Patents

Literature

385 results about "Glyphosate toxicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amongst mammals, glyphosate is considered to have low to very low toxicity. The LD50 of glyphosate is 5,000 mg/kg for rats, 10,000 mg/kg in mice and 3,530 mg/kg in goats. The acute dermal LD50 in rabbits is greater than 2,000 mg/kg.

Methods and compositions for improving plant health

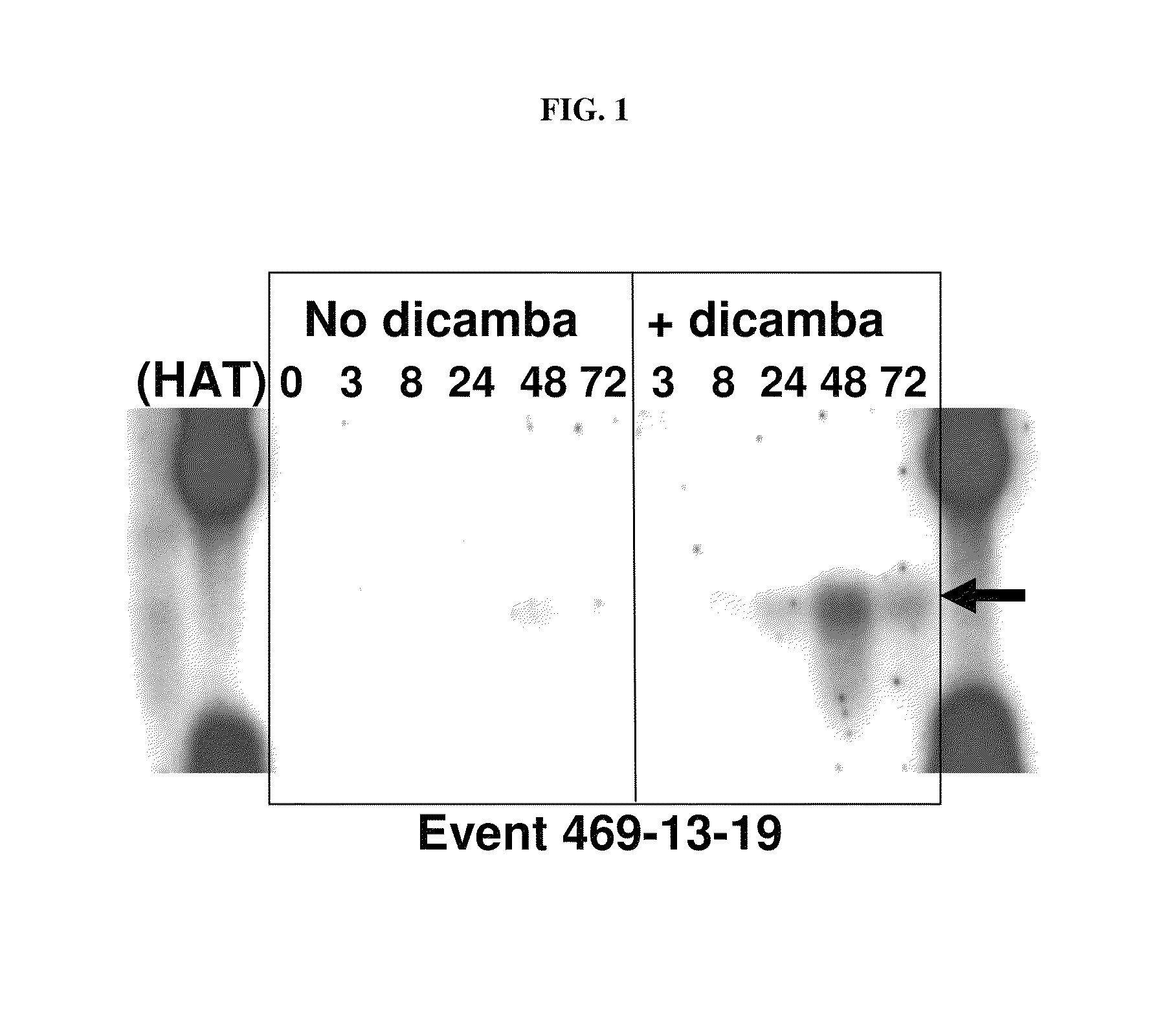

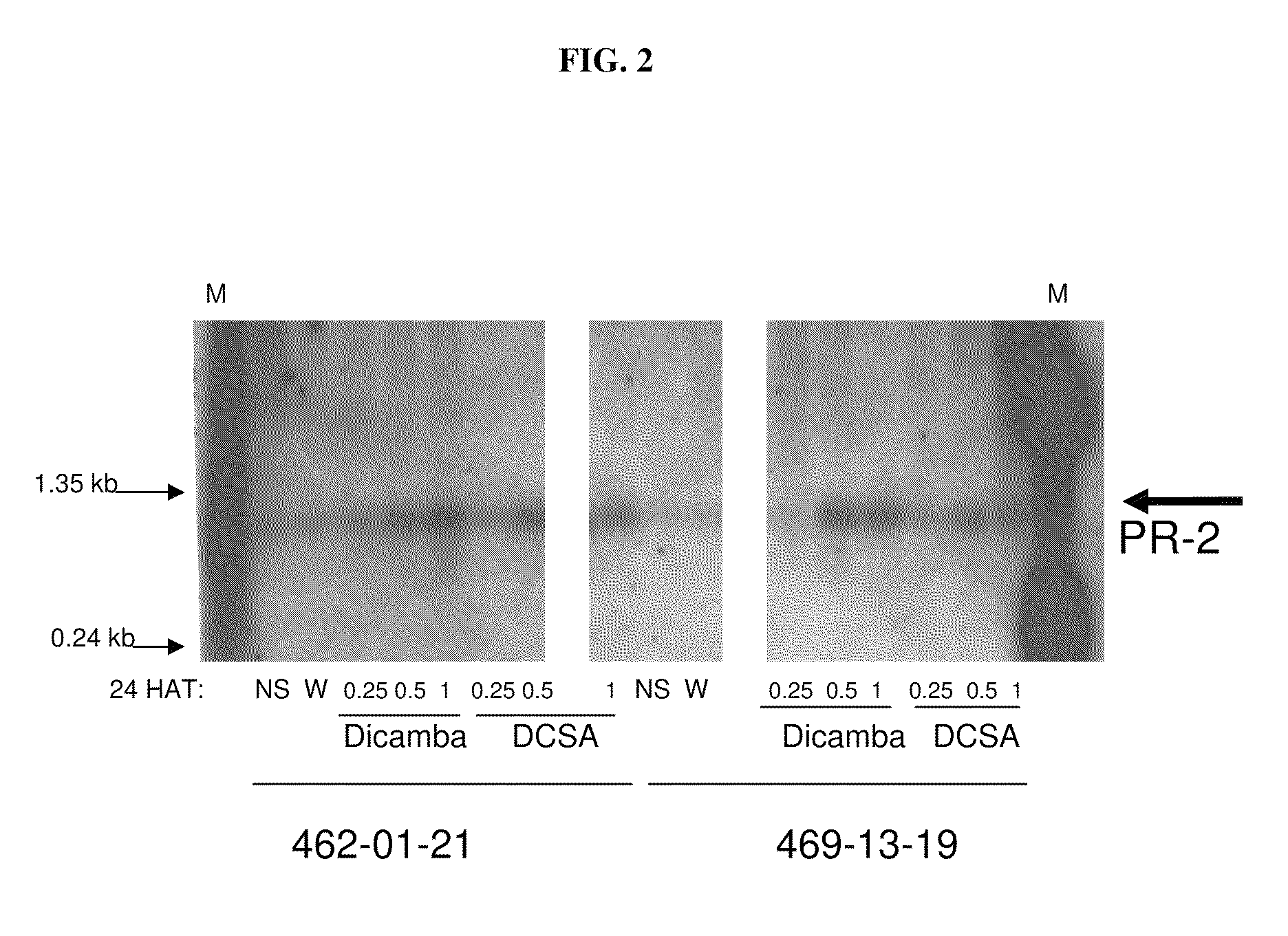

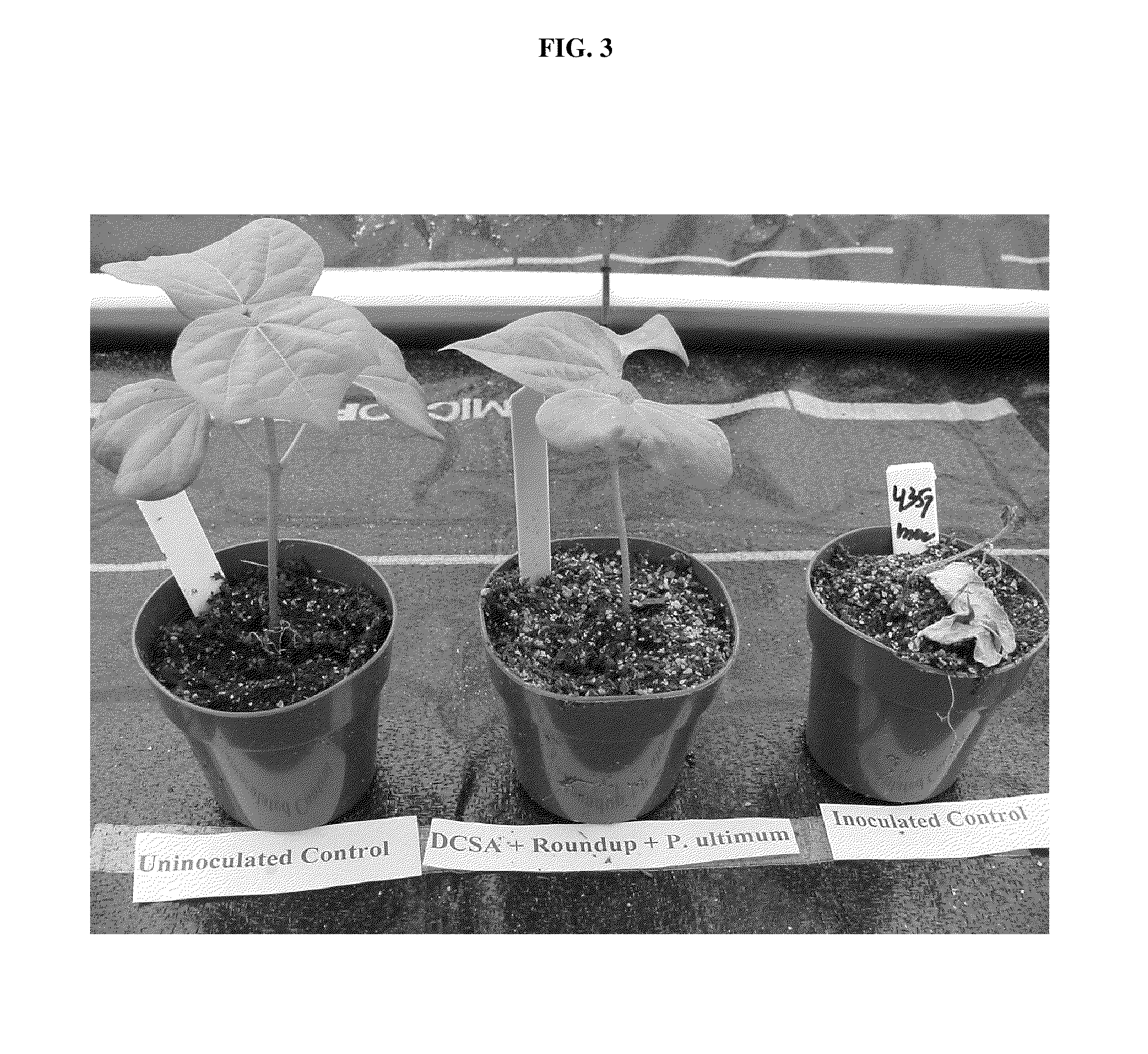

The present invention provides methods and compositions for improving plant health. In particular, application of dicamba or another substrate of DMO, or metabolites thereof including DCSA, to a plant confers tolerance to, or defense against, abiotic or biotic stresses such as oxidative stress including herbicide application, and plant disease, and enhances crop yield. Such application may be in combination with the application of another herbicide such as glyphosate.

Owner:MONSANTO TECH LLC

New adjuvant composition

InactiveUS20060009360A1Improve efficiencyImprove area coverageBiocideDead animal preservationGlycineAdjuvant

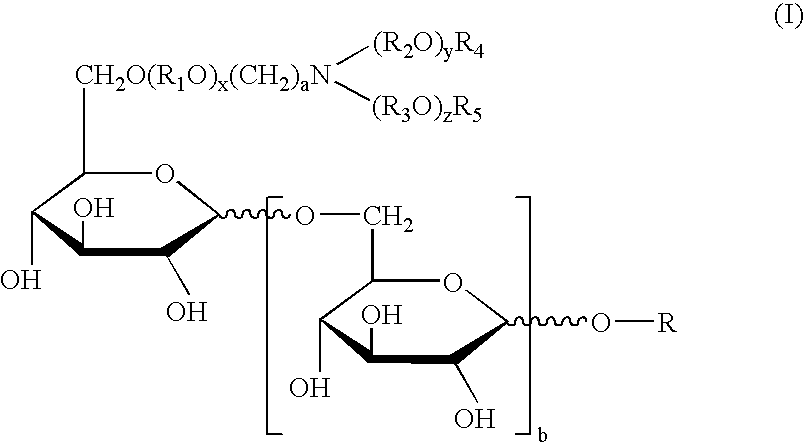

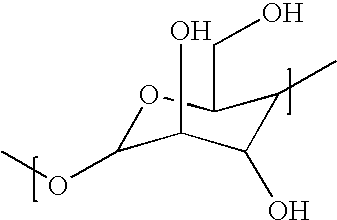

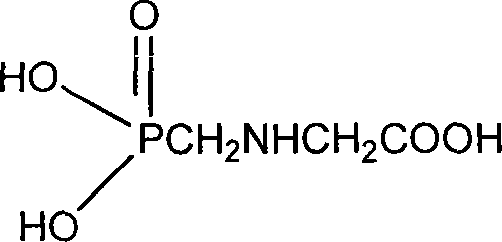

The present invention is directed to pesticidal formulations utilizing novel alkylpolyglycoside amines as adjuvants. The pesticidal formulation need not, but may, include an additional eye irritation-reducing complex. The adjuvant is particularly useful with glyphosate (N-(phosphonomethyl)glycine) compositions. Methods for using these pesticidal formulations are also disclosed.

Owner:COGNIS IP MANAGEMENT GMBH

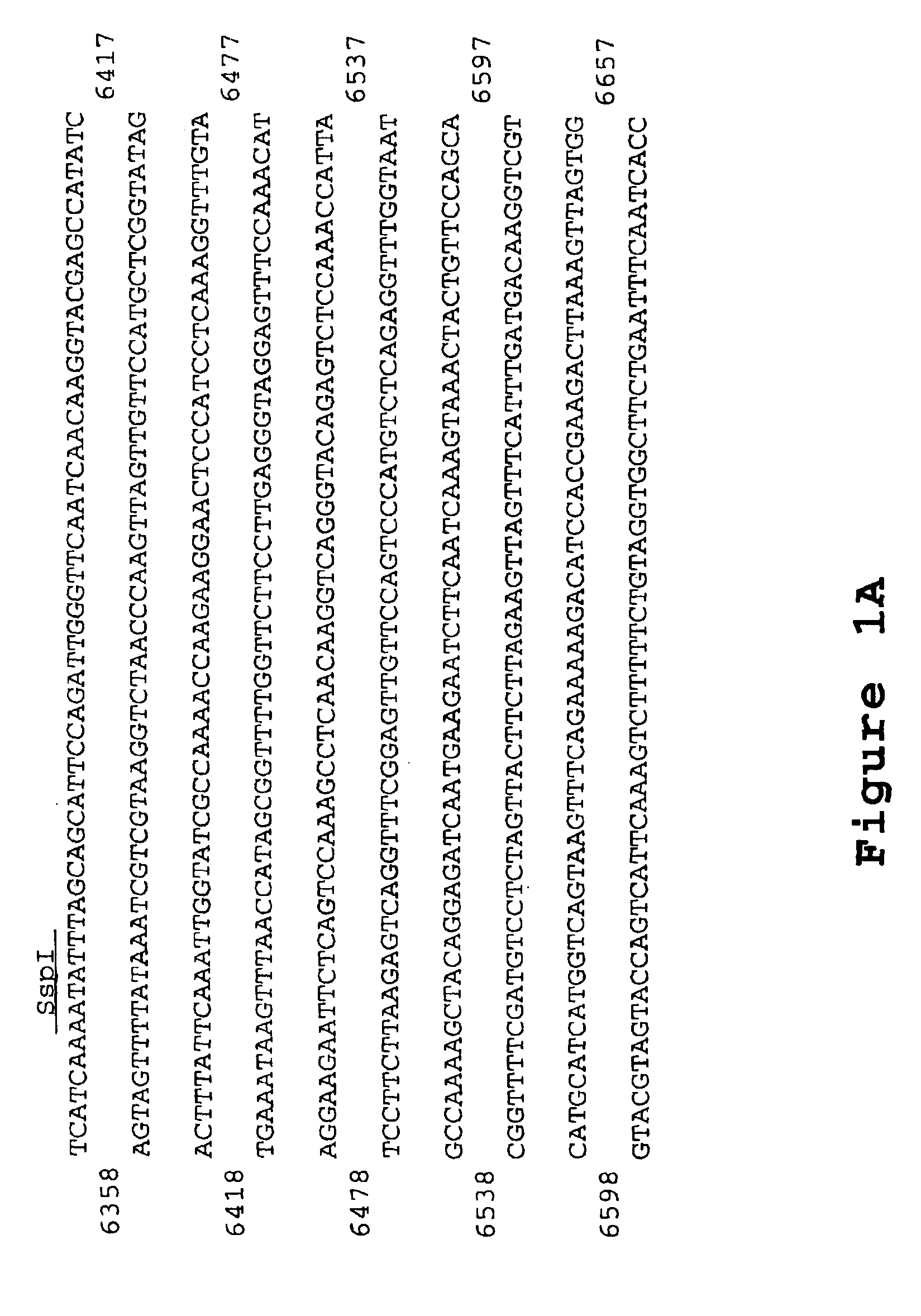

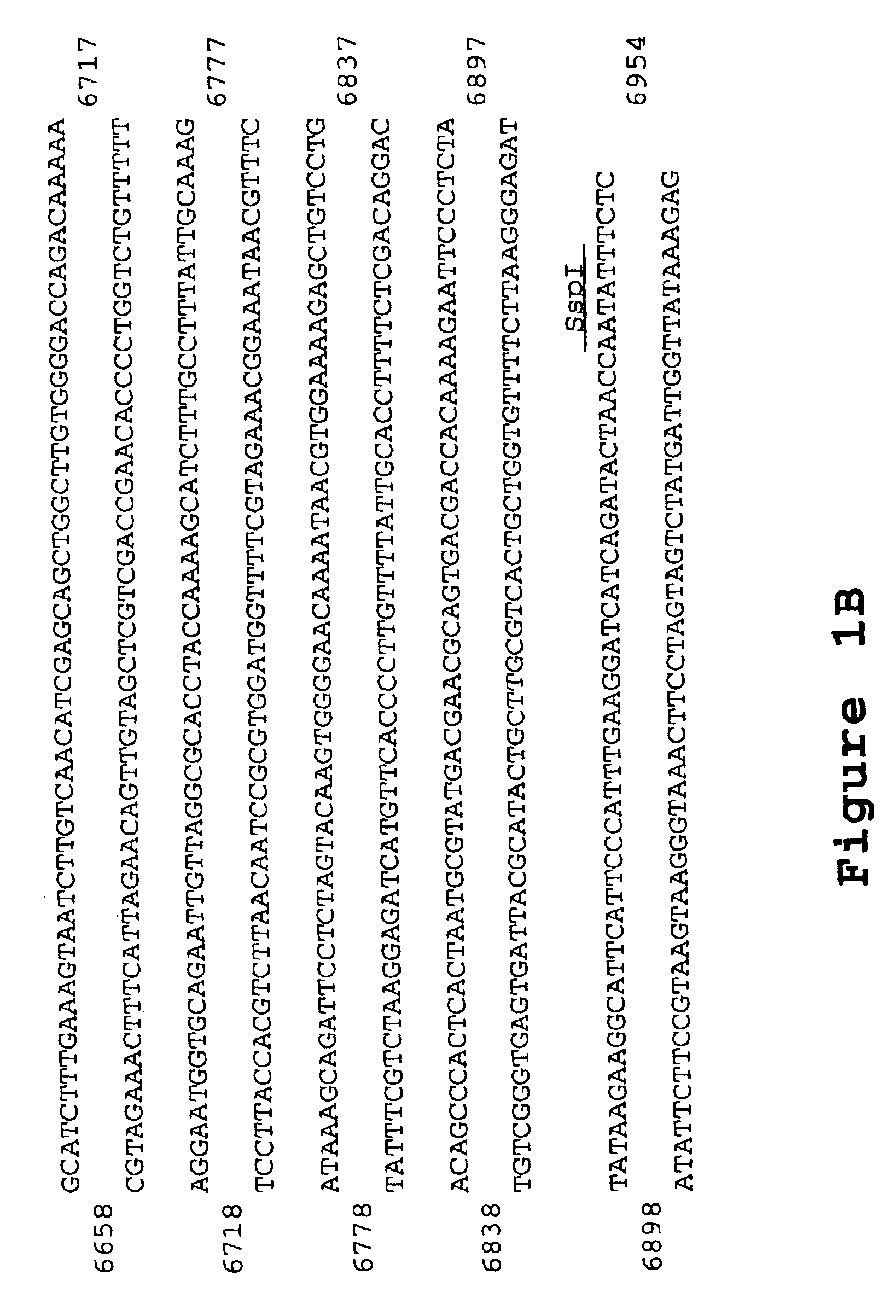

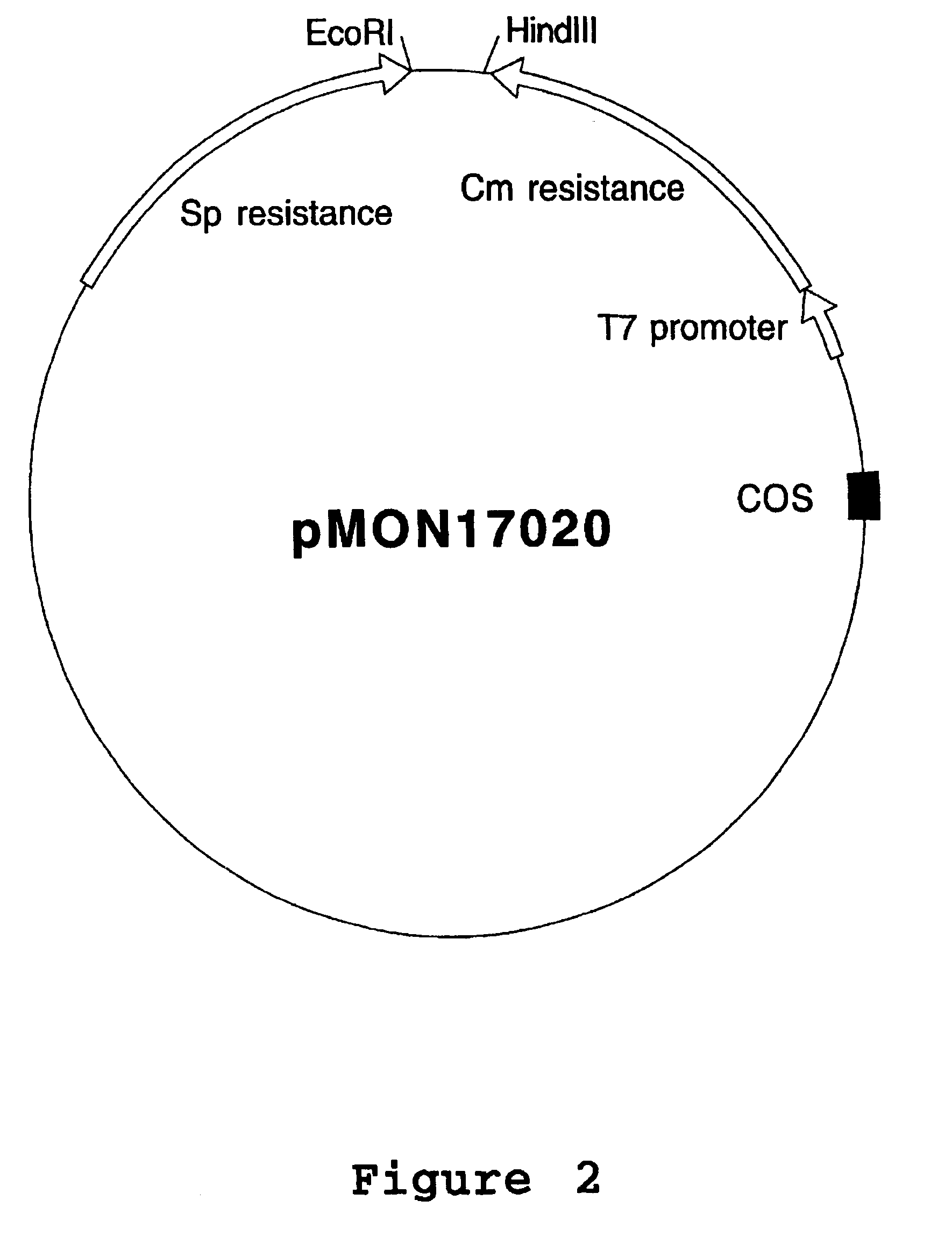

Glyphosate-tolerant 5-enolpyruvylshikimate-3-phosphate synthases

InactiveUSRE39247E1Reduce amount of overproductionGlyphosate toleranceSugar derivativesTransferasesPhosphateGenetically modified crops

Genes encoding Class II EPSPS enzymes are disclosed. The genes are useful in producing transformed bacteria and plants which are tolerant to glyphosate herbicide. Class II EPSPS genes share little homology with known, Class I EPSPS genes, and do not hybridize to probes from Class I EPSPS's. The Class II EPSPS enzymes are characterized by being more kinetically efficient than Class I EPSPS's in the presence of glyphosate. Plants transformed with Class II EPSPS genes are also disclosed as well as a method for selectively controlling weeds in a planted transgenic crop field.

Owner:MONSANTO TECH LLC

Herbicide compatibility improvement

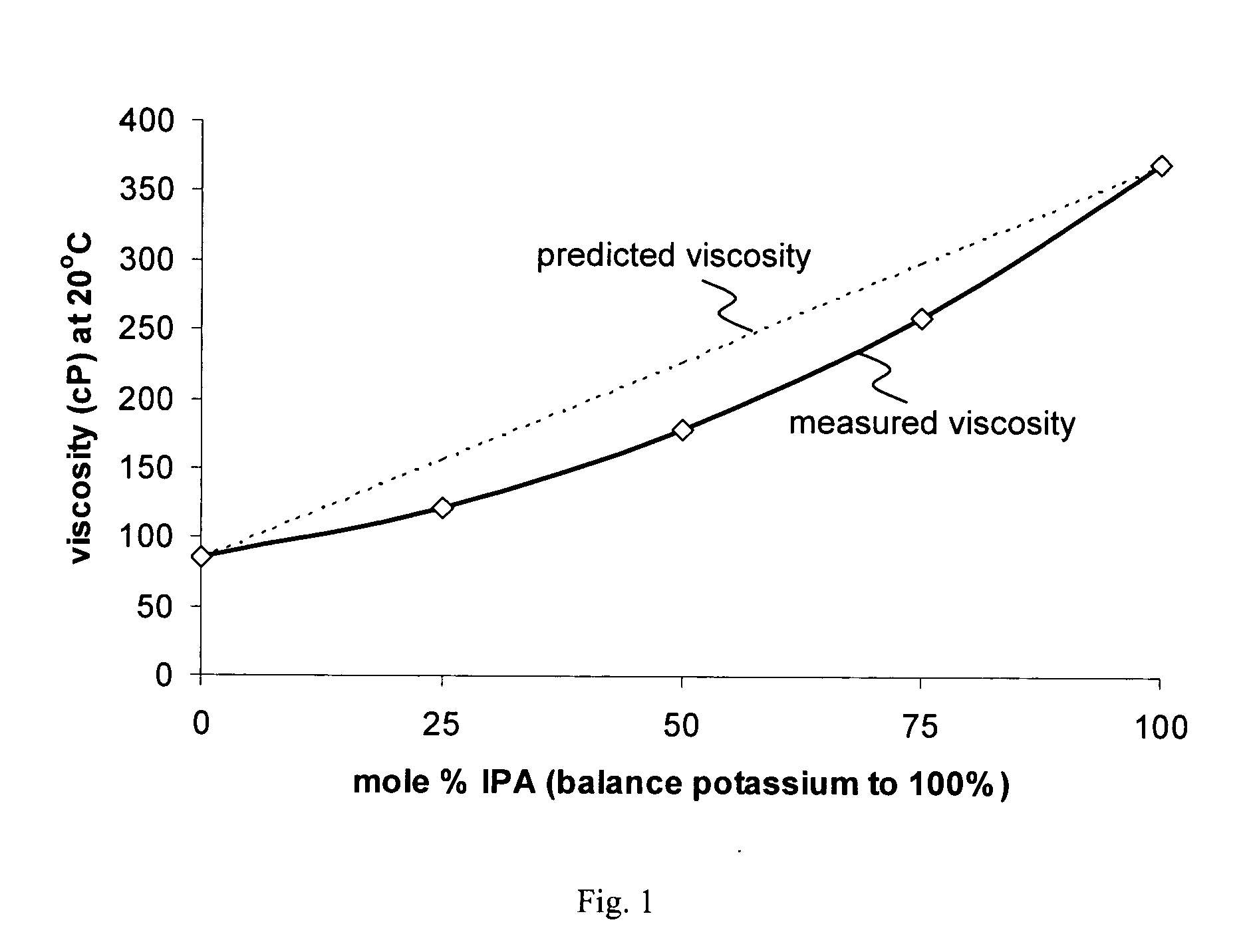

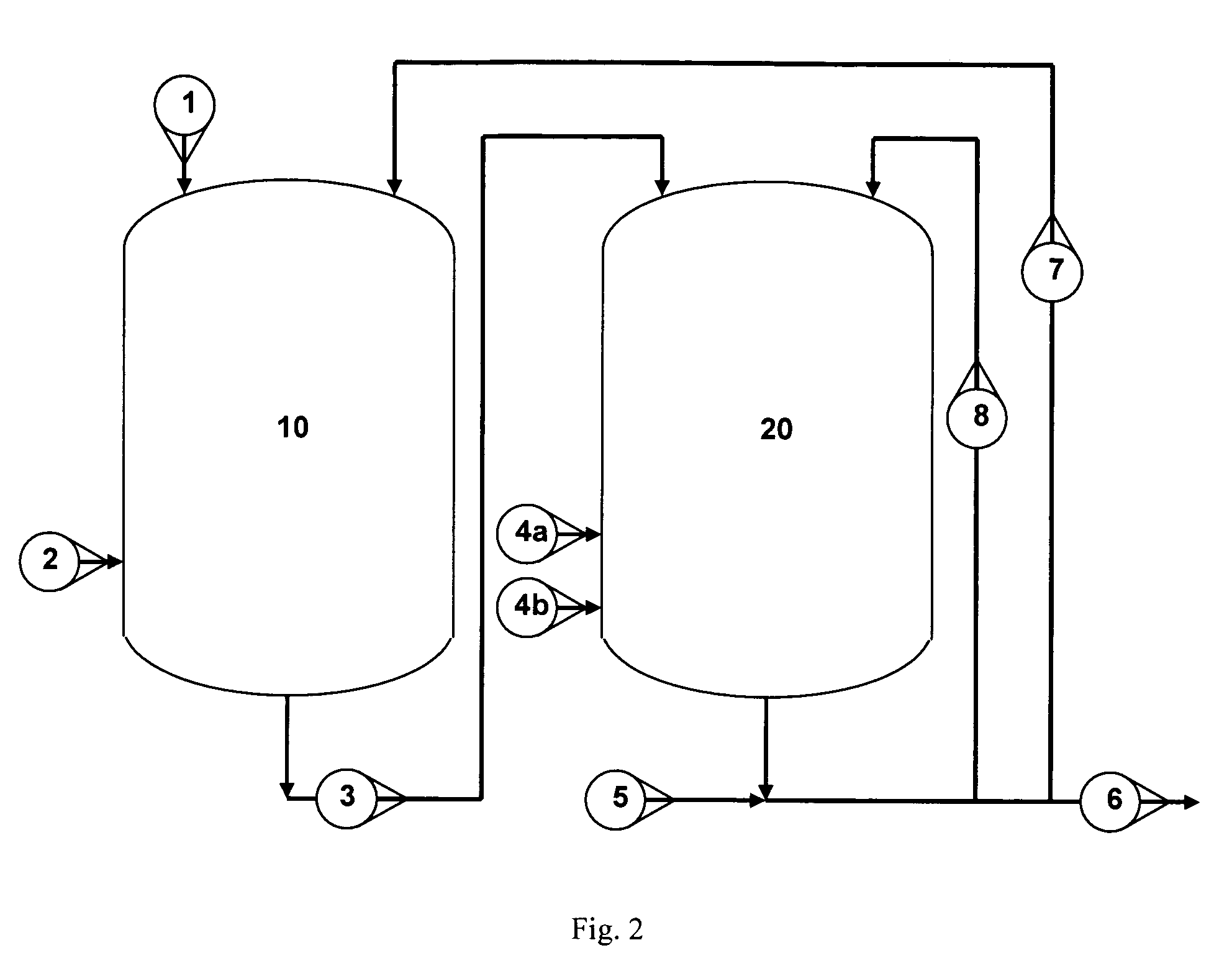

ActiveUS20060270556A1Improved tank-mix compatibilityReduced surfactant compatibilityBiocideDead animal preservationPotassium CationAqueous solution

A herbicidal composition comprises an aqueous solution of one to a plurality of salts of glyphosate at a total glyphosate a.e. concentration not less than about 360 g / l, wherein (a) said glyphosate is in anionic form accompanied by low molecular weight non-amphiphilic cations in a total molar amount of about 110% to about 120% of the molar amount of said glyphosate; and (b) a major amount to substantially all of the low molecular weight non-amphiphilic cations are potassium cations. The composition exhibits improved tank-mix compatibility with a phenoxy-type herbicide salt formulation by comparison with an otherwise similar composition having a lower molar amount of said low molecular weight non-amphiphilic cations.

Owner:MONSANTO TECH LLC

Glyphosate salt herbicidal composition

ActiveUS20060040826A1Improve compatibilityAcceptable surfactant compatibilityBiocideDead animal preservationPotassiumAqueous solution

A herbicidal composition comprises in aqueous solution a mixture of salts of glyphosate at a total glyphosate a.e. concentration not less than about 360 g / l, wherein (a) said glyphosate is in anionic form accompanied by low molecular weight non-amphiphilic cations in a total molar amount of about 100% to about 120% of the molar amount of said glyphosate; (b) said cations comprise potassium and propylammonium (e.g., isopropylammonium) cations in a mole ratio of about 70:30 to about 90:10; and (c) said potassium and propylammonium cations together constitute about 90 to 100 molar percent of all of said low molecular weight non-amphiphilic cations in the composition.

Owner:MONSANTO TECH LLC

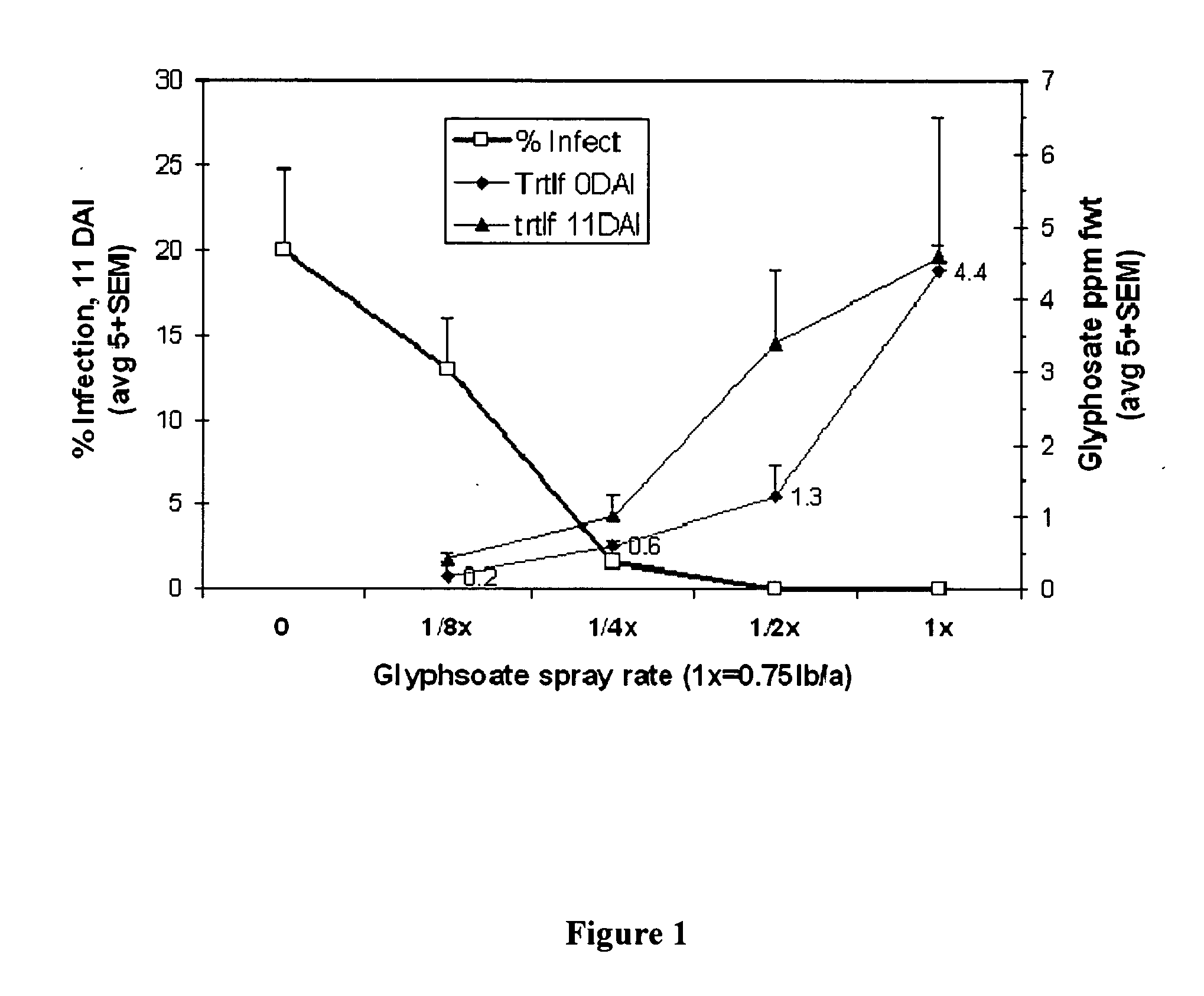

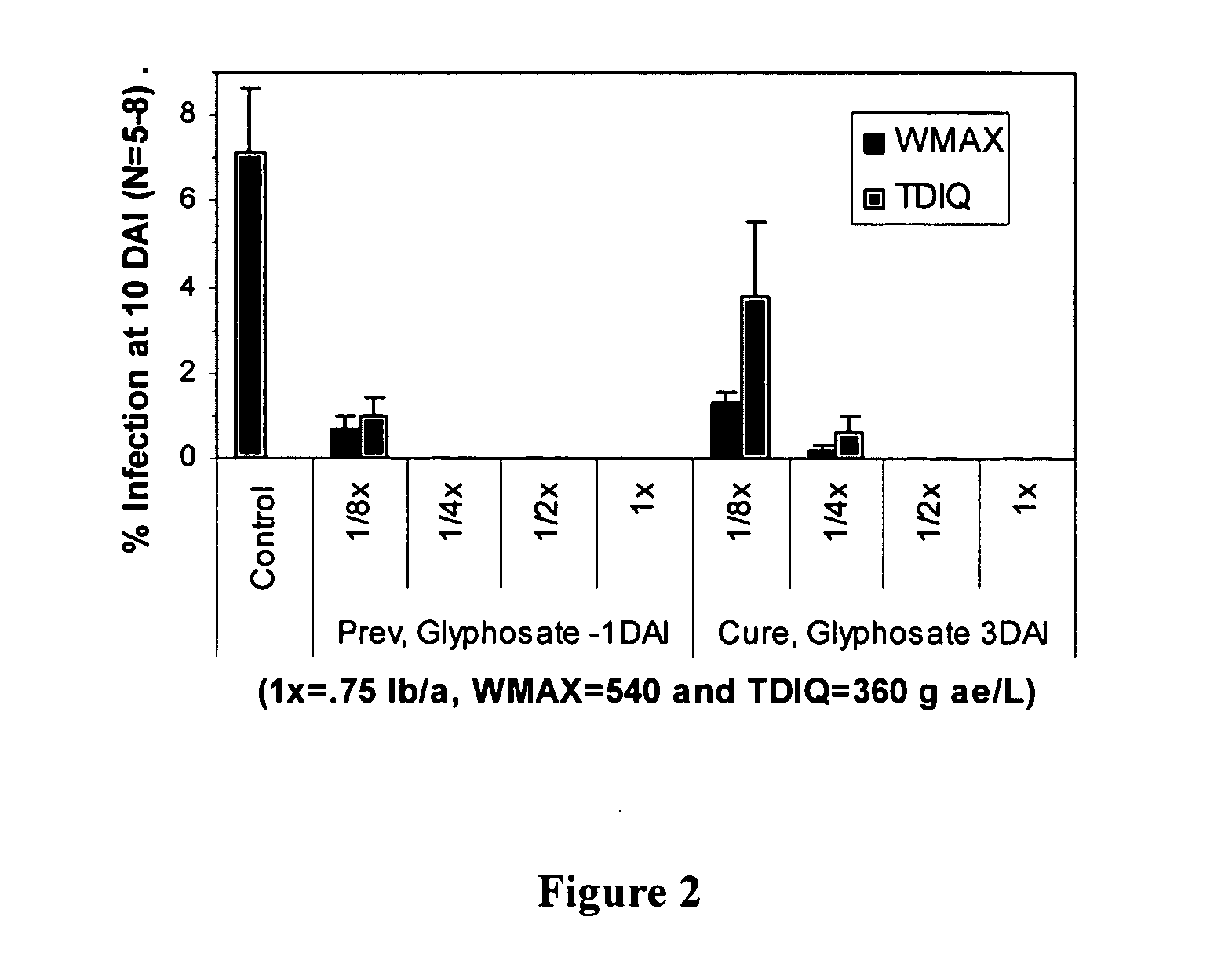

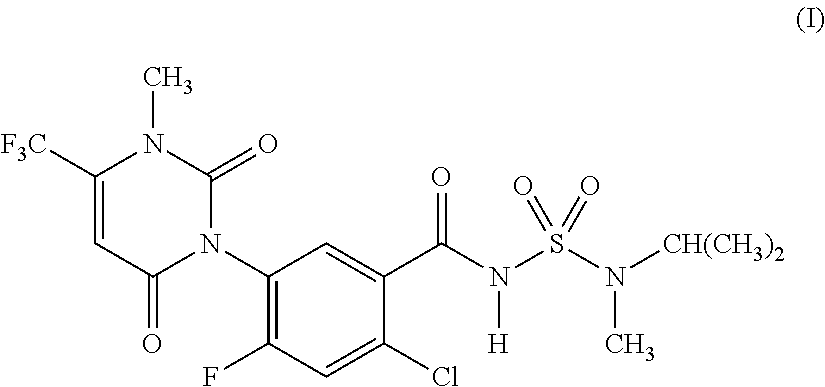

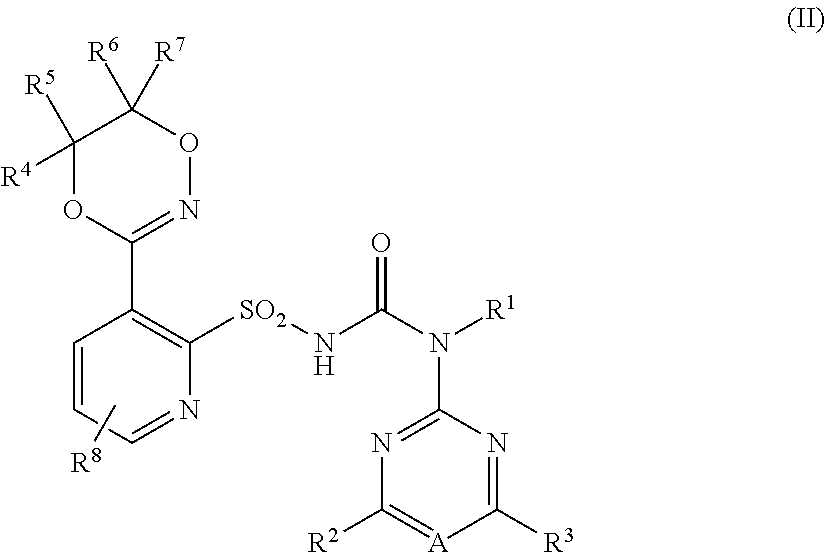

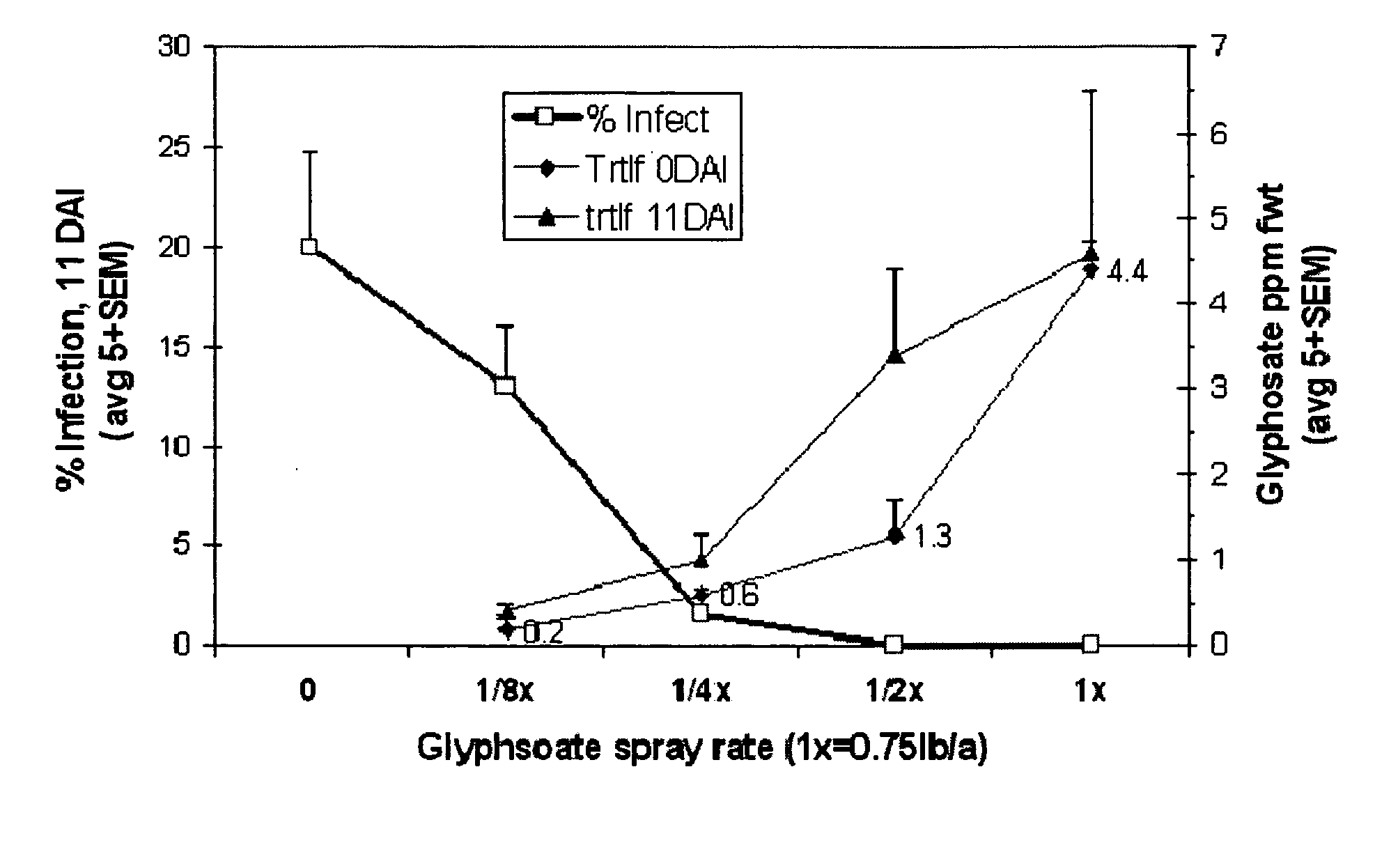

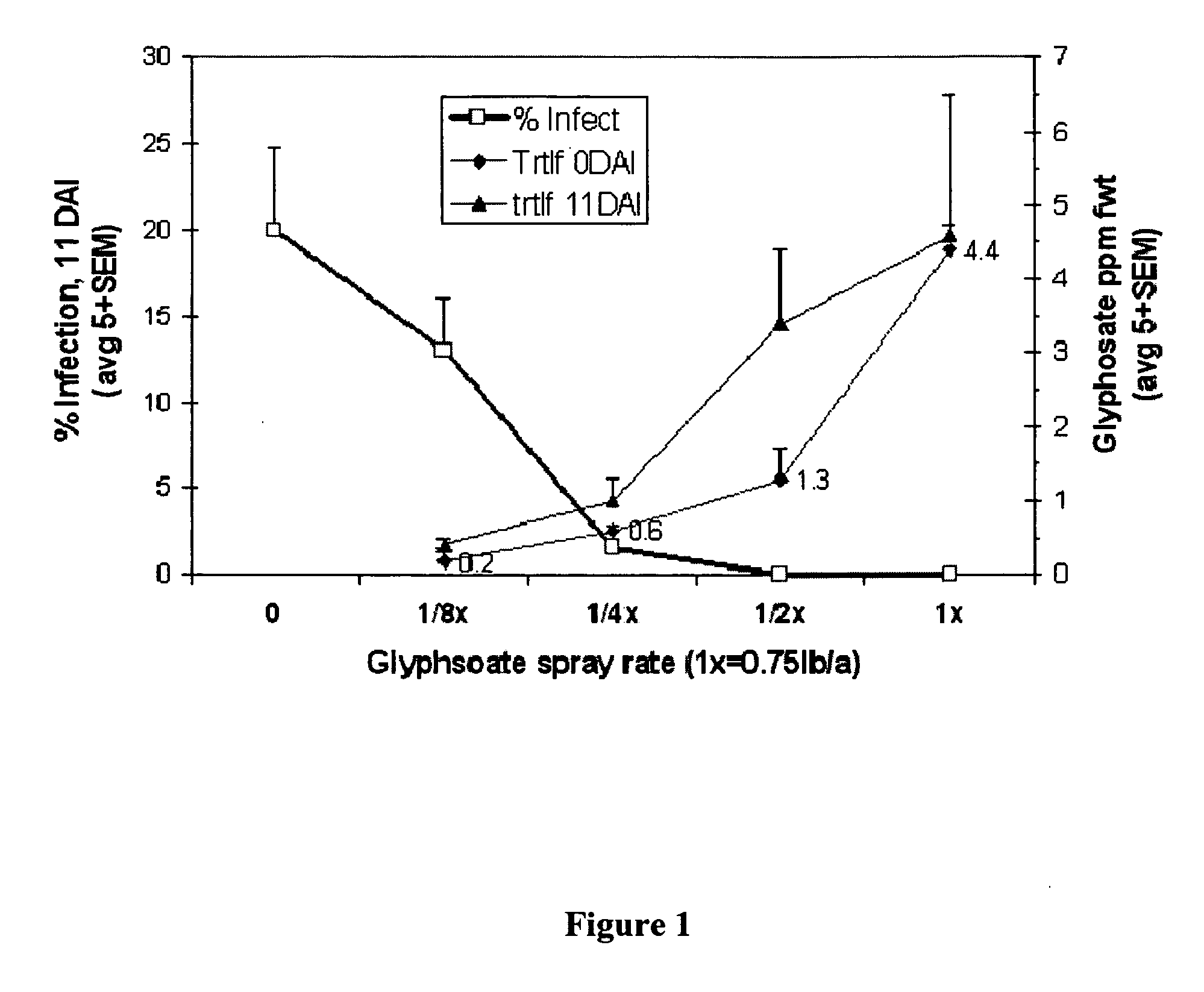

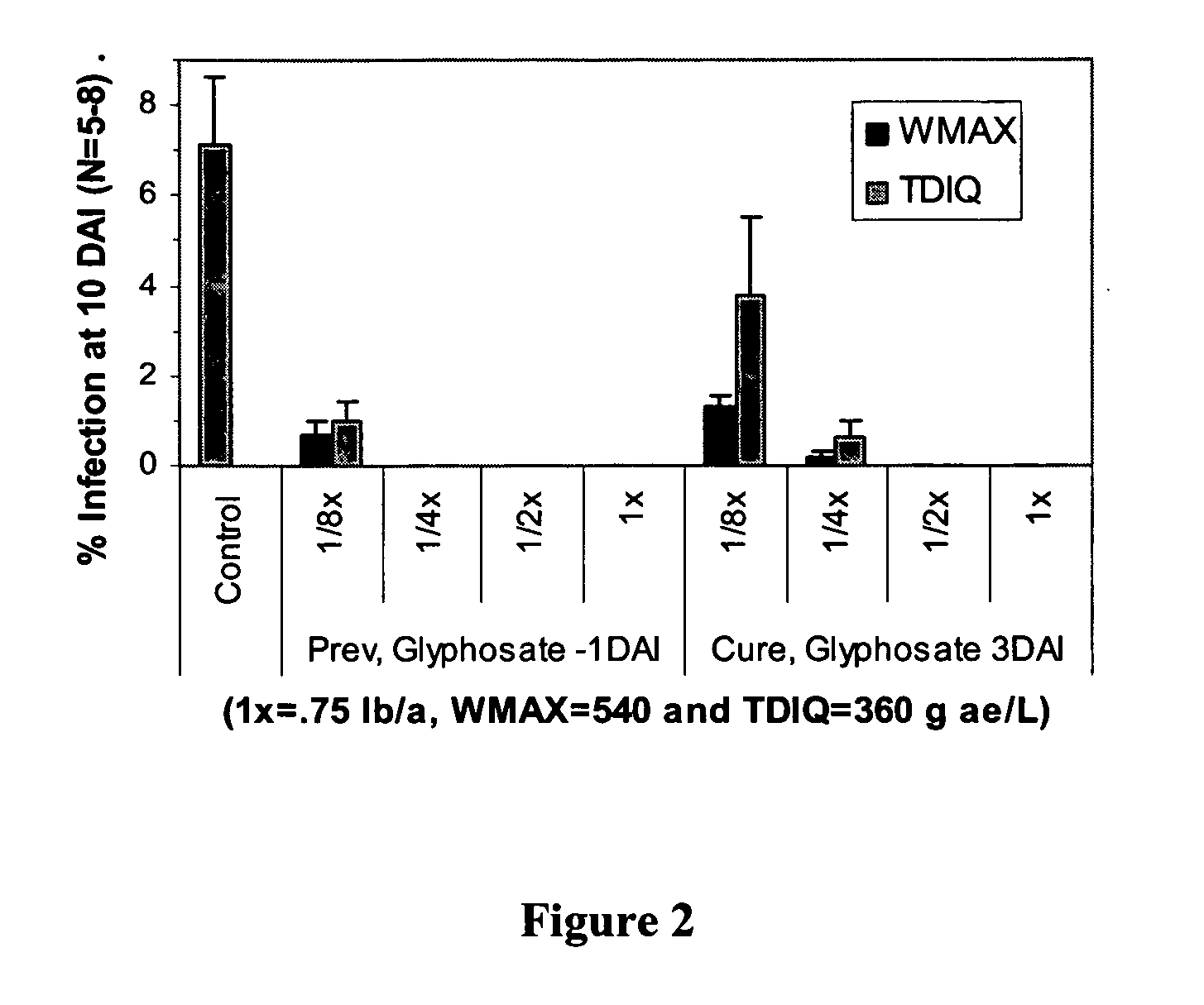

Methods for controlling plant pathogens using N-phosphonomethylglycine

InactiveUS20050223425A1Reduce in quantityAvoid controlBiocideDead animal preservationPlant diseaseGlyphosate toxicity

The present invention relates to compositions and methods for disease control in plants. The compositions for use in the methods of the invention include glyphosate as the active compound. In addition, methods and compositions are disclosed to prevent and treat pest infection in glyphosate tolerant plants.

Owner:MONSANTO TECH LLC

Herbicidal Composition Comprising The Hydrates Of Saflufenacil And Glyphosate Or Glufosinate

Owner:BAYER INTELLECTUAL PROPERTY GMBH

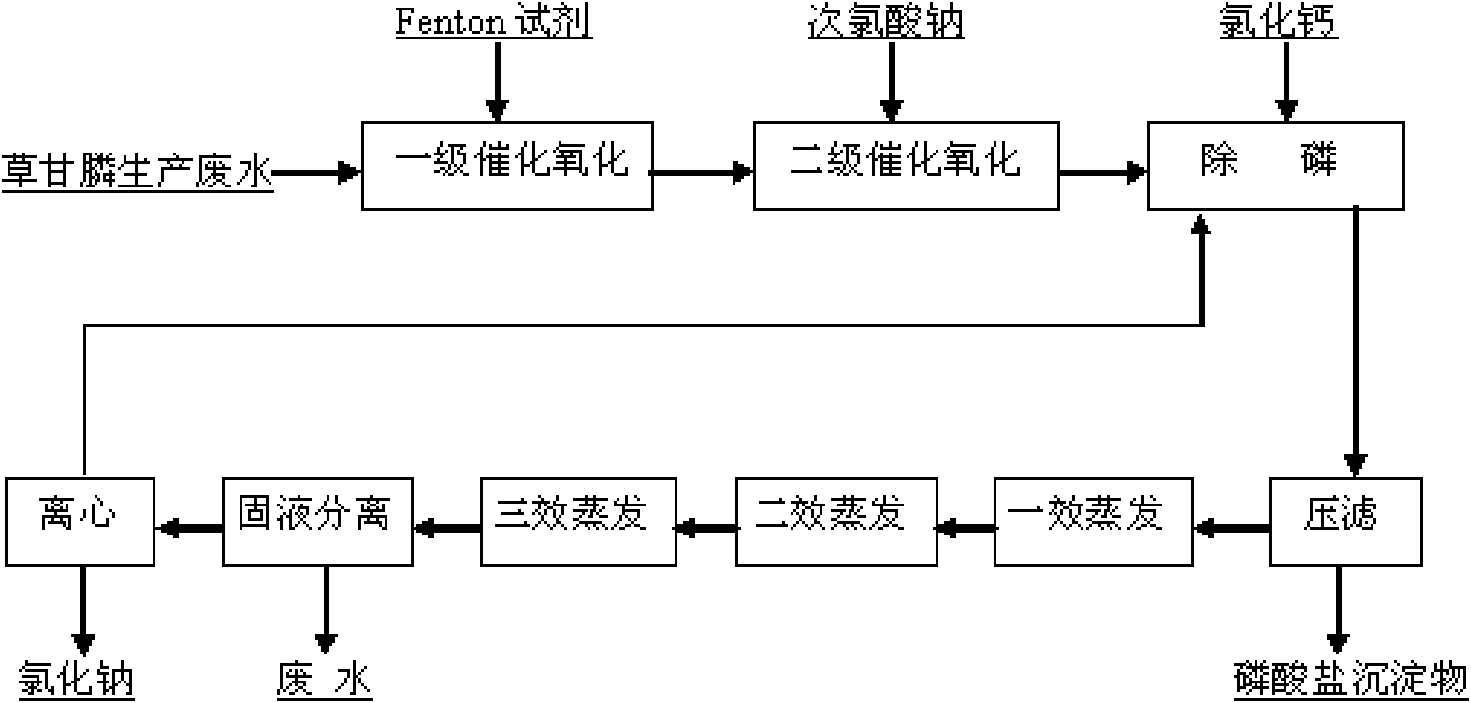

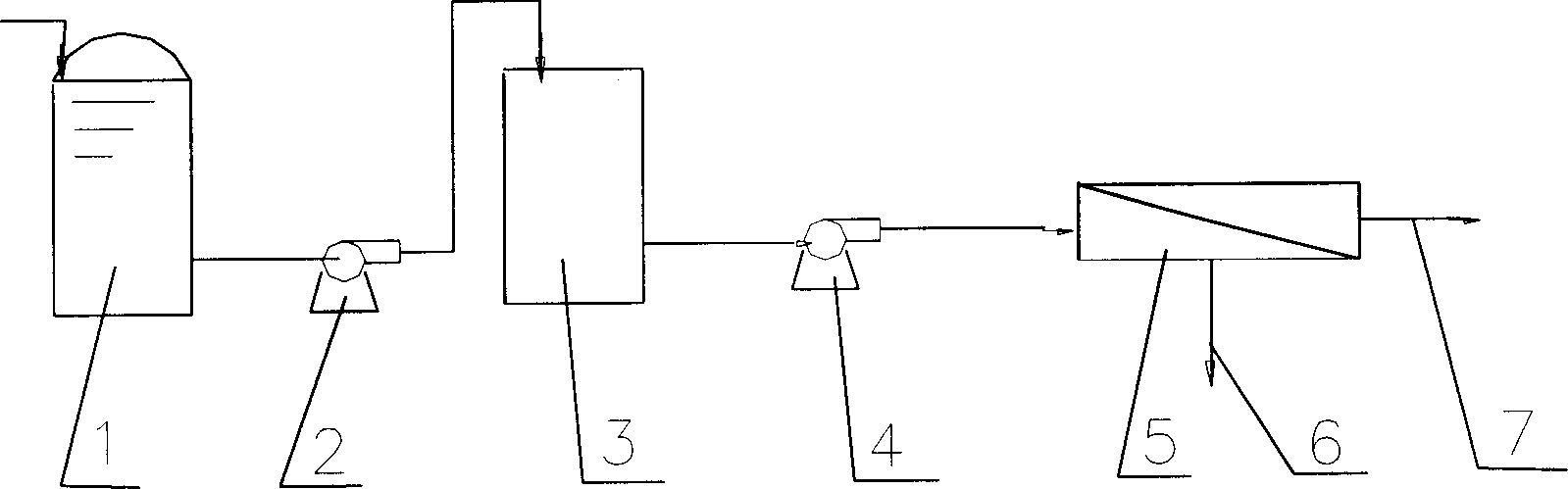

Pretreatment method for glyphosate industrial waste water

InactiveCN101671089AReduce potential threatsQuality improvementMultistage water/sewage treatmentNature of treatment waterSocial benefitsPretreatment method

A pretreatment method for glyphosate industrial waste water relates to the technical field of the treatment method for the industrial waste water from pesticides. The invention provides the pretreatment method for the glyphosate industrial waste water, which can remove glyphosate, sodium chloride and reduce COD cr value. The pretreatment method can effectively remove the vast majority of sodium chloride and glyphosate in the glyphosate industrial waste water by adopting steps such as adjusting Ph value, catalytic oxidation, calcification phosphorus removal, triple effect evaporation crystallized sodium chloride removal and the like, and greatly reduces COD cr value; the pretreated waste water can be discharged into a follow-up biochemical treatment system for biochemical treatment, thus causing waste water to be discharged after reaching standards, being beneficial to the protection of the environment and having good social benefits.

Owner:FUJIAN SANNONG GROUP

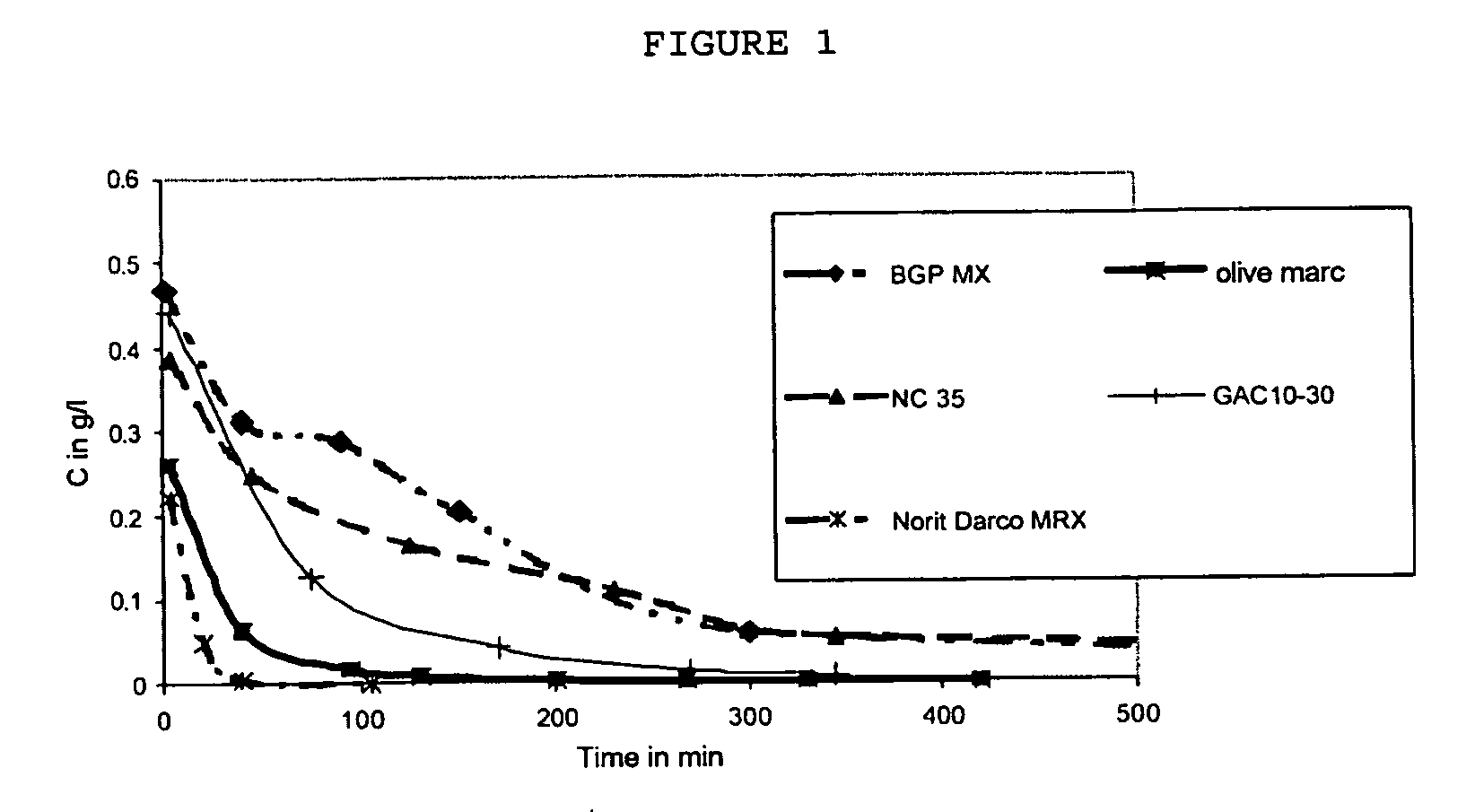

Activated carbon with improved mechanical resistance, and the uses thereof, especially as a catalyst carrier

InactiveUS20070123419A1Strong mechanical propertiesRapidly impregnated with oxidation catalystCarbon compoundsOther chemical processesGas phaseSolvent

The present invention relates to active charcoals with improved mechanical properties. They can advantageously be used in the sweetening of petroleum fractions, as oxidation catalyst support in the conversion of mercaptans to disulphides, but also in any other type of reaction, such as, for example, for the oxidation of cyanide present in water or in the synthesis of glyphosate, and in processes for purification and / or separation by selective adsorption in a liquid phase and / or in a gas phase (decolouration of liquid foodstuffs, water treatment, air treatment, recovery of solvents, and the like).

Owner:LE BEC REMY

Technique for cleanly recovering byproduct methyl chloride of glyphosate acid

InactiveCN1446782ARealize cleaner productionEasy to operateGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationPhosphorus acidChloride

A process for recovering chloromethane from the tail gas exhausted in the procedure of preparing glyphosate by phosphorus acid-phytanic acid method is disclosed. As said tail gas contains chloromethane (20-90%) and impurities (methanol, methylal, H2O and hydrogen chloride), it uses solvent to absorb impurities, or condenses the impurities, or convents the impurities to chloromethane, so obtaininghigh-purity chloromethane.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

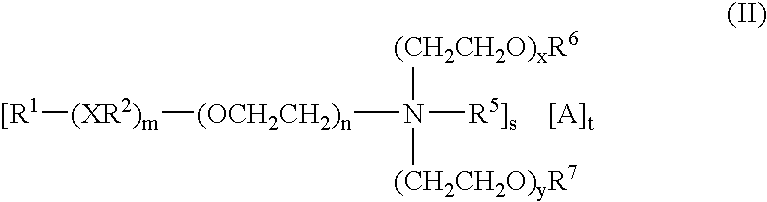

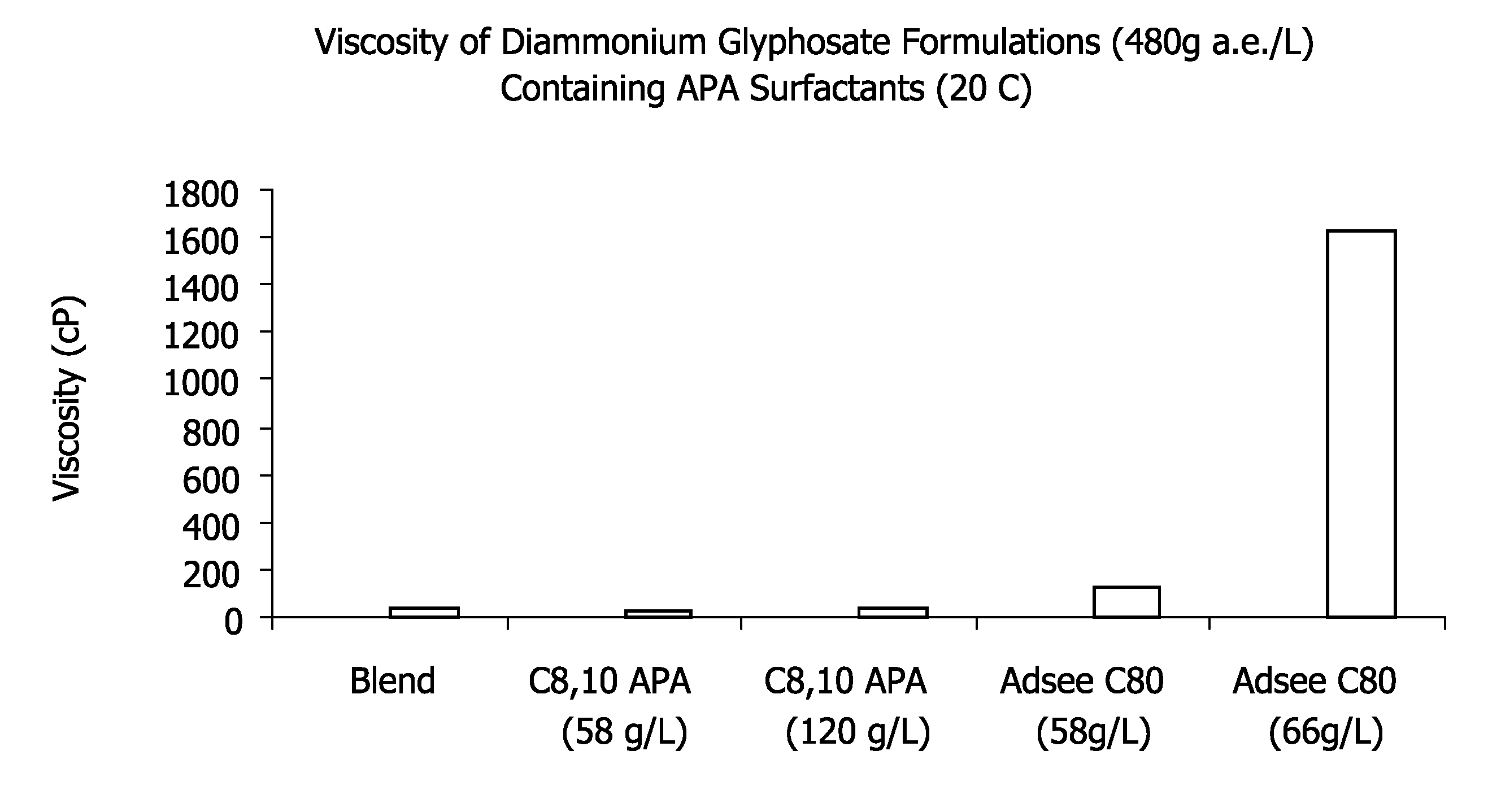

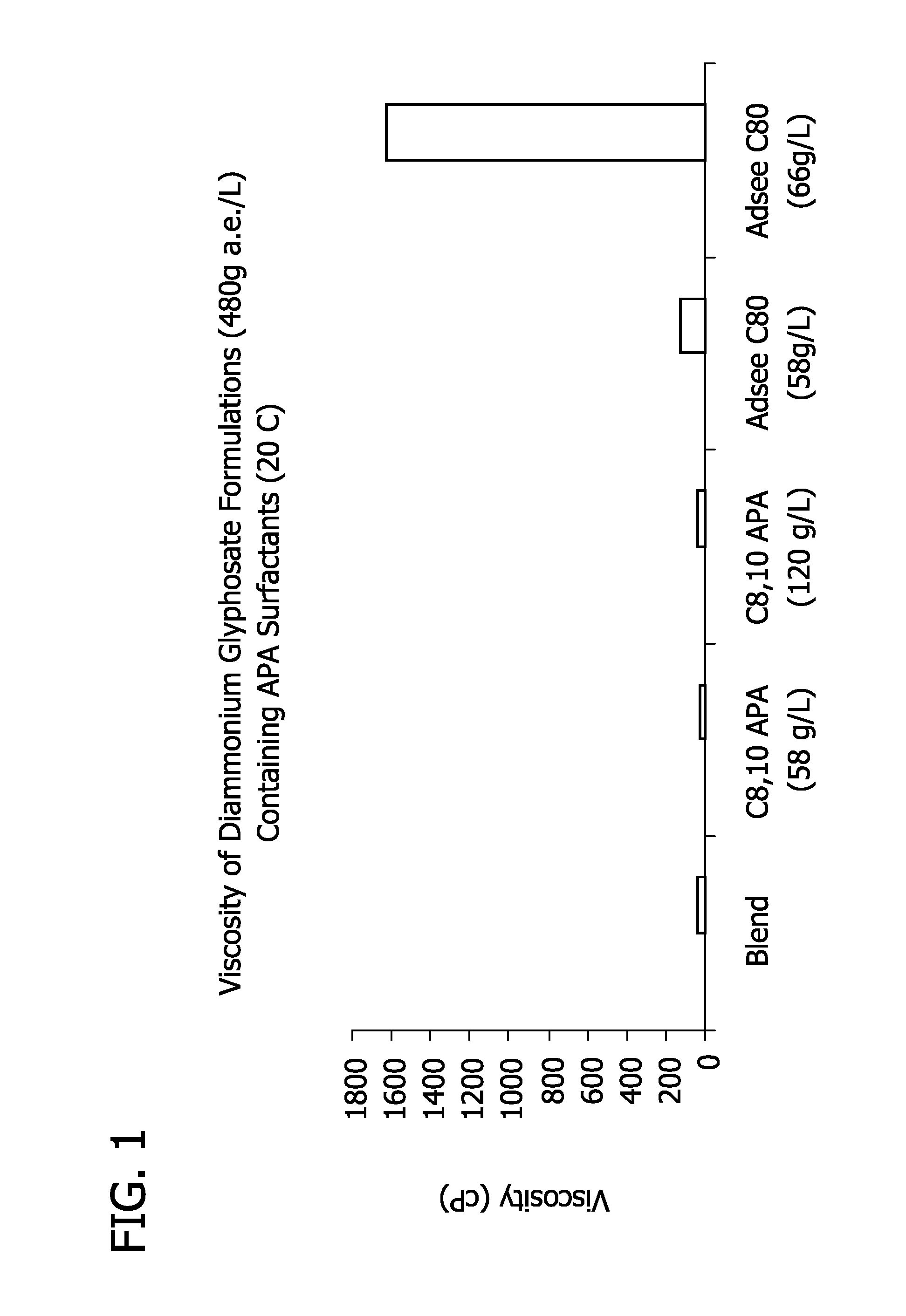

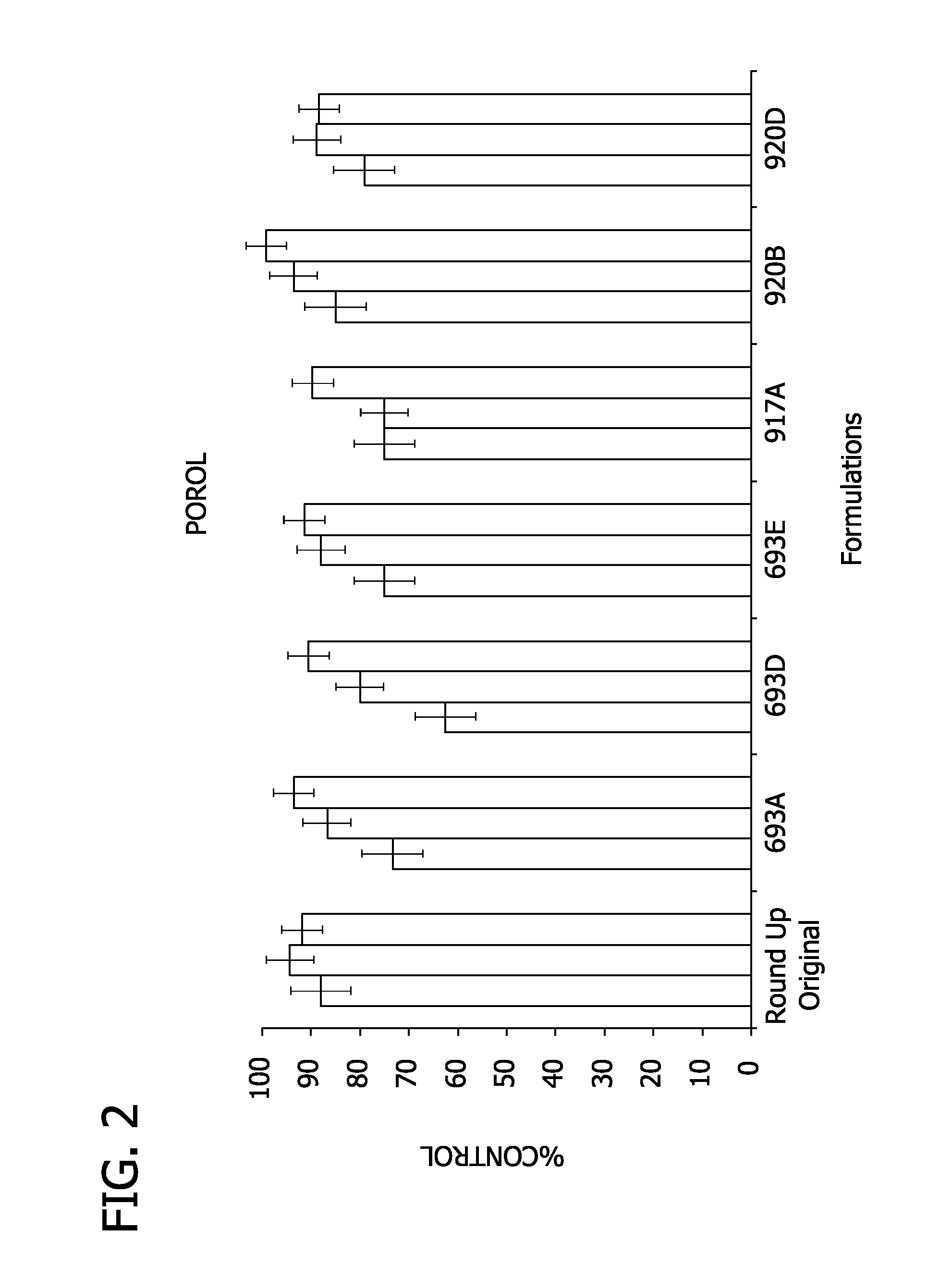

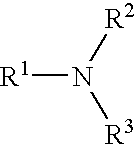

Glyphosate formulations containing amidoalkylamine surfactants

InactiveUS20100113274A1Low toxicityComposition is stableBiocideDead animal preservationSURFACTANT BLENDGlyphosate toxicity

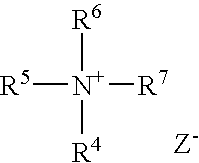

An herbicidal composition comprising (a) glyphosate or a derivative thereof, (b) an amidoalkylamine surfactants having the general structure:wherein R1 is a hydrocarbyl having from about 1 carbon atoms to about 22 carbon atoms, and R2, R3, and R4 are each independently hydrocarbyl having from about 1 carbon atom to about 6 carbon atoms; and (c) at least one co-surfactant.

Owner:MONSANTO TECH LLC

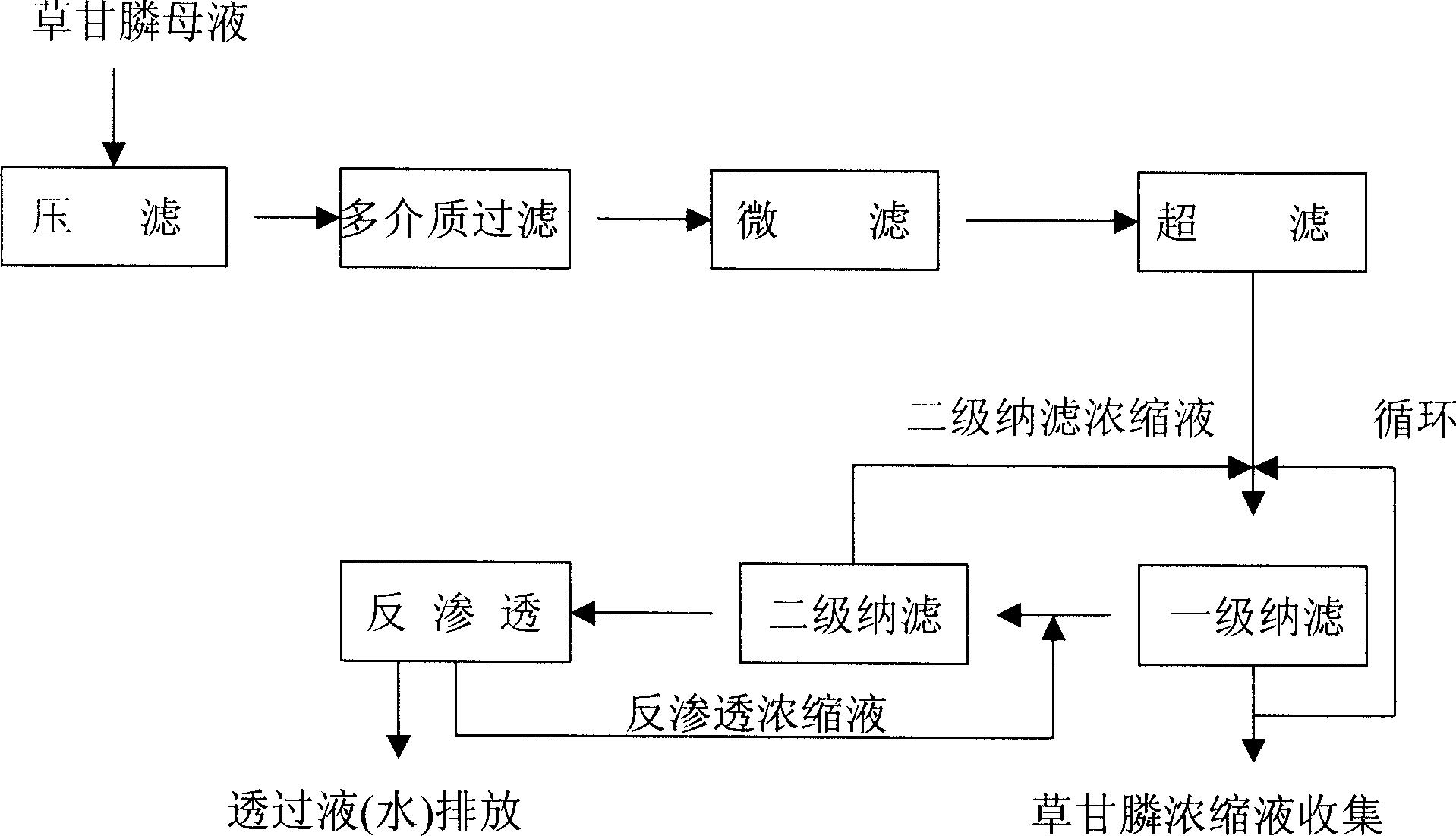

Process for separation and purification of glyphosate from glyphosate solution by membrane technology

InactiveCN1827626AAvoid decompositionQuality improvementBiocideGroup 5/15 element organic compoundsSolid componentDecomposition

The invention discloses a method for extracting glyphosate from heavy glyphosate stock solution by membrane separation technique. It consists of filtering the mother liquid, removing the solid component of the system, then according to the molecular structure, molecular mass, particle size and electric charge, from the big one to the small one, separating step by step by selecting appropriate hyperfiltration membrane, nanofiltration membrane and reverse osmosis membrane to obtain the effective composition of glyphosate. The invention unitizes the separation, concentration and the purification, and is performed at normal temperature. The barrier separation process is excellent in that it is of no change of phase, avoids the decomposition of glyphosate caused by high enrichment and concentration, effectively improves the product quality and yield rate, greatly reduces the energy consumption, is of consecutive operation, low operation cost, and it is energy-saving, highly effective, environment-friendly, furthermore, it can be operated by combining with routine thickening operating unit or be operated individually and is suitable for industrial continuous production.

Owner:捷马化工股份有限公司

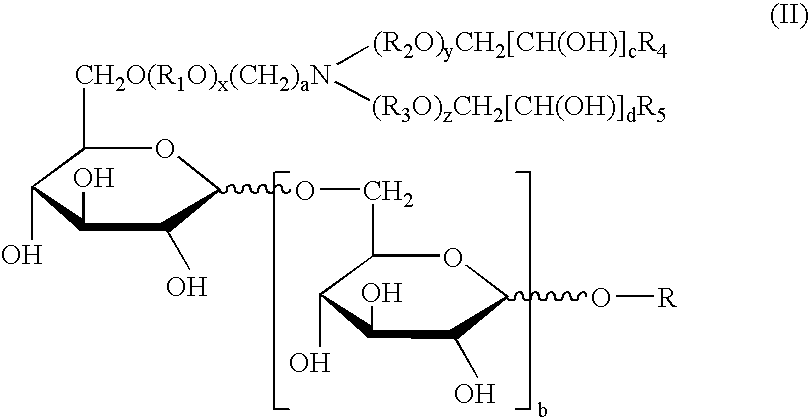

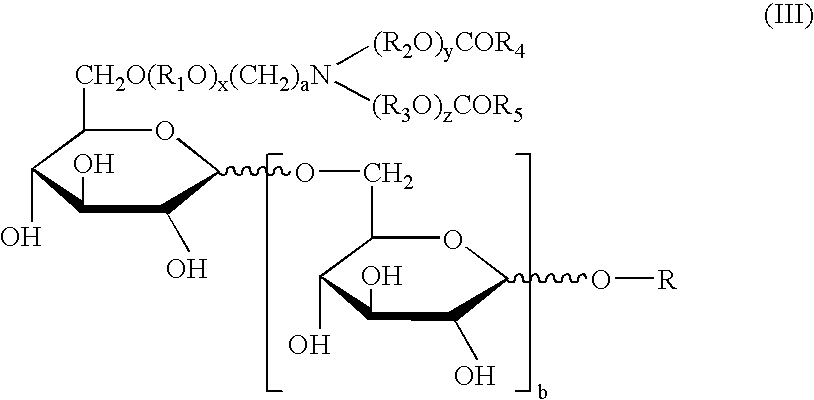

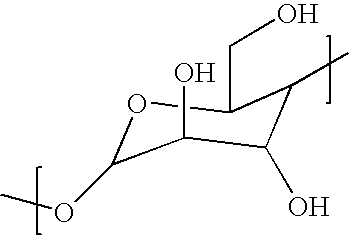

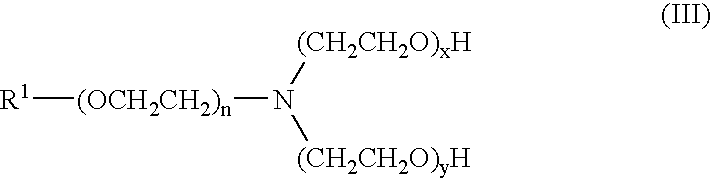

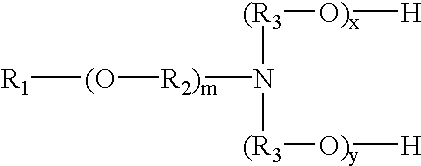

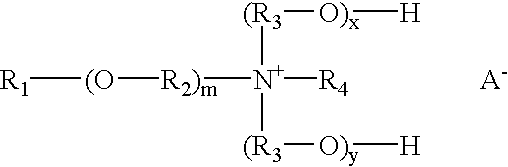

Glyphosate formulations containing etheramine surfactants

InactiveUSRE37866E1Improve performanceGood storage stabilityBiocideDead animal preservationArylSURFACTANT BLEND

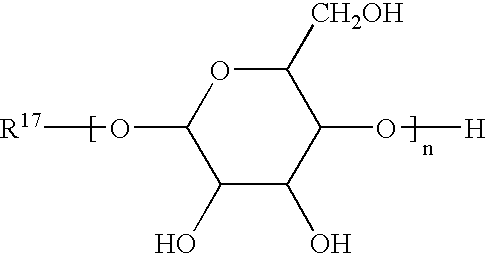

Herbicidal compositions are provided comprising glyphosate or a salt thereof and an etheramine surfactant having the representative chemical structure (a)wherein R1 is a straight or branched chain C6 to about C22 alkyl, aryl or alkylaryl group, m is an average number from 1 to about 10, R2 in each of the m (O-R2) groups is independently C1-C4 alkylene, R3 groups are independently C1-C4 alkylene, and x and y are average numbers such that x+y is in the range from 2 to about 60; or (b)wherein R1 is a straight or branched chain C6 to about C22 alkyl, aryl or alkylaryl group, m is an average number from 1 to about 10, R2 in each of the m (O-R2) groups is independently C1-C4 alkylene, R3 groups are independently C1-C4 alkylene, R4 is C1-C4 alkyl, x and y are average numbers such that x+y is in the range from 0 to about 60, and A- is an agriculturally acceptable anion; or (c)wherein R1 is a straight or branched chain C6 to about C22 alkyl, aryl or alkylaryl group, m is an average number from 1 to about 10, R2 is each of the m (O-R2) groups is independently C1-C4 alkylene, R3 groups are independently C1-C4 alkylene, and x and y are average numbers such that x+y is in the range from 2 to about 60.

Owner:MONSANTO TECH LLC

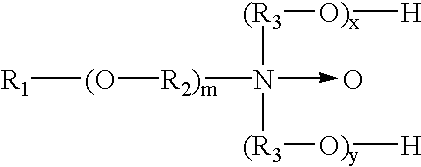

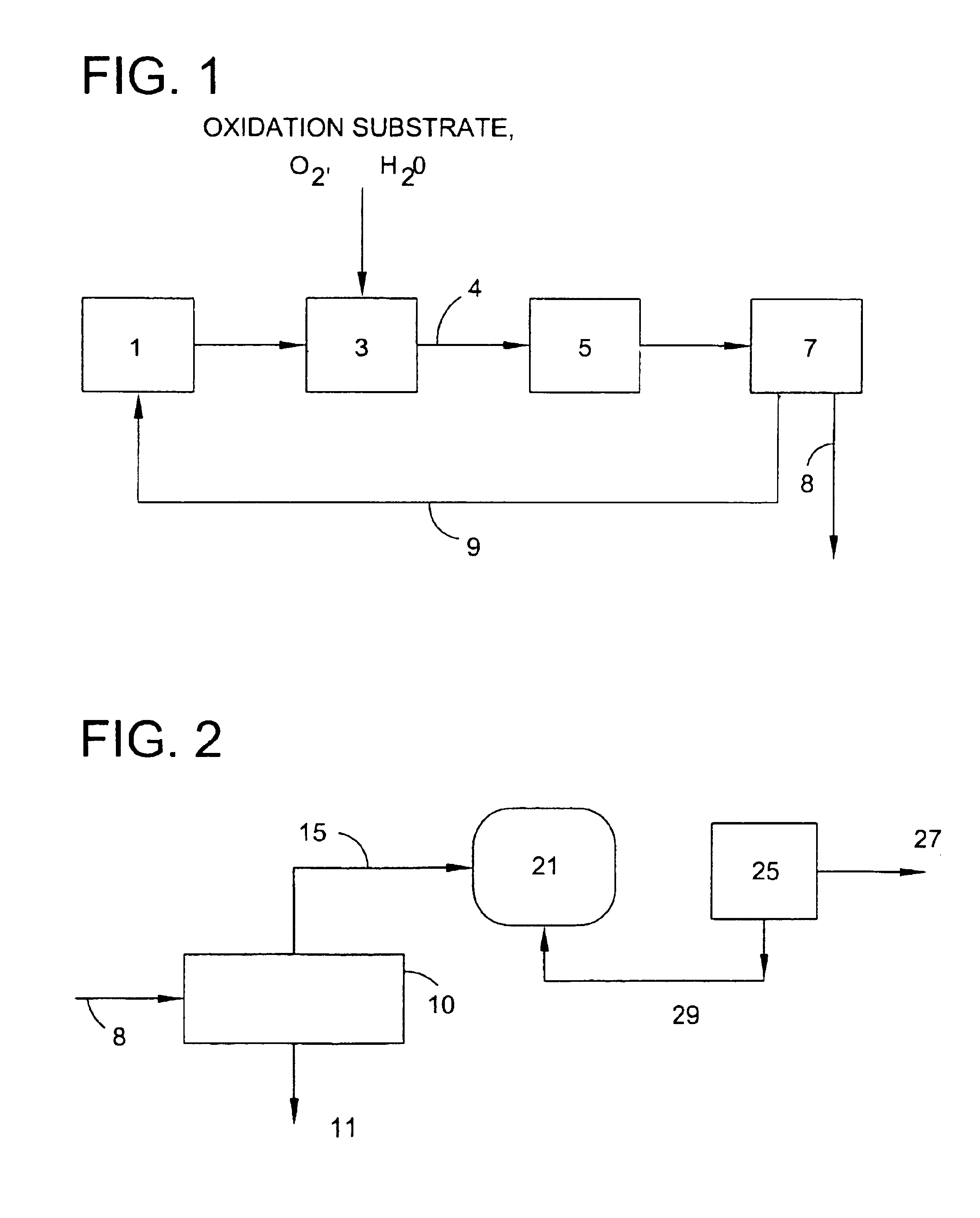

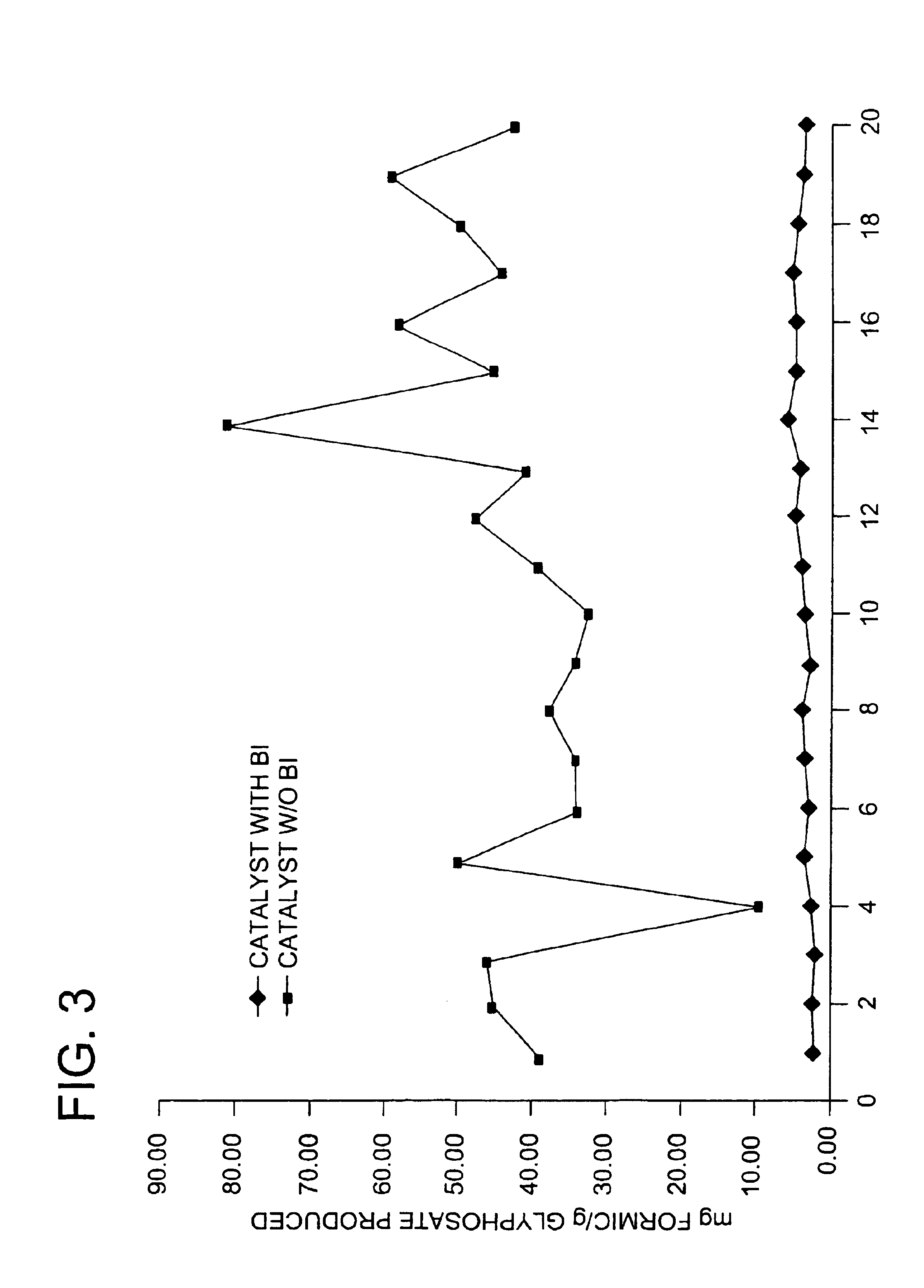

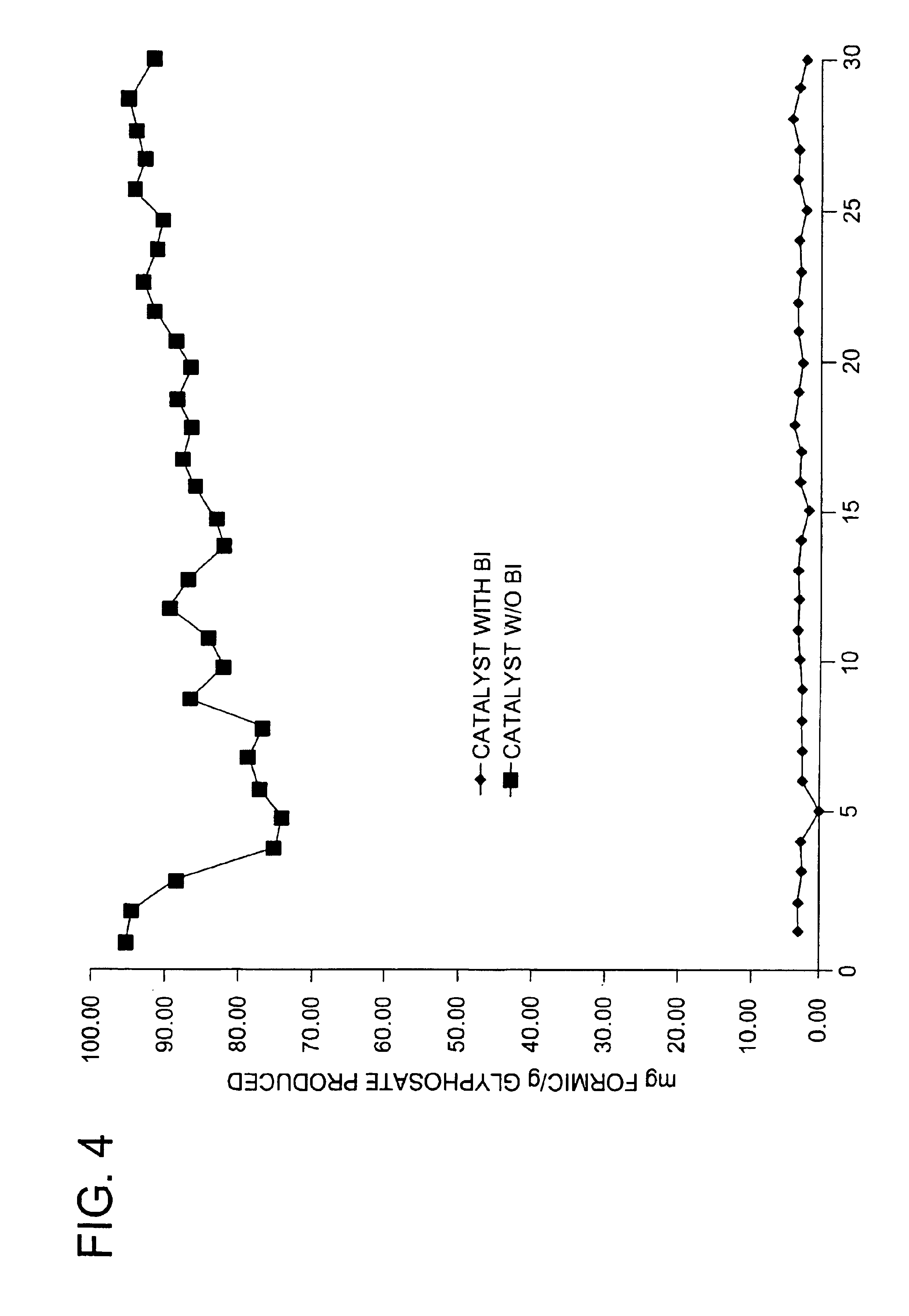

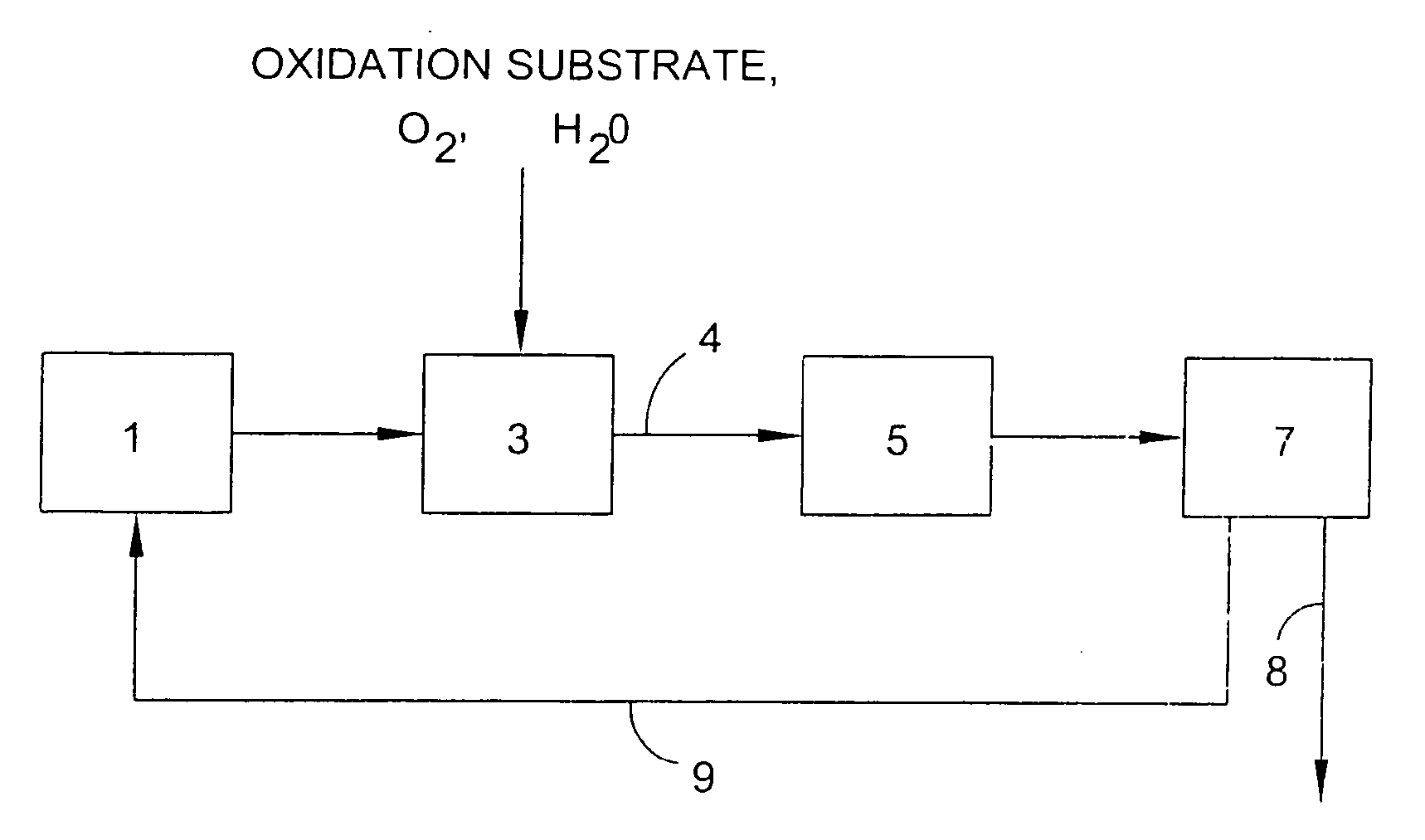

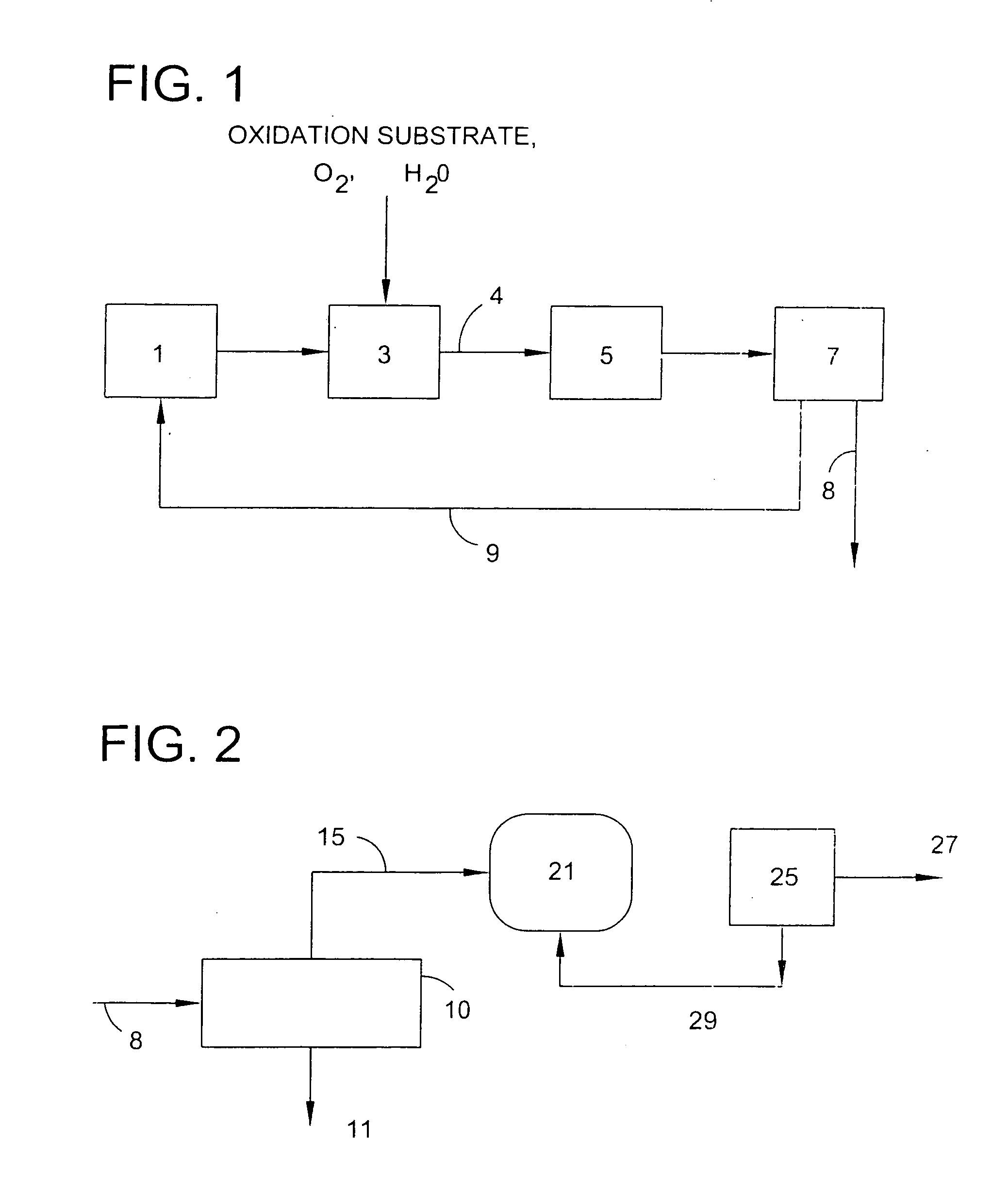

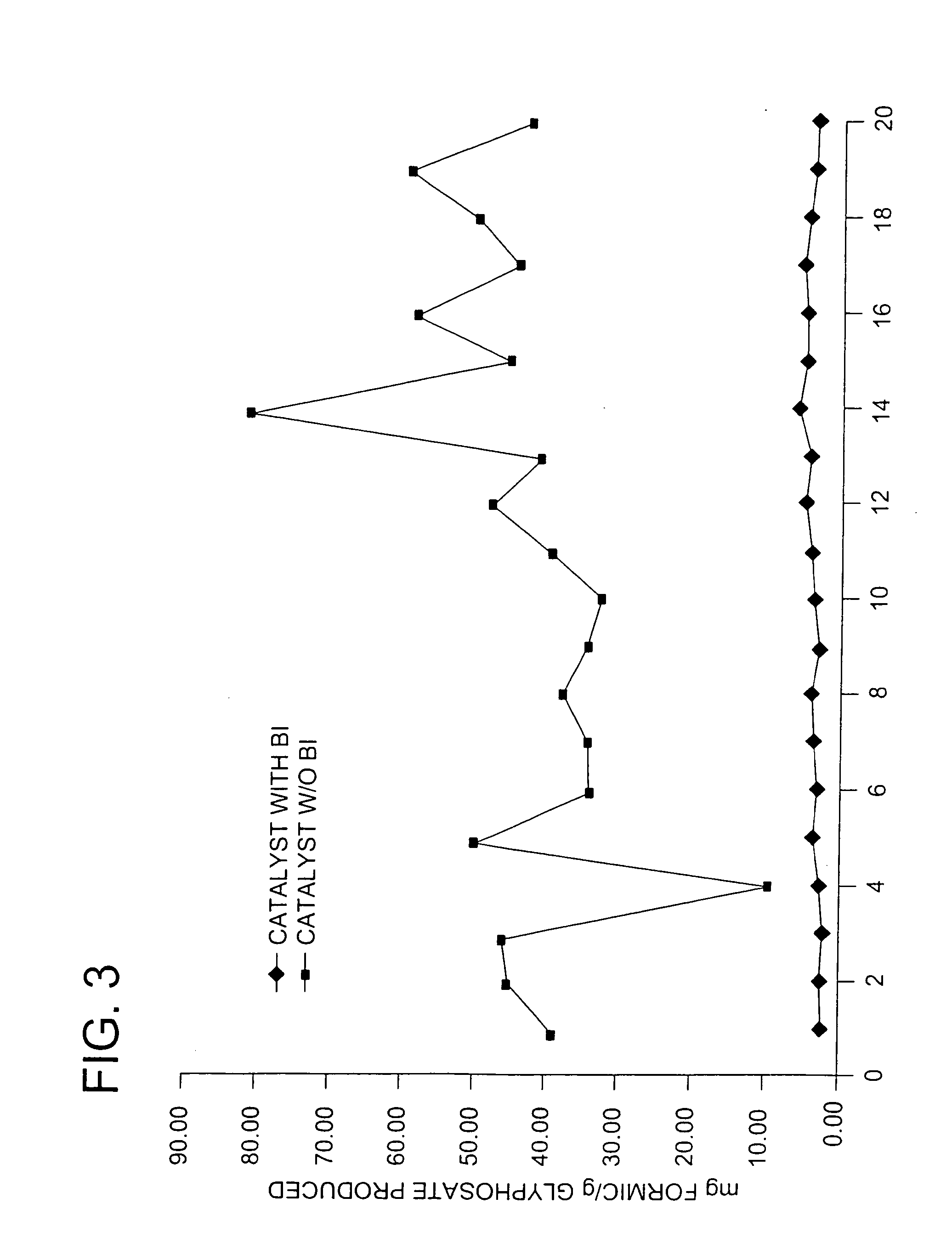

Use of a supplemental promoter in conjunction with a carbon-supported noble-metal-containing catalyst in liquid phase oxidation reactions

InactiveUS6963009B2Promote oxidationHigh activityBiocideGroup 5/15 element organic compoundsTe elementMethyl group

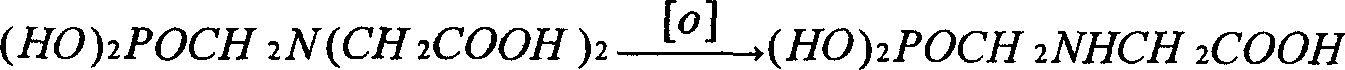

This invention relates to the use of a supplemental promoter in conjunction with a noble-metal-containing catalyst comprising a carbon support in catalyzing liquid phase oxidation reactions.In a particularly preferred embodiment, a supplemental promoter (most preferably bismuth or tellurium) is used in conjunction with a noble-metal-containing catalyst comprising a carbon support in a liquid phase oxidation process wherein N-(phosphonomethyl) iminodiacetic acid (i.e., “PMIDA”) or a salt thereof is oxidized to form N-(phosphonomethyl)glycine (i.e., “glyphosate”) or a salt thereof. The benefits of such a process include oxidation of the formaldehyde and formic acid by-products, and, consequently, decreased final concentrations of those by-products as well as other undesirable by-products, most notably N-methyl-N-(phosphonomethyl)glycine (i.e., “NMG”).

Owner:MONSANTO TECH LLC

Methods for controlling plants pathogens using N-phosphonomethylglycine

InactiveUS20070197474A1Prevent and control plant diseaseReduce in quantityBiocidePhosphorous compound active ingredientsGlyphosate toxicityPathogen

The present invention relates to compositions and methods for disease control in plants. The compositions for use in the methods of the invention include glyphosate as the active compound. In addition, methods and compositions are disclosed to prevent and treat pest infection in glyphosate tolerant plants.

Owner:MONSANTO TECH LLC

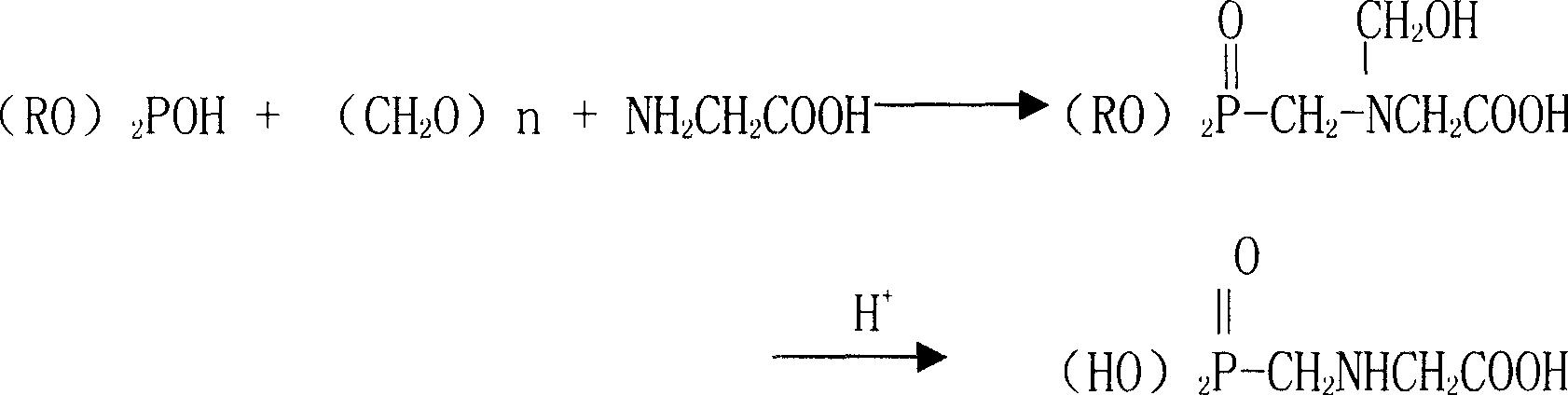

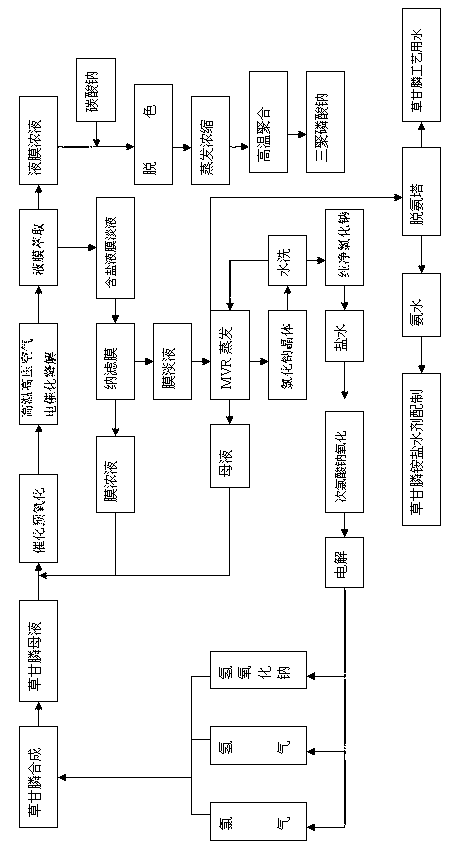

Cyclic production method of glyphosate

ActiveCN103012474AAvoid influenceReduce pollutionBiocideGroup 5/15 element organic compoundsEvaporationHigh pressure

Owner:HANGZHOU JINFADA CHEM IND

EPSP synthase highly tolerant to glyphosate

ActiveUS20050223436A1Improve abilitiesImprove toleranceSugar derivativesTransferasesEPSP synthaseGene

An isolated polypeptide comprising an amino acid sequence that is at least 62% identical to SEQ ID NO:2. The polypeptide, when present in a cell, increases the cell's ability to tolerate glyphosate. Also disclosed are related nucleic acid, antibody, vector, transgenic plant, as well as uses thereof.

Owner:LONGPING BIOTECH (HAINAN) CO LTD

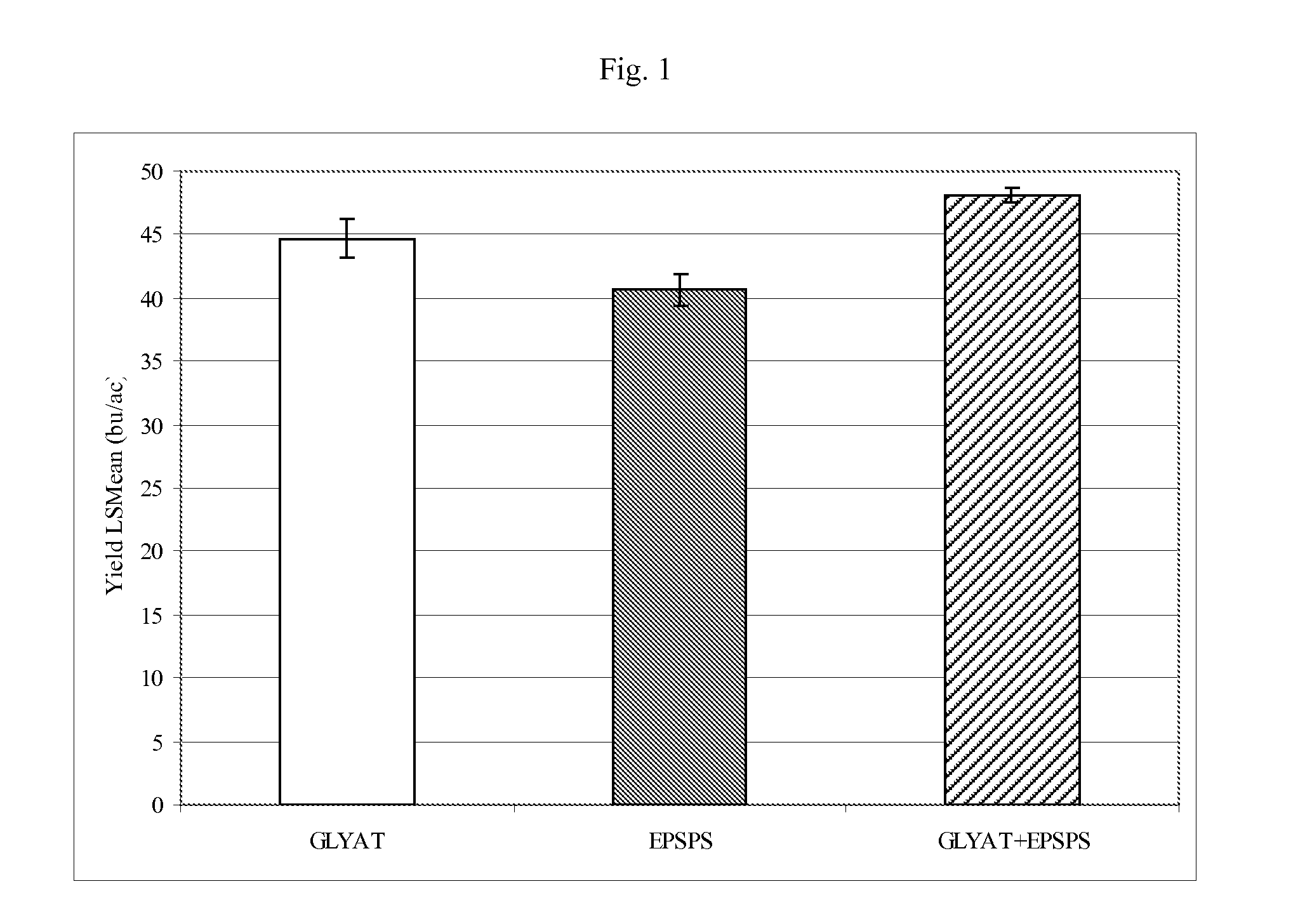

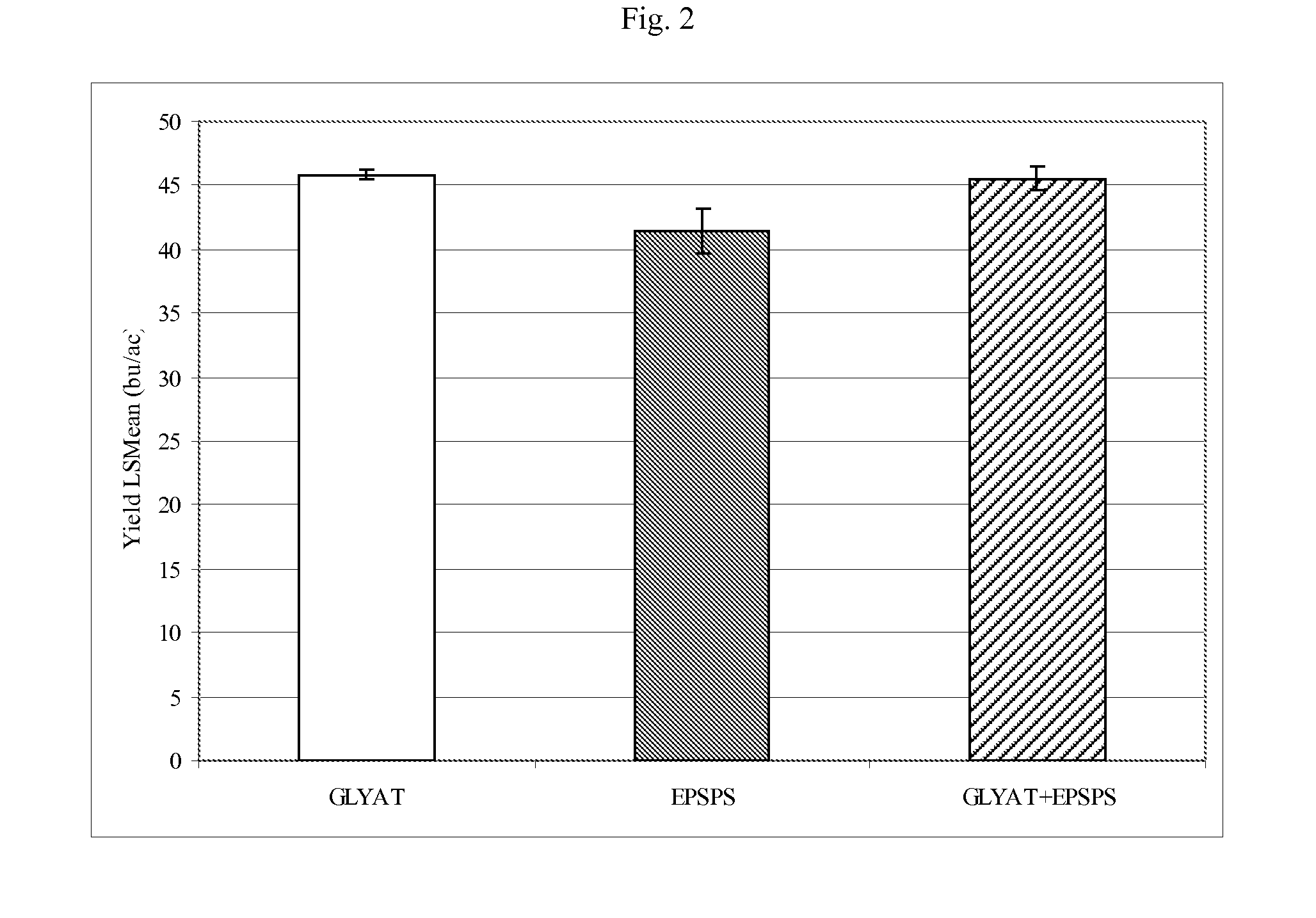

Novel glyphosate-n-acetyltransferase (GAT) genes

Methods and compositions for improving yield in a plant are provided. Methods of improving yield include treating plants with an effective amount of glyphosate, wherein the plant express at least two heterologous polypeptides that impart tolerance to glyphosate via distinct modes of action. In one non-limiting method, the first polypeptide has glyphosate N-acetyl transferase activity and the second polypeptide comprises a glyphosate-tolerant EPSPS polypeptide.

Owner:PIONEER HI BRED INT INC +1

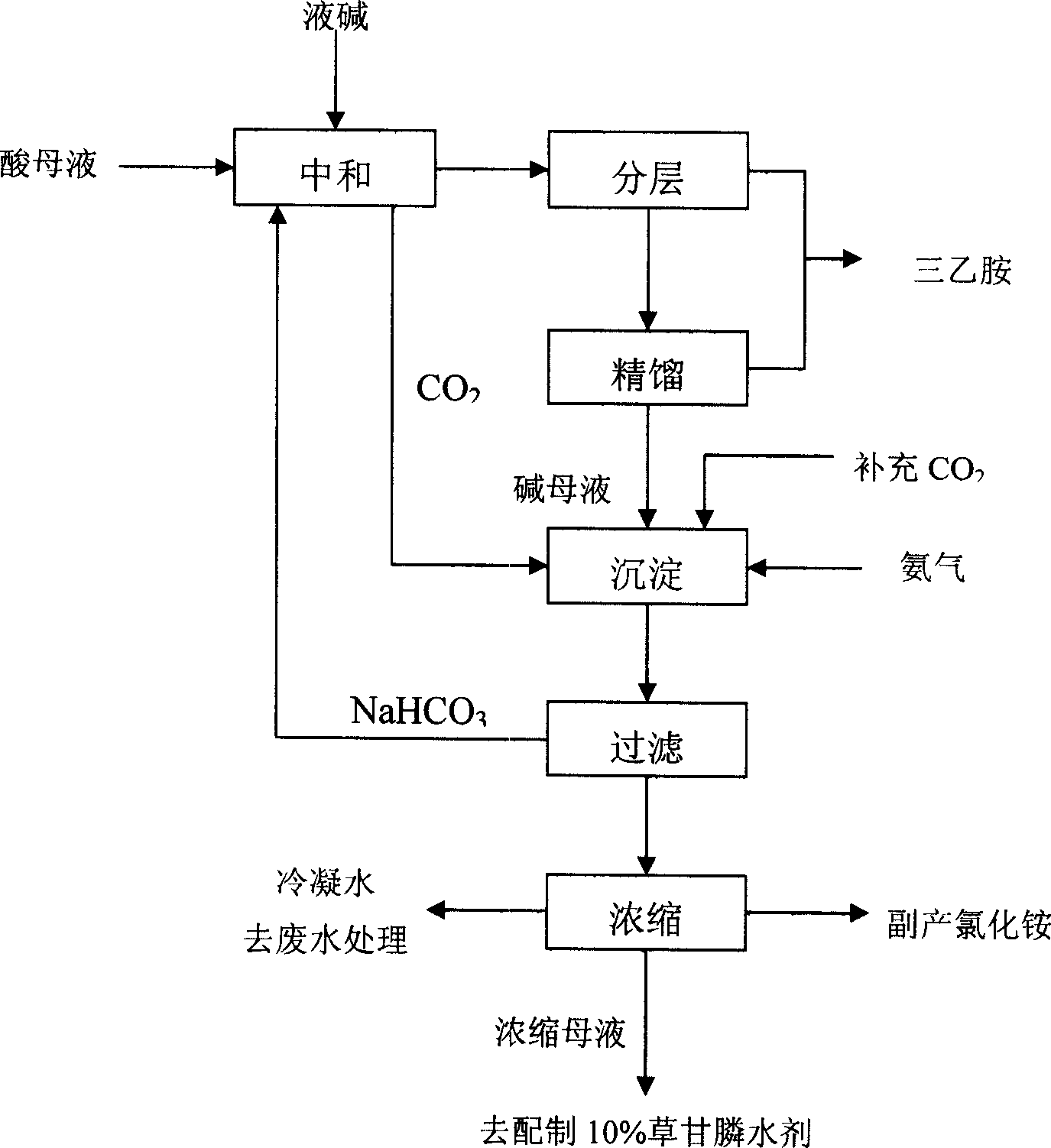

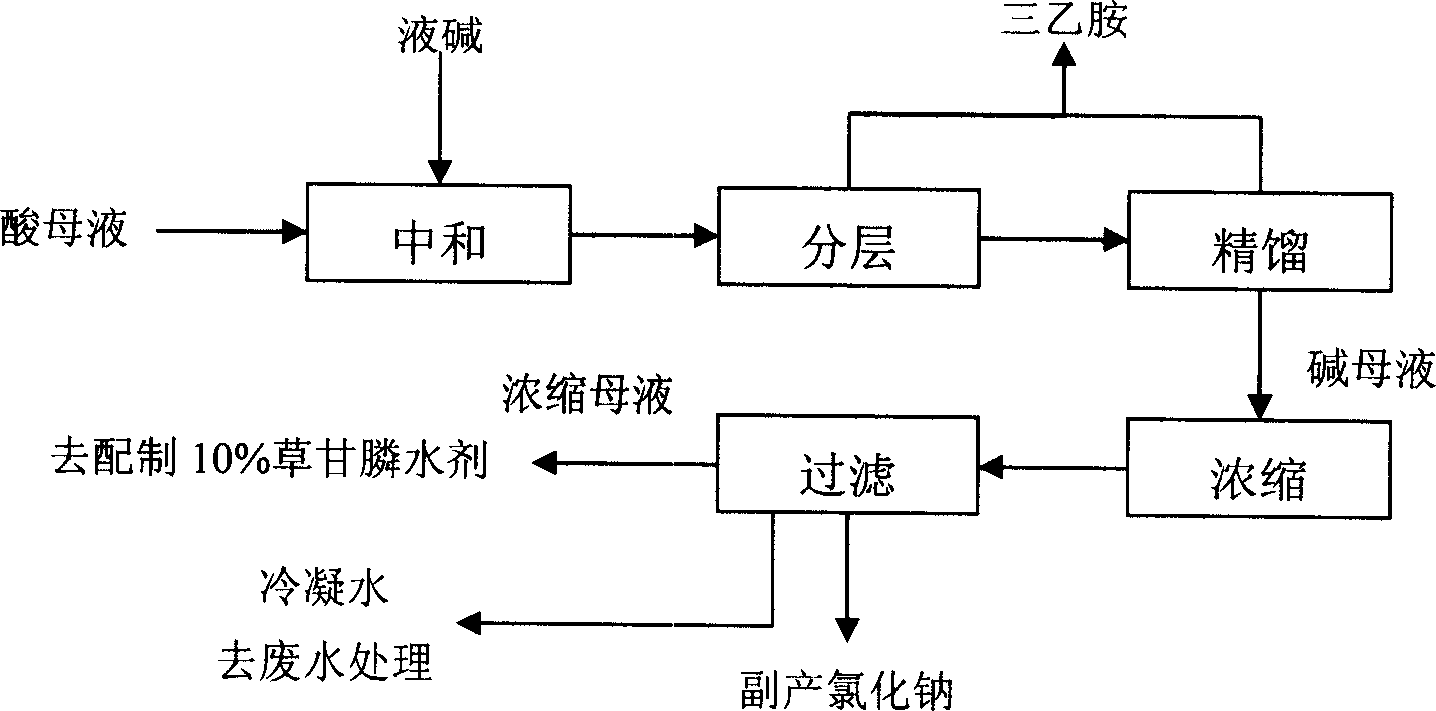

Process for treating glyphosate mother liquid

ActiveCN1648131AReduce solubilityReduce manufacturing costGroup 5/15 element organic compoundsGlyphosate toxicityChemistry

The present invention relates to the process of treating glyphosate mother liquor from glycine synthesis process. The treating process includes the following successive steps: 1) introducing ammonia into glyphosate mother liquor to regulate pH to 7-10, letting stand and recovering triethylamine from the upper layer; and 2) decompression distilling lower layer of the mother liquor, cooling, filtering to eliminate ammonium chloride crystal and to obtain concentrated ammonium glyphosate liquid. The said treating process has low production cost, low power consumption and environment friendship, and can obtain concentrated liquid with raised effect. Furthermore, glyphosate may be separated from the mother liquor to raise total glyphosate yield.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

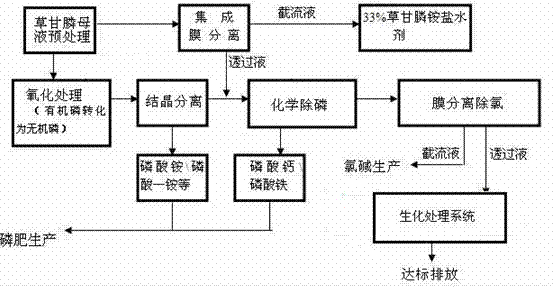

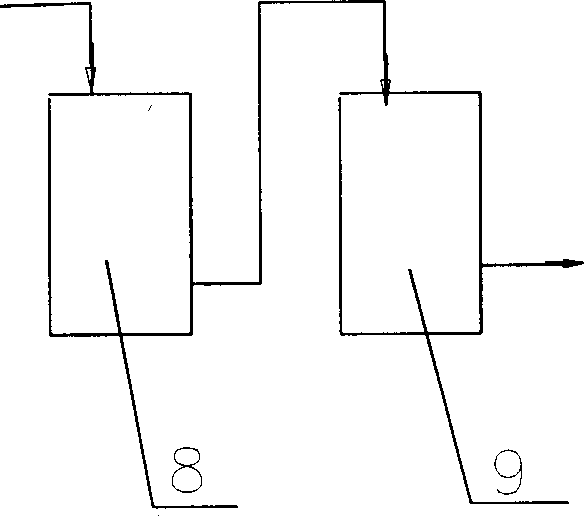

Integrated process for recycling glyphosate mother liquor

ActiveCN102786187AImprove use valueOvercome limitationsGroup 5/15 element organic compoundsChemical industryPre treatmentPhosphate fertilizer

The purpose of the invention is to provide an integrated process for processing mother liquor generated in the process of preparing glyphosate to solve the problems of higher cost and resource solution in glyphosate mother liquor processing. The process comprises the steps of: pre-treatment of mother liquor, integrated film separation, oxidation treatment, crystal separation, chemical phosphorus removal, film separation dechlorination and biochemical treatment. According to the sales condition of water aqua, the dosage of the mother liquor going into a film separation system is adjusted; the market demand is adapted; meanwhile, the cost is controlled; the influences of device maintenance and the like are avoided, and normal operation of a glyphosate production device is guaranteed. The glyphosate obtained from integrated film separation can be used for producing 33% of glyphosate ammonium salt agent; organic phosphorus obtained from crystal separation and chemical phosphorus removal can be applied to phosphate fertilizer production; sodium chloride solution obtained from film separation can be applied to chlor-alkali production, and the other parts can go into biochemical treatment and be discharged with standards.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Process of treating glyphosate producing effluent

ActiveCN101088934AReduce COD valueLow costMultistage water/sewage treatmentWater/sewage treatment by neutralisationMagnesium saltWastewater

The present invention discloses new process of treating glyphosate producing effluent. During glyphosate producing process, certain amount of calcium salt, magnesium salt, calcium salt solution or magnesium salt solution is added into the waste water after filtering, alkali neutralizing and recovering catalyst for full reaction; the resultant is filtered to obtain filter cake containing calcium or magnesium salt of glyphosate; and the filter cake is treated with inorganic acid to obtain glyphosate solution. The process has glyphosate recovering rate up to 95 %, COD eliminating rate up to 95 % and utilization of waste glyphosate water.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Use of a supplemental promoter in conjunction with a carbon-supported, noble-metal-containing catalyst in liquid phase oxidation reactions

InactiveUS20060020143A1High activityPromote oxidationBiocideOrganic chemistry methodsTe elementChemistry

This invention relates to the use of a supplemental promoter in conjunction with a noble-metal-containing catalyst comprising a carbon support in catalyzing liquid phase oxidation reactions, a process for making of an improved catalyst comprising such a supplemental promoter, and an improved catalyst comprising such a supplemental promoter. In a particularly preferred embodiment, a supplemental promoter (most preferably bismuth or tellurium) is used in conjunction with a noble-metal-containing catalyst comprising a carbon support in a liquid phase oxidation process wherein N-(phosphonomethyl)iminodiacetic acid (i.e., “PMIDA”) or a salt thereof is oxidized to form N-(phosphonomethyl)glycine (i.e., “glyphosate”) or a salt thereof. The benefits of such a process include increased oxidation of the formaldehyde and formic acid by-products, and, consequently, decreased final concentrations of those by-products as well as other undesirable by-products, most notably N-methyl-N-(phosphonomethyl)glycine (i.e., “NMG”).

Owner:MONSANTO TECH LLC

Method for separating and concentrating glyphosate stock solution

ActiveCN1775786AAvoid decompositionAvoid reactionSemi-permeable membranesGroup 5/15 element organic compoundsChemistryGlyphosate toxicity

The invention discloses a method for concentrating glyphosate mother solution by membrane separation technique, separating glyphosate mother solution by selectively permeable membrane at normal temperature and high pressure, thus achieving the concentrating effect, and the whole course comprises preprocessing device, pressure pump, concentrating device and auxiliary system, where the concentrating device is the kernel part and for achieving better effect, comprises reverse osmosis and accept filtration or two-stage reverse osmosis. The advantages of the invention: it can effectively concentrate glyphosate mother solution and assure the quality of the glyphosate mother solution, and reduces secondary pollution and energy consumption in the concentrating course. And the invention can be widely applied to the occasions in need of concentrating glyphosate.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

Glyphosate synthesized mother liquor processing method

ActiveCN101348299AReduce processing costsAchieving zero emissionsWater/sewage treatment by oxidationTreated waterPollution

The invention relates to a comprehensive treatment process for mother liquor obtained in glyphosate synthesis by IDA route air oxidation method. Water treated by the process can meet the requirements of glyphosate synthesis, and the treatment process comprises the following steps that membrane treatment is adopted to remove the glyphosate and homolog thereof in the mother liquor; and heavy liquor is used to reclaim the glyphosate, while thin liquor is used to manufacture glyphosate after the formic acid and formaldehyde in the thin liquor are removed. The method can moderately remove the glyphosate and homolog thereof, the formic acid and the formaldehyde in glyphosate mother liquor, and has low treatment cost; moreover, the method does not generate secondary pollution, and can realize the recovery of glyphosate; meanwhile, treated water can be reused for manufacturing glyphosate, thereby realizing zero discharge of waste water during synthesizing glyphosate.

Owner:JIANGSU YANGNONG CHEM +1

High-strength, low viscosity herbicidal formulations of glyphosate

ActiveUS20050032649A1Reduced bioavailabilityReduce molecular weightBiocideDead animal preservationHigh concentrationOxalate

This invention relates to a high-strength herbicidal formulation containing high concentrations of glyphosate monomethylamine or dimethylamine salt and one or more surfactants selected to enhance the herbicidal activity of the glyphosate salts. The formulations exhibit significantly lower viscosity at high concentrations.

Owner:CORTEVA AGRISCIENCE LLC

Glyphosate preparation and method for preparing same

ActiveCN1631894AReduce investmentReduce generationBiocideGroup 5/15 element organic compoundsWastewaterTechnical grade

Disclosed are a glyphosate and its preparing method oxidate oxidate to acquire mixed liquid of glyphosat; bifter hydration, add into glyphosate agent glyphosate preparation to change it into salt, then add surface active agent as assistant into the mixed liquid of salt and the surface active agent is one or several ones from nonion surface active agent or amphoteric surface active agent or organic silicon surface active agent, mix them to be average, acquiring the . In the course, there is no need to separate glyphosate technical grade, while preparation the with the glyphosate technical gradedirectly, which has decreased the amounts of equipment and worker, without drainage of glyphosate mother liquid, it completely makes use of glyphosate technical grade, as well as reduces waste water, benefiting for environmental protection.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

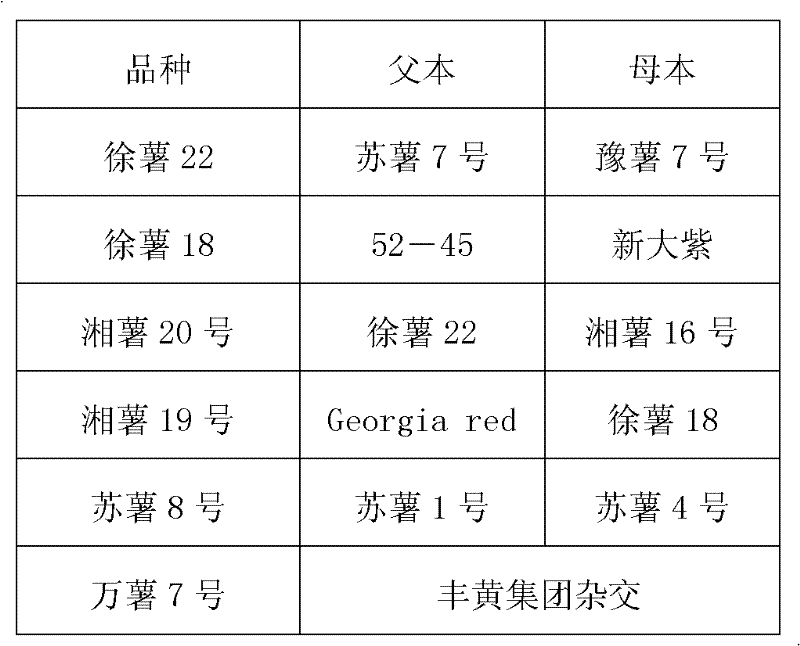

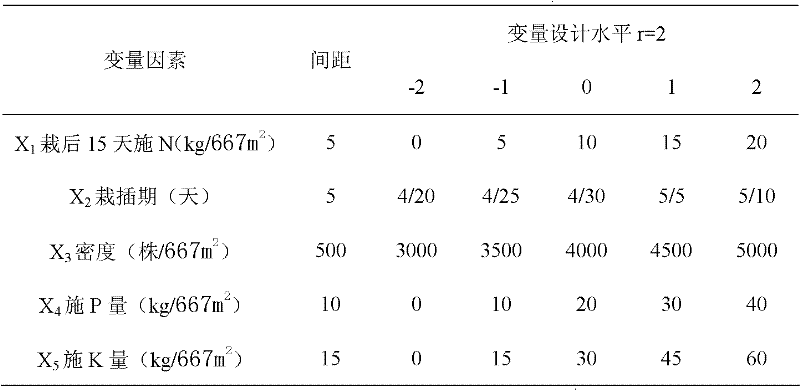

Sweet potato cultivation method in hills and mountains

The invention discloses a sweet potato cultivation method in hills and mountains, comprising the following steps of: A, selecting variety; B, raising seedlings: the seeding time is in March, the seeded potatoes are oblique in rows with head up and tail down, plant ash is covered after seeding, fine soil is covered, dual gold herbicide and glyphosate are sprayed on the ridges, and mulching film is coated; C, planting: considering that the blocks in hills and mountains have different sizes, micro-ridge single-row planting is adopted, the planting time of spring potato is in April, the planting time of summer potato is in May, the head and the middle of seedlings are cut, oblique planting is adopted, soil is covered, and moisture supply is maintained after planting; D, applying fertilizer: sweet potato is potassium-liking crop and the applied fertilizer is mainly organic fertilizer; and E, intertilling, weeding and earthing up: intertilling has the effect on breathing and is performed after planting, the depth becomes shallow, and weeding and earthing up are combined with intertilling. The method is easy and simple to operate, adopts micro-ridge single-row planting, efficiently uses the soil, causes the seedbed to be insulated, prompts the potato tubers to sprout quickly and abundantly, simultaneously can inhibit occurrence of black spot, and increases the yield by 20-30%.

Owner:湖南省作物研究所

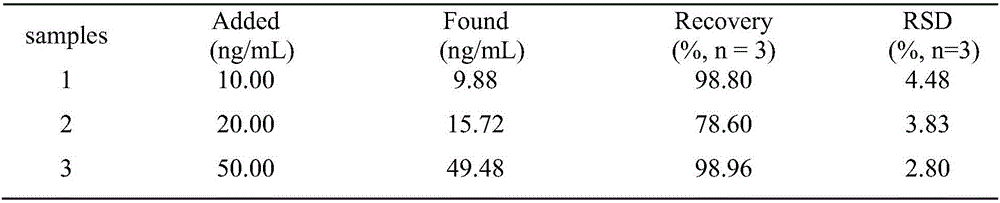

Preparation method of glyphosate molecularly-imprinted electrochemical sensor

ActiveCN106226370AStrong specificityHigh sensitivityMaterial electrochemical variablesFunctional monomerIn situ polymerization

The invention relates to the technical field of molecularly-imprinted and electrochemical polymerization, in particular to a preparation method of a glyphosate molecularly-imprinted electrochemical sensor. The preparation method comprises the following steps that 1, gold nanoparticles are electrochemically deposited on a graphene-modified electrode to obtain a graphene-nanogold-modified electrode; 2, a molecularly-imprinted polymer is polymerized on the surface of the graphene-nanogold-modified electrode in situ through an electrochemical polymerization method to form a layer of a molecularly-imprinted film, wherein the molecularly-imprinted polymer takes pyrrole as a functional monomer and takes glyphosate as a template molecule; 3, the glyphosate template molecule is removed, and then the glyphosate molecularly-imprinted electrochemical sensor is prepared.

Owner:内蒙古普析通用仪器有限责任公司

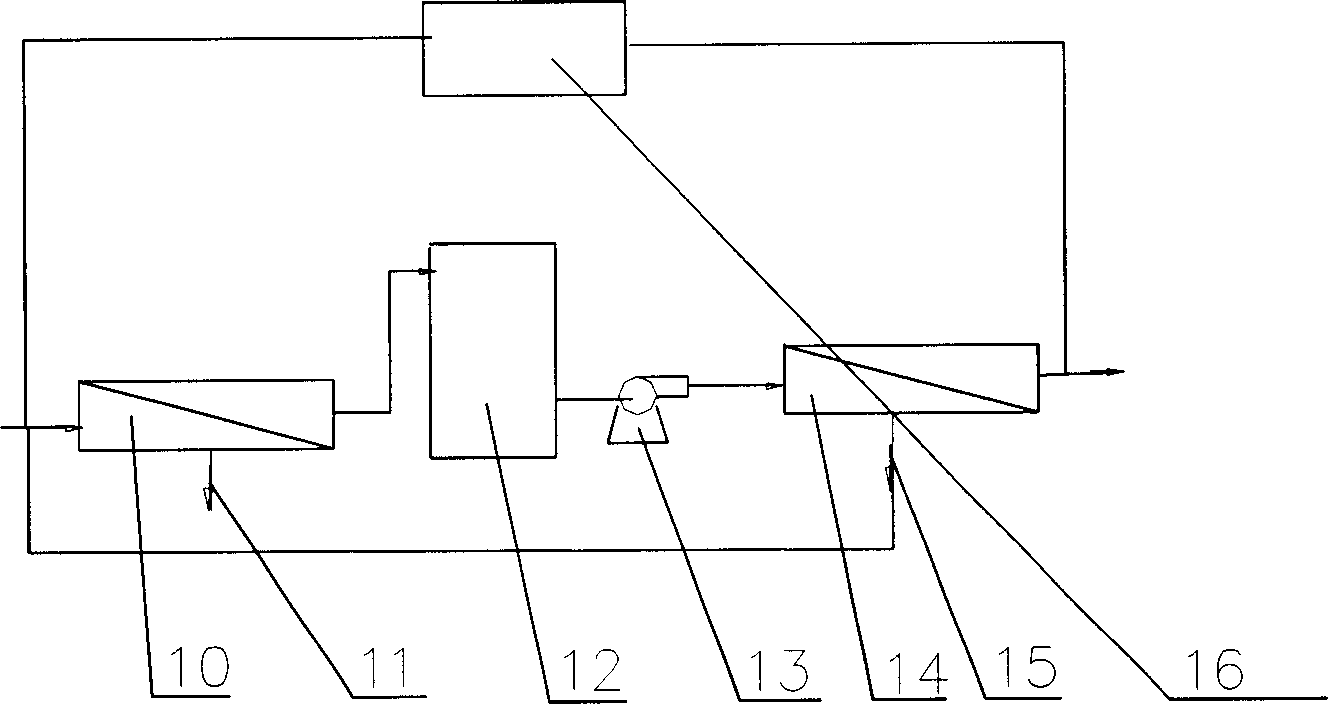

Processing technology for recovering and utilizing mother solution of glyphosate as resource

ActiveCN101659673AImprove throughputReduce flux decay speedGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisFiltrationCatalytic oxidation

The invention relates to a processing technology for recovering and utilizing the mother solution of glyphosate as a resource, which comprises the following concrete steps: firstly, preprocessing themother solution of glyphosate, and then, separating, concentrating and recovering the glyphosate by a membrane combination technique; returning the concentrated solution to a crystallization working section in the production process of the glyphosate after membrane filtration, thereby effectively recovering and utilizing the glyphosate resource; adsorbing the diluted solution with high efficiency,and further recovering and utilizing the glyphosate; and processing the adsorbed solution by catalytic oxidation with high efficiency to recover the sodium chloride resource with higher purity. The invention achieves the purposes of recovering and utilizing the glyphosate in the mother solution as a resource to the maximum extent and efficiency separating, recovering and utilizing the sodium chloride as a resource, has the advantages of economical technology, high efficiency, good system stability, high safety, easy operation, convenient industrial amplification, and the like, solves the problems of the soil salinization caused by applying water agents with high content of sodium chloride, the processing and disposal of solid wastes of the sodium chloride and the environment pollution, and effectively recovers and utilizes the resources of the glyphosate and the sodium chloride in the mother solution of the glyphosate.

Owner:NANJING UNIV OF TECH

New method for treating glyphosate mother liquor

ActiveCN1824667AImprove weed control effectEliminate land salinizationGroup 5/15 element organic compoundsAmmonia gasGlyphosate toxicity

The present invention relates to a treatment method of mother liquor obtained for synthesizing glyphosate by using alkyl ester process. Said method is mainly characterized by that the ammonia gas and carbon dioxide gas are successively introduced into the neutralized alkaline mother liquor, fully reacted and filtered, the filtrate is treated, and can be used for preparing glyphosate water preparation.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com