Pretreatment method for glyphosate industrial waste water

A technology for the production of wastewater and glyphosate, which is applied in natural water treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problems of high CODcr value, failure to achieve the expected treatment effect, and difficulty in achieving the expected effect, etc. problem, to achieve the effect of reducing CODcr value, beneficial to environmental protection, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

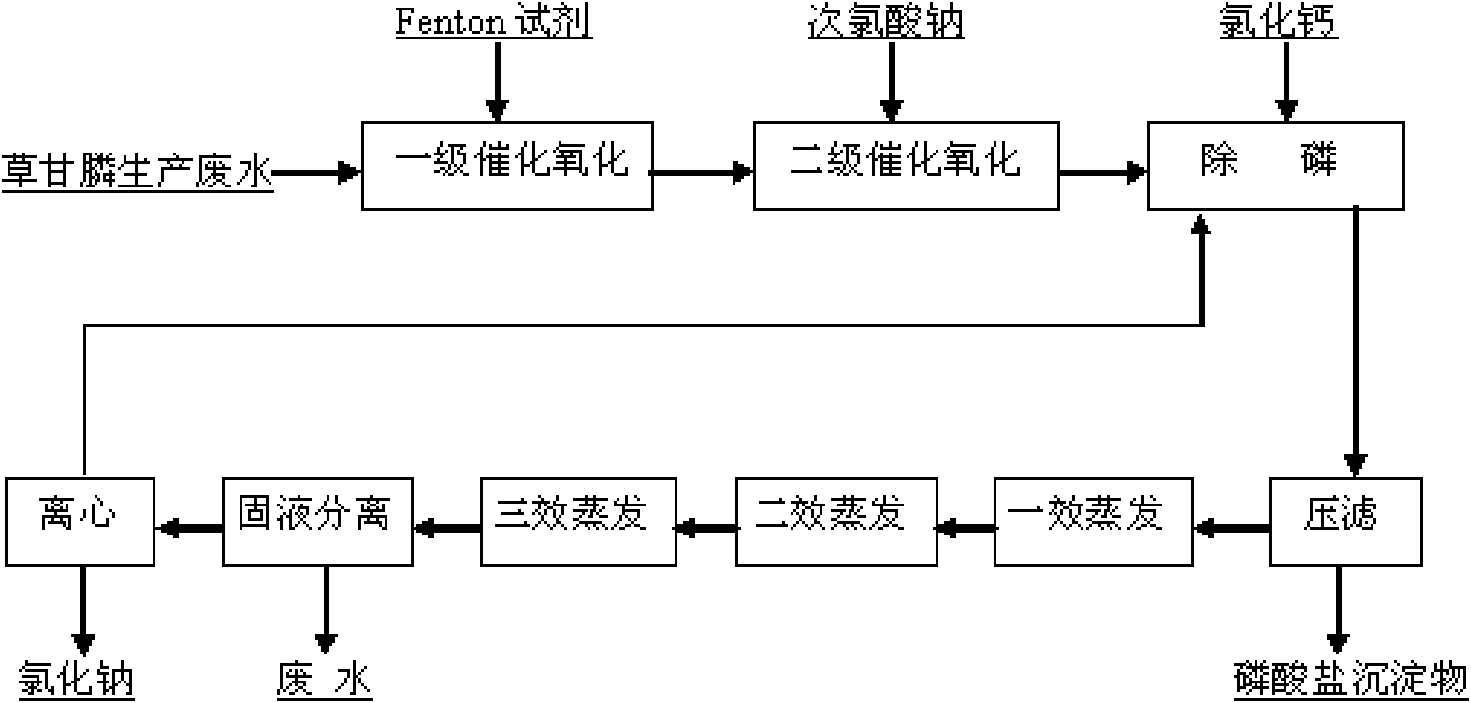

Image

Examples

Embodiment 1

[0028] A kind of pretreatment method of glyphosate production waste water is implemented according to the following steps:

[0029] (1) Adjust the pH value

[0030] Discharge 1000 liters (specific gravity 1.28 g / ml) of glyphosate production wastewater with a glyphosate content of 1.532%, a sodium chloride content of 20.1%, and a CODcr value of 58620 mg / liter into the adjustment tank, and discharge it into the adjustment tank. Add 30% hydrochloric acid solution to adjust the pH value of the wastewater in the pool to 3.5.

[0031] (2) Catalytic oxidation

[0032] The waste water after adjusting the pH value to 3.5 is discharged into the first-level catalytic oxidation tower, and 22500 liters of air are blown into from the bottom of the tower, and in the first-level catalytic oxidation tower, the ratio of 30% hydrogen peroxide and ferrous sulfate is 6: 1 66.7 liters of Fenton’s reagent prepared, reacted for 1.75 hours; then waste water was discharged into the secondary catalyti...

Embodiment 2

[0040] A kind of pretreatment method of glyphosate production waste water is implemented according to the following steps:

[0041] (1) Adjust the pH value

[0042] Containing 1.066% glyphosate, 15.3% sodium chloride, 2000 liters (specific gravity 1.22 grams per milliliter) of the glyphosate production waste water that CODcr value is 38912 is discharged into the adjustment pond, adds 30% hydrochloric acid solution in the adjustment pond, the pond The pH value of the waste water is adjusted to 3;

[0043] (2) Catalytic oxidation

[0044] The waste water after adjusting the pH value to 3 is discharged into the first-level catalytic oxidation tower, and 40000 liters of air are blown into from the bottom of the tower, and in the first-level catalytic oxidation tower, it is 3 by weight to add 30% hydrogen peroxide and ferrous sulfate: 1 Prepare 200 liters of catalytic oxidant Fenton reagent, react for 1.5 hours; then discharge waste water into the secondary catalytic oxidation towe...

Embodiment 3

[0052] A kind of pretreatment method of glyphosate production waste water is implemented according to the following steps:

[0053] (1) Adjust the pH value

[0054] Containing 1.68% glyphosate, 18.5% sodium chloride, 5000 liters (specific gravity 1.25 grams per milliliter) of the glyphosate production waste water that CODcr value is 50112 is discharged into the adjustment pond, adds 30% hydrochloric acid solution in the adjustment pond, the pond The pH value of the waste water is adjusted to 4;

[0055] (2) Catalytic oxidation

[0056] The waste water after adjusting the pH value to 4 is discharged into the first-level catalytic oxidation tower, and 125,000 liters of air are blown into from the bottom of the tower, and in the first-level catalytic oxidation tower, the ratio of 30% hydrogen peroxide and ferrous sulfate is 8 by weight: 1 Prepare 250 liters of catalytic oxidant Fenton reagent, react for 2 hours; then discharge waste water into the secondary catalytic oxidation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com