Regeneration method of activated carbon catalyst used for preparing glyphosate

A technology of activated carbon and catalyst, which is applied in the field of regeneration of activated carbon catalyst for glyphosate preparation, can solve problems such as poor effect, achieve low regeneration cost, reduce production cost, and solve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Alkaline or reducing organic solvent regeneration method

[0033] Take 4 parts of deactivated activated carbon catalyst with 100g each in 4 autoclaves, and wash with 200g each of pyridine, hydrazine hydrate, N,N-dimethylformamide, and ethylenediamine. Treatment conditions: sealed in an autoclave, heated to 170°C, stirred at 500rpm for 4h, cooled to room temperature, filtered, washed with water to neutral, dried at 110°C to constant weight, and regenerated activated carbon catalyst was obtained, which was recorded as "Re-1-" 1. Re-1-2, Re-1-3, Re-1-4". The aforementioned method was used to evaluate the regeneration effects of the four regenerated catalysts, and the results are shown in Table 1.

[0034] Table 1 The regeneration effect of organic solvents on deactivated catalyst

[0035] Sample serial number

Embodiment 2

[0036] Example 2 Alkaline or reducing inorganic aqueous solution regeneration method

[0037] Take 5 parts of deactivated activated carbon catalyst with 100 g each in 5 autoclaves, and wash with 200 g each of aqueous solutions of potassium hydroxide, sodium carbonate, ammonium bicarbonate, ammonia, and ammonium sulfide (the mass fraction of each aqueous solution is 5%). The treatment conditions were the same as those in Example 1, to obtain a regenerated activated carbon catalyst, which was successively written as "Re-2-1, Re-2-2, Re-2-3, Re-2-4, Re-2-5". The aforementioned method was used to evaluate the regeneration effect of five regenerated catalysts, and the results are shown in Table 2.

[0038] Table 2 The regeneration effect of inorganic aqueous solution on deactivated catalyst

[0039] Sample serial number

Embodiment 3

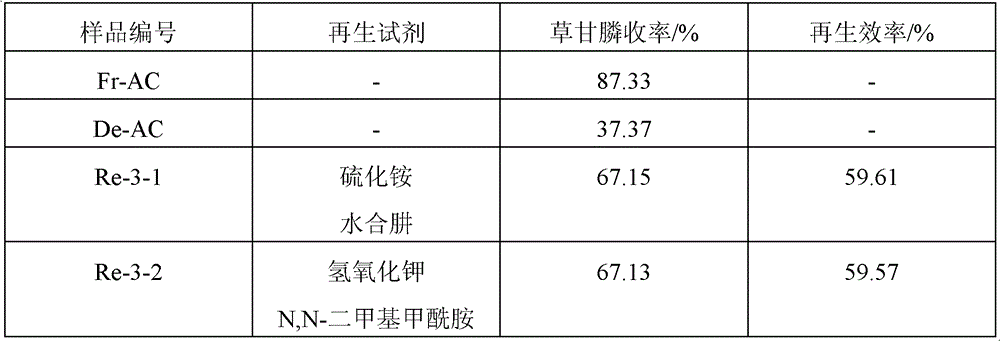

[0040] Example 3 Inorganic-organic mixed solution regeneration method

[0041] Put 100g of deactivated activated carbon catalyst into the autoclave, add 100g of 5% by mass ammonium sulfide aqueous solution, and then add 100g of hydrazine hydrate; another 100g of deactivated activated carbon catalyst into the autoclave, add 100g of 5% by mass potassium hydroxide aqueous solution, Then add 100 g of N,N-dimethylformamide. The treatment conditions were the same as in Example 1, and the regenerated activated carbon catalyst was obtained, which was recorded as "Re-3-1" and "Re-3-2" in turn. The aforementioned method was used to evaluate the regeneration effects of the two regenerated catalysts, and the results are shown in Table 3.

[0042] Table 3 Regeneration effect of inorganic-organic mixed solution regeneration method

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com