Processing method of S tube for concrete pump truck/trailer pump

A technology of concrete conveying pump and processing method, which is applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline damage/wear prevention, etc. problems, to achieve the effect of convenient operation, guaranteed service life and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

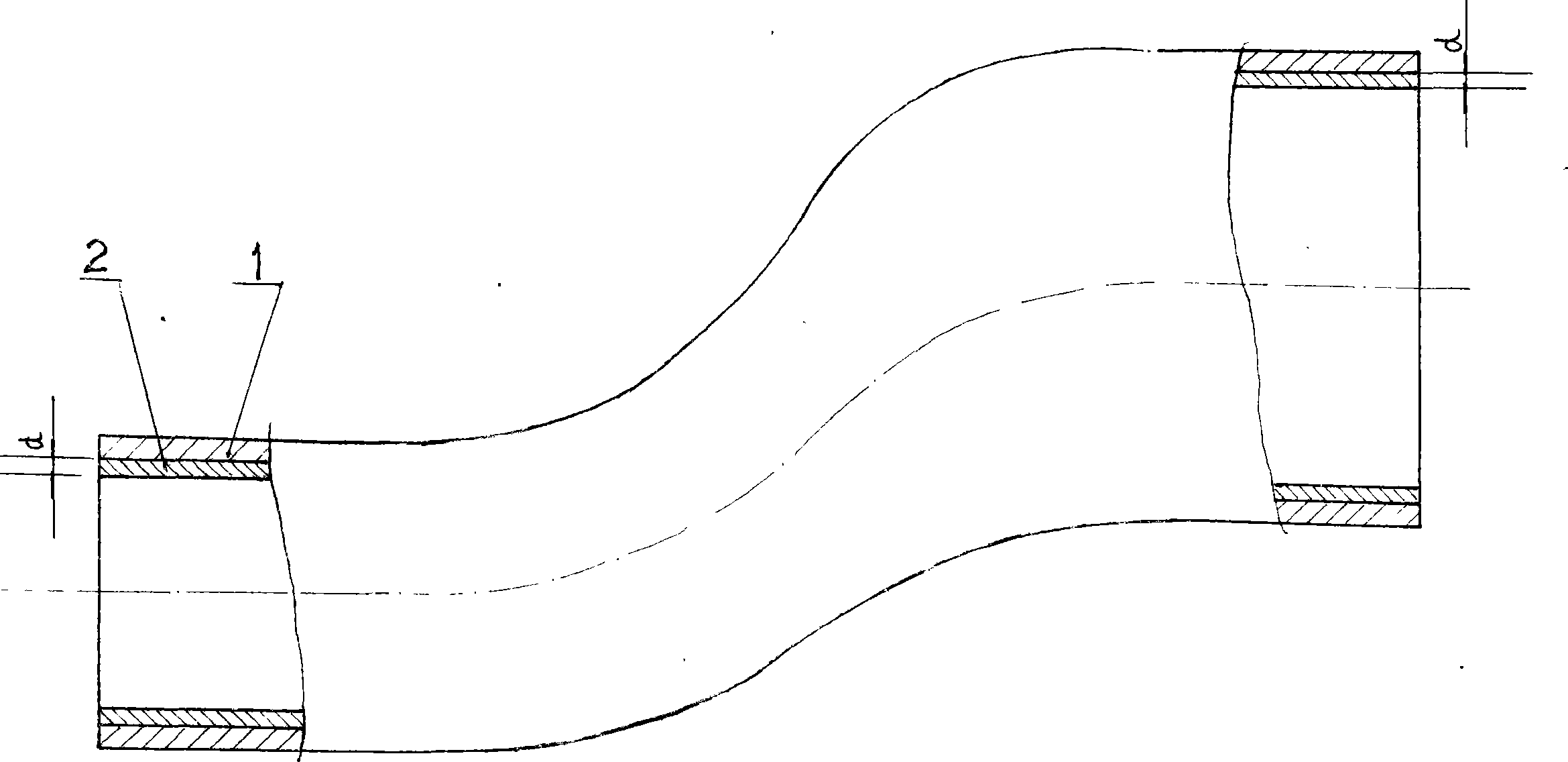

[0019] 5 mm thick steel plate is used as the material of the pipe body 1, and a 3 mm thick wear-resistant layer is surfacing welded with a 3 mm thick wear-resistant layer under the conditions of 120A and 30V using the German-made Audi-100T welding rod.

Embodiment 2

[0021] 8 mm thick steel plate is used as the material of the pipe body 1, and a 4 mm thick wear-resistant layer 2 is surfacing welded under the conditions of 130A and 30V using the German-made Audi-147 flux-cored welding wire, and a 500t hydraulic press is molded into an S pipe .

Embodiment 3

[0023] 10 mm thick steel plate is used as the material of the pipe body 1, and a 5 mm thick wear-resistant layer 2 is surfacing welded under the conditions of 130A and 32V using the Audi-150 welding electrode produced in Germany. The 500t hydraulic press is profiled into an S pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com