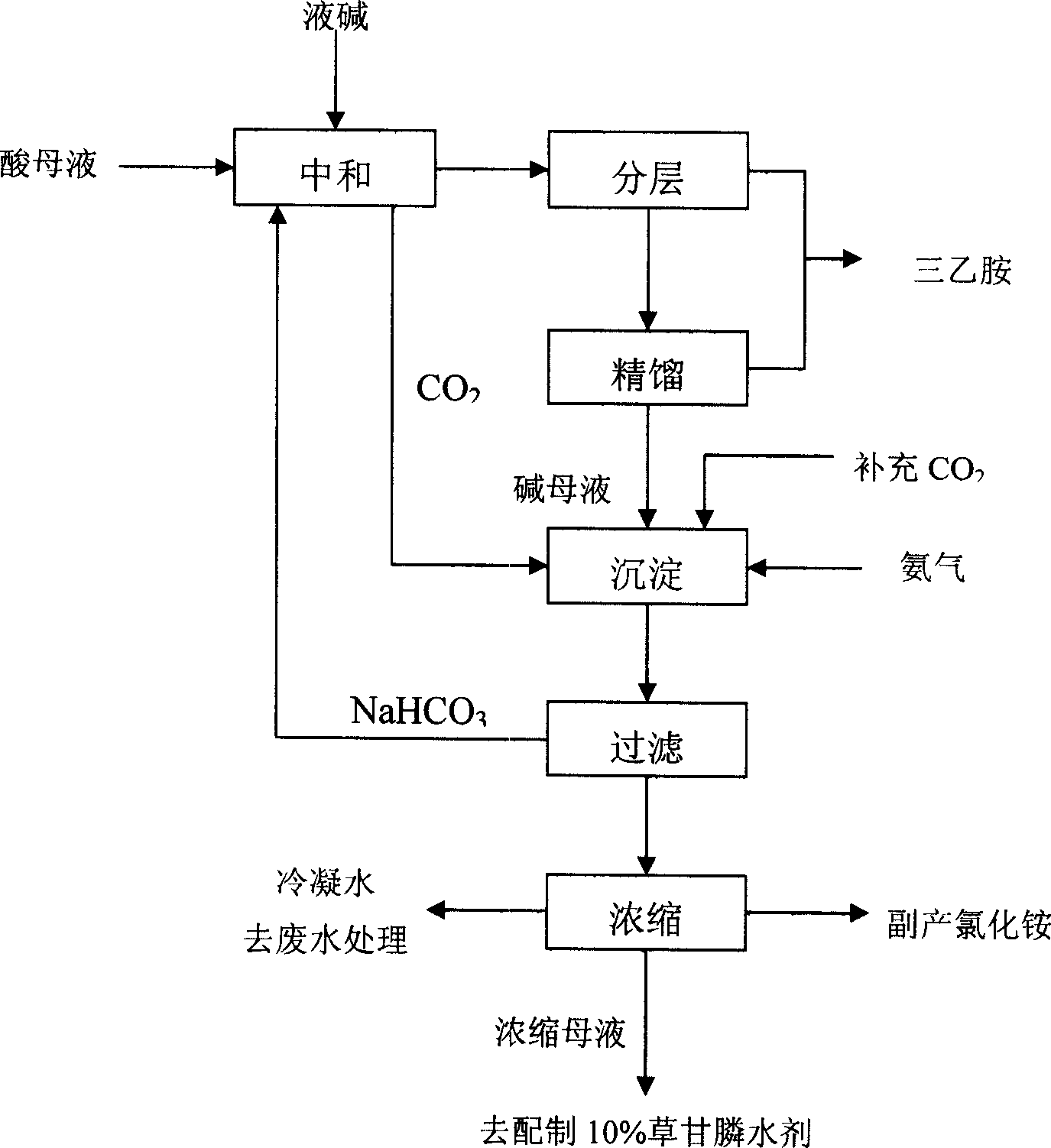

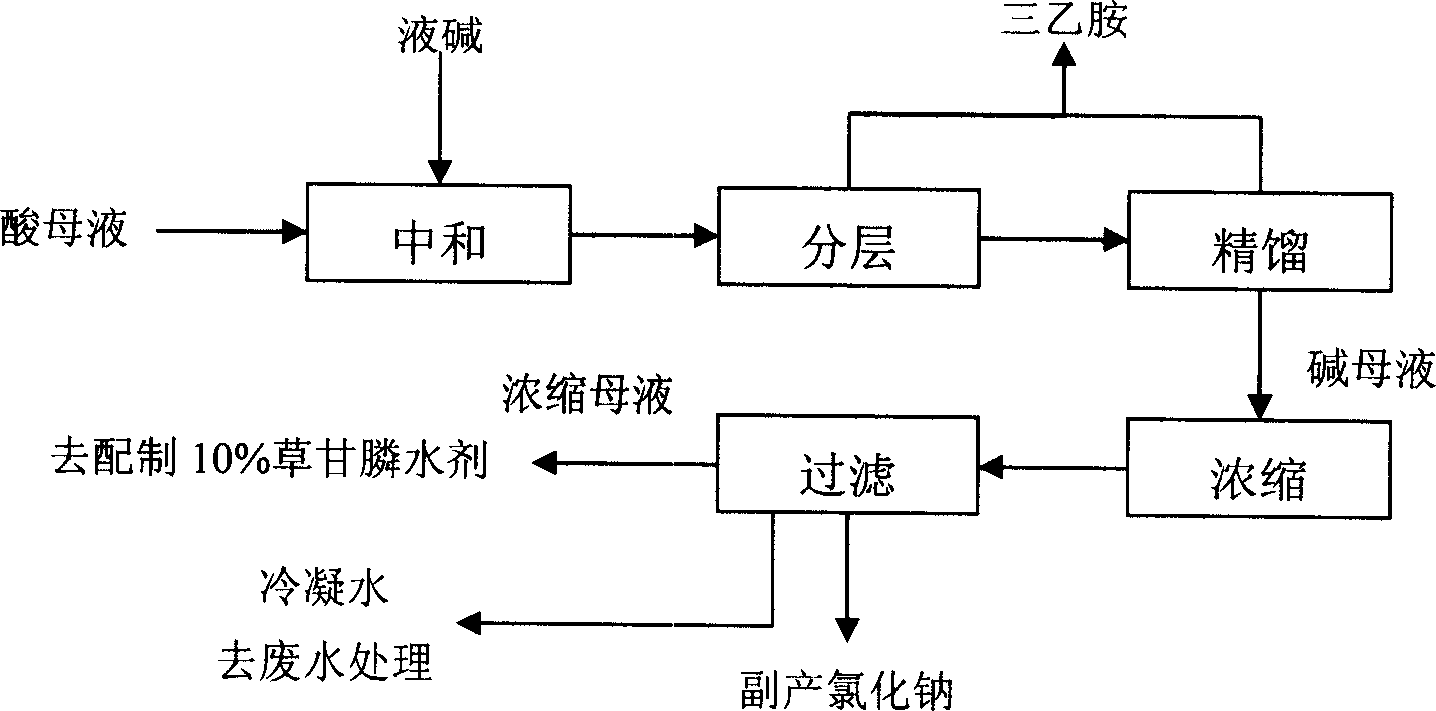

New method for treating glyphosate mother liquor

A glyphosate mother liquor and treatment method technology, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve poor soil dispersibility, high sodium chloride content, and sticky soil and other problems, to achieve the effect of improving weeding effect, significant economic benefits, and eliminating land salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the 1000g alkali mother liquor after reclaiming triethylamine in the preparation glyphosate production process, first feed 25g of ammonia gas, then feed into 65g of carbon dioxide gas, after fully stirring, filter to obtain 113g of sodium bicarbonate. The filtrate was concentrated and filtered to obtain 32 g of ammonium chloride. A metered amount of glyphosate acid is added to the concentrated filtrate until the glyphosate content is 10%, to obtain a 10% glyphosate aqueous solution.

Embodiment 2

[0022] In the 1000g alkali mother liquor after reclaiming triethylamine in the preparation glyphosate production process, first feed 75g of ammonia gas, then feed into 200g of carbon dioxide gas, after fully stirring, filter to obtain 343g of sodium bicarbonate. The filtrate was concentrated and filtered to obtain 42 g of ammonium chloride. A metered amount of glyphosate acid is added to the concentrated filtrate until the glyphosate content is 10%, to obtain a 10% glyphosate aqueous solution.

Embodiment 3

[0024] Get the 1000g acidic mother liquor in the glyphosate production process, add the sodium bicarbonate 343g that produces in the embodiment 2, collect the carbon dioxide gas 151g that produces, the pH value after the reaction is 5.4, adds 30%NaOH516g again, the pH value is 11, divides layer, the upper layer gets 206g of triethylamine, and the lower floor mother liquor is distilled to get 13g of triethylamine; in the alkali mother liquor, first pass into 75g of ammonia gas, then pass into the collected carbon dioxide gas, and add 49g of carbon dioxide gas, after fully stirring, Filtration yielded 352 g of sodium bicarbonate. The filtrate was concentrated and filtered to obtain 41 g of ammonium chloride. A metered amount of glyphosate acid is added to the concentrated filtrate until the glyphosate content is 10%, to obtain a 10% glyphosate aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com