Cast-in-situ construction method of beam flange plates of acoustic barriers through movable mold base vehicles

A technology of mobile formwork and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., and can solve problems such as difficulties in flange plate cast-in-place construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

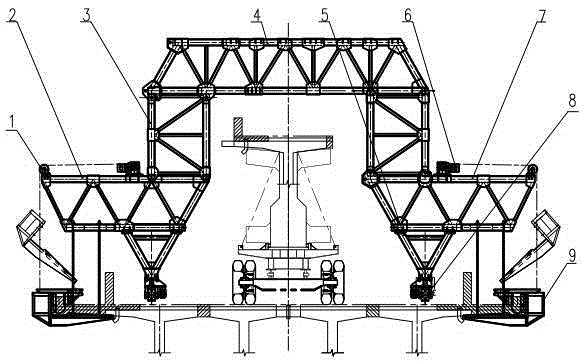

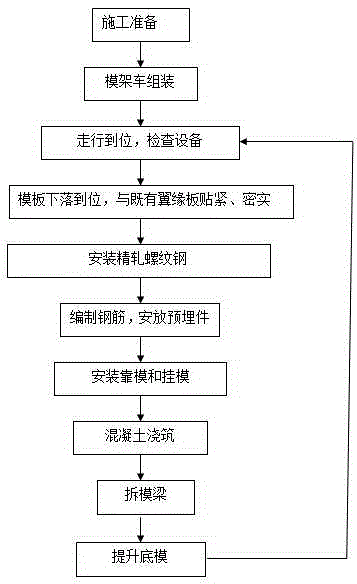

[0025] According to attached figure 1 It can be seen that this application specifically relates to a casting-in-situ construction method for the flange plate of the sound barrier beam of the mobile formwork vehicle. Pouring construction. The specific construction process is as follows: construction preparation → formwork truck assembly → walk in place, check equipment → formwork falls in place → install fine-rolled rebar → prepare steel bars, place embedded parts → install hanging formwork and formwork → concrete pouring → formwork removal → Raise the bottom mold and transition. This method is based on the practical experience of engineering construction.

[0026] The principle of the construction method in this application: the construction conditions can be divided into single-line or double-line, with or without track laying, and catenary on one or both sides. Mobile formwork trucks for construction.

[0027] Its specific construction process is as follows:

[0028] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com