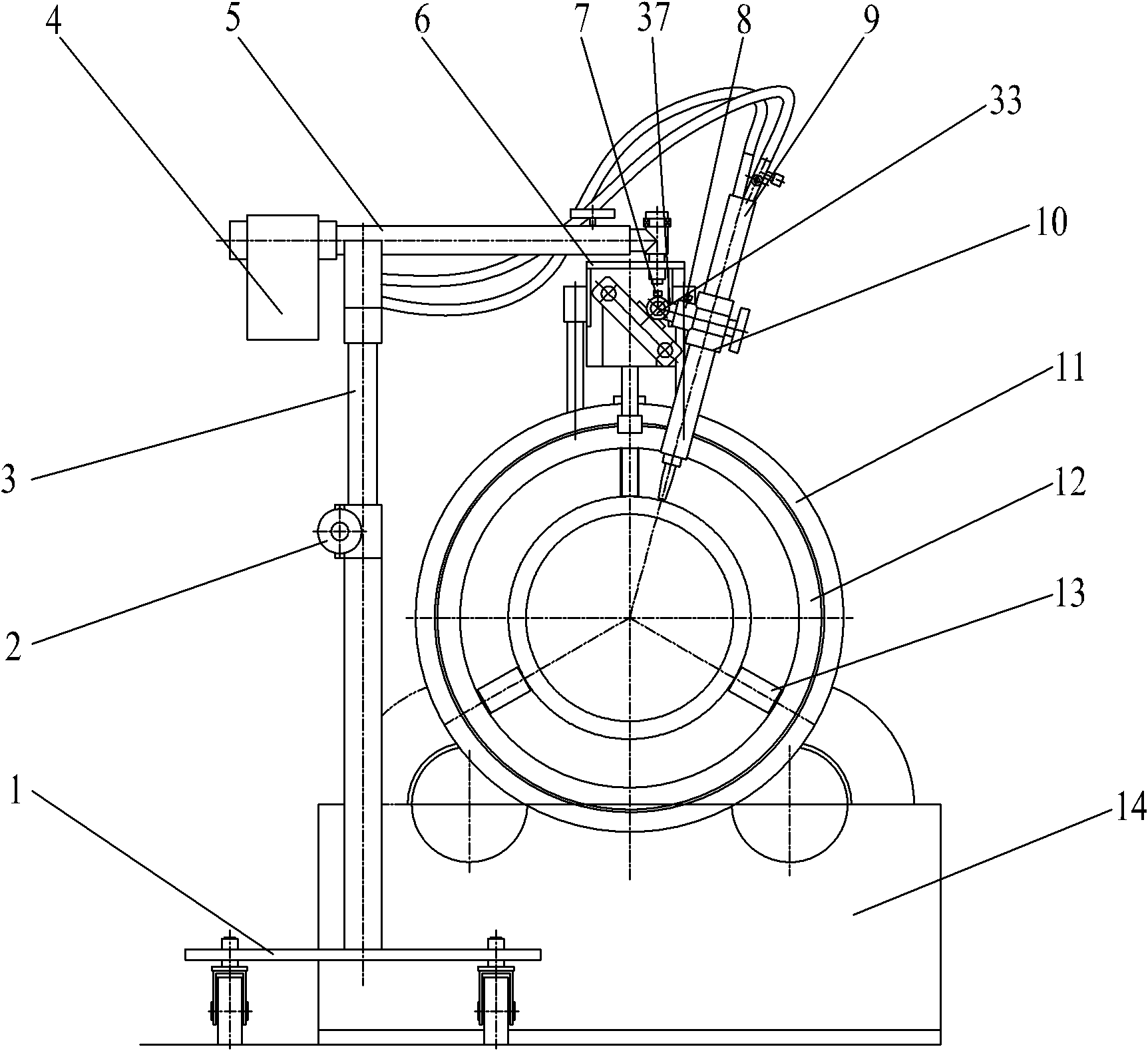

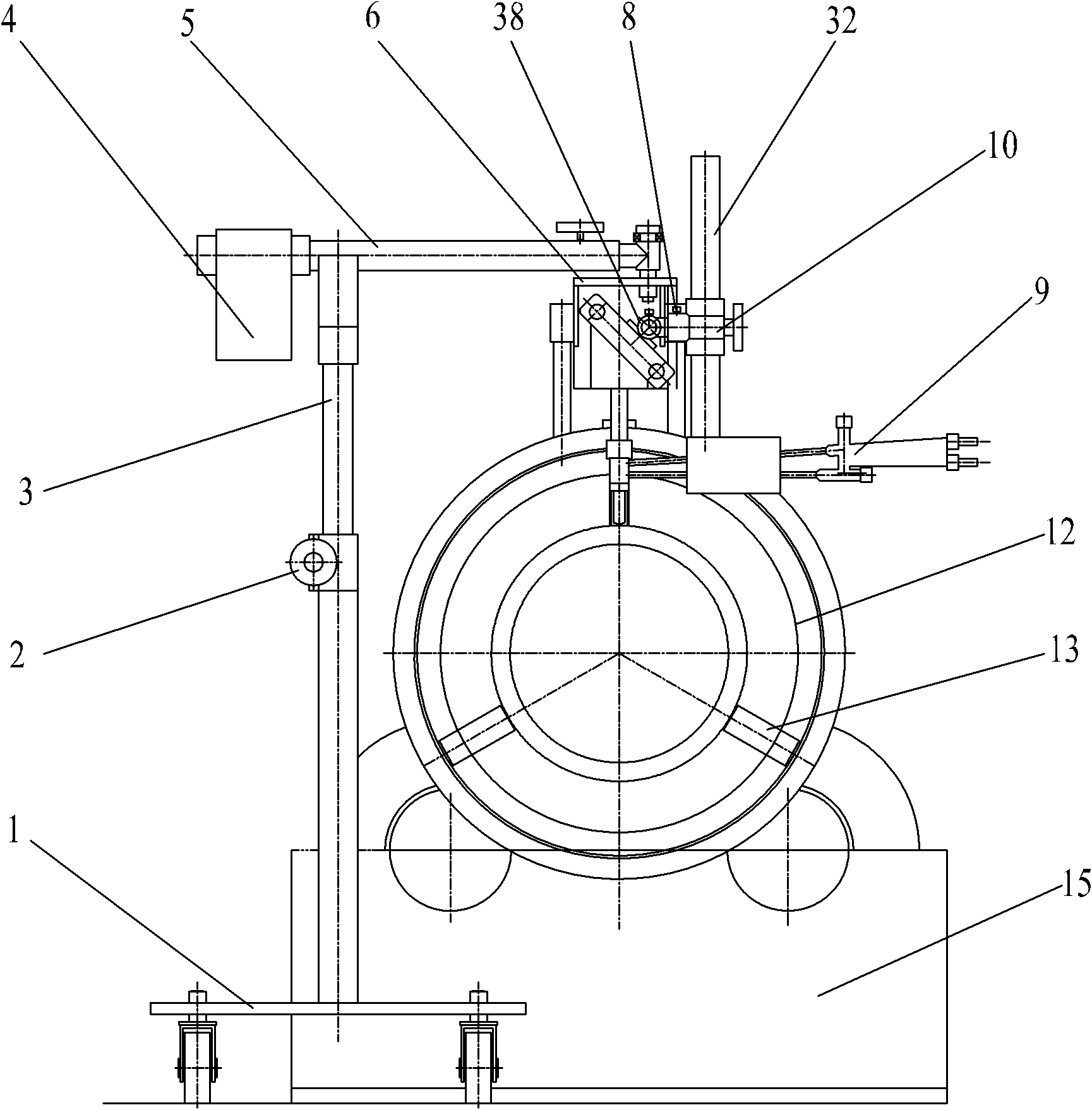

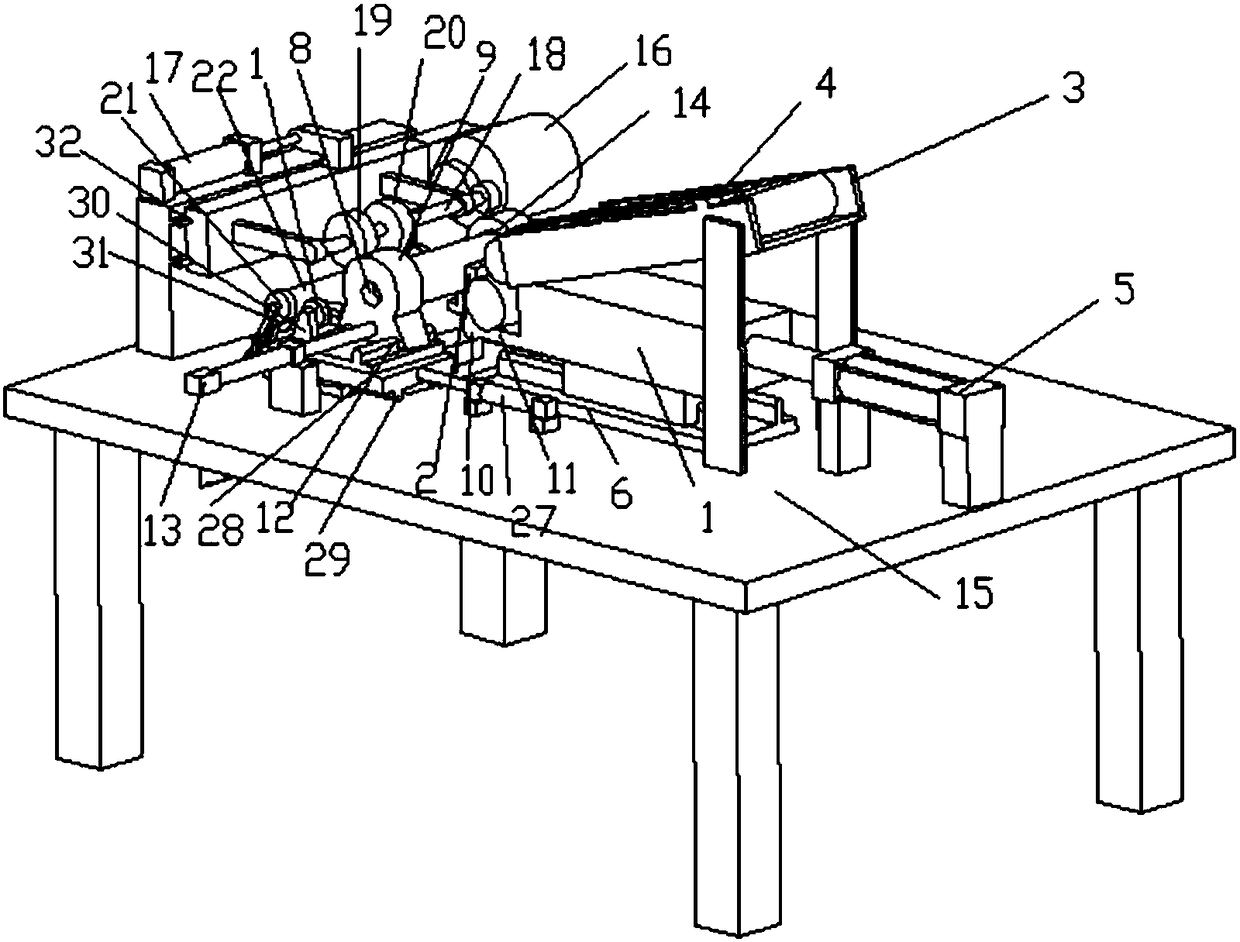

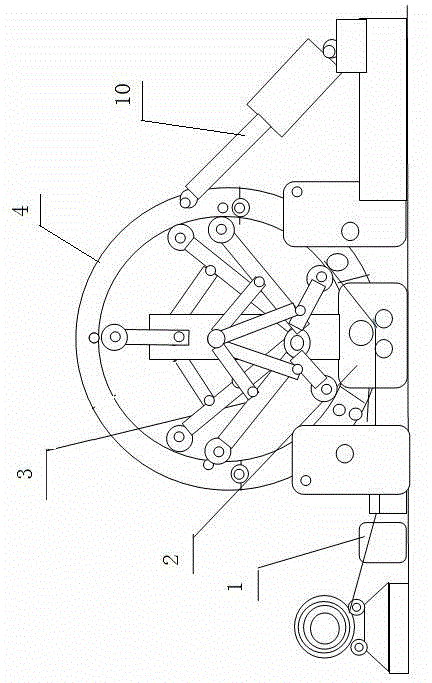

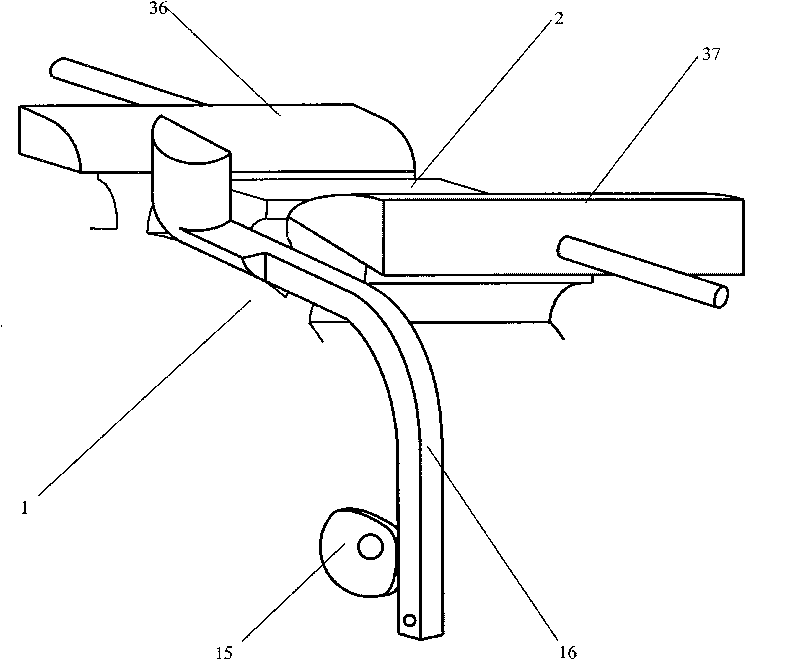

Manual three-dimensional pipe bending machine

The invention discloses a manual three-dimensional pipe bending machine. The machine comprises a machine frame, a clamping die (1), a bending die (2), a following explorator (4), a core shaft rod, a first handle (15), a second handle (16), a third handle (17) and a center shaft, wherein the clamping die (1), the bending die (2) and the following explorator (4) are arranged at one end of the machine frame, the core shaft rod is arranged at the other end of the machine frame, the first handle (15) is provided with a rotary arm and used for pushing the bending die to bend pipes, the second handle (16) and the third handle (17) are used for pushing the clamping die and the following explorator to clamp the pipes, and the center shaft is used for fixing the bending die and is much longer than the rotary arm. The three-dimensional pipe bending machine is simple in structure and convenient to operate.

Owner:ZJMECH TECH

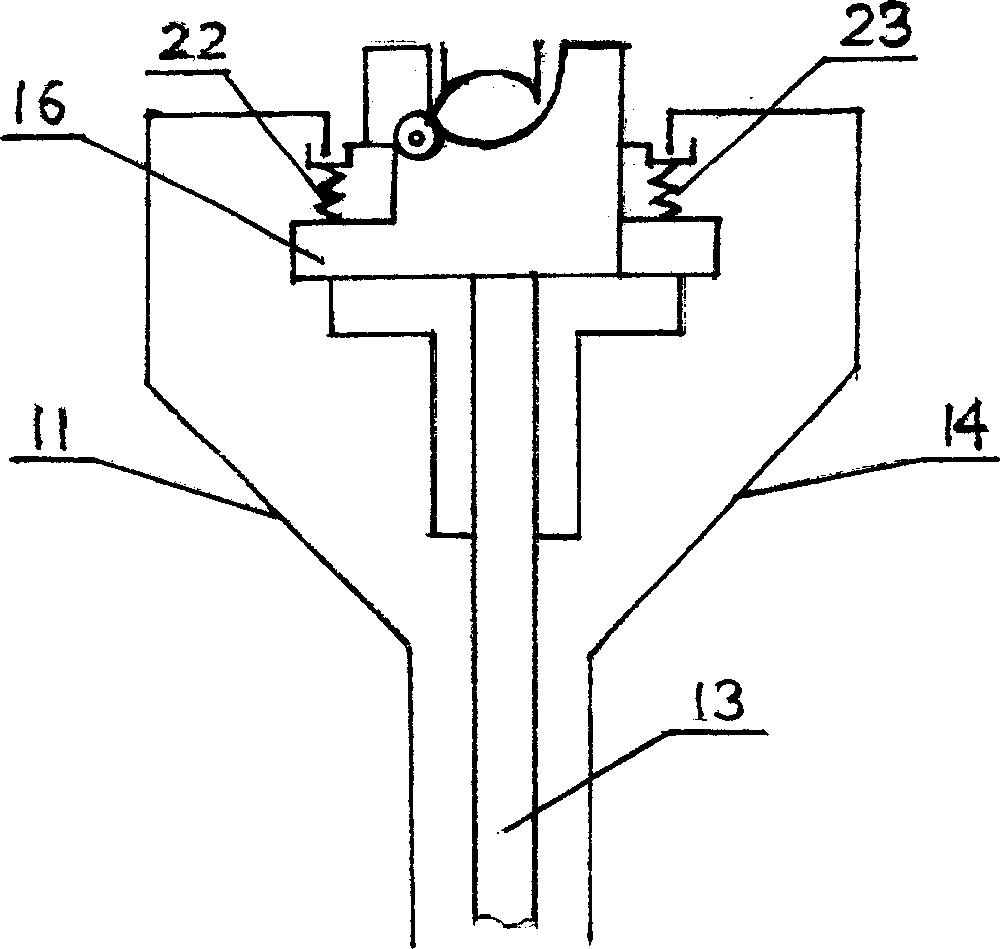

Saddle-shaped pipe end cutting device

The invention relates to a saddle-shaped pipe end cutting device, comprising a roll-over stand and a base, wherein the base is provided with a stand column which is provided with a cross arm; end part of the cross arm is provided with a hanging bracket by a pin roll; the hanging bracket comprises a s bracket body which is provided with a slider shaft; the slide shaft is in slip connection with a slider which is provided with a regulating spring; the slider is provided with a cutting torch adjusting sleeve in a hinged mode, and the cutting torch adjusting sleeve is provided with a cutting torch; a fixed pinch roller and a movable pinch roller are arranged at the lower part of the bracket body; a locating sleeve is arranged between the movable pinch roller and the fixed pinch roller; the locating sleeve is provided with an explorator; the fixed pinch roller and the locating sleeve are in rolling contact opposite to the other side the side in which the explorator is arranged; and the movable pinch sleeve and the explorator are in rolling contact. The saddle-shaped pipe end cutting device of the invention has the advantages of compact structure, low processing cost and high processingprecision and is convenient to process and operate, is used for saddle-shaped pipe ends and cutting processing of beveled edges of the saddle-shaped pipe ends, and processing of parallel and level pipe ends and cutting processing of beveled edges of the flush pipe ends.

Owner:WUXI HUAGUANG IND BOILER

Special-shaped edge trimmer

InactiveCN102500816ABacklash to offset meshingTroubleshooting Damaged Cutting ToolsMetal sawing devicesCopying process control systemsExploratorPiston

The invention discloses a special-shaped edge trimmer which comprises a rack. A center shaft is arranged on a center shaft seat. The center shaft seat is arranged on the rack. An explorator is arranged on a flange at one end of the center shaft. An upper die is arranged on a piston of a die pressing oil cylinder. A cylinder body of the die pressing oil cylinder is arranged on a die pressing oil cylinder seat. The die pressing oil cylinder seat is arranged on the rack. An explorator wheel and a cutting saw blade are arranged on a cutter shaft. The cutter shaft is arranged on a cutter seat. The cutter seat is arranged on a guide rail. The guide rail is arranged on the rack. A cylinder body of a cutter seat working cylinder is arranged on the rack. A piston part of the cutter seat working cylinder is connected with the cutter seat. The cutter seat ensures the explorator wheel to be clung to the explorator. A center shaft gear is arranged at the shaft end of the center shaft. A rack is meshed with the center shaft gear under the action of a rack limit wheel. A piston of a rack working oil cylinder is connected with the rack. The invention solves the problem that a machine cannot normally work because a cutting tool is damaged due to instant acceleration of rotation of the explorator of the special-shaped edge trimmer.

Owner:东莞市亚峰五金机械有限公司

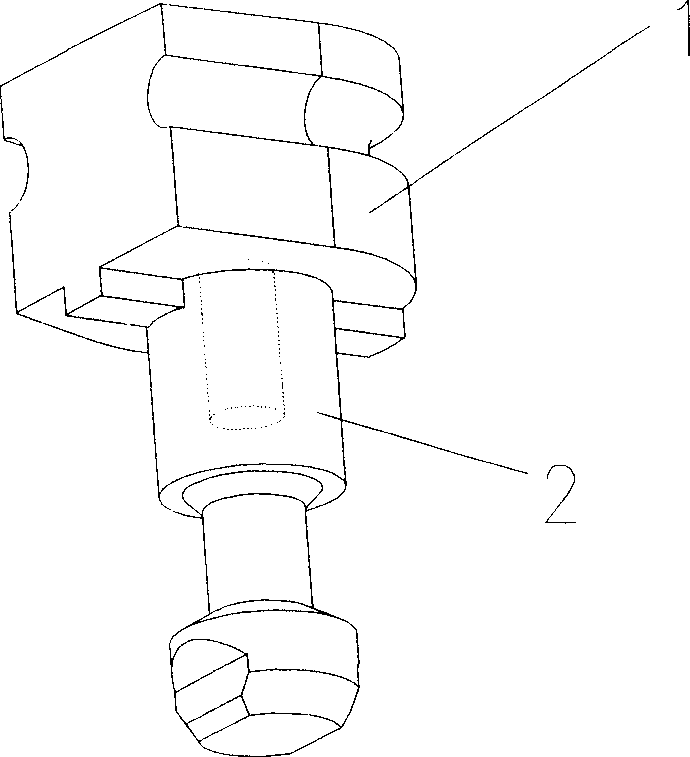

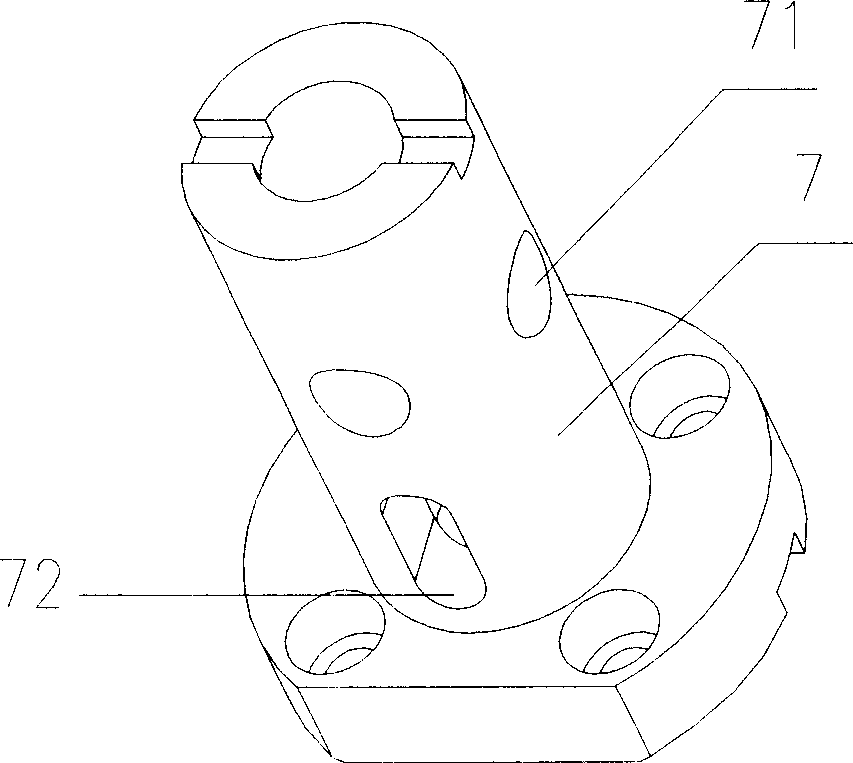

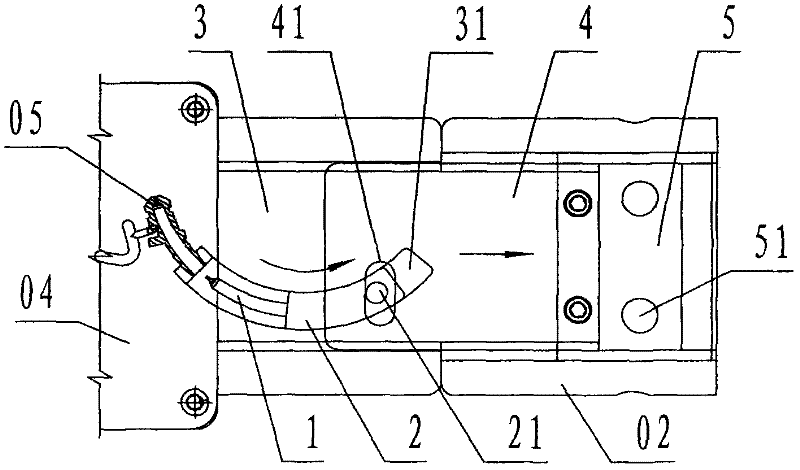

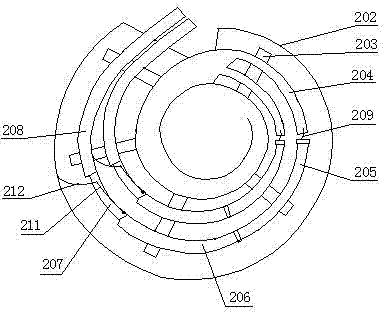

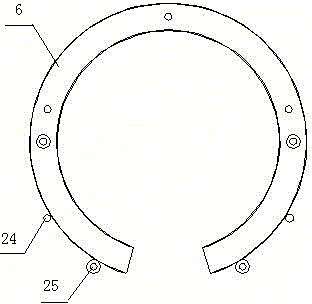

Explorator core loosing apparatus for arc sliding core

The invention discloses an explorator core loosing apparatus for an arc sliding core. The apparatus comprises an arc loosing core (1), an arc slide block (2), an explorator (3) and a drive board (4). According to the invention, the apparatus composed of the arc loosing core, the arc slide block, the explorator and the drive board is utilized for opening a die, an inclined guide pillar drives a transverse slide block and the drive board to move transversely, a poking aperture in the drive board draws a poking pin on the arc slide block and drives the arc slide block with one end connected withthe arc loosing core to slide in an arc guiding chute of the explorator, and the arc slide block drives the arc loosing core to pull out a core from an arc bore tunnel of a product along the arc track of the arc guiding chute; therefore, the problems and shortcomings of complex construction, large volume, high cost and low reliability in the prior art are overcome; utilization of an injection mould which pulls out a core from a product that is provided with an arc bore tunnel by using the explorator core loosing apparatus enables the purposes of simplifying construction, reducing volume and cost and improving reliability to be realized.

Owner:NINGBO SHUANGLIN MOULD CO LTD

Fixed bead ring processing method

The invention discloses a fixed bead ring processing method which can ensure locating hole machining precision, save work materials and shorten processing cycle. The fixed bead ring processing method comprises the following steps: cutting; punching a bottom hole of a 16 taper hole by a punching die; punching the inner / outer diameter of a fixed bead ring by a punching die, and processing front and rear fixed bead rings by different dimensions of moulds; softly grinding the front planes and the reverse planes of the fixed bead rings; drilling two locating holes and chamfer angles by a locating hole jig; premilling a 16-hole conical surface; softly grinding the front planes and the reverse planes of the fixed bead rings; turning the inner / outer diameters of a fixed bead rings and chamfer angles; processing round position hole and chamfer angles, including processing the front fixed bead ring: drilling round position holes and the chamfer angles by a jig; and processing the rear fixed bead ring: drilling semi-circle position holes and chamfer angles by a milling die; quenching with a continuous furnace, and tempering with a chamber furnace; hard grinding the front plane and the reverse plane of the fixed bead ring; precisely processing the diameter of the 16 bottom hole to the required demands with the aid of a bottom hole ream die and a reamer; reaming the two locating holes with a locating hole ream die; aligning 16-taper hole datum plane chamfer angles by using an explorator; precisely grinding the front plane and the reverse plane of the fixed bead ring; and boring and milling the 16-hole conical surface.

Owner:WUJIANG SHUANGJING BEARING

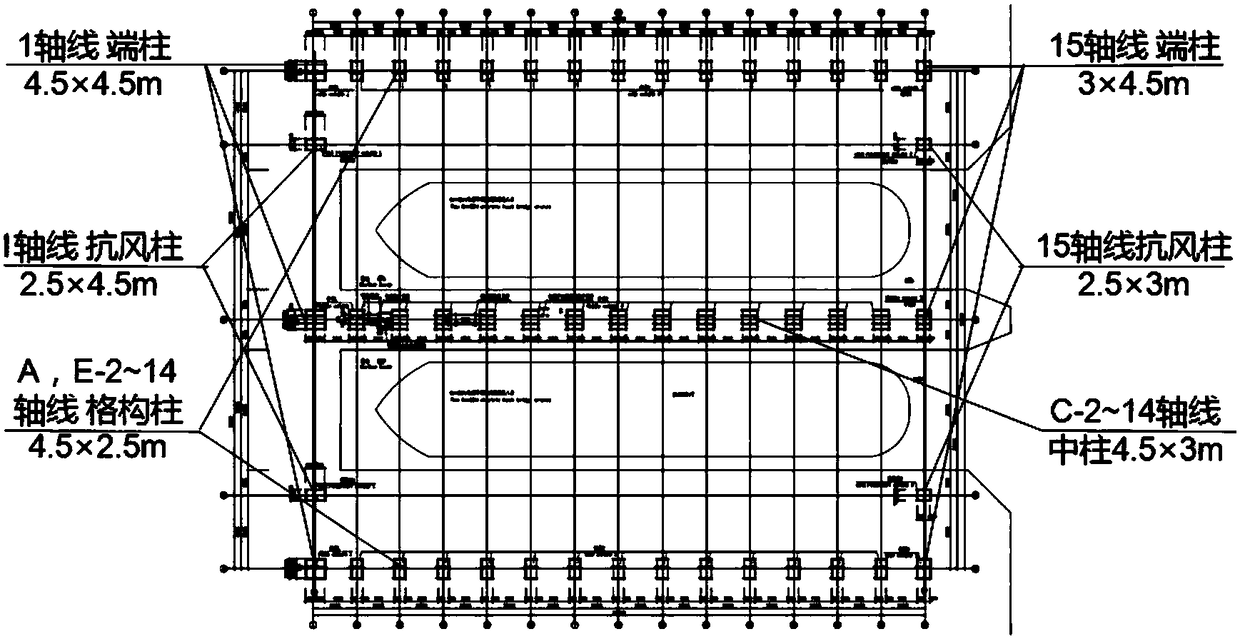

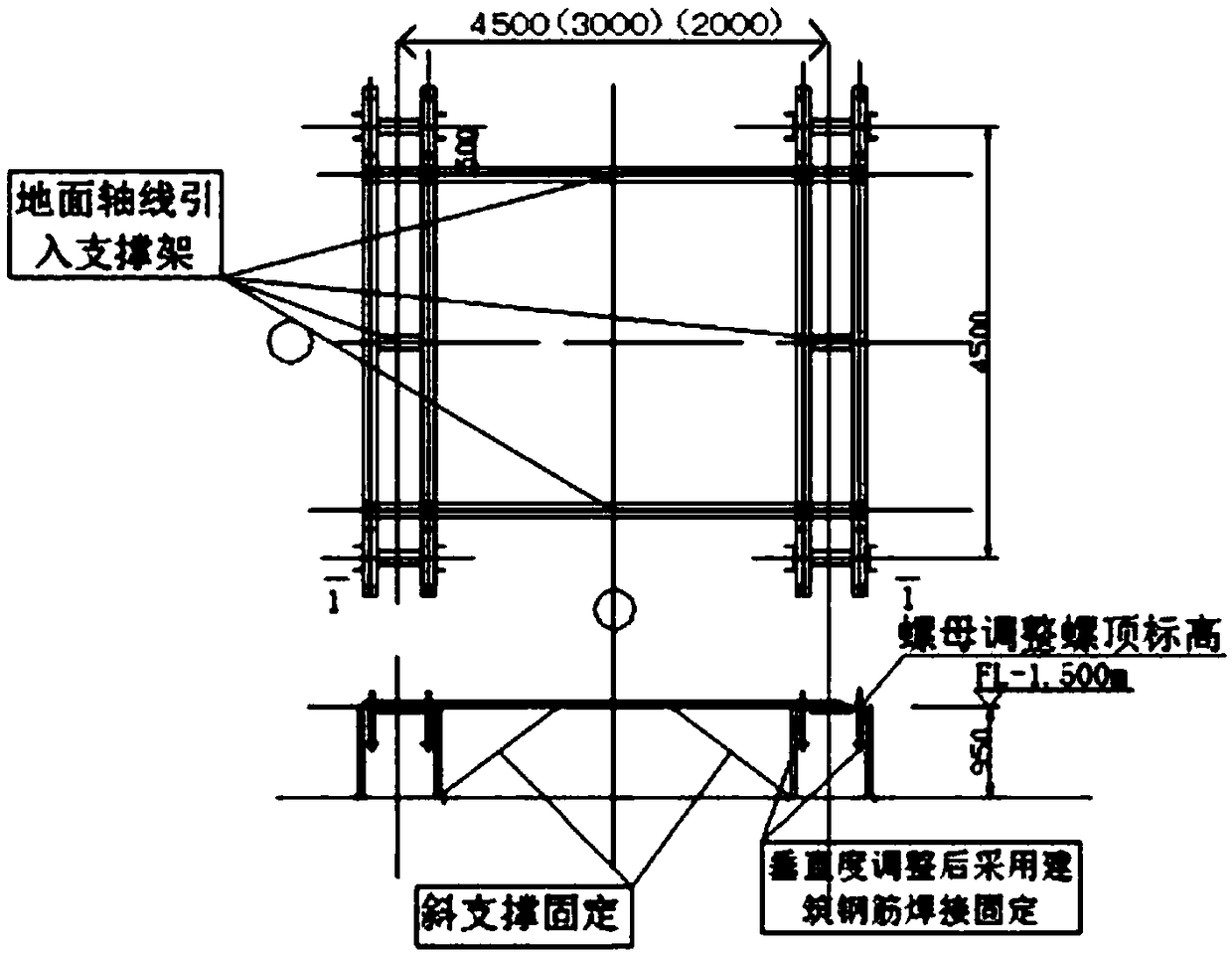

Construction technology of extra-large steel structure canopy under severe conditions

The invention discloses a construction technology of an extra-large steel structure canopy under severe conditions. The construction technology of the extra-large steel structure canopy under severe conditions comprises the steps that for graphic design drawings of the extra-large steel structure canopy, the TEKLA software is adopted to check and correct the graphic design drawings of the extra-large steel structure canopy based on a three-dimensional technology, so that all structural components can be accurately staked out; for the assembly and manufacture of large components in the extra-large steel structure canopy, location of an explorator is realized by means of surface positioning or hole positioning; for the installation of extra large section steel columns in the extra-large steel structure canopy, effective anti-rolling reinforcement is carried out, and a foundation anchor is inbuilt by a positioning bracket technology. An all-weather steel structure canopy construction scheme enables steel structural components to be accurate in size and hole positions are matched, thereby effectively avoiding the repair work of the components caused by the design and manufacturing quality problems; at the same time, the entire construction scheme has high safety and security, effectively reduces engineering risks, and can effectively ensure the progress, quality and safety of a construction project.

Owner:CCCC THIRD HARBOR ENG

Cast-in-situ construction method of beam flange plates of acoustic barriers through movable mold base vehicles

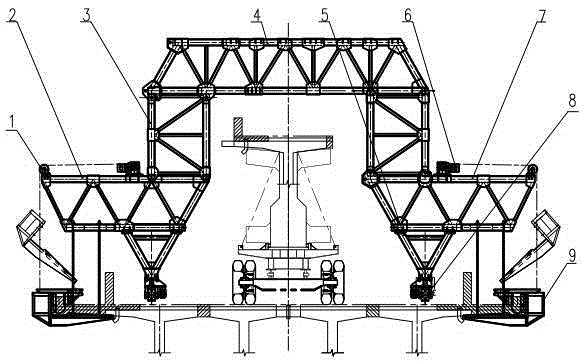

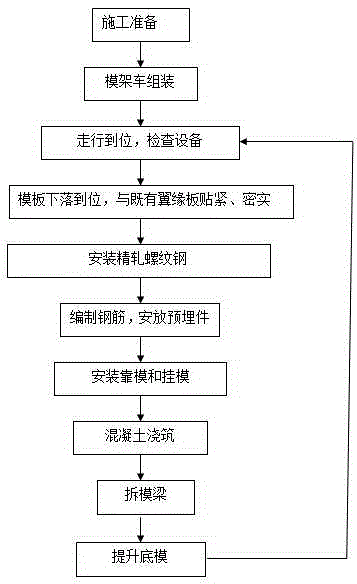

InactiveCN105401525AEasy to operateGood stability and securityNoise reduction constructionBridge erection/assemblyEngineeringExplorator

The invention discloses a cast-in-situ construction method of beam flange plates of acoustic barriers through movable mold base vehicles, and relates to the technical field of bridge construction. The cast-in-situ construction method comprises the specific construction technological processes of preparing for construction; assembling the mold base vehicles; enabling the mold base vehicles to run to proper positions, and inspecting equipment; enabling templates to drop off to proper positions; enabling finish rolling screw-thread steel to be mounted; binding reinforcing bars, and placing embedded parts; mounting hanging molds and explorators; casting concrete; disassembling molds; lifting bottom molds and shifting to another site. According to the construction method disclosed by the invention, the problem that the cast-in-situ construction of flange plates of a high pier is difficult is solved; besides, the construction method is safe and reliable, and is simple and convenient to apply.

Owner:CHINA RAILWAY SIXTH GROUP

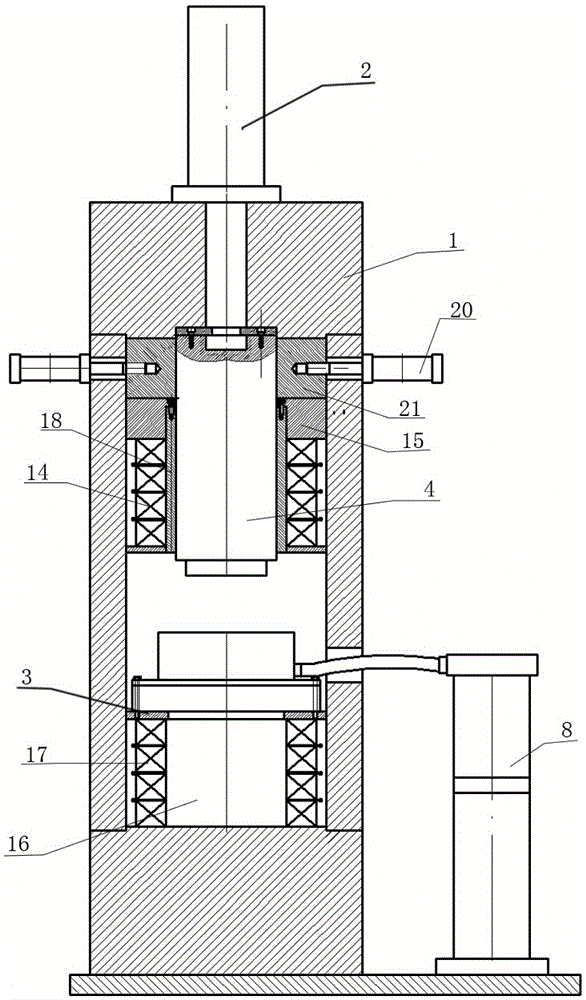

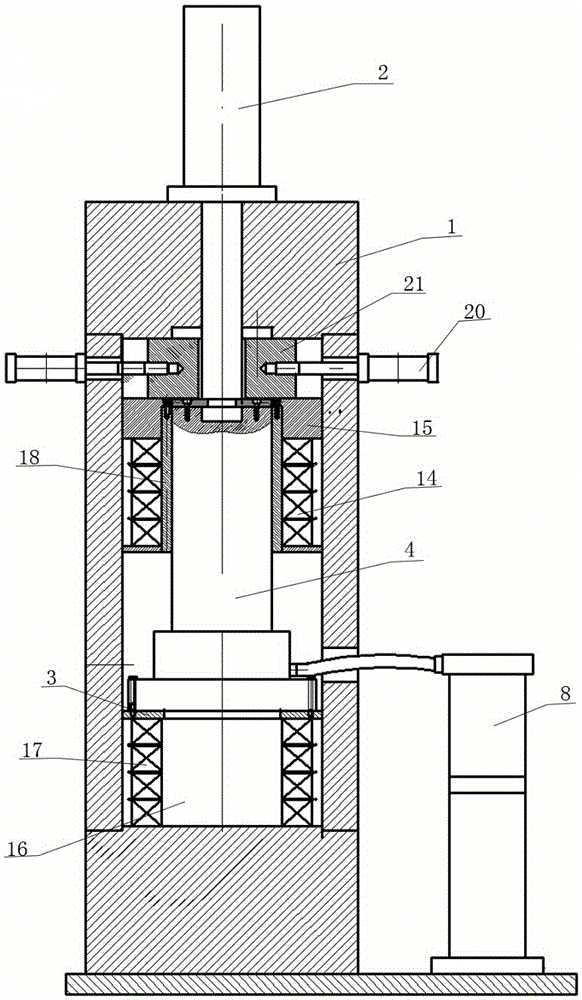

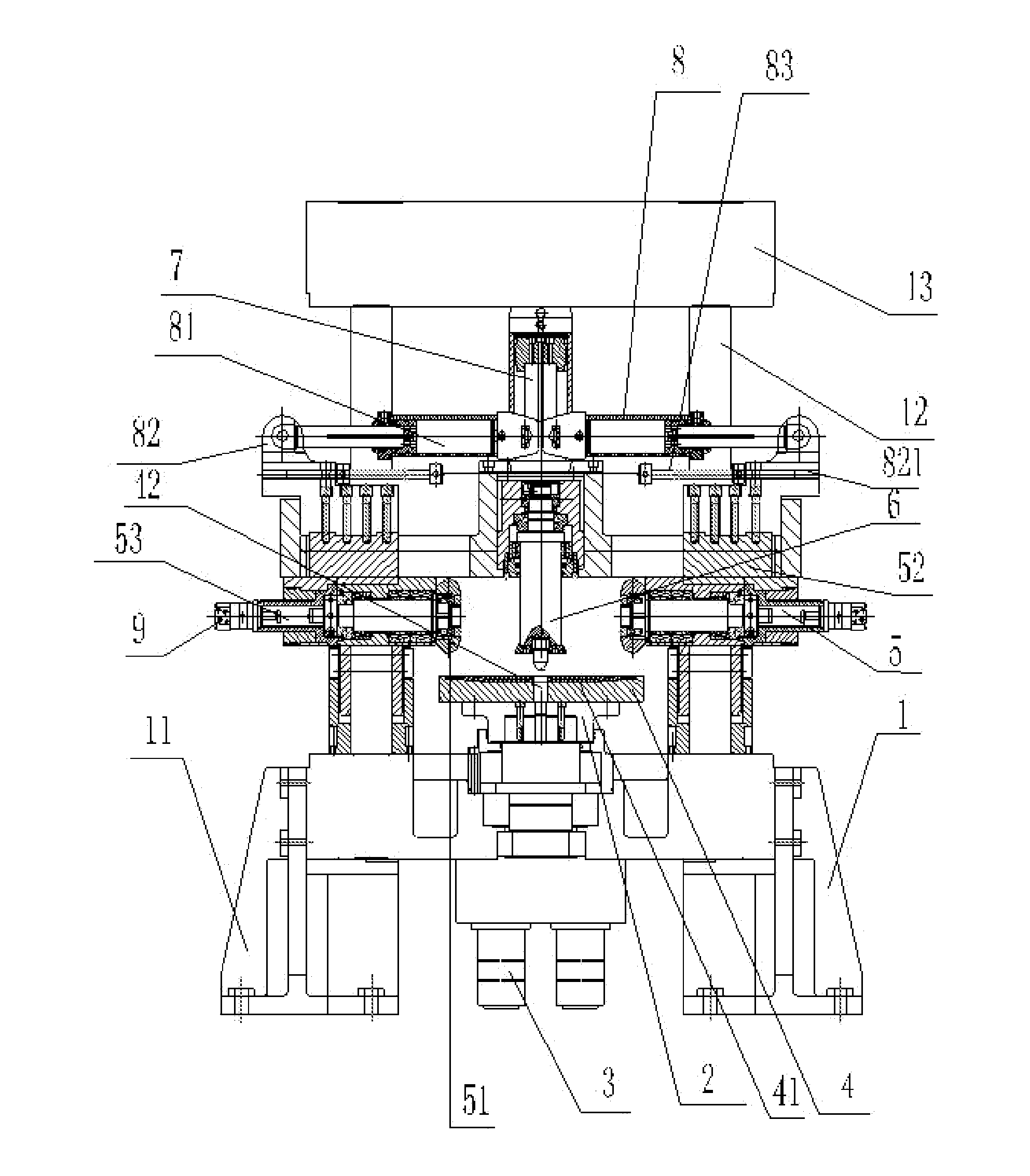

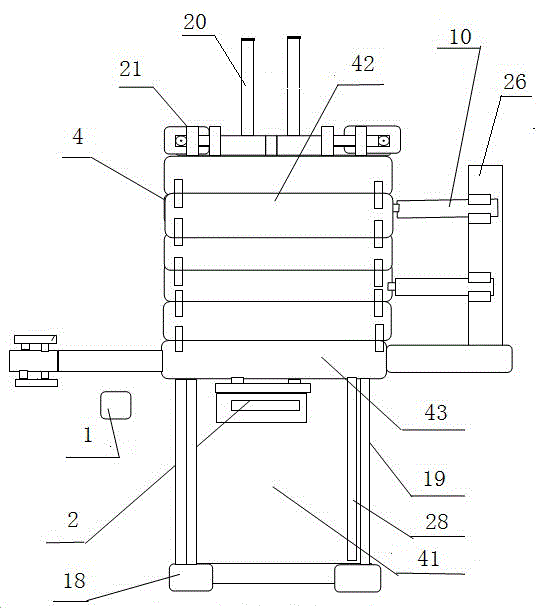

Magnetic-field isostatic press provided with film dry bag

The invention relates to an isostatic press for magnetic powder formation, in particular to a magnetic-field isostatic press provided with a film dry bag. By adoption of the magnetic-field isostatic press provided with the film dry bag, the problems that an existing magnetic-field isostatic press cannot press non-circular workpieces, is low in efficiency and cannot achieve automation easily, and the intensity of an oriented magnetic field is low are solved. The magnetic-field isostatic press provided with the film dry bag comprises a rack. An upper oil cylinder is arranged at the top of the rack. A workbench is arranged in the middle of the rack. An isostatic mold is placed on the workbench. Oriented magnetic field devices are arranged above and below the isostatic mold. The isostatic mold comprises a high-pressure cavity and the dry bag in the high-pressure cavity. The dry bag is composed of a supporting connection part which is located on the upper portion and is in seal connection with the inner wall of the high-pressure cavity and a working part which is located on the lower portion. A porous breathable rigid explorator is further fixed in the high-pressure cavity. The working part of the dry bag is made of a film material. A magnetic powder tamping mechanism is further arranged outside the high-pressure cavity. The magnetic-field isostatic press provided with the film dry bag can be used for pressing non-circular workpieces and is high in automation degree, and the intensity of an orientated magnetic field is high.

Owner:董中天

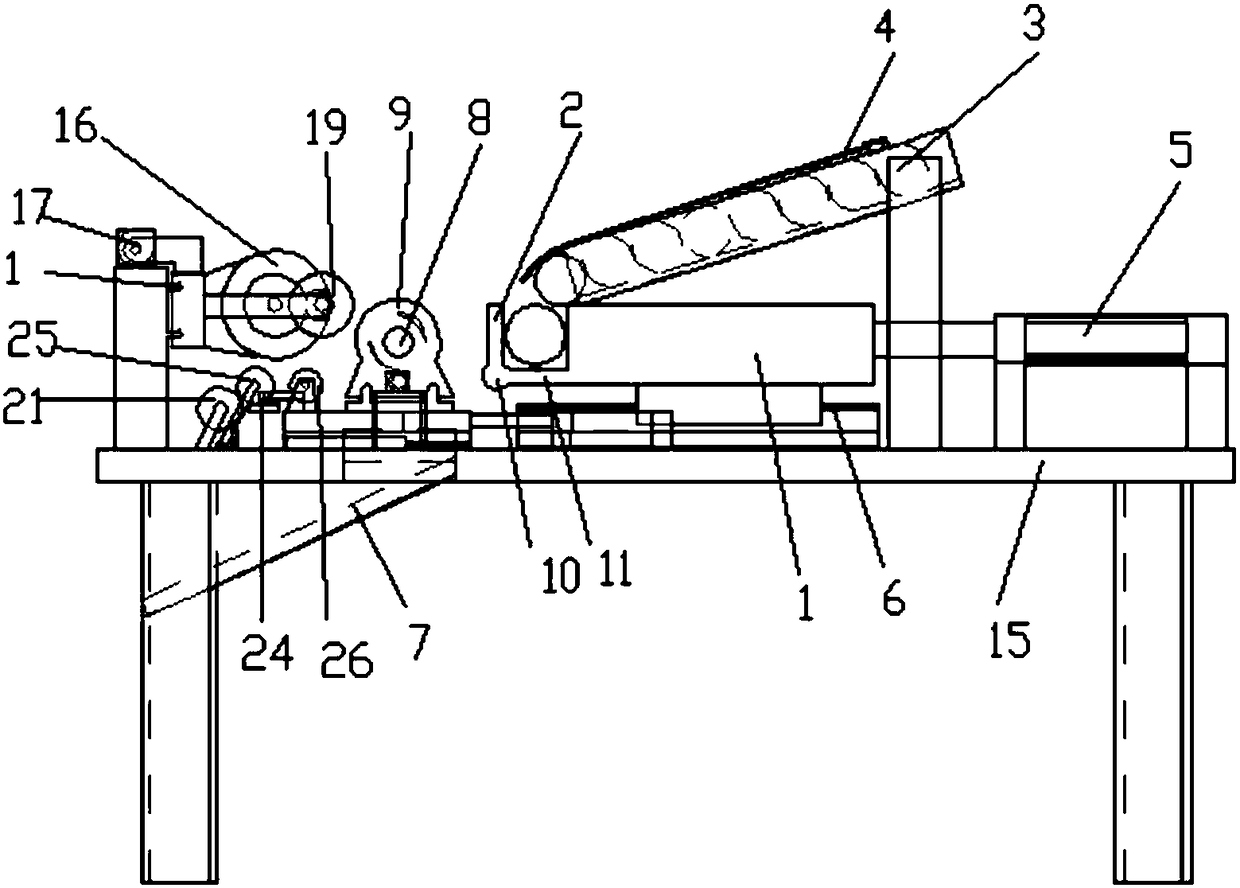

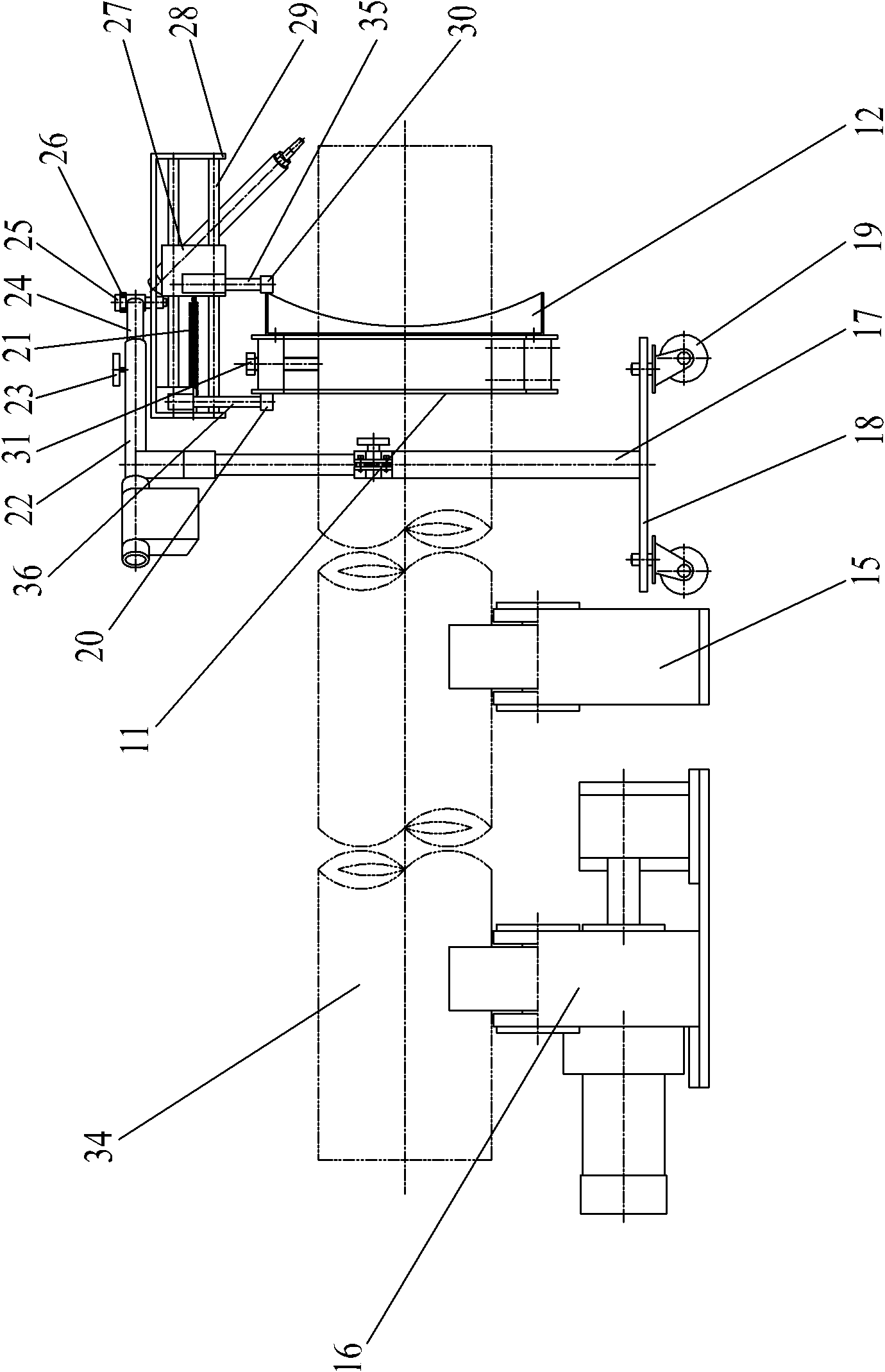

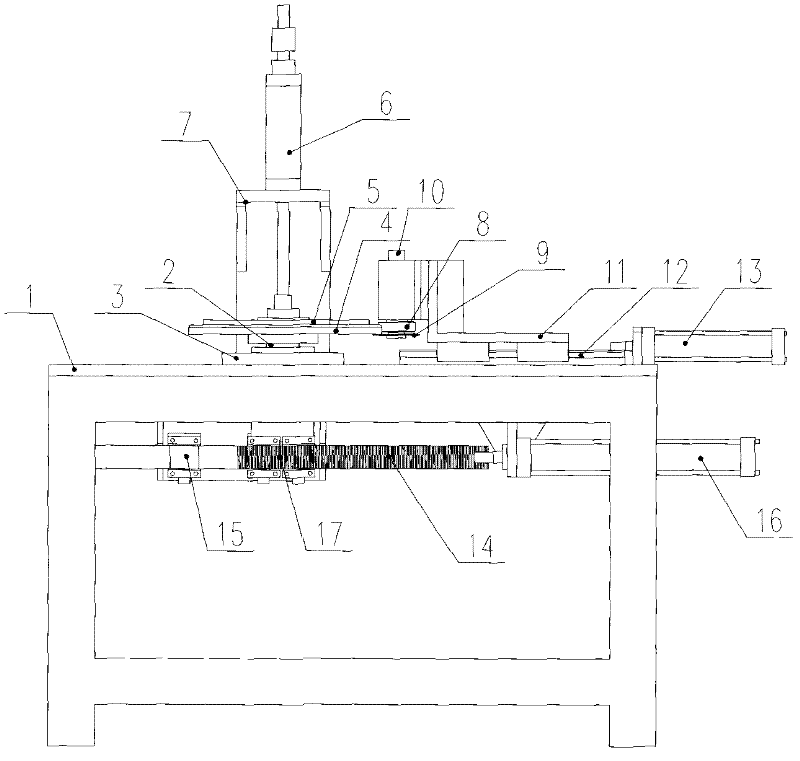

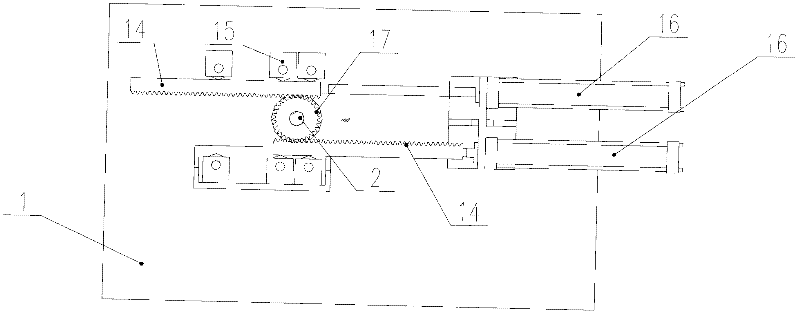

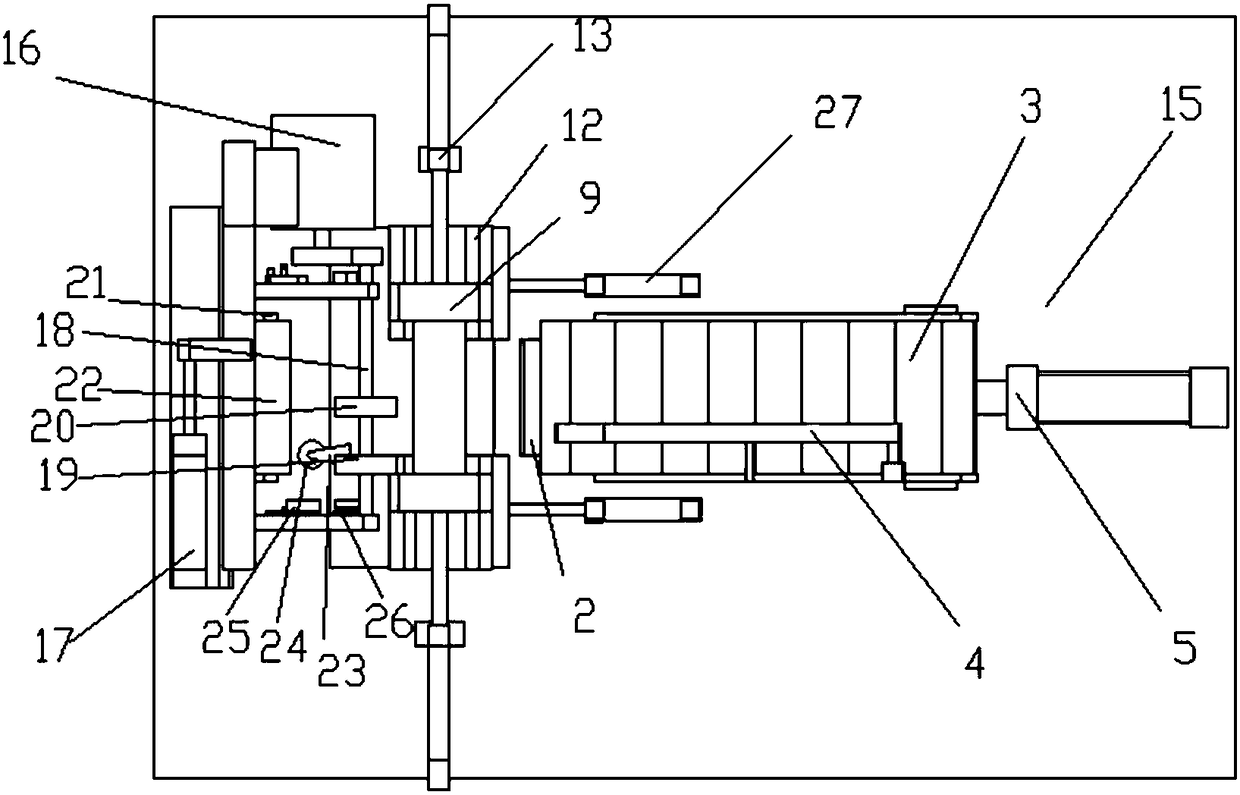

Two-explorator hammer handle machining and polishing equipment

InactiveCN108247511AImprove processing efficiencyReduce labor costsPolishing machinesGrinding drivesEngineeringExplorator

The invention relates to the technical field of hammer machining, in particular to two-explorator hammer handle machining and polishing equipment. Conveying, clamping, machining and polishing are controlled in a unified mode through a control electric box. A feeding device automatically achieves feeding for a conveying device through the gravity action, automatic conveying, clamping and correctionare achieved, a hammer handle to be machined is fed to a machining tool through an explorator air cylinder to be machined, the machining distance or depth is limited through explorators, polishing devices which are coaxially rotated carry out polishing after cutting machining is finished, manual operation is not needed in the whole process, the machining efficiency is greatly improved, the laborcost is saved, machining precision is high and uniform, and the equipment is suitable for large-scale use and popularization.

Owner:SHAODONG HEXIE HARDWARE ELECTROMECHANICAL CO LTD

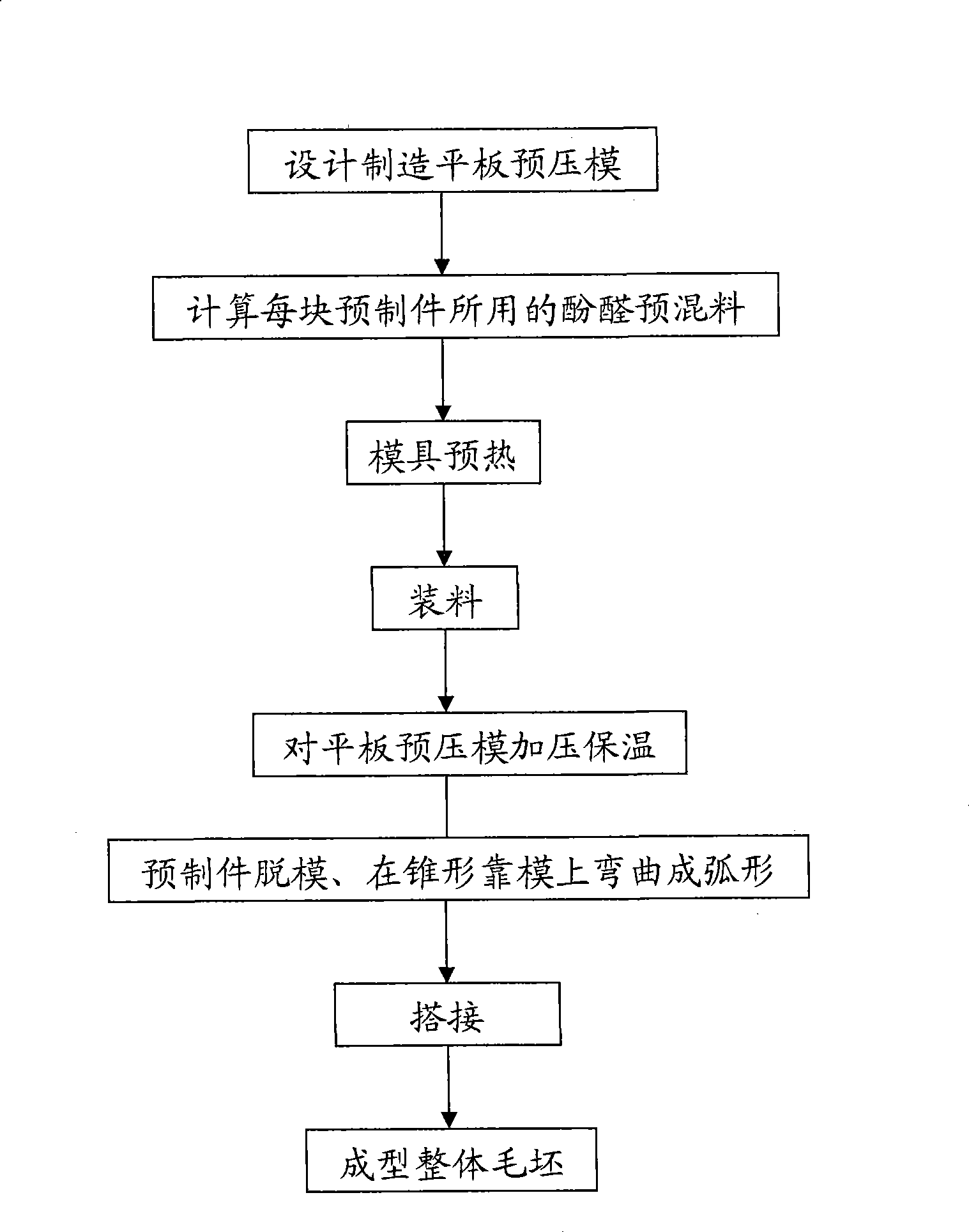

Cone phenolic resin composites structural parts whole-blank precast-products lapping forming technique

The invention relates to a related joint forming process of a conical metlbond composite material structure and an overall blank preformed unit. The shape of the conical metlbond composite material structure is unfolded and differentiated, and the related joint width of the preformed unit is taken as the basis of the size, thus a tablet prepressing mold can be designed and manufactured; the charge amount of each preformed unit is calculated; metlbond premix compound is horizontally and evenly added in the preheated prepressing mold, a hydraulic press pressurizes on the preformed unit, demoulding is carried out after holding the temperature for 10-30 minutes; the preformed unit after demoulding is immediately bent into an arc preformed unit by a conical explorator; cooling is carried out for 15-30 minutes; the preformed unit is put in the preheated overall forming mold for related joint, the overall blank is obtained by sealing the preformed unit by a gum cover and pumping to be in vacuum. By adopting the process, one third of the metlbond premix compound can be saved in production, the production cost is greatly reduced; the original processing period of 4 days is reduced to 2.5 days, thus improving the production efficiency; the loading difficulty and labor intensity are lowered, the controllability of the process is improved, the thickness of the product is even and complete, and the stability of the product quality is greatly improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

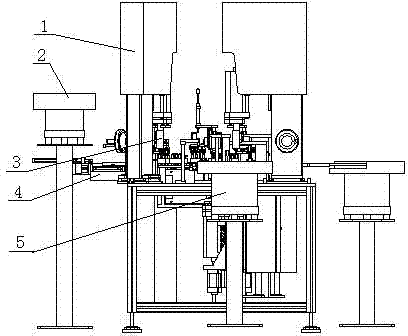

Full-automatic welding machine for producing lighter

InactiveCN102773602ASave production spaceLabor savingNon-electric welding apparatusUltrasonic weldingPulp and paper industry

The invention provides a full-automatic welding machine for producing a lighter. The full-automatic welding machine comprises a machine body, an oil cover finishing plate, an automatic oil cover feeding mechanism, an oil cover and machine shell welding mechanism, a bottom plate finishing plate, an automatic bottom plate feeding mechanism, a bottom plate and machine shell welding mechanism and a rotating disk, wherein an oil cover finishing plate is connected with the automatic oil cover feeding mechanism; the bottom plate finishing plate is connected with the automatic bottom plate feeding mechanism; the rotating disk is arranged on the machine body; and the rotating disk is connected with a machine shell explorator. The full-automatic welding machine for producing the lighter adopts ultrasonic welding, and is convenient, fast, clean and good in welding effect. The full-automatic welding machine for producing the lighter is reasonable in structural design; and in the whole process, the machine shell explorator is driven by the rotating disk, so that the processing operation between a machine shell and an oil cover as well as a bottom plate can be sequentially completed, the production efficiency is improved when the production space is saved, full-automatic production can be realized, the labor is saved, and the safety of production is guaranteed.

Owner:LANGXI DONGHAI PHOTOELECTRIC TECH

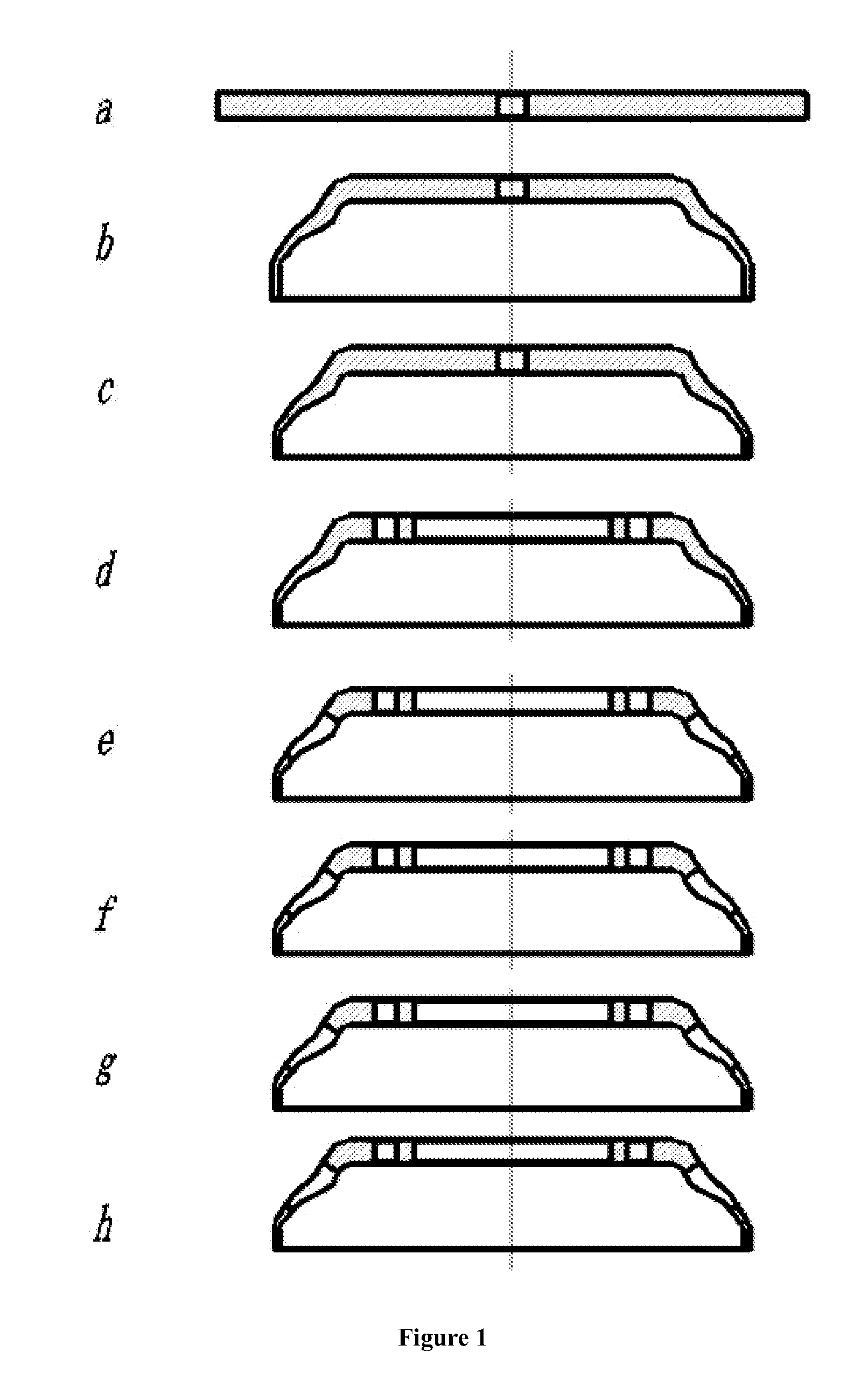

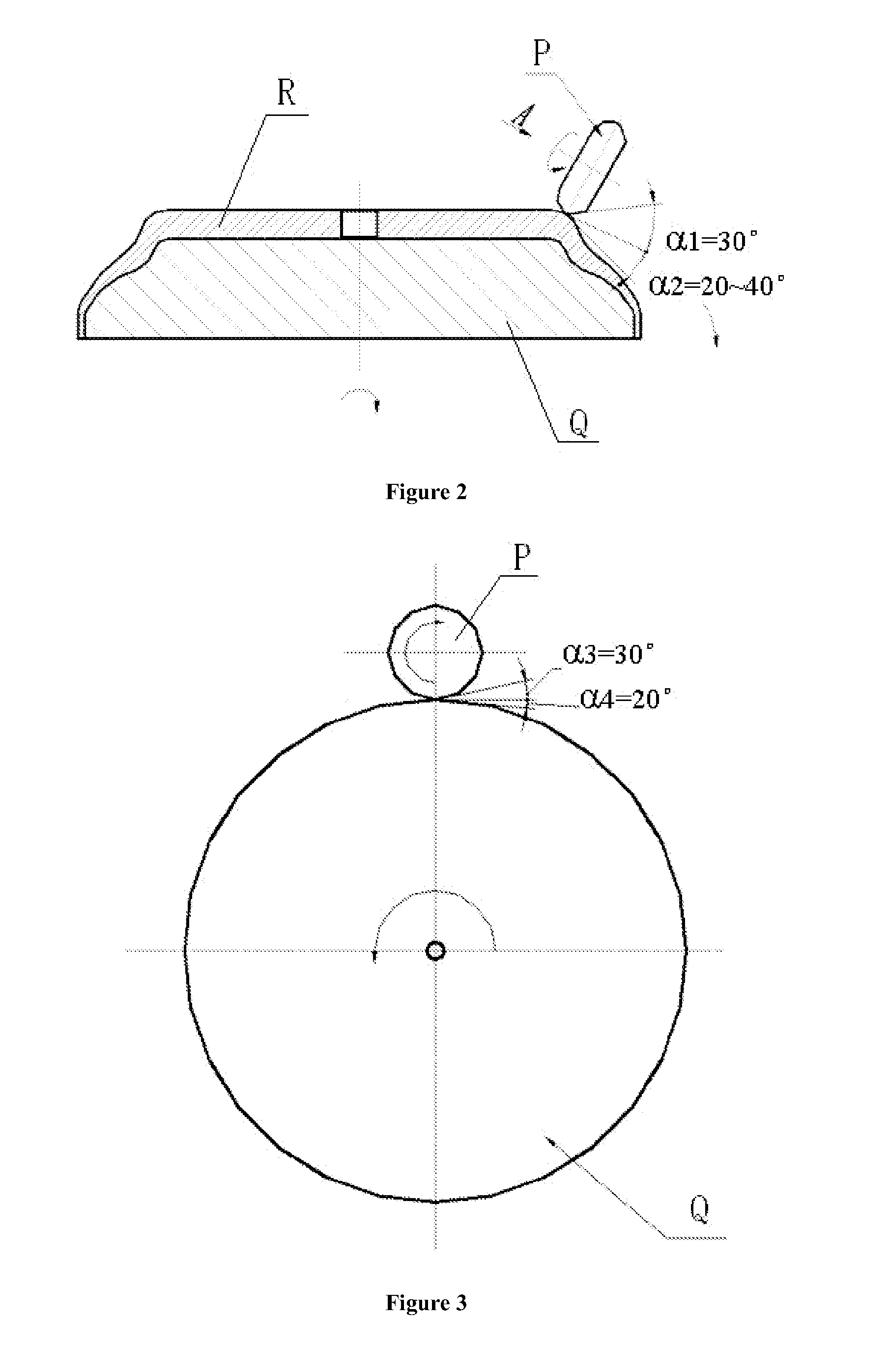

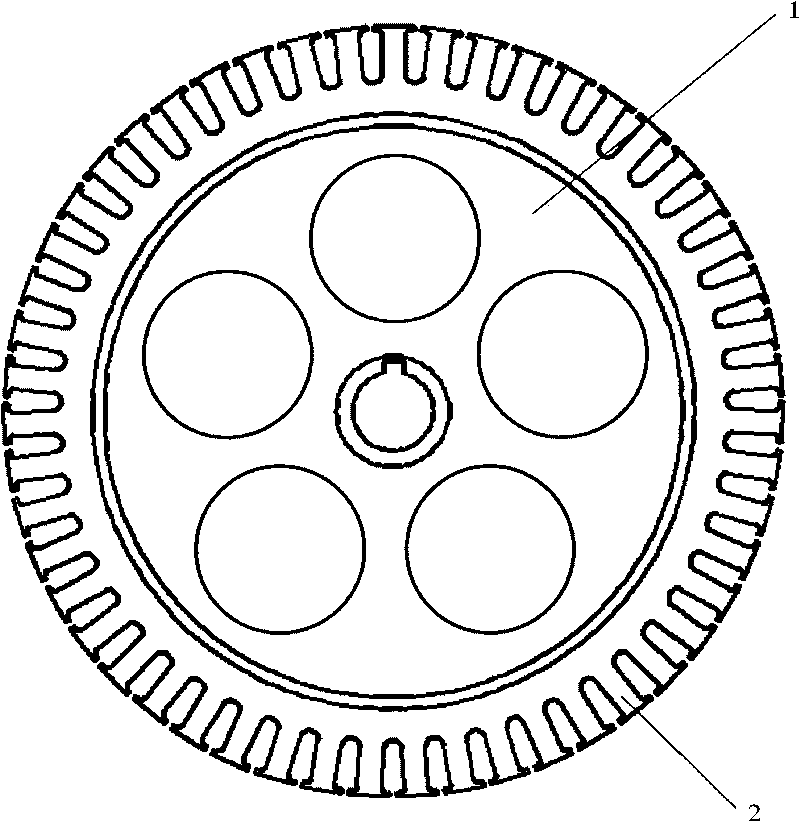

Rolling forming method of wheel disc

InactiveUS20120117806A1Large deformationStrong forceRimsMetal-working apparatusDynamic balanceExplorator

The invention provides a rolling forming method of wheel disc, which comprises the following steps: (1) Baiting a circular blank; (2) placing the circular blank in a cavity of a rolling explorator and adopting at least two rolling wheels symmetrically arranged along the circumferential direction of the rolling explorator to perform planar synchronous staggered rolling on the circular blank in the cavity of the rolling explorator; (3) performing trimming and sizing; and (4) stretch forming. The rolling forming method of wheel disc of this invention can precisely form various geometric sections with gradual deformation. The formed product has a uniform mass in the axial direction and the circumferential direction, and has a high dynamic balance precision. The invention can make the blank deform precisely, enhance the production efficiency, and reduce the cost, therefore the invention has good application and popularization prospect.

Owner:SHANGHAI XINGPU SPINFORMING WHEEL

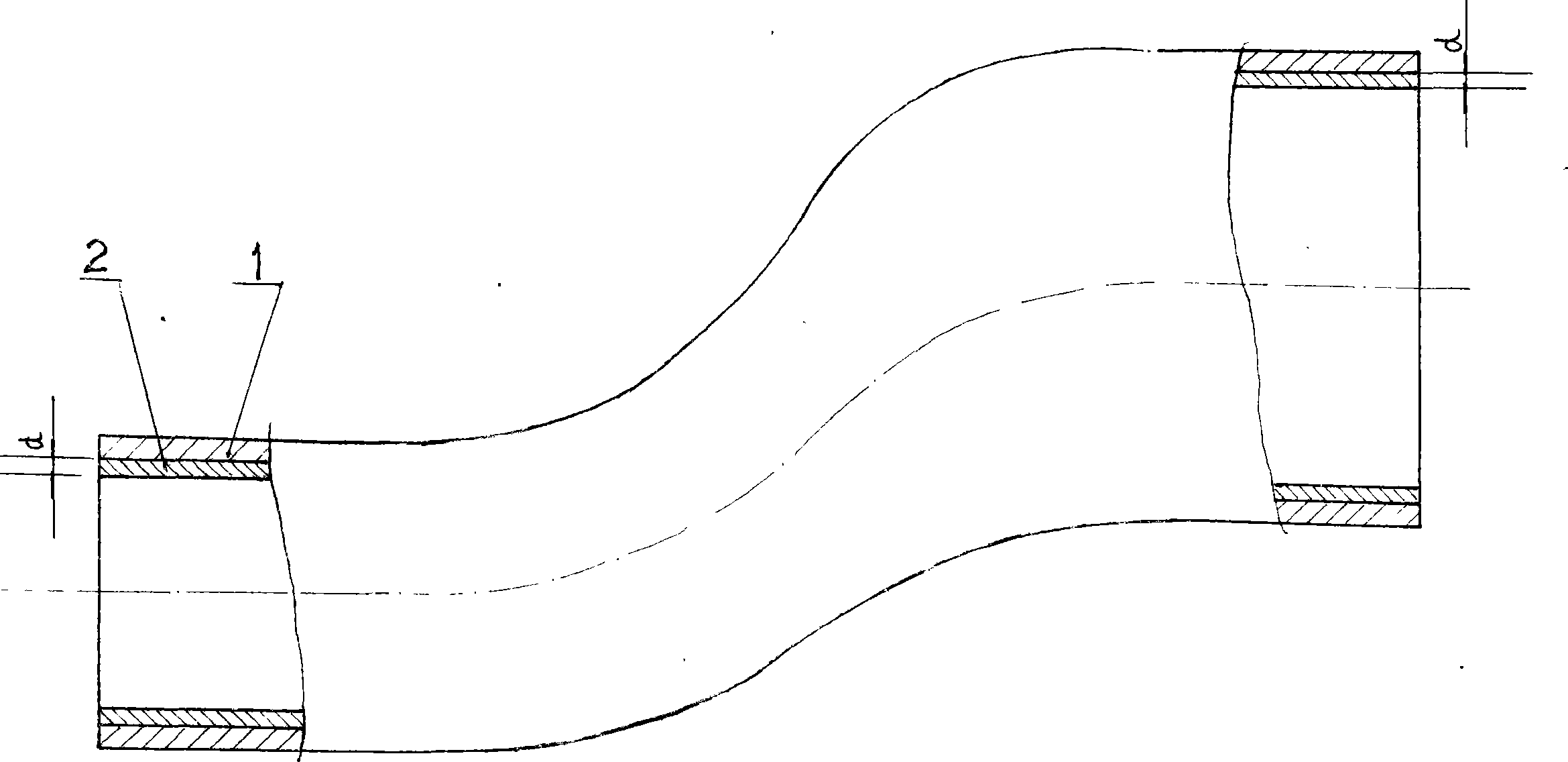

Processing method of S tube for concrete pump truck/trailer pump

InactiveCN101224537AUse the same effectImprove work efficiencyPipe protection against damage/wearSheet steelExplorator

The invention discloses a processing method of an S-shaped pipe used for a concrete pumping vehicle / tractive pump. A wear-resisting layer 2 with the thickness of d is surfaced by wearable material on a plane-typed steel plate which is taken as a pipe body 1; the steel plate where the wear-resisting layer 2 is surfaced is pressed into the S-shaped pipe with two heads with different sizes by an explorator forming process. The processing method changes the normal processing technology used for the S-shaped pipe that the surfacing is achieved after the forming, the operation is convenient, the working efficiency of the surfacing is improved, the uniformity and firmness of the surfacing layer are ensured, and the service life of the S-shaped pipe is prolonged.

Owner:周卓林

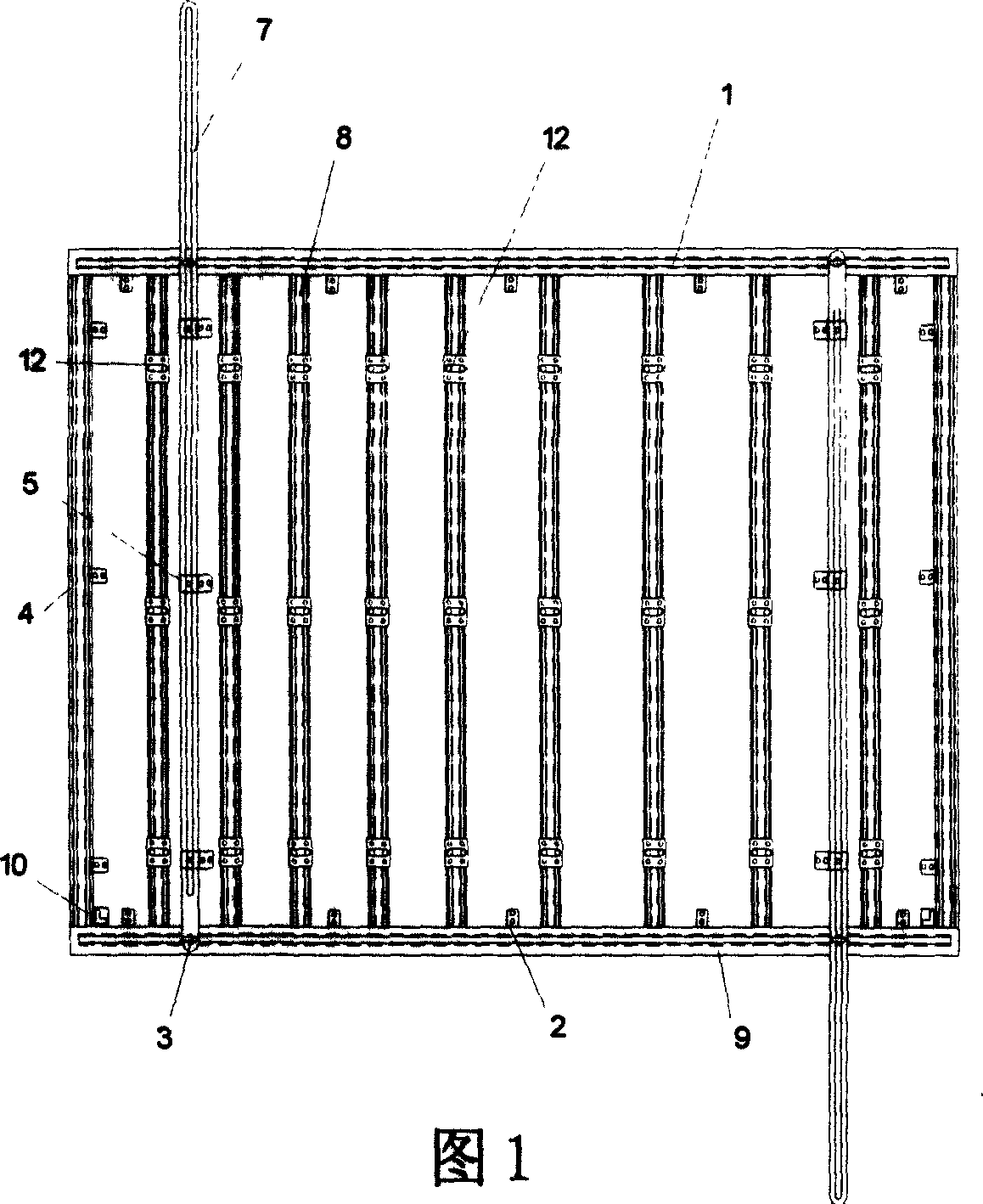

Automatic winding and forming device of tank and forming method

InactiveCN104476192AAvoid curlAvoid deformationWelding/cutting auxillary devicesOther manufacturing equipments/toolsExploratorPressure vessel

The invention discloses an automatic winding and forming device of a tank and a forming method. The automatic winding and forming device of the tank comprises a discharging device, a winding device, an assistant winding device, a shell ring clamp, a shell ring butt point welding device and a hydraulic system. The shell ring clamp comprises a main body of the clamp, an exchangeable explorator, and a shell ring end face stop pin. The automatic winding and forming device of the tank is capable of integrating the winding, positioning, aligning, and point welding, can be used for producing the tanks of products, such as a pressure container, a powder and particle material carrier vehicle, and a fuel tanker, and has the advantages of high production efficiency, safety and reliability.

Owner:SHANDONG XINGBANG IND EQUIP

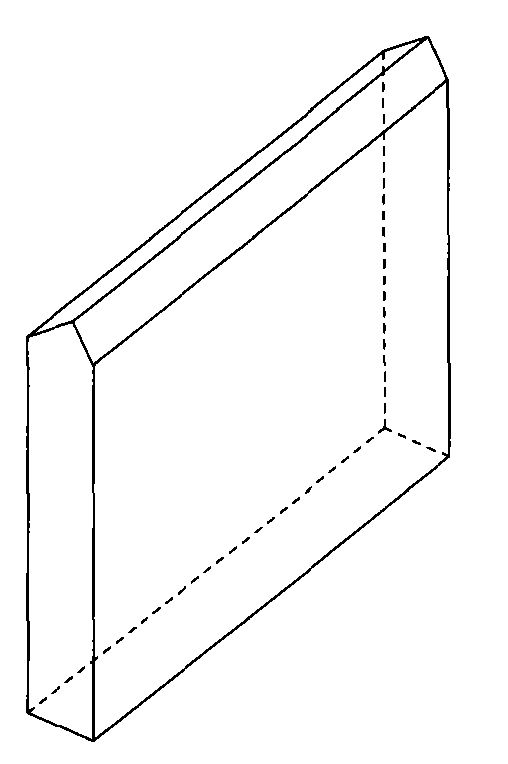

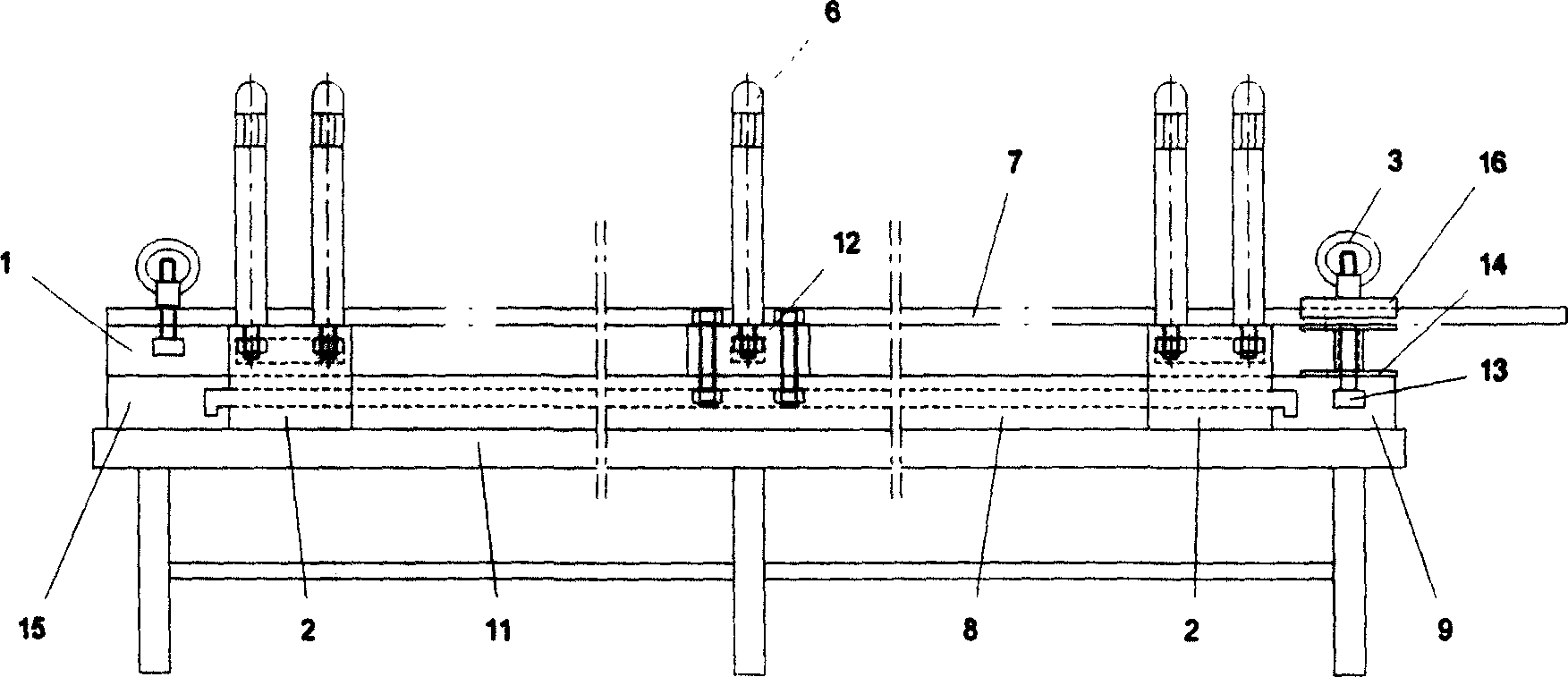

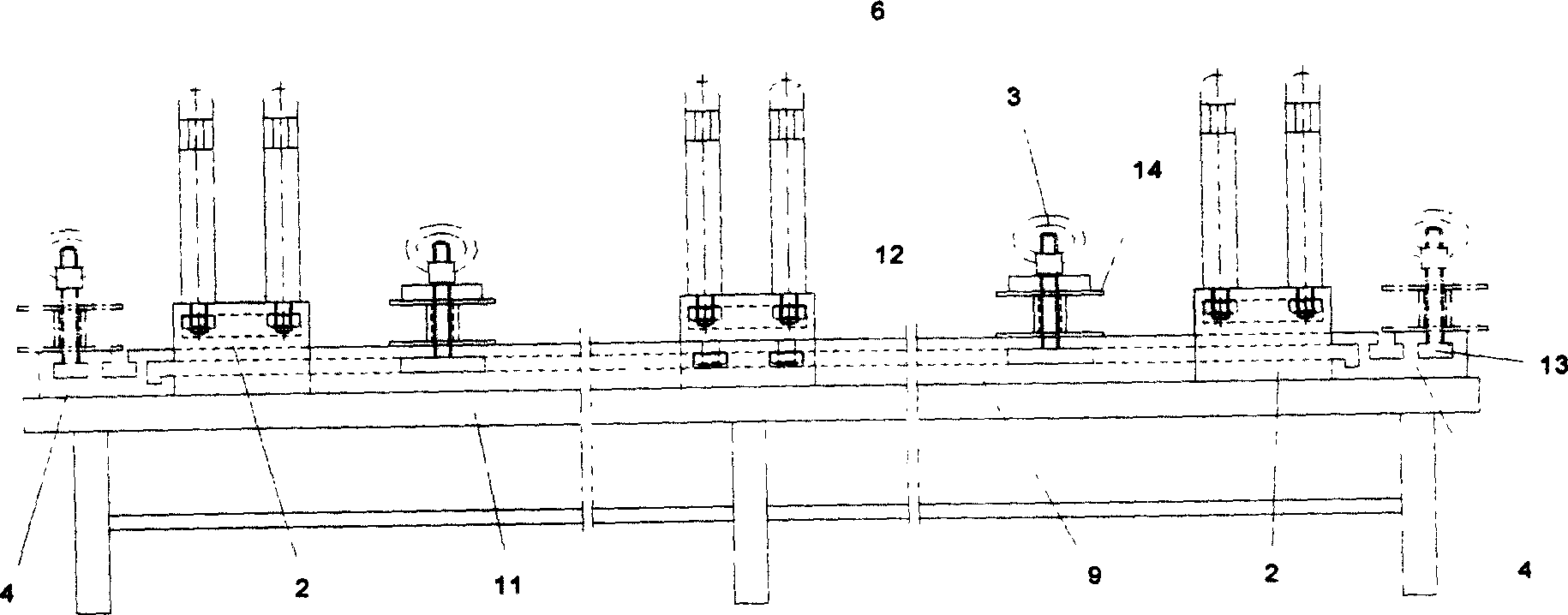

Metal explorator machining platform for machining box

The metal exploratory machining platform for machining box includes one work bench; and one rectangular frame comprising under frame, under frame slide way and two tracks on the work bench. Inside the rectangular frame, there are middle slide way, angle regulating slide way, three upright fixing blocks, locating block and uprights on the blocks. The present invention can fix, locate and assemble the plates of the insulating box under production precisely, is used mainly for machining various kinds of insulating boxes in different sizes, and has the advantages of simple structure, easy use and high production efficiency.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

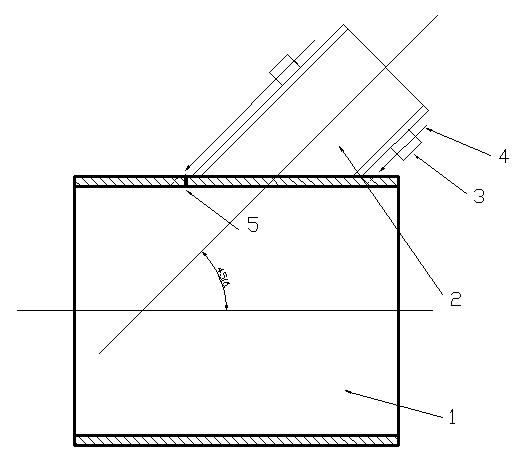

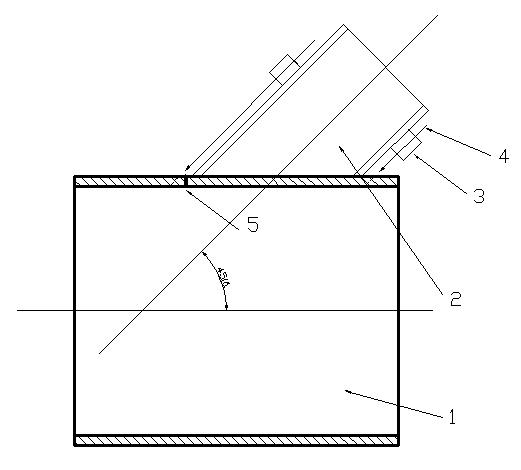

Slant-hole gas cutting method of large-scale thick-wall forgeable piece tube

The invention discloses a slant-hole gas cutting method of a large-scale thick-wall forgeable piece tube. The method is characterized by comprising the following steps of: (1) lofting and marking: lofting by using a computer technology according to a drawing size, marking an opening position line on the tube according to the lofting size, marking a plurality of gas cutting lead hole position lines at the inner side of the opening position line and marking a mounting position line for cutting an explorator at the inner sides of the lead holes; (2) manufacturing the explorator through cutting; cutting one end of the explorator according to a correlation line between the mounting position of the explorator and the contact surface of the tube, wherein the explorator is a cylinder made by rolling a thin steel plate; (3) firstly, drilling a plurality of gas cutting lead holes on the tube; (4) mounting the explorator on the tube; (5) mounting a semi-automatic cutting machine on the explorator, selecting a cutting nozzle according to the cutting thickness and then trying a cutting trail; and (6) cutting in segments and adjusting an upper sliding rod of the semi-automatic cutting machine during cutting so as to adjust the distance between the cutting nozzle and the cutting surface in any time. The invention does not need any equipment and greatly improves the efficiency than manual cutting.

Owner:HANGZHOU BOILER GRP CO LTD

Multifunctional small punch grinding device

The invention discloses a multifunctional small punch grinding device and relates to the technical field of small-punch grinding. The multifunctional small punch grinding device comprises a main shaft, a workpiece fixing part, a transmission shaft, a gear set and a handle, wherein the main shaft, the workpiece fixing part, the transmission shaft, the gear set and the handle are arranged in the left-right direction, the workpiece fixing part is used for fixing a workpiece at the left end of the main shaft, the transmission shaft is arranged in the left-right direction and connected with the main shaft, when the handle is shaken, the gear set, the transmission shaft and the main shaft are sequentially driven to rotate, and the workpiece is driven to rotate. The multifunctional small punch grinding device further comprises a floating sliding block, a lever, an explorator and an idler wheel, wherein the floating sliding block can move up and down, the idler wheel enables the floating sliding block to be delivered to a floating sliding block adjusting screw along an explorator track through the lever, the floating sliding block and the explorator track synchronously float up and down, up-down floatation is converted into up-down elasticity which is used for adjusting the spring and operating the distance of a grinding wheel of a grinder, and therefore grinding machining of special-shaped parts such as an oval-shaped part can be achieved. The multifunctional small punch grinding device has the advantages of being multifunctional and convenient to use and can be appropriate for ordinary die making factories and machining and repair of die small punches in a circle, square, other equilateral polygons, flat, oval shape and the like in the process of repair when a die is used.

Owner:东莞市勤展实业有限公司

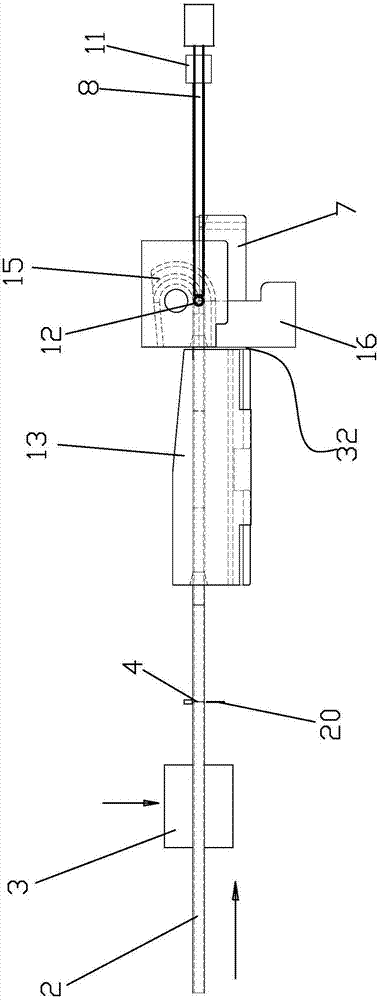

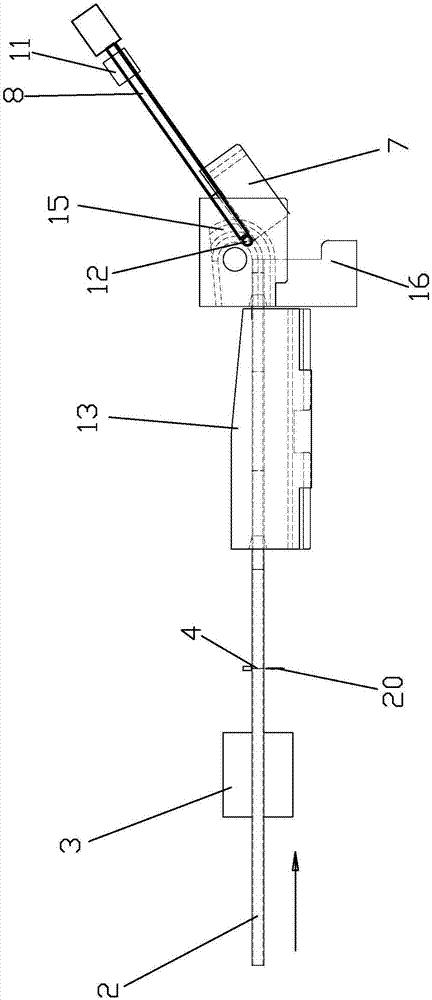

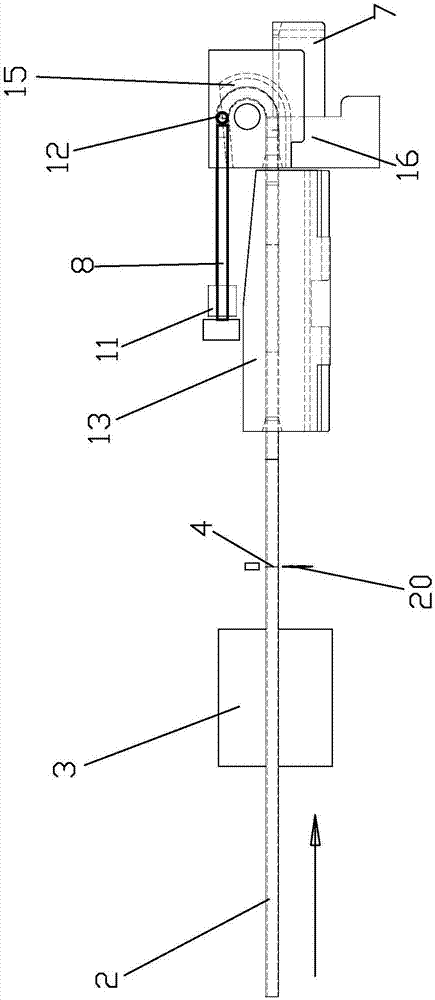

Rotary type winding machine of bicycle motor

InactiveCN101697442ALow costWith independent intellectual property rightsManufacturing dynamo-electric machinesWinding machineEngineering

The invention is an automatic winding machine used for winding a winding of a bicycle motor. The winding machine mainly comprises the functional modules of a rotary winding motion mechanism, a wire pressing motion mechanism, a wire pressing supporting rack height adjusting mechanism, a bicycle motor iron core rotating mechanism, a counting mechanism, a tensioning mechanism and the like, wherein the most remarkable characteristics of the winding machine is that: two opposite circular arc-surface explorators are used for leading enamelled wires to a groove, and the uniform winding is realized by using the wire pressing mechanism to adjust the height of a winding coil. When the enamelled wires are wound around a supporting rack (2), because of the blocking of the circular arc-surface explorators of a back wire rack (36) and a front wire rack (37), the enamelled wires are limited and led to a wire groove between the supporting racks; and when the enamelled wires are wound to the outside of the left side (or right side) of the wire groove, a left wire pressing rack (16)(or right wire pressing rack (21)) is driven by a cam (15) (or a cam (20)) to easily press down the enamelled wires to a proper height. By reasonably adjusting the rotary speed of a left screw rod (17), the heights of the wire pressing supporting racks can be gradually adjusted, so that the uniform winding of the coil is realized, and the winding density of the enamelled wires can be dynamically adjusted and controlled. In the winding process, an enamelled wire roller (34) rotates in the same direction as the winding direction, so that the torsional stress of the enamelled wires generated in the process of winding the coil can be released. The winding machine is characterized in simple structure, high efficiency, low cost and automatic counting, and can be widely used for winding the coil of the motor of the bicycle and the coil similar to the armature.

Owner:帅立国

U-shaped pipe chipless forming all-in-one machine and working method thereof

The invention discloses a U-shaped pipe chipless forming all-in-one machine and a working method thereof. According to the technical scheme, the all-in-one machine is characterized in that the all-in-one machine comprises a rack which is provided with a feeding device, a clamping device for clamping a pipe fitting, a bending device, an anti-bevel device for preventing the pipe fitting from generating a bevel in bending, and a cutting mechanism, and the bending device comprises a mounting plate which can be driven to turn over; and the mounting plate is provided with an explorator which is turned over along with the mounting plate so as to bend the pipe fitting. In the invention, an anti-bevel pipe casing is abut against a copper pipe port all the time in the bending of the copper pipe to prevent the side of the copper pipe with small pipe diameter from extending, and the pipe port can be prevented from deforming effectively; the U-shaped pipe quality is guaranteed, and a mandril is inserted into the bending position of the copper pipe, so that the copper pipe can be prevented from wrinkling and deforming effectively.

Owner:中山市中科智能制造研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com